Aluminum anode oxidation dual-test-piece experiment device

An experimental device and anodic oxidation technology, applied in anodic oxidation, electrolytic components, electrolytic process, etc., can solve the problem that the quality and speed of aluminum anodic oxidation film cannot meet the needs of research, and the secondary oxidation time is long (generally at least 6 hours or more) , human influence factors and other problems, to achieve the effect of fast speed, reduced influence, high quality of anodic oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

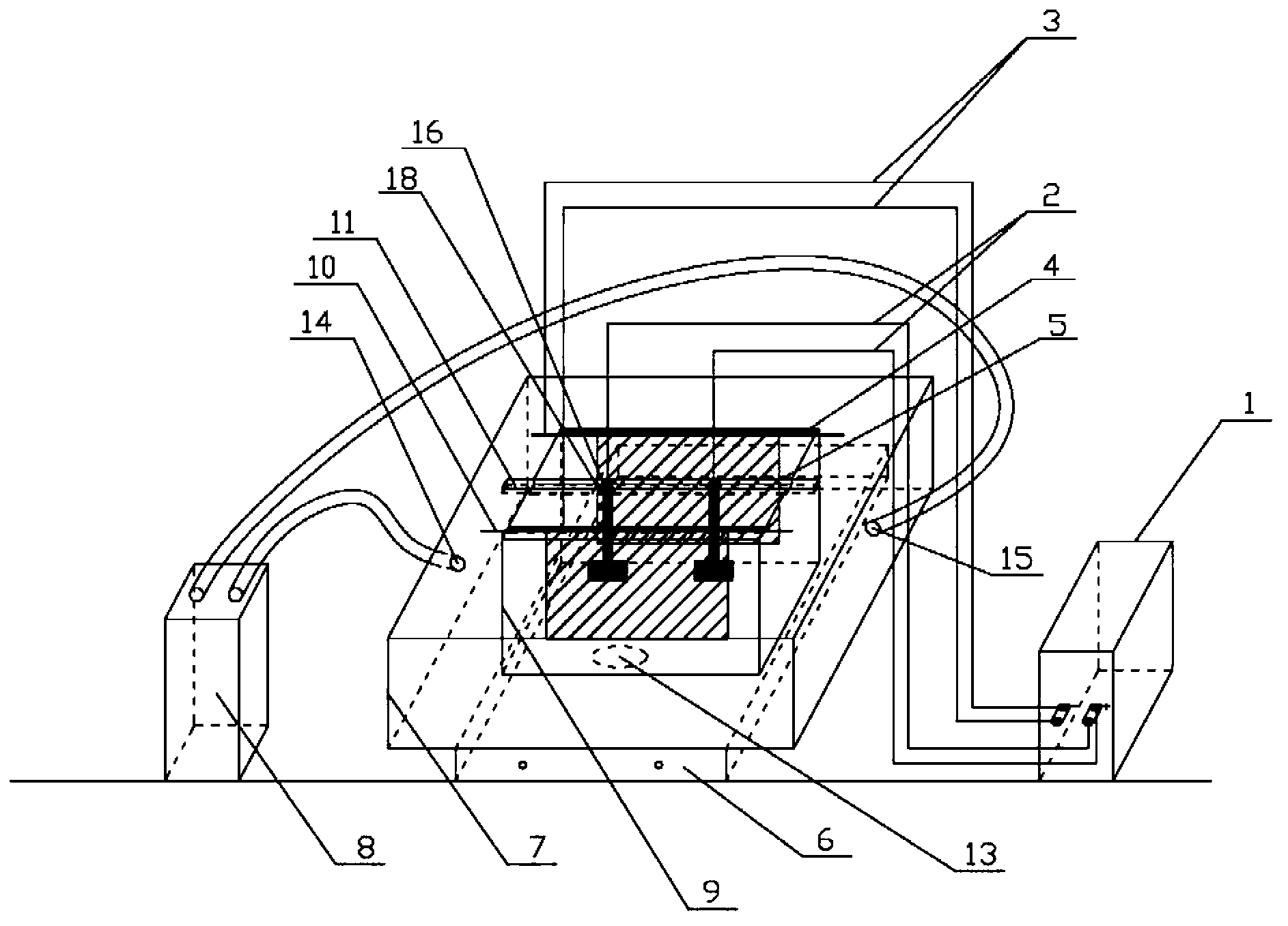

[0015] Example: such as figure 1 , this aluminum anodic oxidation double-specimen experimental device includes a DC stabilized power supply 1 and a glass container 9, the glass container 9 is customized by the factory, and the shape is a cuboid, with a length of 210mm, a width of 140mm, and a height of 150mm . The upper end of the glass container 9 is provided with a symmetrical thin groove 4 for placing the electrode stainless steel bracket. The depth of the thin groove 4 is 10mm, the width of the thin groove 4 is 3mm, and the distance from the two ends is 10mm. A pair of combined lead electrodes 10 are placed in the slot 4 in parallel and symmetrically, 30 mm from the bottom of the glass container, and the distance between the combined lead electrodes 10 is about 95 mm.

[0016] The combined lead electrode 10 is composed of a lead electrode plate and a stainless steel sheet, wherein the lead electrode plate has a length of 200 mm, a height of 120 mm, and a thickness of 3 mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com