Patents

Literature

454results about How to "Save cleanup time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

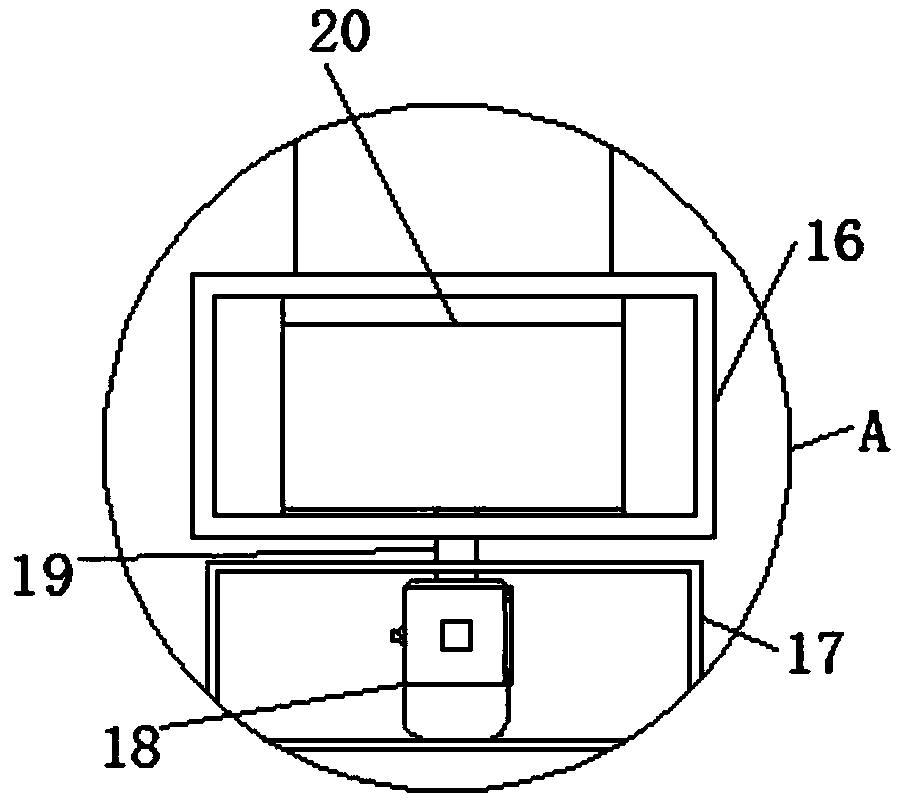

Intelligent restaurant management method and system

InactiveCN106529822AIncrease the number of dinersIncrease incomeResourcesApplication serverApproaches of management

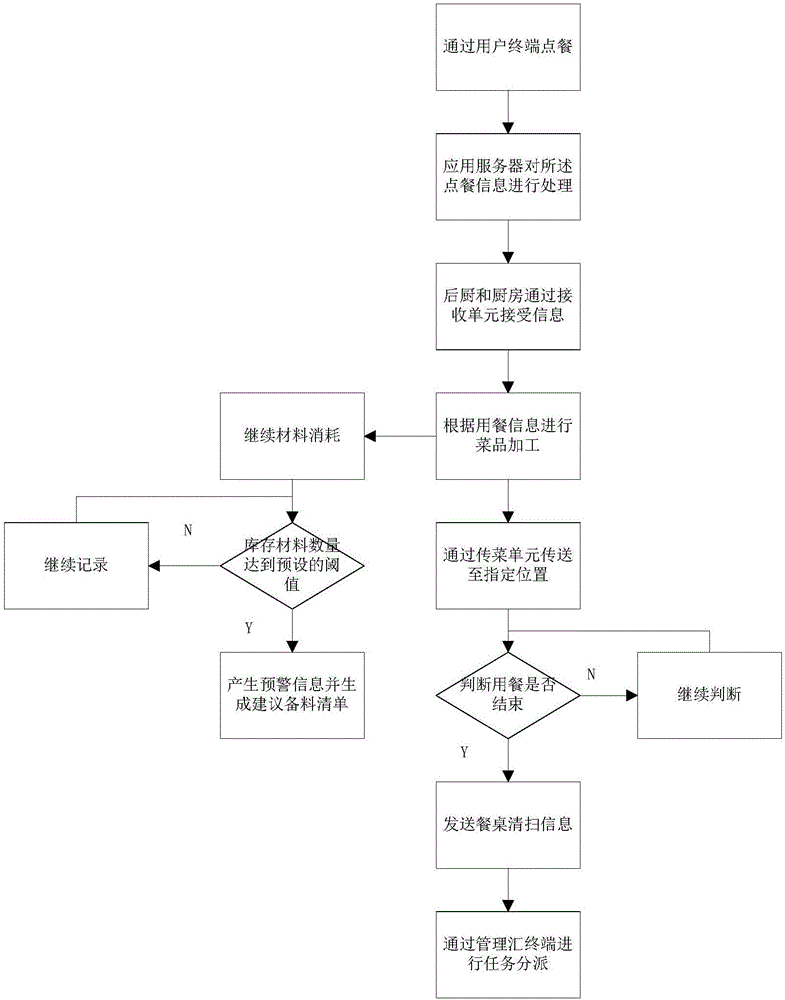

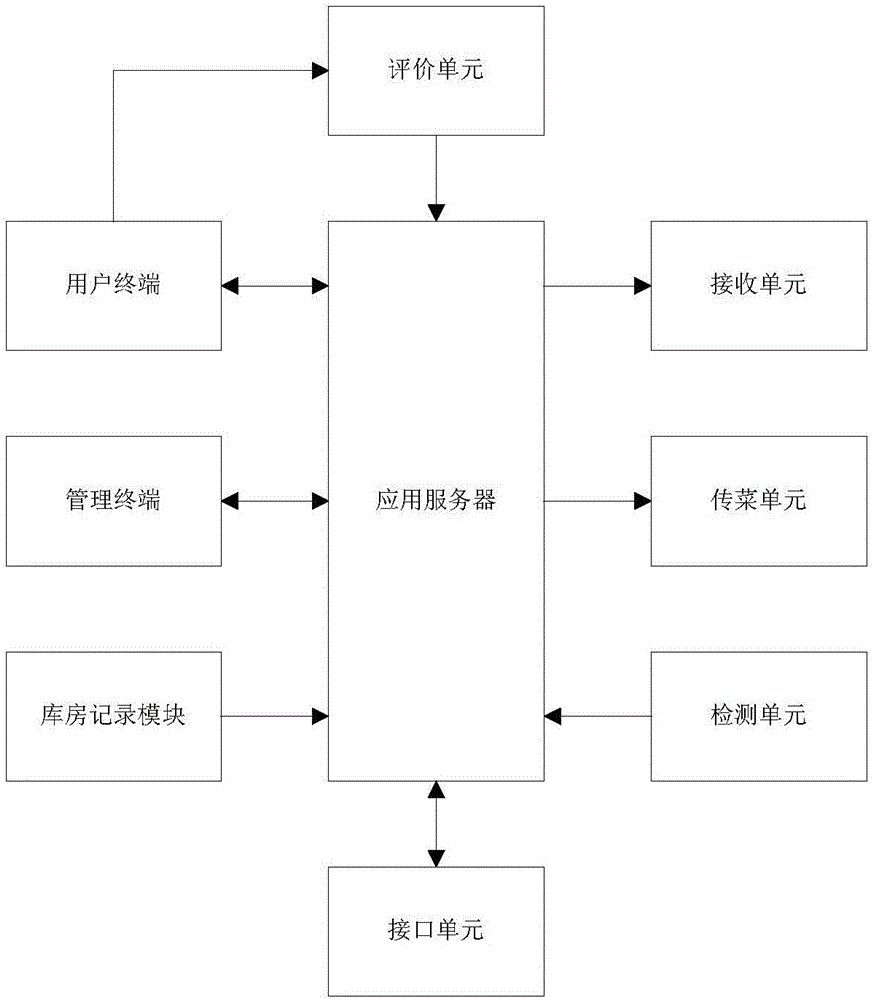

The invention relates to an intelligent restaurant management method and system. The method includes the following steps: food ordering information of a user is transmitted to an application server through a user terminal, and the food ordering information at least includes selected dish information, remark information, dining time and a dining position; and the application server processes the food ordering information, sends processed food ordering information to a receiving unit, and a kitchen and a storehouse complete dish processing according to received information of the receiving unit, and dishes are transferred to the designated position in the food ordering information through a dish transfer unit. The intelligent restaurant management method provided by the invention can provide services such as self-service food ordering and settlement for users, avoids the circumstances of ordering errors and delivery errors caused by human factors, improves the degree of satisfaction of users, and enhances competitiveness of an enterprise.

Owner:赵云龙

Sectional cutting and overall craning method for supporting beam in deep foundation pit multilayered reinforced concrete

ActiveCN103510523AImprove turnover rateGuaranteed Quality ControlFoundation testingExcavationsSupporting systemReinforced concrete

The invention discloses a sectional cutting and overall craning method for a supporting beam in deep foundation pit multilayered reinforced concrete. The method comprises the steps of internal force measurement, cutting and dismantling, transferring in the foundation pit, entirely craning of the supporting beam, off-site crushing of the supporting beam and the like. The method is to construct on an underground horizontal thin slab structure without special requirement on the construction platform. A steel pipe supporting system of the underground thin slab structure is not required to be reinforced, but holes and expansion joint positions are reserved for the underground horizontal thin slab to be locally reinforced. When the supporting beam is cut off and dismantled, the steel pipe stand is not required for the lower part. The single input of the steel pipe stand material is greatly reduced on the site, and the steel pipe stand can be dismantled in advance to improve the turnover rate of the steel pipe stand.

Owner:何金城

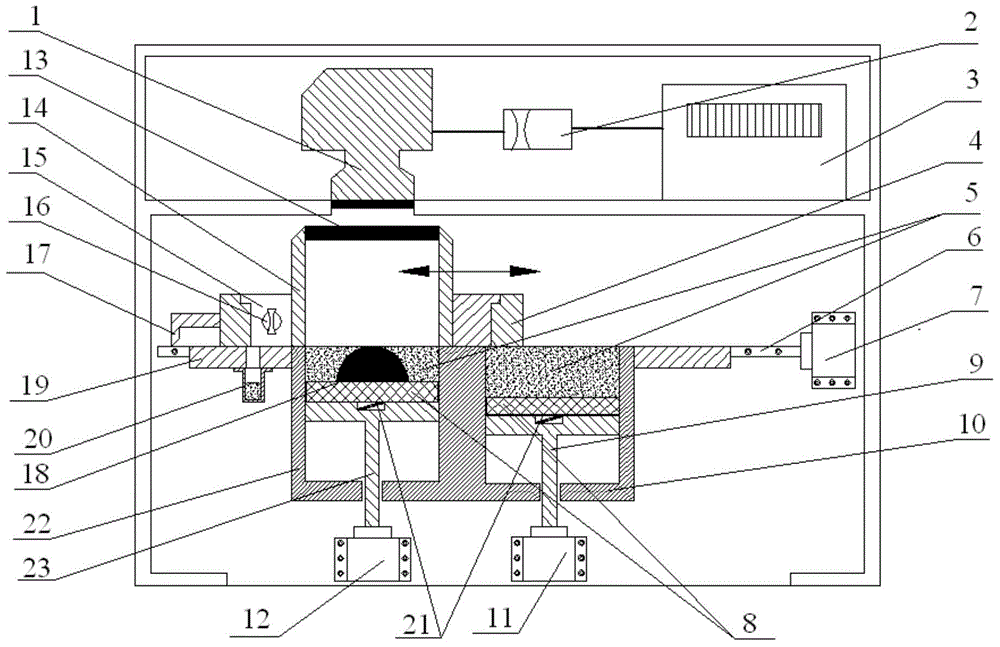

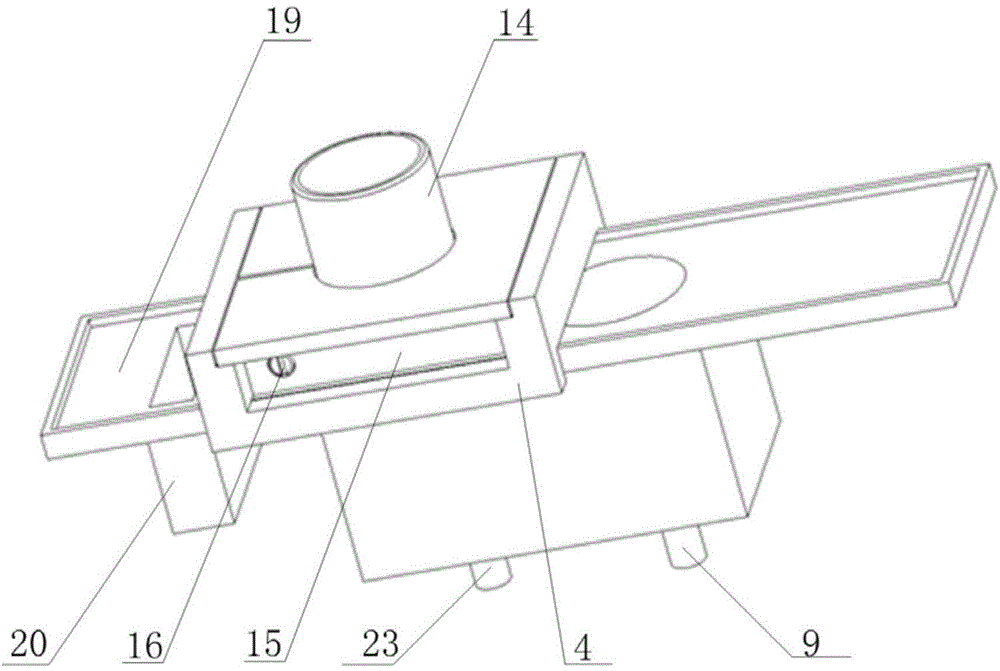

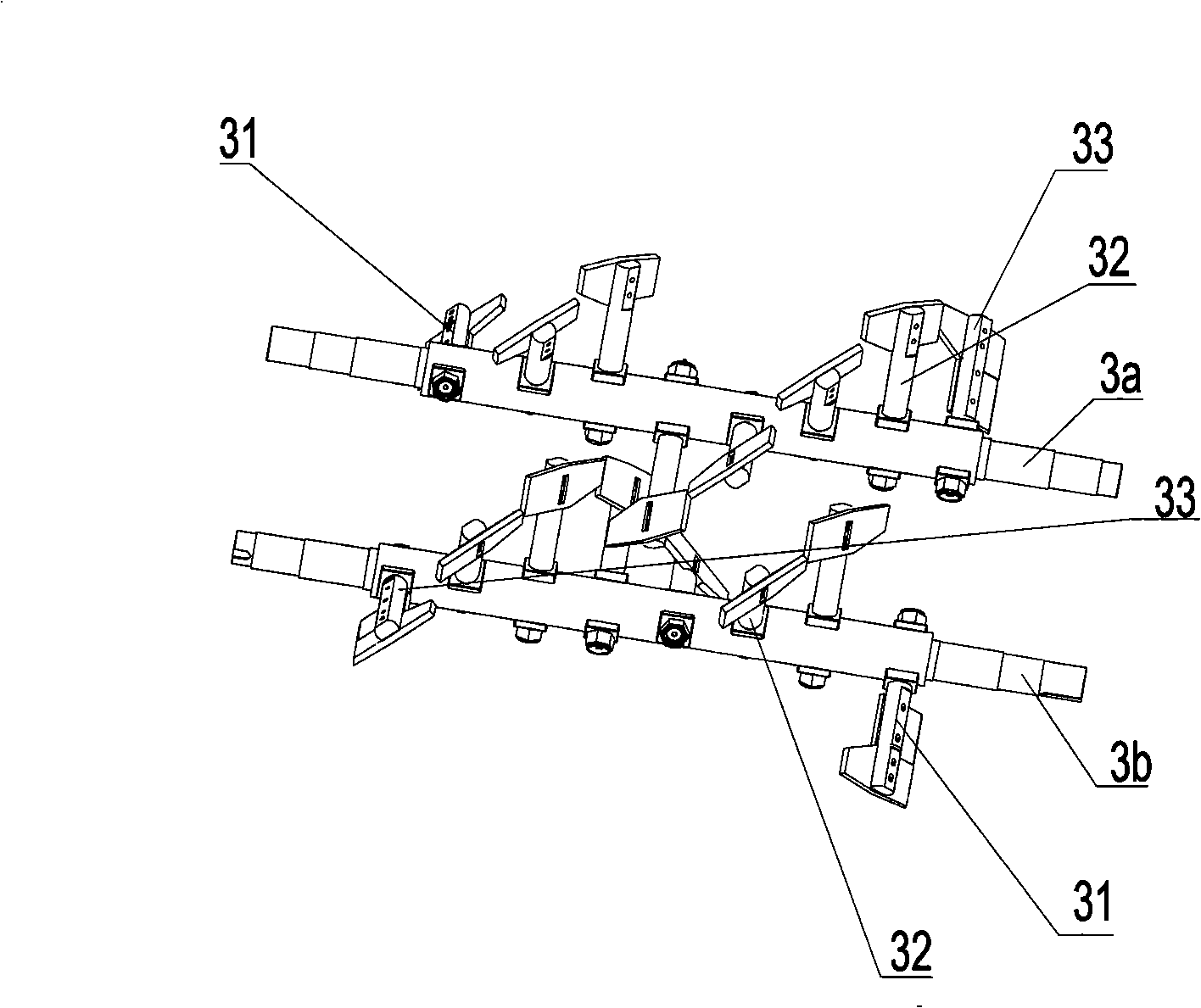

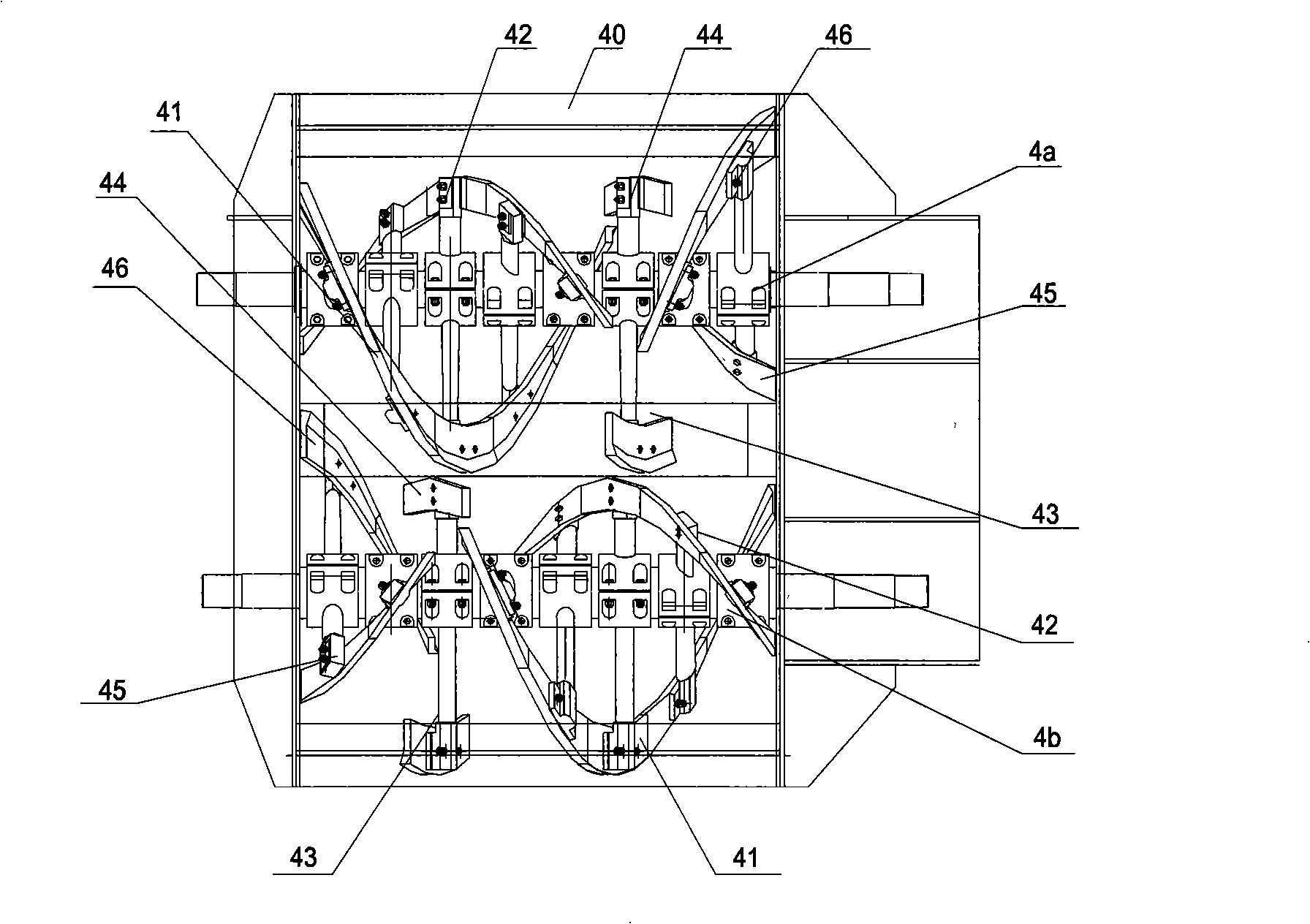

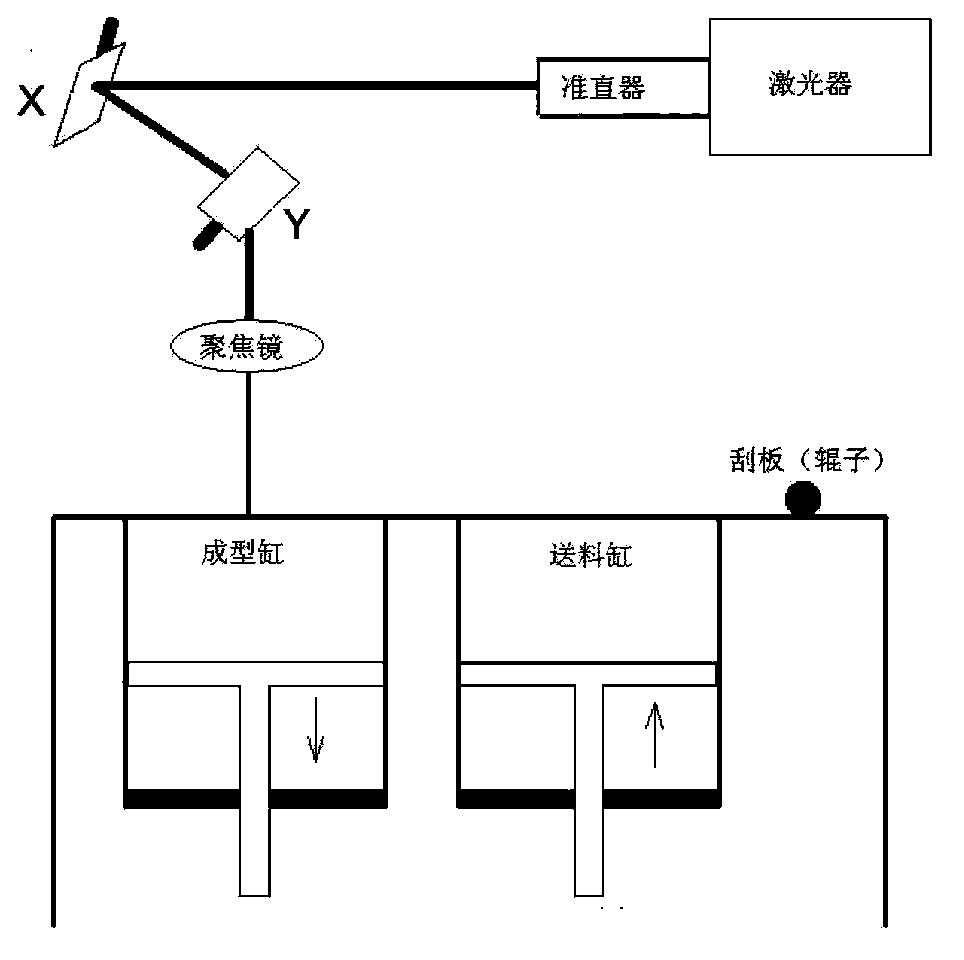

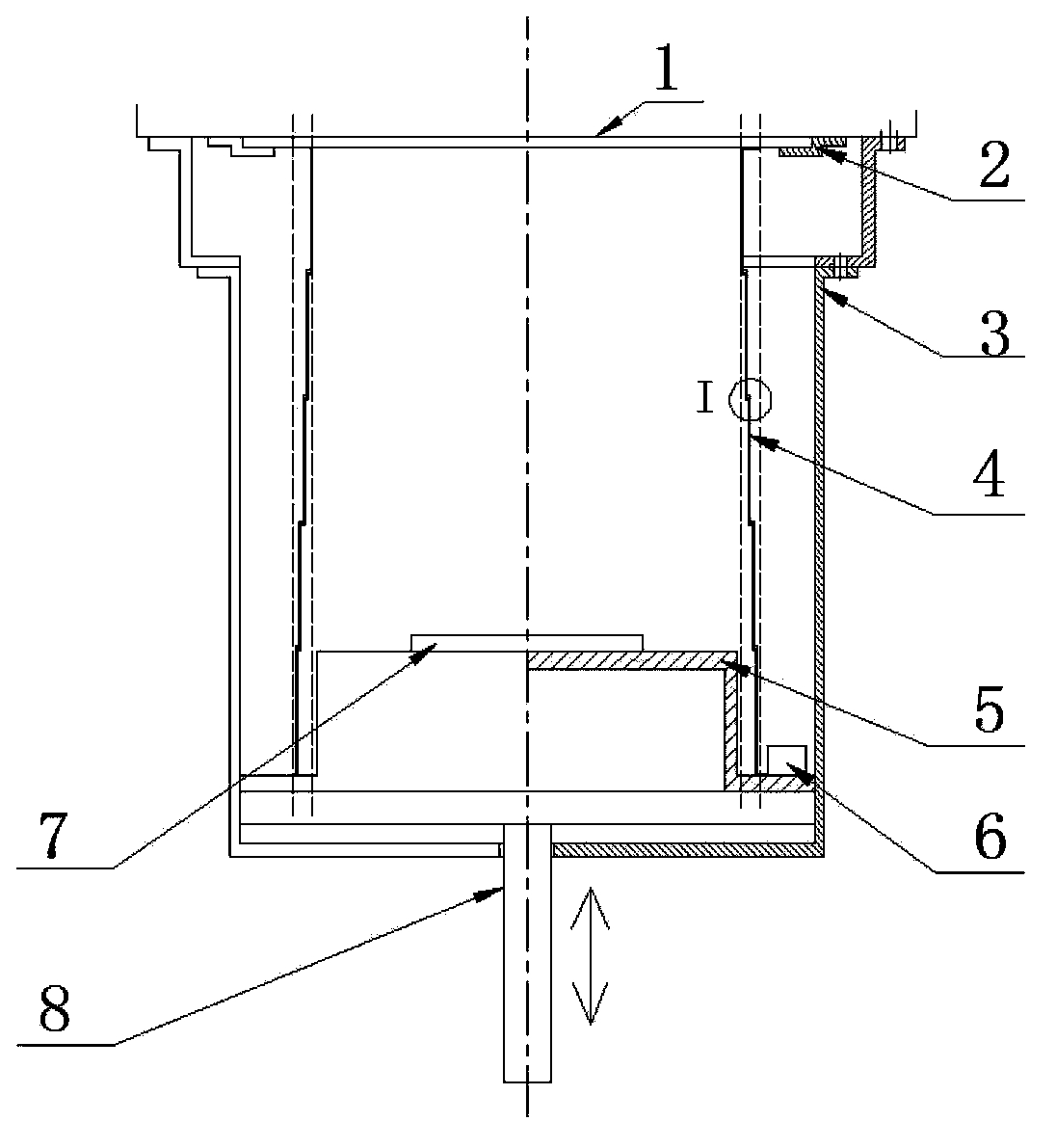

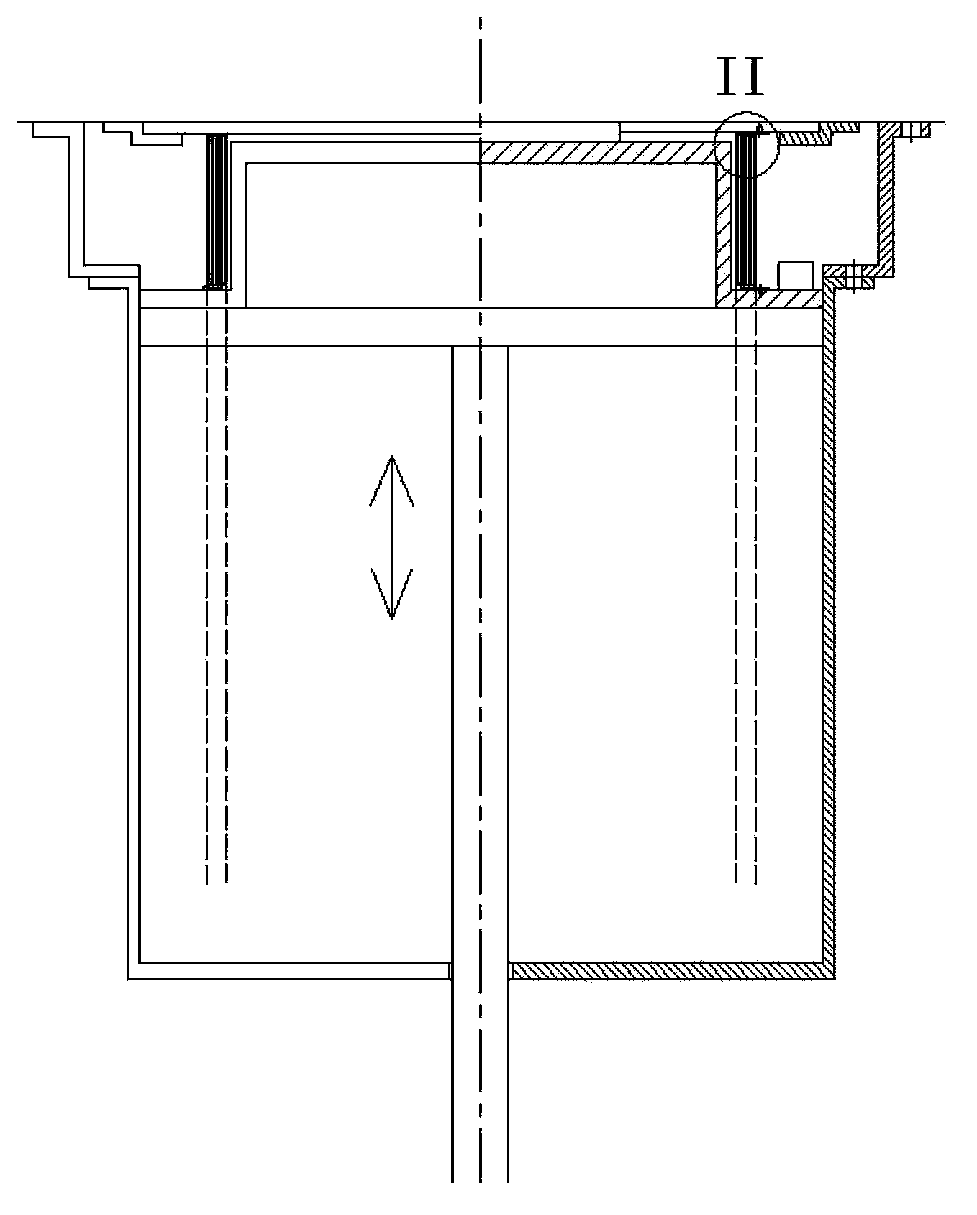

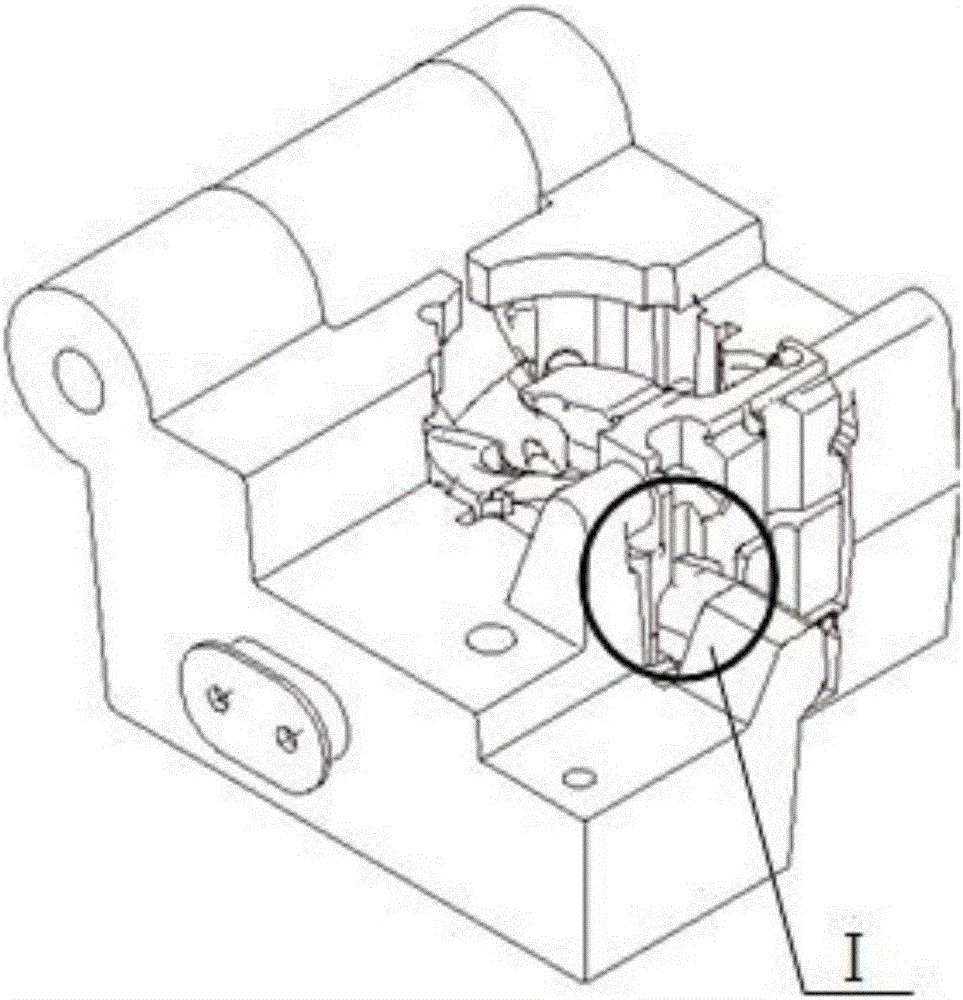

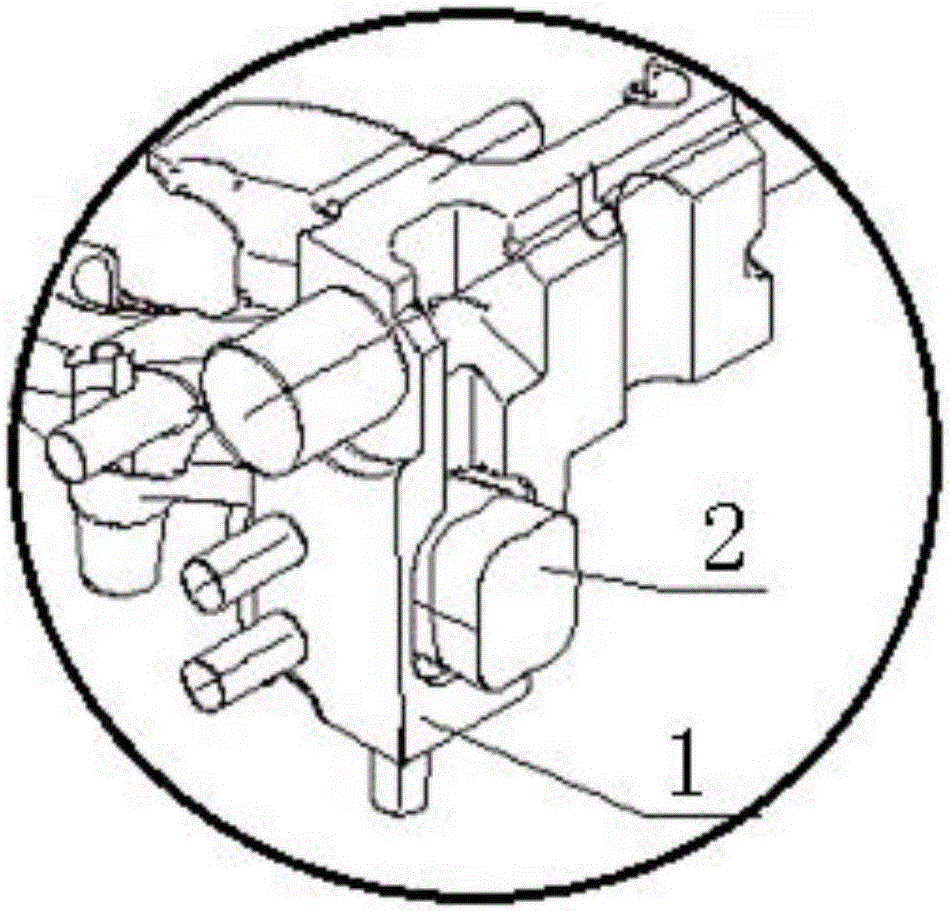

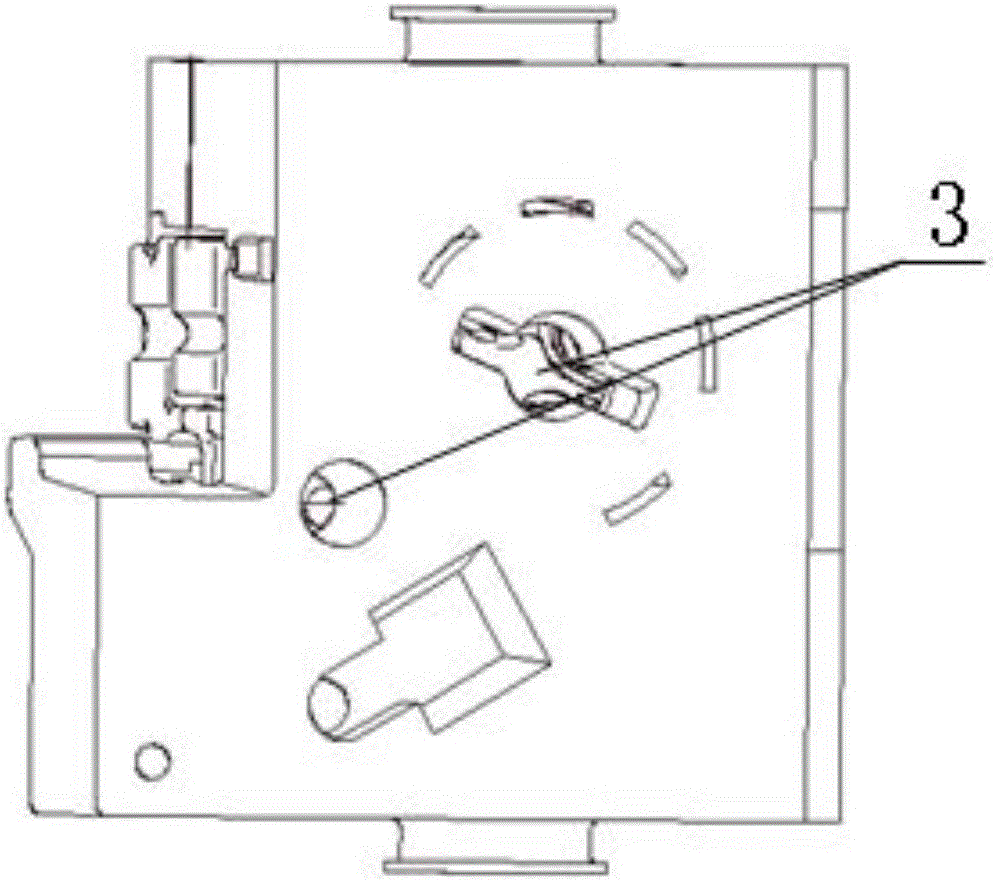

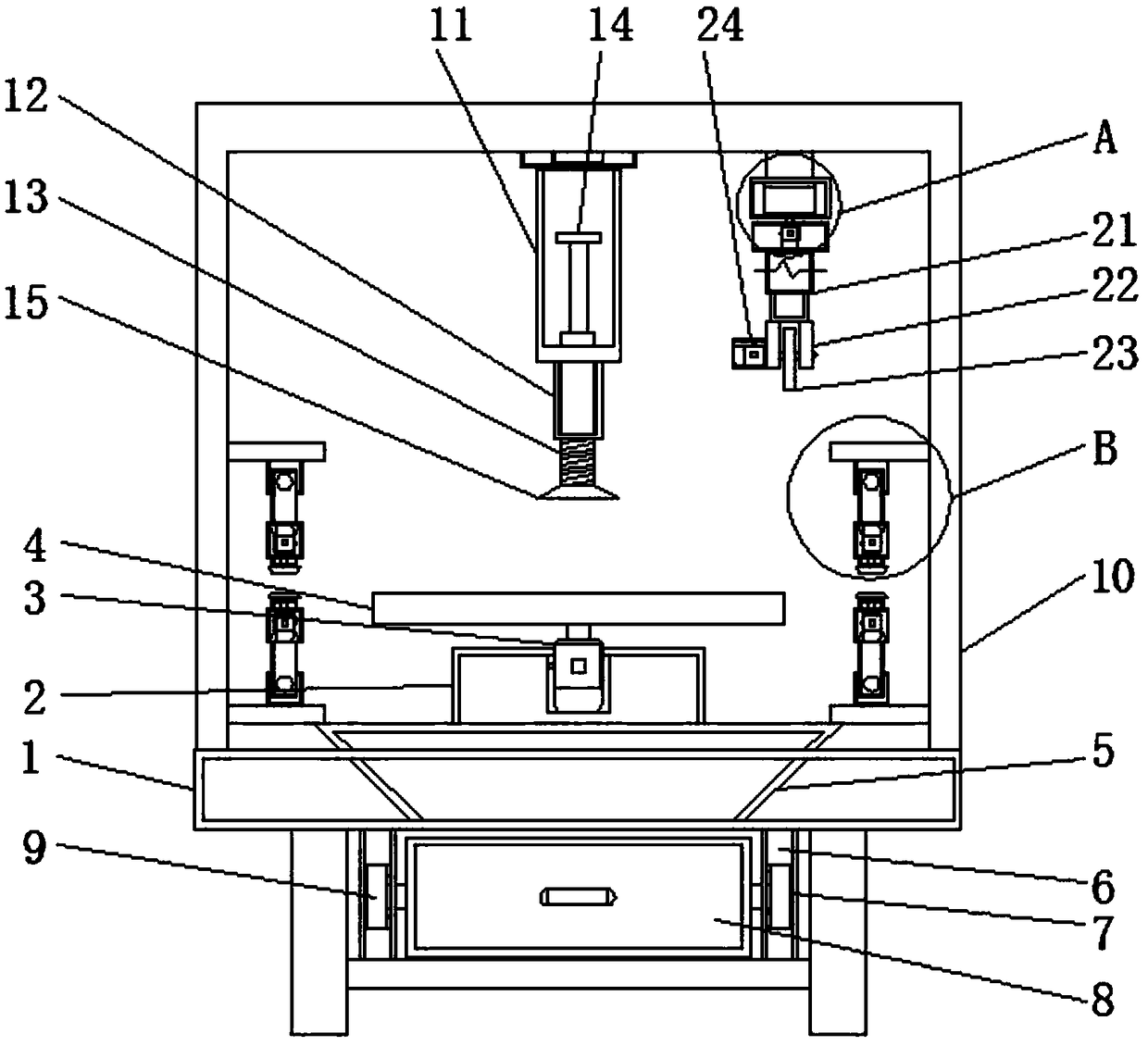

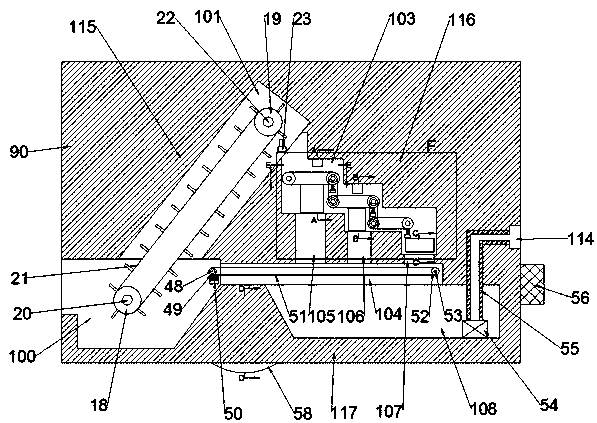

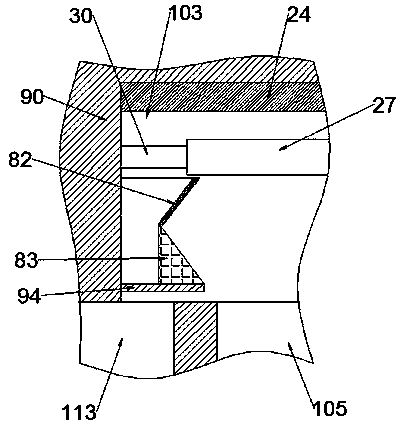

Dual-cylinder tabletop-type selective laser melting molding equipment and dual-cylinder tabletop-type selective laser melting molding method

The invention discloses dual-cylinder tabletop-type selective laser melting molding equipment and a dual-cylinder tabletop-type selective laser melting molding method. The dual-cylinder tabletop-type selective laser melting molding equipment comprises a sealed molding chamber, an optical transmission system, a powder spreading device, a molding cylinder and a powder cylinder, wherein a molding platform is arranged on the upper part of the molding cylinder and the powder cylinder; a movable platform is arranged above the molding platform; the molding platform serves as a guide rail of the movable platform, so that the movable platform can move left and right on the molding platform; the molding platform is provided with a powder spreading device and a powder acquiring system; the powder acquiring system comprises a powder acquiring base platform and a powder acquiring barrel, the powder acquiring barrel is arranged on the upper part of the powder acquiring base platform. Aiming at key points of a direct precious metal molding system, namely powder recovering and clearing, the dual-cylinder tabletop-type selective laser melting molding equipment is provided with the powder acquiring structure which can be completely taken out easily, and no powder is remained on the inner corners of the molding cylinder / powder cylinder, so that material wastes in a molding process are reduced, and the dual-cylinder tabletop-type selective laser melting molding equipment can be applied to direct molding of individual parts made of precious metals such as gold, silver and platinum in the bijouterie industry.

Owner:GUANGZHOU LEIJIA TECH CO LTD

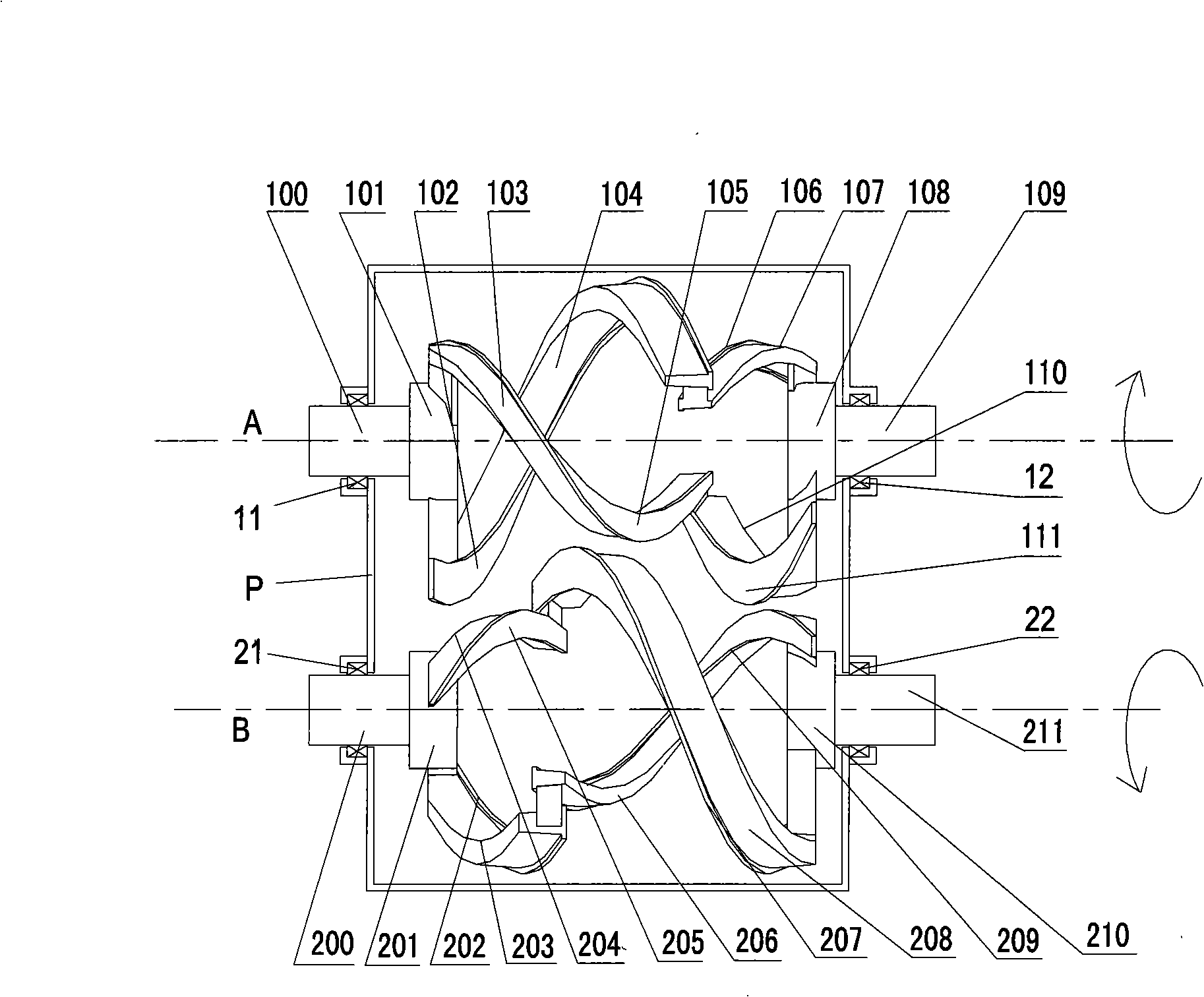

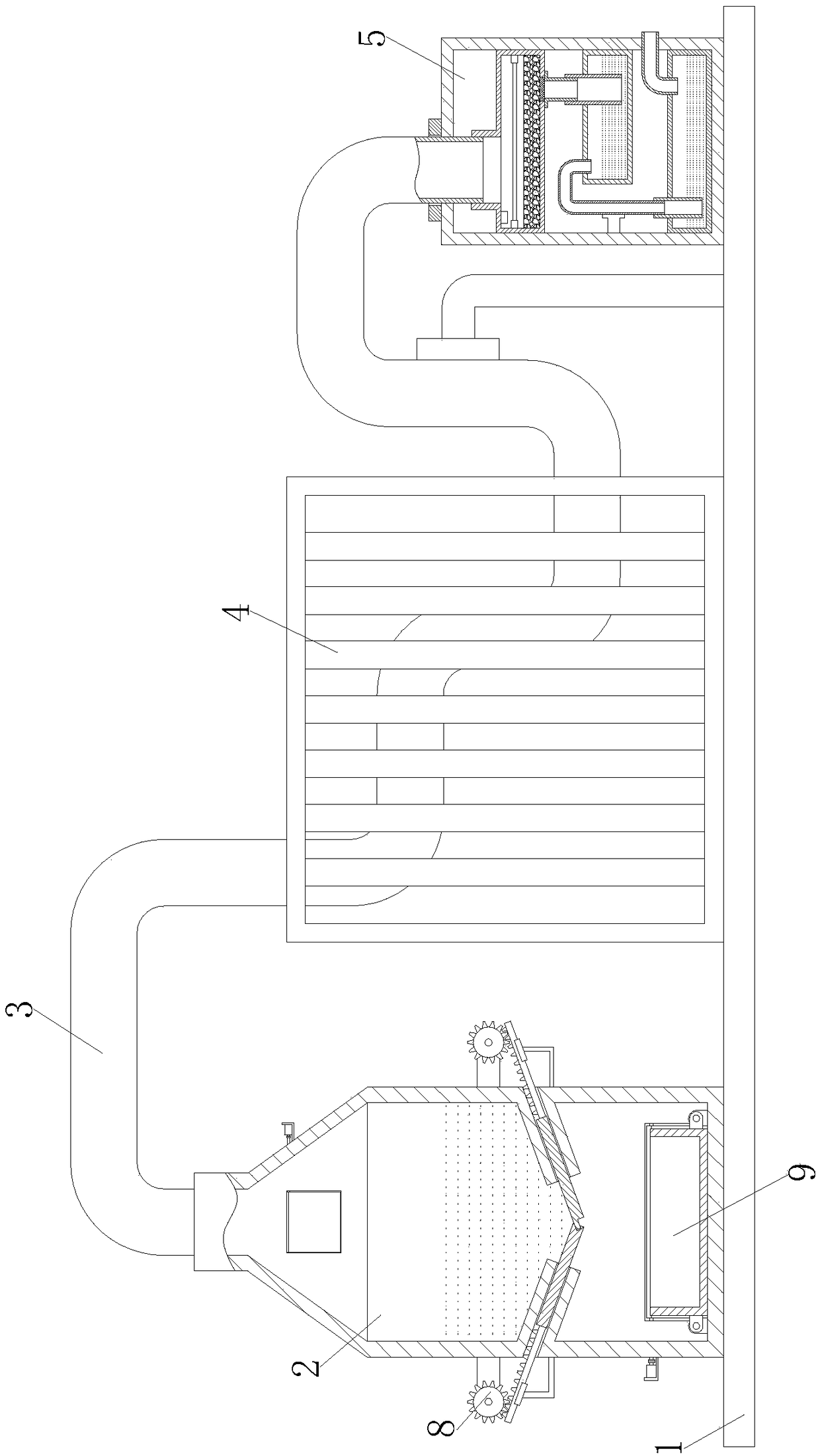

Double-helix shaft double-helical ribbon concrete batch plant

InactiveCN101347961ANot easy to hold the shaft and agglomerateSpeed up the flowCement mixing apparatusFistHorizontal axis

The invention relates to a double spiral axis double spiral ribbon concrete mixing plant, which relates to a mixer for clay or cement and other materials which turns around the horizontal or basically horizontal axis. The concrete mixing plant is provided with a machine body, a first agitation system and a second agitation system. The fist agitation system is provided with a left spindle head, a right spindle head and four spiral axes which are connected with the left and right spindle heads. The second agitation system is provided with the left spindle head, the right spindle and the four spiral axes which are connected with the left and right spindle heads. The direction of the spiral of an internal return unit shaft is opposite to that of the spiral of an internal feeding unit shaft; and the direction of the spiral of an external feeding unit shaft is opposite to that of the spiral of the external return unit shaft. The left and right spindle heads of the first agitation system and the second agitation system are connected with a bearing bracket arranged on the machine body. The speed at which the spindle axes move relative to materials is larger;, so the materials are subject to smaller resistance when being mixed in the mixer, the cement is difficult to curdle around the axes, and the materials flow smoothly in the mixer, thus ensuring that the mixer has .lower energy consumption and higher mixing efficiency, reducing cleaning time and increasing the service efficiency of the mixer.

Owner:蔡达棋

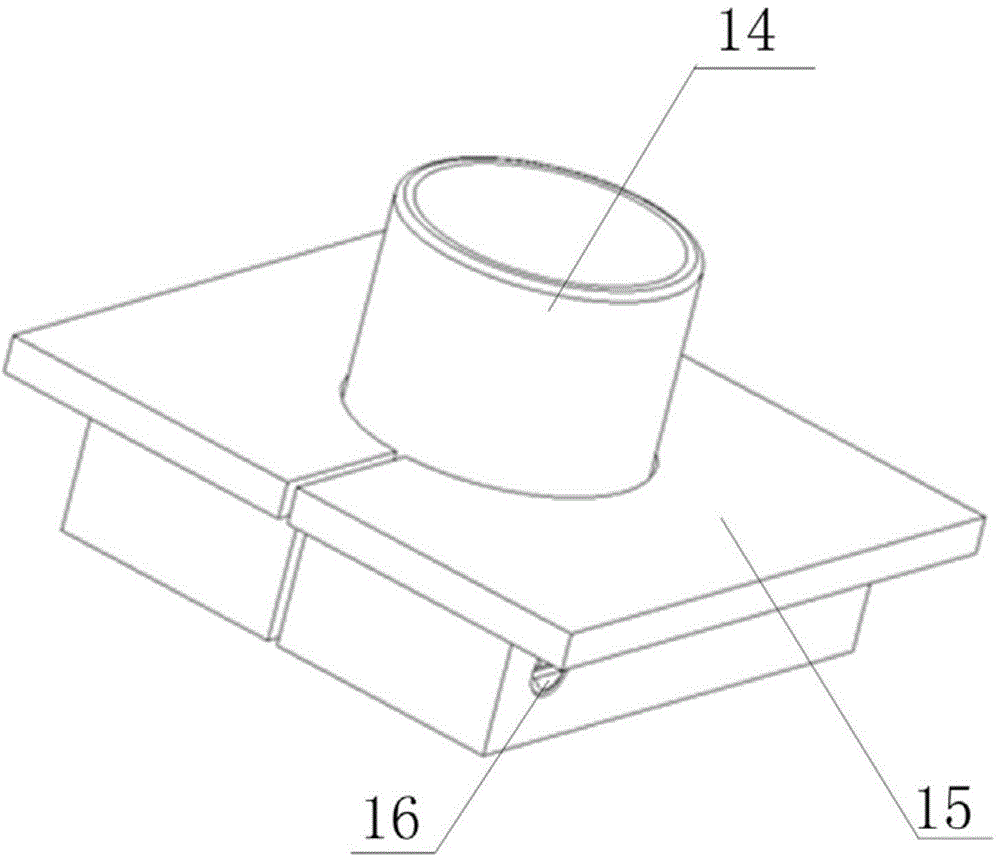

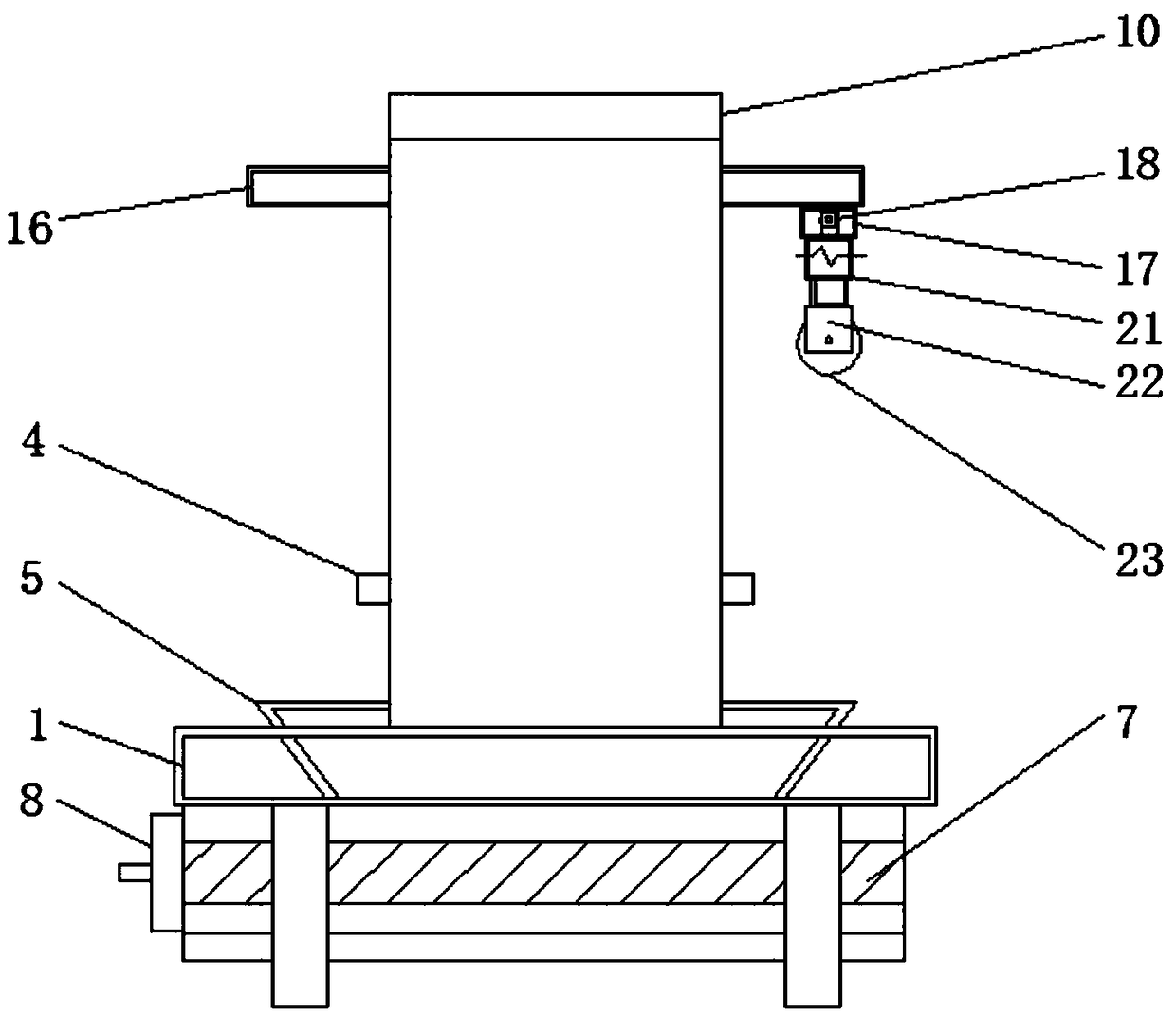

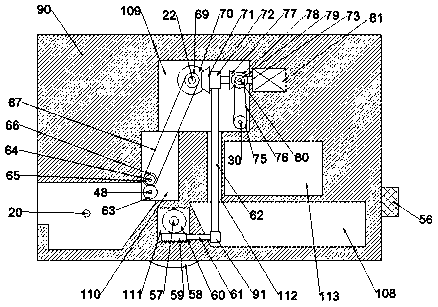

Foldable changeable forming device for selective laser melting

The invention discloses a foldable changeable forming device for selective laser melting. The foldable changeable forming device is characterized by comprising a forming substrate, a base plate and a telescopic cover reduced from bottom to top gradually. The forming substrate is fixed on the base plate, the lower end of the telescopic cover is fixed to the periphery of the base plate, the base plate is connected with an upper plate of an electric push bar through a lower clamping part, and the upper end of the telescopic cover is connected with the lower surface of a forming face through an upper clamping part. After finishing the forming process, parts can be taken out and residual powder can be cleaned by only removing the foldable changeable forming device.

Owner:XI AN JIAOTONG UNIV +1

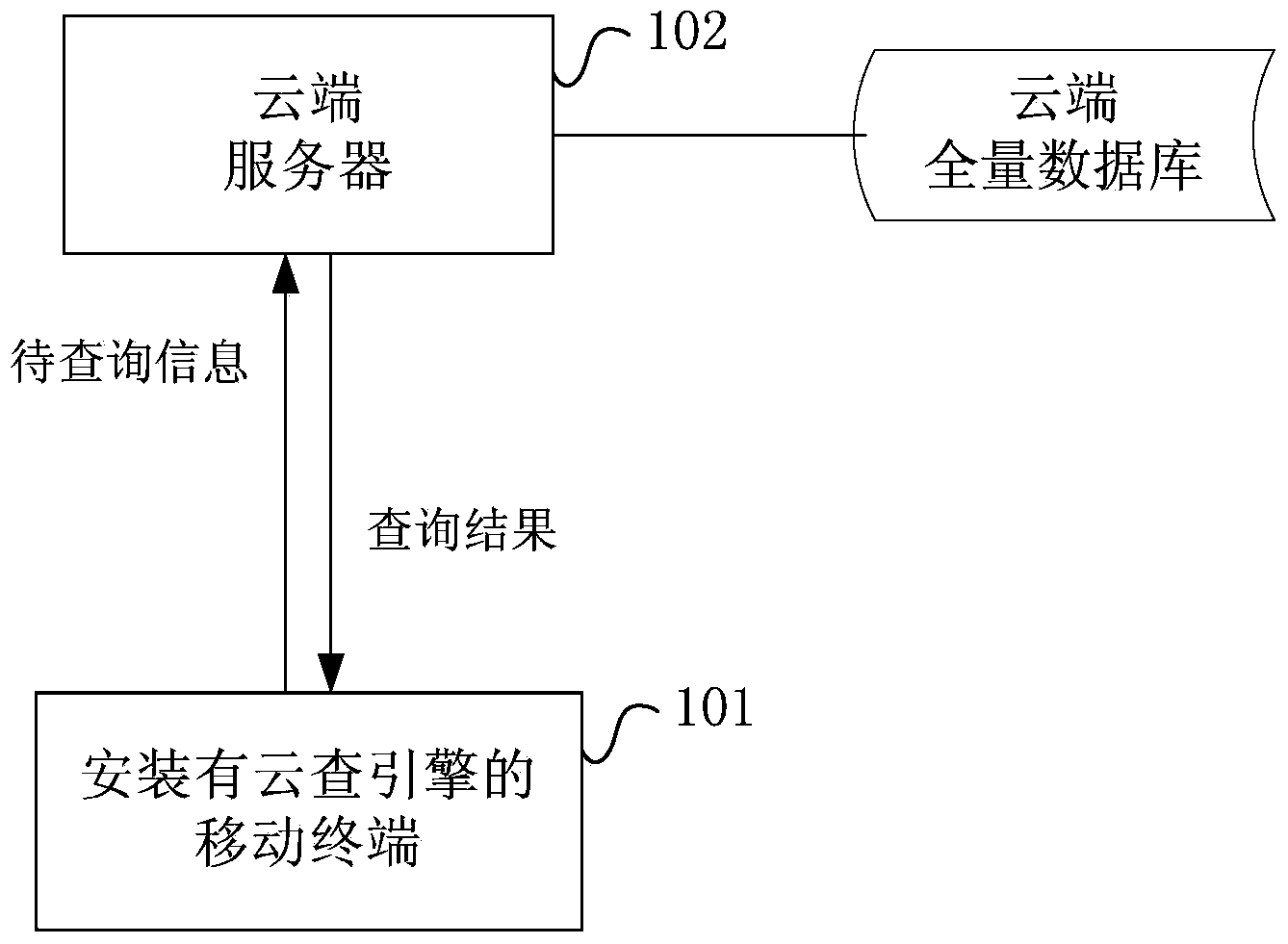

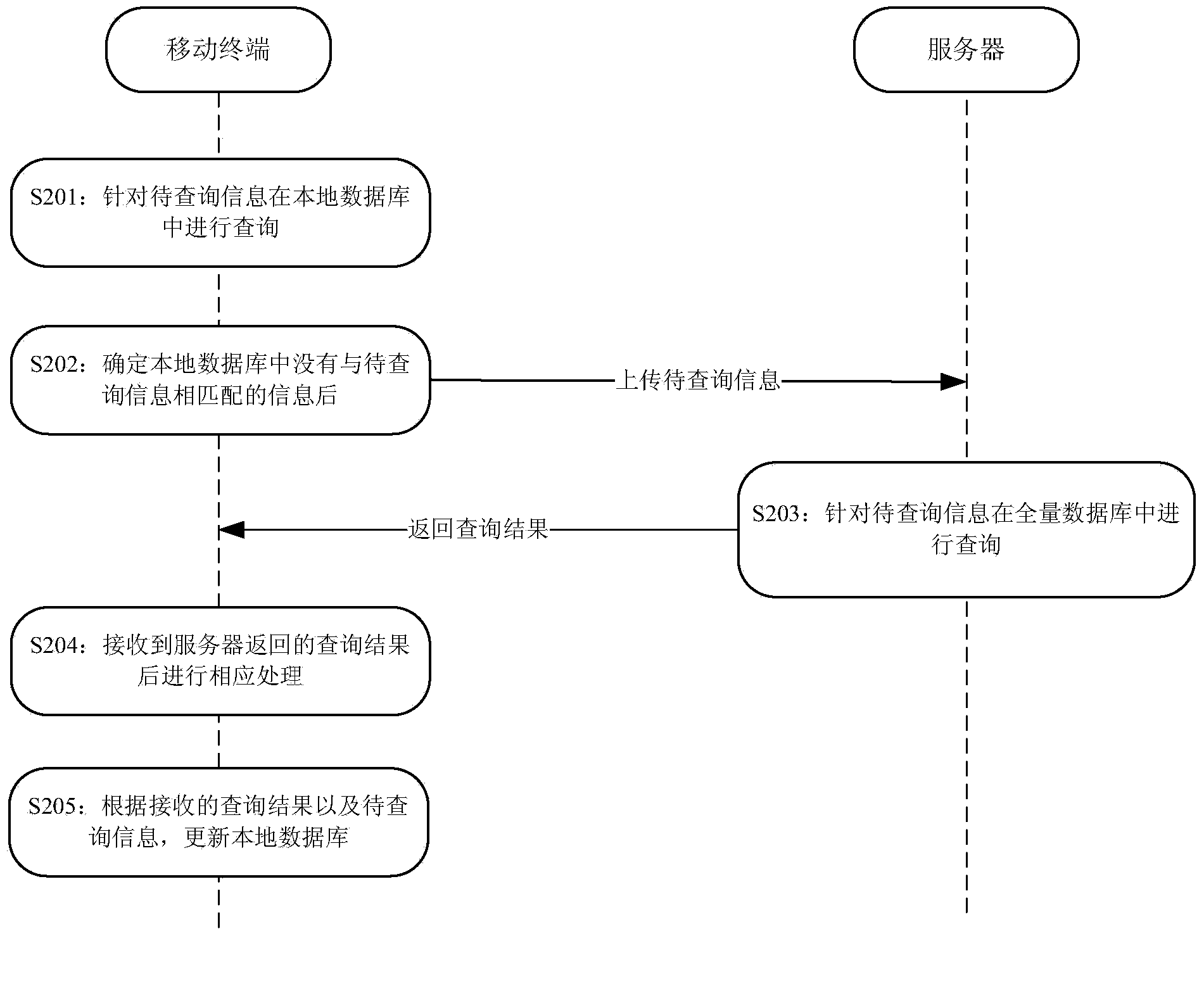

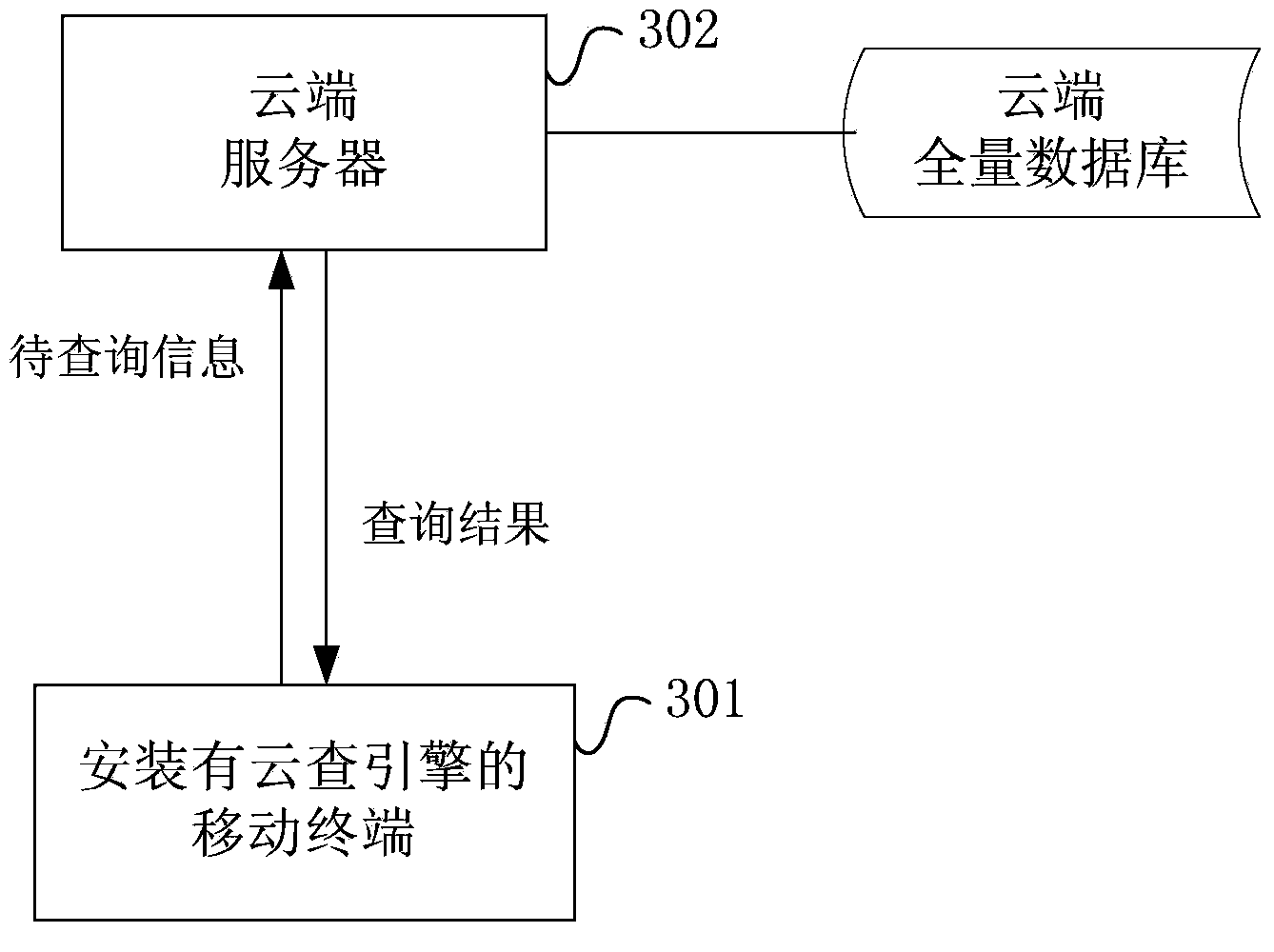

Query and memory space cleaning method and system based on cloud server

InactiveCN104317956AQuery is validEasy to cleanSpecial data processing applicationsComputer scienceOperating system

The invention discloses a query and memory space cleaning method based on a cloud server and a query and memory space cleaning system thereof, wherein the memory space cleaning method based on the cloud server comprises the following steps of: scanning the memory space by a mobile terminal and taking a path of a currently scanned catalogue as to-be-queried information and inquiring it in a local database; confirming that information matched with the to-be-queried information is absent from the local database in the mobile terminal, and uploading the to-be-queried information to the server; collecting garbage from corresponding catalogues by the mobile terminal according to the cleaning strategies of the content returned by the server. Through application of the method and the system, the query efficiency can be improved so as to save the memory space and further improve the cleaning efficiency.

Owner:BEIJING QIHOO TECH CO LTD +1

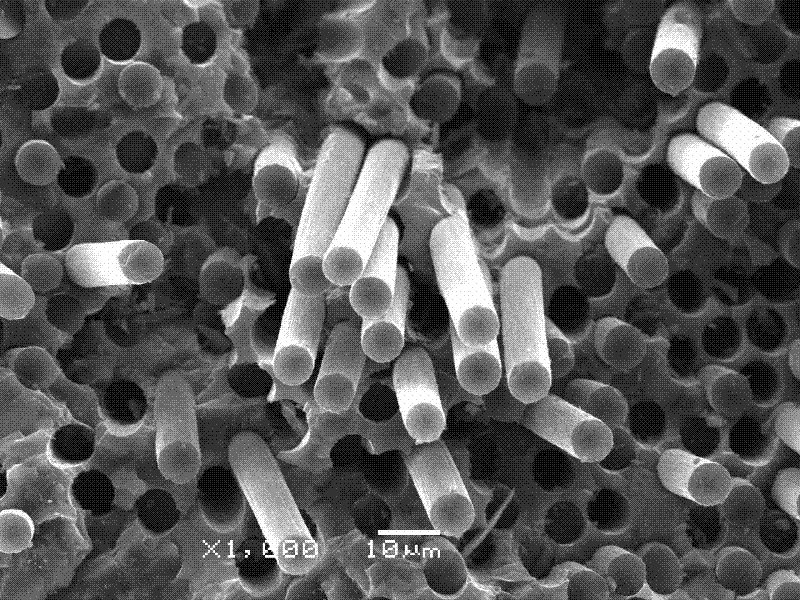

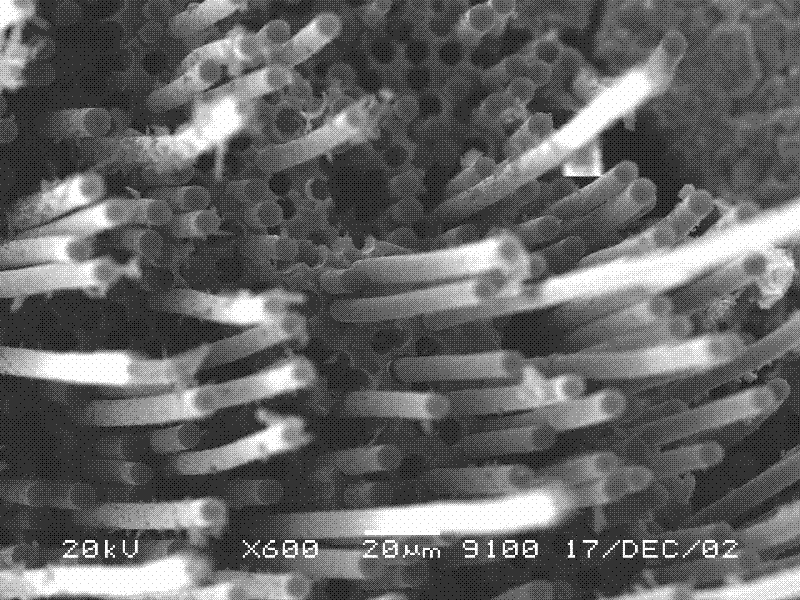

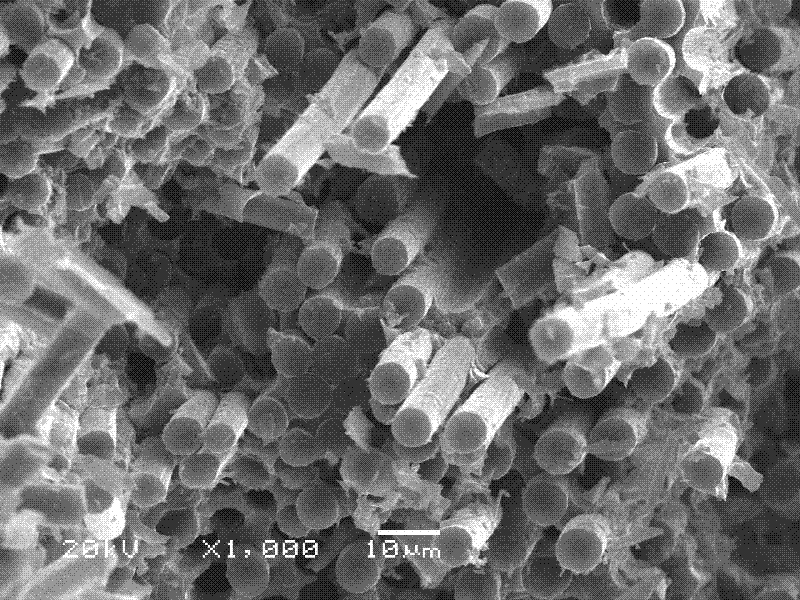

Method for preparing carbon-fiber-reinforced silicon carbide composite material

The invention discloses a method for preparing a carbon-fiber-reinforced silicon carbide composite material, and the method comprises the following steps: preparing a carbon-fiber woven fabric, and placing the carbon-fiber woven fabric under a vacuum condition with a pressure of less than 500 Pa, and then dipping the carbon-fiber woven fabric by using a polycarbosilane precursor solution for 2-12hours; drying the dipped carbon-fiber woven fabric in the air at room temperature; then placing the dried carbon-fiber woven fabric under a vacuum condition with a pressure of less than 500 Pa again,raising the temperature of the carbon-fiber woven fabric to 1000-1600 DEG C at a temperature rise speed of 1-30 DEG C / min, then carrying out heat preservation on the carbon-fiber woven fabric for 30-240minutes so as to carry out splitting decomposition on the carbon-fiber woven fabric; repeating a cycle of dipping, drying in the air and splitting decomposition until when a cycle is finished, the weight of a sample is increased by no more than 1% compared with that of the sample obtained when the last cycle is finished, thus a Cf / SiC composite material is obtained. The method disclosed by the invention has the advantages that no shielding gas atmosphere is required, and the dust on the surface of the sample can be reduced, thereby reducing the cleaning times of a furnace body and the sample, and the like; and by using the method disclosed by the invention, products with strong high-temperature resistant properties and high antioxidant properties can be provided.

Owner:NAT UNIV OF DEFENSE TECH

Method for cleaning and descaling phosphoric acid storage tank

InactiveCN101758048ASave cleanup timeReduce cleanup costsHollow article cleaningPhosphoric acidChemistry

The invention discloses a method for cleaning and descaling a phosphoric acid storage tank, which comprises the following steps: preparing a cleaning solution from 2 to 6 mass percent of nitric acid, 2 to 6 mass percent of sulphuric acid, 4 to 8 mass percent of hydrofluosilicic acid and 0.01 to 0.02 mass percent of sustained release agent; and heating the cleaning solution, adding the cleaning solution into the phosphoric acid storage tank, starting a stirrer to stir the mixed solution and dipping scales in the storage tank with the cleaning solution to clean and remove the scales, wherein the sustained release agent is sodium molybdate or ATMT; temperature at which the cleaning solution is heated is 50 to 80 DEG C; and the scales in the storage tank are dipped for 24 hours. By adopting the method of the invention, the cleaning time of the phosphoric acid storage tank is shortened, cleaning cost is reduced and the operating ratio of a device is increased. The cleaning solution in the method is simple to prepare, convenient to use and recyclable. The method is applied to wet-process phosphoric acid production factories.

Owner:WENGFU (GRP) CO LTD

Fluorocarbon rubber with easy demoulding and tear resistance and preparation method thereof

The invention provides a fluorocarbon rubber with easy demoulding and tear resistance and banburying method thereof, comprising the following components: 100 parts of crude fluororubber; 4-6 parts of high activity magnesium oxide; 2-4 parts of calcium hydroxide; 1.5-6 parts of iron oxide red; 0.4-1.0 part of rubber ingredient WS280; 0-1.0 part of rhine 54; 0-1.0 part of brazil carnauba wax; 1.2-2.4 parts of bisphenol AF; 0.4-1.0 part of benzyltriphenylphosphonium chloride; and appropriate calcium silicate or barium sulphate added according to hard requirement. The invention also provides two banuring methods of fluorocarbon rubber with easy demoudling and tear resistance. The product of the invention has good demoulding performance, and the produced trimming after vulcanization can be taken down along with the product, thus reducing clearing time of operators and avoiding waste production caused by reduction of mould temperature. By the improvement of banburying method of fluorocarbon rubber, dispersion performance of fluorocarbon rubber can be improved, thus improving demoulding performance thereof in vulcanization and reducing tear of product, so that scrap rate of product in one specification caused by tear is reduced to 0.15% from 0.36% (reduced by near 60%).

Owner:QINGDAO TKS SEALING IND

Cylinder cover casting method

InactiveCN105964939AReduce in quantityReduce the difficulty of cleaningAdditive manufacturing apparatusFoundry mouldsAdhesiveMaterials science

The invention discloses a cylinder cover casting method. A sand mold is designed according to a cylinder cover, and is cut to multiple sand core units; an upper water cavity sand core is designed as a complete integral structure, and is provided with a through hole; the through hole totally wraps the outer periphery of an air way sand core; a gap is formed between the inner wall of the through hole of the upper water cavity sand core and the air way sand core; the upper water cavity sand core and the air way sand core are synchronously and integrally printed; then, all the sand core units are combined as a whole to form the complete sand mold; and the sand mold is cast to obtain the cylinder cover. The cylinder cover casting method reduces the sand core number, can effectively shorten the core assembly working time, enables the upper water cavity sand core to have no binding gaps, cannot generate cracks in pouring, improves the casting quality, needs no adhesive, and solves the problem of fire boiling caused by no drying of the adhesive in the casting pouring process.

Owner:四川共享铸造有限公司

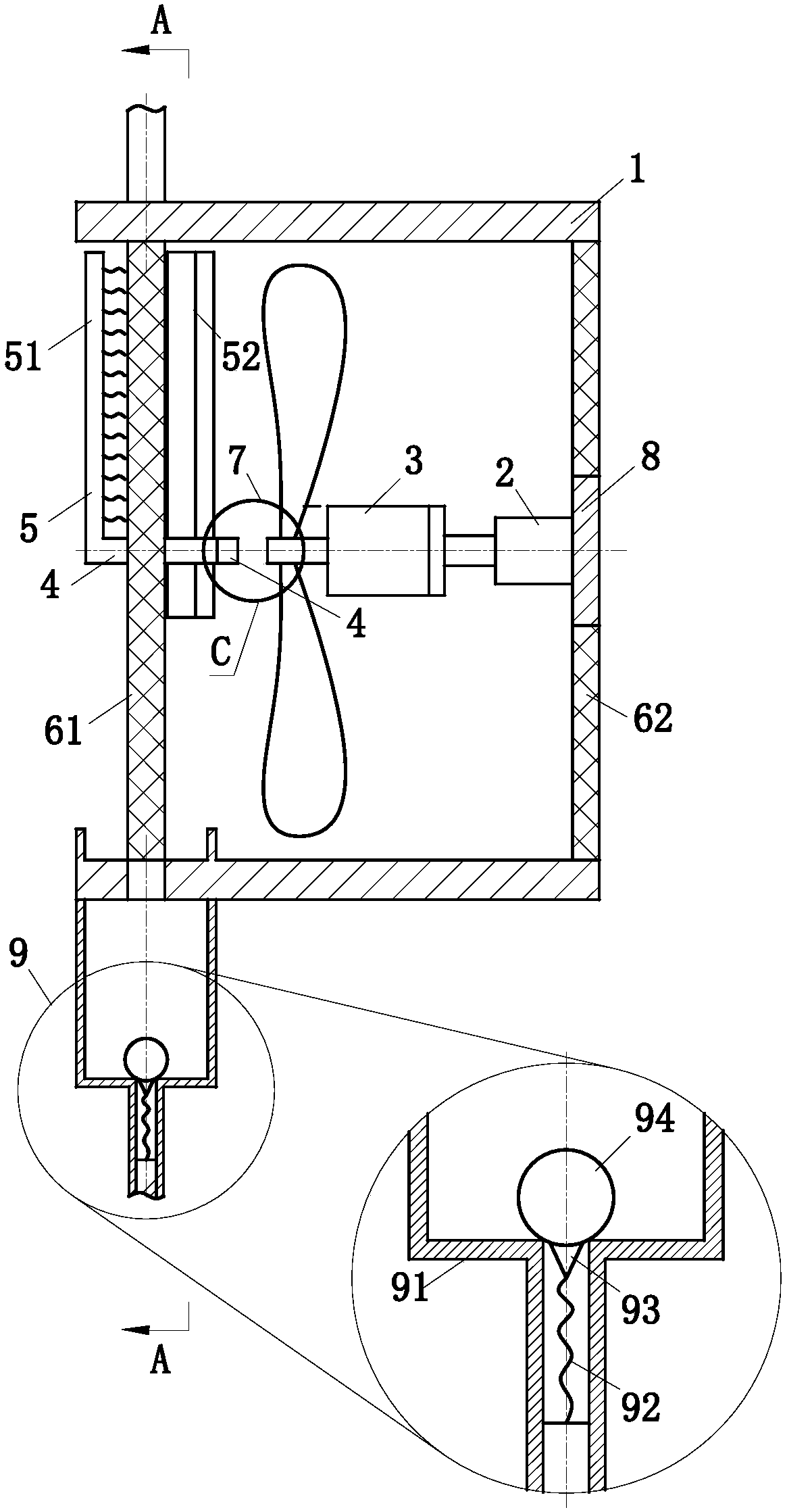

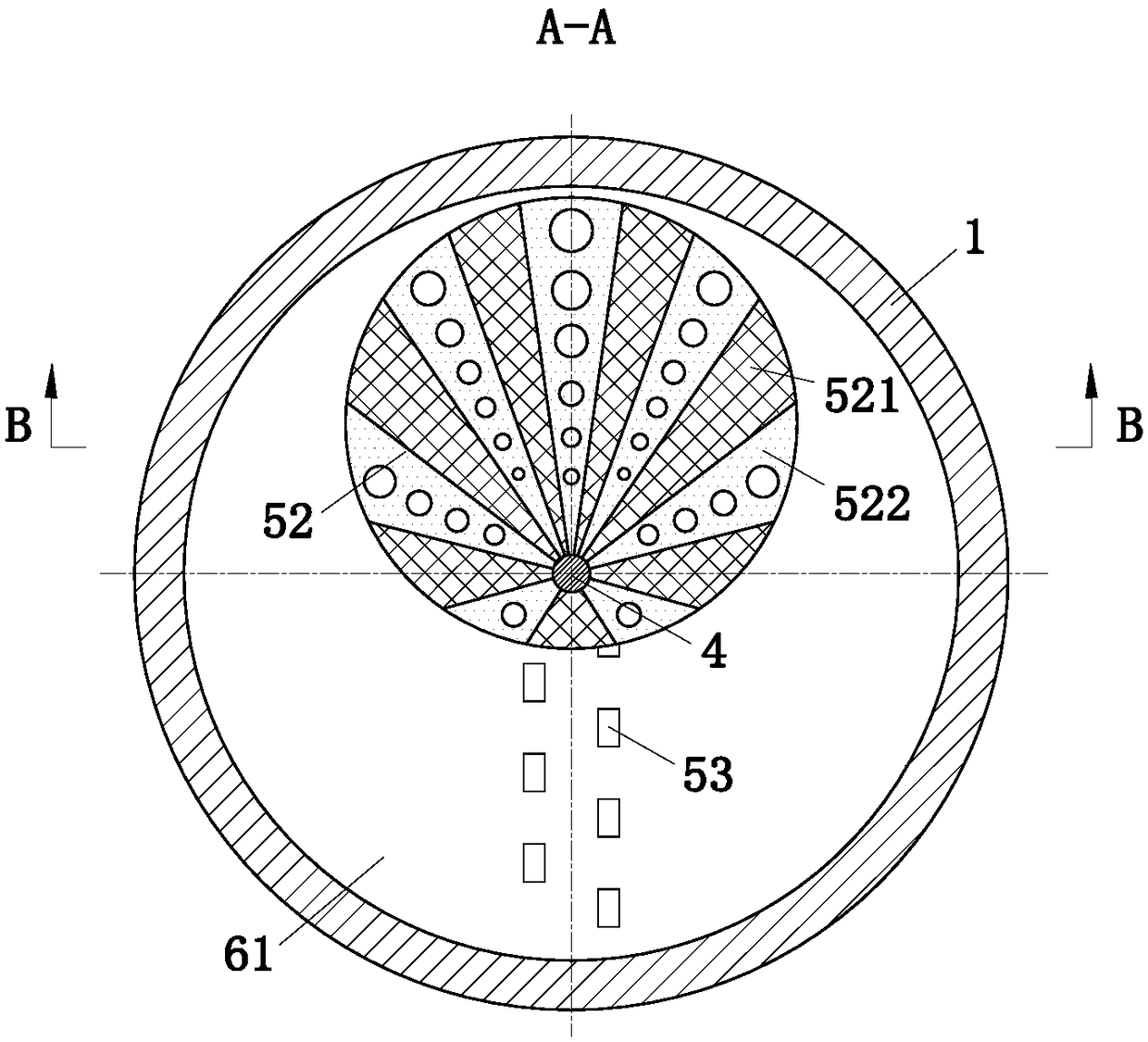

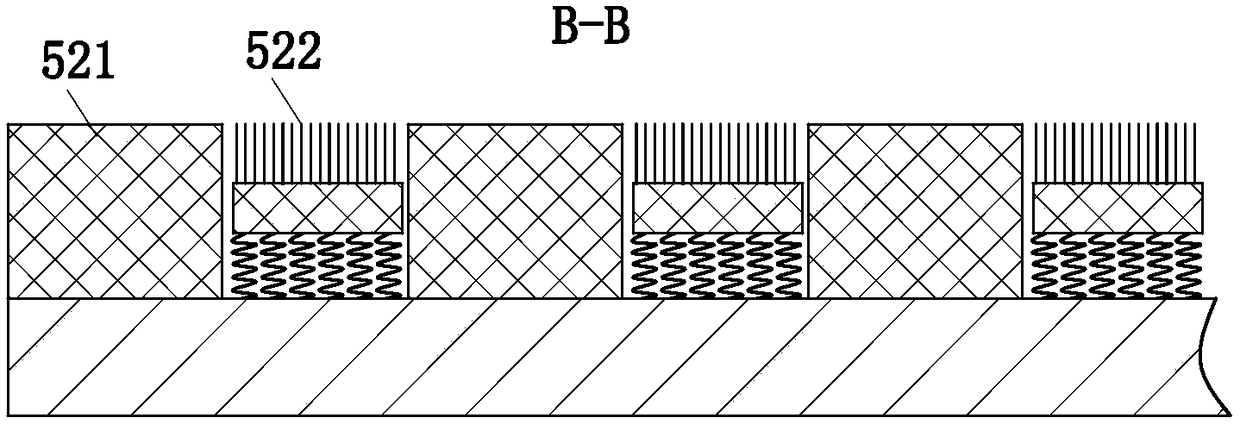

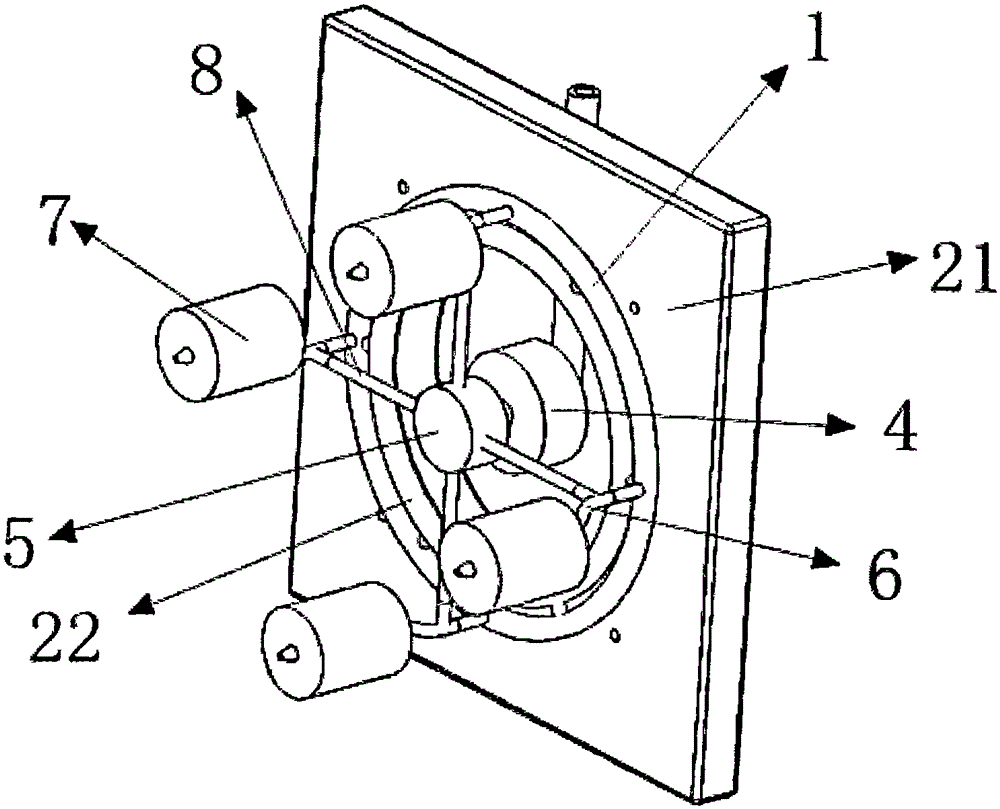

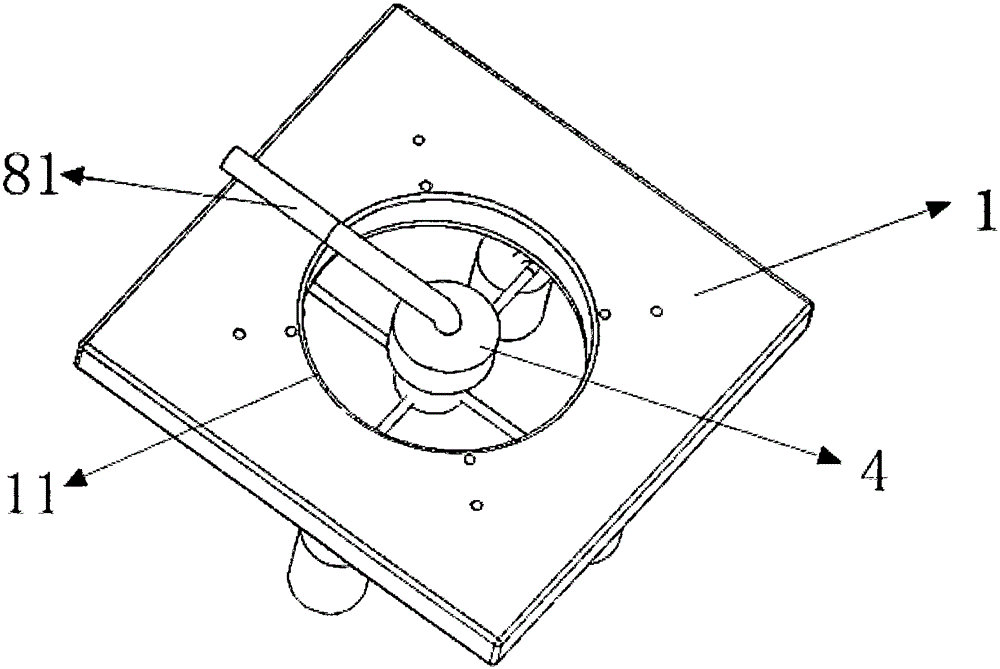

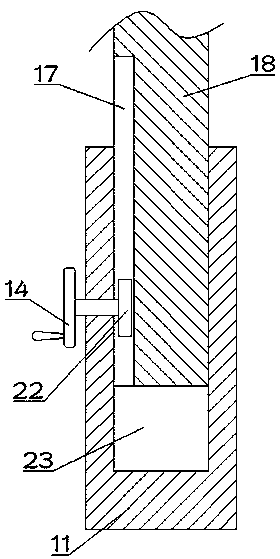

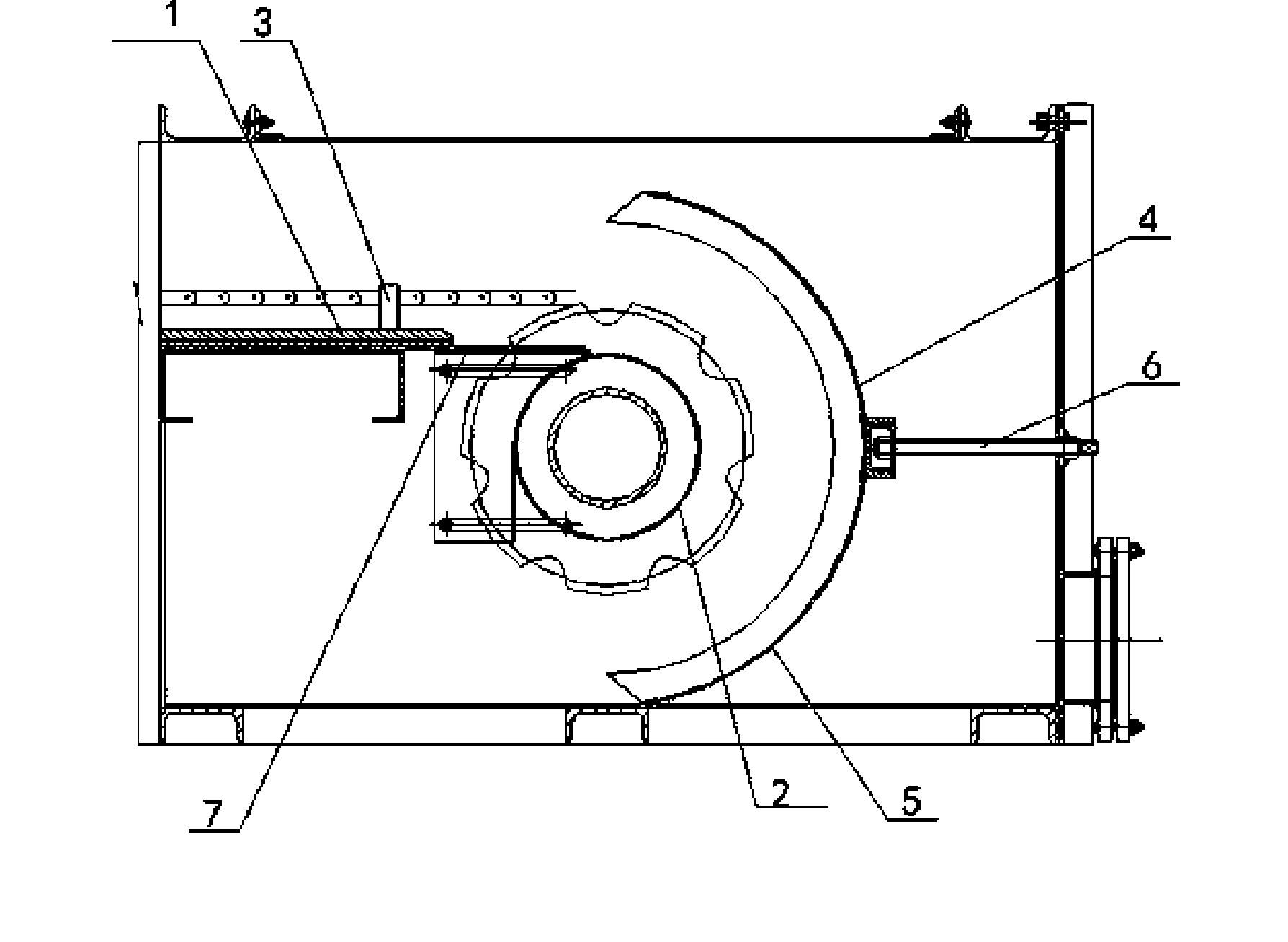

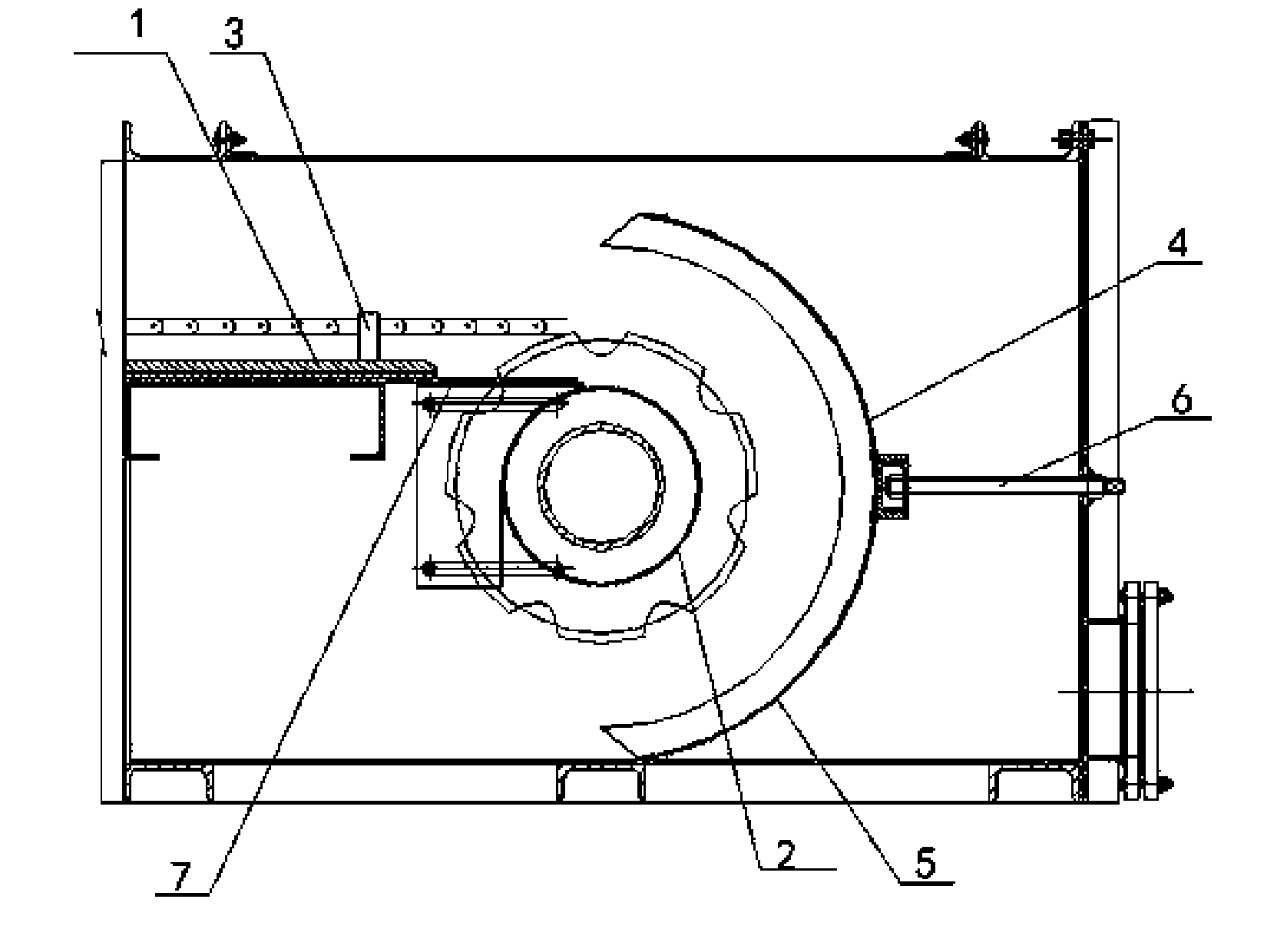

Exhaust fan

InactiveCN108591089AImplement automatic cleanupClean up in timePump componentsPump installationsEngineeringClutch

The invention belongs to the technical field of exhaust fans, and particularly relates to an exhaust fan. The exhaust fan comprises a machine shell, an electric cylinder, a motor, a fan blade, a connecting shaft, a dust removal device, an air inlet mesh cover, an air outlet mesh cover, a clutch device, a mounting plate and a drainage device; the air inlet mesh cover is fixedly connected to the inner wall of the left end of the machine shell, and the air outlet mesh cover is fixedly connected to the inner wall of the right end of the machine shell; a first opening is formed in the center of theair outlet mesh cover, and the electric cylinder is fixedly installed in the first opening through the mounting plate; and the non-output end of the motor is fixedly connected to the end part of thecylinder rod of the electric cylinder; the clutch device matched with the dust removal device is arranged at the end of the rotating shaft of the motor; the dust removal device is rotationally arranged at the center of the air inlet mesh cover through a connecting shaft; and a spraying pipe is arranged above the air inlet mesh cover, and the drainage device is arranged below the air inlet mesh cover. The exhaust fan is mainly used for cleaning the mesh cover of the exhaust fan, the mesh cover can be automatically cleaned, and the cleaning efficiency is improved.

Owner:佛山市土禾设备实业有限公司

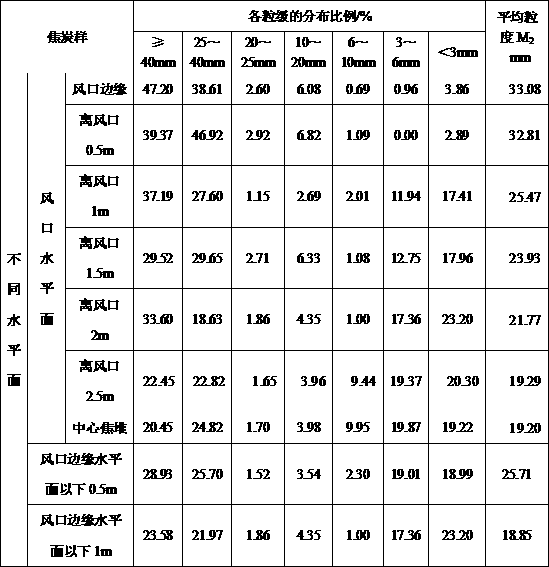

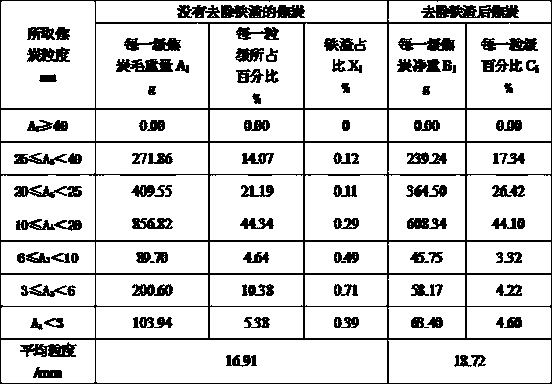

Method for evaluating coke degradation degree in blast furnace

ActiveCN108676944AReflect degraded behaviorAccurate guidanceBlast furnace detailsProcess efficiency improvementCombustionSlag

The invention provides a method for evaluating the coke degradation degree in a blast furnace. The method comprises the following steps that particle size analysis is carried out on coke entering theblast furnace on the previous day before damping down; when the blast furnace damps down, coke samples are taken; stemming in the coke is removed, and iron particles are taken out by a magnet for thefirst time; the particle size is graded; the coke which is taken out from each grade of coke is put into a muffle furnace for combustion correspondingly; after the coke is taken out, residual iron slags are taken out again by using the magnet; the iron slags are weighed; the weight percentage Xi of the residual iron slags taken out for each grade accounting for the coke of the same grade in the muffle furnace is calculated correspondingly; the net coke net weight Bi in the furnace with each particle size grade is calculated; the percentage Ci of the coke for each grade in the furnace accounting for the total weight of the coke is calculated; the average particle size M2 is calculated; the difference value M is calculated; the M is used for representing the degradation degree of the coke inthe blast furnace; and the shape and the size of a tuyere convolution zone are judged, and whether the coal gas distribution in the blast furnace is reasonable or not is analyzed so as to adaptivelyadjust the air inlet area and the air inlet speed of the blast furnace.

Owner:武汉钢铁有限公司

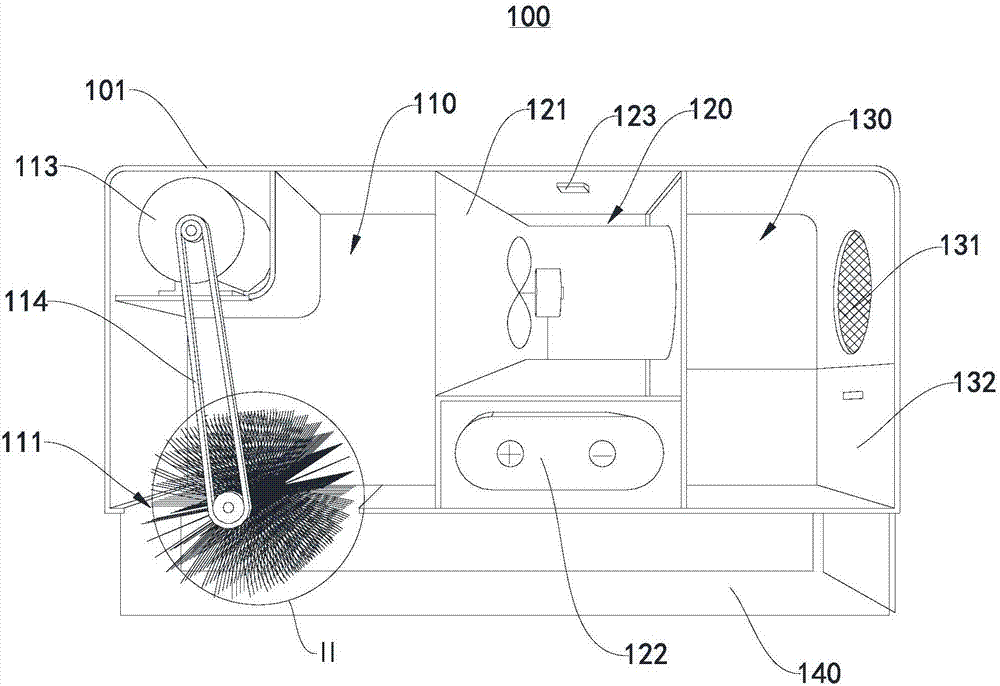

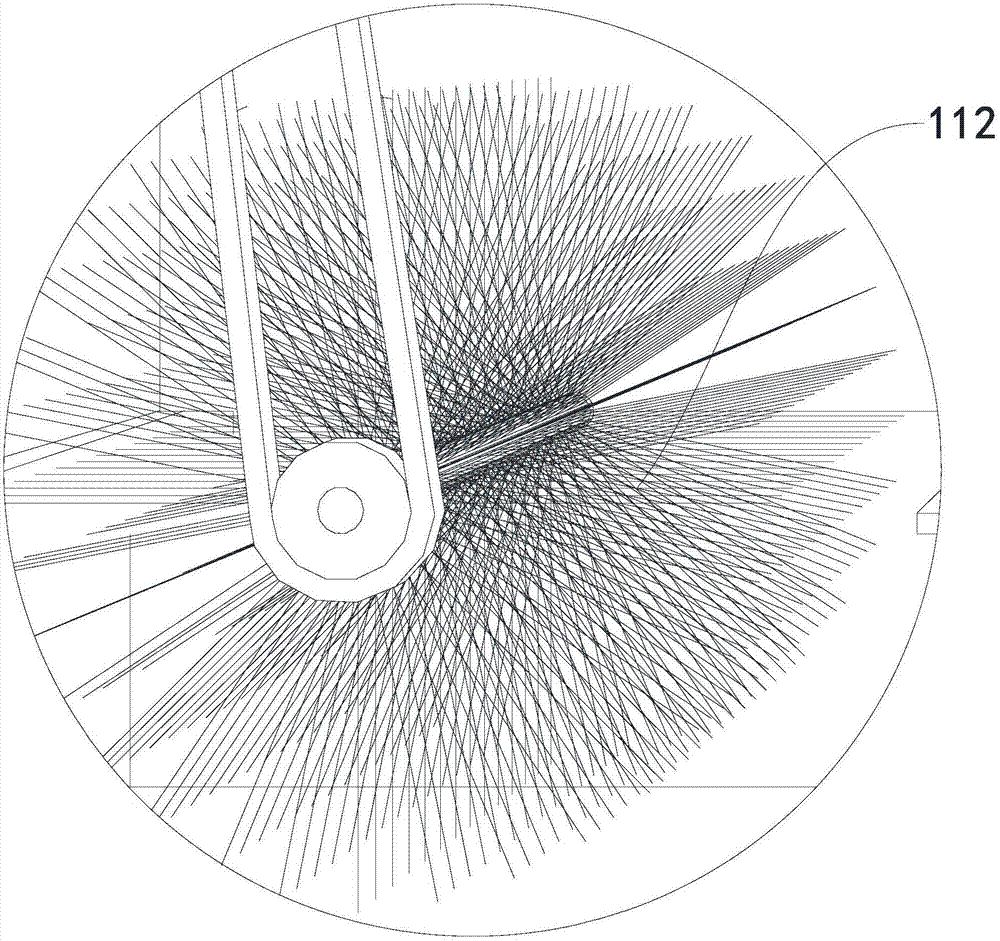

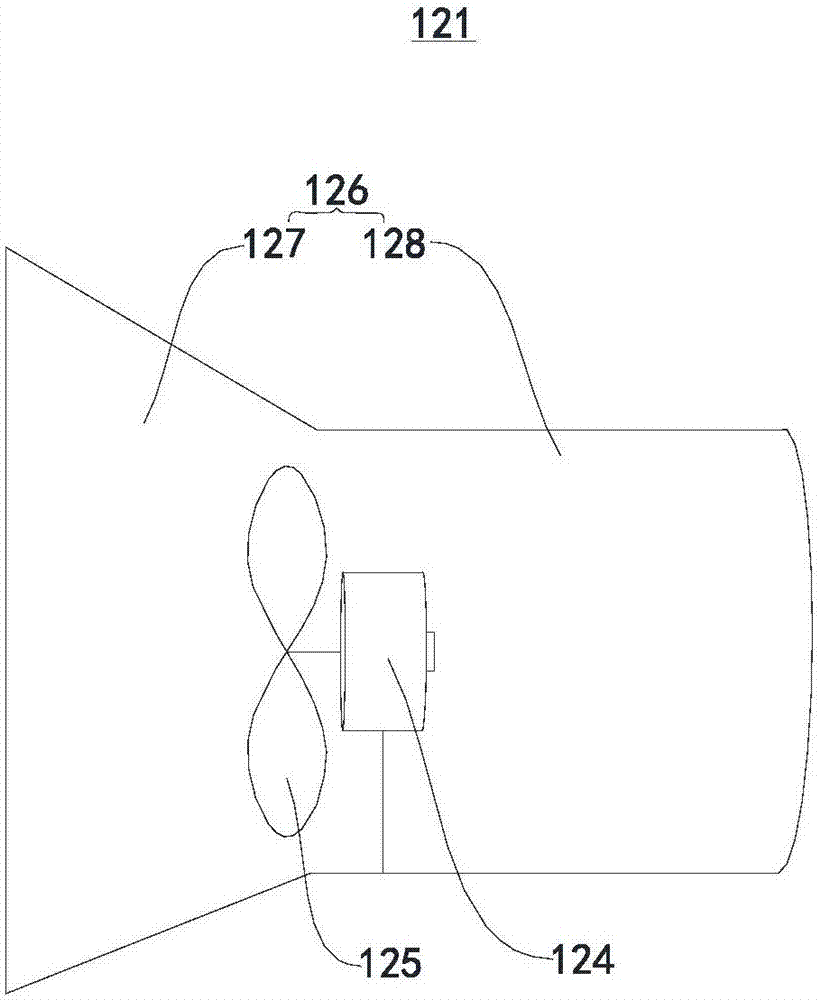

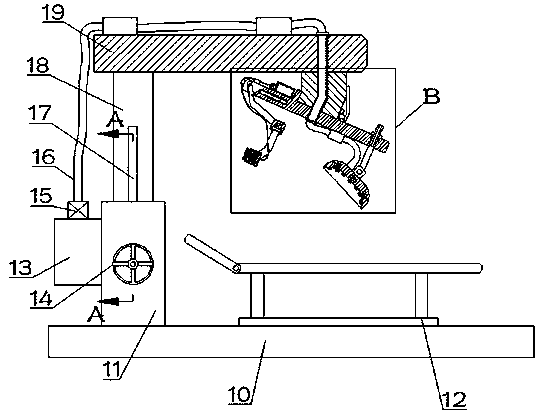

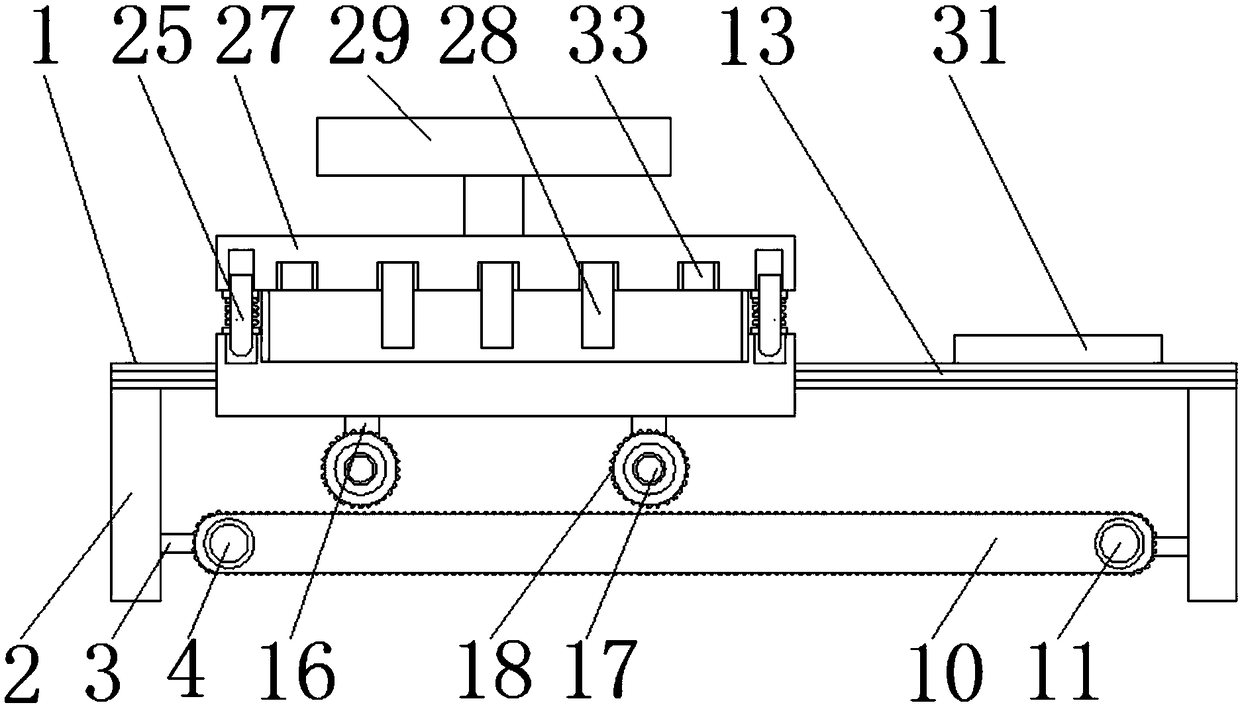

Window groove accumulated dust cleaning machine and full automatic window groove cleaner

The invention relates to the field of cleaning equipment and provides a window groove accumulated dust cleaning machine which comprises a housing, a brush and a dust collection assembly, a dust cleaning cavity and a dust collection cavity which are mutually communicated are formed in the housing, the brush is rotationally mounted in the cleaning cavity and partially stretches out of the cleaning cavity, and the dust collection assembly is arranged in the dust collection cavity. According to the window groove accumulated dust cleaning machine, the brush rotation dust collection manner and the dust collection assembly dust collection manner are used in a matched manner, the cleaning effect of the window groove is improved greatly, and the cleaning time of the window groove is greatly shortened. Besides, the invention further provides a full automatic window groove cleaner which comprises rollers, a moving motor and the window groove accumulated dust cleaning machine, and the rollers are mounted at the bottom of the housing of the window groove accumulated dust cleaning machine and electrically connected with the moving motor. Automatic cleaning can be realized, the human cost is reduced, the cleaning speed of the window groove is fast simultaneously, and the cleaning time is saved.

Owner:GUIZHOU INST OF TECH

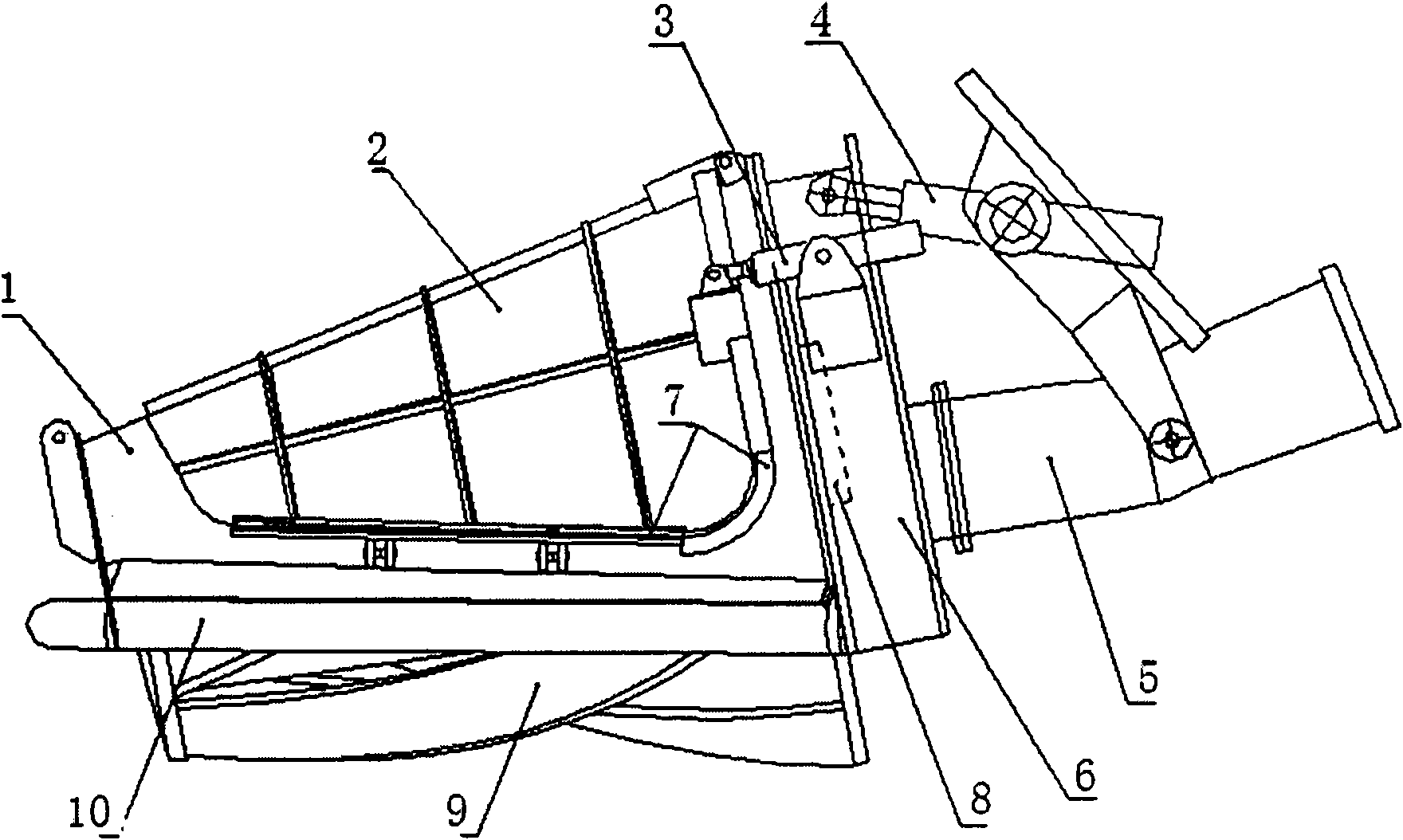

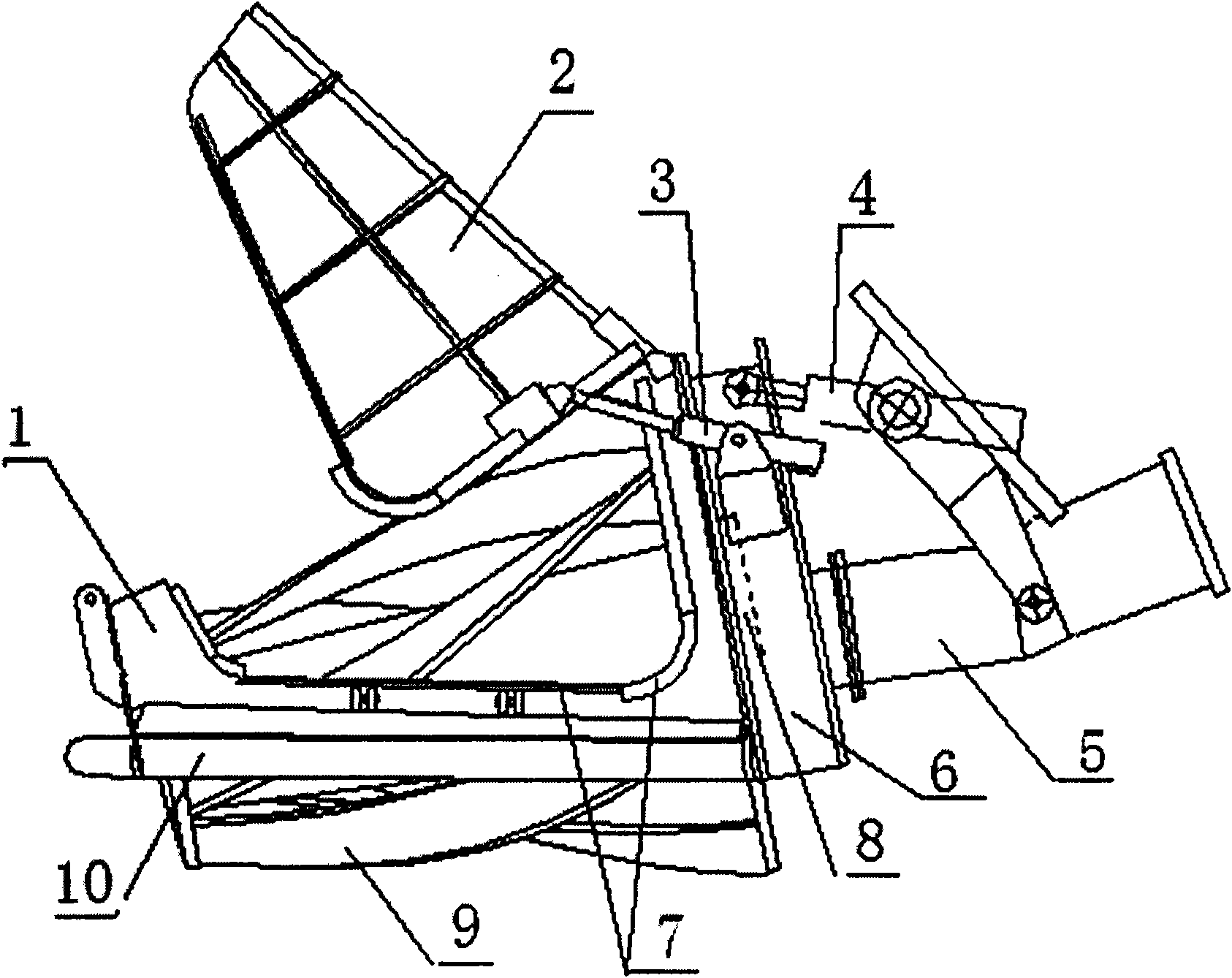

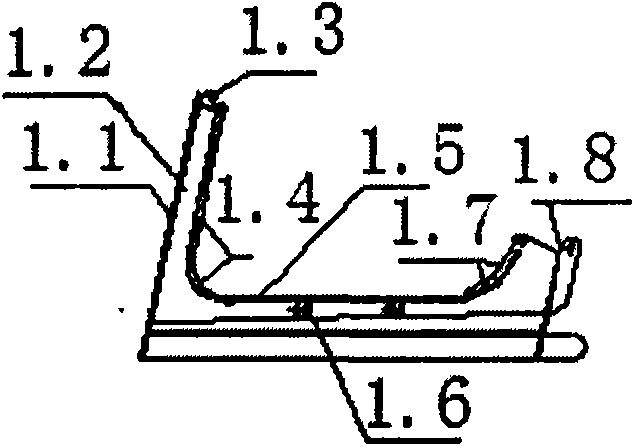

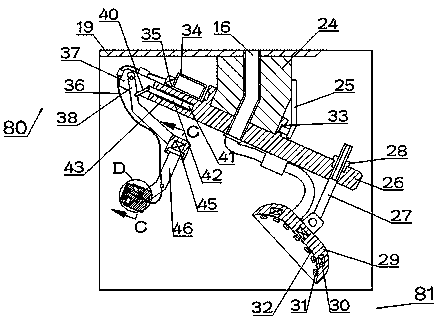

Environment-friendly dredger dredging reamer

ActiveCN101538873AAvoid enteringImprove dredging time utilizationMechanical machines/dredgersHydraulic cylinderHydraulic structure

The invention relates to an environment-friendly dredger dredging reamer, belonging to the field of dredging technology. The environment-friendly dredger dredging reamer comprises a reamer and a non-proliferation cover, and is characterized in that the non-proliferation cover consists of a fixed cover and a movable cover, wherein, the fixed cover is connected with the movable cover by a shaft, and the movable cover is connected with a hydraulic cylinder and is controlled to be opened by a hydraulic structure mode. The dredging reamer saves the time used for clearing out sundries, improves the utilization rate of dredging time of a dredger, and reduces the dredging cost. The proposal has the advantages of being convenient for dredging construction, reducing working strength of construction personnel, improving the construction efficiency of environment-friendly dredging, etc. The invention has good promotional value.

Owner:CCCC TIANJIN ECO ENVIRONMENTAL PROTECTION DESIGN & RES INST CO LTD

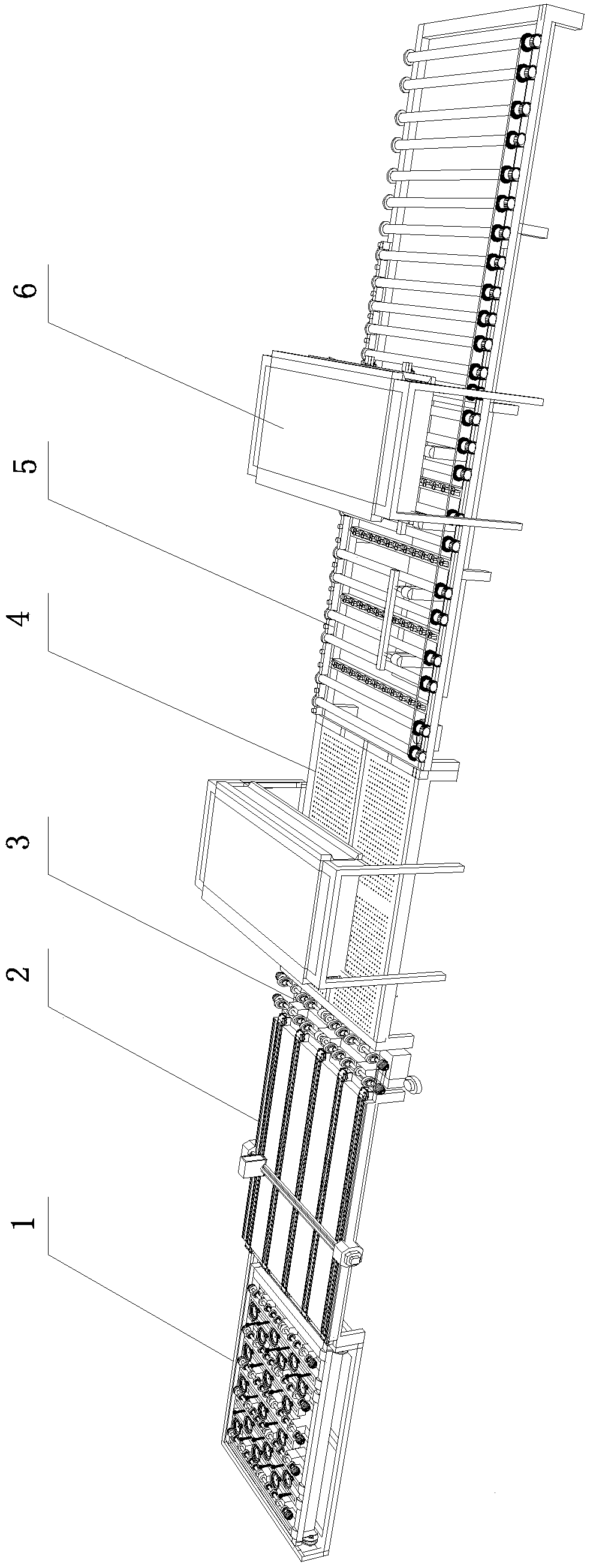

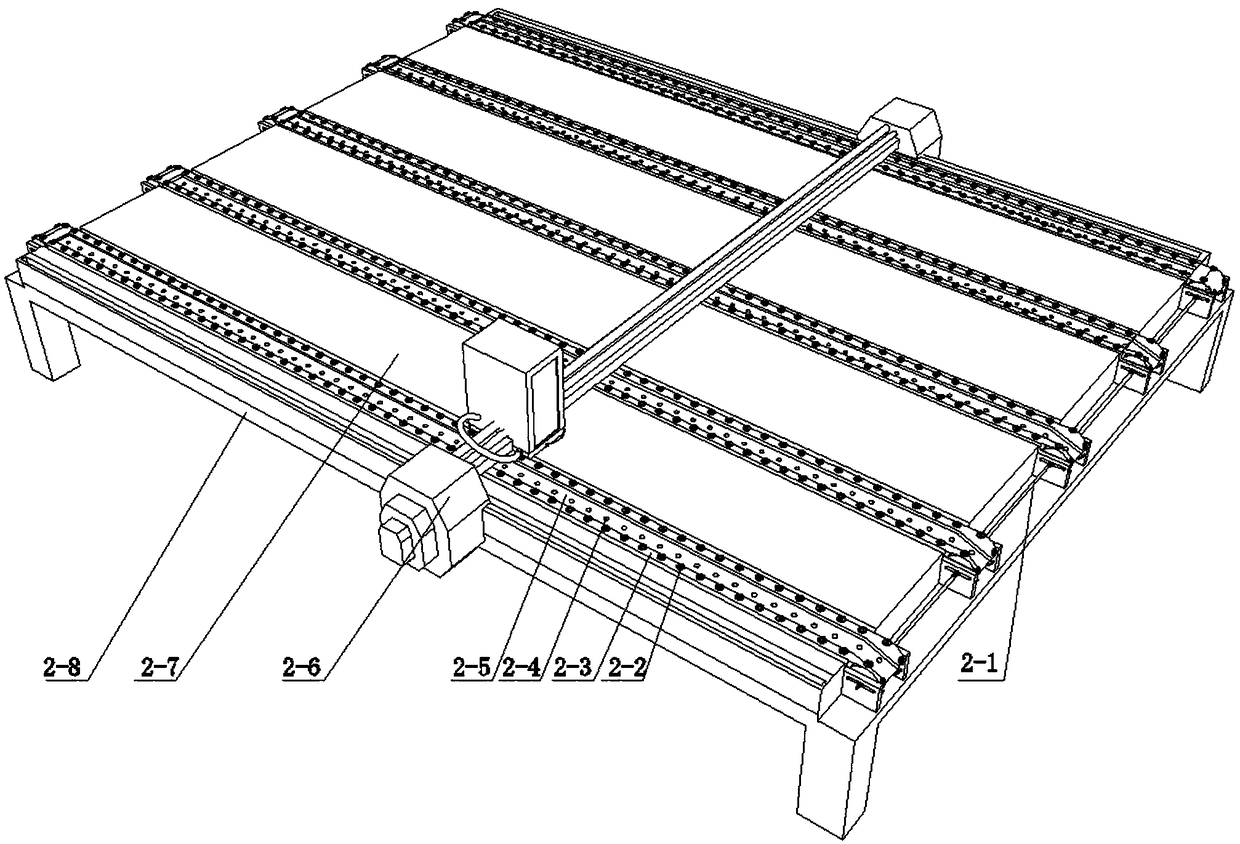

Full-automatic glass slitting and edge-grinding assembly line

PendingCN108943422ALow processing and production costsHigh degree of automationWorking accessoriesStone-like material working toolsTime efficientWater resources

The invention relates to a full-automatic glass slitting and edge-grinding assembly line. The assembly line is sequentially provided with a full-automatic glass loading machine, a full-automatic glasscutting machine, an automatic glass breaking table and a full-automatic glass edge grinding machine in the moving direction of glass. The assembly line can achieve the effects of full-automatic glassloading, feeding, cutting, breaking and edge grinding, the trouble of manual glass loading, manual cutting, manual breaking and manual edge grinding is avoided, moreover, the production environment protection efficiency of workers in each link is improved, machining of the glass is finer, the resource waste is reduced by utilizing recycling of the water resources, meanwhile, the equipment is protected, the automation degree is high, the production efficiency is high, the product percent of pass is high, the labor is saved, the time is saved, the glass slitting cost is reduced, and the safetyis high.

Owner:鹏凯(天津)玻璃有限公司

Plastic edge trimming machine integrating cutting and rough edge grinding

The invention discloses a plastic edge trimming machine integrating cutting and rough edge grinding. The plastic edge trimming machine comprises a workbench, a material hopper, a first fixing frame, asecond sliding groove, a hydraulic device, a fixing block and a second rotation shaft; a base is arranged on the upper side face of the workbench, a first motor is arranged in the base, a storing platform is arranged on the upper side of the first motor, and the material hopper is arranged under the storing platform; a drawer is arranged on the inner side face of the supporting plate; an outer threaded solid rod is arranged on the inner side of an inner threaded hollow rod, and a disc is arranged at the lower end of the outer threaded solid rod; the hydraulic device is arranged on the lower side face of a hollow block; a cutting blade is arranged on the inner side face of a side plate; movable shafts are arranged on the inner side faces of third fixing frames; and second rotation shafts are arranged on the lower side faces of fourth motors, and grinding discs are arranged at the lower ends of the second rotation shafts. According to the plastic edge trimming machine integrating cutting and rough edge grinding, the material hopper is arranged, and therefore waste materials and powder can be treated in a concentrated mode.

Owner:东至县科创塑料制品有限公司

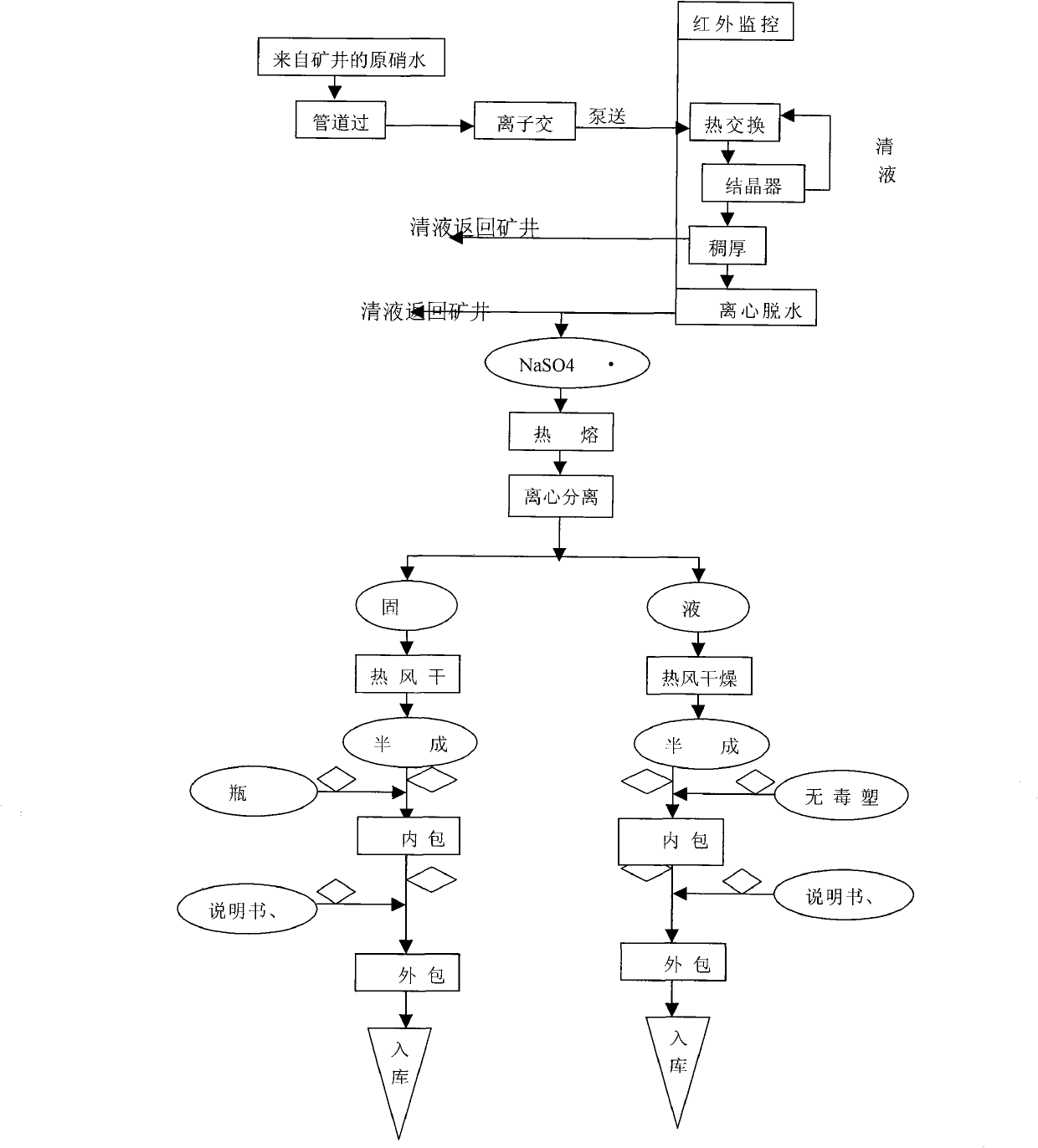

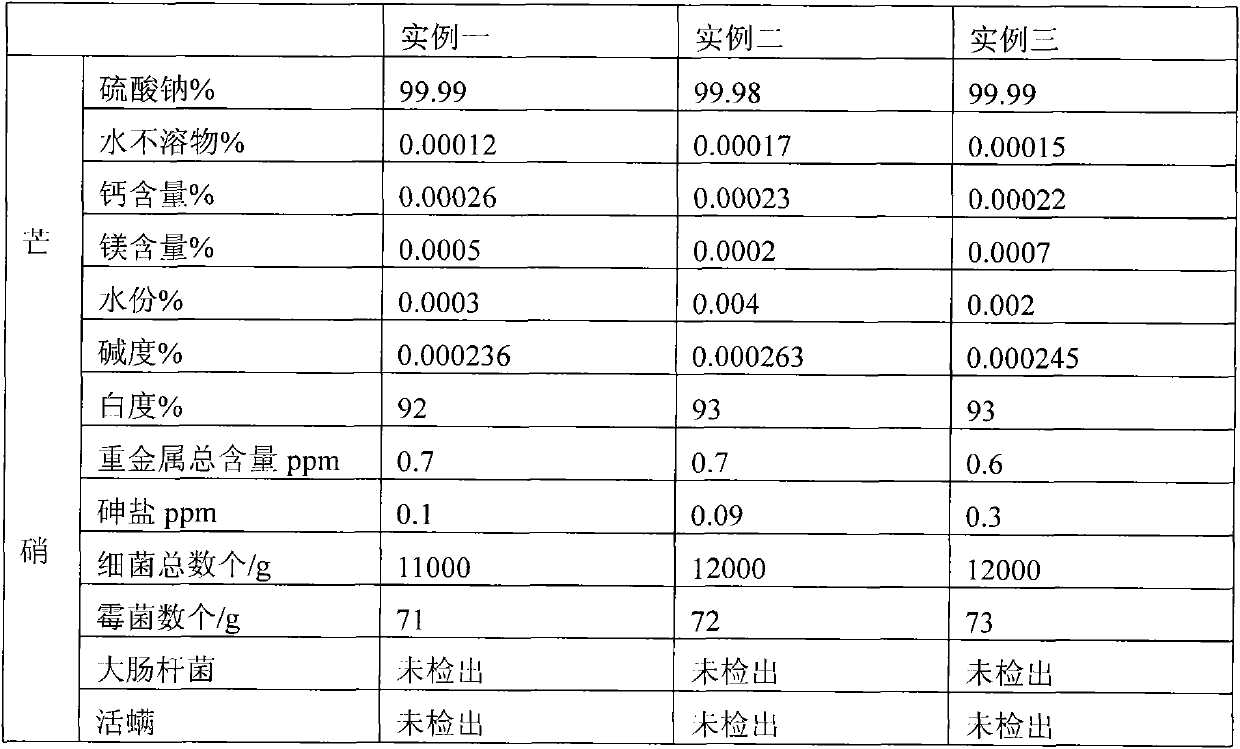

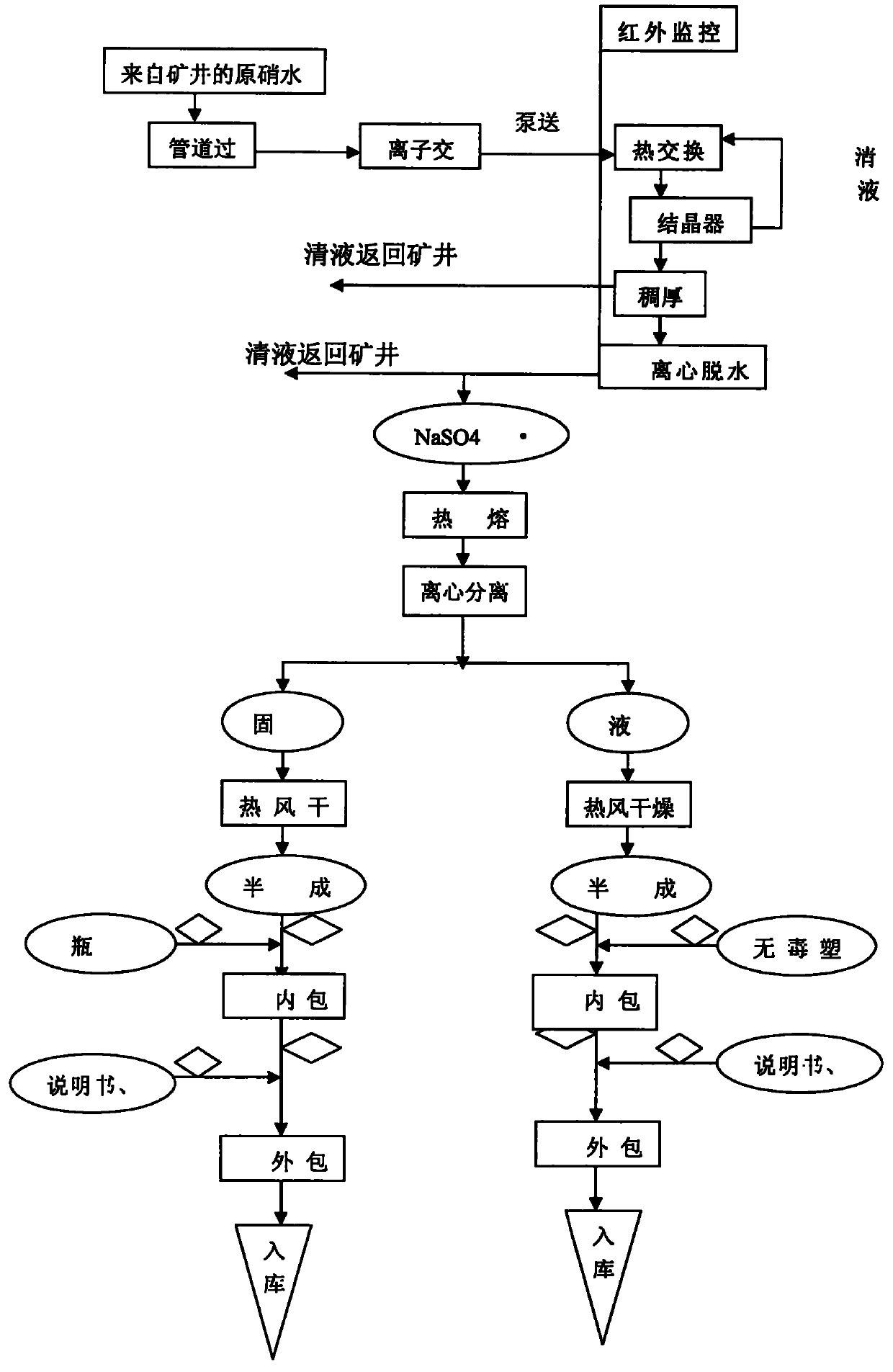

Technique for manufacturing anhydrous medicinal mirabilite

ActiveCN101948123AMonitor drynessMonitor cleanlinessAlkali metal sulfite/sulfate purificationIon exchangeEngineering

The invention relates to a technique for manufacturing anhydrous medicinal mirabilite. The method comprises the following steps: under the monitoring of an on-line infrared computer automatic monitoring system and the regulation and control of a porous plate liquid balance flowmeter, when the indoor air cleanliness of a production shop achieves a certain index, removing mechanical impurities from original nitrate solution (transported underground) with a certain concentration through a pipeline filter, purifying by ion exchange to obtain fine nitrate solution with low content of metallic ion impurities, inputting the fine nitrate solution into a continuous crystallization system, carrying out continuous solid-liquid separation on the crystallized crystal slurry through a strap type centrifugal machine to obtain medicinal mirabilite crystals, melting the medicinal mirabilite crystals in a steam heating or electric heating mode, carrying out solid-liquid separation, respectively drying solid and liquid with hot air to obtain the anhydrous medicinal mirabilite, and finally, carrying out aseptic packaging by using an automatic packaging system. On the premise of ensuring high product purity and conformity to GMP requirements, the invention has more ideal unit productivity.

Owner:四川省川眉药业有限公司

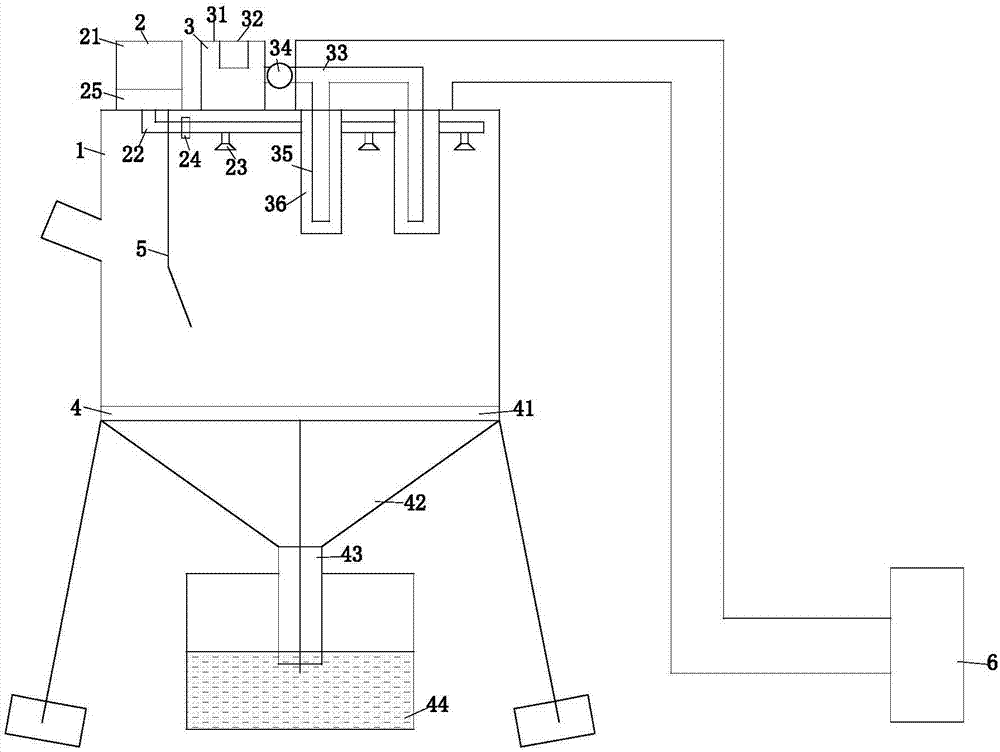

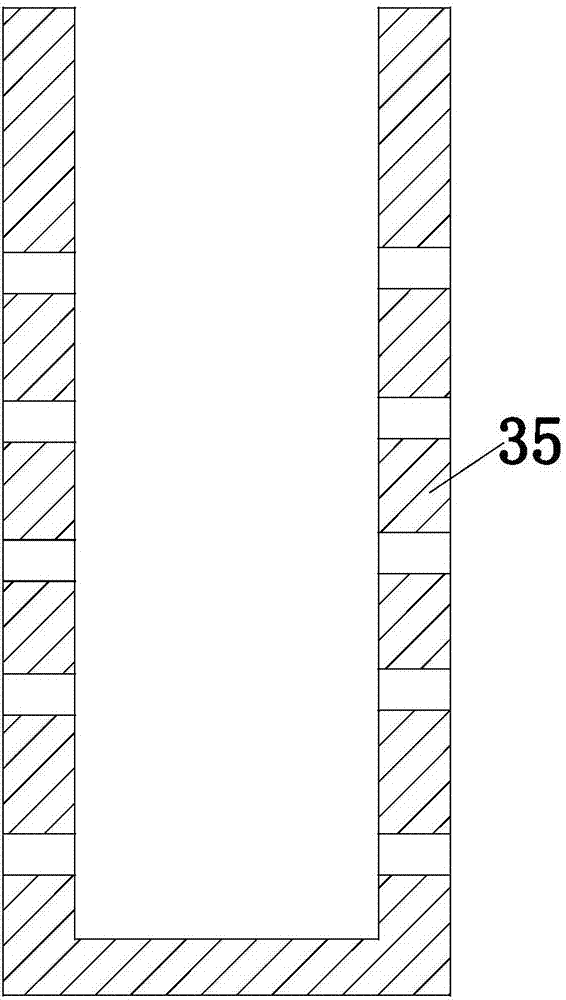

Industrial dust remover

InactiveCN107158868AImprove filtering effectDust removal speed is fastCombination devicesInlet channelSprayer

The invention relates to the field of environment-friendly appliances, particularly an industrial dust remover. The industrial dust remover comprises a shell, a water sprayer, a dust remover, a collecting device, a baffle plate, a blower and a controller, wherein the shell is provided with a gas inlet channel and a gas outlet channel; the gas outlet channel is connected with the blower; and the blower is used for drawing out the purified gas. The industrial dust remover is characterized in that traveling wheels are arranged under the shell; the water sprayer is installed on the top of the shell, and used for settling dust obtained by the collecting device and cleaning the collecting device; the dust remover is installed in the upper position inside the shell, and used for removing dust in the gas; the collecting device is used for collecting and storing the dust generated in the dust removal process; the baffle plate is installed inside the shell in the position adjacent to the gas inlet channel; and the bottom of the baffle plate is arranged obliquely. The industrial dust remover is used for reducing the dust discharge amount in industrial production, can enhance the dust settling rate and clean the collecting device, and has better filtering effects.

Owner:贵州南剑环保节能科技有限公司

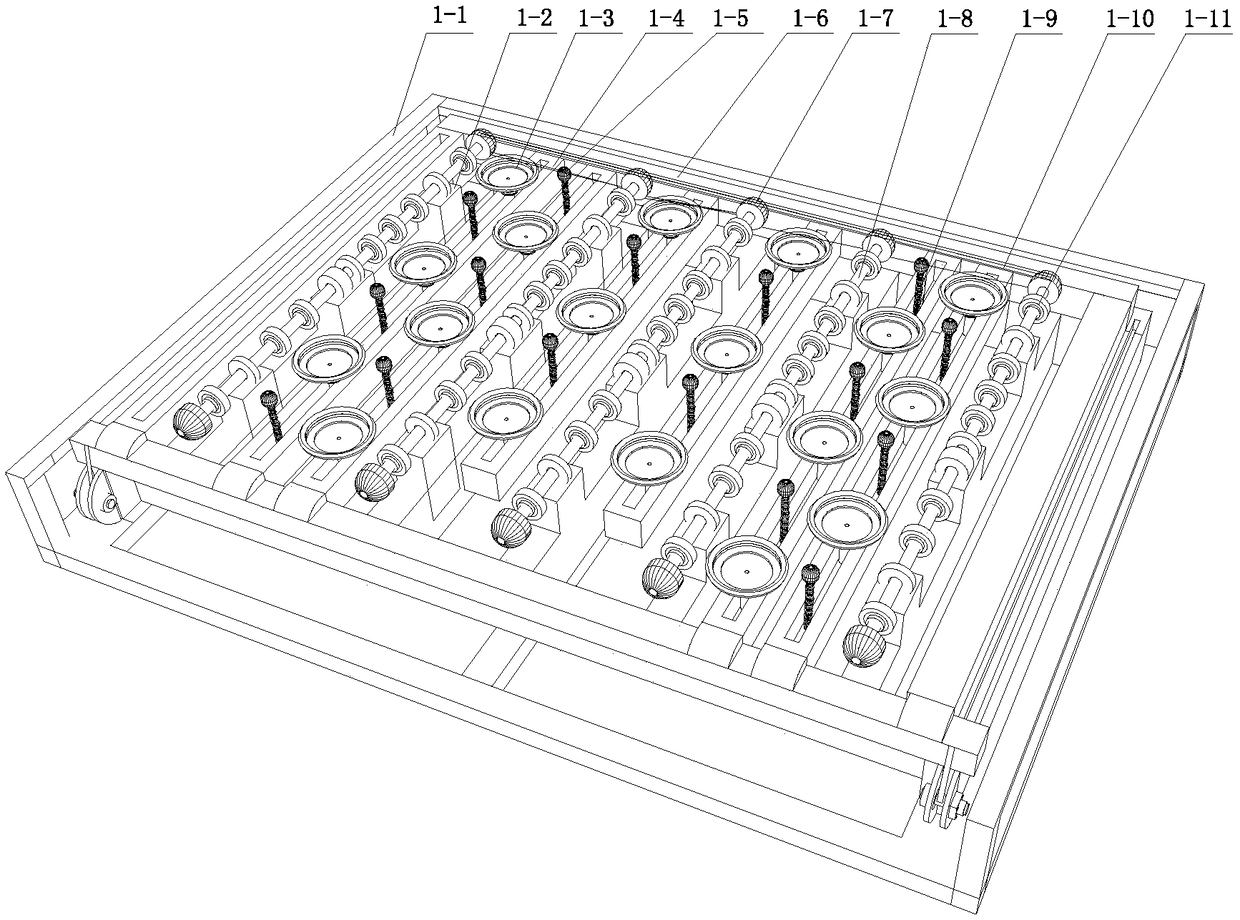

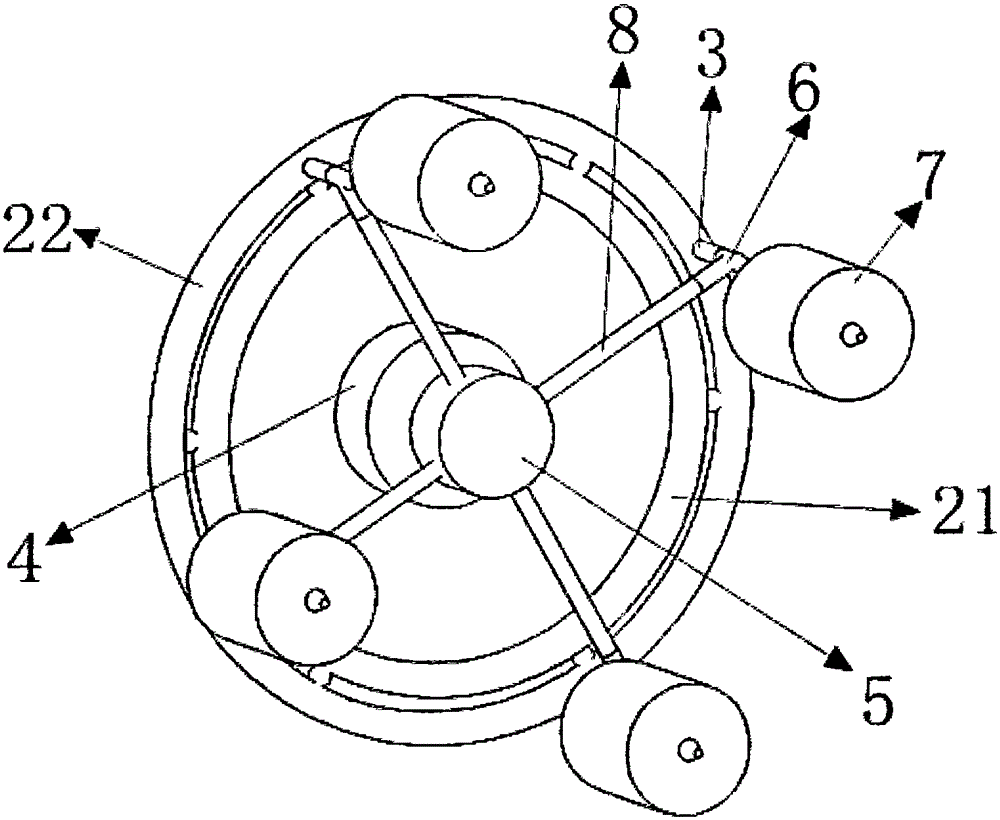

Double-ring rotary spray washing device for multi-head mold

The invention relates to an inner ring and outer ring rotary spray washing device for a multi-head mold. The inner ring and outer ring rotary spray washing device is characterized by comprising an outer ring, an inner ring and a spray washing assembly. The inner ring and the outer ring can rotate relatively by supporting each other. The spray washing assembly comprises two to eight shower nozzles, a liquid inlet pipe and a collecting box; the shower nozzles are fixedly connected with the collecting box through pipelines; the shower nozzles are fixed outside the outer ring or the inner ring; a rotary joint is arranged between the collecting box and the liquid inlet pipe; and the tail ends of the connection parts between the pipelines and the shower nozzles are bent so as to convert an impact force of high pressure air into rotation motion power. The double-ring rotary spray washing device has the positive effects that because the shower nozzles are adopted for cleaning, the cleaning time is greatly shortened; and since the shower nozzles rotate along the inner ring and the outer ring and rotate per se, when a mechanical arm is used, no-dead-angle all-directional repeated cleaning of the mold and the surface of a part can be realized, and the residue cleaning effect is improved greatly.

Owner:胡洋 +1

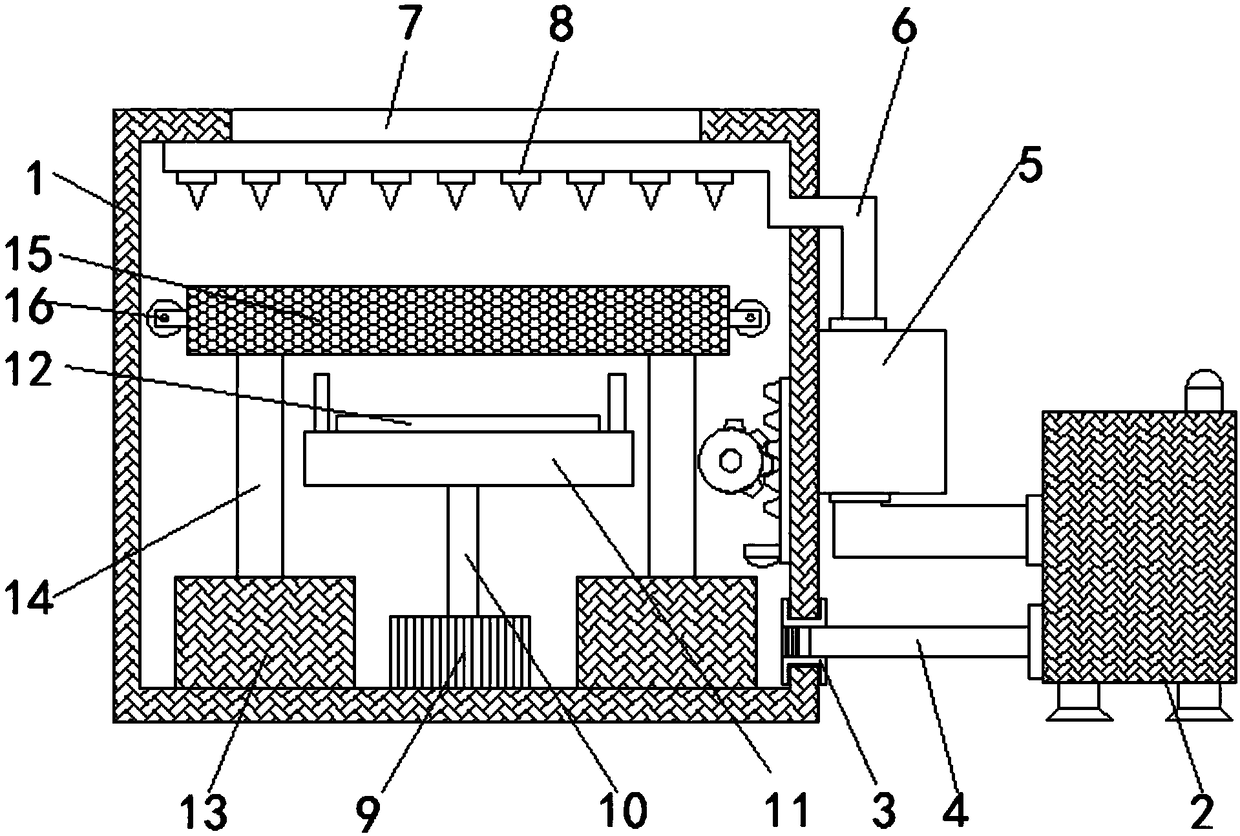

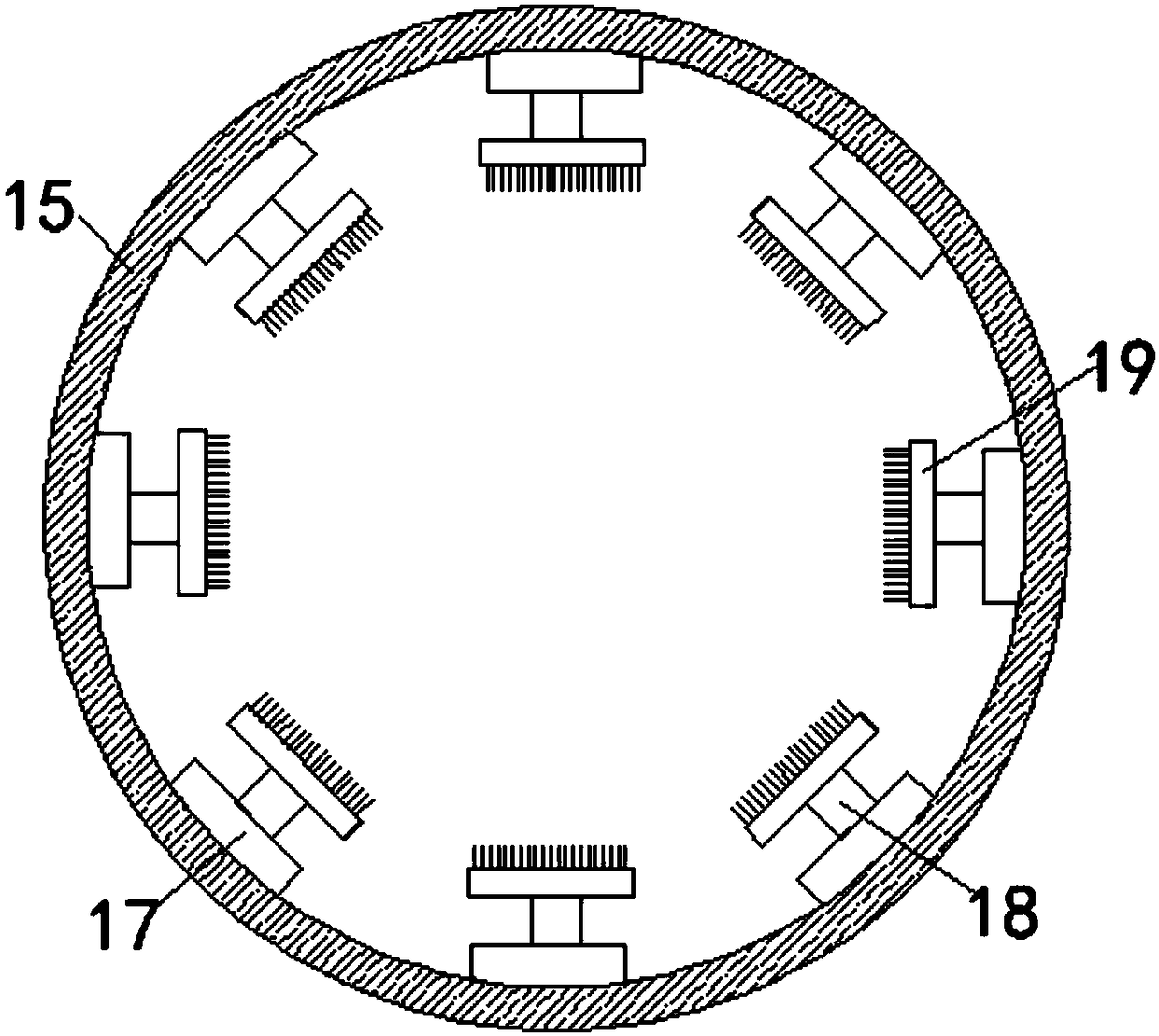

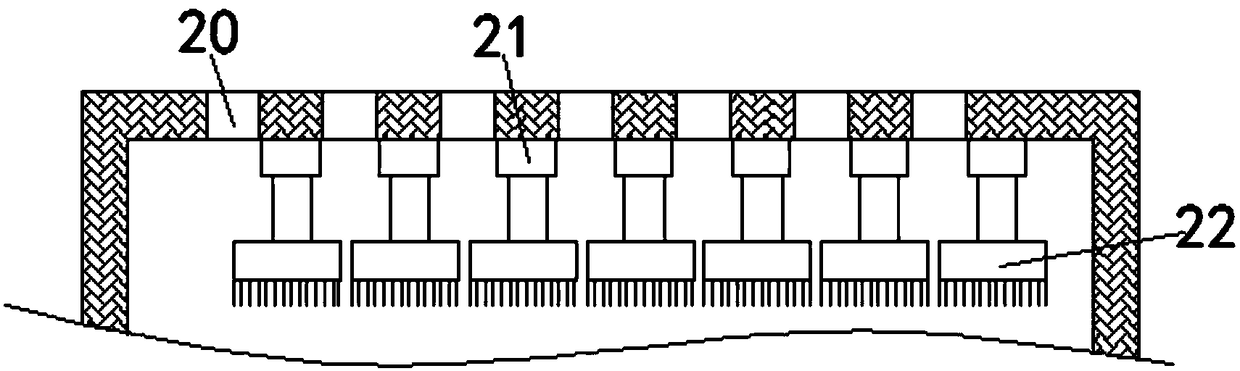

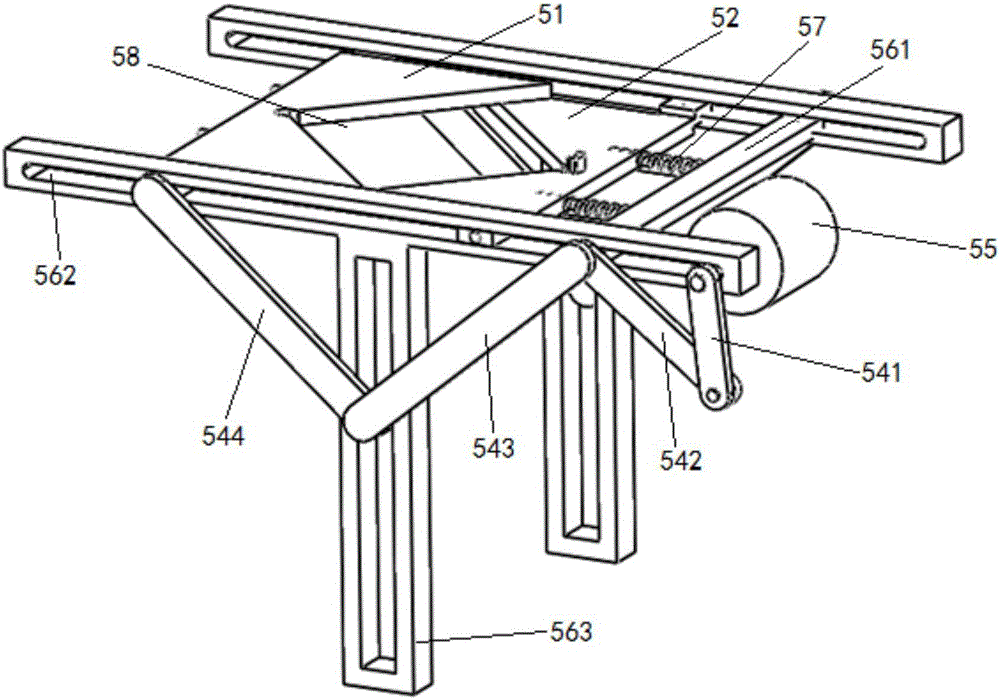

All-dimensional cleaning device for decoration facility

ActiveCN108543725AGuaranteed cleanlinessSave cleanup timeCleaning using toolsCleaning using liquidsSynchronous motorWater storage tank

The invention relates to the technical field of decoration facility cleaning, and discloses an all-dimensional cleaning device for a decoration facility. The all-dimensional cleaning device for the decoration facility comprises a machine body, wherein a water storage tank is arranged on the right side of the machine body; a water outlet is formed in the right side of the machine body; a water outlet pipeline is inserted into the inner surface of the water outlet; one end, far away from the water outlet, of the water outlet pipeline is fixedly connected to an input end of the right side of thewater storage tank; and multiple layers of filter screens are fixedly connected to the inner surface of the water outlet pipeline. According to the all-dimensional cleaning device for the decoration facility, through arranging a synchronous motor, a first brushing plate, a drive motor, a second brushing plate, a stepping motor and a cleaning brush roller, the decoration facility can be all-dimensionally cleaned, an thorough cleaning effects on stains on the outer surface of the decoration facility is achieved through an all-dimensional cover type cleaning is further achieved, and the cleanliness of the decoration facility is ensured for the next use by working personnel, so that the cleaning time of the working personnel is greatly saved.

Owner:日照新睿招商发展有限公司

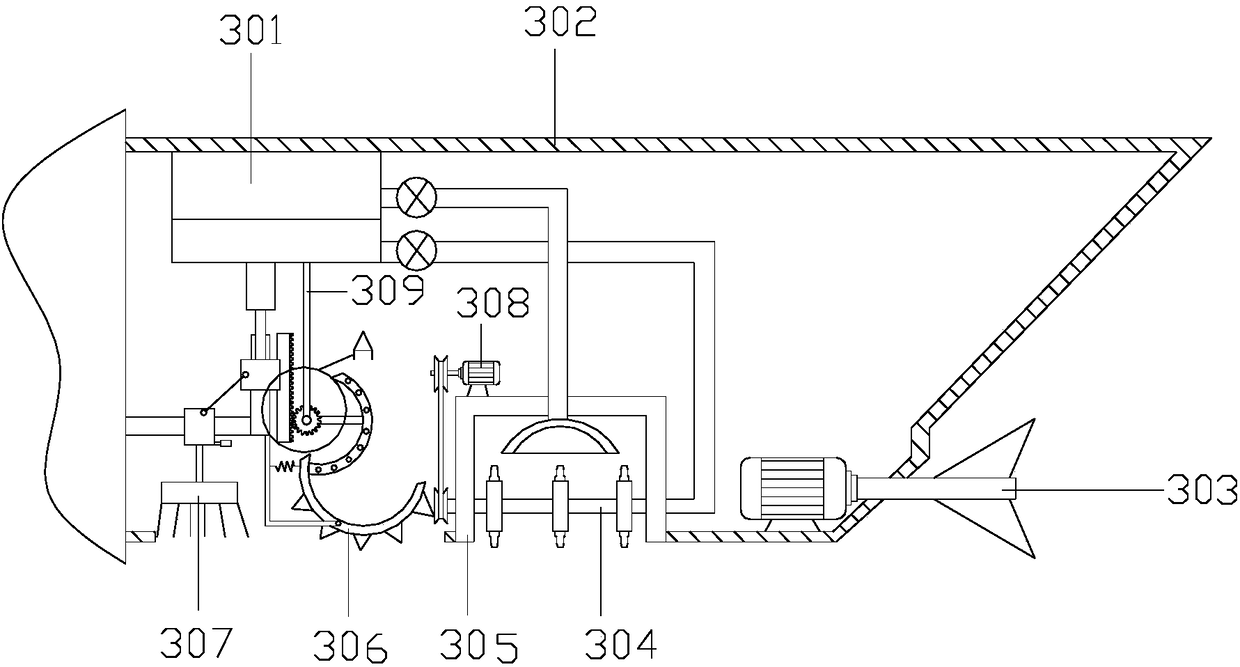

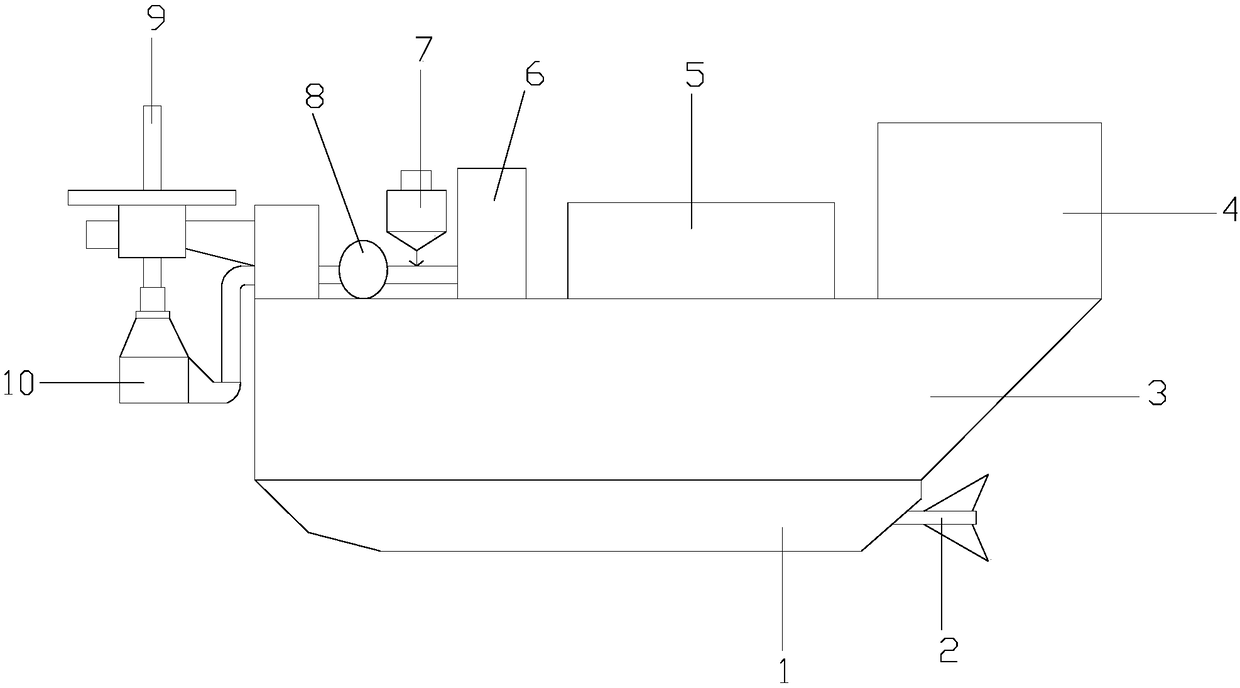

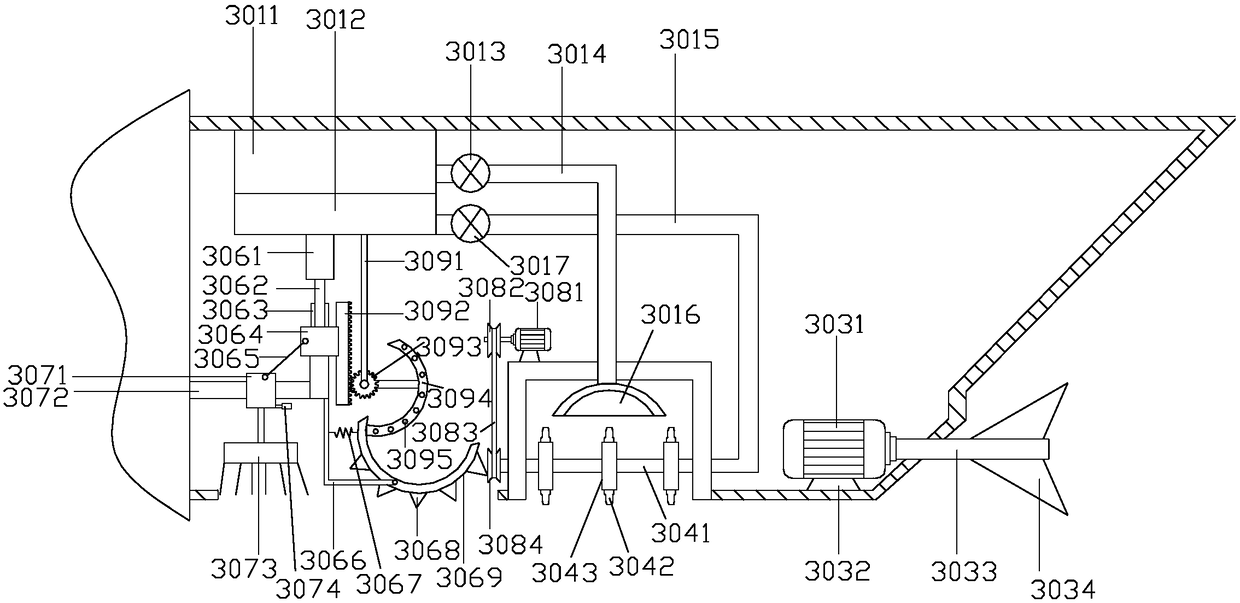

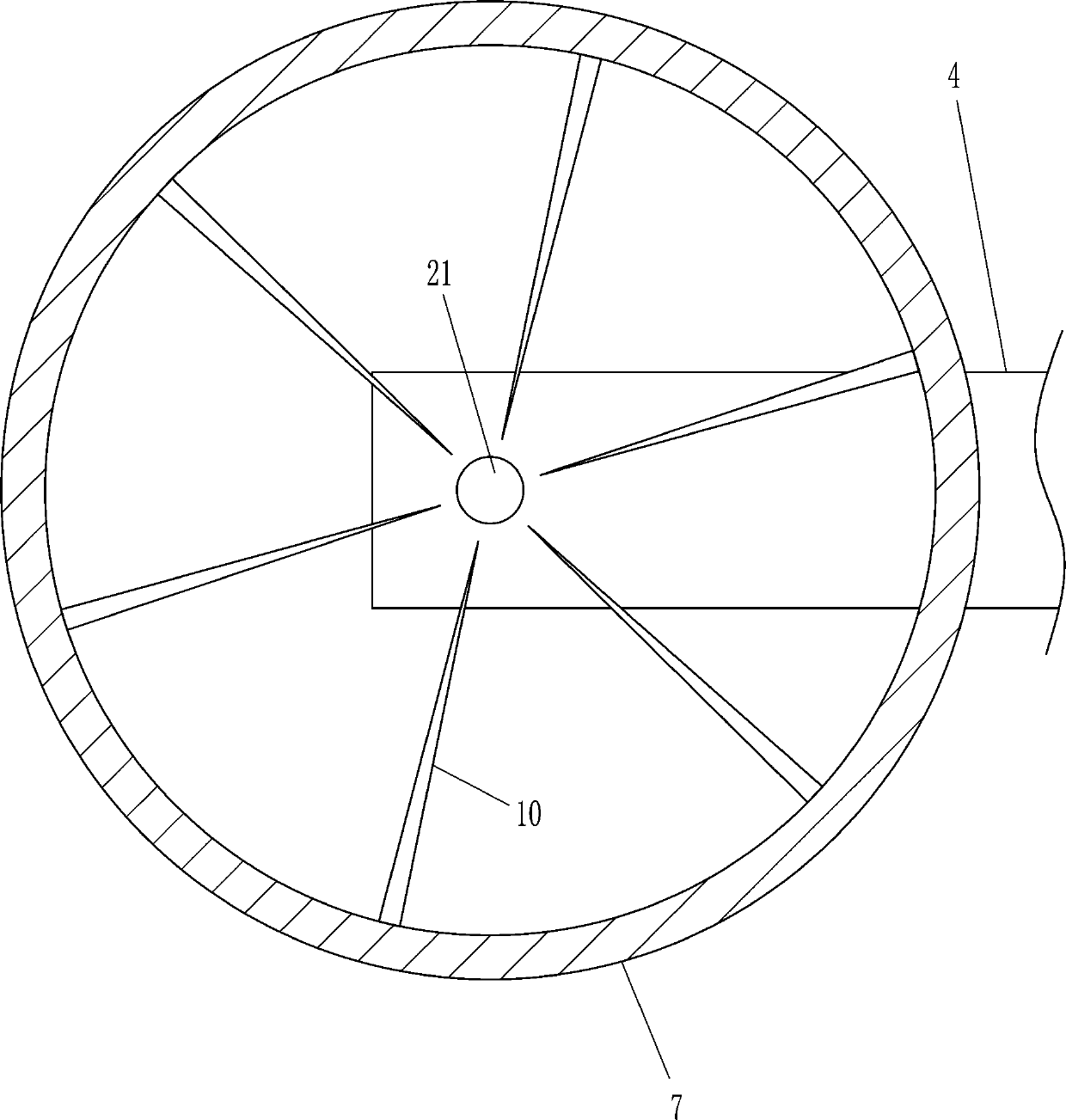

River channel dredging device for ships

InactiveCN108532663AExtended service lifeSave cleanup timeWaterborne vesselsMechanical machines/dredgersSludgeEngineering

The invention discloses a river channel dredging device for ships. The river channel dredging device structurally comprises a ship fixing base, a propeller, an efficient repairing and dredging mechanism, an operation chamber, a dewatering system, a mixing tank, flocculants, a rotor pump, a guide plate lifter and a garbage crusher. The propeller is fixedly embedded into the right end of the ship fixing base, and is communicated with the ship fixing base. The water channel dredging device has the advantages that a second motor drives a first fly wheel to rotate, the first fly wheel drives a second fly wheel to rotate through a driving belt, the second fly wheel drives a second air pipe to rotate, a rotating plate sleeving the second air pipe rotates, a nozzle blows up deposited sludge whilerotating, a sludge pump is started up, and blown loose sludge is sucked by a through hole in a suction cover back to a sludge recovery cabin through a sludge pipeline, so that labor and cleaning timeare saved, and cleaning effect is improved; the water channel dredging device can work in a dim environment; service life of the dredging device is prolonged.

Owner:谢彬彬

Face cleaning device for beauty

InactiveCN110623578AEasy to cleanGuaranteed cleaning effectDevices for pressing relfex pointsBathroom accessoriesGear wheel

Owner:XIAMEN ZHAIYUAN COMMODITY CO LTD

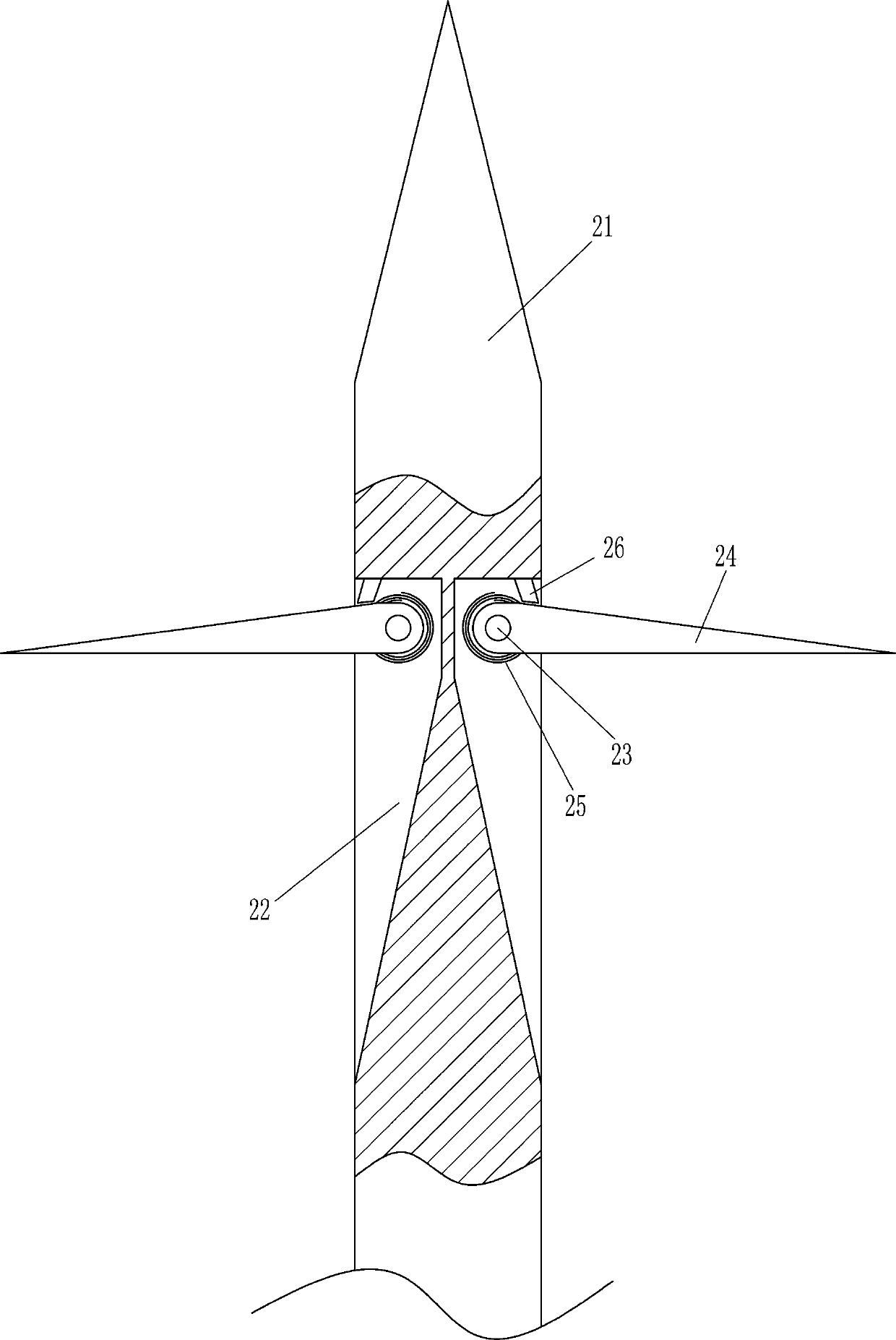

Rapid apple dicing device

ActiveCN110253641AImprove continuityCutting time is shortMetal working apparatusFood treatmentEngineeringPuncturing

The invention relates to a dicing device, and particularly relates to a rapid apple dicing device. The rapid apple dicing device is capable of cutting apples automatically with a high speed and capable of automatically removing residues. According to the technical implementing scheme, the device comprises a bottom plate, a collecting box, a fixing plate, an inclined plate, a connecting block, a mounting ring, a fixing block, etc., wherein the collecting box is arranged at the left side of the top part of the bottom plate; and the fixing plate is arranged in the middle of the top part of the bottom plate. According to the device, a puncturing rod, baffle rods and a blade are arranged to automatically dice an apple, and that people manually dice the apple is avoided; the apple is continuously diced, so that the working efficiency is improved, the dicing time is shortened, and people can quickly dice the apple; a vibrating plate and a residue discharging hole are arranged, so that people conveniently remove the residues on the apple, and the trouble of manually removing the apple residues is reduced; and people can quickly remove the apple residues.

Owner:安徽皖蜀春酒业销售有限公司

Book shelf sorting device and matched sorting method

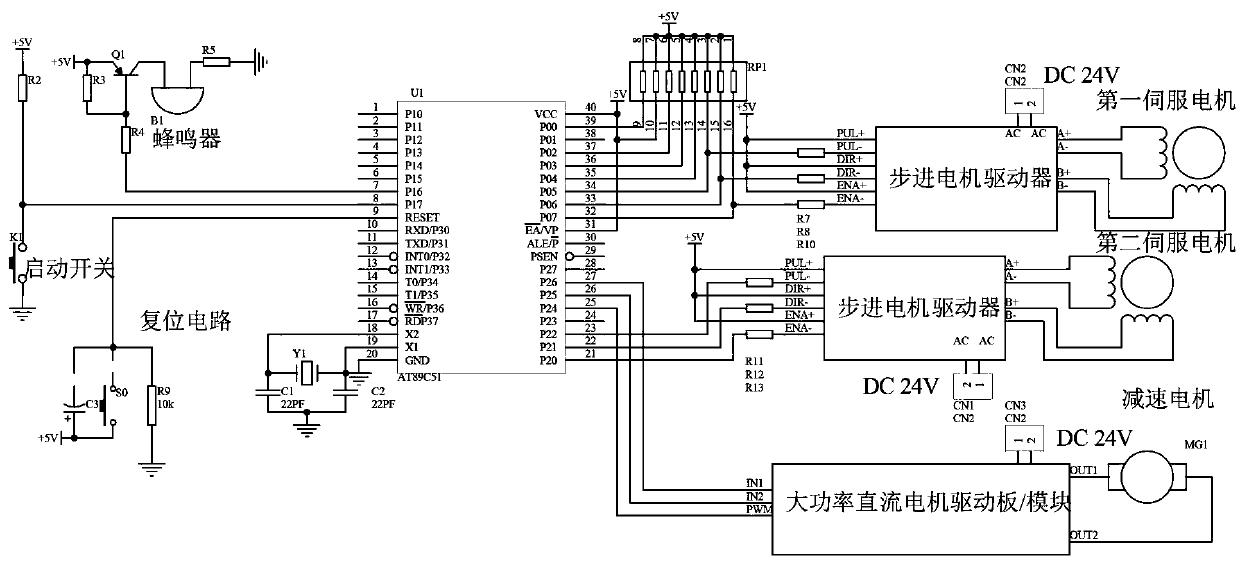

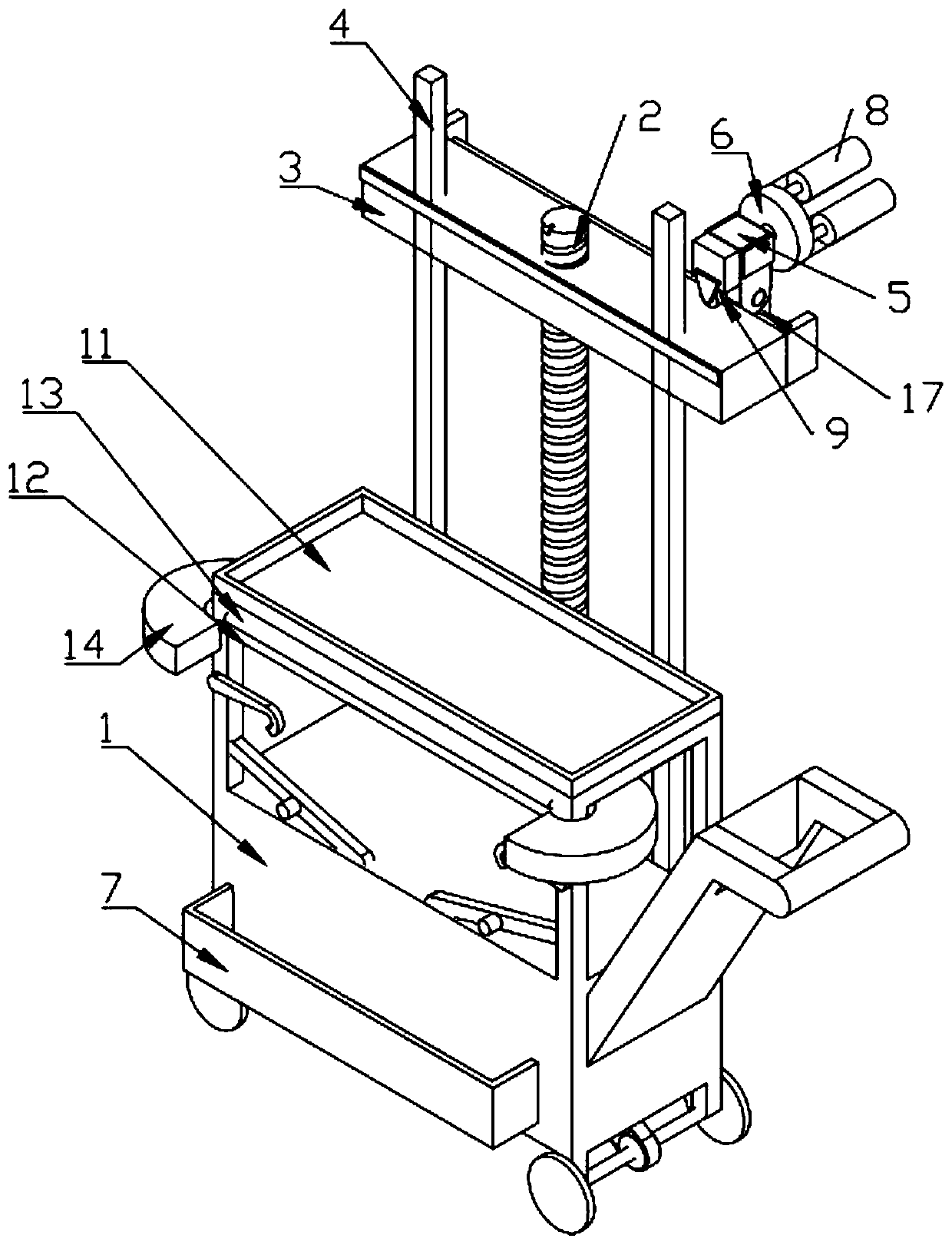

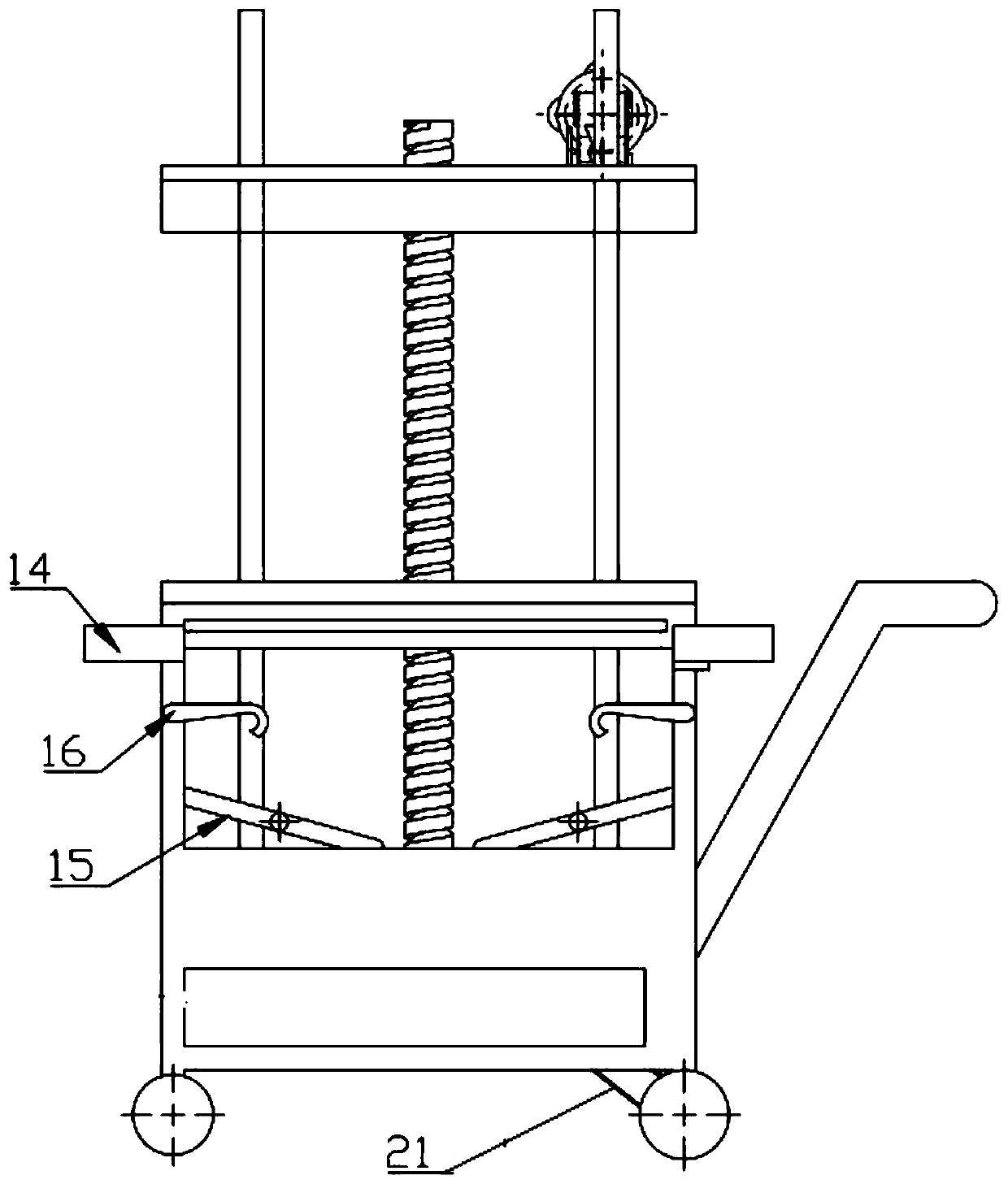

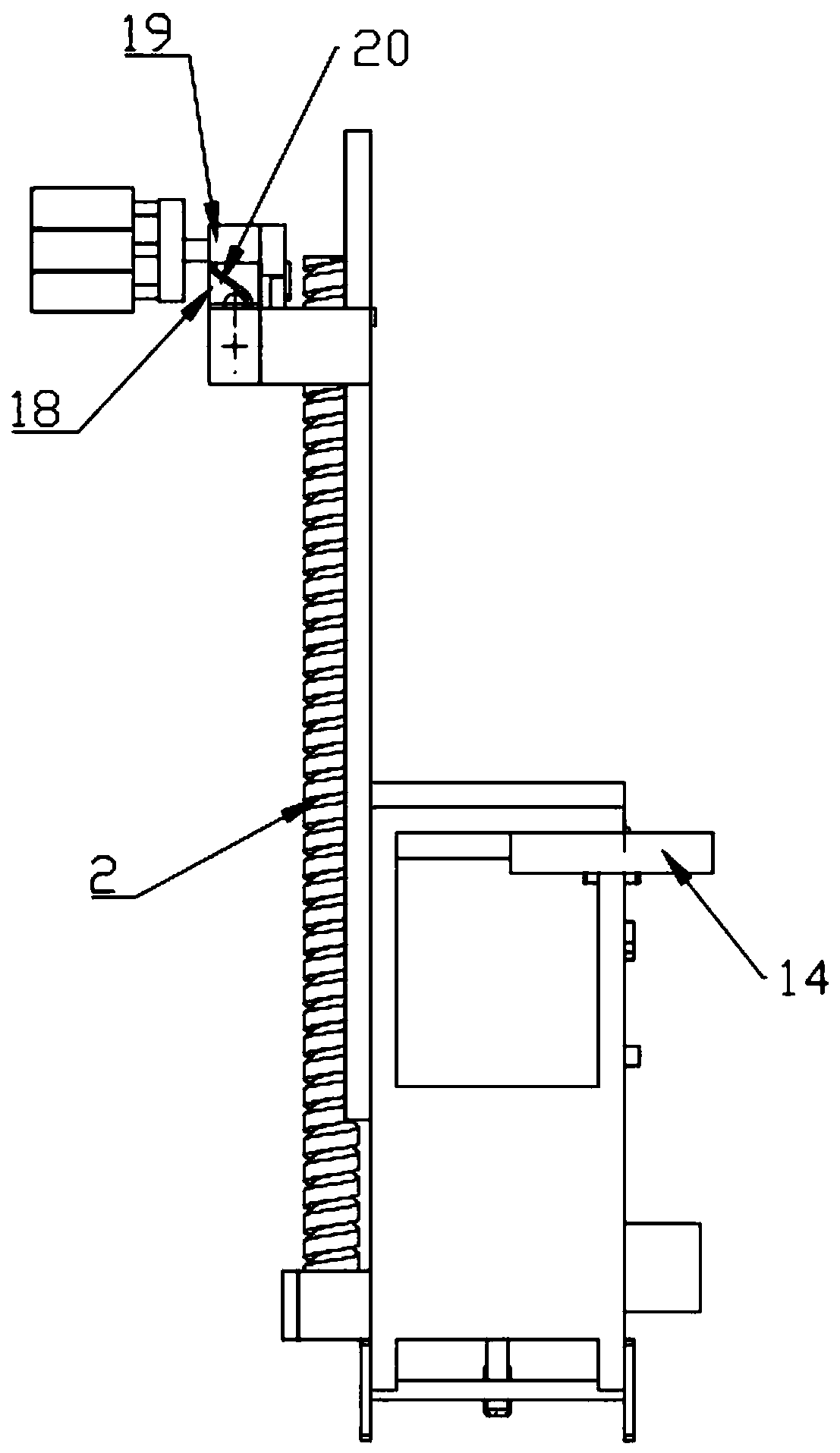

ActiveCN110292258AImprove the efficiency of organizing and placing booksReduce labor intensityBook-troughsDirt cleaningEngineeringNoise reduction

The invention relates to the field of matching facilities in libraries, in particular to a book shelf sorting device and a matched sorting method. The shortcomings of the background technology in alldirections of technology improvement are overcome. The book shelf sorting device includes a walking trolley, wherein the walking trolley is provided with a machine box, a cleaning mechanism, a noise reduction mechanism and a book placing platform; the cleaning mechanism is installed on the side wall of the machine box, and a balance weight is arranged at the bottom of the other corresponding sideof the machine box; the noise reduction mechanism is installed on the inner wall of the machine box, and the book placing platform is positioned above the machine box; and the cleaning mechanism includes a sliding block driven by a lead screw. The book shelf sorting device has the advantages of flexible structure, low cost, reducing the work intensity of staffs, and reducing the interference to borrowers.

Owner:ZHENGZHOU TECHN COLLEGE

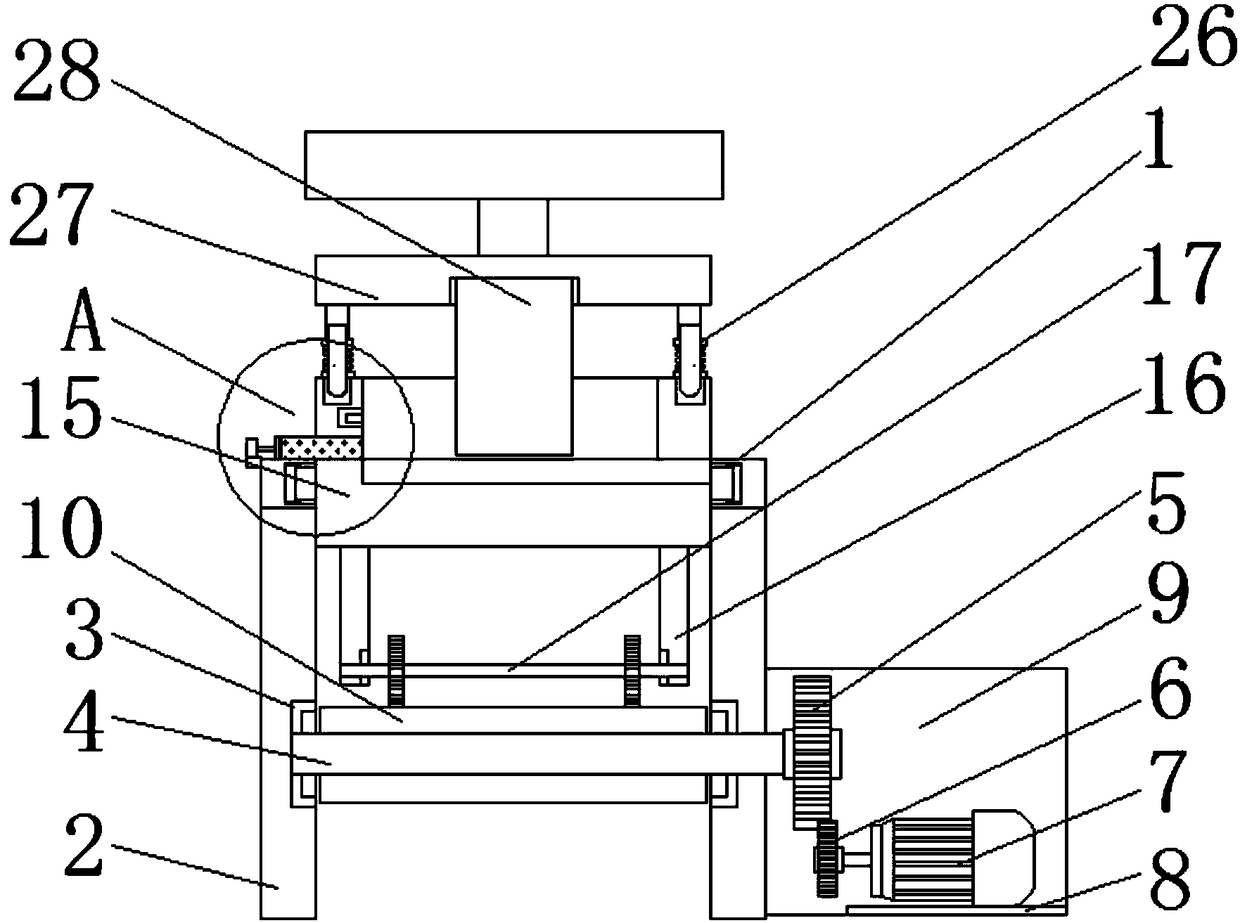

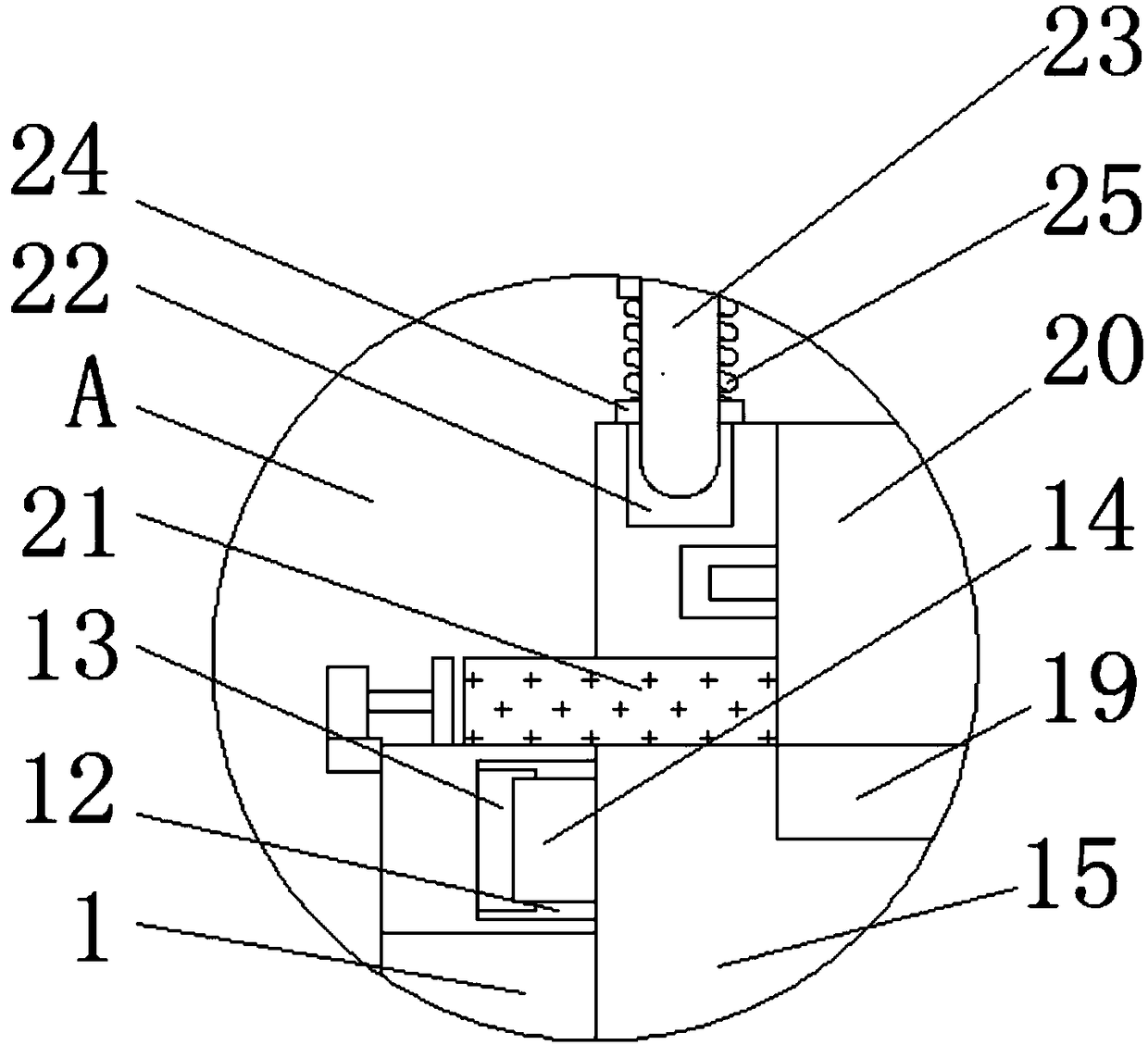

Forming device for hollow brick production

The invention relates to the technical field of hollow brick production, and discloses a forming device for the hollow brick production. The forming device for the hollow brick production comprises aworkbench, a supporting column is fixedly connected to the bottom of the workbench, a connecting rod is fixedly connected to the surface of the supporting column, a first roller is fixedly connected to the connecting rod through a bearing, and a driven gear is fixedly connected to the right end of the first roller. According to the forming device for the hollow brick production, a positive and negative rotation motor is arranged to enable a driving gear to rotate, so that a moving platform can move in the conduction of a driving belt, a fixing sliding rail is arranged and matched with a fixingsliding block to support the moving platform while moving the moving platform conveniently; a rotating gear is arranged to enable the moving platform to be moved in the action of the driving belt, formed hollow bricks can be moved out of the moving platform from a discharging opening conveniently; and a reset spring is arranged, a pressure module generates tension and provides protection to a diebox when pressing the hollow bricks.

Owner:ANHUI KUNMENG NEW TYPE BUILDING MATERIAL CO LTD

Scraper conveyer

The invention discloses a scraper conveyer which comprises a material chute (1); both ends of the material chute (1) are provided with drums (2); both ends of each drum (2) are provided with scraper chains in a matching way; scrapers (3) are arranged on the scraper chains at interval sections; and one end of each drum (2) is provided with an arc-shaped baffle (4). One arc-shaped baffle is arranged on one end of each drum, so materials which are taken by the scrapers to the tail part in a return process are scrolled back to the upper end of the material chute along the arc-shaped baffles and taken away by the scrapers, so that no material is piled and blocked at the tail part of the equipment; and the arc-shaped baffles are provided with water leaking poles, so that the liquid flows out from the water leaking holes when the solid and liquid of the materials are separated and the solid is taken away by the scrapers, is separation efficiency is greatly improved, and a liquid runner is not blocked.

Owner:GUIZHOU CHITIANHUA PAPERS

Automatic cleaning machine for river floating garbage

InactiveCN110700219ACollect thoroughlyImprove cleaning efficiencyWater cleaningWater storageDrive shaft

The invention discloses an automatic cleaning machine for river floating garbage. The automatic cleaning machine comprises a machine body, wherein a water inlet cavity is formed in the machine body; acommunicating conveying cavity is formed in the upper side of the water inlet cavity; a communicating recycling cavity is formed in the right side of the water inlet cavity; and a communicating waterstorage cavity is formed in the lower side of the recycling cavity. The floating garbage continuously enters the water inlet cavity along with river water, and meanwhile, a power shaft, a driving bevel gear, a large bevel gear, a driving shaft and a toothed belt driving wheel are driven to rotate, so that a toothed belt moves. According to the automatic cleaning machine, the cleaning efficiency of the river garbage can be greatly improved, the cleaning speed is increased, the cleaning time is shortened, and the fatigue and danger of manual cleaning are reduced.

Owner:南京溧水高新产业股权投资有限公司

Multifunctional hot blast heater

InactiveCN108954816AReduce labor intensityImprove combustion efficiencyGas treatmentDispersed particle separationSlagEngineering

The invention relates to a multifunctional hot blast heater which comprises a base plate and a hot blast heater body installed on the base plate. The hot blast heater body is connected with an air exhaust pipe, the air exhaust pipe is provided with heat exchange pipes installed on the base plate and distributed in the length direction of the base plate in parallel in a matched manner, the tail endof the air exhaust pipe is connected with a purifying device capable of purifying waste gas generated by burning of fuel in the hot blast heater body, guide plates are distributed in the hot blast heater body in the length direction of the base plate symmetrically, first sliding grooves are formed in the guide plates, isolation mechanisms capable of isolating the interior of the hot blast heaterbody are installed in the first sliding grooves in a sliding manner, collecting mechanisms installed at the bottom of the hot blast heater body and used for collecting and conveying furnace slags aredistributed below the isolation mechanisms, and a conveying mechanism for conveying the fuel into the hot blast heater body is further installed on the base plate. By means of the multifunctional hotblast heater, automatic feeding, furnace slag removal and waste gas treatment of the hot blast heater are achieved; and the interior of the hot blast heater body is divided into two parts through theisolation mechanisms, fuel burning and furnace slag separating are isolated, and the space is reasonably used.

Owner:芜湖新农夫机械股份有限公司

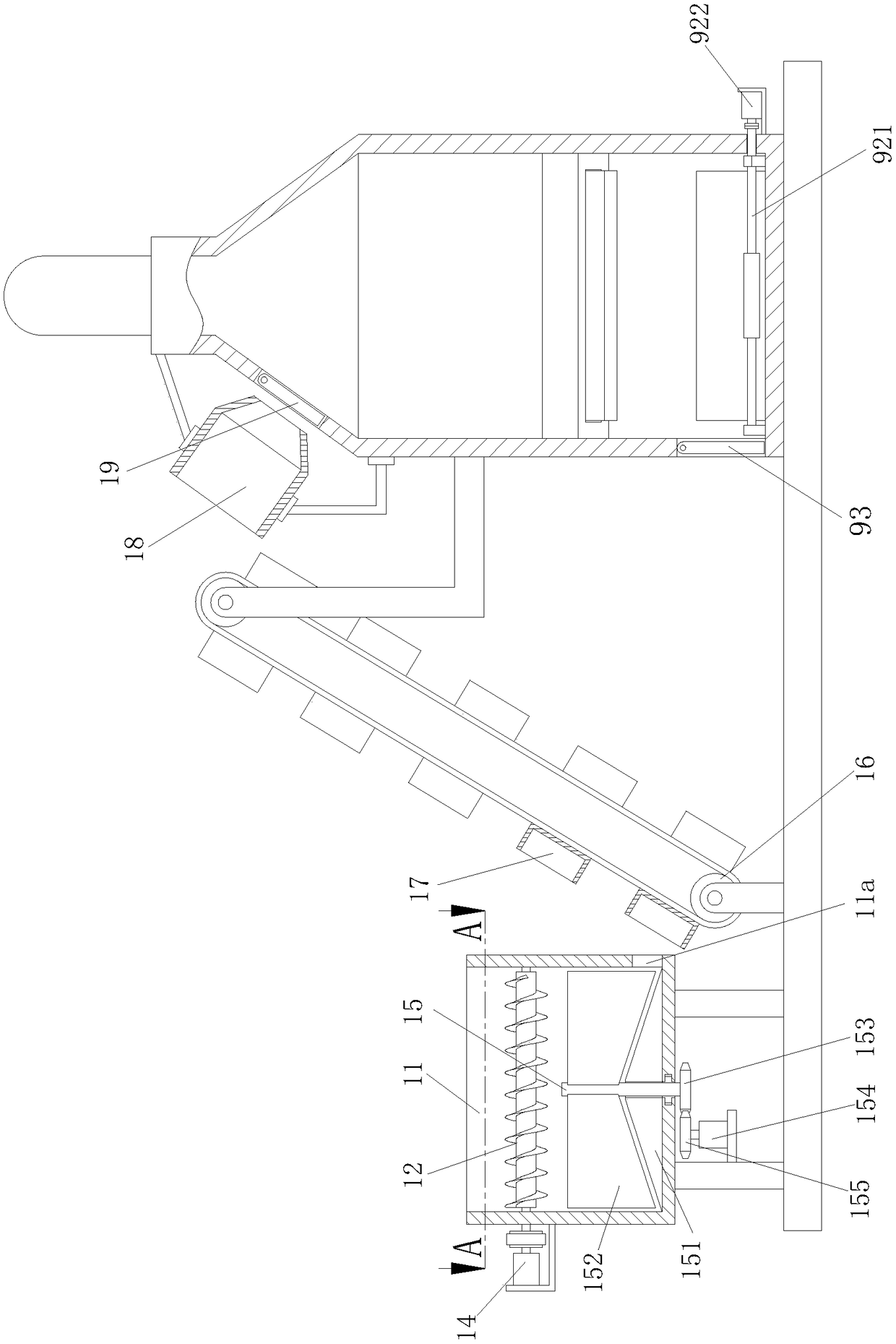

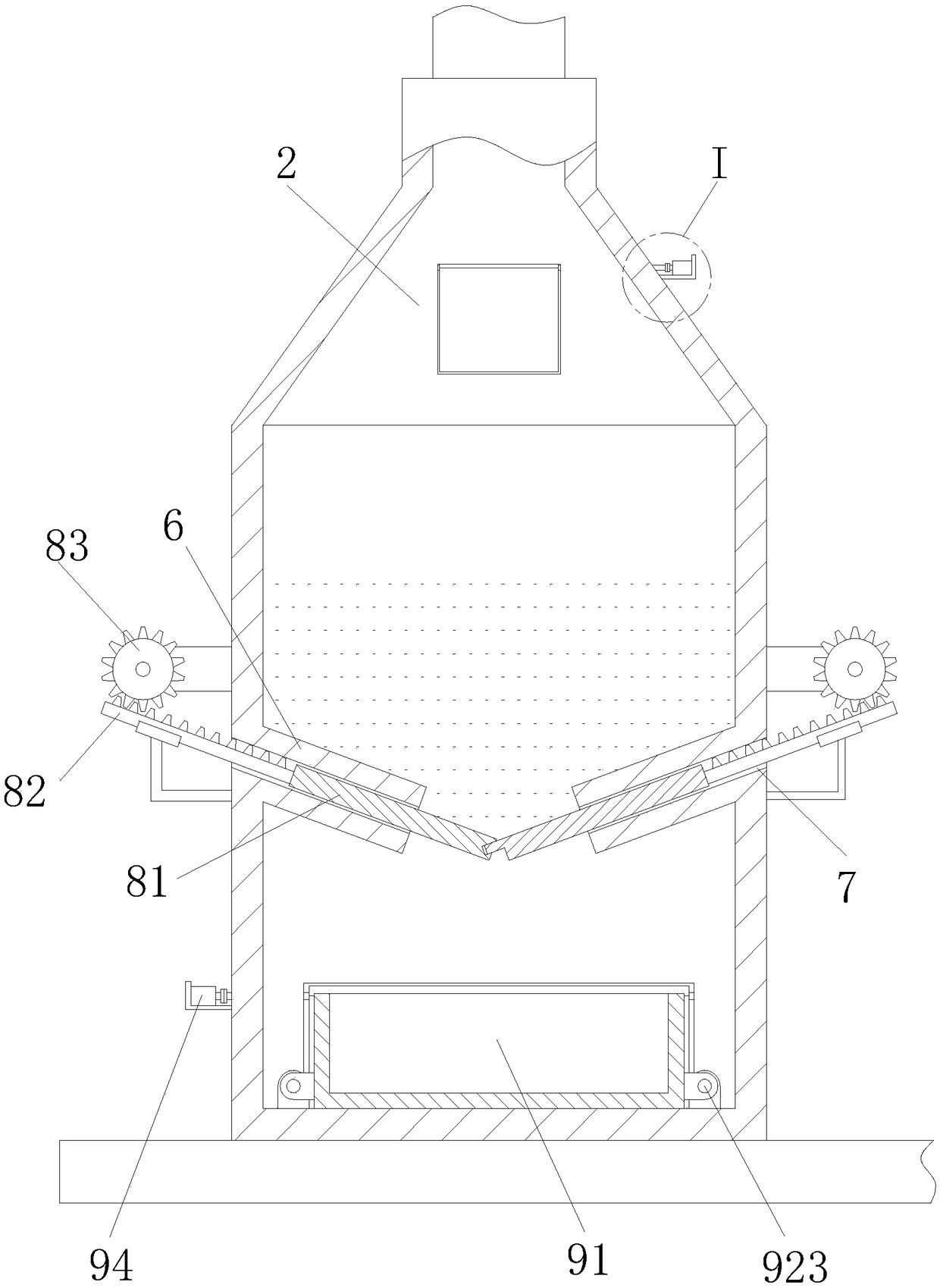

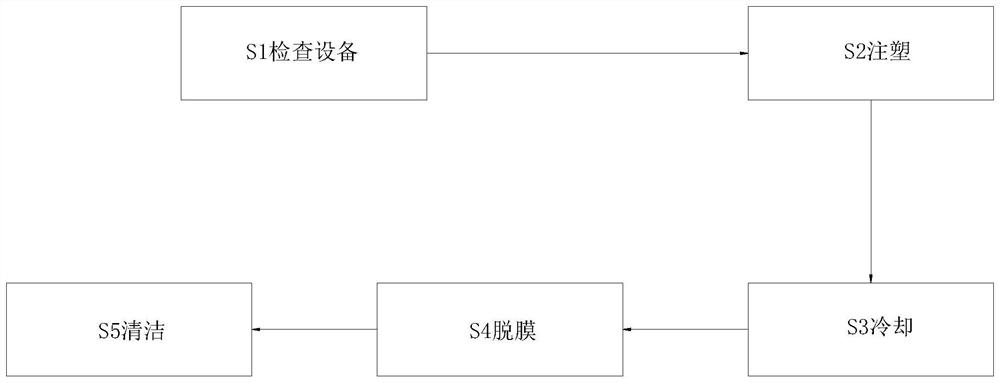

Injection molding method for environment-friendly plastic box

InactiveCN112829175APrevent overflowAffect production qualityDomestic articlesAir pumpProcess engineering

The invention relates to an injection molding method for an environment-friendly plastic box. Plastic box machining and manufacturing equipment is used and comprises a workbench and a placing table rotatably arranged on the outer wall of the workbench, a feeding device is arranged at the top of the workbench, a cooling device is arranged above the placing table, a dismounting device is arranged above the placing table, and a cleaning device is arranged above the placing table. According to the injection molding method for the environment-friendly plastic box provided by the invention, through cooperation of a current-conducting plate, an air pump and a battery, when the battery makes contact with the current-conducting plate, the air pump is powered on, airflow generated in the air pump is jetted to a feed hopper through an air blowing pipe, and therefore waste remaining on the inner wall of a mold box after demolding can be automatically cleaned, the waste in the mold box is prevented from being accumulated, the production quality of the plastic box is influenced, the cleaning time is saved, the working efficiency is improved, and the manpower is saved.

Owner:王晓春

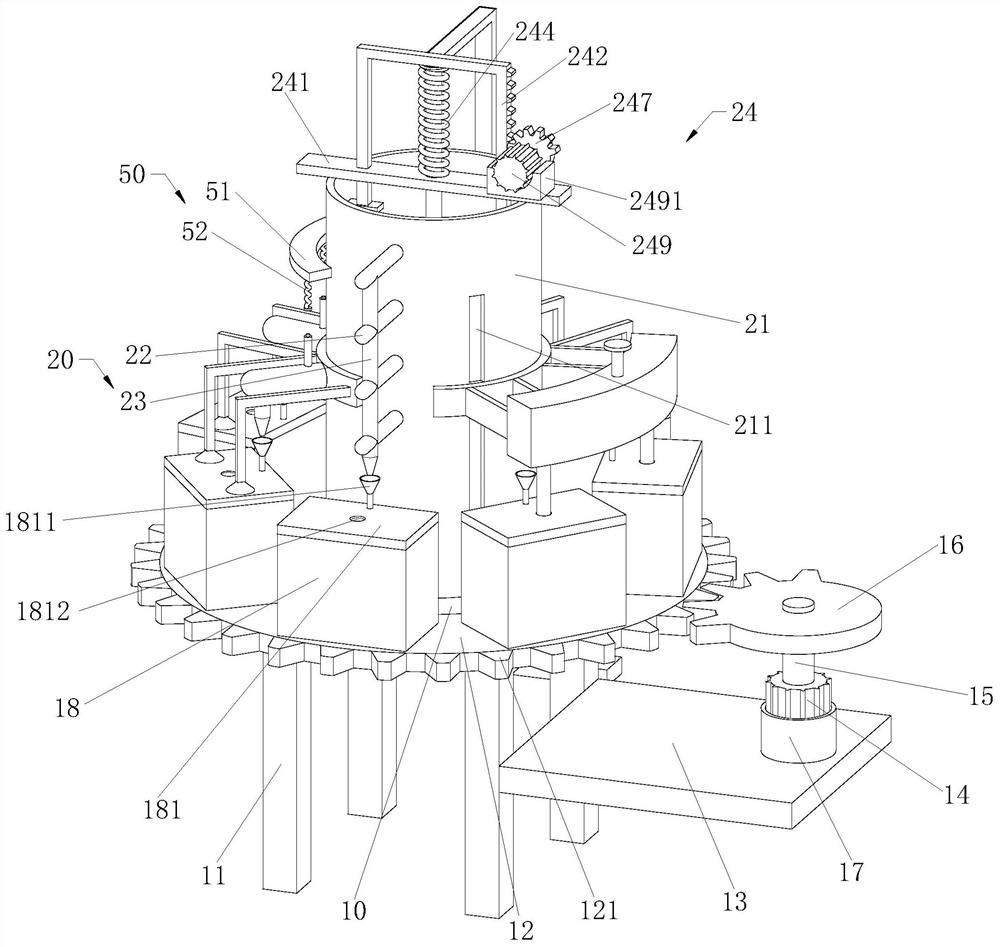

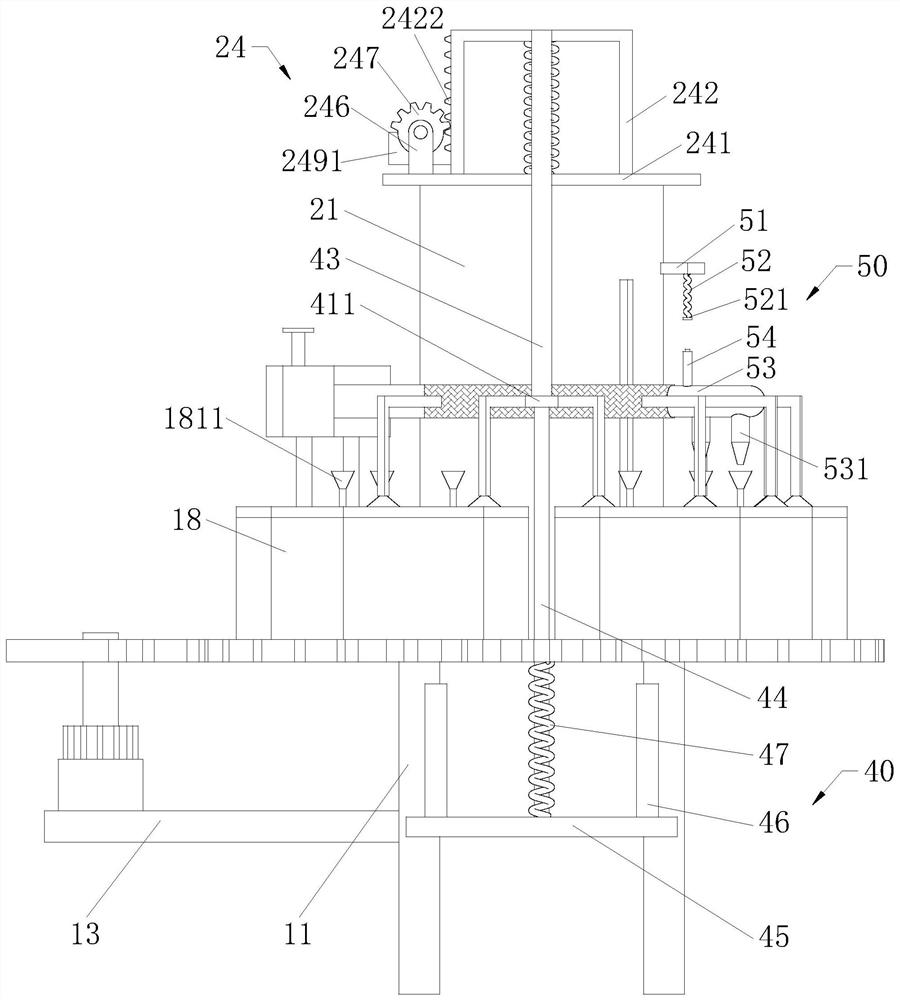

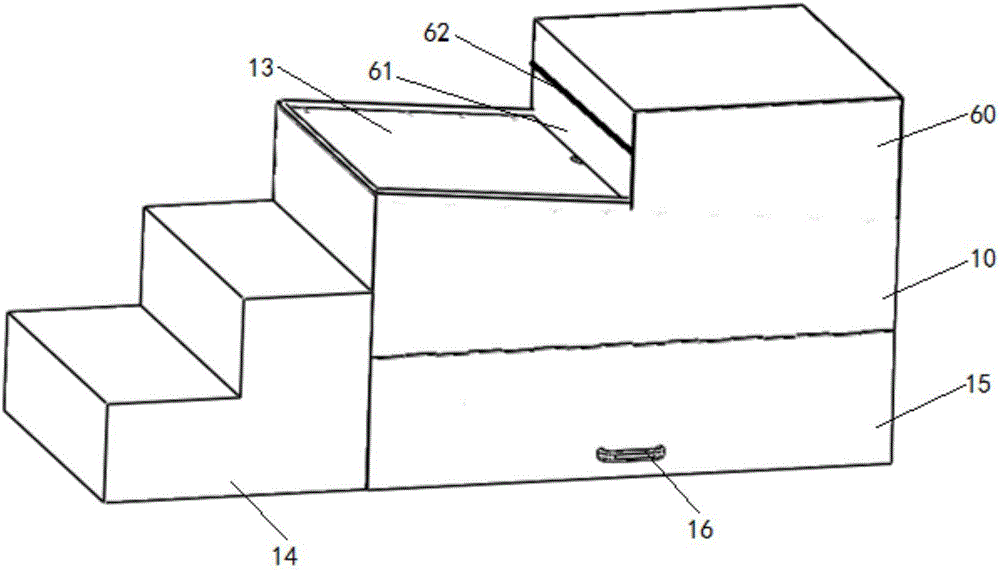

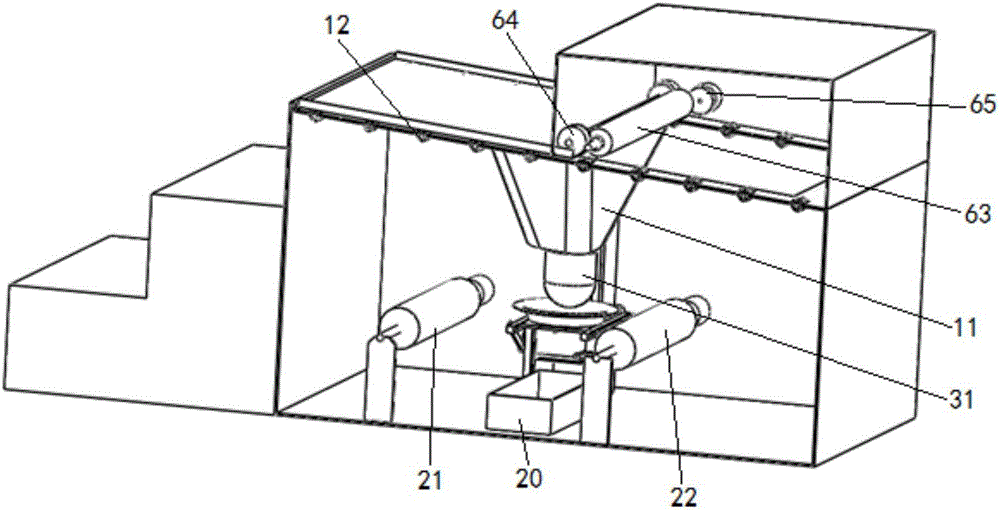

Pet excrement treatment nanny machine and pet excrement treatment method

InactiveCN106305441AGuaranteed continuous feedPrevent leakageAnimal housingEngineeringCompanion animal

The invention discloses a pet excrement treatment nanny machine and a pet excrement treatment method. The pet excrement treatment nanny machine comprises a shell frame, and an automatic excrement treatment device and a main controller which are arranged in the shell frame, wherein the automatic excrement treatment device comprises a feeding mechanism, a molding mechanism, a sealing mechanism and a mouth locking and shearing mechanism; the feeding mechanism comprises a feed roller, a tubular membrane and a material receiving roller; the molding mechanism comprises an upper die and a lower die which are used for pressing a membrane into a containing cavity in a matching way; the sealing mechanism comprises a rotary platform, and the rotary platform can rotate around the axis of the rotary platform; the mouth locking and shearing mechanism comprises a guide rail bracket, and an upper mouth locking plate, a lower mouth locking plate and a shear knife which are arranged on the guide rail bracket; an excrement inlet is formed in the shell frame at the upper end of the feeding mechanism. The pet excrement treatment nanny machine is compact in structure and simple to use, is capable of automatically and continuously collecting and packaging the excrement of a pet, and achieves the effects of cleaning and disinfection treatment, thus guaranteeing the health of the pest and a human body.

Owner:SHANGHAI DIANJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com