Method for preparing carbon-fiber-reinforced silicon carbide composite material

A composite material and silicon carbide technology, which is applied in the field of preparation of carbon fiber reinforced silicon carbide composite materials, can solve problems such as no obvious improvement, and achieve the effects of less dust deposition, good crystallization performance and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

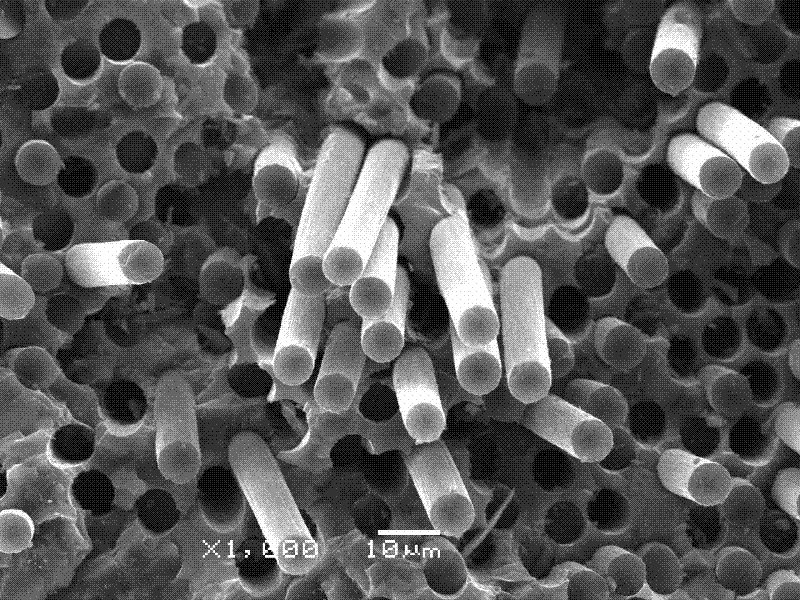

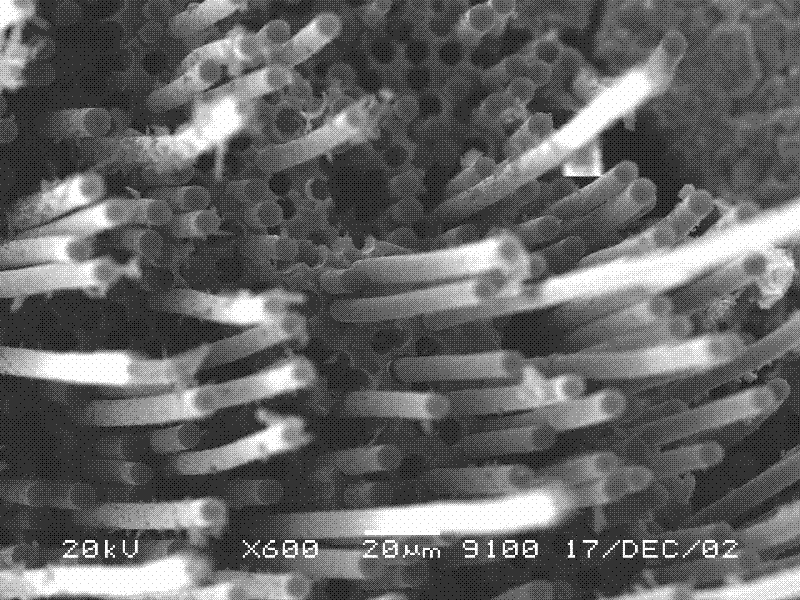

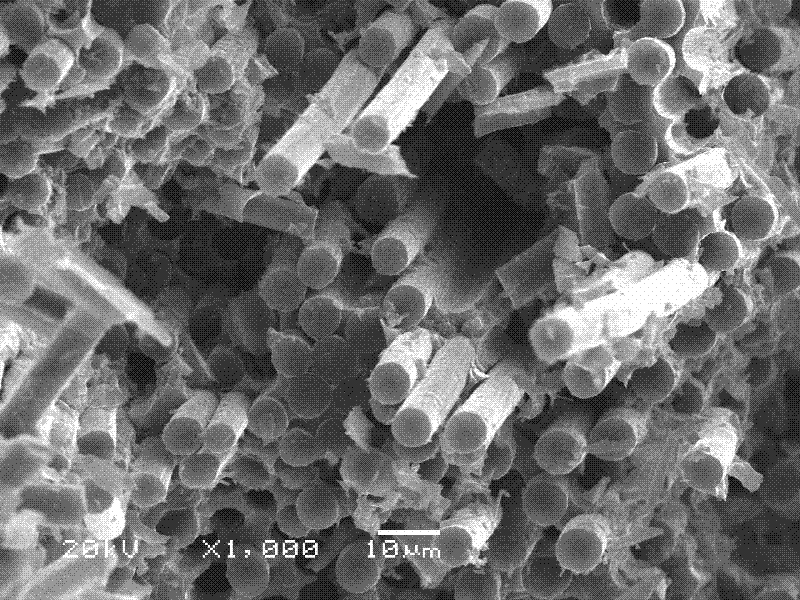

Image

Examples

Embodiment 1

[0027] A method for preparing a carbon fiber reinforced silicon carbide composite material of the present invention, comprising the following steps:

[0028] (1) Impregnation: prepare a three-dimensional four-way carbon fiber braid and place it in a pressure tank, evacuate the pressure tank to a pressure <500 Pa, and impregnate with a polycarbosilane-xylene solution with a mass concentration of 30% for 4 h;

[0029] (2) Drying: Take out the impregnated three-dimensional four-way carbon fiber braid and put it on the sample holder, and dry it at room temperature for 2 h;

[0030] (3) Cracking: Place the dried three-dimensional four-way carbon fiber braid in a high-temperature cracking furnace, vacuumize until the pressure in the cracking furnace is less than 50 Pa, raise the temperature to 1200°C at a heating rate of 10°C / min, and keep warm after reaching the temperature 120 min for pyrolysis; keep the vacuum pump on during the whole process of pyrolysis (including heating, heat...

Embodiment 2

[0033] A method for preparing a carbon fiber reinforced silicon carbide composite material of the present invention, comprising the following steps:

[0034] (1) Impregnation: Prepare the carbon fiber two-dimensional cloth body and place it in a pressure tank, evacuate the pressure tank to a pressure of <500 Pa, and impregnate it with a polycarbosilane-xylene solution with a mass concentration of 70% for 4 h;

[0035] (2) Drying: Take out the impregnated carbon fiber two-dimensional cloth body and place it on the sample rack, and dry it at room temperature for 2 h;

[0036] (3) Cracking: Place the dried carbon fiber two-dimensional cloth body in a high-temperature cracking furnace, vacuumize until the pressure in the cracking furnace is less than 50 Pa, and raise the temperature to 1200°C at a heating rate of 10°C / min. Keep warm for 120 min for cracking; keep the vacuum pump on during the cracking (the whole process includes heating up, keeping warm and cooling down);

[0037...

Embodiment 3

[0039] A method for preparing a carbon fiber reinforced silicon carbide composite material of the present invention, comprising the following steps:

[0040] (1) Impregnation: Prepare a three-dimensional four-way carbon fiber braid and place it in a pressure tank, evacuate the pressure tank to a pressure of <500 Pa, and impregnate it with a polycarbosilane-toluene solution with a mass concentration of 40% for 6 h;

[0041] (2) Drying: Take out the impregnated three-dimensional four-way carbon fiber braid and put it on the sample holder, and dry it at room temperature for 3 h;

[0042] (3) Cracking: Place the dried three-dimensional four-way carbon fiber braid in a high-temperature cracking furnace, vacuumize until the pressure in the cracking furnace is less than 50 Pa, raise the temperature to 1400°C at a heating rate of 20°C / min, and keep warm after reaching the temperature 60 min for pyrolysis; keep the vacuum pump on during the whole process of pyrolysis (including heating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com