Double-ring rotary spray washing device for multi-head mold

A spray washing device and rotary technology, applied in cleaning methods and appliances, chemical instruments and methods, cleaning methods using gas flow, etc., can solve the problems of difficult cleaning, poor cleaning effect, and time-consuming single-hole nozzles, etc. Achieve the effect of shortening the cleaning time and improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

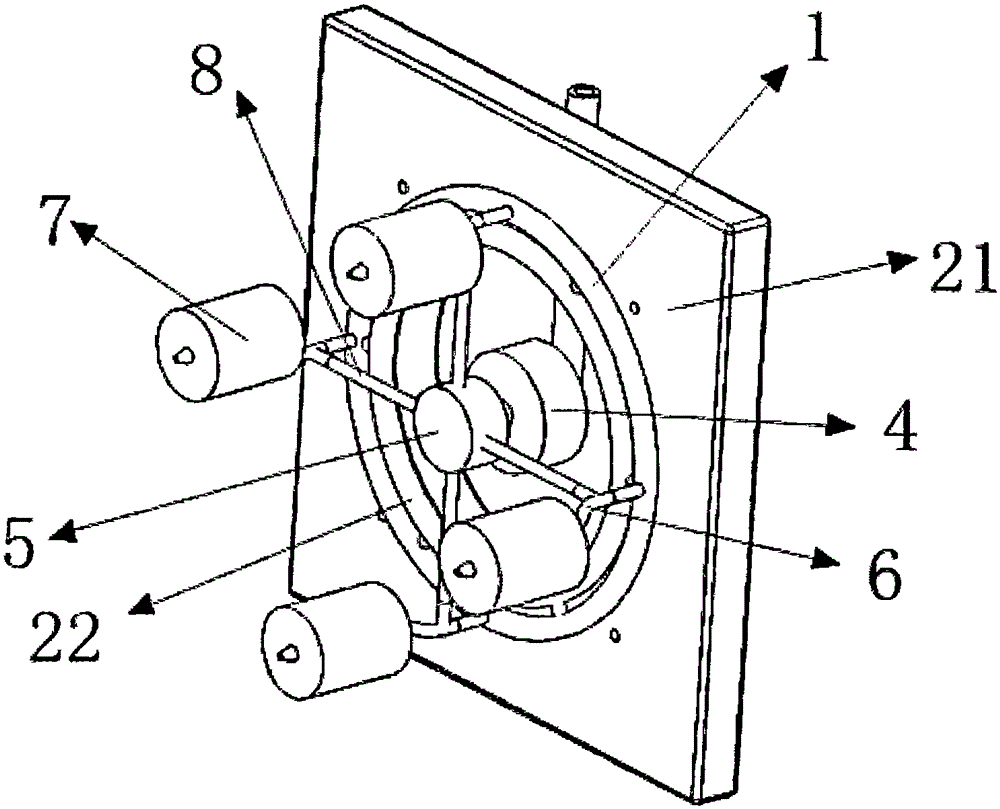

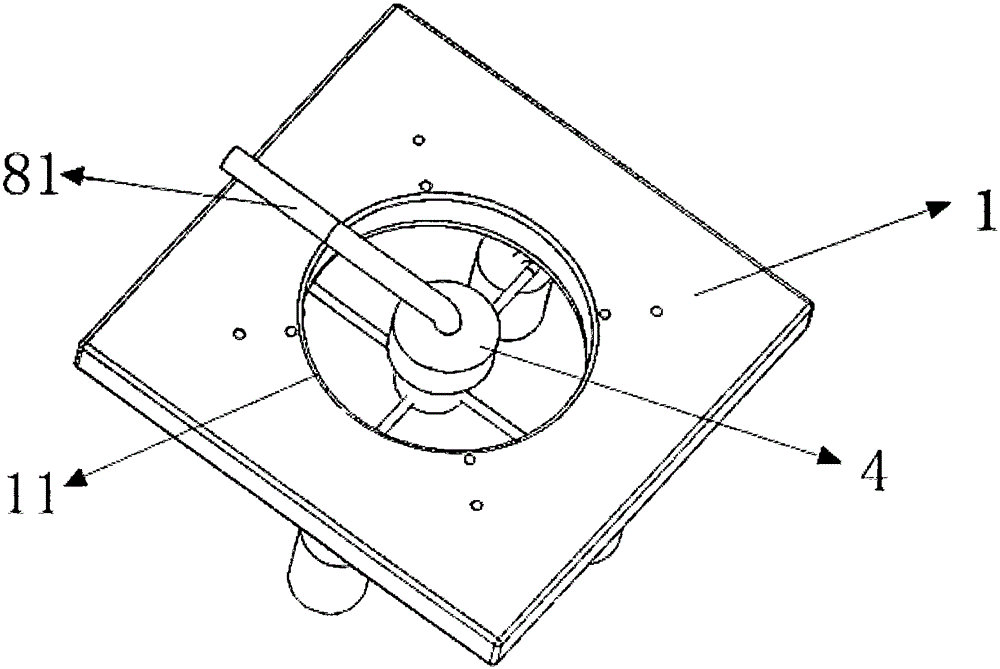

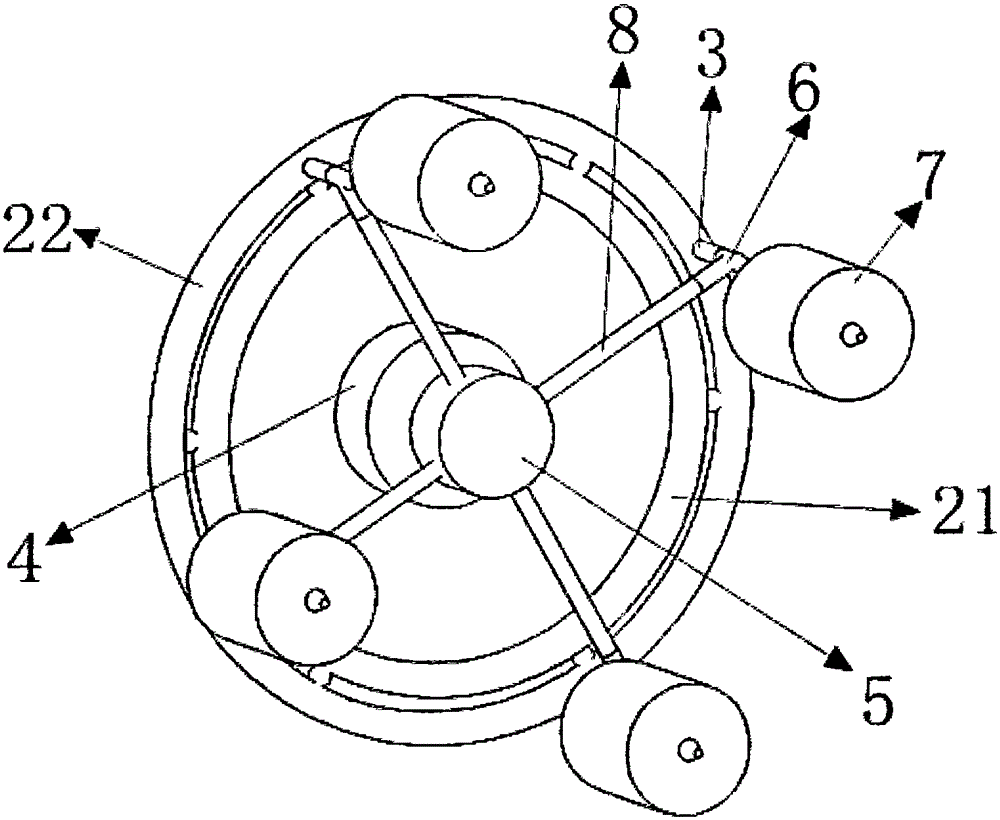

[0026] In the figure: 1 is the fixed plate, 11 is the hole, 21 is the inner ring, 22 is the outer ring, 3 is the rod, 4 is the rotary joint, 41 is the air inlet of the rotary joint, 42 is the rotary head, 43 is the output of the rotary head Air port, 5 is the liquid collection box, 51 is the air inlet of the liquid collection box, 52 is the air outlet of the liquid collection box, 6 is the pipe, 61 is the air inlet of the pipe, 62 is a curved shape, 63 is the air outlet of the pipe, and 64 is the pipe Fixed end, 7 is shower nozzle, and 71 is shower nozzle air inlet, and 72 is shower nozzle air outlet, and 73 rotating nozzles, and 8 is pipe, and 81 is liquid inlet pipe, and 9 is rod.

[0027] A rotary joint 4 is provided, and the air inlet end 41 of the rotary joint is fixedly connected with the liquid inlet pipe 81, and a hole 11 is provided in the center of the fixed plate 1, and the rotary joint 4 is passed through the hole 11, and then the pipe is fixed by welding or pressin...

Embodiment 2

[0044] The main structure and action are the same as the first embodiment, except that the pipe 6 is fixed on the inner ring 21 and the outer ring 22 is fixed on the fixed plate 1 . The inner ring 21 will drive the nozzle 7 to rotate along the outer ring 22 under the support of the outer ring 22 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com