Injection molding method for environment-friendly plastic box

A technology of injection molding and plastic boxes, which is applied in the direction of household components, household appliances, and other household appliances, can solve the problems of reducing work efficiency, time-consuming, and cumbersome steps, and achieves the goal of saving manpower, saving cleaning time, and improving work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

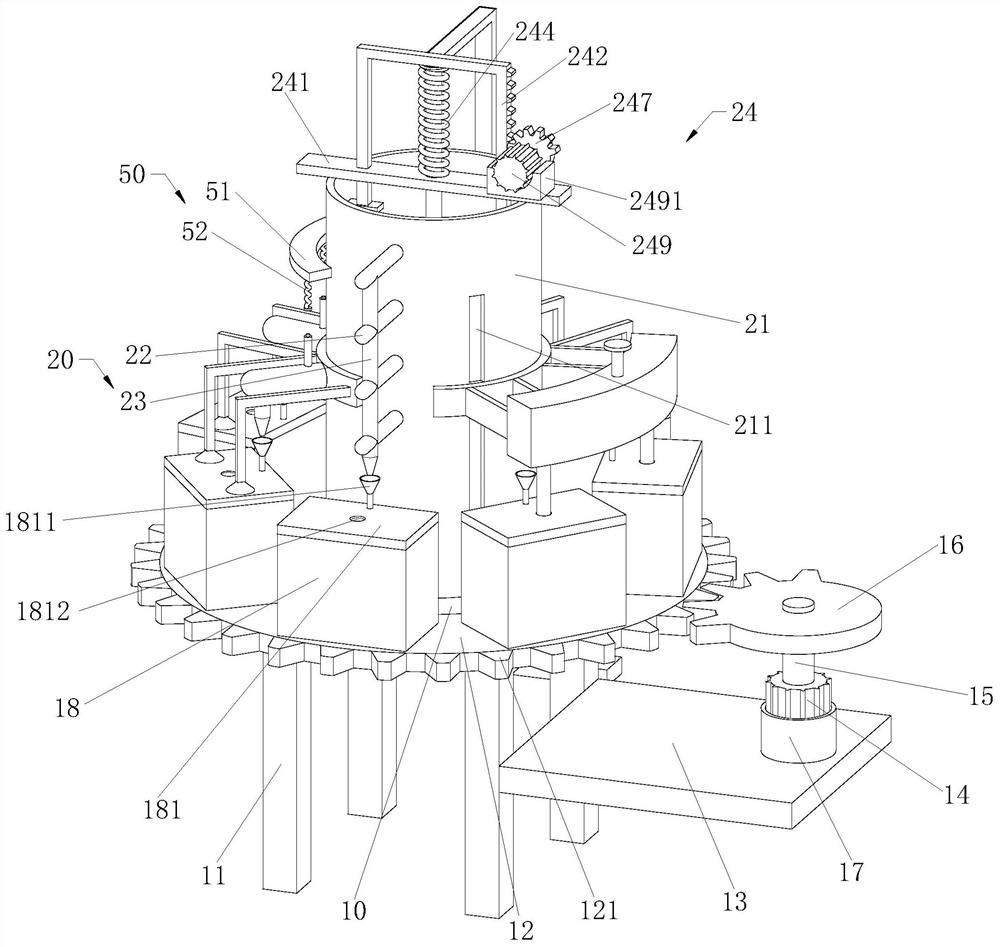

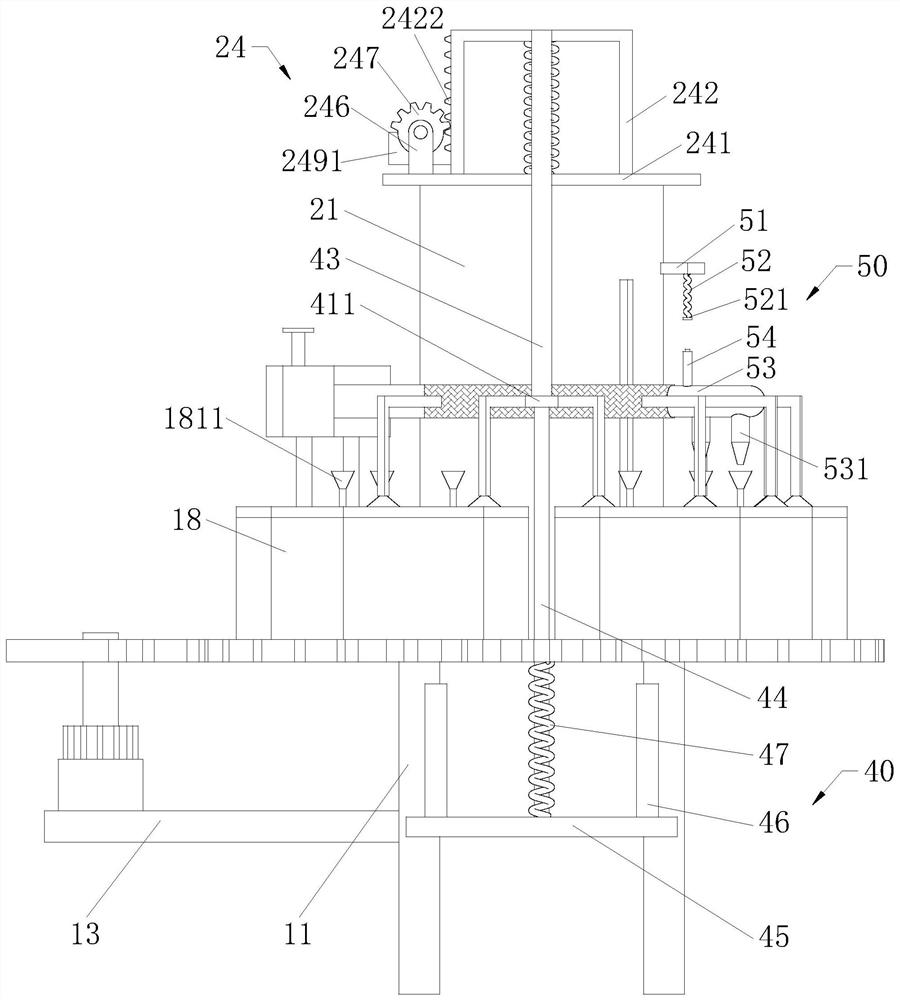

[0038] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

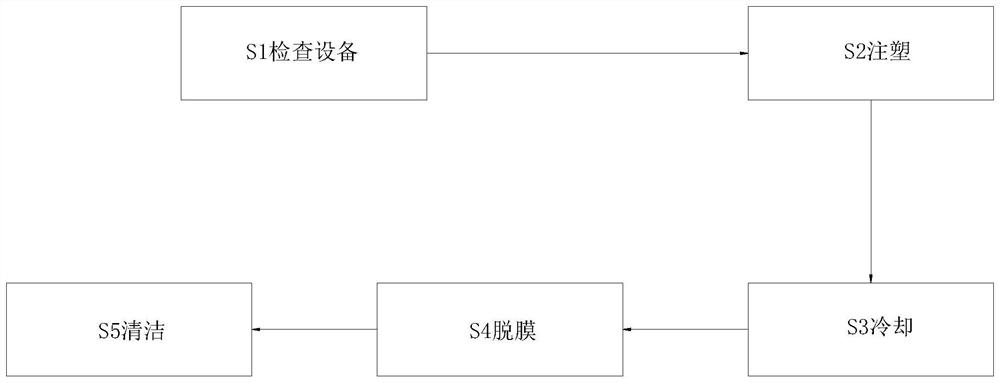

[0039] Such as Figure 2 to Figure 7 As shown, an injection molding method for an environmentally friendly plastic box uses plastic box processing and manufacturing equipment. The equipment includes a workbench 10 and support legs 11 symmetrically arranged at the left and right ends of the bottom of the workbench 10. The left end of the support leg 11 is open. The lower U-shaped structure, the outer wall of the workbench 10 is rotated to be provided with a placement platform 12, the top of the placement platform 12 is in a ring structure, the height of the placement platform 12 is the same as the height of the workbench 10, and the outer wall of the placement platform 12 is provided with a gear 121 , wherein the right end of the vertical section of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com