Dual-cylinder tabletop-type selective laser melting molding equipment and dual-cylinder tabletop-type selective laser melting molding method

A technology of laser selective melting and forming equipment, which is applied in the field of additive manufacturing of metal parts, can solve the problems of not paying more attention to powder waste, expensive materials, and unsuitable precious metals, so as to save recycling and cleaning time and greatly increase competitiveness , the effect of preventing powder waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

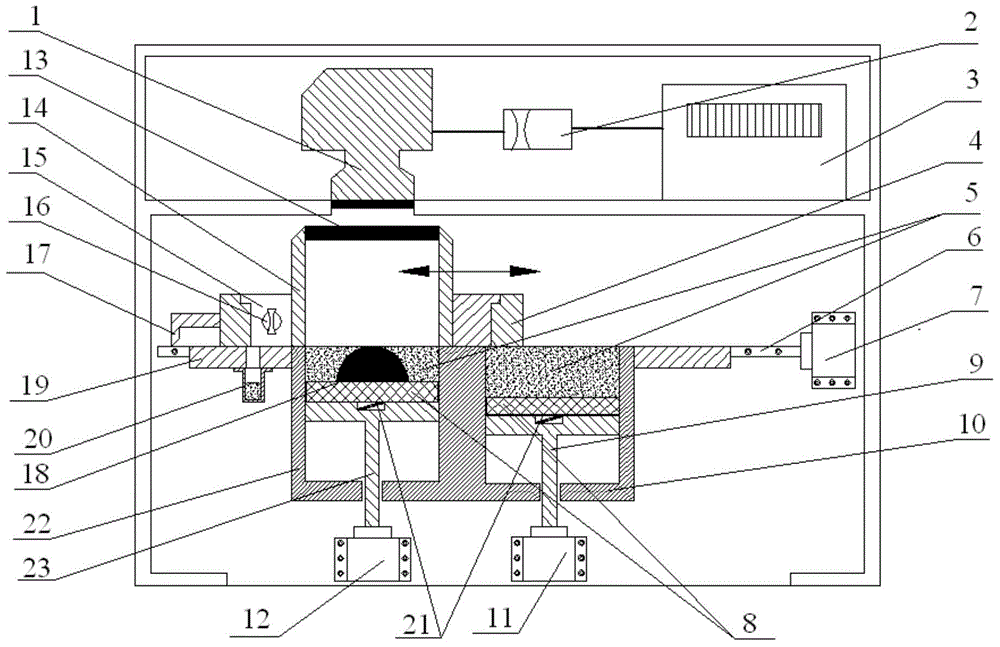

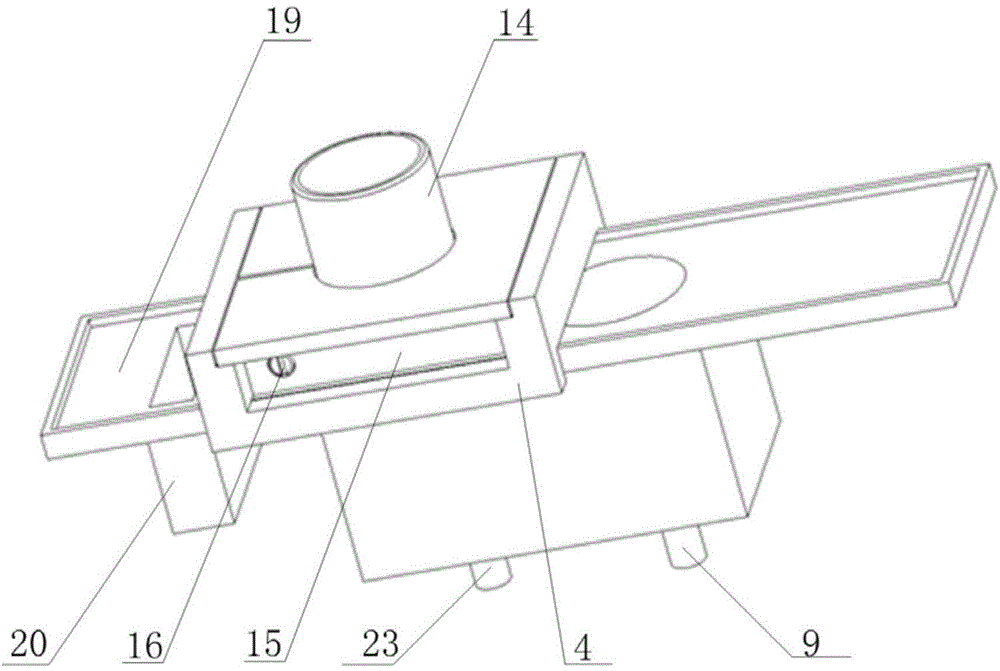

[0032] Such as Figures 1 to 4b shown. The double-cylinder desktop type laser selective melting molding equipment of the present invention includes a sealed molding chamber, an optical transmission system, a powder spreading device 17, a molding cylinder 22, a powder material cylinder 10, a gas circulation purification device, and a control system. The molding cylinder 22 and A forming platform 19 is arranged above the powder material cylinder 10, and a mobile platform 4 is arranged above the forming platform 19. The forming platform 19 is used as a guide track of the mobile platform 4, so that the mobile platform 4 moves left and right thereon;

[0033] Powder spreading device 17 and powder taking system are set on the mobile platform 4;

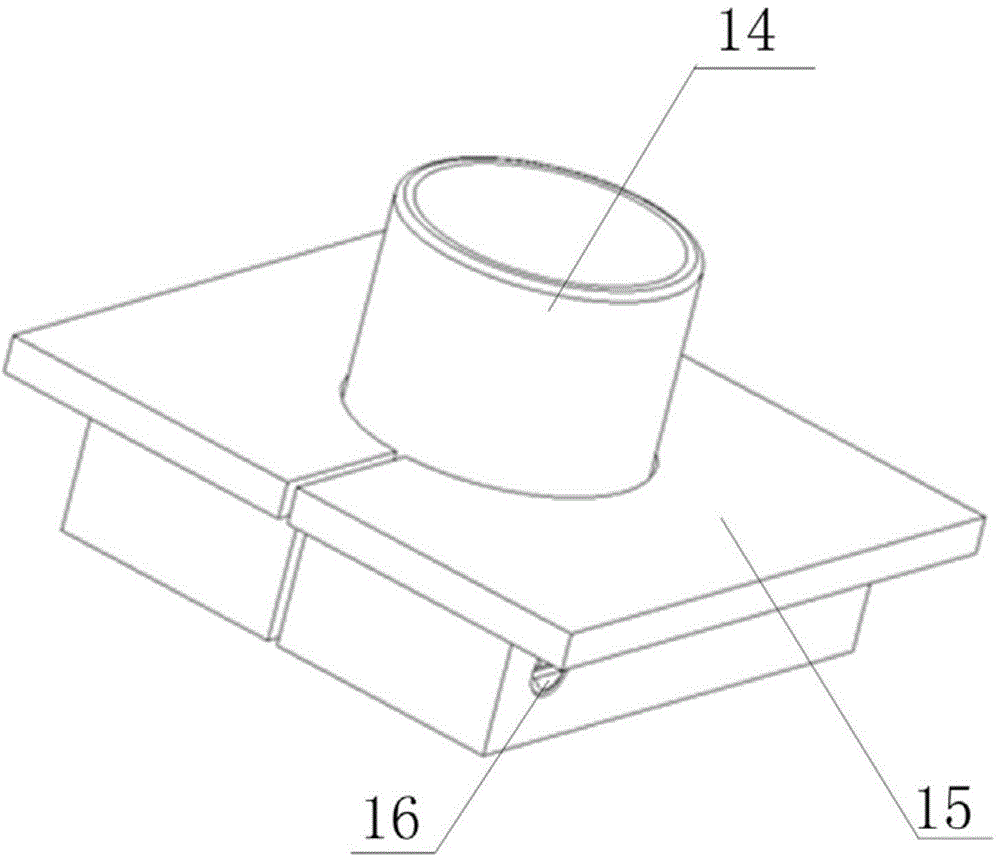

[0034] The powder-taking system includes a powder-taking base 15 and a powder-taking cylinder 14 , and the powder-taking cylinder 14 is arranged above the powder-taking base 15 .

[0035] The optical transmission system includes a laser 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com