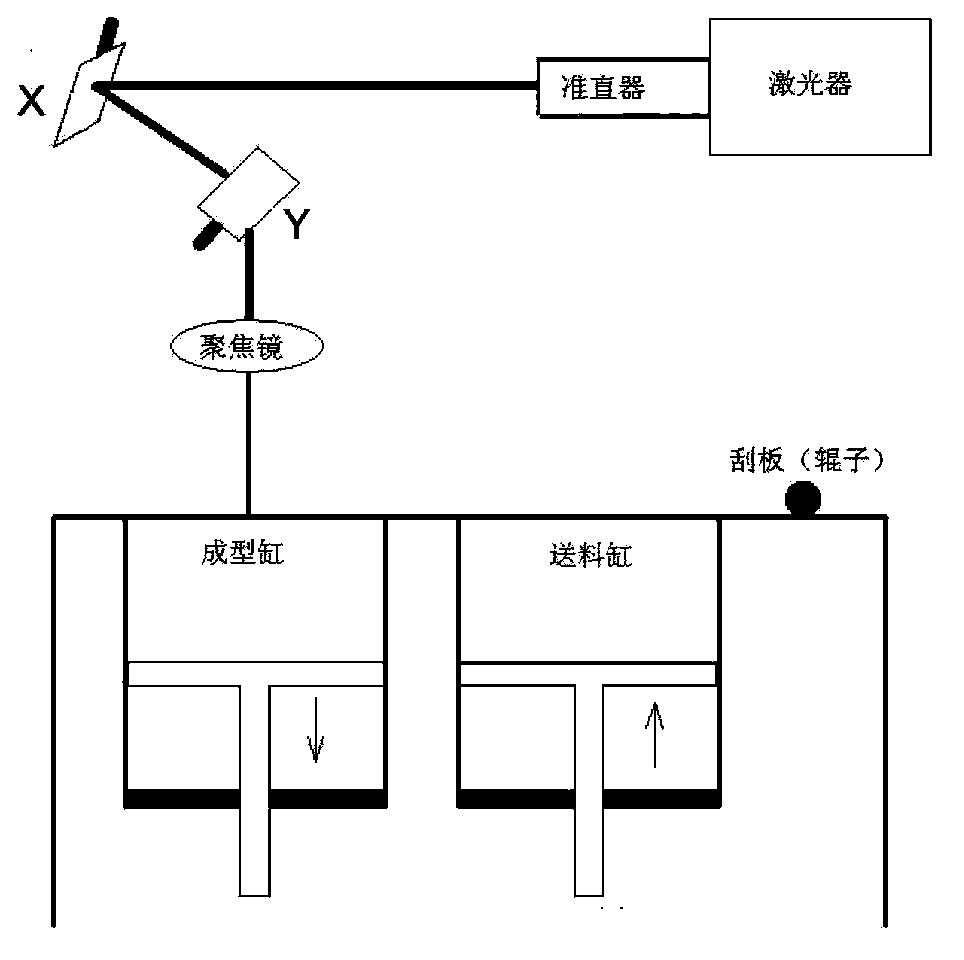

Foldable changeable forming device for selective laser melting

A laser selective melting and selective laser melting technology, applied in the field of 3D printing laser selective melting rapid prototyping, can solve the problems of labor consumption, poor effect, time-consuming powder recovery, etc., to improve the labor environment, save the cleaning operation process, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

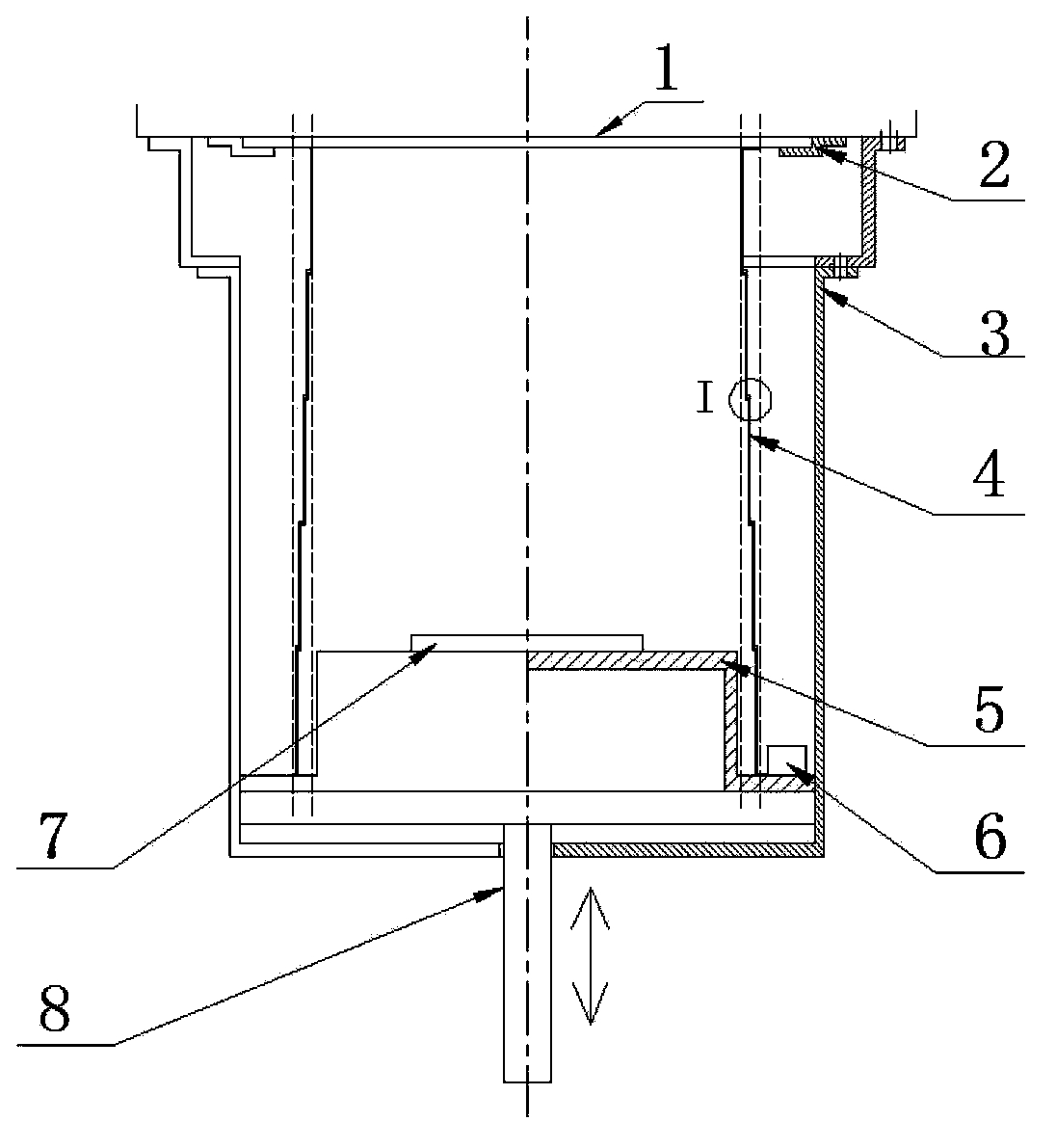

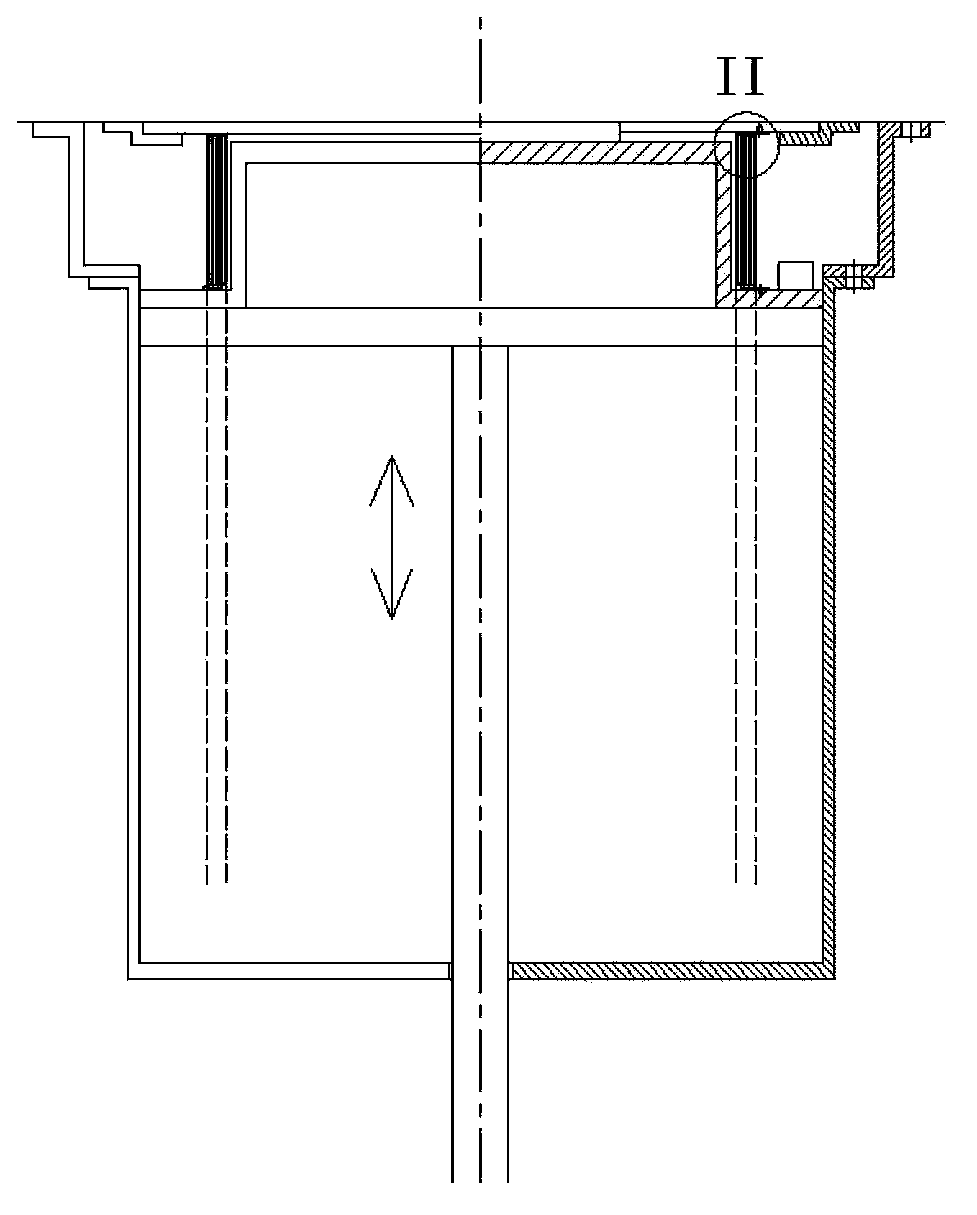

[0021] Such as figure 2 As shown, a foldable and easy-to-change forming device for laser selective melting and forming is set in the cylinder body 3 of the original forming cylinder, including a forming base plate 7, a bottom plate 5, and a telescopic cover 4 that gradually shrinks from bottom to top. The forming substrate 7 is fixed on the base plate 5 , the lower end of the telescoping cover 4 is fixed on the periphery of the base plate 5 , and the base plate 5 is connected to the upper plate of the electric push rod 8 through the clamping member 6 . The upper end of the telescopic cover 4 is connected with the lower surface of the forming surface 1 (connected with the upper end of the original forming cylinder) through the clamping part 2 .

[0022] At the beginning of forming, the electric push rod 8 pushes the bottom plate 5 and the forming base plate 7 up, so that the forming base plate and the forming surface 1 are flush. At this time, the telescopic cover 4 also short...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com