Double-helix shaft double-helical ribbon concrete batch plant

A technology of mixing device and concrete, which is applied in cement mixing device, clay preparation device, chemical instrument and method, etc., can solve the problems such as concrete not easy to stick to the shaft, easy to stick to the shaft and agglomerate, and material flow is not smooth, etc. Wide range of use, improved mixing efficiency, and reduced cleaning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following embodiments will further illustrate the present invention in conjunction with the drawings.

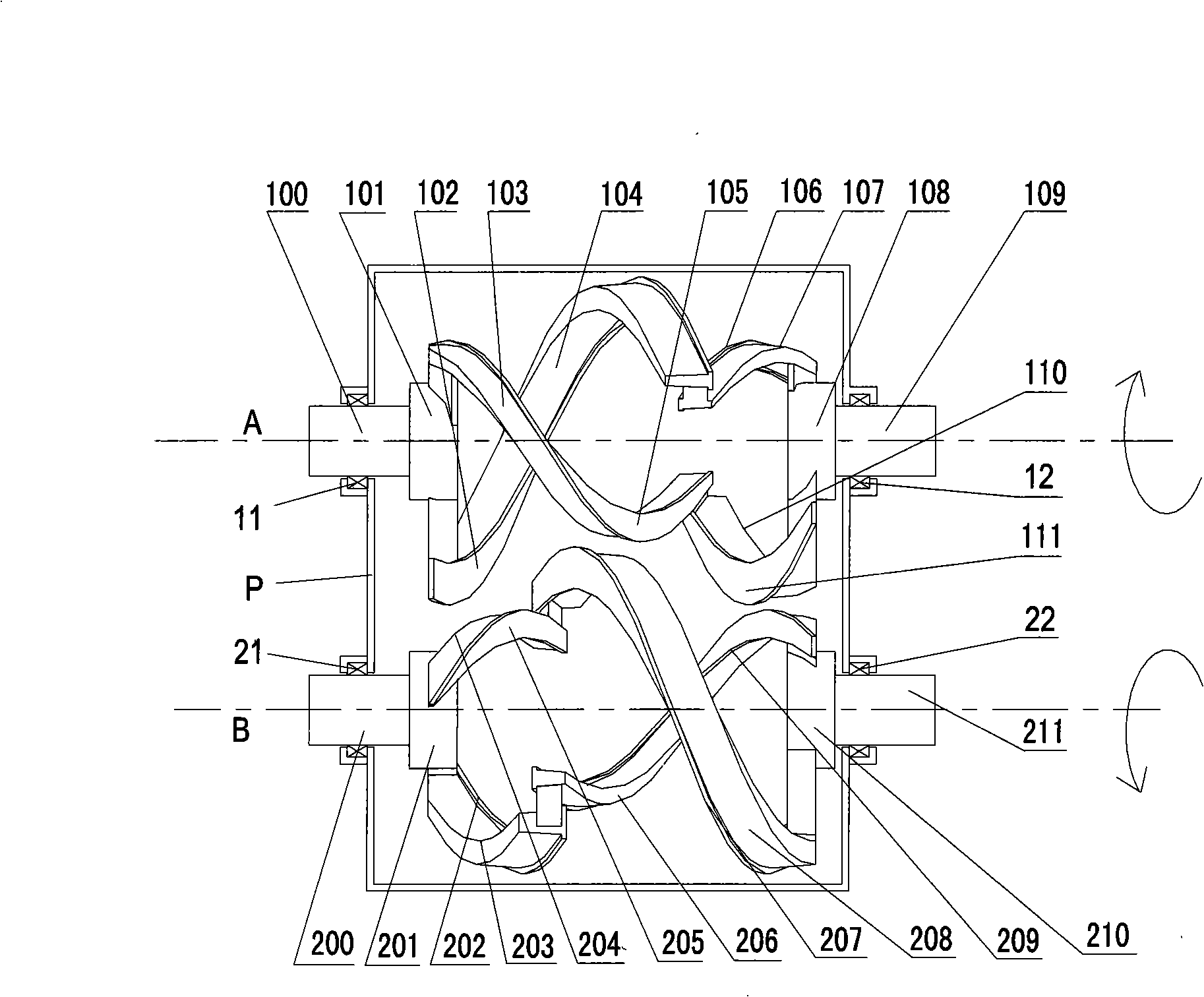

[0026] See image 3 , The present invention is provided with a body P, a first stirring system A and a second stirring system B.

[0027] The first mixing system A is provided with a left shaft head 100, a right shaft head 109 and 4 screw shafts. The 4 screw shafts include an inner return unit shaft 107, an outer return unit shaft 110, an outer feed unit shaft 104 and an inner feed unit The shaft 103, the left end of the outer feed unit shaft 104 and the left end of the inner feed unit shaft 105 are respectively connected to the left shaft head 100, the right end of the outer feed unit shaft 104 is connected to the left end of the inner return unit shaft 107, the inner return unit shaft The right end of 107 is connected with the right shaft head 109, the right end of the inner feeding unit shaft 103 is connected with the left end of the outer return unit shaft 110, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com