Patents

Literature

79results about How to "Affect production efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

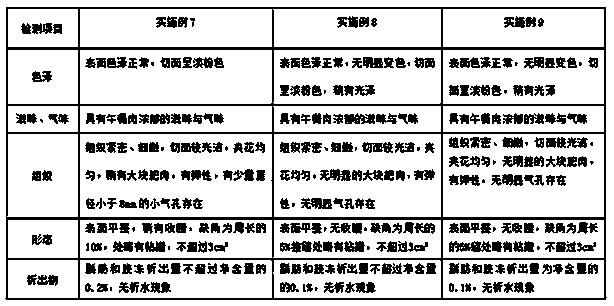

Spicy lunch meat can and preparation method thereof

InactiveCN104187759AReduce typesImprove securityFood ingredient functionsFood preparationChemistrySodium triphosphate

The invention discloses a spicy lunch meat can and a preparation method thereof. The spicy lunch meat can is prepared from the following raw materials: pig meat, chicken meat, corn starch, salt, white granulated sugar, I+G, monosodium glutamate, sodium tripolyphosphate, sodium pyrophosphate, xanthan gum, konjac gum, dried chilli powder or fresh red pepper, Chinese jujube powder, D-sodium erythorbate, spice and salt water. The spice is a mixture of semen myristicae and ground pepper according to a ratio of 1:2-4; and the preparation method comprises the steps of pretreating raw materials; pickling; chopping; loading and sterilizing. The spicy lunch meat has the characteristics of tight tissue, smooth cutting surface, high resilience, thick meat fragrance and fine mouthfeel, and can enhance appetite.

Owner:遂宁市三丰食品有限公司

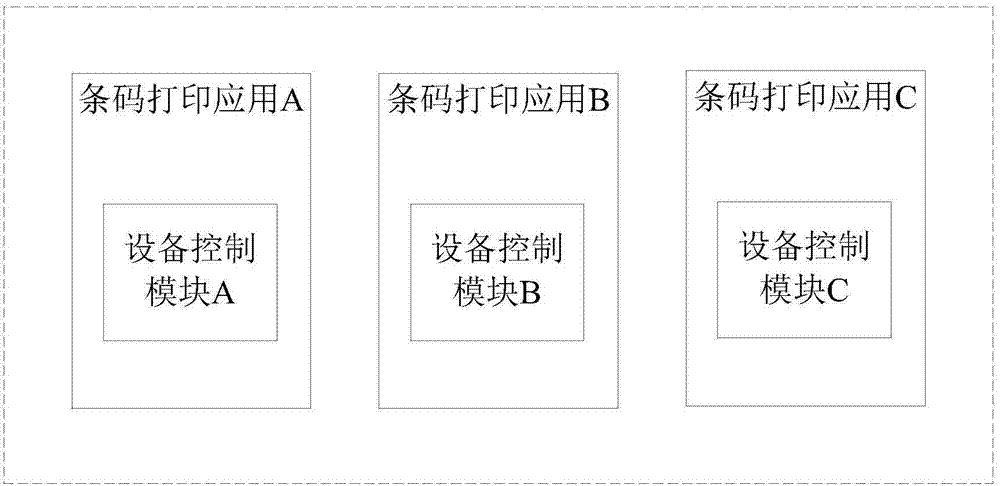

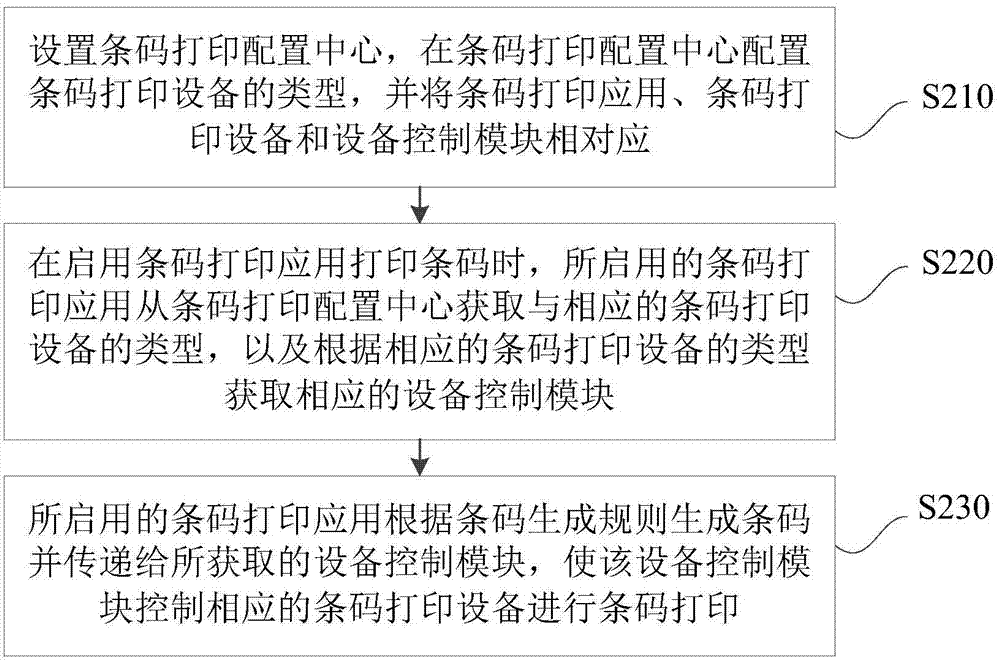

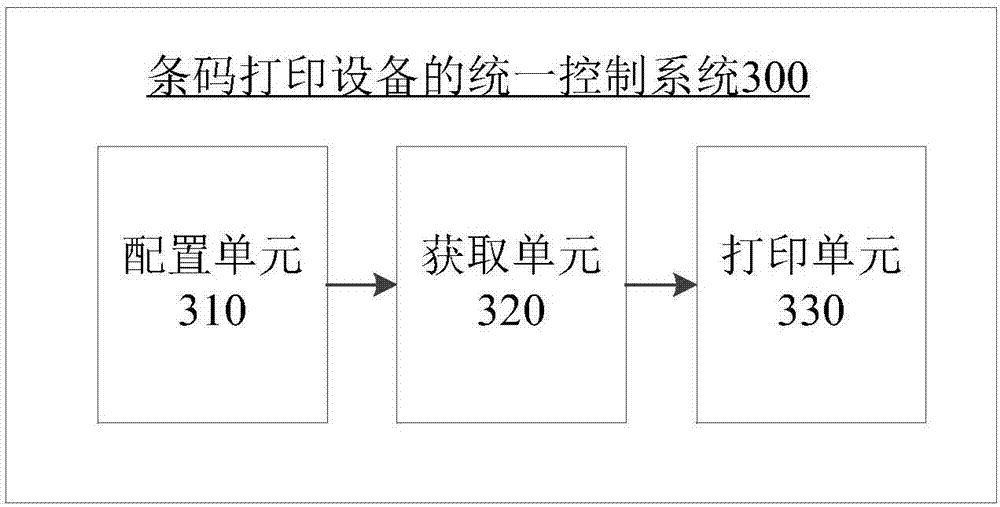

Unified control method and system for bar code printing equipment

ActiveCN104772992AReduce workloadAffect production efficiencyTypewritersOther printing apparatusWorkloadSoftware engineering

The invention provides a unified control method and system for bar code printing equipment. The method comprises the following steps: a bar code printing configuration center is arranged, the type of the bar code printing equipment is configured at the bar code printing configuration center, and the types of each bar code printing application and each bar code printing equipment correspond to each equipment control module; one bar code printing application acquires the type of the corresponding bar code printing equipment from the bar code printing configuration center when started to print a bar code, and acquires the corresponding equipment control module according to the type of the corresponding bar code printing equipment; the started bar code printing application generates the bar code according to the bar code generation rules and transmits the bar code to the acquired equipment control module, so that the equipment control module controls corresponding bar code printing equipment to print the bar code. With adoption of the method and the system, workload of a development worker can be reduced, the development period can be shortened, and the production efficiency of products is not affected by a bar code recognition link.

Owner:GOERTEK INC

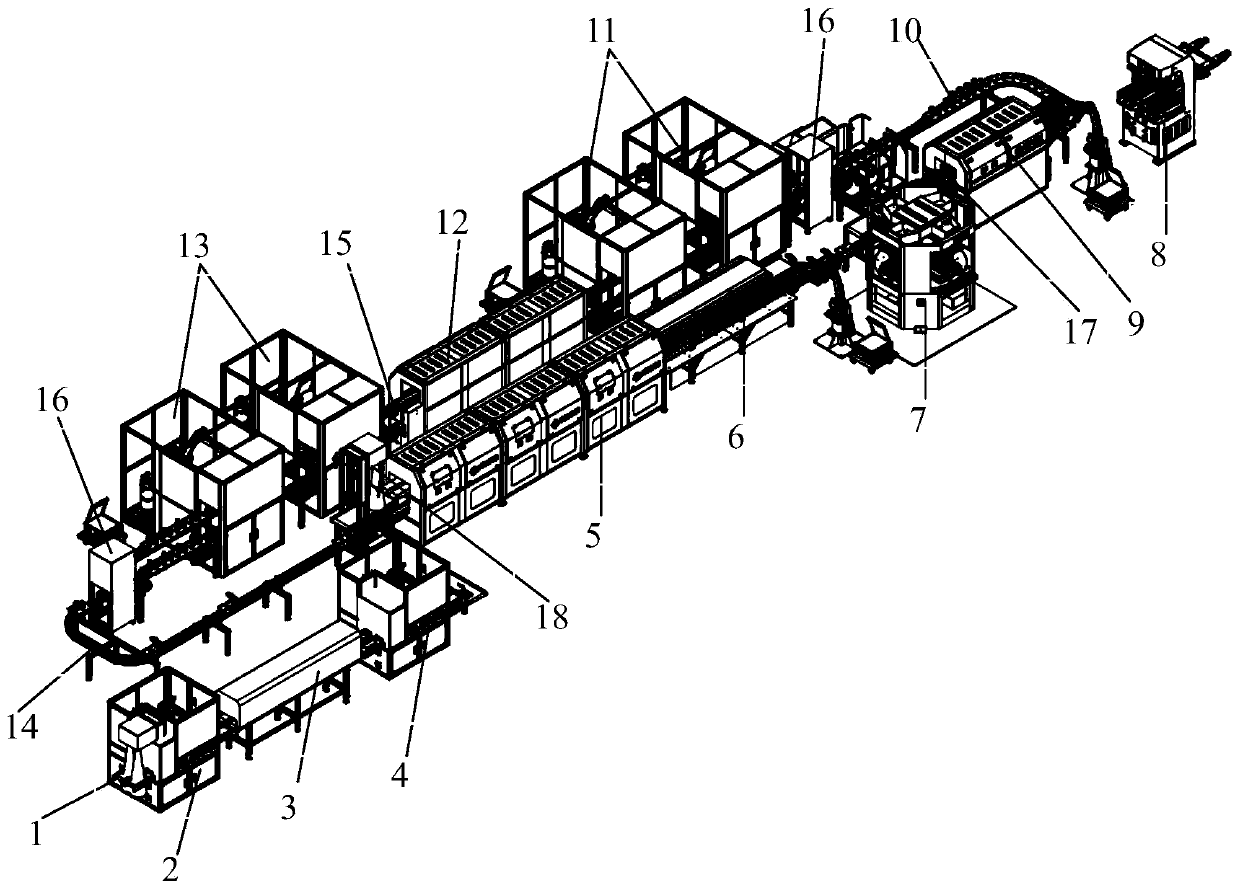

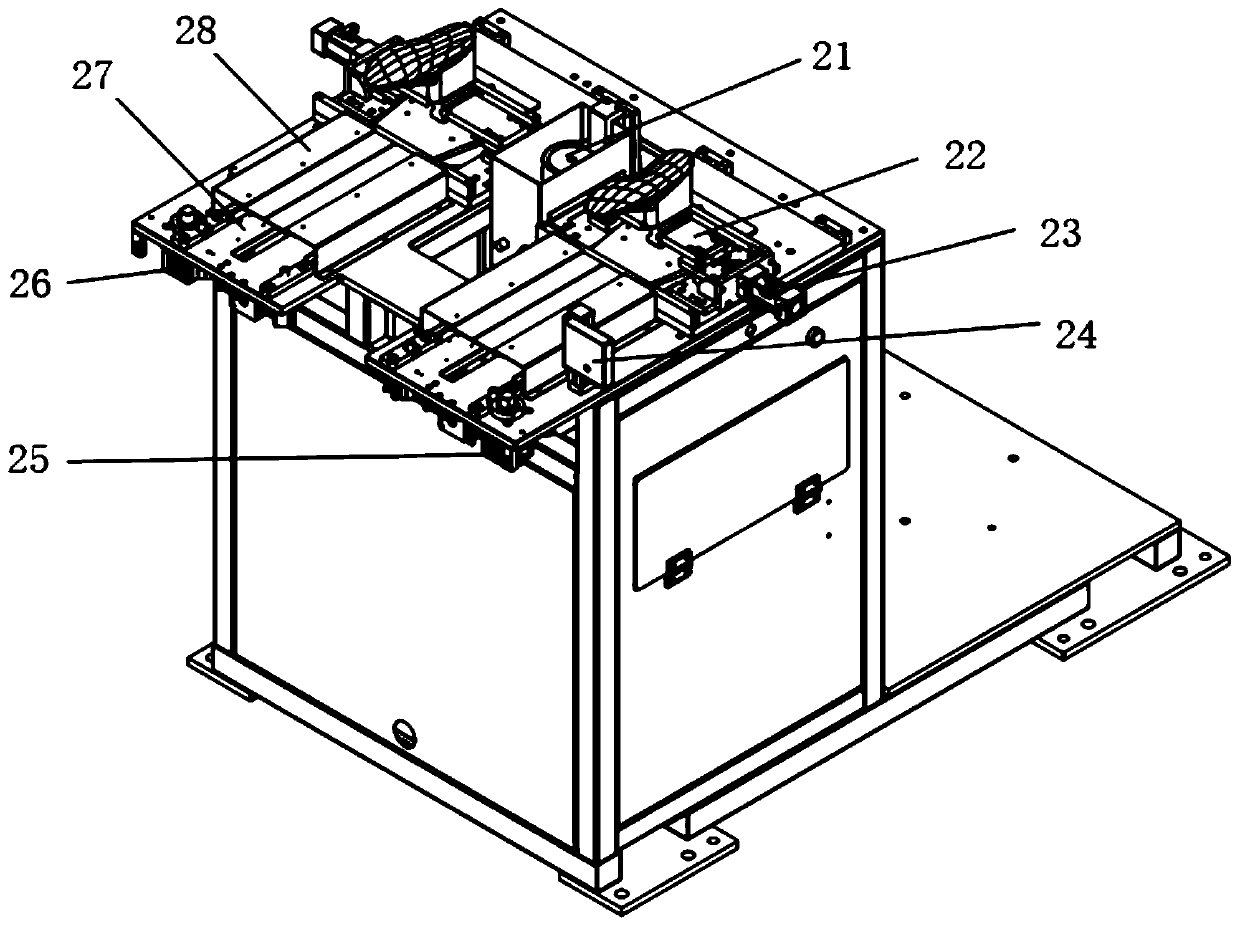

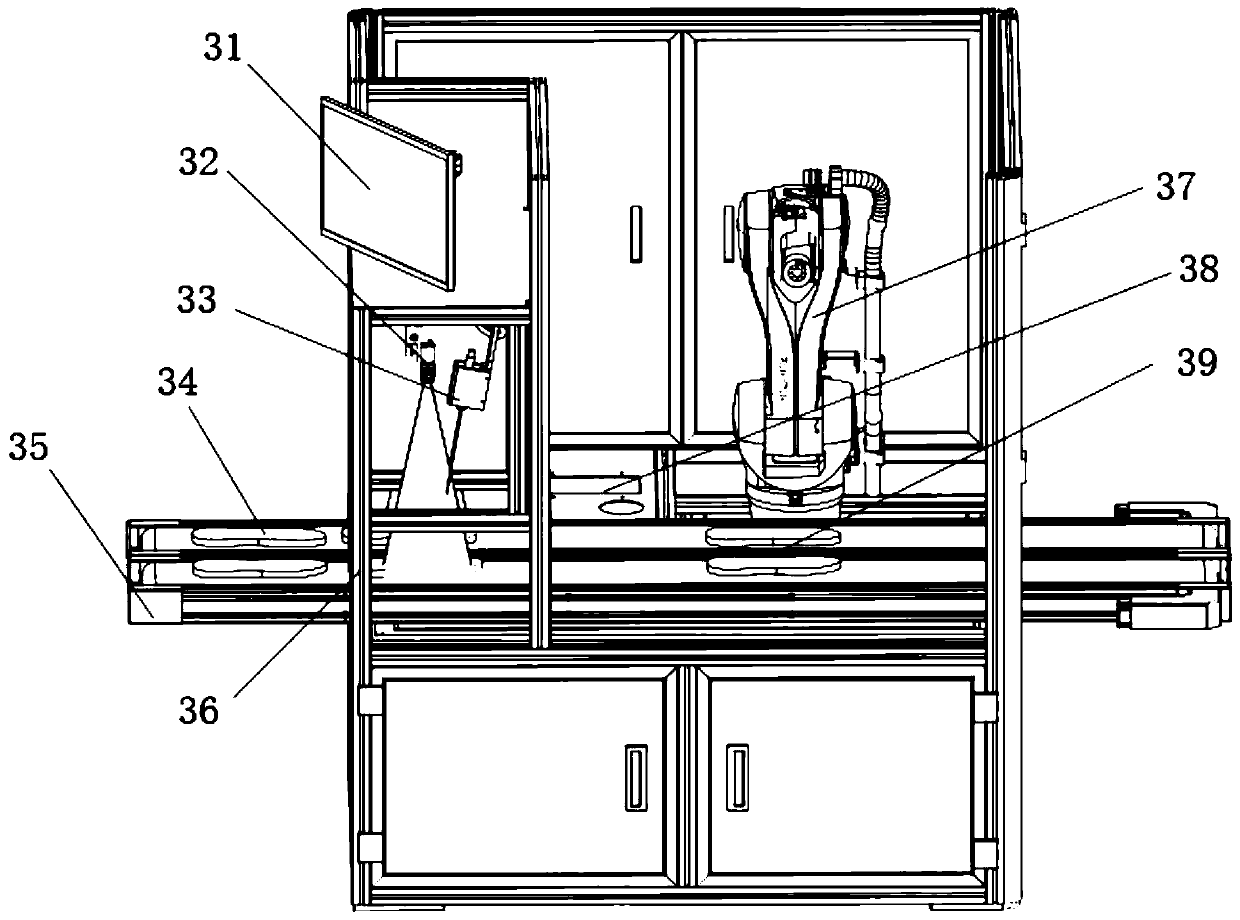

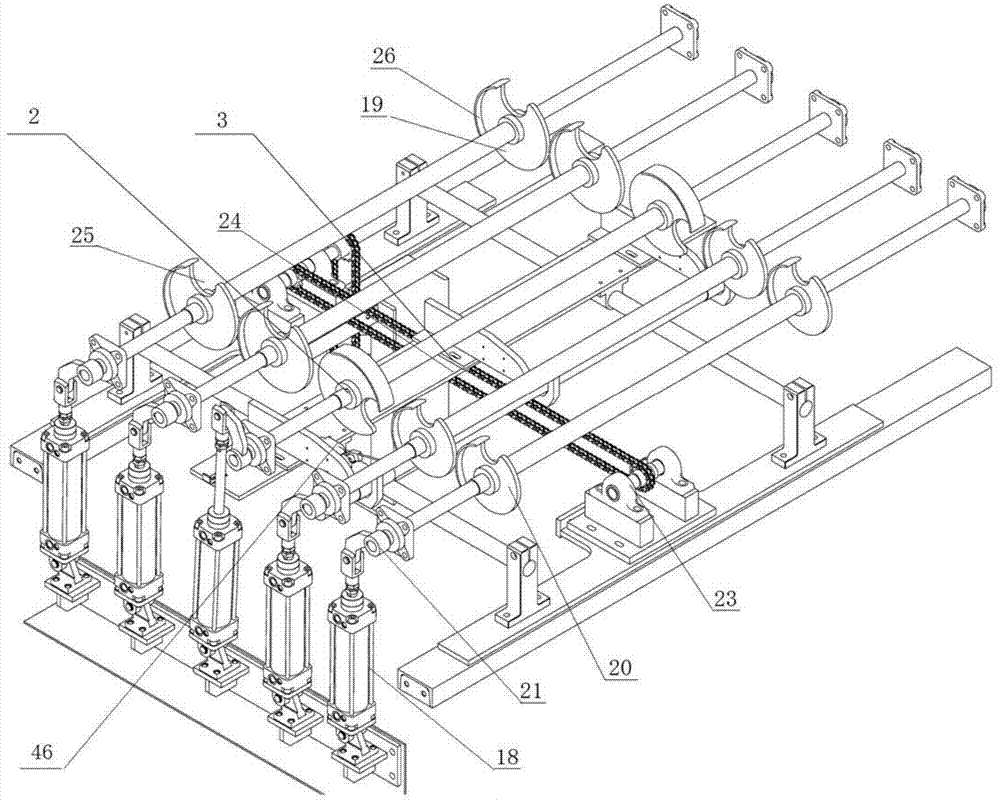

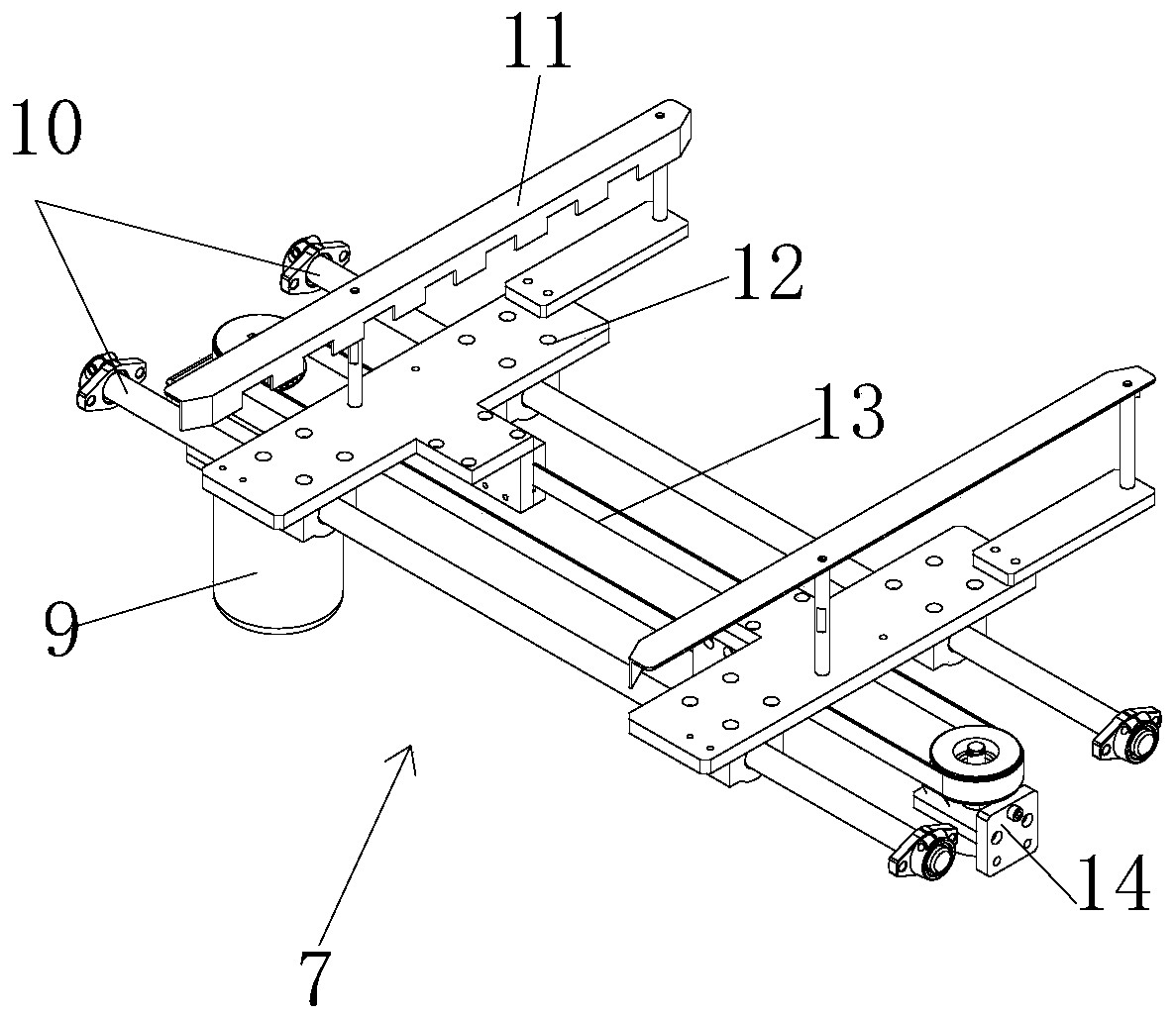

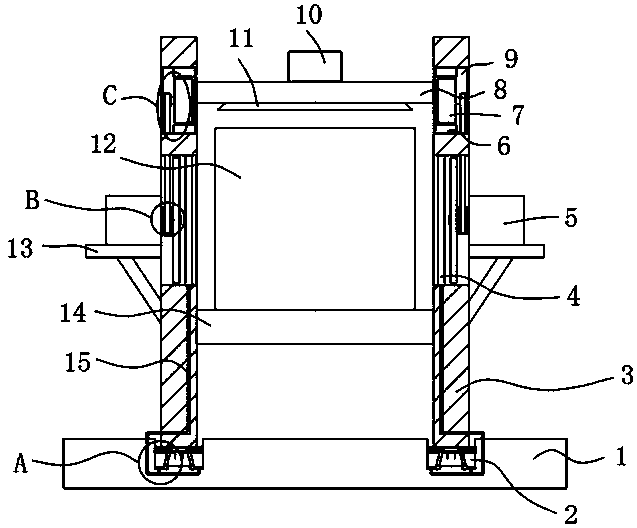

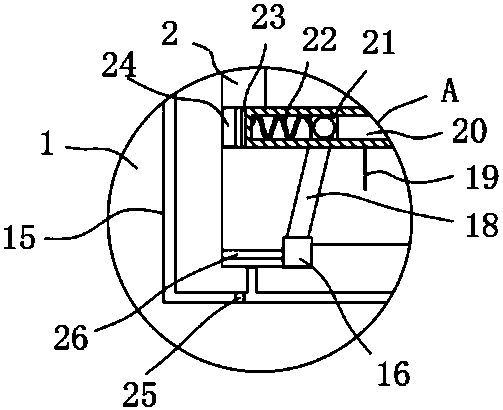

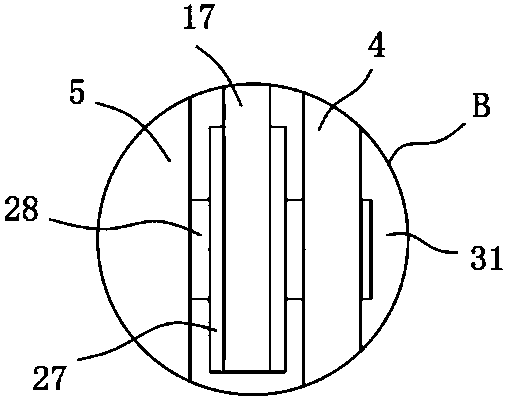

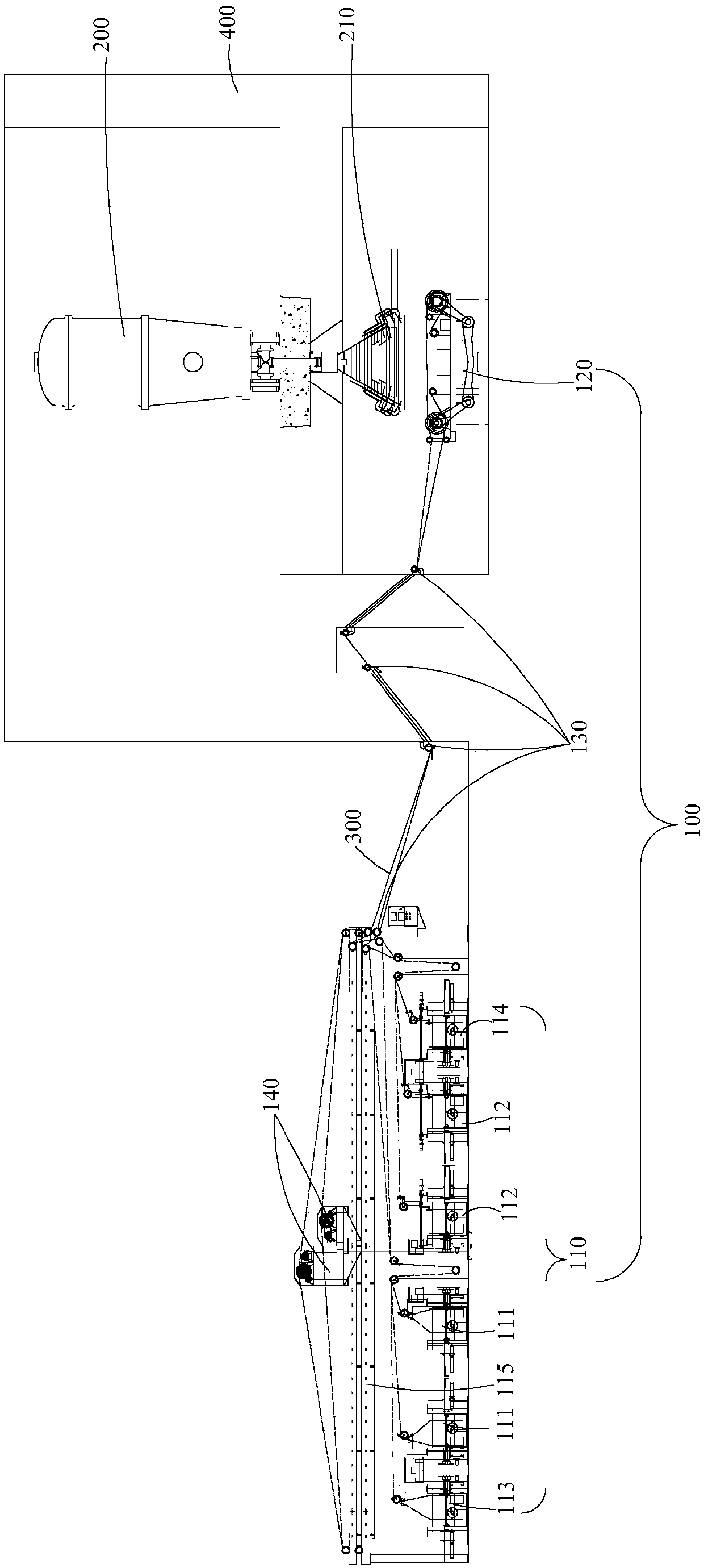

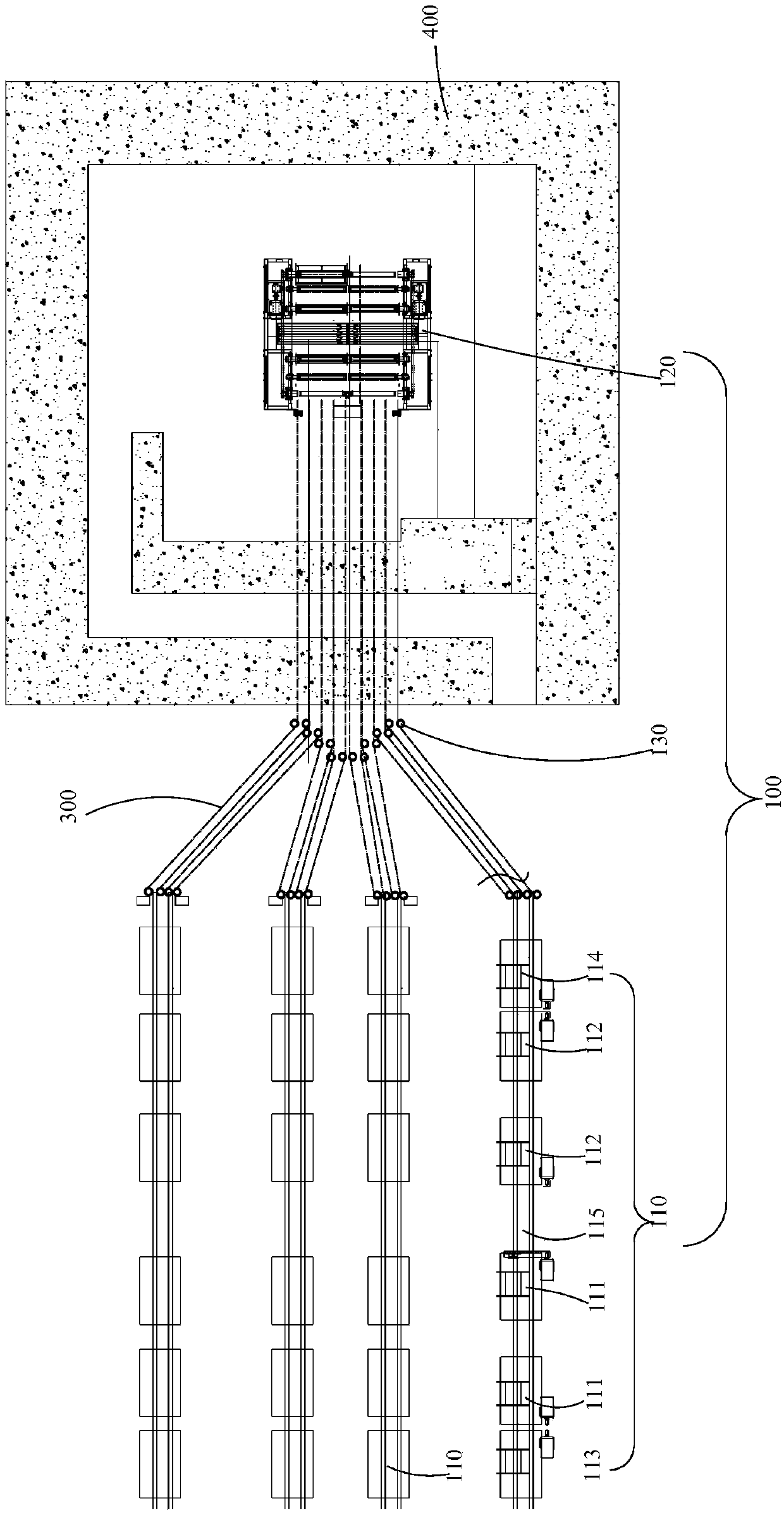

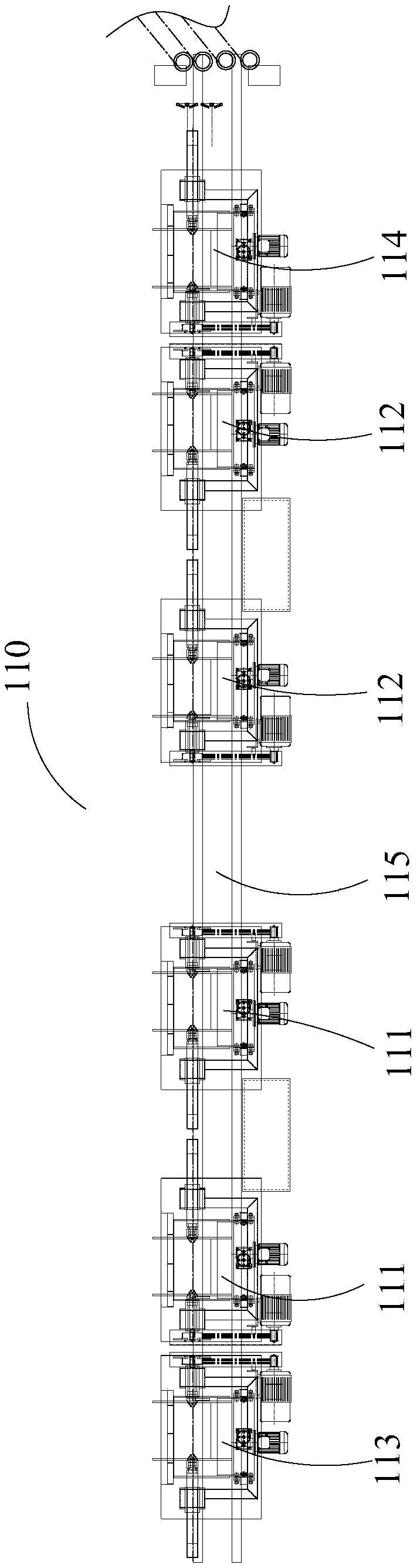

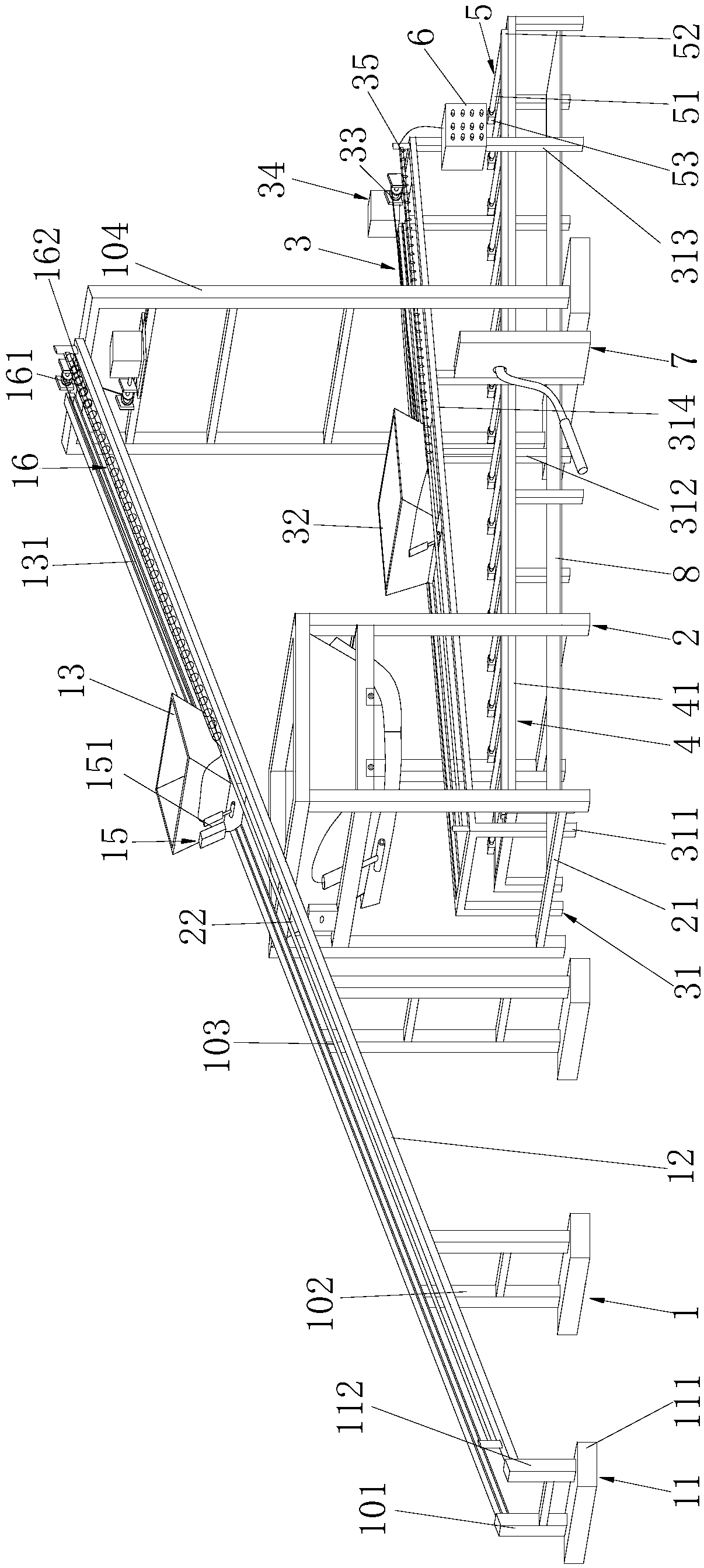

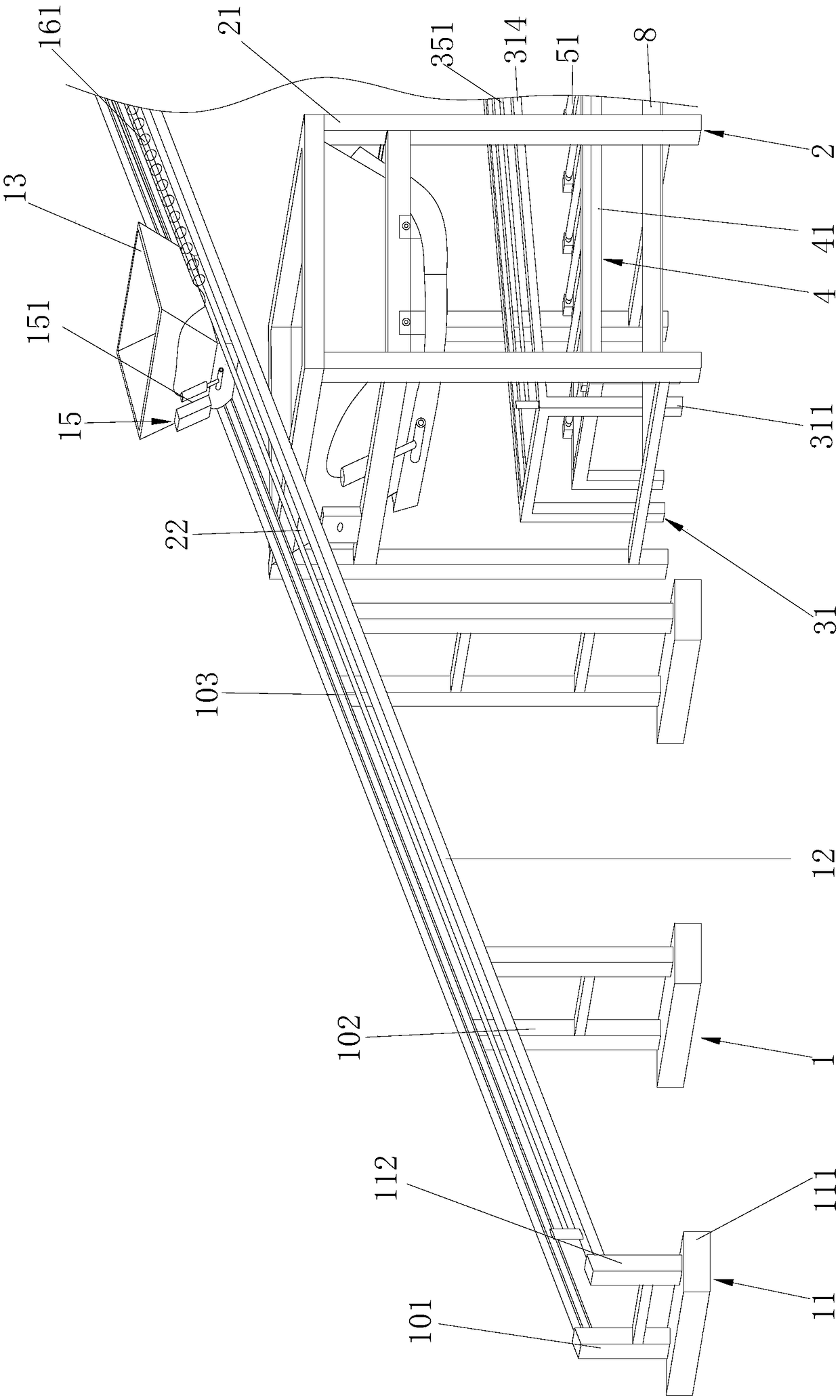

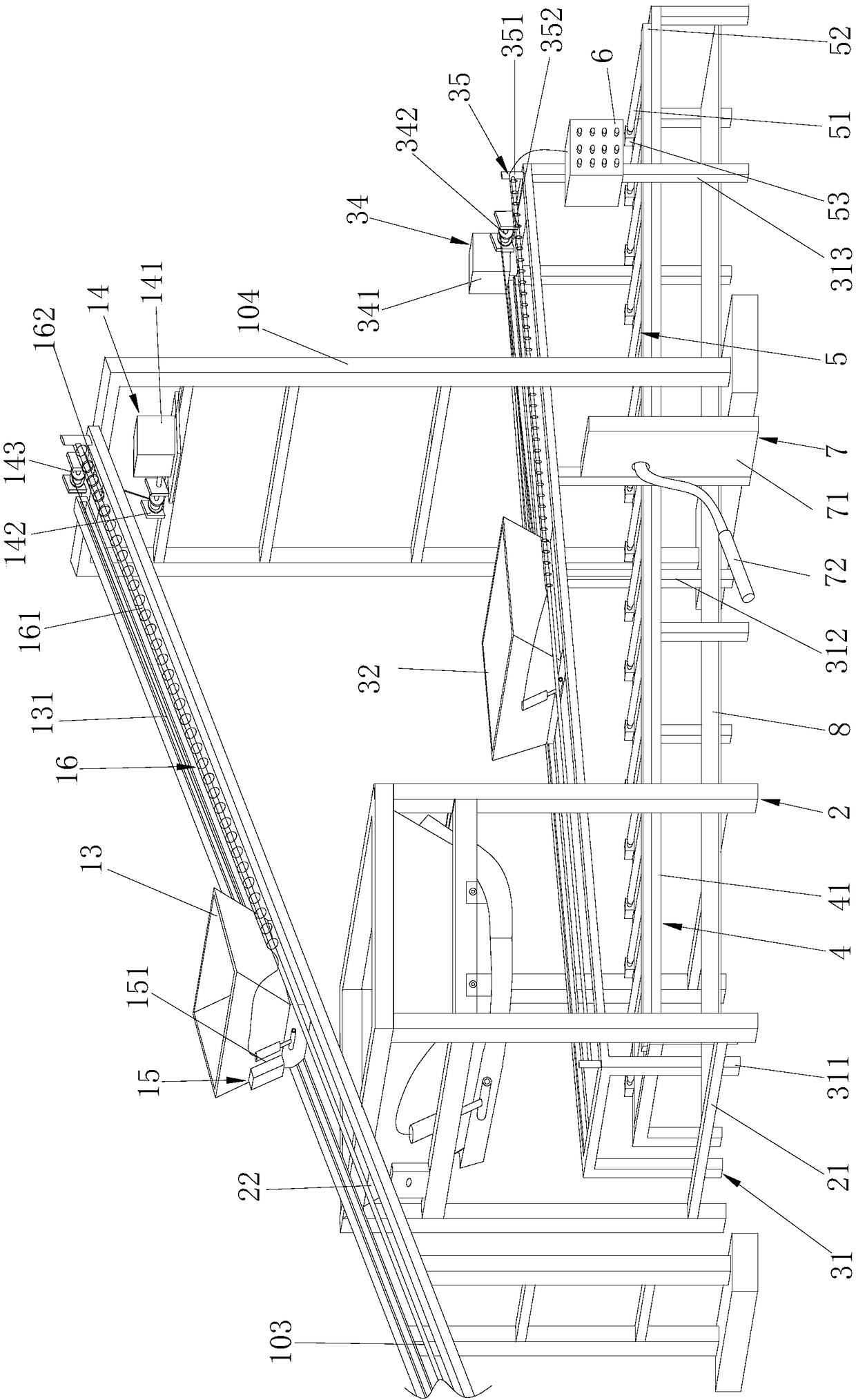

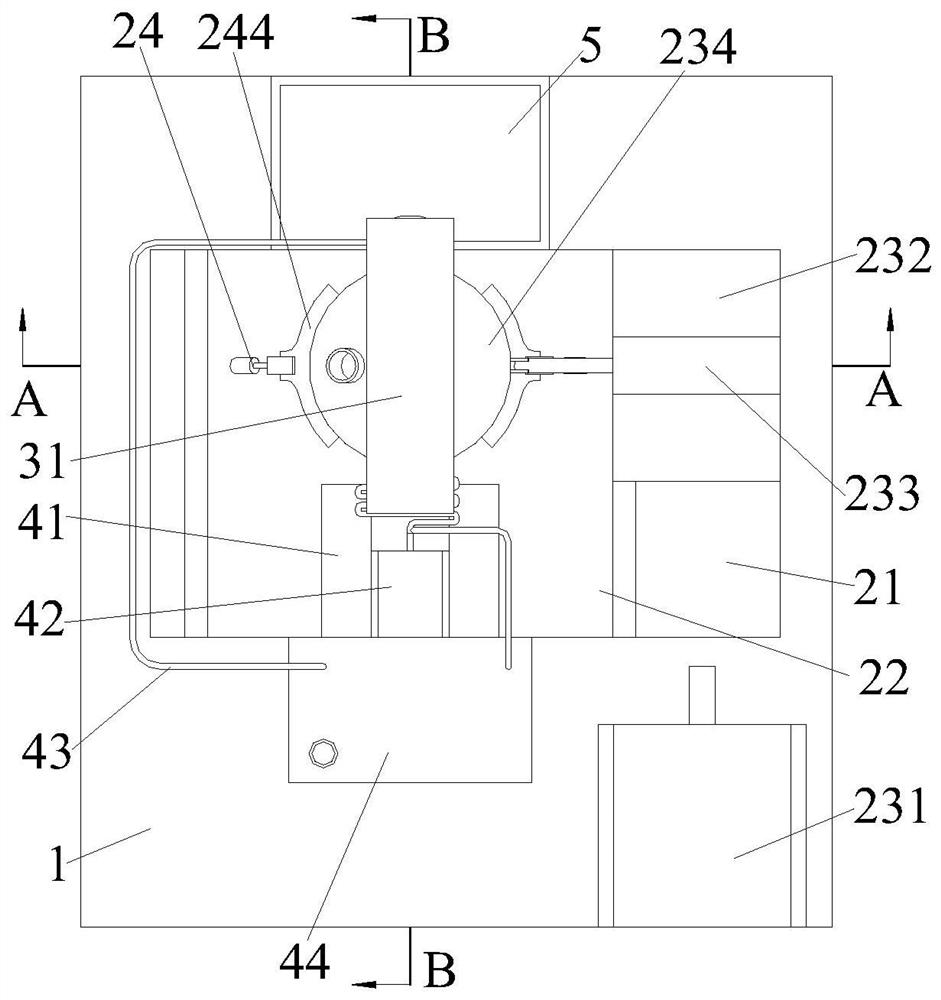

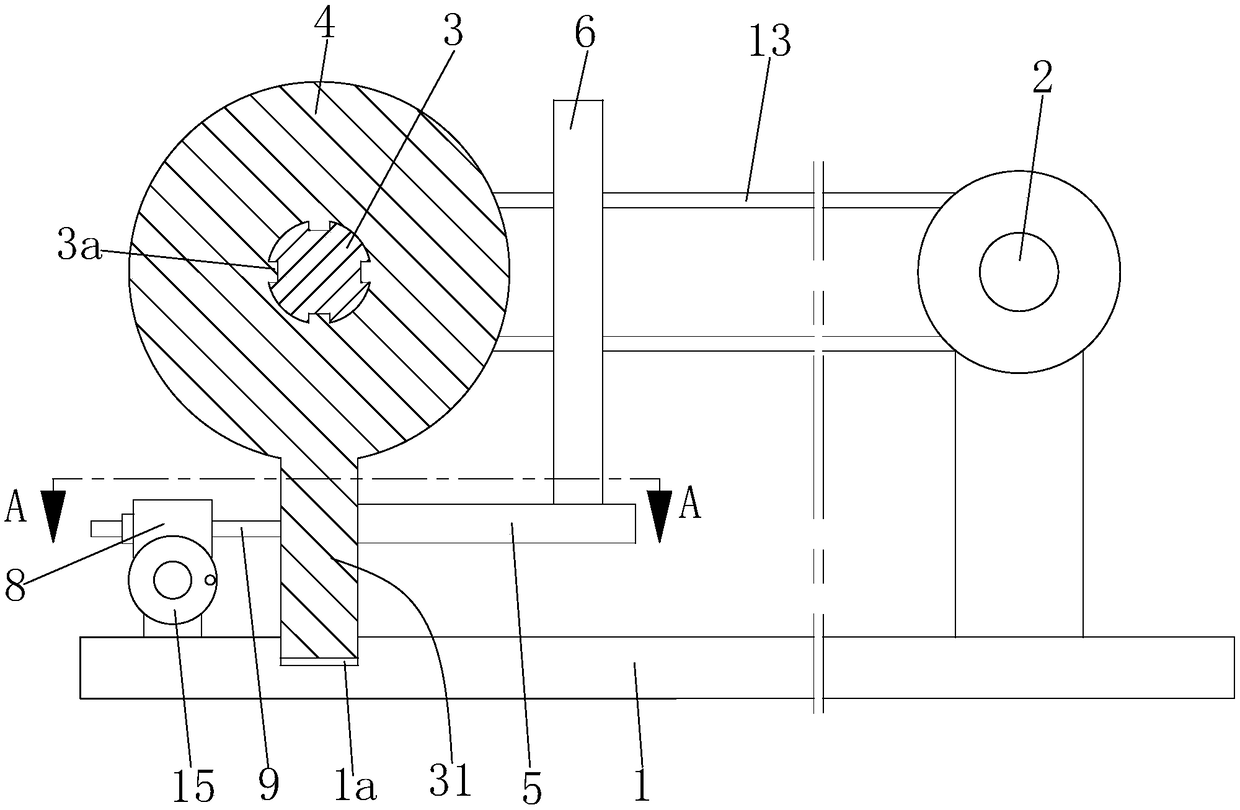

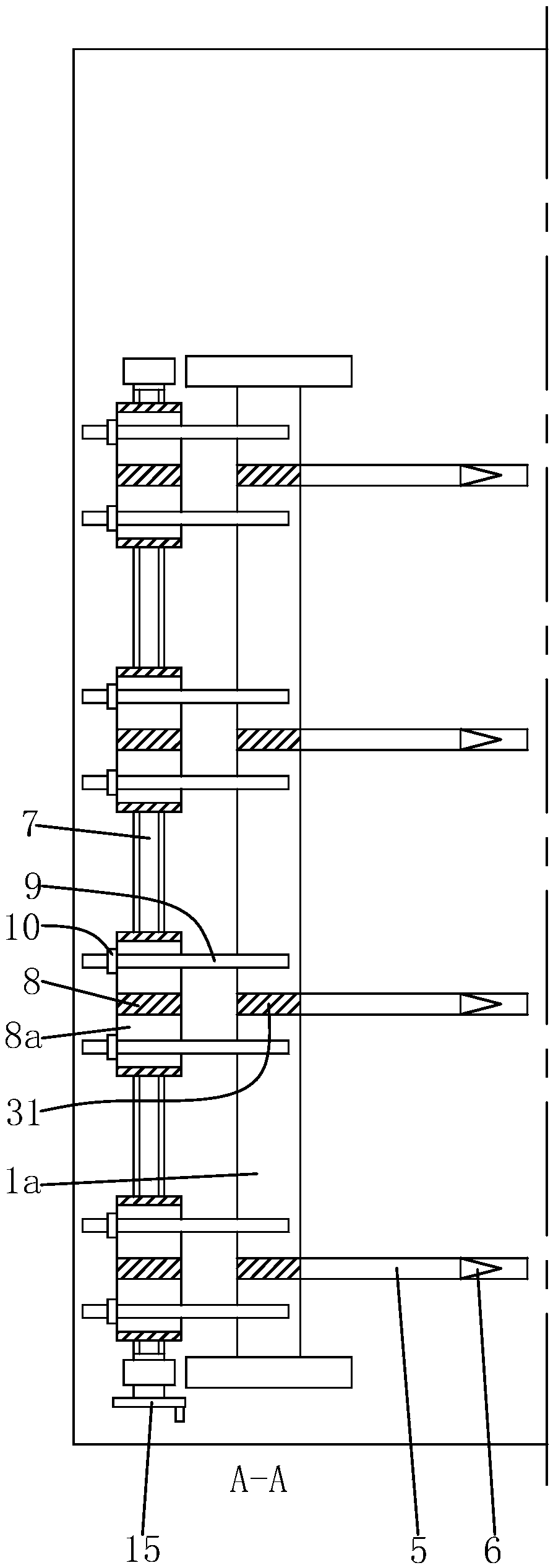

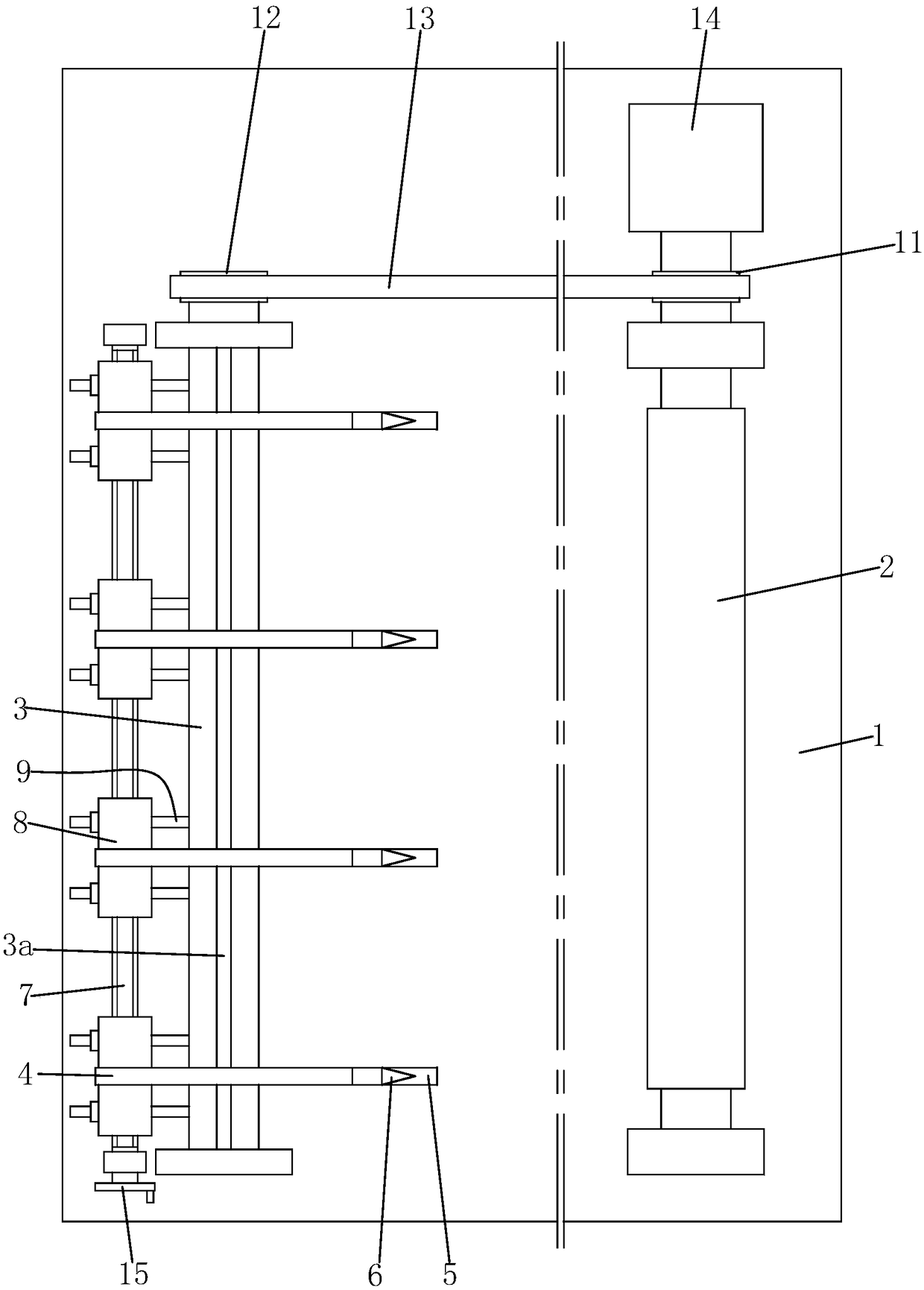

Shoemaking production line

PendingCN110025084AReduce production efficiencyIncrease productivityShoe gluingProduction lineLine segment

The invention discloses a shoemaking production line. The shoemaking production line comprises a sole line body and a vamp line body. A sole feeding station, a sole treating agent spraying station, asole treating agent oven, a sole glue spraying station, a secondary glue oven and a sole combining station are sequentially arranged on the sole line body. A vamp feeding station, a vamp treating agent spraying station, a vamp treating agent oven, a vamp glue spraying station, the secondary glue oven and the sole combining station are sequentially arranged on the vamp line body. The vamp line bodycomprises an annular lower vamp line body. An I-shaped upper vamp line body is arranged above a line segment, from the front side of the vamp treating agent spraying station to the rear side of the vamp glue spraying station, of the lower vamp line body. Lifting mechanisms communicated with the upper vamp line body and the lower vamp line body are arranged on the front side of the vamp treating agent spraying station and the rear side of the vamp glue spraying station of the vamp line body. In front of the secondary glue oven, the sole line body and lower vamp line body gather to the sole combining station. The sole line body is located above the lower vamp line body.

Owner:NINGBO CIXING

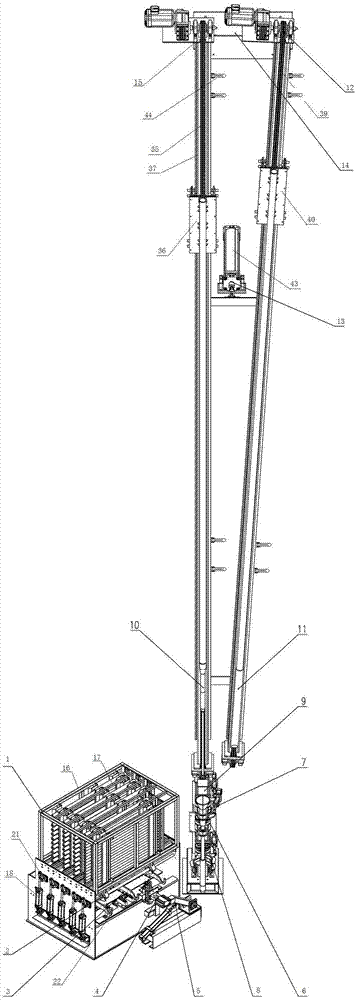

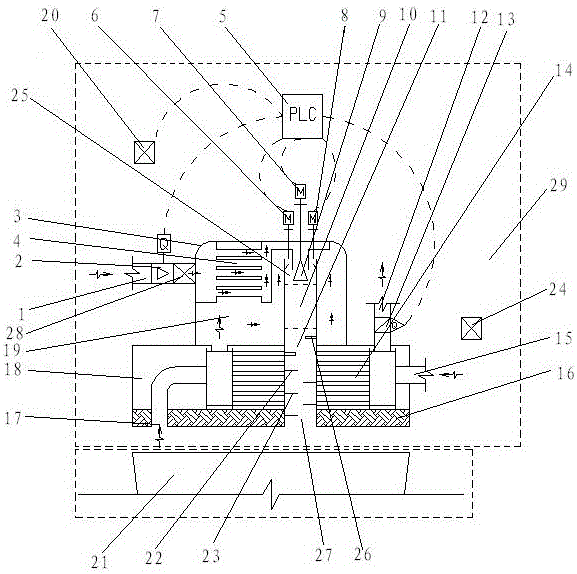

Full-automatic temperature-measurement sampling device outside furnace and method thereof

ActiveCN104266863AEasy to controlImprove stabilityWithdrawing sample devicesThermometer applicationsHeating timeAutomatic control

The invention belongs to the field of metallurgical technology and in particular relates to a full-automatic temperature-measurement sampling device outside a furnace. When a refining worker measures the temperature and carries out sampling, the position of the insertion point and the insertion depth of a temperature measurement gun are controlled automatically, the heating time of the temperature measurement gun can be controlled accurately, the stability is improved and the factors influencing the accuracy can be reduced; compared with a manual temperature measurement method, the device can acquire the temperature value with high precision, and the sample components have low fluctuation, therefore, the influences on the production efficiency of a continuous casting machine and the quality of a casting blank are reduced; and besides, the labor intensity is lower than that of the manual temperature measurement and sampling, and the device does not need to adapt to a severe environment, the personal risk of the temperature measurement personnel is reduced, and the personnel safety and the body health of the operators can be effectively protected.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

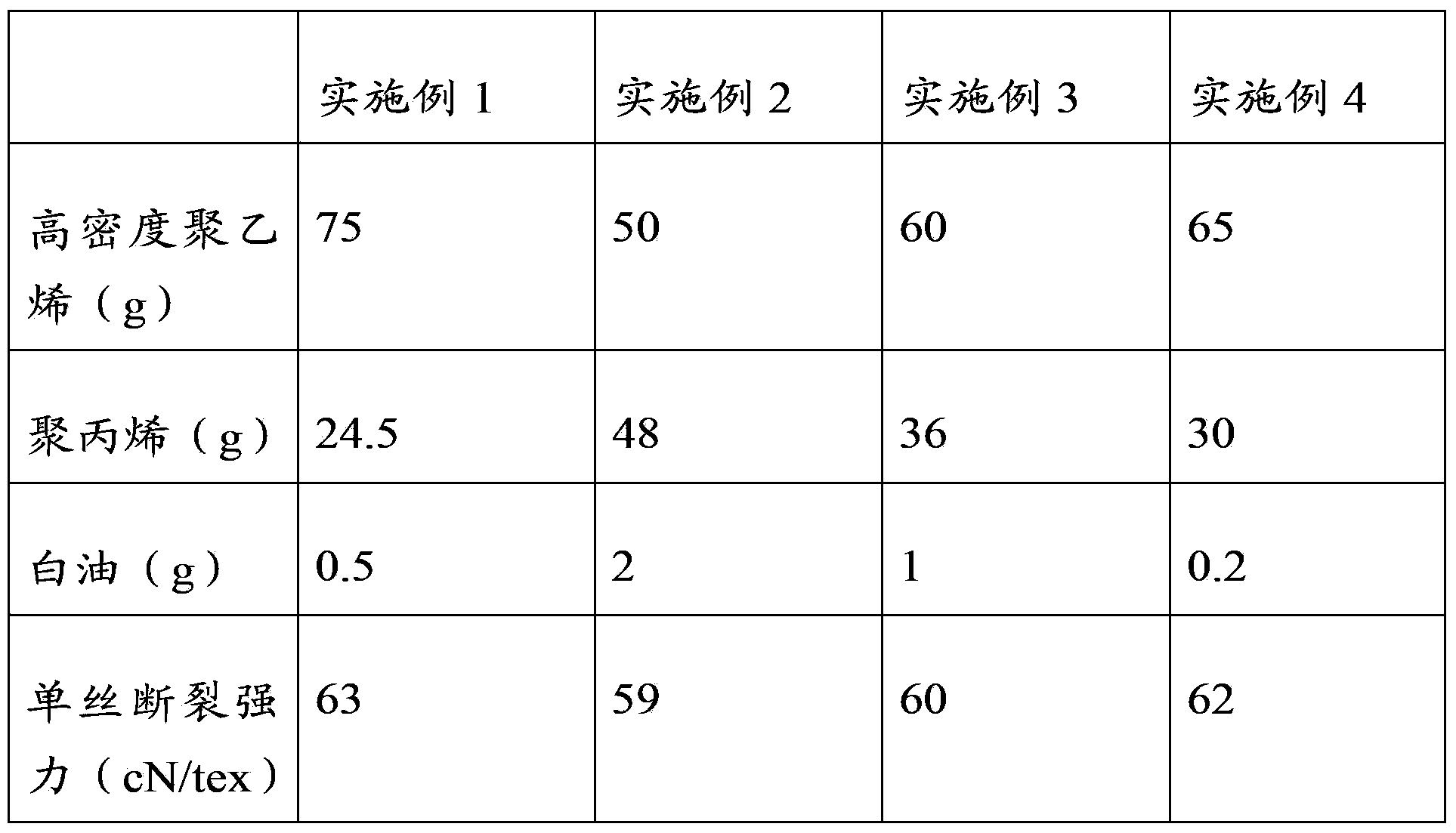

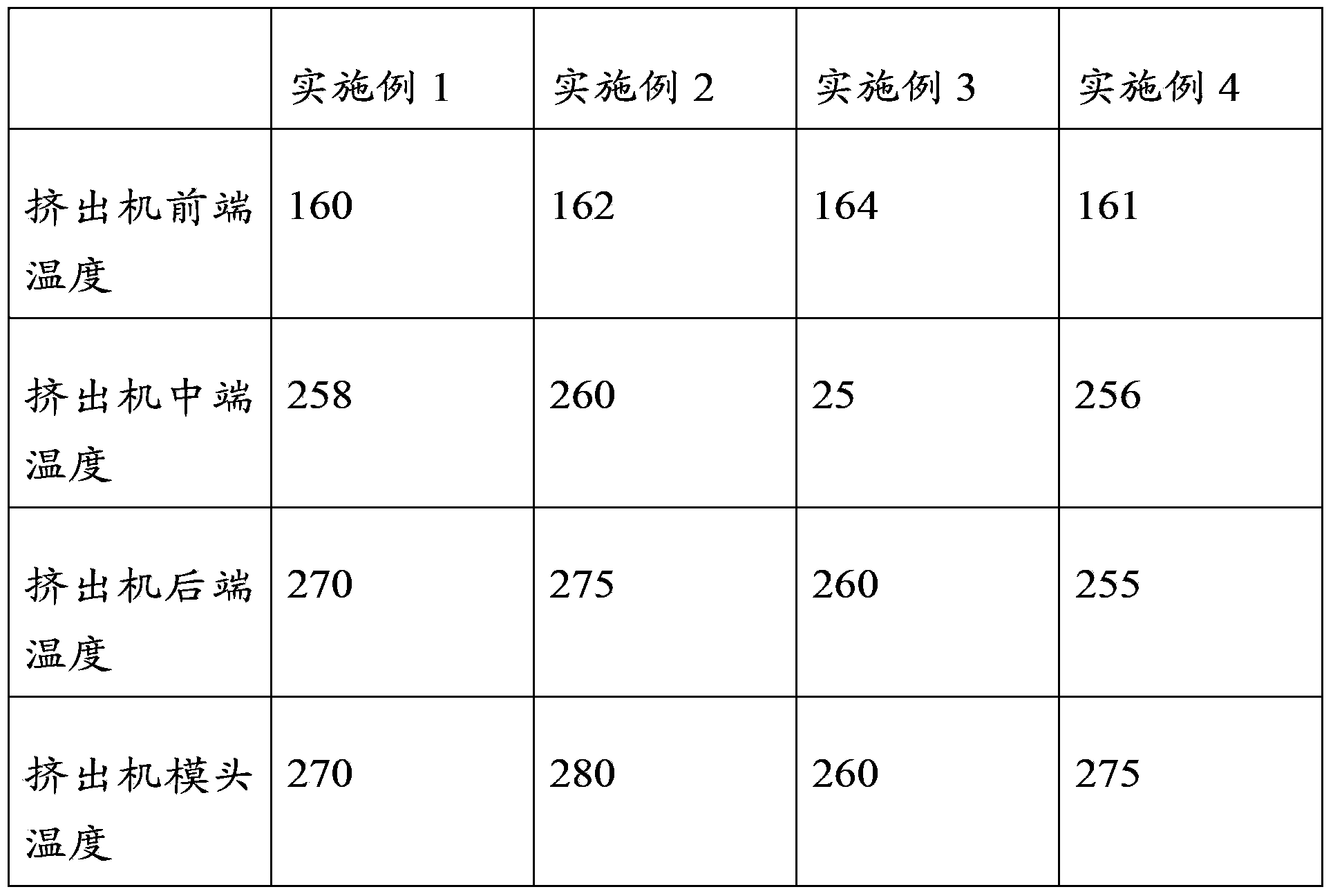

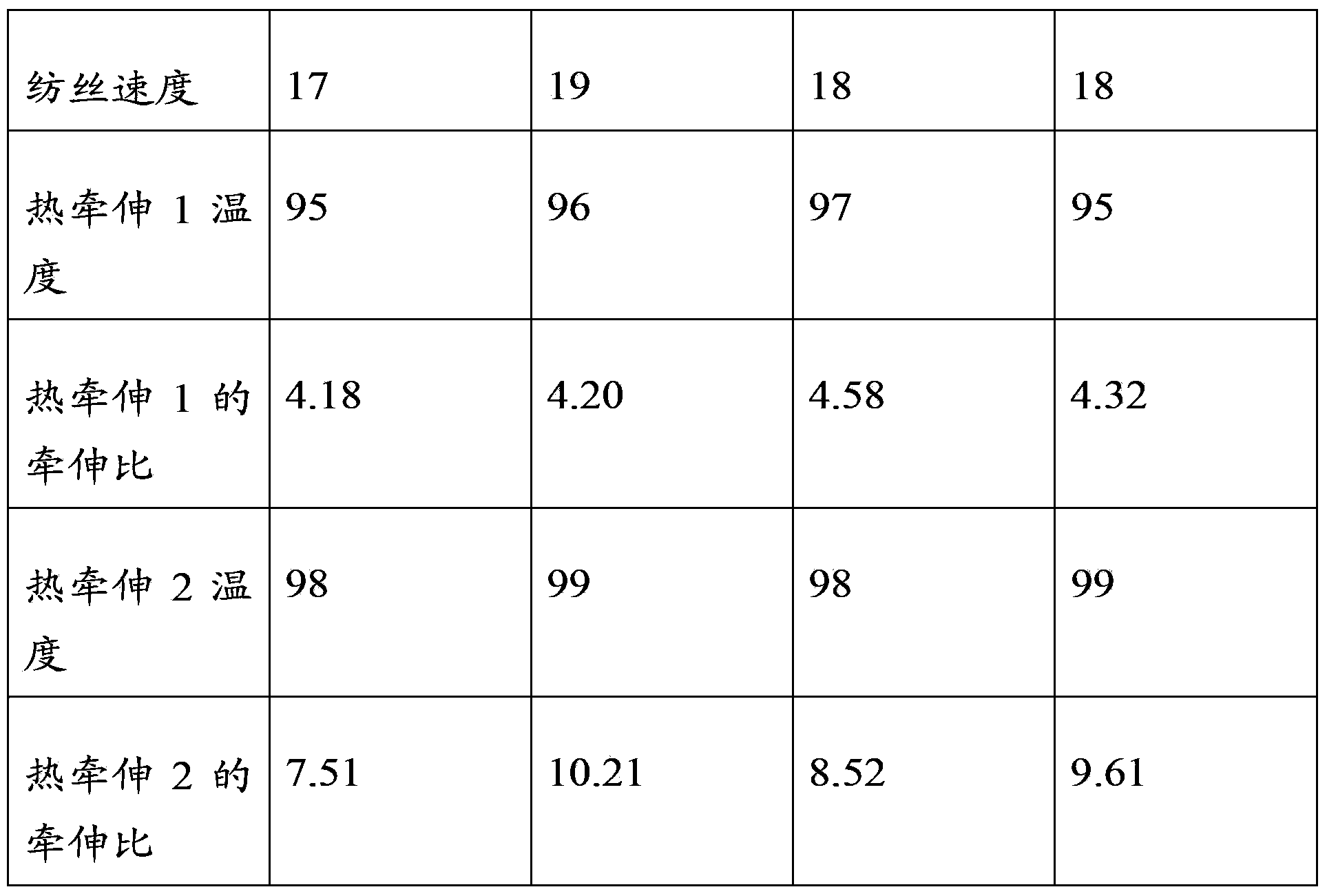

Monofilament filter fabric for coal washing and preparation method thereof

InactiveCN103432822AImprove breaking strengthIncrease productivityFiltration separationConjugated synthetic polymer artificial filamentsBreaking strengthEconomic benefits

The invention relates to the field of the filter materials and in particular relates to a monofilament filter fabric for coal washing and a preparation method thereof. The monofilament filter fabric is prepared from the following raw materials by weight percent: 50-75% of high density polyethylene, 24.5-48% of polypropylene and 0.2-2% of white oil. The preparation method of the monofilament filter fabric comprises the following step of: forming primary filaments through extrusion, wherein the front-end heating temperature of an extruder used for extrusion ranges from 160 to 164 DEG C, while the middle-end heating temperature of the extruder ranges from 255 to 260 DEG C and the rear-end heating temperature of the extruder ranges from 255 to 275 DEG C; the heating temperature of a die head ranges from 260 to 280 DEG C; the extrusion speed ranges from 17 to 19 m / min. Compared with the monofilament filter fabric in the prior art, the monofilament filter fabric has the advantages that the breaking strength is obviously improved; no breakage is caused in the monofilament weaving process to affect the production efficiency of a waving machine; as a result, the production efficiency is improved and the economic benefit is increased; meanwhile the service life of the filter fabric is prolonged; in addition, the appearance of the filter fabric is also improved so that the competitive force of the product can be improved.

Owner:JIXI HENGRUN FILTER CLOTH

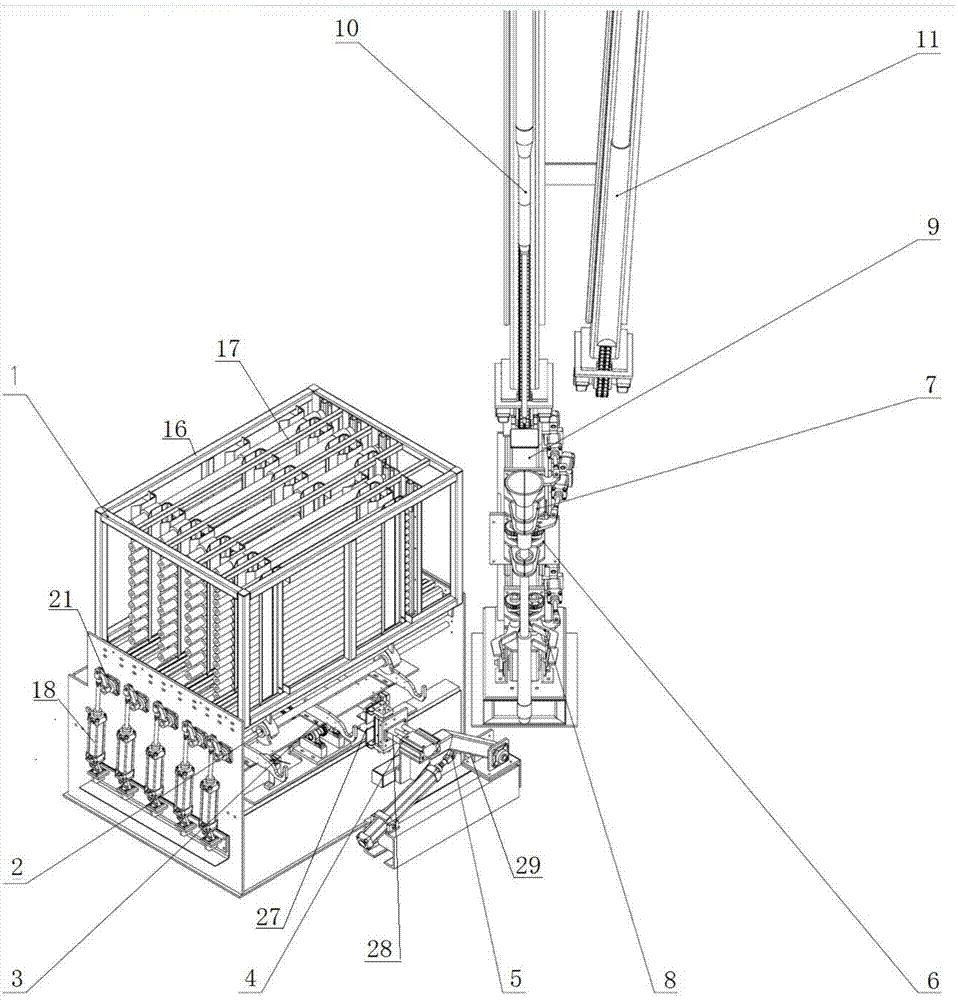

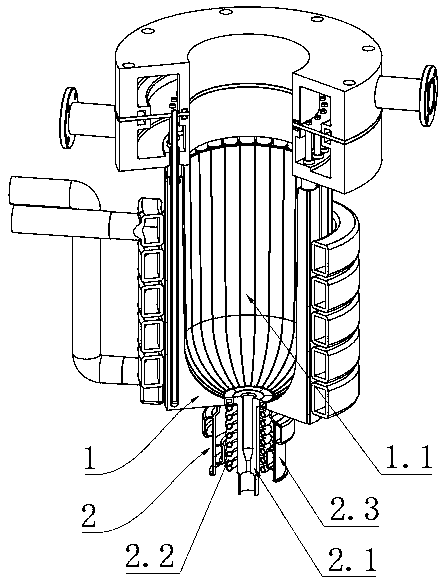

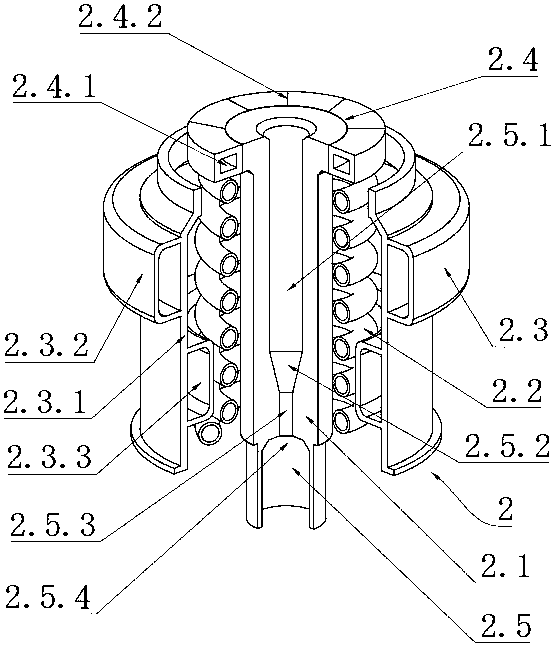

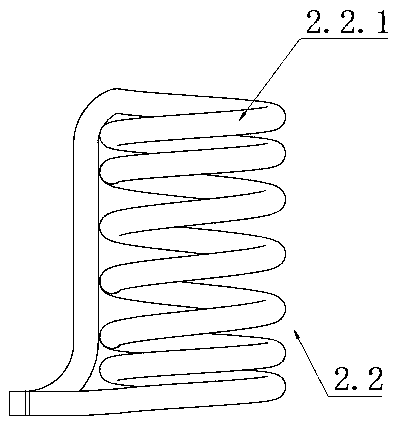

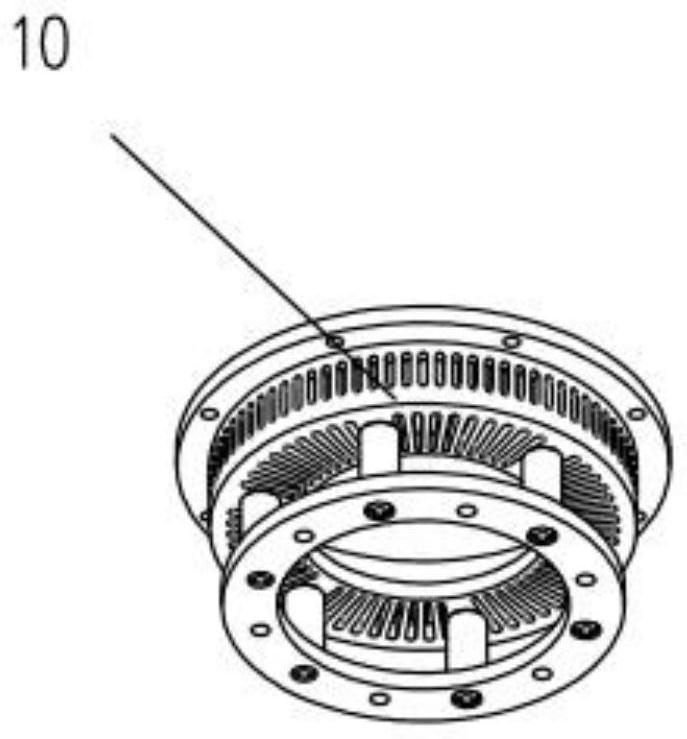

Titanium alloy smelting atomization powder manufacturing equipment and manufacturing technology thereof

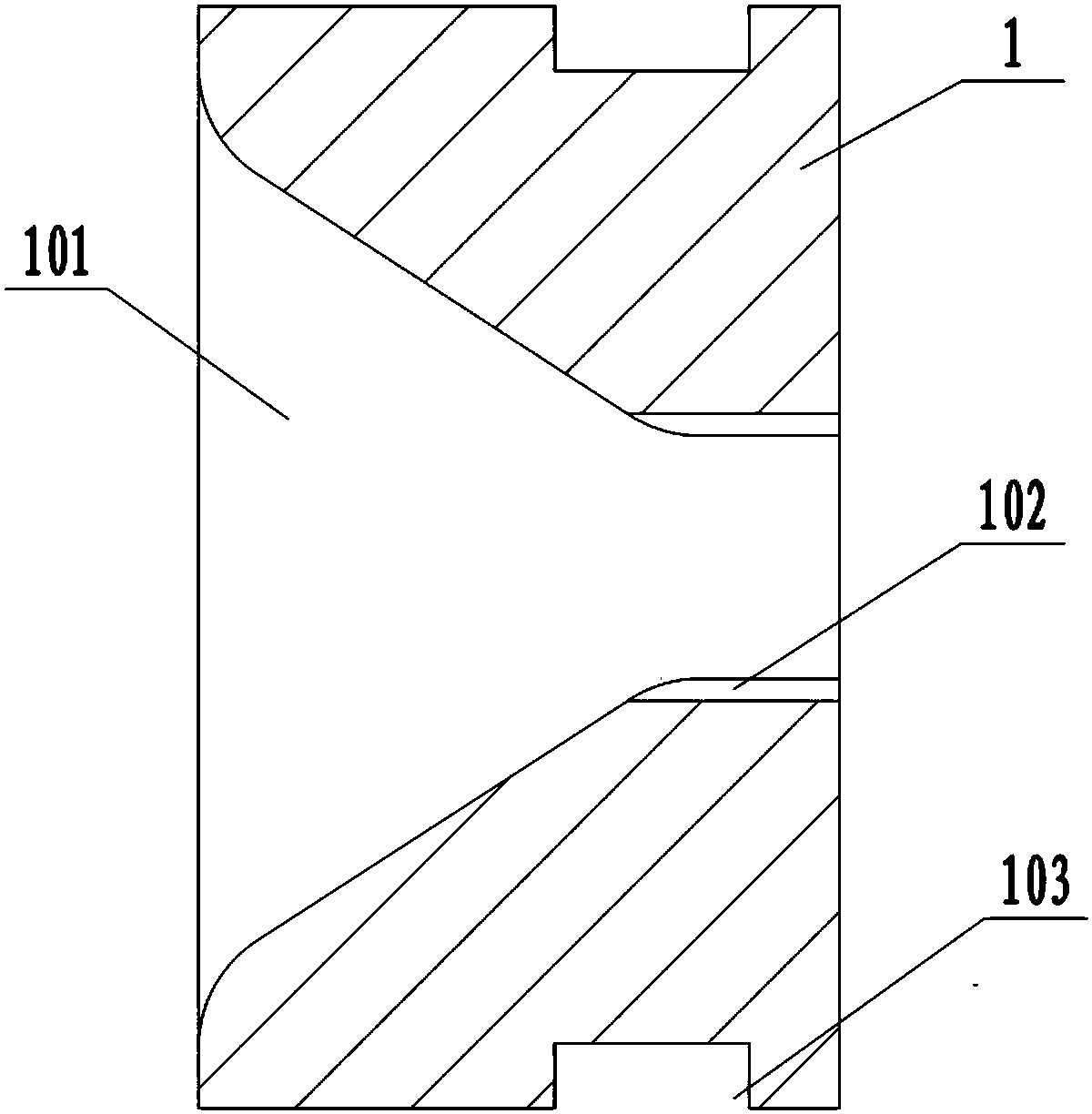

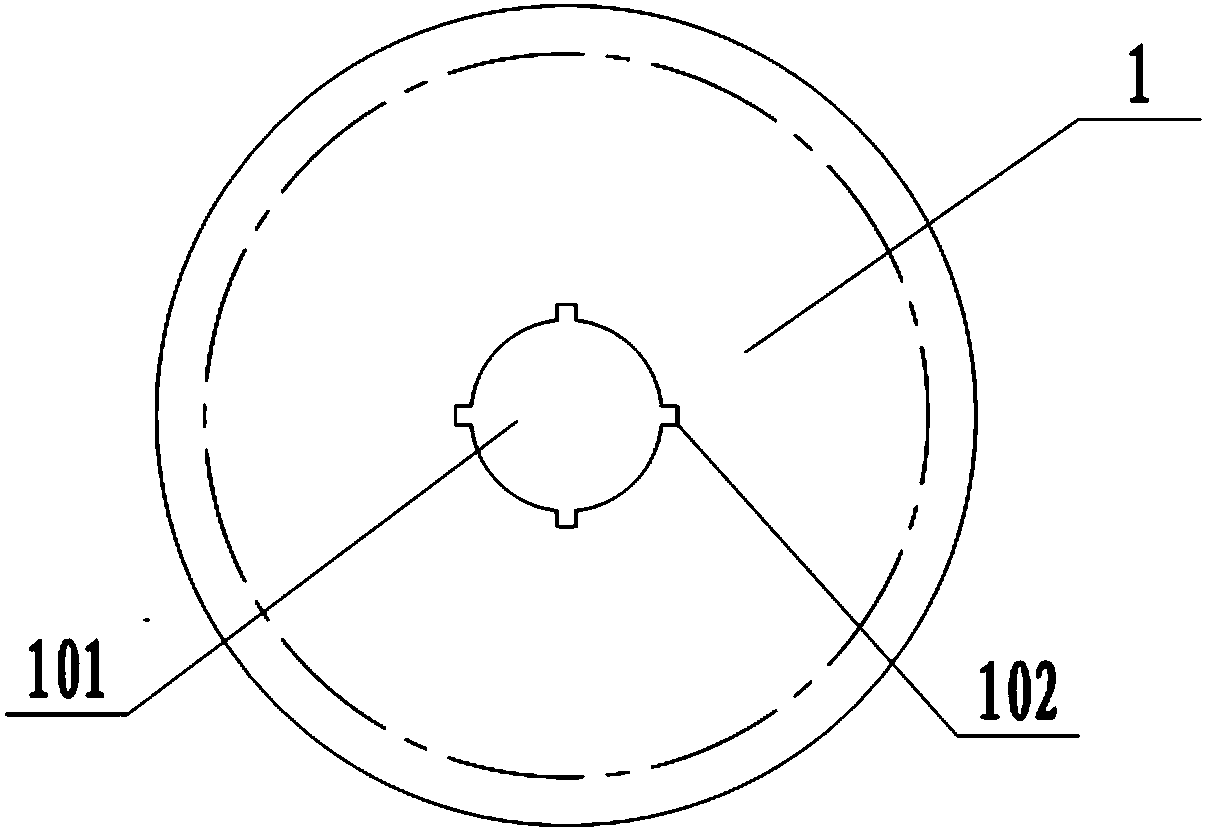

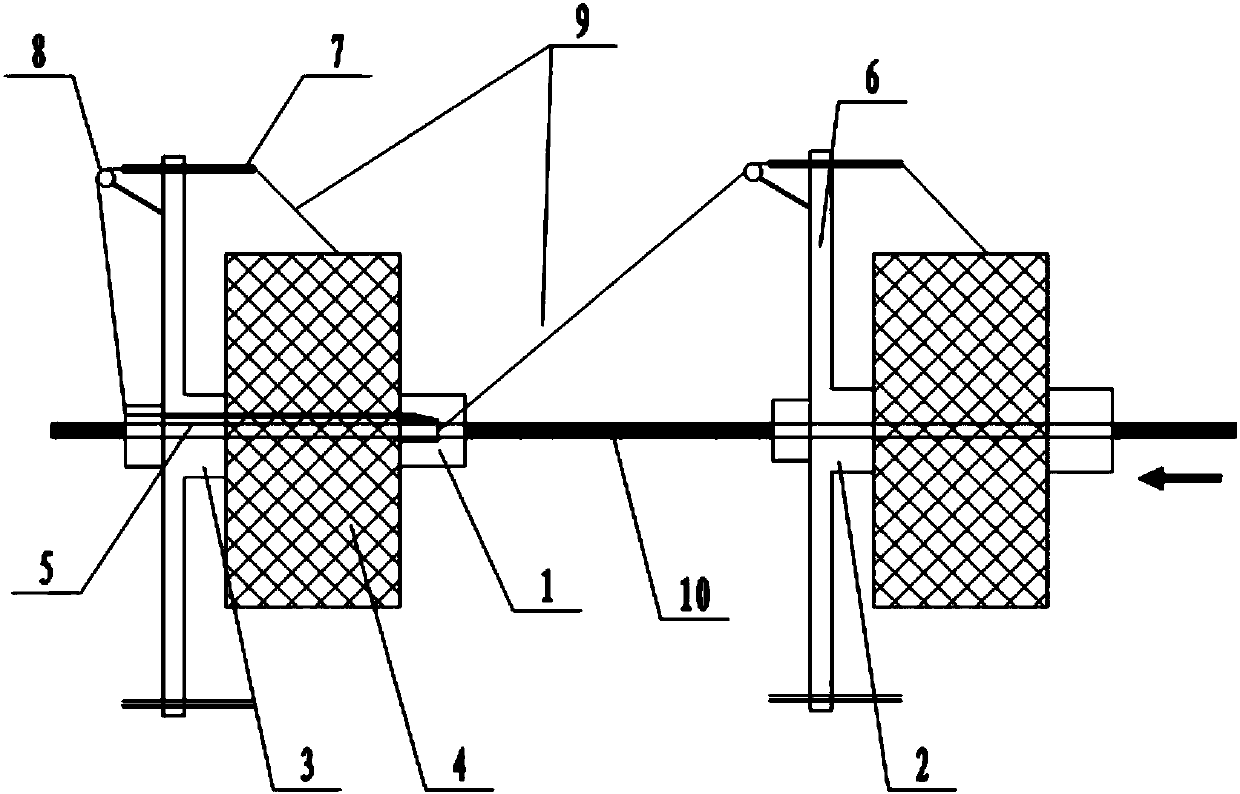

The invention discloses titanium alloy smelting atomization powder manufacturing equipment and a manufacturing technology thereof. The titanium alloy smelting atomization powder manufacturing equipment comprises a crucible body (1); a smelting cavity (1.1) is formed in the crucible body (1); a pouring hole (1.2) through which smelted titanium alloy liquid flows out is formed in the lower end of the crucible body (1); a heating mechanism (2) is arranged at the lower part of the crucible body (1); the heating mechanism (2) comprises a heating pipe (2.1), an auxiliary heating coil (2.2) and a water cooled hood (2.3); the heating pipe (2.1) is arranged at the lower part of the pouring hole (1.2); the auxiliary heating coil (2.2) sleeves the heating pipe (2.1); the water cooled hood (2.3) sleeves the auxiliary heating coil (2.2). The titanium alloy smelting atomization powder manufacturing equipment and the manufacturing technology have the advantages that kish in the crucible body is little, the probability of blocking is low, the liquidity of titanium alloy liquid flowing from the smelting cavity to an atomization cavity is good and the titanium alloy liquid is not prone to being interrupted, and the atomization powder manufacturing efficiency is high.

Owner:宁波中物力拓超微材料有限公司

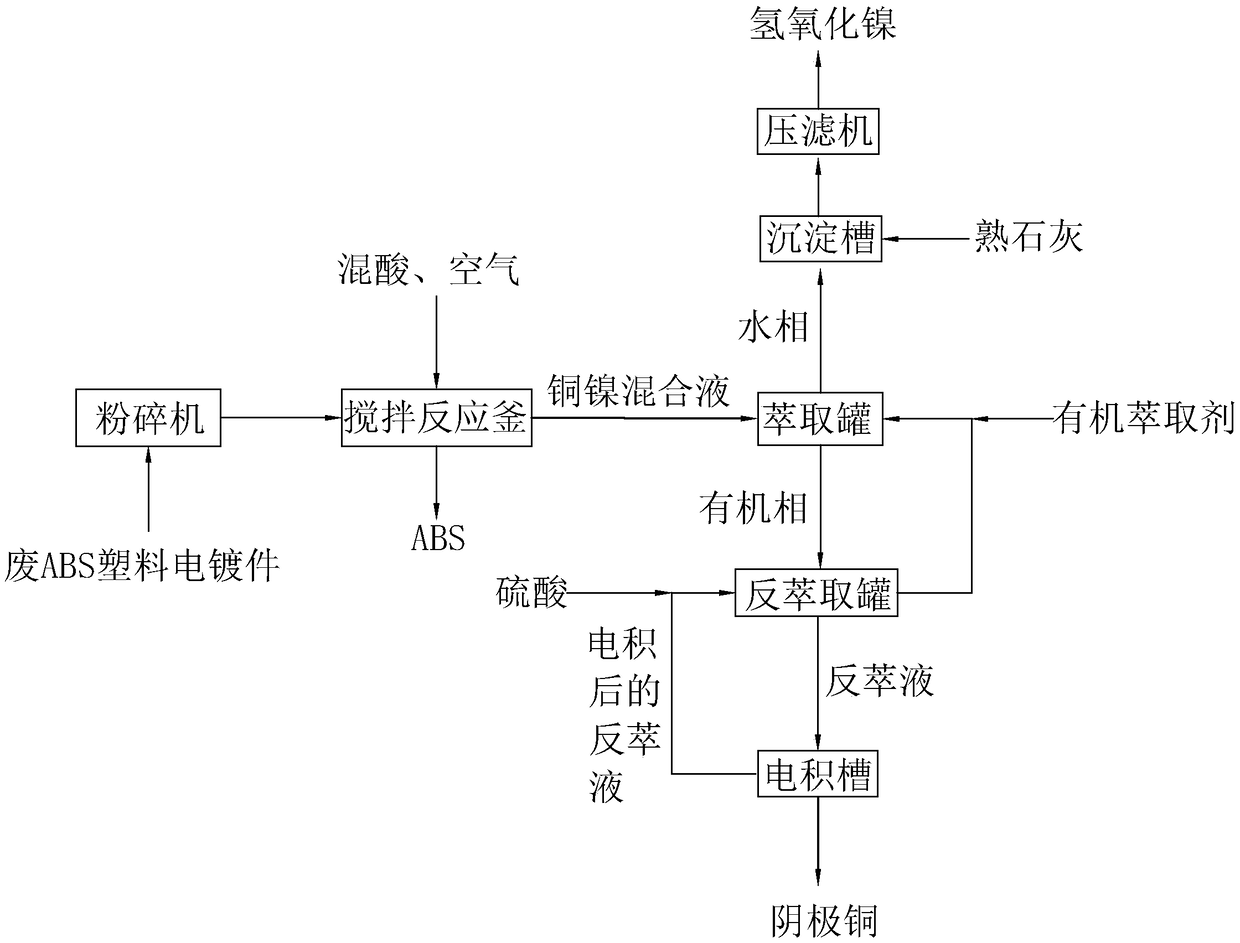

Metal recycling process and recycling device for waste abs plastic electroplating parts

ActiveCN107058741BAchieve separationPromote productionPhotography auxillary processesProcess efficiency improvementNickel oxide hydroxideEngineering

The invention discloses a metal recycling process and a recycling device for waste ABS plastic electroplated parts. The metal recycling process of waste ABS plastic electroplating parts includes the following steps: Step1: crush waste ABS plastic electroplating parts; Step2: add mixed acid to the waste ABS plastic electroplating parts after crushing, and feed air to react; Step3: After the reaction, Press filtration to obtain the copper-nickel mixed solution, add an organic extractant to the copper-nickel mixed solution, and separate; Step4: The organic phase is back-extracted with sulfuric acid, and the stripped solution is electrowinning to form cathode copper, and the water phase is adjusted to pH 6 with slaked lime. Nickel hydroxide was obtained by filtration, and dried under pressure filtration. The beneficial effects of the invention are: the process can concentrate copper into metal copper under the premise of realizing the separation of copper and nickel, and improve the application value of copper.

Owner:温州科锐环境资源利用有限公司

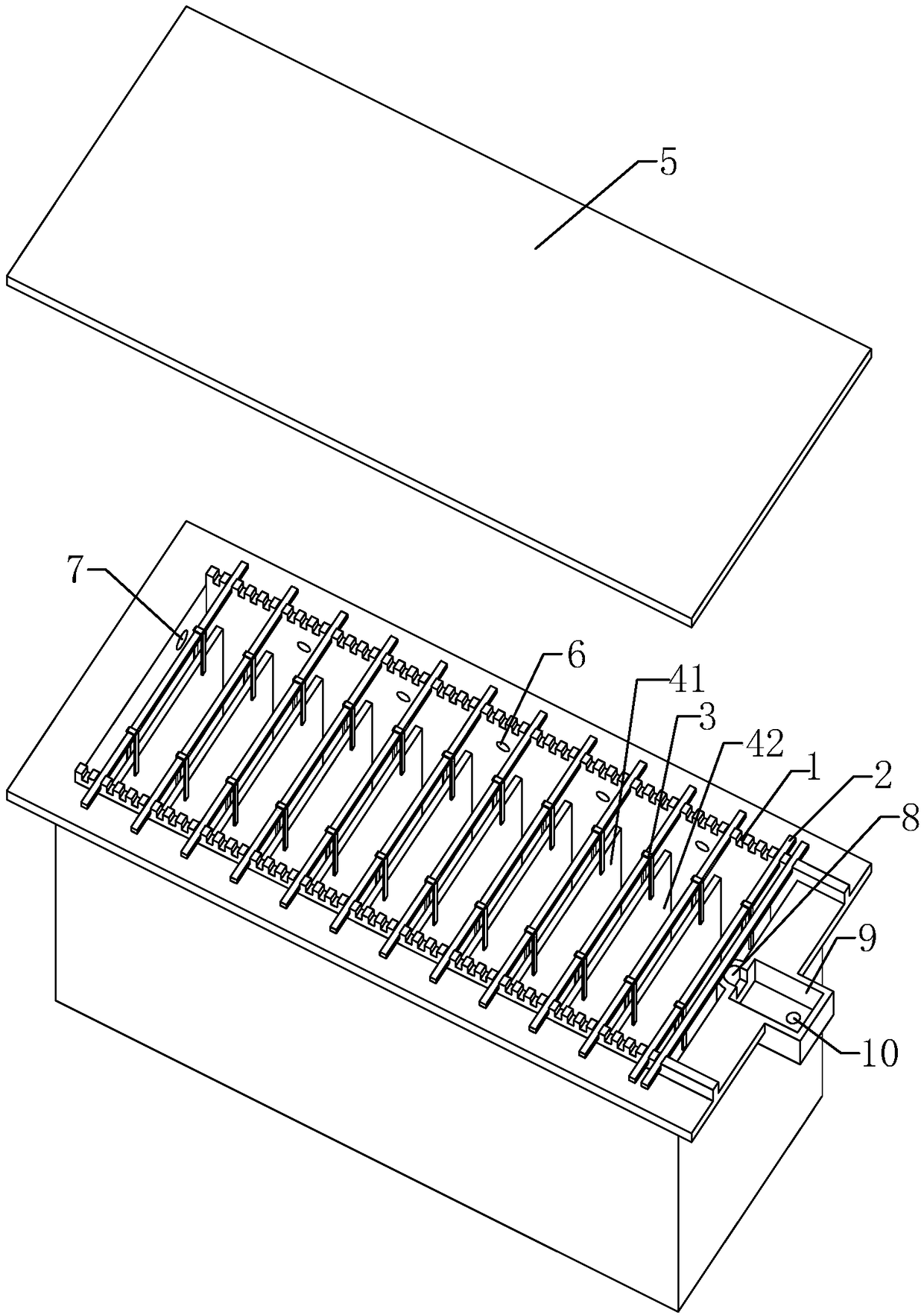

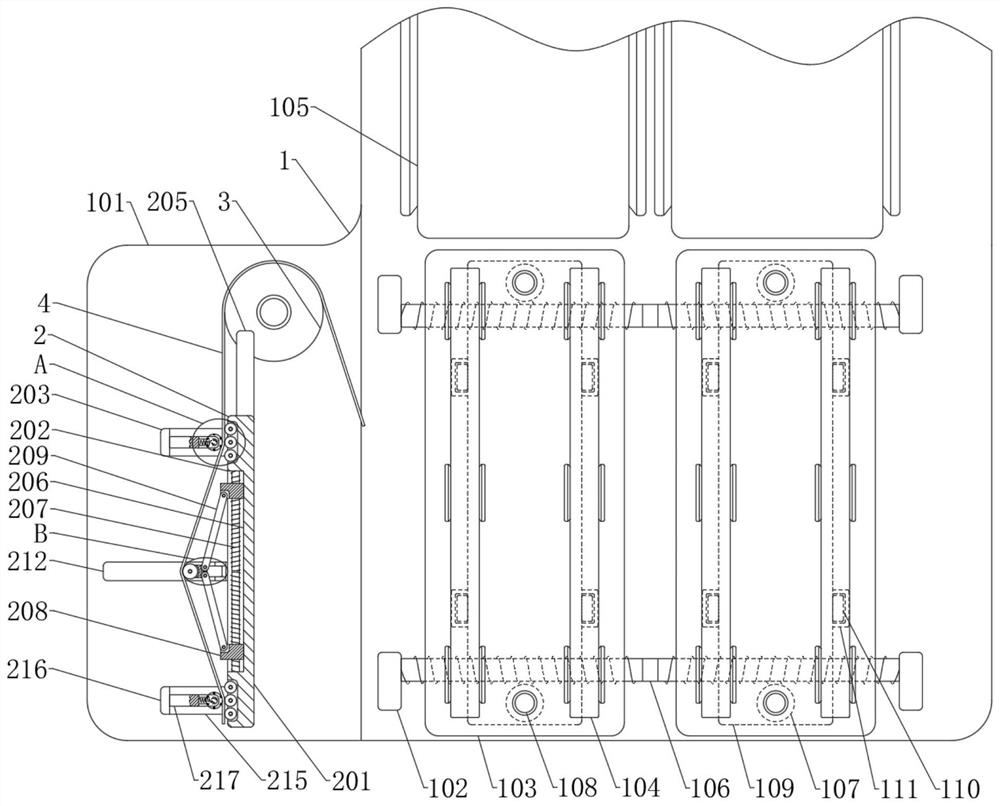

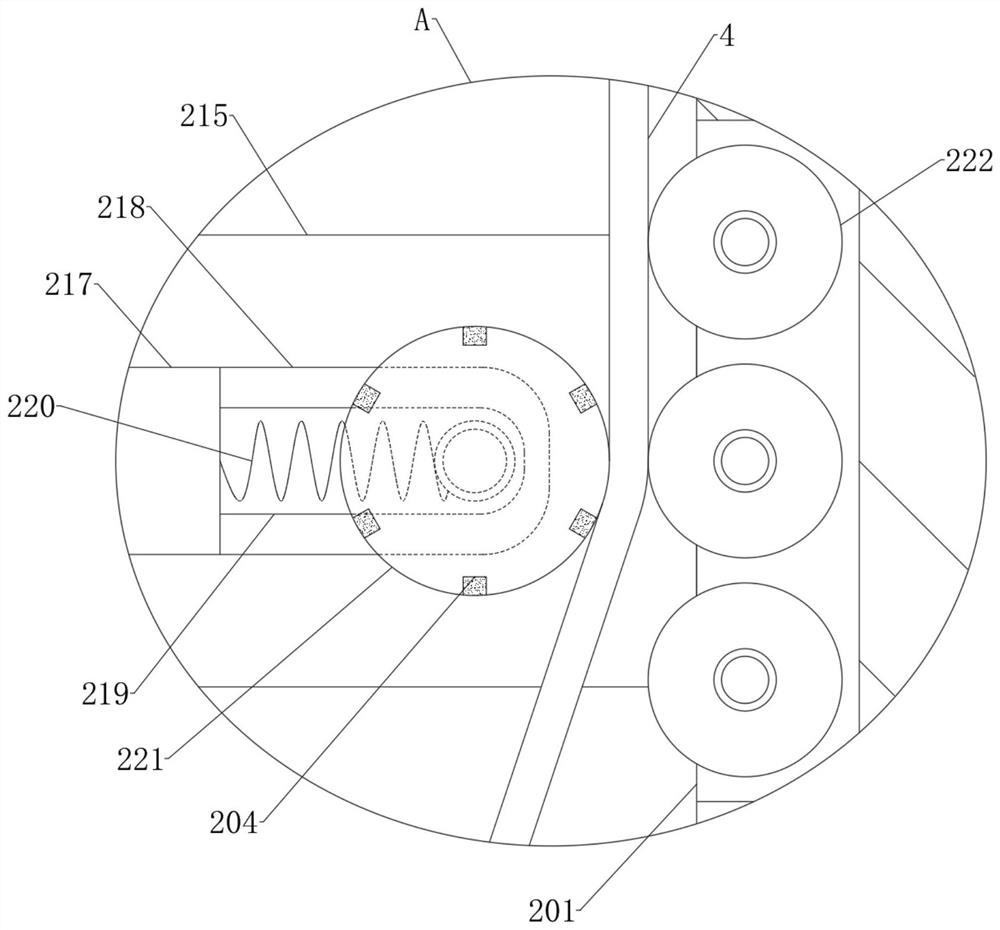

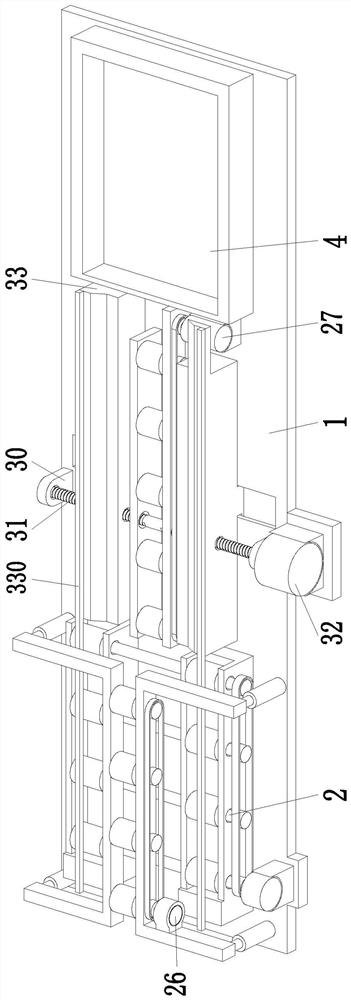

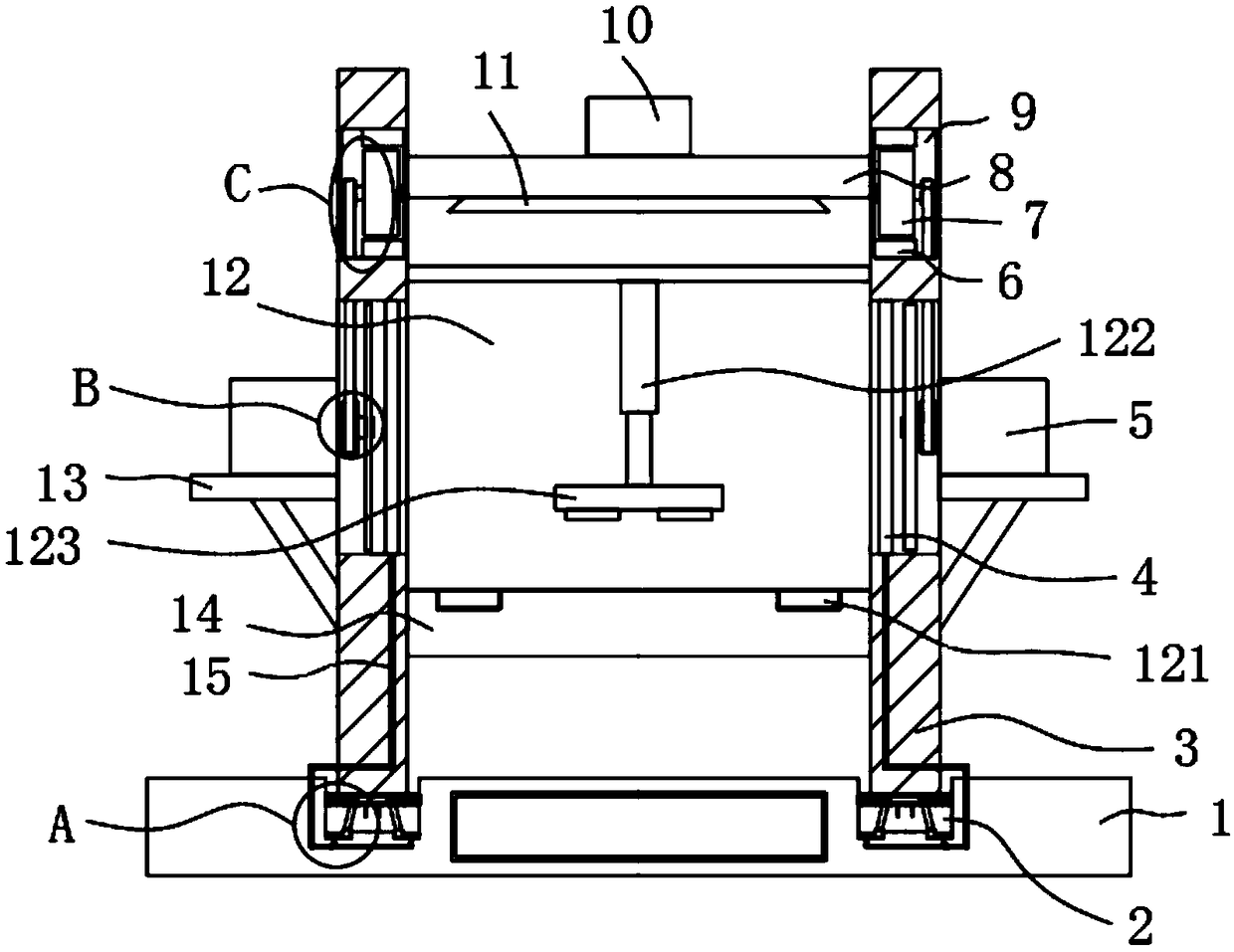

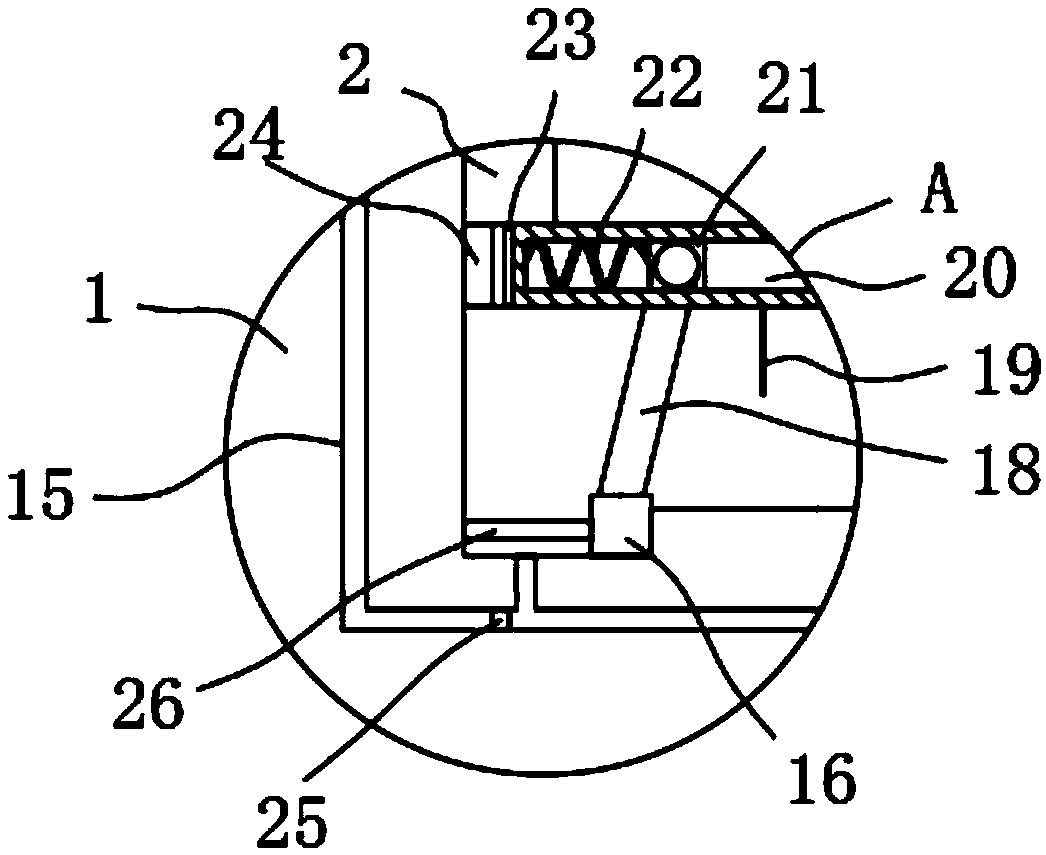

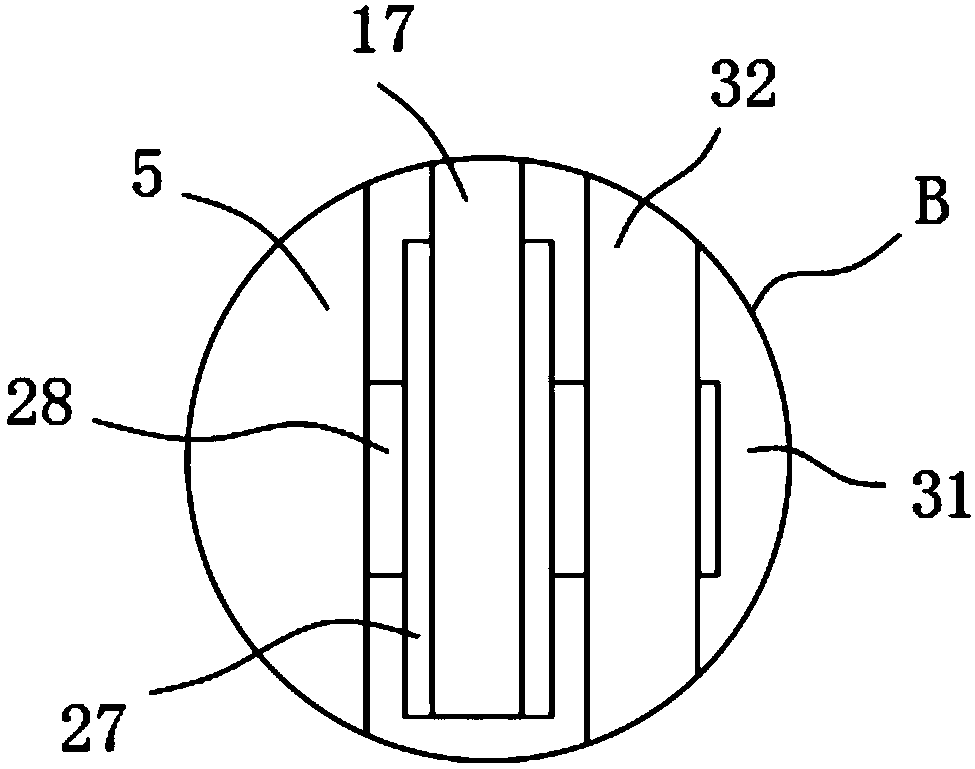

Fitting transfer device for new energy vehicle fitting manufacturing

InactiveCN109809181ALow input costAffect production efficiencyConveyor partsTransfer mechanismElectrical and Electronics engineering

The invention discloses a fitting transfer device for new energy vehicle fitting manufacturing. The device comprises a placing mechanism and a mated transfer mechanism; the placing mechanism comprisesa main control chassis and a support chassis; a first motor is fixed on the side surface, relative to the main control chassis, of the support chassis; the first motor is in transmission connection with multiple transmission rods rotationally connected between the main control chassis and the support chassis at equal intervals; and support wheels are fixedly clamped on the outer walls of the multiple transmission rods at equal intervals. In the fitting transfer device for new energy vehicle fitting manufacturing, a traditional fitting transfer device is changed to the movable transfer deviceconsisting of the placing mechanism and the transfer mechanism; users can transfer vehicle fittings on a conveying belt to the upper part of the placing mechanism for placement through the placing mechanism in the use process; then, the vehicle fittings are transferred to a support plate through the transfer mechanism; and the device can reduce the enterprise equipment investment cost, and prevents the influence on the production efficiency of a whole production line by faults.

Owner:江四胜

Efficient ladle baking device

The invention provides an efficient ladle baking device. The efficient ladle baking device comprises a baking device body, a cover and a flame retardant layer, wherein the lower end of the baking device body is connected with the upper end of the cover; the lower end of the cover is connected with the flame retardant layer; the lower end of a burner composed of a conical body, a flow mixing cavity, an electronic igniter, a combustion cavity and a firing stabilizer is arranged at the lower end of the flame retardant layer, and the upper end of the burner is arranged on the upper portion inside the baking device body; the upper end of the burner is connected with an air cavity through an electric adjustment valve; an air heat exchanger is installed on the lower portion of the air cavity; one end of the air heat exchanger is connected with a smoke inlet, and the other end of the air heat exchanger is connected with a smoke outlet; an air inlet is formed in the lateral surface of the cover; the upper end of the burner is provided with a fuel gas inlet communicating with an outlet of a fuel gas heat exchanger; the conical body is arranged at the fuel gas inlet of the burner; an inlet of the fuel gas heat exchanger is connected with a fuel gas pipeline through a fuel gas valve and a flowmeter; and the ladle baking device is further provided with an intelligent control device. The efficient ladle baking device has the advantages of saving energy and labor, improving safety performance and the like.

Owner:大连新瑞晨环保科技有限公司

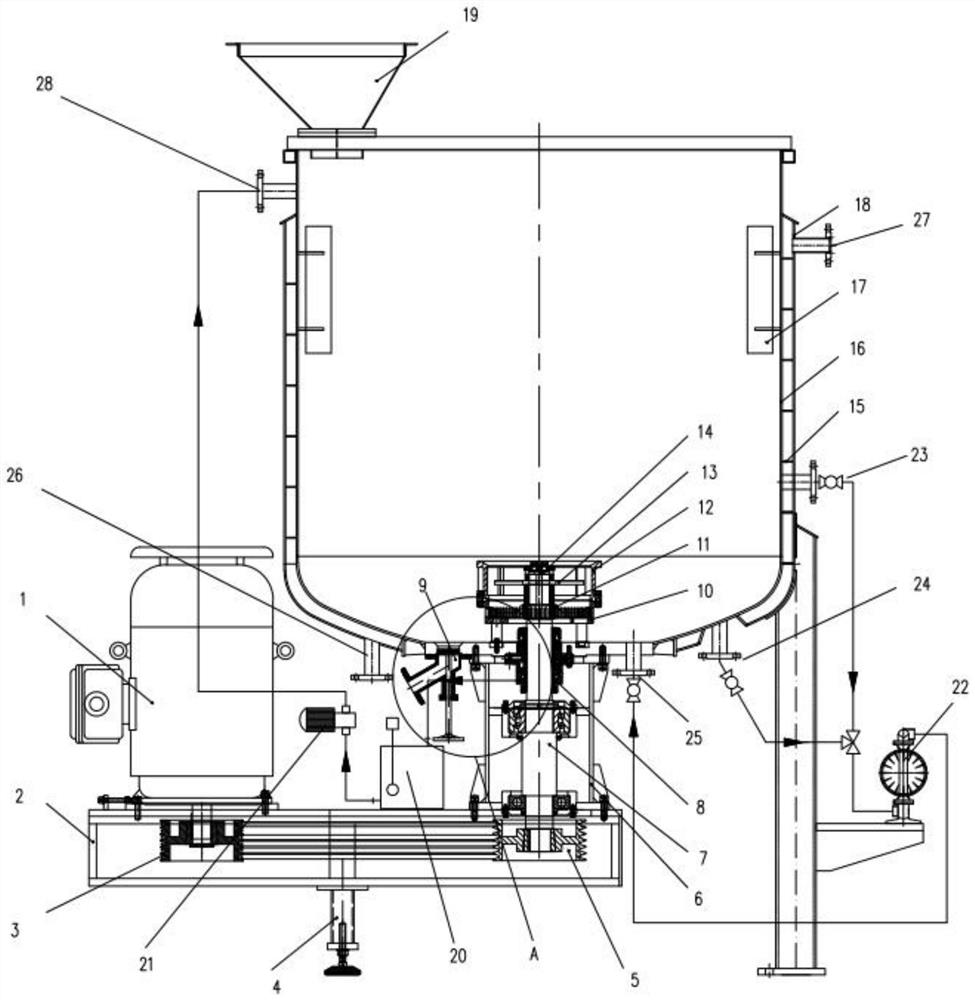

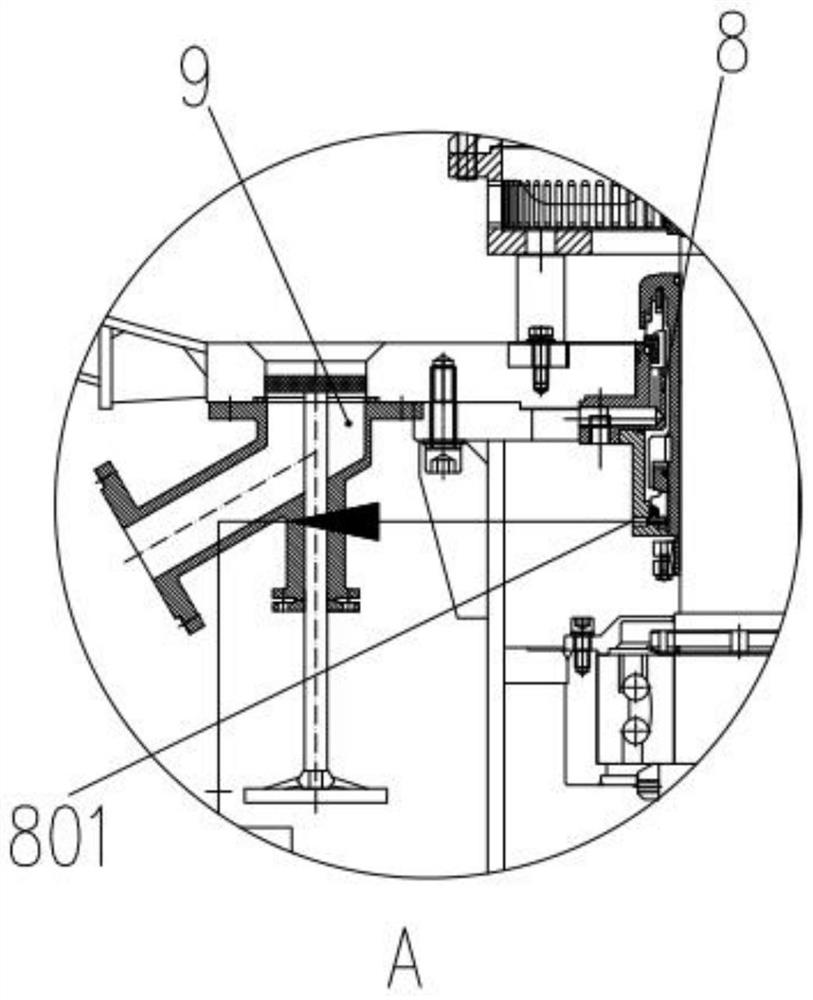

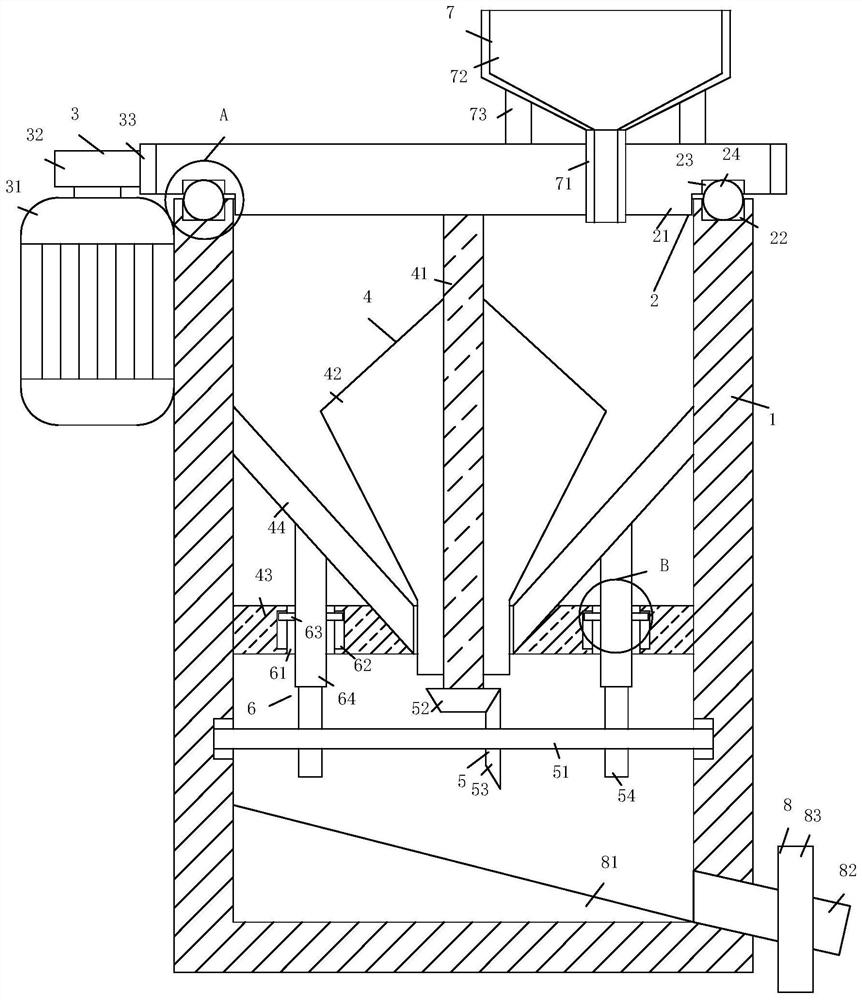

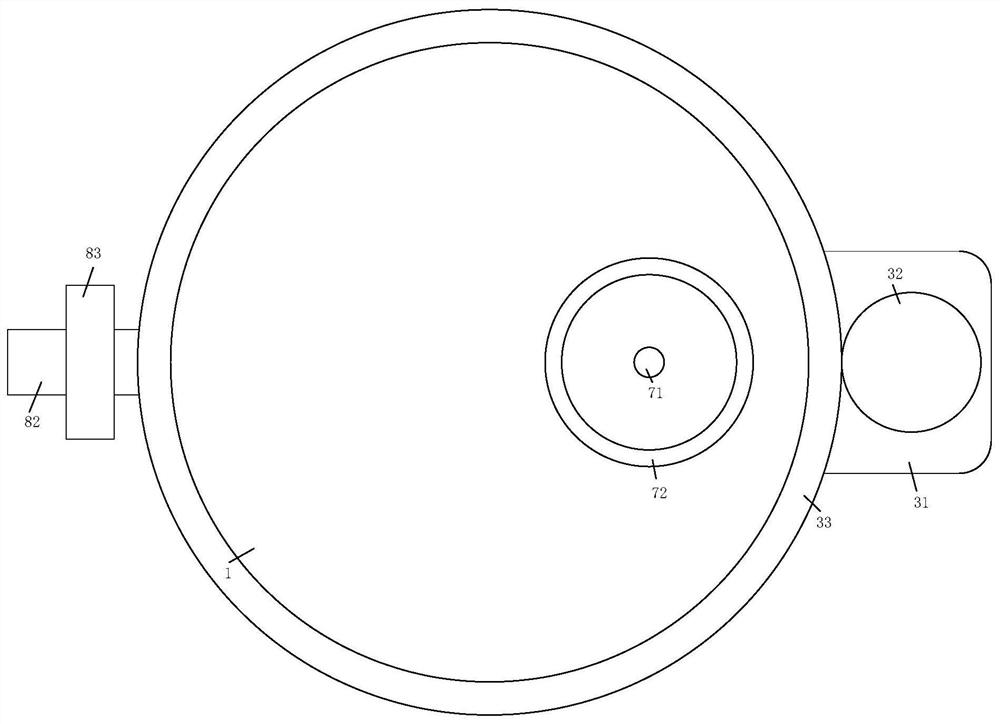

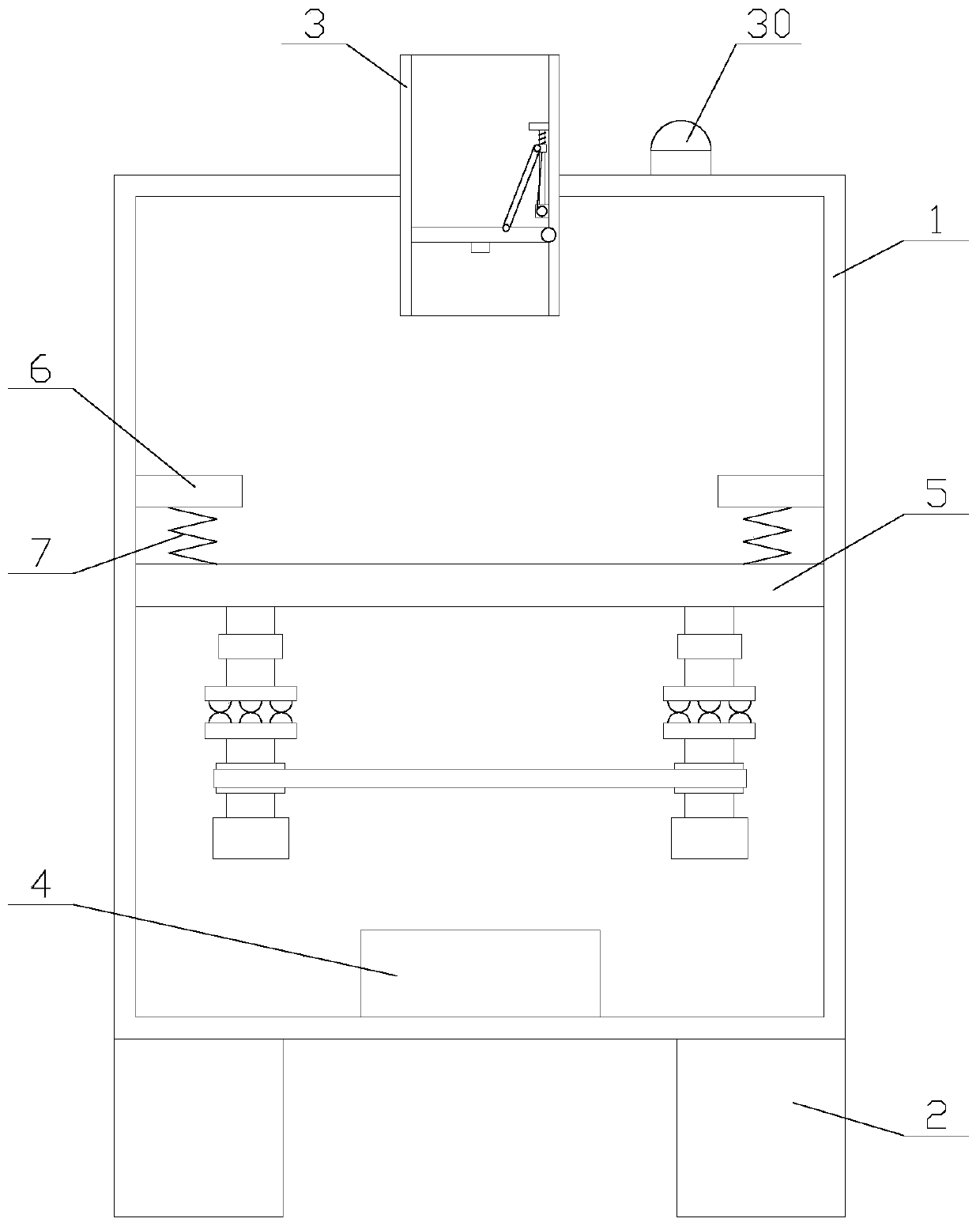

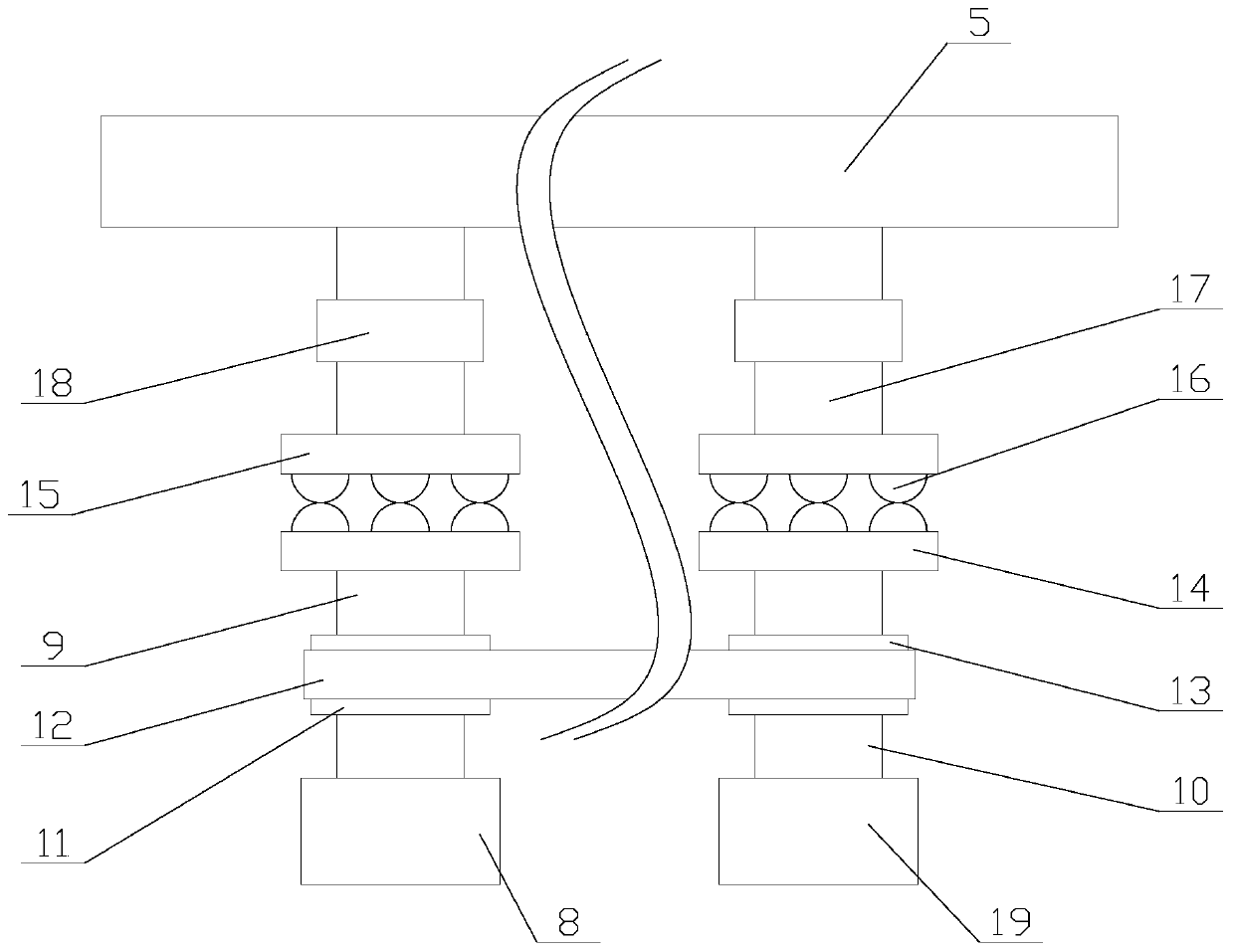

Wet crushing equipment capable of efficiently preventing precipitation

ActiveCN112657636AGood drainageAvoid short circuitFlow mixersRotary stirring mixersElectric machineDrive shaft

The invention discloses wet crushing equipment capable of effectively preventing precipitation. The equipment comprises a machine base and a main kettle body, the main kettle body is arranged above the machine base through a kettle body mounting supporting column on one side of the machine base, a shearing system is arranged in the main kettle body, and the machine base is of a cuboid cavity structure. A motor is fixedly arranged on one side of the table board of the machine base through a motor installation base, an output shaft of the motor penetrates through the top face of the machine base and is arranged in a cavity of the machine base, a driving belt wheel is fixedly arranged on the output shaft of the motor, and the motor drives the driving belt wheel to start to operate after being started, and the driving belt wheel transmits power to a driven belt wheel in a belt transmission mode. The driven belt wheel drives a transmission shaft to rotate, the transmission shaft drives a rotor, a first fly-cutter and a second fly-cutter to rotate at a high speed, a high-vacuum area is formed in the area near the stator and the rotor, therefore, surrounding materials are sucked in, the materials are sheared by the shearing system, uniform suspension liquid is formed, and the operability of different materials is greatly improved.

Owner:安徽儒特实业有限公司

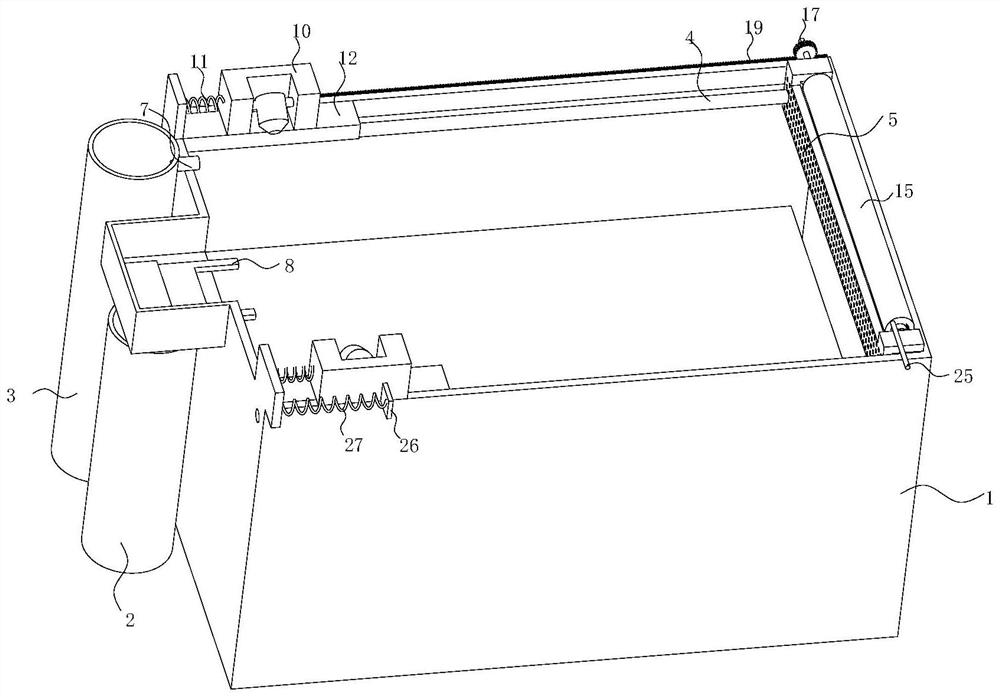

Textile machine bracket

InactiveCN108842261AAvoid damageAffect production efficiencyLoomsAuxillary apparatusMechanical energyInternal energy

The invention discloses a textile machine bracket. The textile machine bracket comprises a base, wherein the base is connected with two vertical plates through a buffer device, a bearing plate is fixedly connected between the two vertical plates, a textile machine body is arranged on the bearing plate, a mounting plate is also arranged between the two vertical plates, the mounting plate is locatedabove the bearing plate, each vertical plate is provided with a heat dissipation device and a power generation device, and the mounting plate is further provided with a velvet suction device. The textile machine bracket has the advantages that mechanical energy is converted into internal energy of water, the vibration is reduced, the damage of parts is avoided while frequent replacement is avoided, the production efficiency of a textile machine is increased, wind power is generated so as to form air convection, so that temperature exchange of the air is achieved, water in a sponge pad absorbsheat through volatilization, so that the temperature is further lowered, a heat dissipation function is achieved, internal parts are prevented from aging, and the service life of equipment is prolonged.

Owner:李亚丽

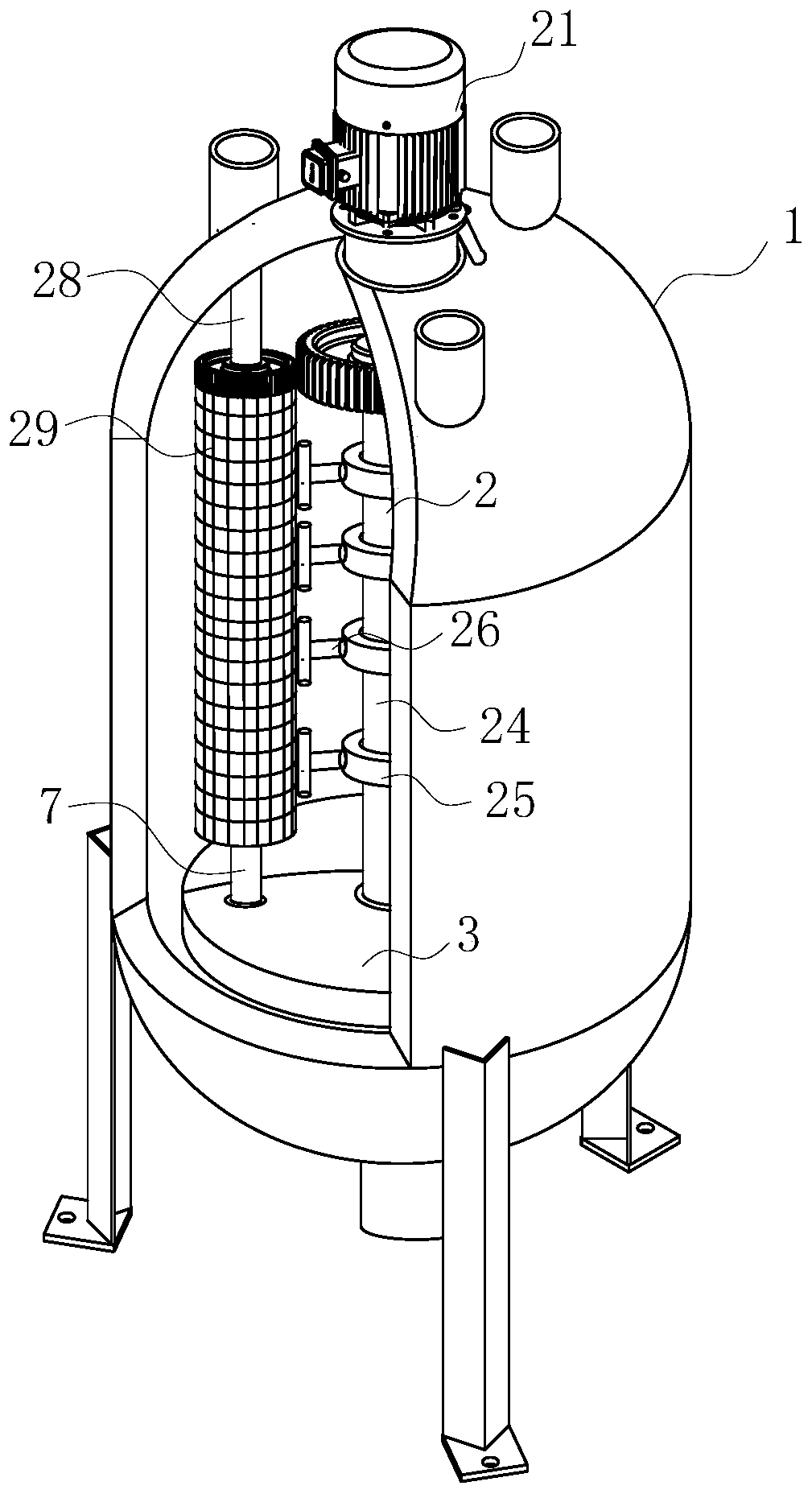

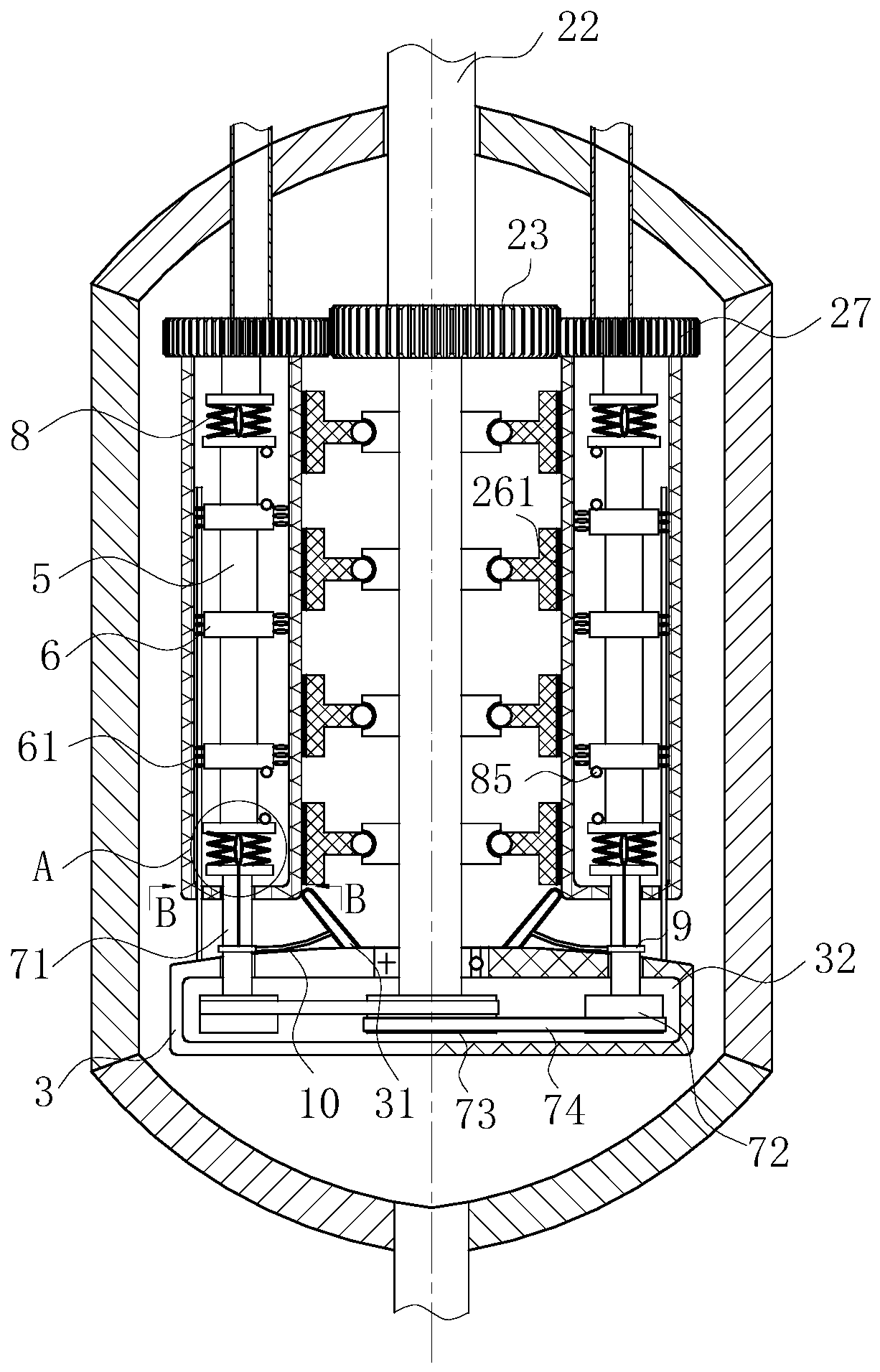

Reaction kettle for producing stone-like coating

InactiveCN110339802AEasy to filter and crushAvoid cloggingTransportation and packagingMixer accessoriesDrive shaftProduction quality

The invention belongs to the technical field of stone-like coating production equipment, and in particular relates to a reaction kettle for producing a stone-like coating. The reaction kettle comprises a reaction tank; a raw material stirring and mixing device is arranged in the reaction tank; the output end of a stirring motor is connected with a drive shaft, and the bottom end of the drive shaftpasses through the reaction tank to be connected with a driving gear; the bottom end of the driving gear is connected with a stirring shaft, and the rotating shaft is uniformly provided with rotatingdiscs; the side wall of each rotating disc is hinged with one corresponding vibrating hammer through one corresponding hinge joint column; a plurality of driven gears are rotatably connected to a hollow cavity rotating shaft through a bearing, and the plurality of driven gears mesh with the driving gear; the hollow cavity rotating shaft is installed at the top end of the reaction tank, and the hollow cavity rotating shaft is in communication with a raw material inlet; and the bottom end surfaces of the plurality of driven gears are respectively connected with an elastic filter mesh cylinder,and the outer side wall of the elastic filter mesh cylinder is in contact with the outer end surface of each vibrating hammer. The reaction kettle provided by the invention can prevent a block-shapedadhesive material from being generated in the production process of the stone-like coating to affect the production quality and production efficiency of the stone-like coating.

Owner:李智

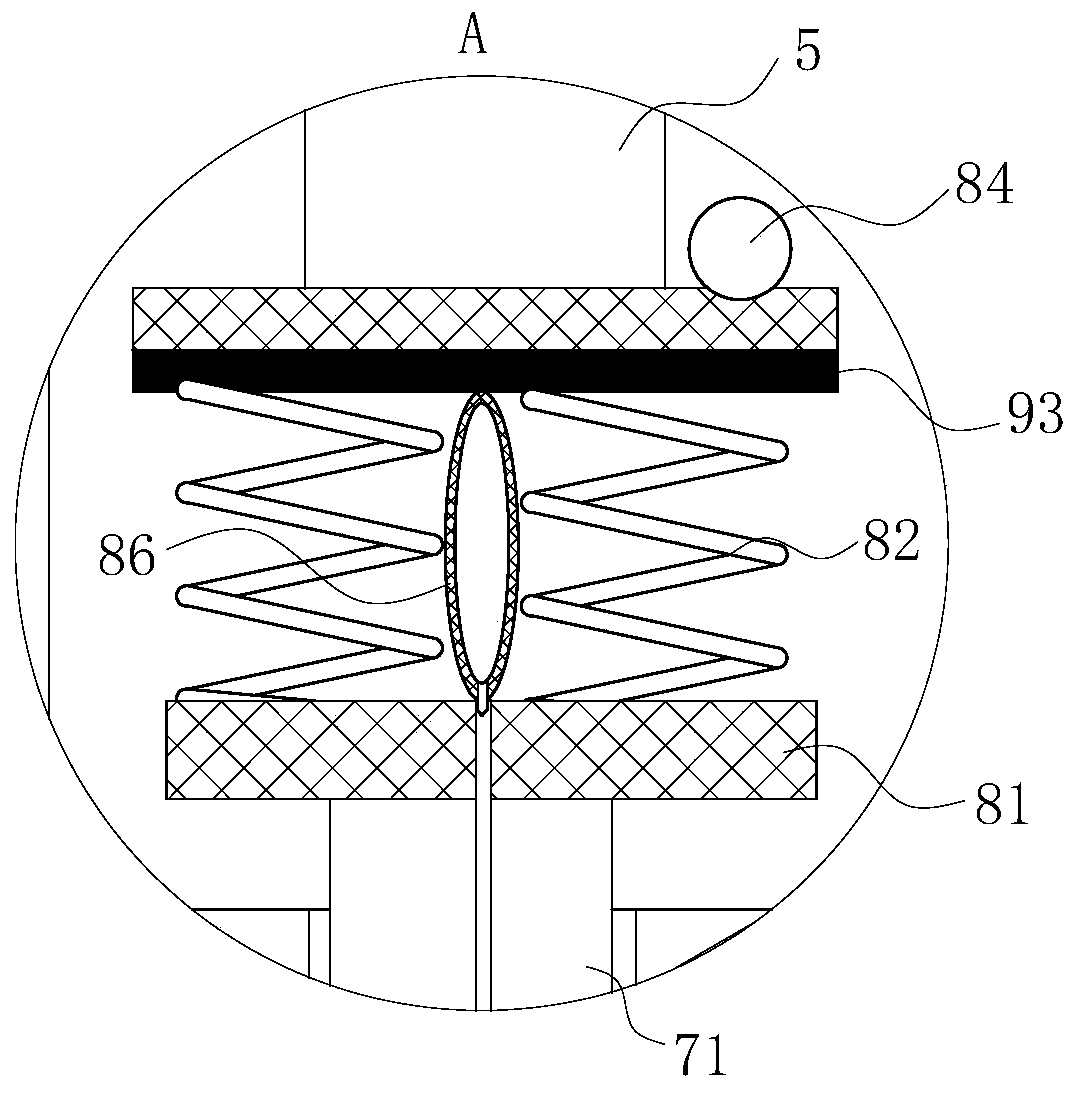

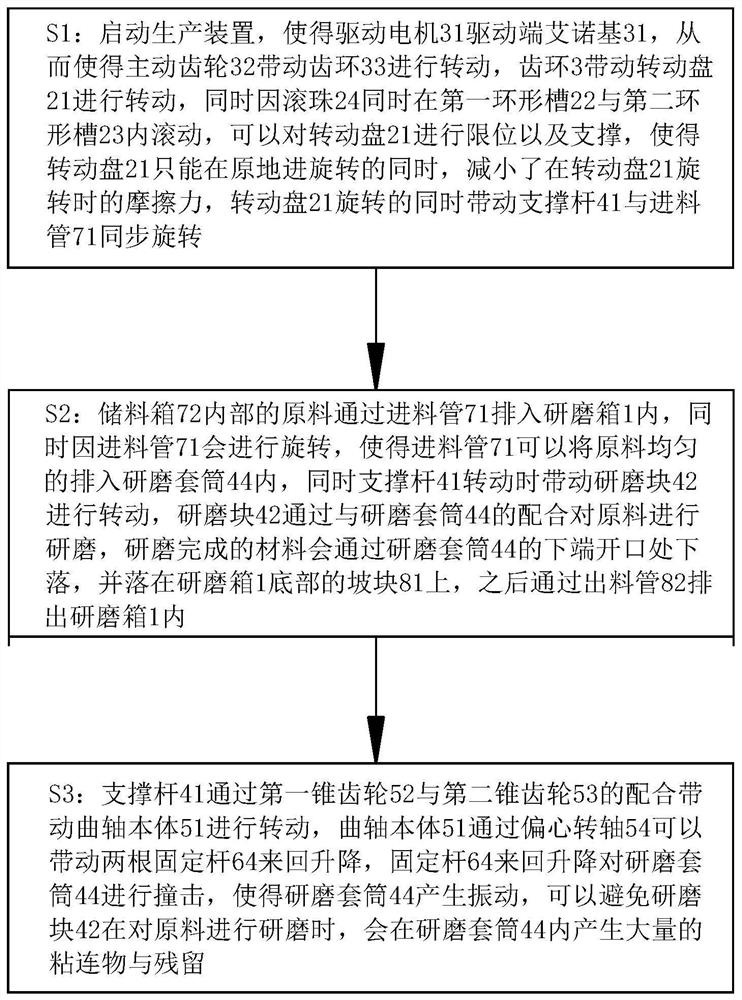

Sodium hydroxide production process for experiments

The invention relates to the field of sodium hydroxide production, in particular to a sodium hydroxide production process for experiments. A production device used in the process comprises a grindingbox with an upper opening, a rotating mechanism is arranged at the upper opening of the grinding box, and a driving mechanism is fixedly connected to the outer side wall of the top end of the grindingbox. During use, a driving motor is firstly started, the driving motor drives a rotating disc to rotate, the rotating disc simultaneously drives a grinding block and a first bevel gear to rotate, andthe grinding block rotates to grind raw materials in a grinding sleeve; and the first bevel gear drives a crankshaft body to rotate through engagement with a second bevel gear, the crankshaft body repeatedly drives fixing rods to jack up and drop down through eccentric rotating shafts, the fixing rods impact the grinding sleeve back and forth, the grinding sleeve is vibrated, the adhesion of a large amount of raw materials caused by grinding and extrusion of the grinding block in the grinding sleeve is avoided, and meanwhile, the influence on the production efficiency of a grinding device isavoided.

Owner:牡丹江永兴化工有限公司

Composite interlaced yarn having variegated colour effect

The invention relates to a composite interlaced set yarn with dye effect, which is compositely made at a middle and low speed on a composite interlaced set yarn machine by adopting two or a plurality of sorts of yarn different in dry-hot shrinkage and yarn classes or color absorbing degrees. Due to the character differences in the nature of each component of the composite interlaced set yarn, the fabric surface of the products weaved by the invention can generate various mixed-color flash effects. If the invention is processed again by different dyeing processes, the invention can obtain dyeing effects of different characteristics, very natural star point-shaped, rain-shaped and strip-shaped dyeing effects. Simultaneously due to slight differences in nature among the components in selected materials, the physico-chemical properties of the product is uniform and the invention can not affect other characteristics except dyeing.

Owner:SHENGHONG GRP CO LTD

Device and method for automatic monitoring and screening of edge sealing system

ActiveCN113333328AIncrease productivityImprove production efficiencySortingStructural engineeringMechanical engineering

The invention discloses a device and method for automatic monitoring and screening of an edge sealing system. The device comprises a secondary stacking table arranged at a gypsum board conveying line and an edge sealing detection mechanism arranged on the secondary stacking table. According to the device and method for automatic monitoring and screening of the edge sealing system, an edge sealing wheel is sleeved with an edge sealing belt to carry out edge sealing on a gypsum board, the edge sealing detection mechanism detects the rotation condition of the edge sealing wheel to detect whether the edge sealing belt is broken or not, and the gypsum boards without edge sealing are conveyed to the corresponding area through the secondary stacking table, so that the problem that the production efficiency of the gypsum boards is affected due to the fact that the gypsum boards without edge sealing and the gypsum boards with edge sealing are mixed and stacked and need to be screened and classified is solved; and the edge sealing detection mechanism detects the breakage position of the edge sealing belt, the secondary stacking table screens the gypsum boards according to the breakage position of the edge sealing belt, the screening accuracy is further improved, the situation that part of gypsum boards subjected to edge sealing after edge sealing belt breakage and gypsum boards without edge sealing are conveyed to the same area to be mixed and stacked and need to be screened again is avoided, and the production efficiency of the gypsum boards is further improved.

Owner:井冈山北新建材有限公司

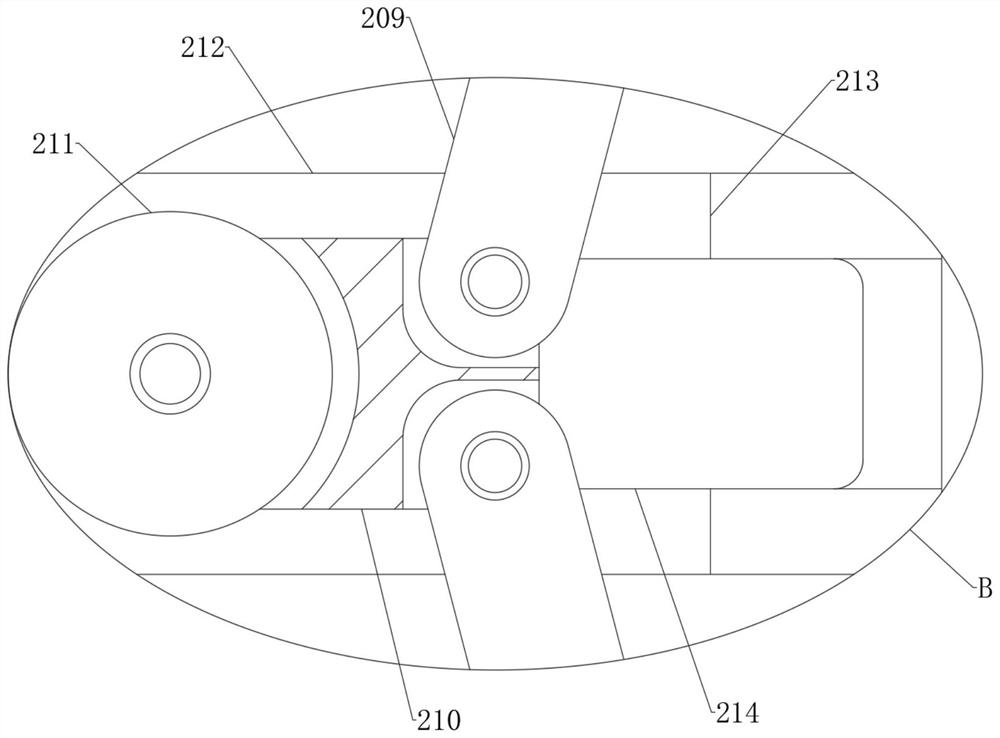

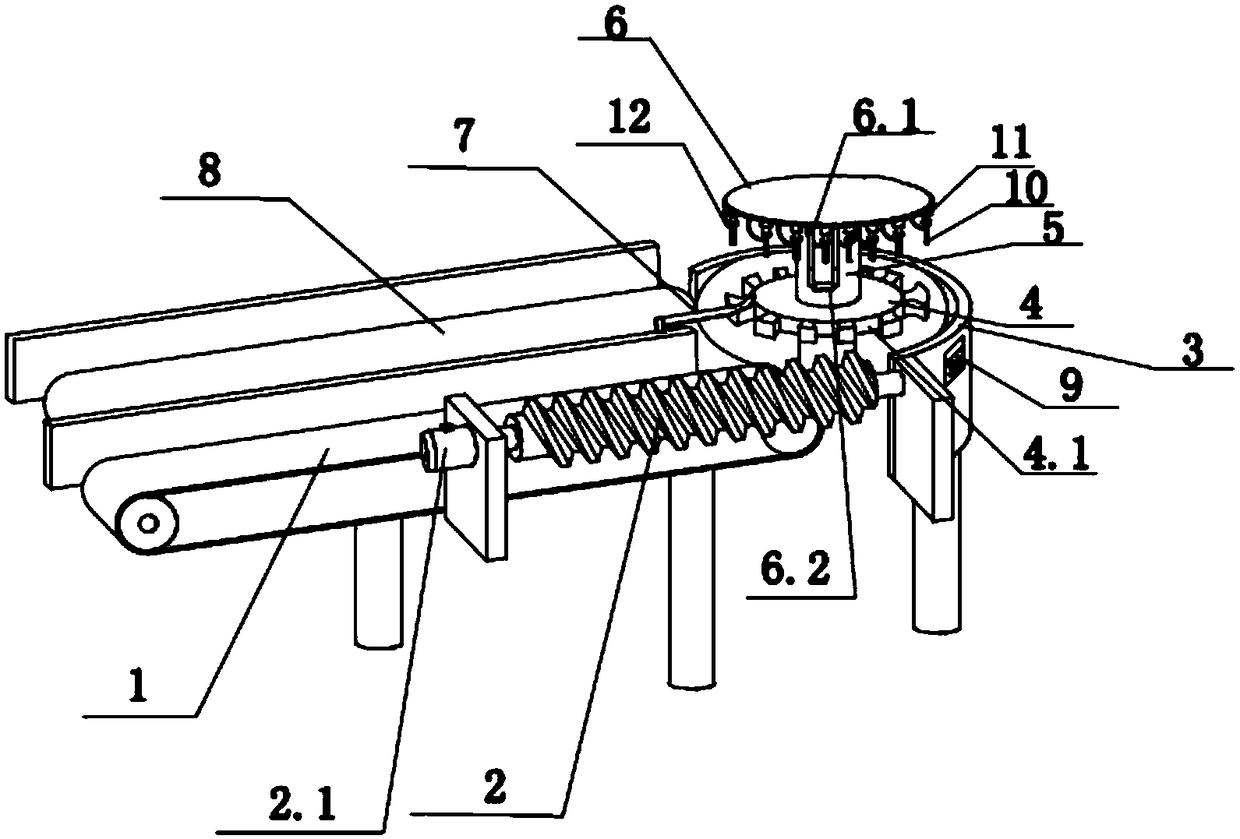

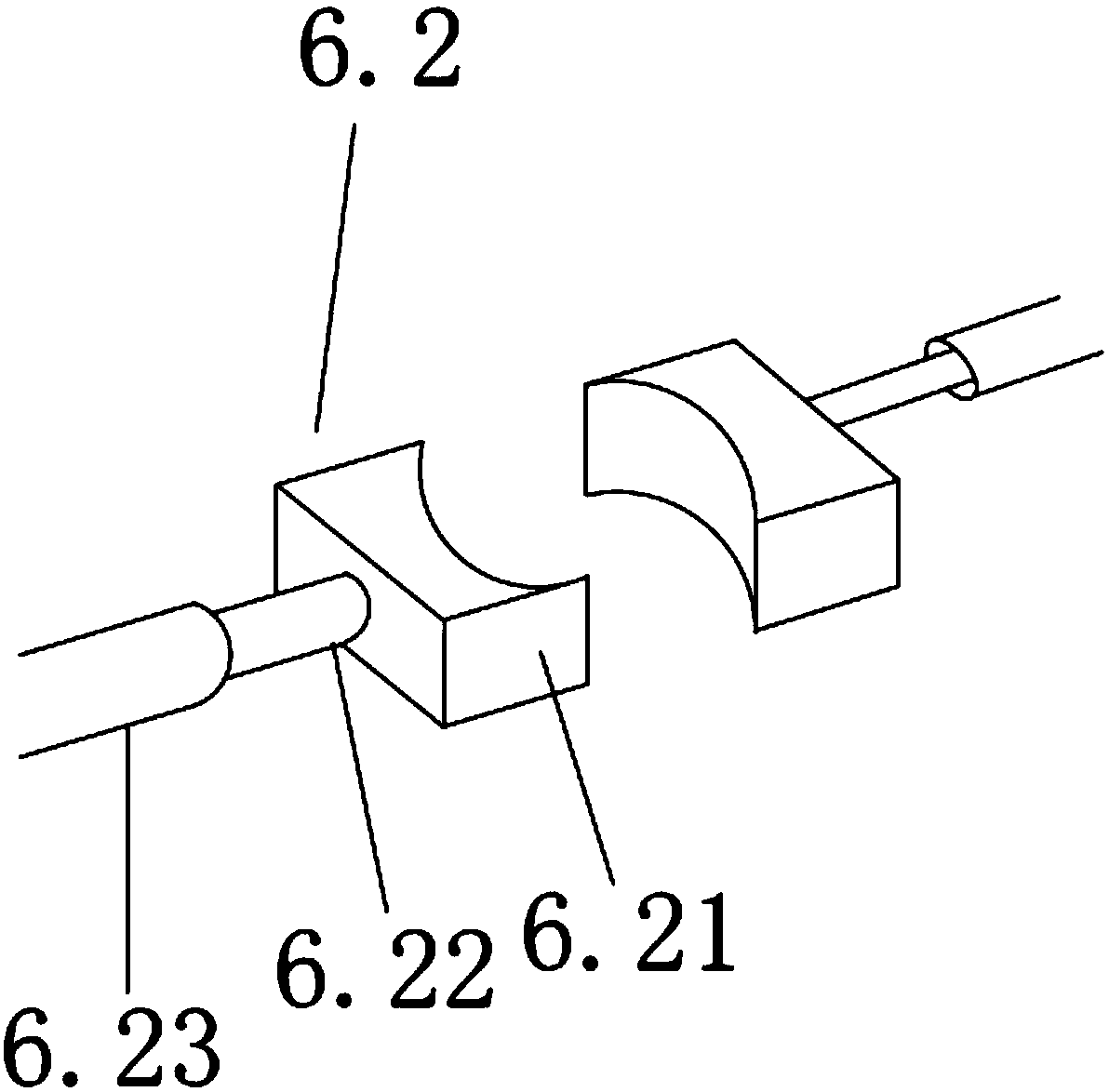

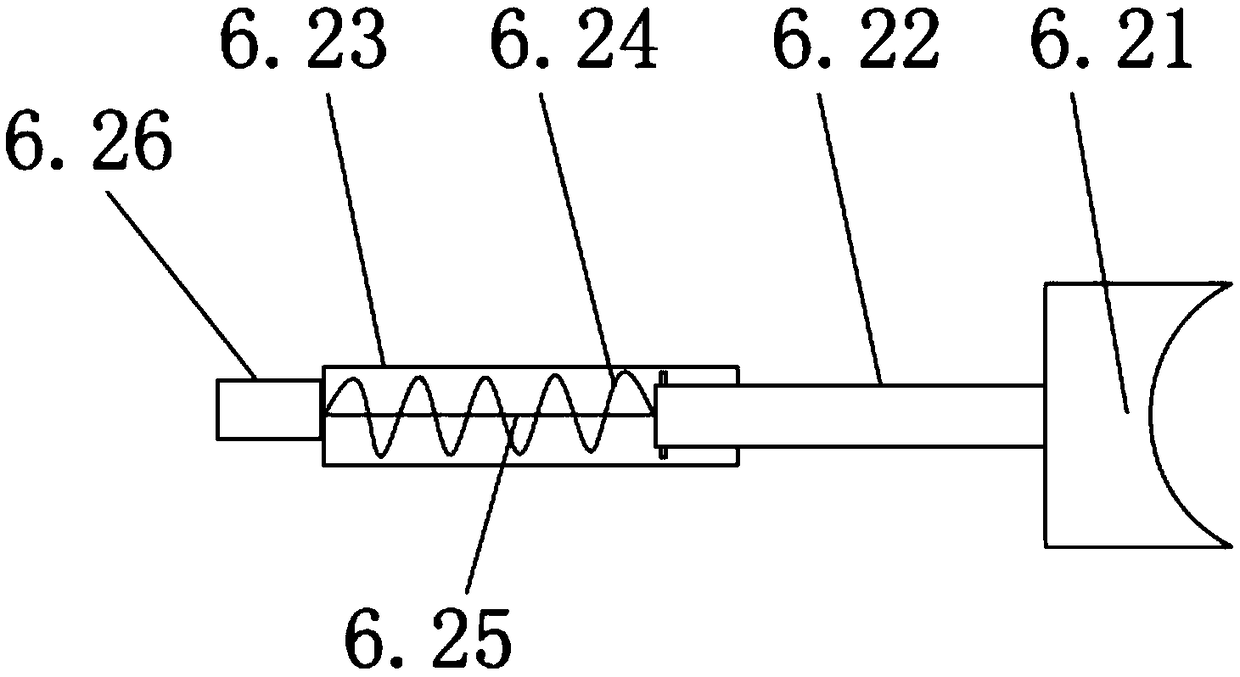

Drink filling bottle circularly rotating and continuously and precisely sterilizing and drying device

InactiveCN108981358APrecise entryAvoid damageHollow article cleaningDrying gas arrangementsSpray nozzleEngineering

The invention provides a drink filling bottle circularly rotating and continuously and precisely sterilizing and drying device and belongs to the field of filling bottle sterilizing and drying. The drink filling bottle circularly rotating and continuously and precisely sterilizing and drying device comprises an inlet conveying belt, a bottle guiding frame, a conveying turntable, a bottle clampinggroove, a rotating column, a sterilizing and drying turntable, an extending gripper air cylinder, a fixing ripper, a bottle discharging limiting bar, an outlet conveying belt, a control panel, a spraynozzle, an air cylinder, a hose and a sterilizing and drying module. The drink filling bottle circularly rotating and continuously and precisely sterilizing and drying device comprises the extendinggripper air cylinder and the fixing ripper, so that before the spray nozzle moves downwards for steam spray sterilizing and drying, the extending gripper air cylinder moves downwards and the fixing gripper fixes a drink filling bottle, and the spray nozzle can avoid deviation during downward movement; the extending gripper air cylinder and the fixing gripper can achieve guiding effects on the spray nozzle, the spray nozzle can precisely enter the filling bottle, so that damage to the filling bottle due to inaccurate entering of the spray nozzle into the filling bottle can be reduced as well asinfluence on normal drink filling production and production efficiency can be avoided.

Owner:刘业倩

Cabling yarn binding machine with stranding mold

The invention belongs to the technical field of optical cable manufacturing equipment, and provides a cabling yarn binding machine with a novel stranding mold. The cabling yarn binding machine comprises a machine frame and a mold body, and is characterized in that the mold body is provided with a beam cable channel for a cable core to pass, the cross section of the beam cable channel is circular,the inner wall of the mold body is provided with at least one yarn guiding slot, chamfers of the yarn guiding slots are set in a polished manner, the mold body is arranged at the end, which is close to a first hollow rotating shaft, of a second hollow rotating shaft, a small-opening end of the beam cable channel is arranged in a mode of facing towards the first hollow rotating shaft, the first hollow rotating shaft is internally provided with an in-shaft yarn guiding pipe, and the in-shaft yarn guiding pipe is communicated with the beam cable channel. The cabling yarn binding machine realizesdirectional abrasion for the stranding mold, does not cause influences for the roundness of the stranding mold after long-time use and improves the service life of the stranding mold.

Owner:SHANDONG PACIF OPTICS FIBER & CABLE CO LTD

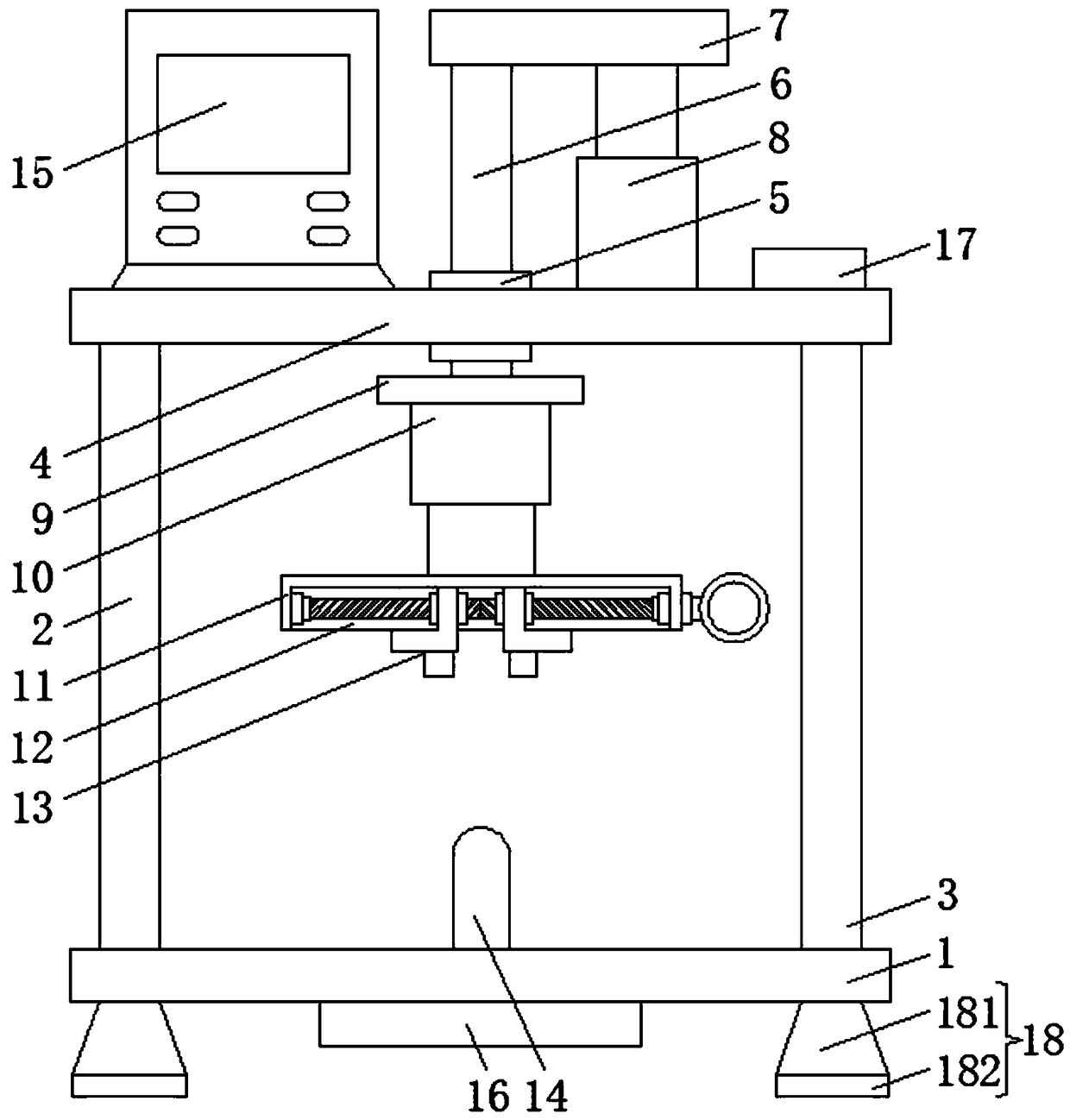

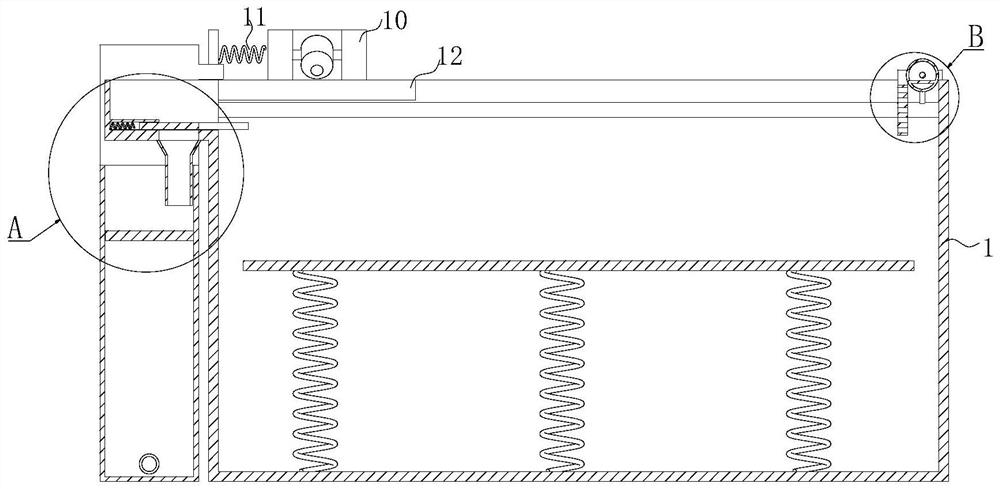

Detection device for spring production

The invention discloses a detection device for spring production. The detection device comprises a base plate and a display device. The upper surface of the base plate is fixedly connected with the lower surface of a top plate through a support plate and two support rods. The support plate is arranged on the left side of the lower surface of the top plate. The support rods are arranged on front and back sides of the lower surface of the right side of the top plate. A sliding sleeve sleeves the center place of the upper surface of the top plate. A sliding rod sleeves the interior of the slidingsleeve. The top end of the sliding rod is fixedly connected with the lower surface of a connection rod. The lower surface of the connection rod is fixedly connected with the upper surface of the topplate through an electric pushing rod. According to the invention, by setting the electric pushing rod, a pressure sensor, a threaded column, a threaded cylinder, a clamping block and a display device, so it is convenient for a worker to calculate elastic coefficients of the spring and fix springs in different sizes, effects on detection of the spring by the worker are avoided; and effects on production efficiency of the spring can be avoided.

Owner:江苏省溧水弹簧厂(普通合伙)

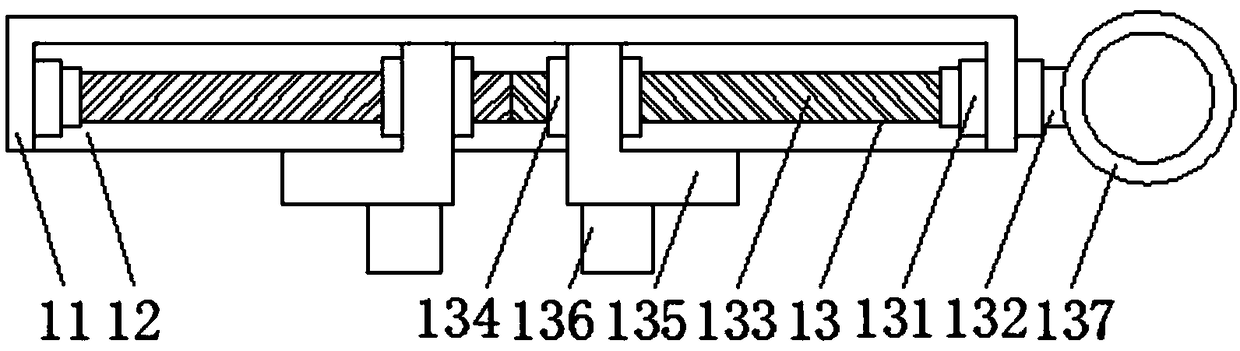

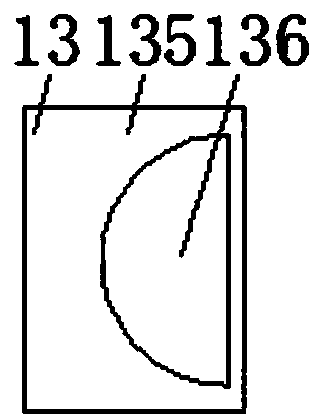

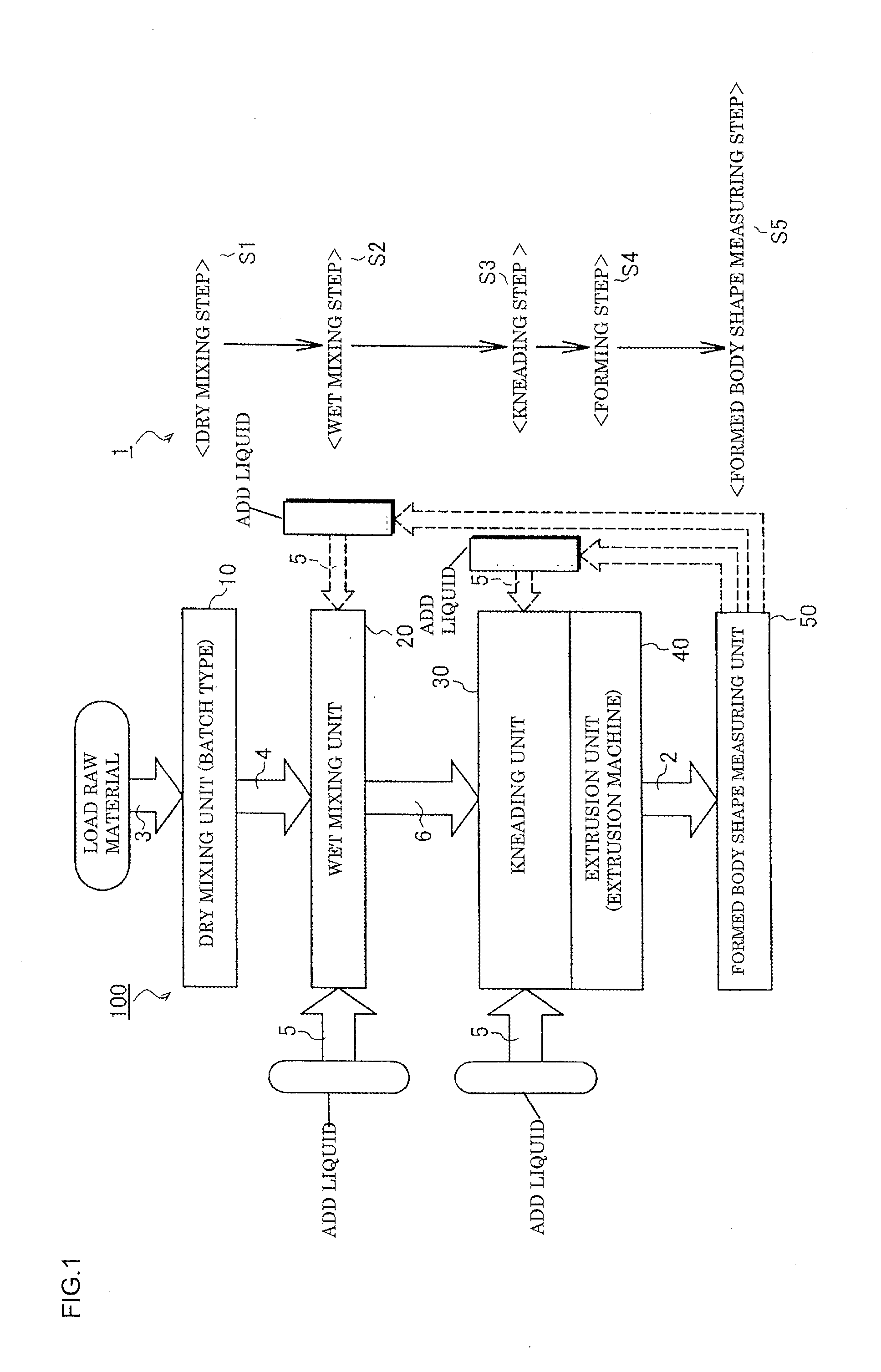

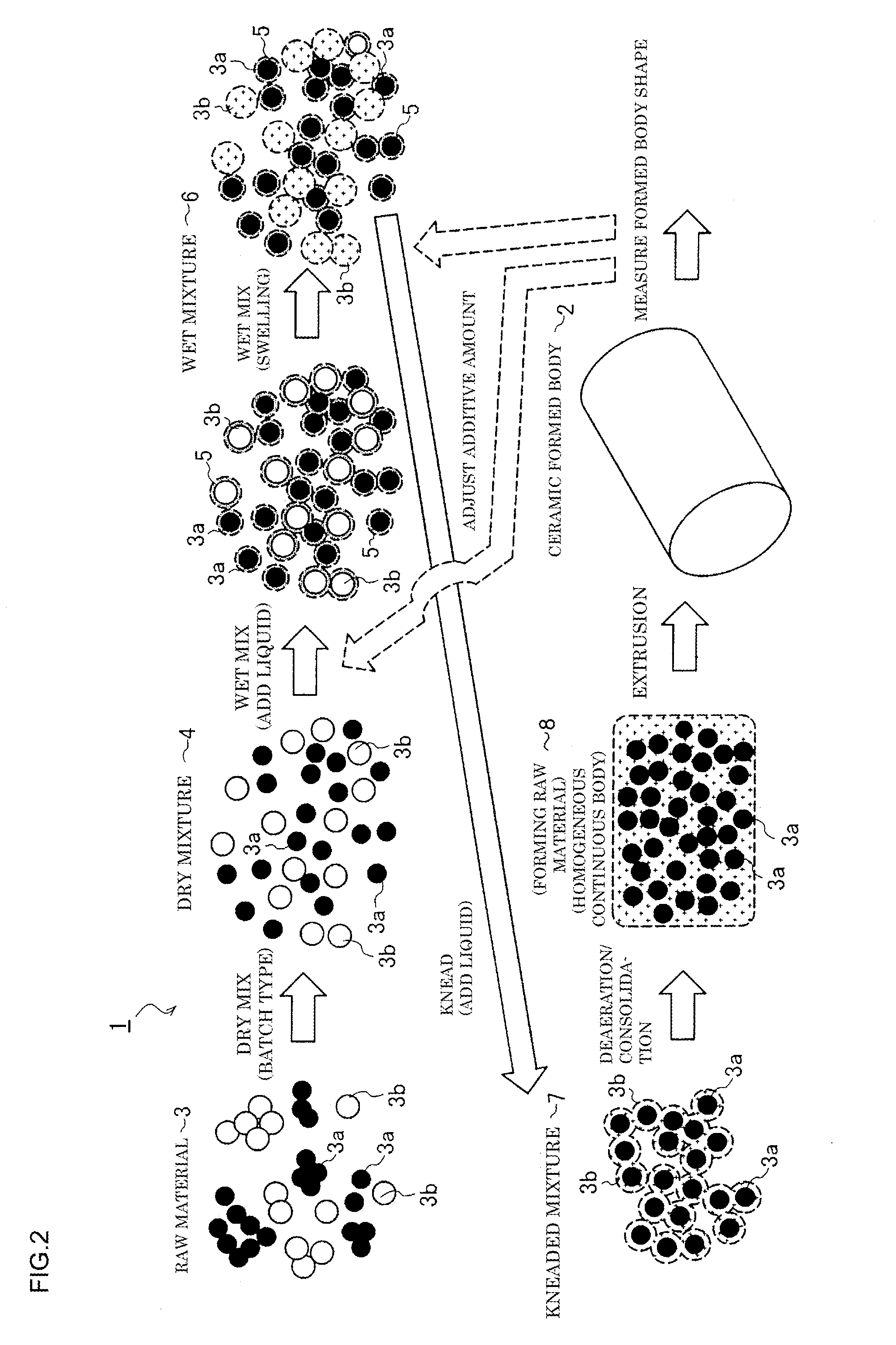

Method for manufacturing ceramic formed body, and apparatus for manufacturing ceramic formed body

ActiveUS20160288367A1Low torqueImprove shapeAuxillary shaping apparatusClay mixing apparatusPlasticizerMetallurgy

A manufacturing method includes: a dry mixing step of dry mixing a raw material by batch processing; a wet mixing step of adding liquid to a dry mixture obtained at the dry mixing step, the liquid including at least one type of water, surfactant, lubricant and plasticizer, while wet mixing; a kneading step of kneading a wet mixture obtained at the wet mixing step; and a forming step of extruding a kneaded mixture (forming raw material) obtained at the kneading step to make a ceramic formed body. In the kneading step, the liquid is further added during kneading of the wet mixture.

Owner:NGK INSULATORS LTD

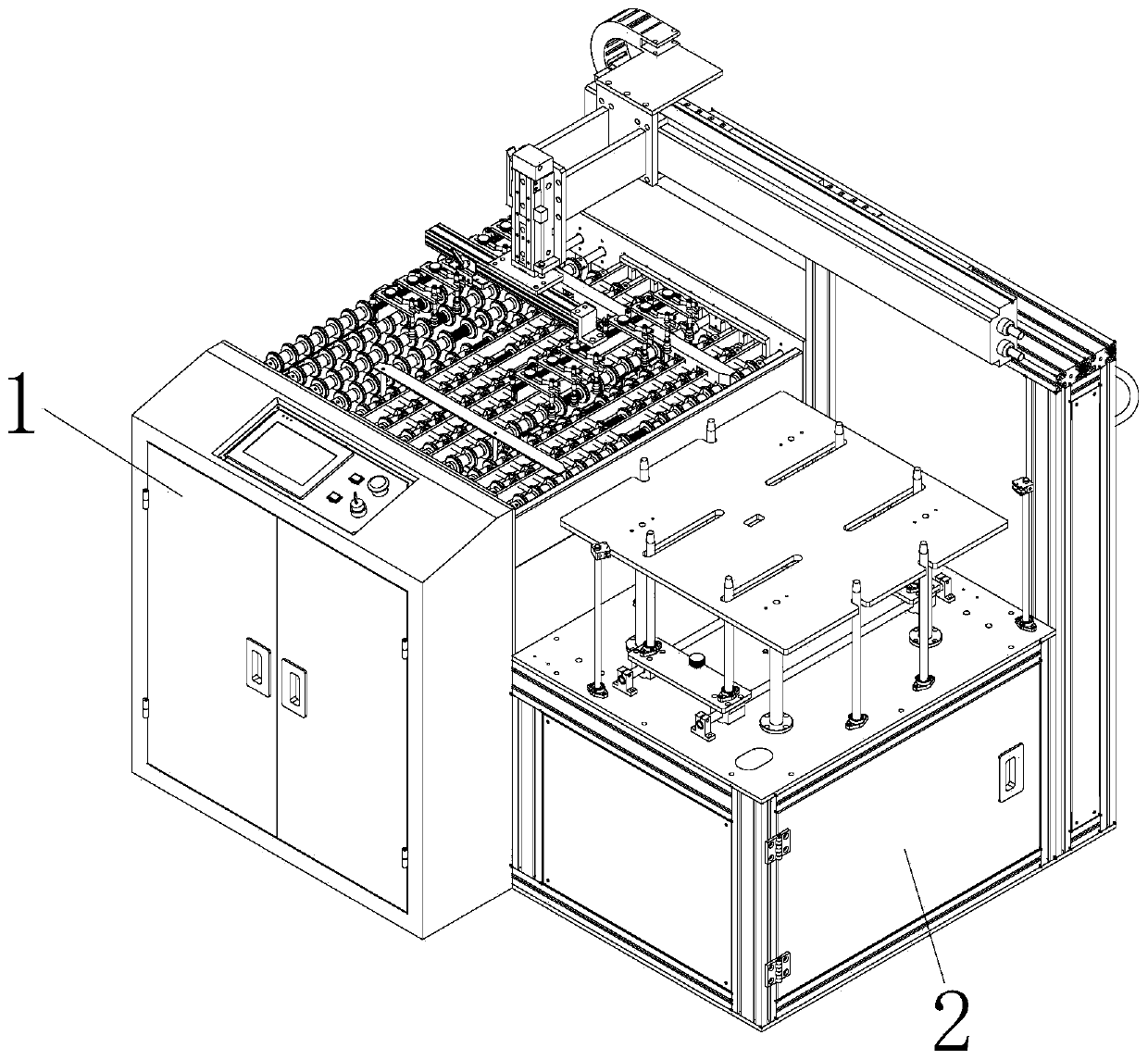

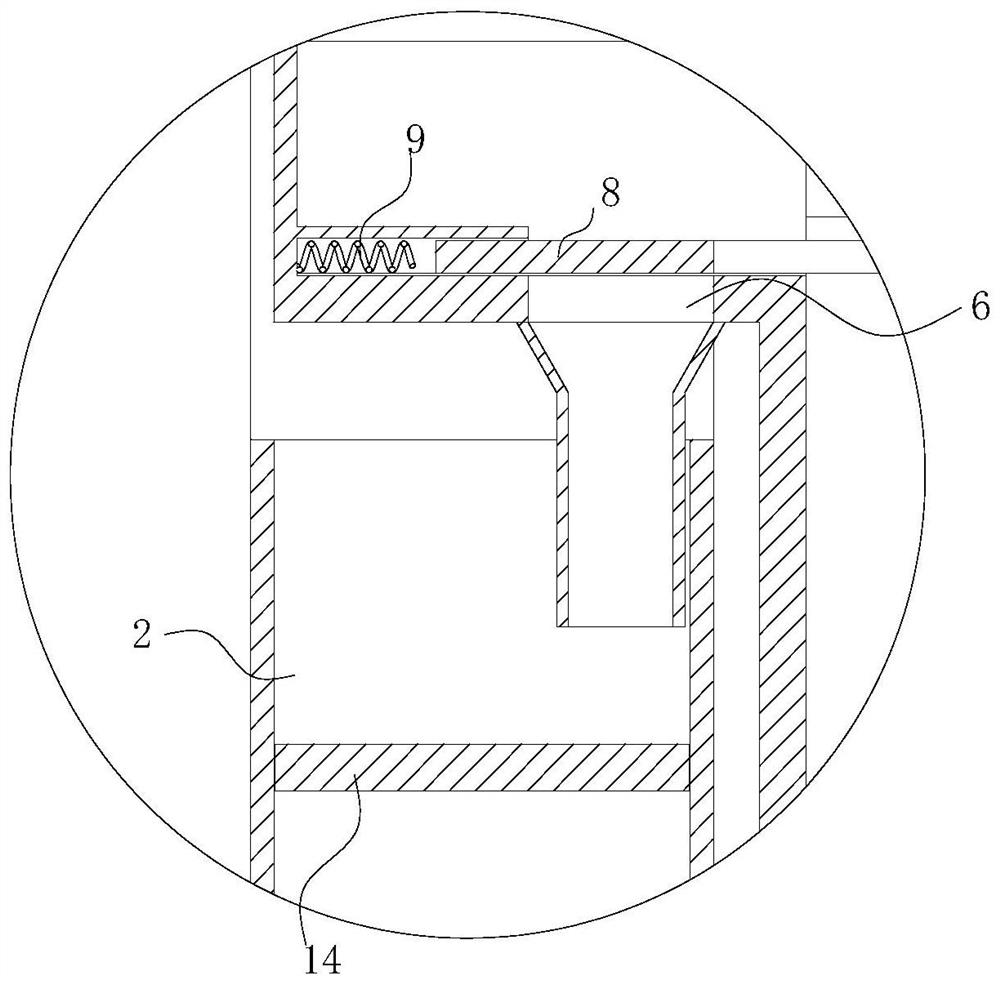

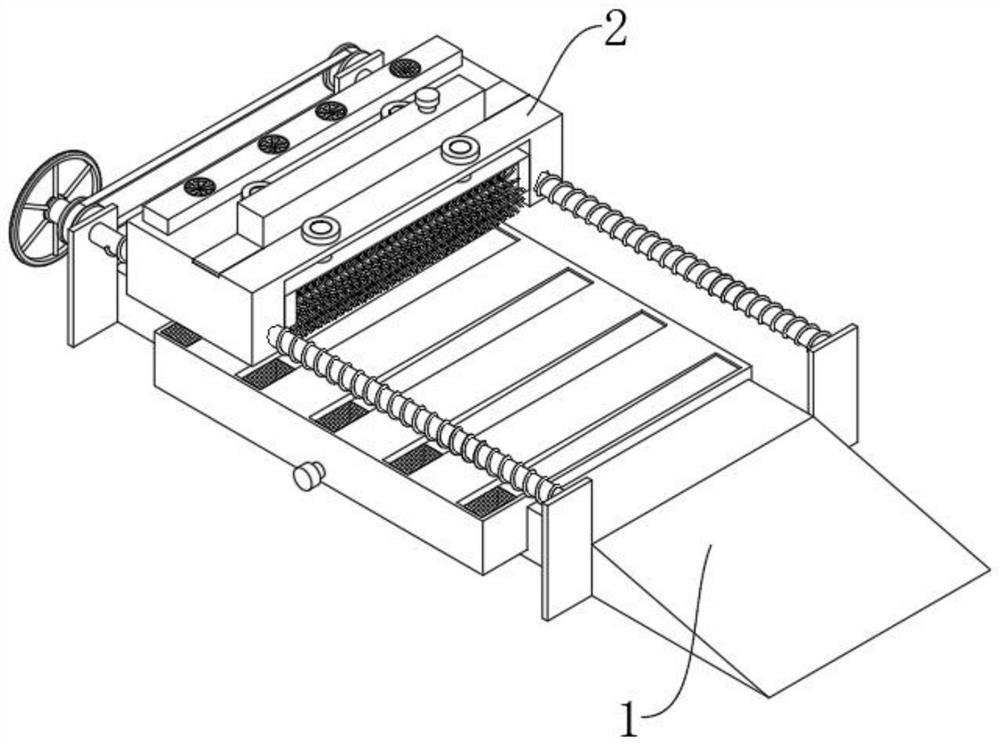

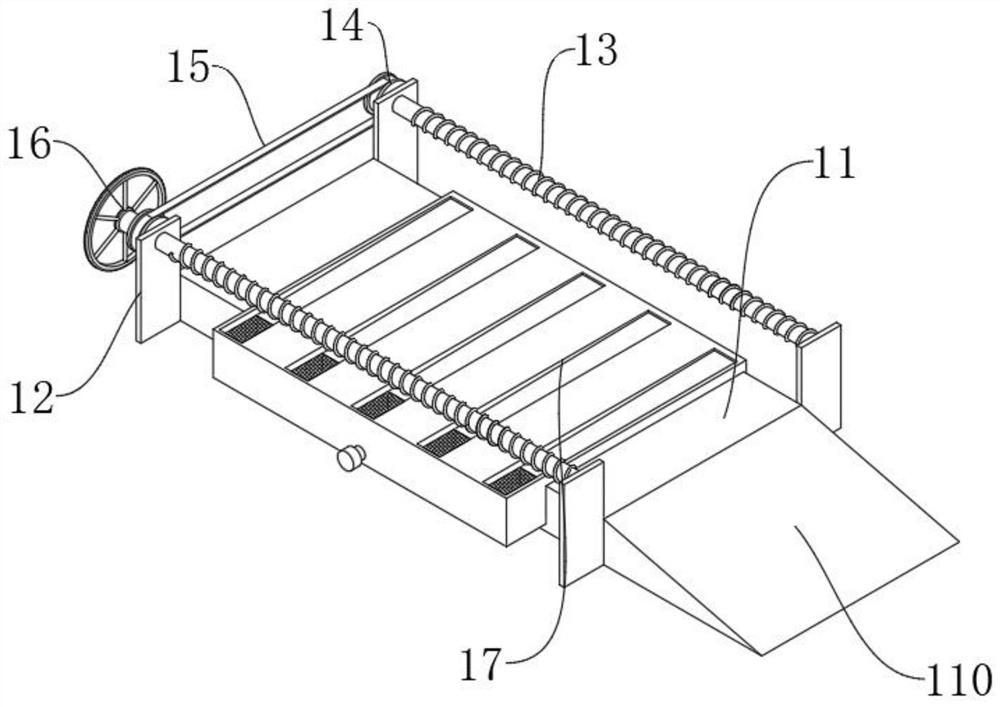

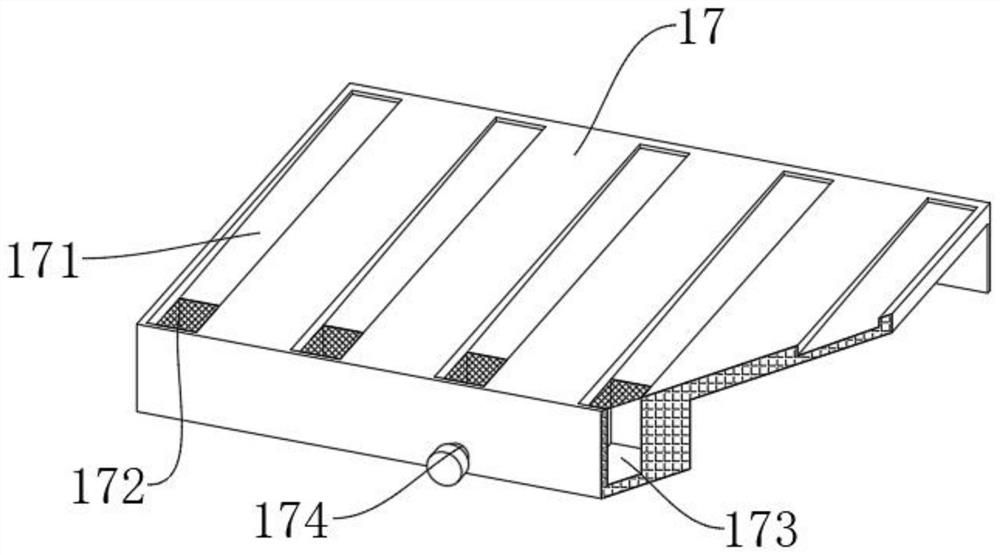

Substrate pretreatment equipment for producing new materials

ActiveCN113182270AAvoid pollutionAffect production efficiencyPlastic recyclingMultistage water/sewage treatmentMegasonic cleaningProcess engineering

The invention discloses substrate pretreatment equipment for producing new materials in the field of new material production. The substrate pretreatment equipment mainly comprises a cleaning box with a built-in ultrasonic transmitter, a cleaning mechanism is slidably mounted at the upper end of the cleaning box, the cleaning mechanism is used for cleaning dirt suspended on the liquid level of cleaning liquid in the cleaning box, and along the sliding direction of the cleaning mechanism, a dirt collecting barrel and a cleaning liquid supplementing barrel are arranged at one end of the cleaning box. According to the substrate pretreatment equipment, automatic cleaning can be carried out on the dirt suspended on the liquid level of the ultrasonic cleaning liquid, the dirt leaves the ultrasonic cleaning box, liquid is automatically supplemented into the ultrasonic cleaning box, it is guaranteed that the cleaning liquid in the ultrasonic cleaning box is sufficient and clean, and the situation that substrates are polluted, and the production efficiency of the new materials is affected is avoided.

Owner:上海纽氪曼科技有限公司

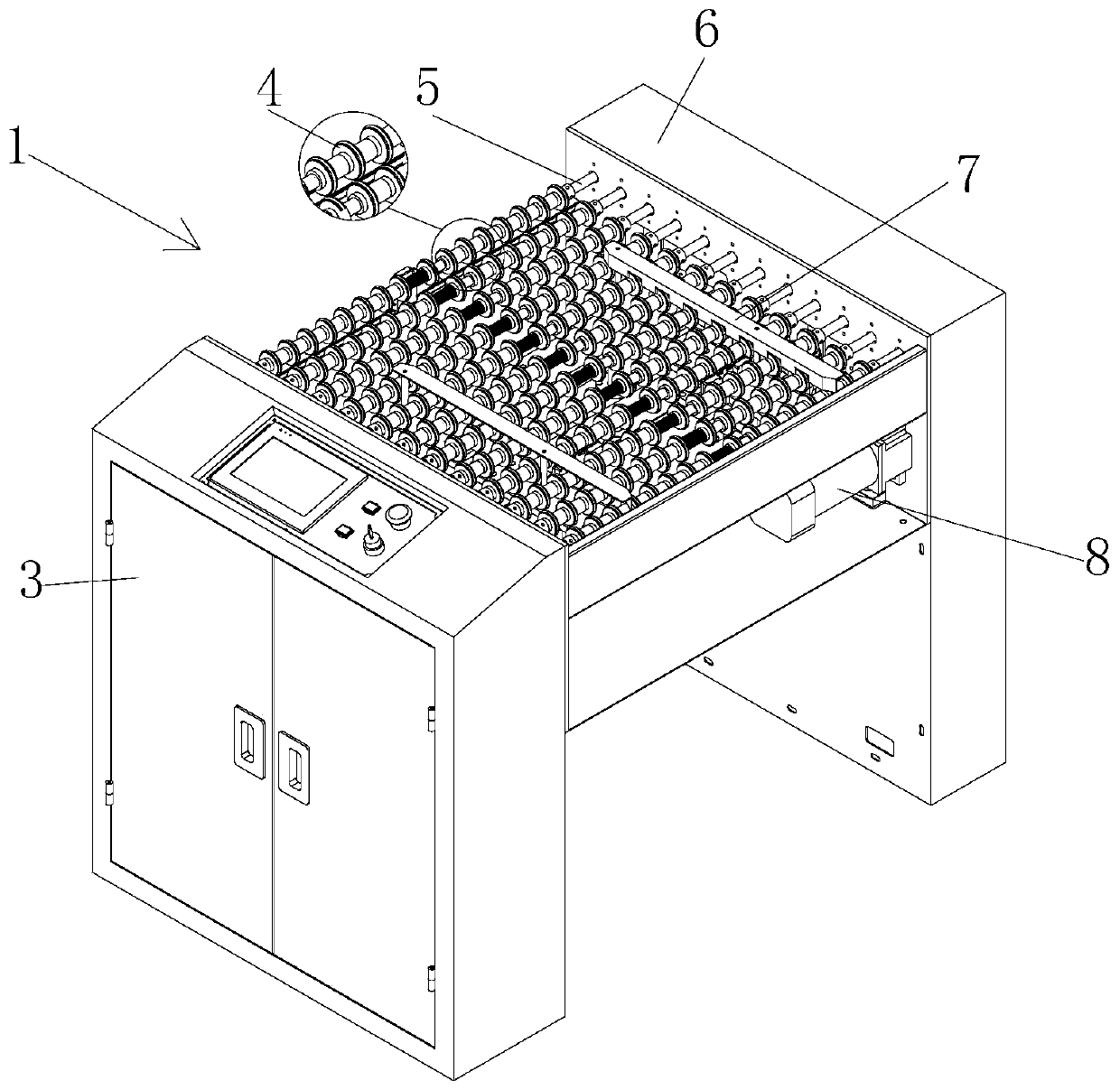

Irradiation production process device

PendingCN109950000AReduce the number of winding turnsFully play the roleCable/conductor manufactureWire rodSteering wheel

The present invention provides an irradiation production process device. The device comprises: four sets of two-in and two-out wire take-up and pay-off devices configured to pay off two wire rods to be irradiated and take up wire rods after irradiation and arranged in parallel; an under-beam device located at the periphery of the two-in and two-out wire take-up and pay-off devices, wherein each set of the two-in and two-out wire take-up and pay-off devices can transmit the wire rods to be irradiated on the under-beam device, and after the wire rods to be irradiated on the under-beam device areirradiated by an electron accelerator, the wire rods are returned to the two-in and two-out wire take-up and pay-off devices; and a plurality of steering wheel sets respectively arranged on the two-in and two-out wire take-up and pay-off devices and the under-beam device and configured to guide the wire rods to go in and out the under-beam device. The two-in and two-out wire take-up and pay-off devices are employed to achieve take-up and pay-off of the wire rods, namely achieve eight-in and eight-out of the wire rods so as to improve the irradiation speed, allow the electron accelerator to fully develop the functions and improve the production efficiency.

Owner:山西壹泰科电工设备有限公司

Corynebacterium glutamicum genes encoding proteins involved in homeostasis and adaptation

InactiveUS20050277115A1Efficient producerImprove production efficiencyHydrolasesAntibody mimetics/scaffoldsBiological bodyAntisense nucleic acid

Isolated nucleic acid molecules, designated HA nucleic acid molecules, which encode novel HA proteins from Corynebacterium glutamicum are described. The invention also provides antisense nucleic acid molecules, recombinant expression vectors containing HA nucleic acid molecules, and host cells into which the expression vectors have been introduced. The invention still further provides isolated HA proteins, mutated HA proteins, fusion proteins, antigenic peptides and methods for the improvement of production of a desired compound from C. glutamicum based on genetic engineering of HA genes in this organism.

Owner:POMPEJUS MARKUS +4

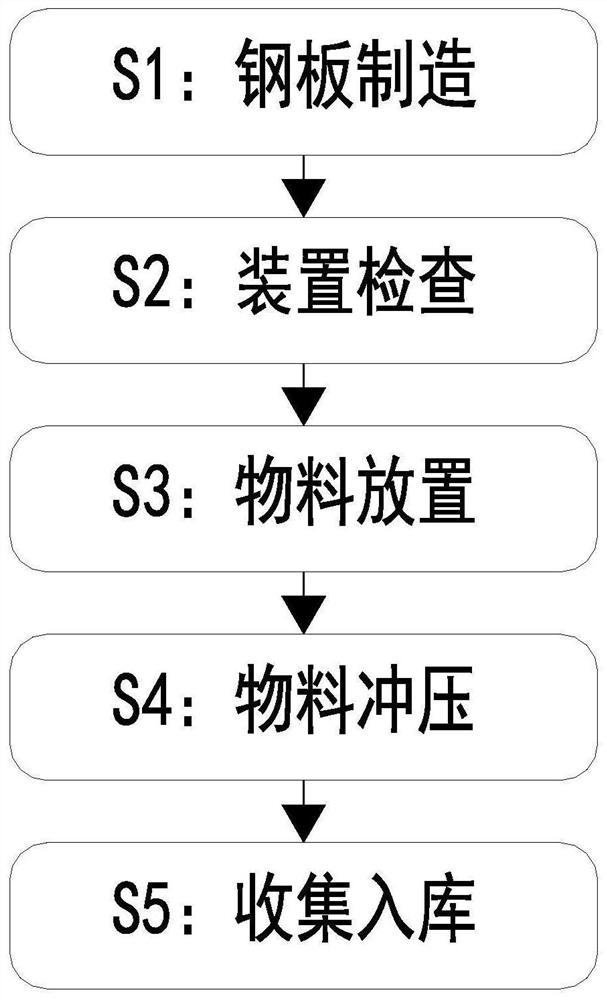

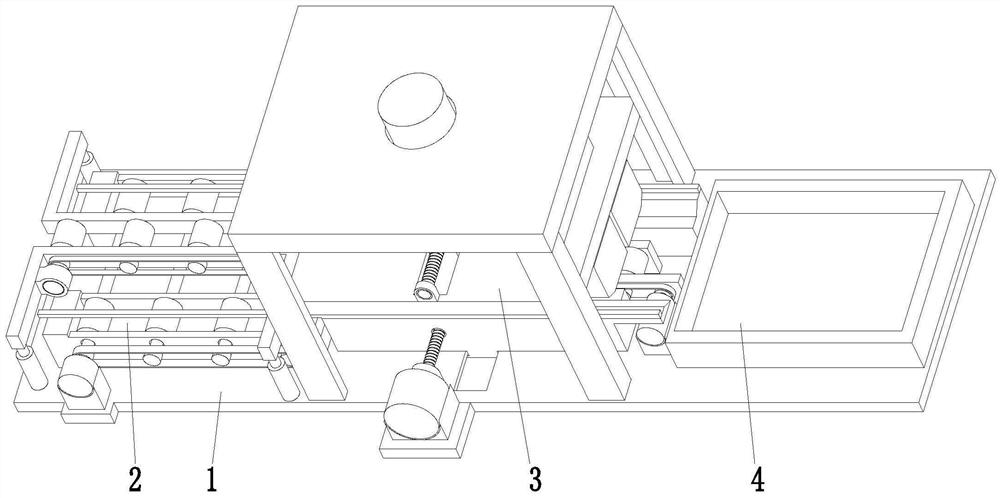

Waterproof material manufacturing technology for building construction

PendingCN112893579AImprove efficiencyEasy to wear outMetal-working feeding devicesPositioning devicesSteel platesManufacturing engineering

The invention relates to a waterproof material manufacturing technology for building construction. A waterproof material manufacturing device for building construction is adopted in the waterproof material manufacturing technology for building construction and comprises a base, a conveying mechanism, a stamping mechanism and a material collecting box; the conveying mechanism, the stamping mechanism and the material collecting box are sequentially arranged on the upper end surface of the base from left to right. According to the technology, the following problems existing in the process of producing steel plate water-stop belts in a rolling manner in the prior art can be solved: the width specifications of the steel plate water-stop belts are more, so that the production efficiency of the steel plate water-stop belts is influenced by the process of dismounting and replacing related spare and accessory parts when the steel plate water-stop belts with different specifications need to be produced; a rolling production line is long, the number of rolling parts is large, the time needed for maintaining, replacing and replacing the multiple rolling parts is long, and thus the cost for maintaining and replacing the related rolling parts on the rolling production line is high.

Owner:刘宝琴

Grinding device for new material pipe production

InactiveCN109129049AAvoid damageAffect production efficiencyGrinding carriagesRevolution surface grinding machinesMechanical energyEngineering

The invention discloses a grinding device for new material pipe production. The grinding device comprises a base, two vertical plates are connected to the base through buffering devices, a bearing plate is fixedly connected between the two vertical plates, a grinding device body is installed on the bearing plate, an installing plate is arranged between the two vertical plates and located over thebearing plate, each vertical plate is provided with a heat dissipation device and a power generation device, and a dust suction device is arranged on the installing plate. According to the grinding device for new material pipe production, mechanical energy is converted into internal energy of water, vibration is reduced, and the condition that the production efficiency of the grinding device is influenced due to frequent replacement can be avoided while part damage is avoided; air force is generated, air convection is formed, and air achieves temperature exchange; and meanwhile, water in a sponge mat absorbs heat through volatilization, the temperature is further lowered, the heat dissipation effect is achieved, and the condition that the service life of the device is shortened due to internal part aging is avoided.

Owner:薛鸿展

Small-sized concrete block processing equipment

PendingCN109483712AIncrease productivityHighly creativeFeeding arrangmentsAuxillary shaping apparatusEngineeringMaterial storage

The present invention discloses small-sized concrete block processing equipment; the processing equipment comprises a material charging device, a material storage device, a first material feeding device and a second material feeding device, wherein the material charging device comprises a plurality of material charging support bases, a material charging sliding rail is obliquely connected with upper ends of the material charging support bases, and a material charging hopper is slidably connected with the material charging sliding rail; the material storage device is arranged at a lower end ofthe material charging sliding rail and comprises a material storage support frame, and a material storage hopper is arranged on the material storage support frame; the first material feeding device comprises a first conveying frame, and a first material feeding hopper is connected with an upper end of the first conveying frame and connected with a second pulling mechanism arranged on the first conveying frame through a second steel cable; the second material feeding device comprises a second conveying frame and a mold conveying mechanism, a controller is connected with a side end of the secondconveying frame, and the mold conveying mechanism comprises a plurality of first rollers which are parallel to each other and arranged at an upper end of the second conveying frame; the processing equipment can be more efficient and more safe to process small-sized prefabricated concrete members, and has novel structure and high creativity.

Owner:CCCC FIRST HARBOR ENG +1

High-efficiency graphene production equipment with quantifying function

The invention relates to high-efficiency graphene production equipment with a quantifying function. The high-efficiency graphene production equipment with the quantifying function comprises a main body, a placement table, a microwave emitter, four brackets, a quantifying mechanism and a vibrating mechanism; the quantifying mechanism comprises a driving component and a baffle plate; the driving component comprises a first motor, a wire spool, a pull wire, a sliding block, a first spring, a regulating rod and a fixed plate; the vibrating mechanism comprises a second motor, a rotating shaft, a transmission shaft, a transmission component and two vibrating components; each vibrating component comprises a first turntable, a second turntable and a vibrating rod; through the quantifying mechanism, the high-efficiency graphene production equipment with the quantifying function can realize quantitative feeding; the influence on the production effect of graphene caused by too much or too littlefeeding is avoided; through the vibrating mechanism, the placement table can be driven to move up and down, so that the influence on the production efficiency of the graphene caused by accumulating materials is avoided.

Owner:虞伟明

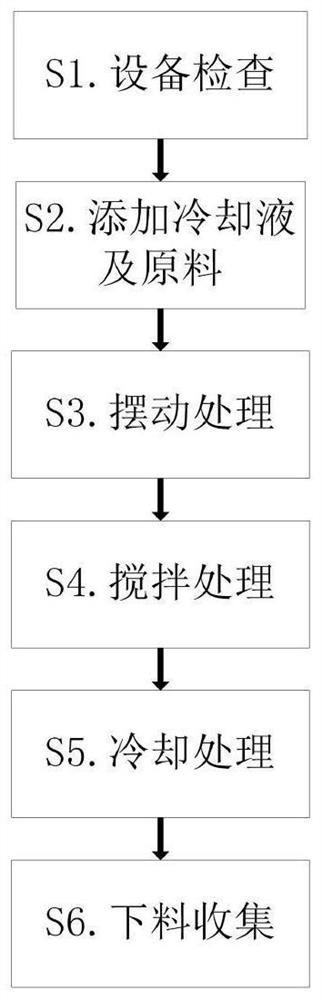

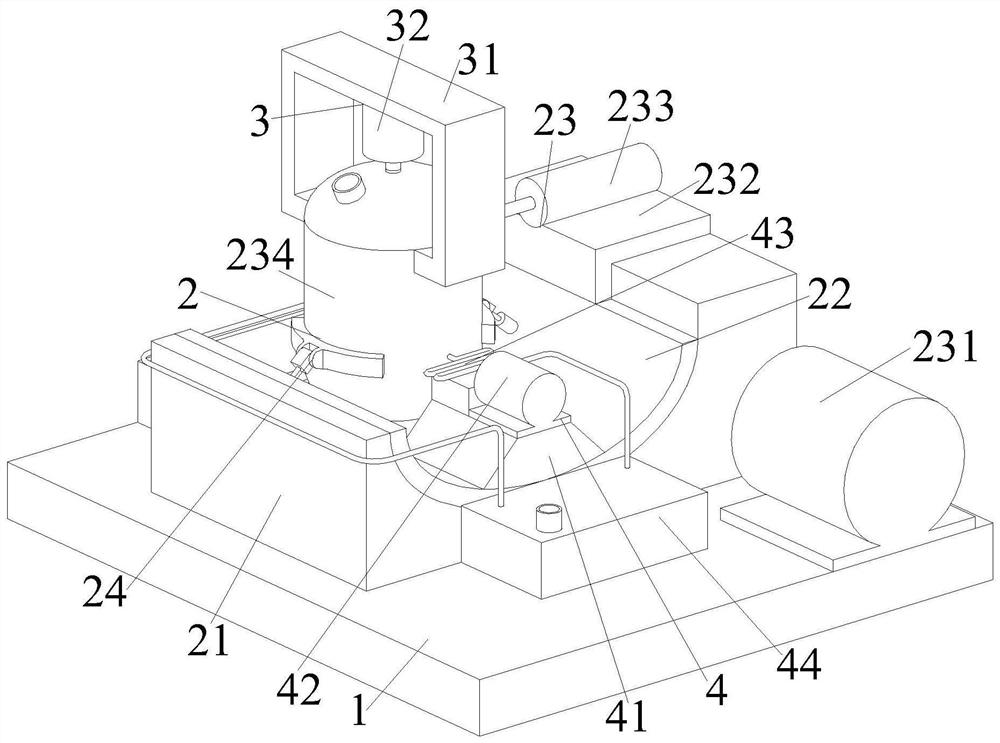

Preparation method of industrial water reducer

ActiveCN112076664AAffect production efficiencyReduce the laborious process of manual mixingShaking/oscillating/vibrating mixersTransportation and packagingProcess engineeringIndustrial water

The invention relates to an industrial water reducer preparation method, and a device comprises a bottom plate, a swing device, a stirring device, a cooling device and a collection frame, wherein theswing device is installed in the middle of the upper end of the bottom plate, the stirring device is installed at the upper end of the swing device, the cooling device is installed in the middle of the swing device, and the collection frame is arranged at the rear end of the swing device. According to the preparation method of the industrial water reducing agent, the invention solves the problemsthat when the industrial water reducing agent is manually prepared, raw materials of the industrial water reducing agent are generally and directly placed in the same container manually, then the rawmaterials are directly mixed and stirred manually, so the manual stirring is difficult to conduct due to the fact that the number of the raw materials is large, and raw materials are difficult to be fully mixed through manual stirring; the problems that when an existing industrial water reducing agent manufacturing device is used for preparing an industrial water reducing agent, the raw materialsof the industrial water reducing agent are generally and directly mixed and stirred through a stirring device, and in the stirring process, a large amount of heat generated during raw material mixingis difficult to remove, so the manufacturing efficiency of the water reducing agent is affected.

Owner:湖南鼎力特新材料有限公司

Laminated strip safety cutting device for processing polytetrafluoroethylene cable wrapping tape

InactiveCN109049031AAffect production efficiencyLabor intensiveMetal working apparatusEngineeringDrive motor

The invention relates to the technical field of wrapping tape production and processing, and particularly relates to a laminated strip safety cutting device for processing a polytetrafluoroethylene cable wrapping tape. The laminated strip safety cutting device comprises a bottom plate, the left side and the right side of the bottom plate are correspondingly provided with a first rotating shaft anda second rotating shaft, the first rotating shaft is connected with a driving motor, a plurality of separating plates are arranged on the second rotating shaft in a sliding mode, the bottom of the separation plates is in sliding fit with the bottom plate, cutting knifes are correspondingly arranged on the right side of the separation plates, and adjusting shifting rod mechanisms are correspondingly arranged on the left side of the separating plates, the first rotating shaft and the second rotating shaft are connected through a belt mechanism. According to the laminated strip safety cutting device, the problem that after the existing winding tape cutting device cut the wrapping tape, the cut wrapping tape is still wrapped on the same winding shaft, the phenomenon of mutual stacking can occur is solved, then the production efficiency is influenced, the labor intensity is increased, the wrapping tape with different widths cannot be cut, and great limitation is achieved.

Owner:芜湖新农夫机械股份有限公司

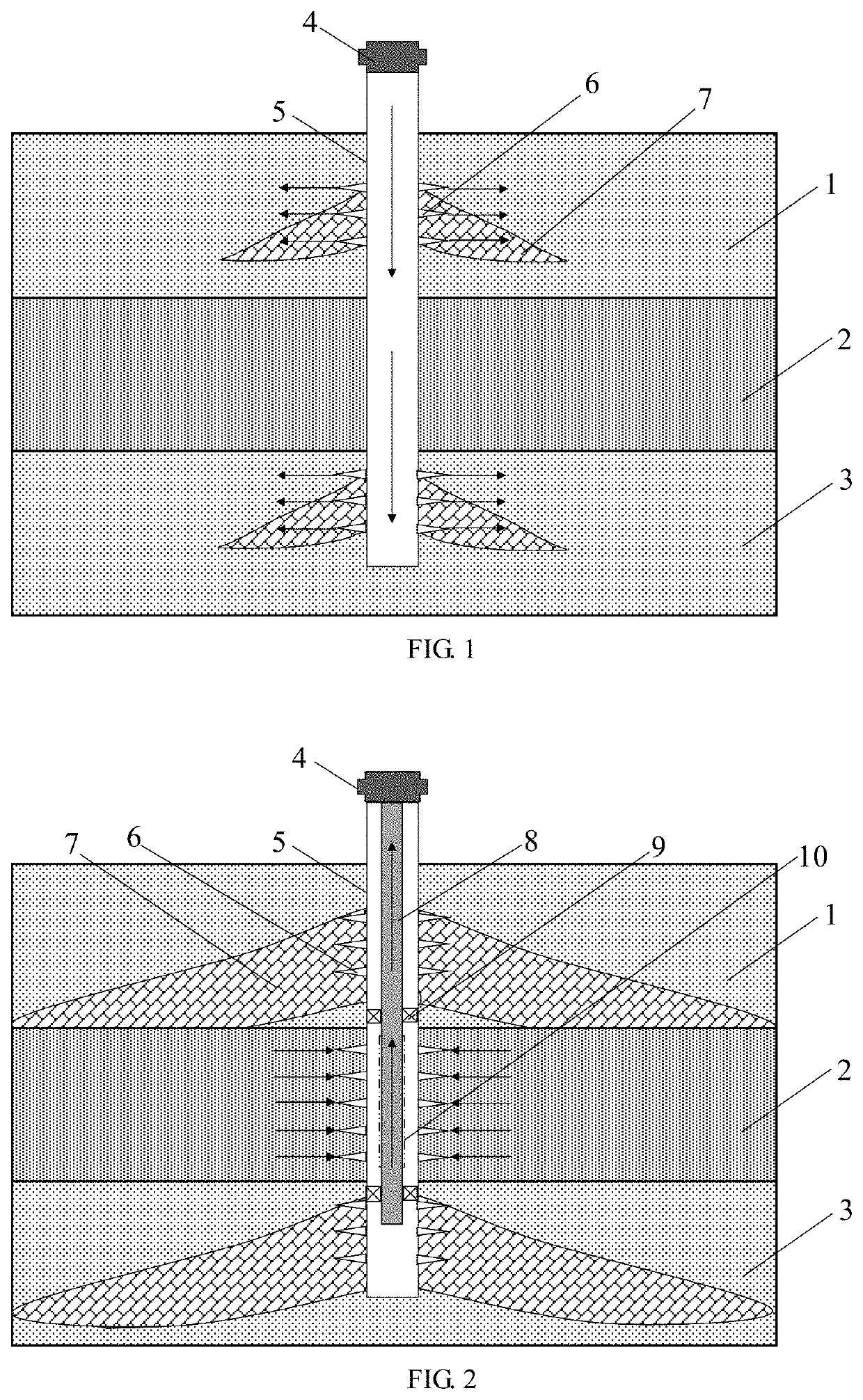

Method for enhancing gas recovery of natural gas hydrate reservoir

ActiveUS10830019B1Easy to operateSimple structureConstructionsFluid removalThermodynamicsSoil science

A method for improving the gas recovery of a natural gas hydrate reservoir by using artificial impermeable layers is described. Artificial impermeable layers are formed by injecting cement slurry into the permeable overburden and underburden layers. When depressurization exploitation is performed, a large amount of seawater can be effectively blocked from entering a hydrate layer, and a production pressure difference between the hydrate layer and the production well is effectively increased, so that a hydrate decomposition rate and the gas recovery are improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Food production weighing device capable of avoiding residual oil stains and using method thereof

InactiveCN112525320AEasy to cleanReduce labor intensityWeighing auxillary devicesEnvironmental engineeringFood products

The invention relates to the technical field of food production, in particular to a food production weighing device capable of avoiding residual oil stains. The device comprises a weighing device anda cleaning device arranged above the weighing device, the cleaning device at least comprises a supporting frame and an ash removing device, wherein the ash removing device comprises an ash removing shell, an ash removing roller is rotationally arranged in the ash removing shell, an ash removing brush and a flushing device are arranged on the outer wall of the ash removing roller, the flushing device comprises a water tank, and the bottom of the water tank communicates with a plurality of spray heads; a clean device which comprises a clean shell, wherein a clean roller is rotationally arrangedin the clean shell, and a clean cotton strip is arranged on the outer wall of the clean roller; and a drying device which comprises a drying box, wherein an electric heating net is arranged in the drying box, a blowing fan is arranged above the electric heating net, and air outlet holes are formed in the bottom of the drying box. The top of the weighbridge can be subjected to ash removal, flushing, cleaning and drying, residual oil stains and impurities on the top of the weighbridge can be conveniently removed, and waste liquid can be conveniently collected.

Owner:尧浪

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com