Sodium hydroxide production process for experiments

A technology of sodium hydroxide and production process, applied in the direction of grain processing, etc., can solve the problems of delaying raw materials, affecting the efficiency of the grinding device, clogging, etc., and achieve the effect of avoiding accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

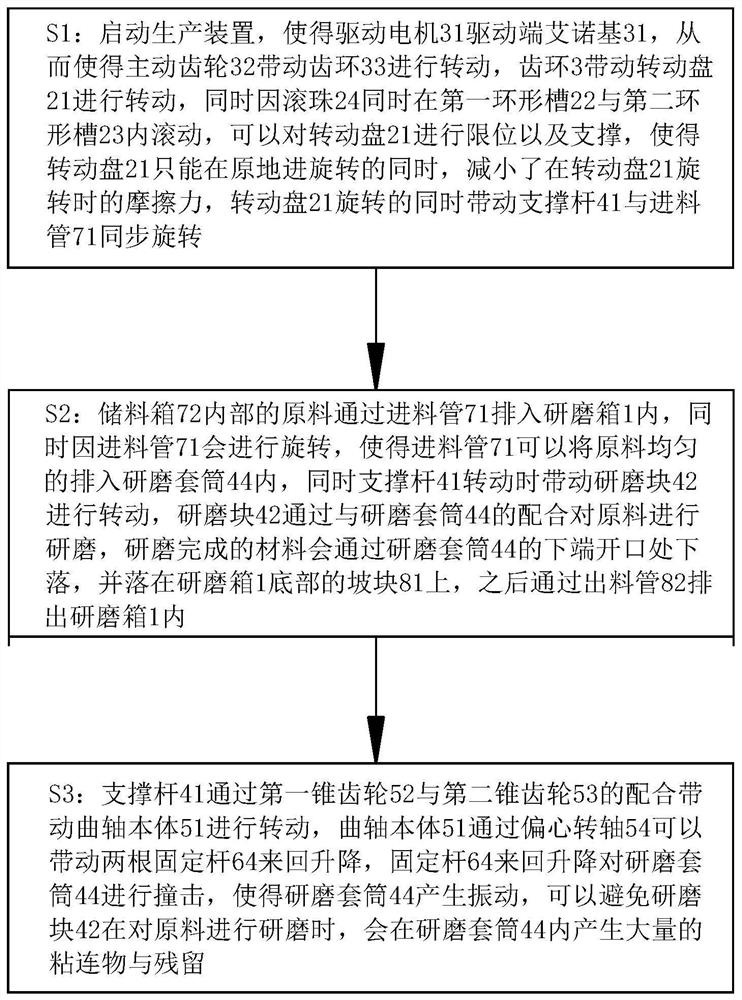

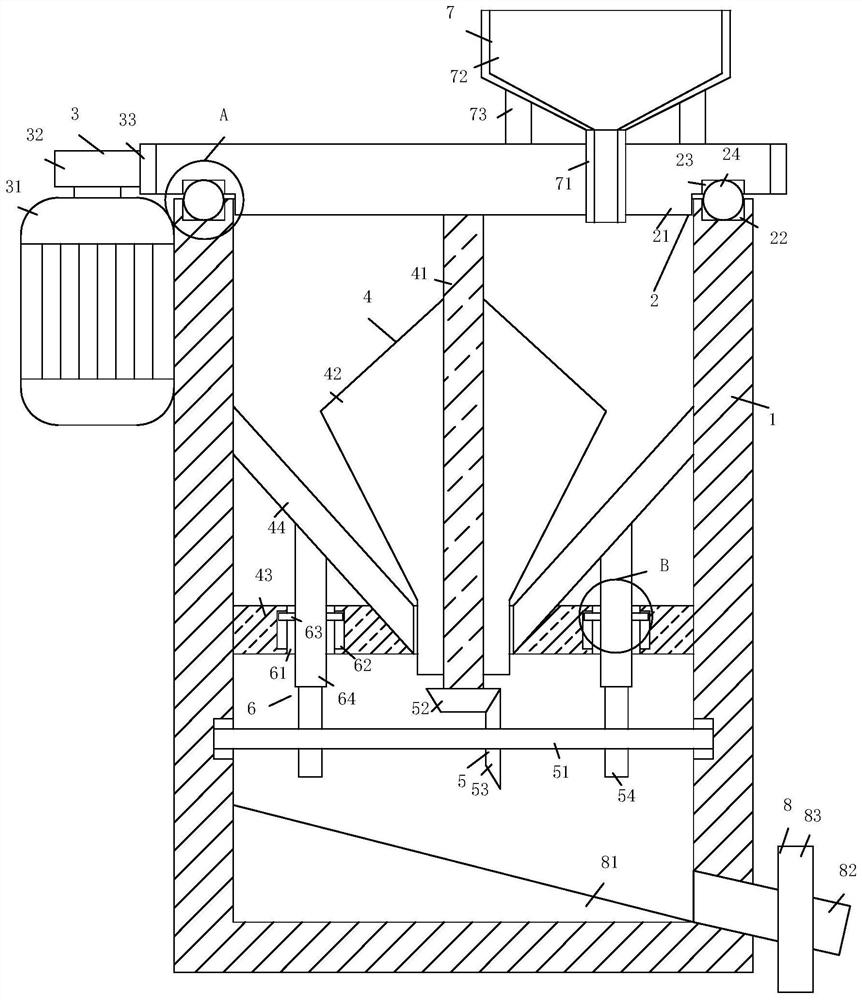

[0029] like Figure 1-Figure 6 Shown, a kind of experimental sodium hydroxide production technique of the present invention comprises the following steps:

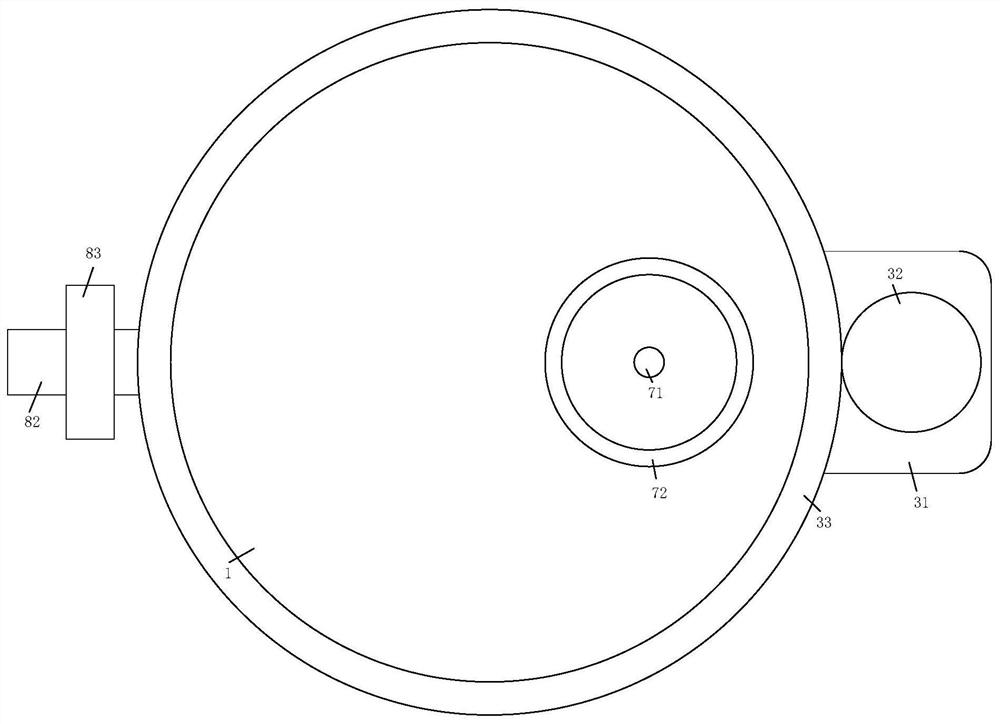

[0030] S1: Start the production device, so that the driving motor 31 drives the Ainoji 31, so that the driving gear 32 drives the gear ring 33 to rotate, and the gear ring 3 drives the rotating disc 21 to rotate, and at the same time, the ball 24 is in the first annular groove 22 and Rolling in the second annular groove 23 can limit and support the rotating disk 21, so that the rotating disk 21 can only rotate in situ, reducing the friction when the rotating disk 21 rotates, and the rotating disk 21 rotates Simultaneously drive the support rod 41 to rotate synchronously with the feed pipe 71;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com