Small-sized concrete block processing equipment

A technology for concrete blocks and processing equipment, applied in auxiliary molding equipment, clay preparation devices, manufacturing tools, etc., can solve the problems of slow production speed, time-consuming and laborious, etc., and achieve the effect of improving production efficiency, clear division of labor, and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

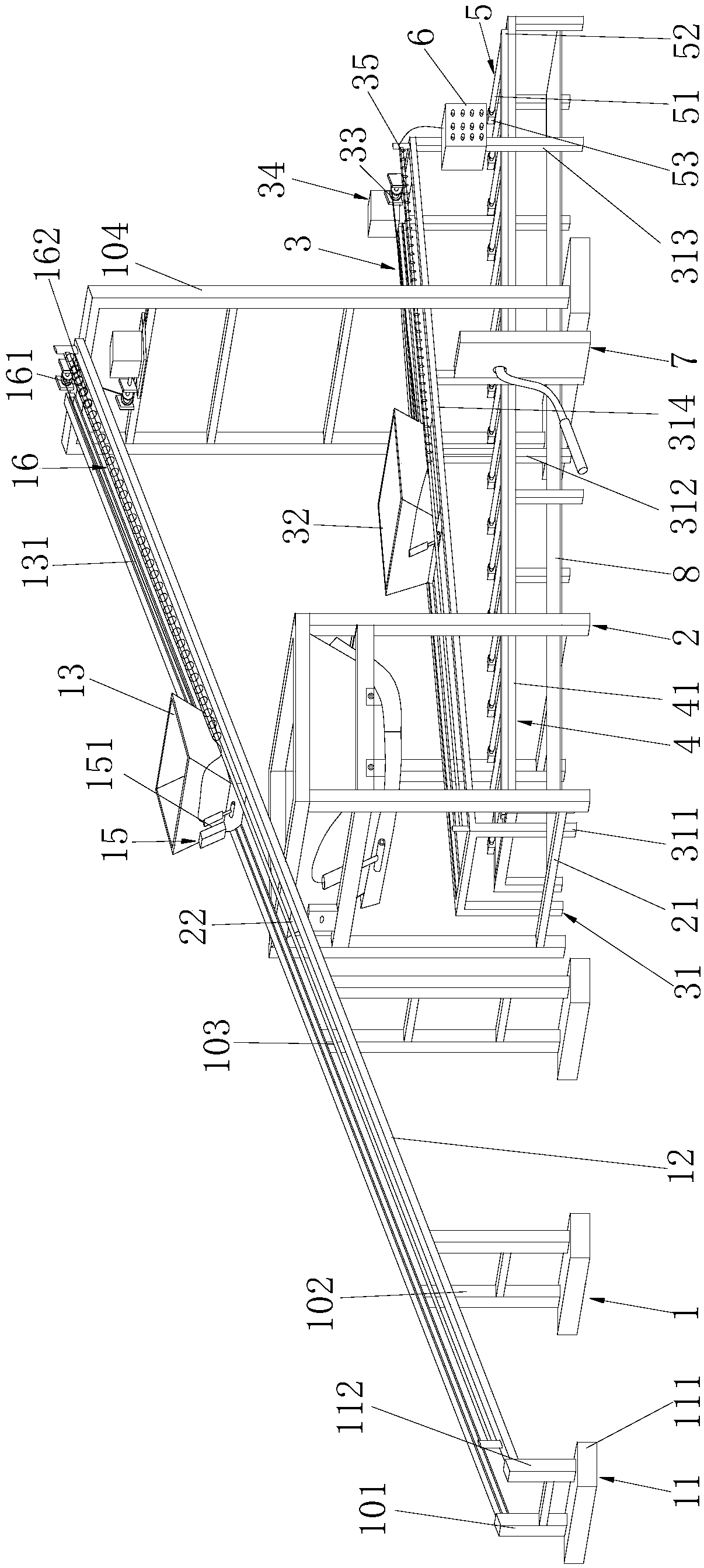

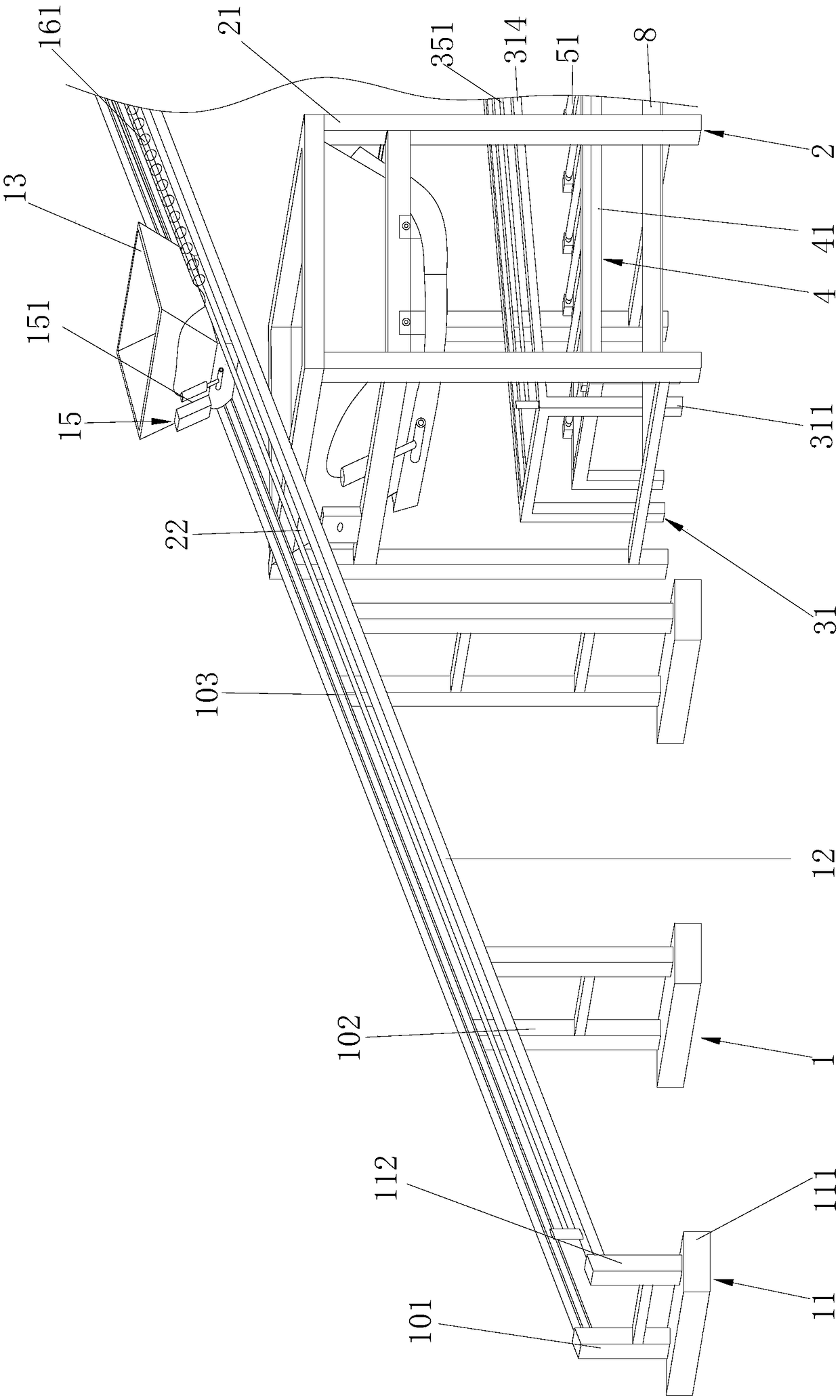

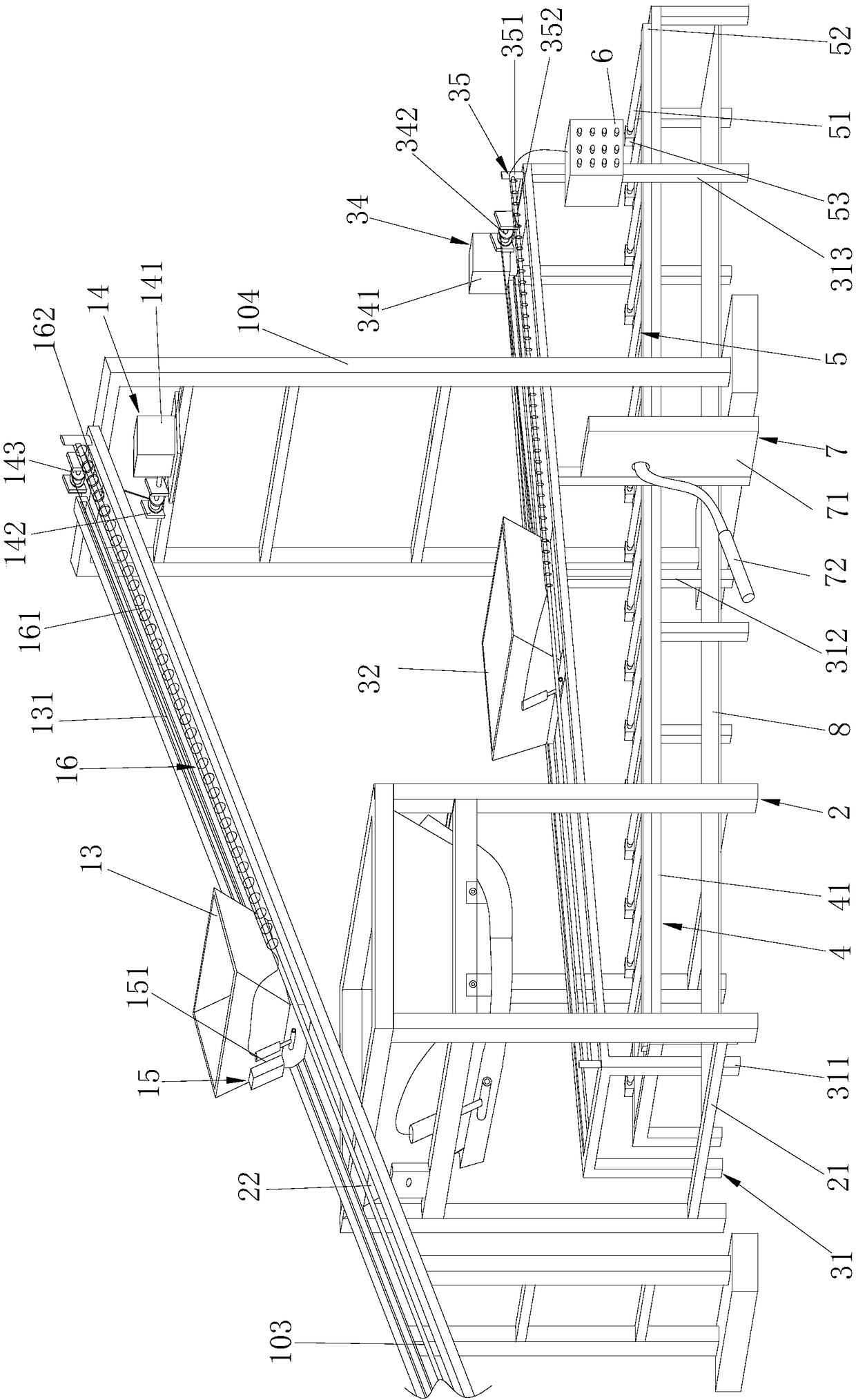

[0038] The present invention is described in detail below in conjunction with accompanying drawing:

[0039] combine Figure 1 to Figure 5 , a small concrete block processing equipment, including a feeding device 1, a storage device 2, a first feeding device 3 and a second feeding device 4. The feeding device 1 includes a plurality of feeding supports 11 , and upper ends of the plurality of feeding supports 11 are obliquely connected with a feeding slide rail 12 . A loading hopper 13 is slidably connected to the loading slide rail 12 , and the loading hopper 13 is connected to the first pulling mechanism 14 arranged on the upper end of the loading support 11 through a first steel cable 131 .

[0040] The material storage device 2 is arranged at the lower end of the feeding slide rail 12 , and the material storage device 2 includes a material storage bracket 21 on which a storage hopper 22 is arranged. The first feeding device 3 includes a first conveying frame 31 , and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com