Patents

Literature

185results about How to "Easy to wear out" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

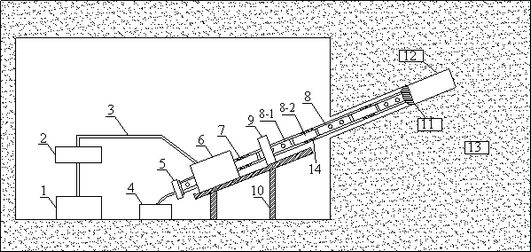

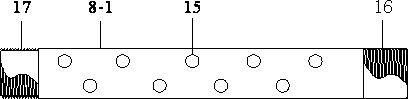

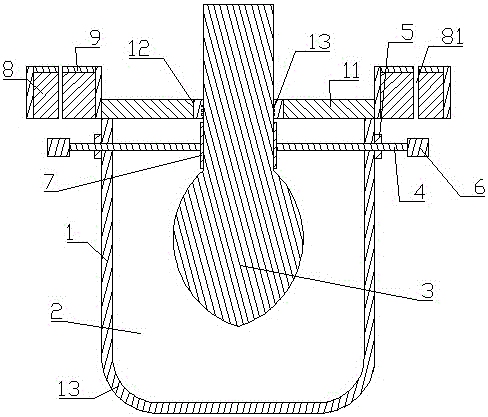

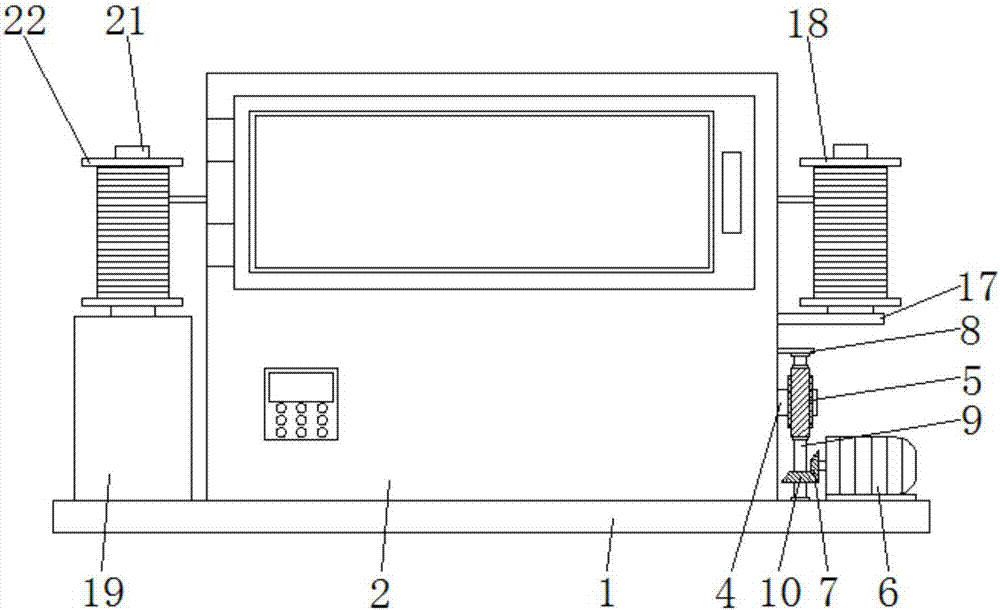

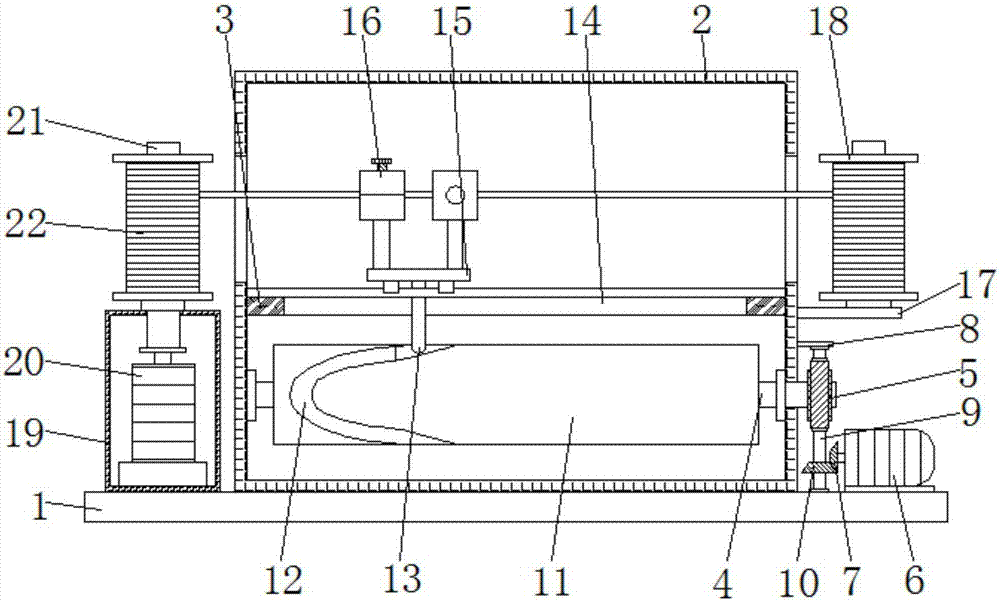

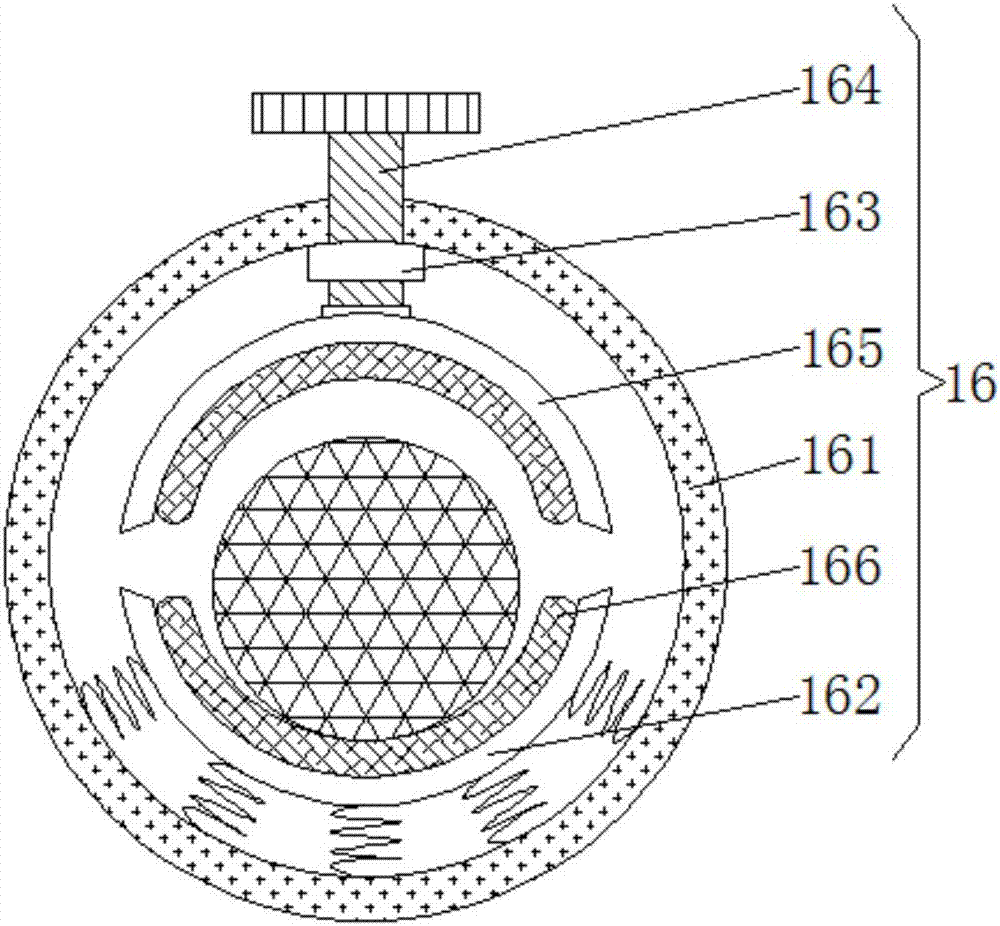

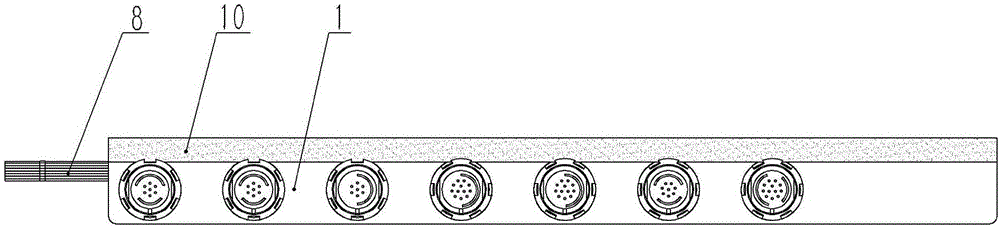

Gas extraction and drilling cooperative drilling and protecting integrated system for soft coal seams and process

ActiveCN102587828AOvercome the problem of frictional resistanceReduce displacementDrilling rodsGas removalHydraulic pumpAir compressor

A gas extraction and drilling cooperative drilling and protecting integrated system for soft coal seams and process belong to soft coal seam cooperative drilling and protecting systems and process. The gas extraction and drilling cooperative drilling and protecting integrated system mainly consists of a control table, a hydraulic pump station, an air compressor, a feeding device, a drill stem, a hole protecting tube, a drill bit and the like. The hole protecting tube is located in the drill stem, and the hole protecting tube and the drill stem are synchronously connected and drill cooperatively. The depth of a drilled hole is equal to the length of the hole protecting tube. Finally, the hole protecting tube penetrates through the drill bit, and the drill stem is withdrawn while the hole protecting tube is remained in the hole to realize functions of supporting a hole wall and extracting gas. The system and the process are convenient in operation, the hole protecting tube and the drill stem realize cooperative drilling and protecting, the hole protecting tube is easy to be remained in the drilled hole, problems that the hole collapses and the hole protecting tube is difficult to be fed to the drilled hole can be resolved, the hole protecting depth is high, the hole wall can be supported more effectively, deformation and collapse are prevented, accordingly high gas extraction concentration and flow of the soft coal seams are guaranteed, and the gas extraction and drilling cooperative drilling and protecting integrated system for soft coal seams and the process are particularly applicable to quite soft coal seams with the value of the firmness factor f smaller than 0,3.

Owner:CHINA UNIV OF MINING & TECH

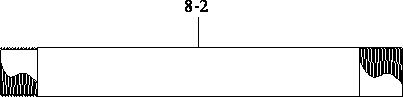

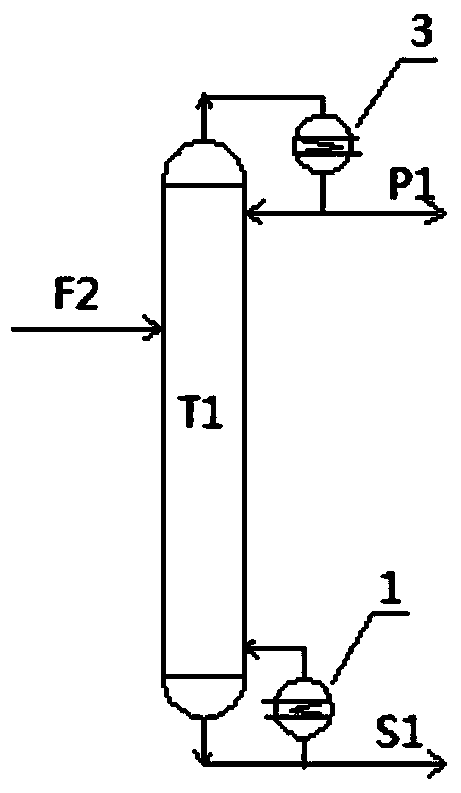

Method for separating ethyl acetate-ethyl alcohol compound

InactiveCN103467286AReduce dosageEasy to recycleOrganic compound preparationCarboxylic acid esters preparationExtractive distillationEthyl acetate

The invention provides a method for separating ethyl acetate-ethyl alcohol, which comprises the following steps: adopting ethyl acetate-ethyl alcohol compound in any proportion as a raw material, taking ionic liquid or a double solvent composed of ionic liquid and an organic solvent as an extraction agent, and extracting ethyl acetate and ethyl alcohol in sequence after the raw material goes through an extractive distillation stage and an extraction agent recycle stage, wherein the extraction agent is used circularly after being extracted in the recycle stage. Compared with the prior art, the new method has the advantages that the energy can be conserved by more than 40%, the environment pollution can be avoided, the product purity is high, the industrialization is facilitated, the equipment cost is low, and the economic benefit is good.

Owner:TIANJIN CLEANTECH TECH

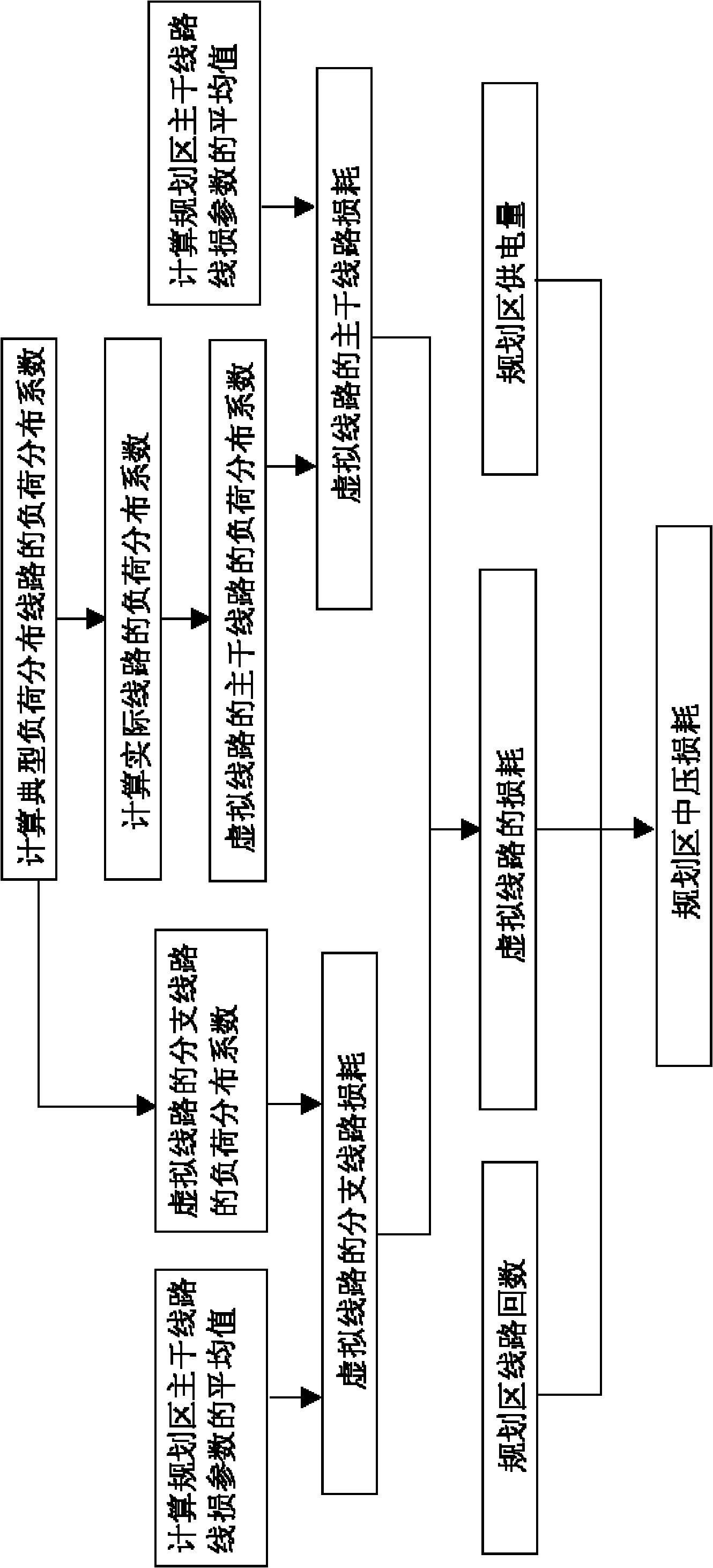

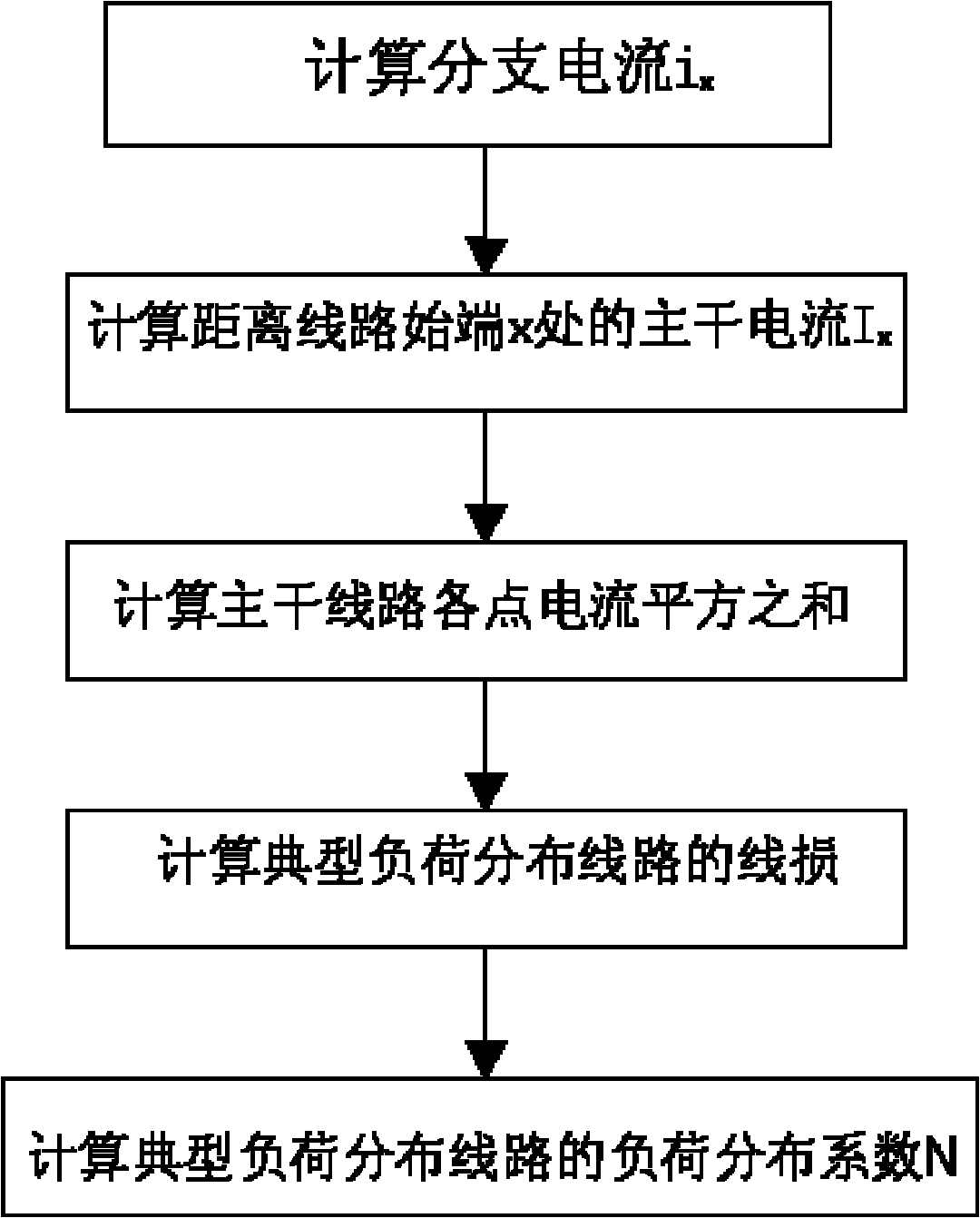

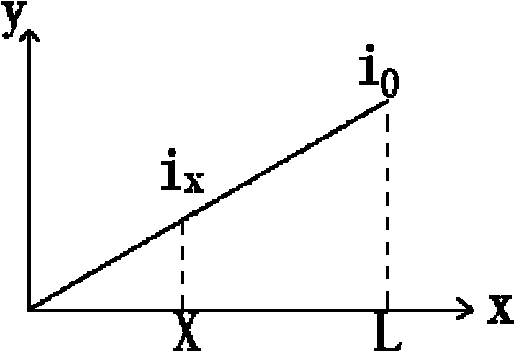

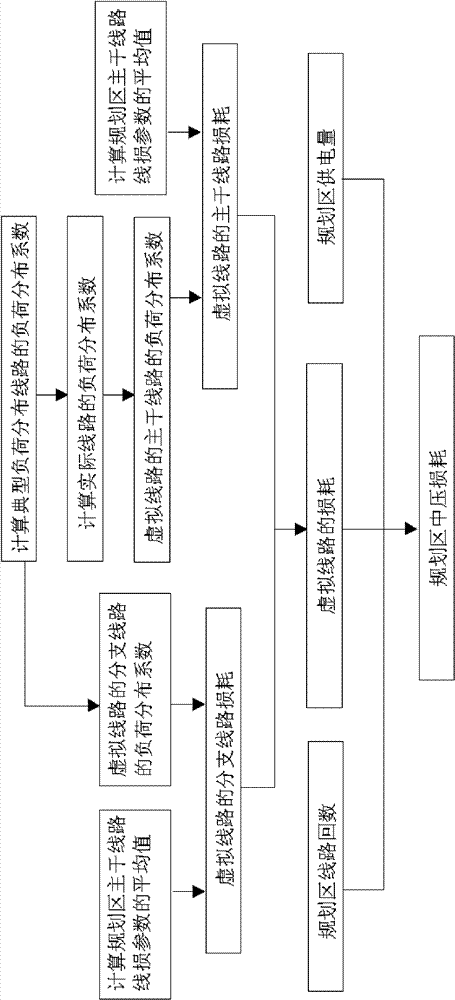

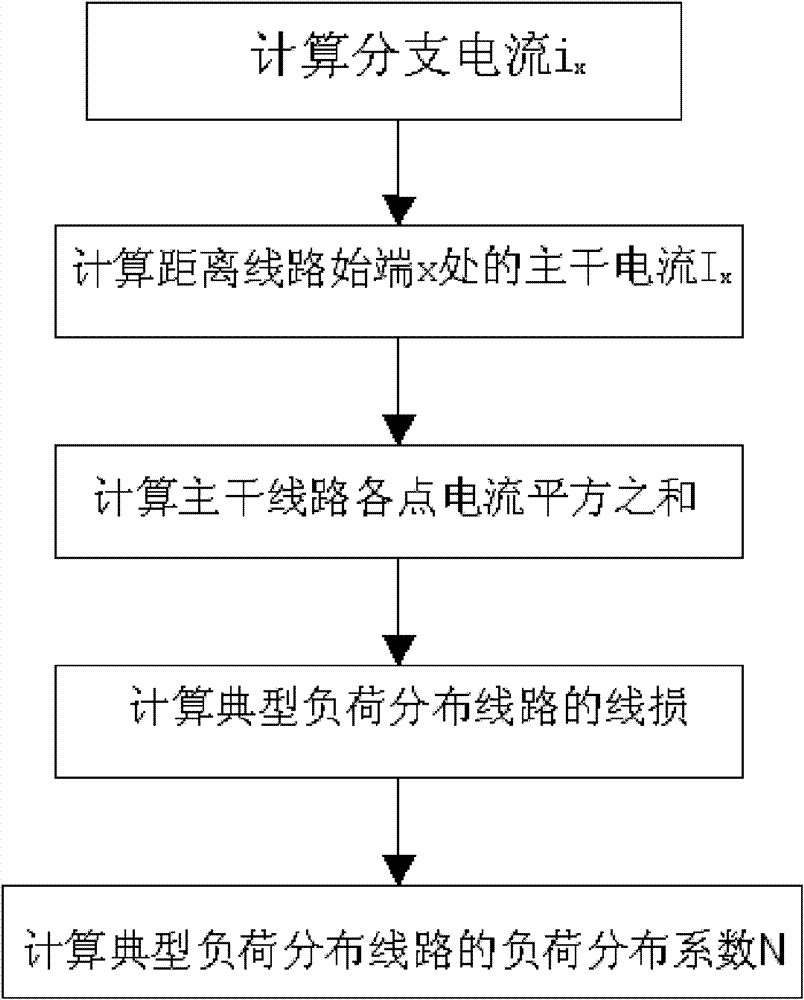

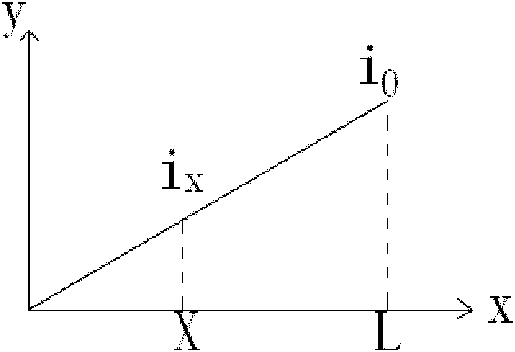

Load distribution based method for calculating recently planned annual line loss of medium-voltage distribution network

ActiveCN102033999AEasy to wear outSolving complex and time-consuming problemsSpecial data processing applicationsLoad distributionComputer science

The invention relates to a load distribution based method for calculating recently planned annual line loss of a medium-voltage distribution network. The method comprises the following steps of: (1) calculating a load distribution coefficient of a typical load distribution line; (2) calculating a load distribution coefficient of an actual line; (3) virtualizing a return line, wherein parameters related to line loss calculation are all average parameters, and the loss of the return line is used as the average loss of the medium-voltage line of the planning area; (4) calculating the loss of a trunk line of the virtual line; (5) calculating the loss of a branch line of the virtual line; and (6) calculating the loss of the medium-voltage line in the planning area. The method has reasonable design, solves the problem that the failure of acquisition of the load data of a recently planned annual distribution network causes difficulty in line loss calculation, realizes the quick estimation of the line loss of the whole planning area and has the characteristics of simple operation, easier obtaining of collected data and short calculation time.

Owner:TIANDAQIUSHI ELECTRIC POWER HIGH TECH CO LTD

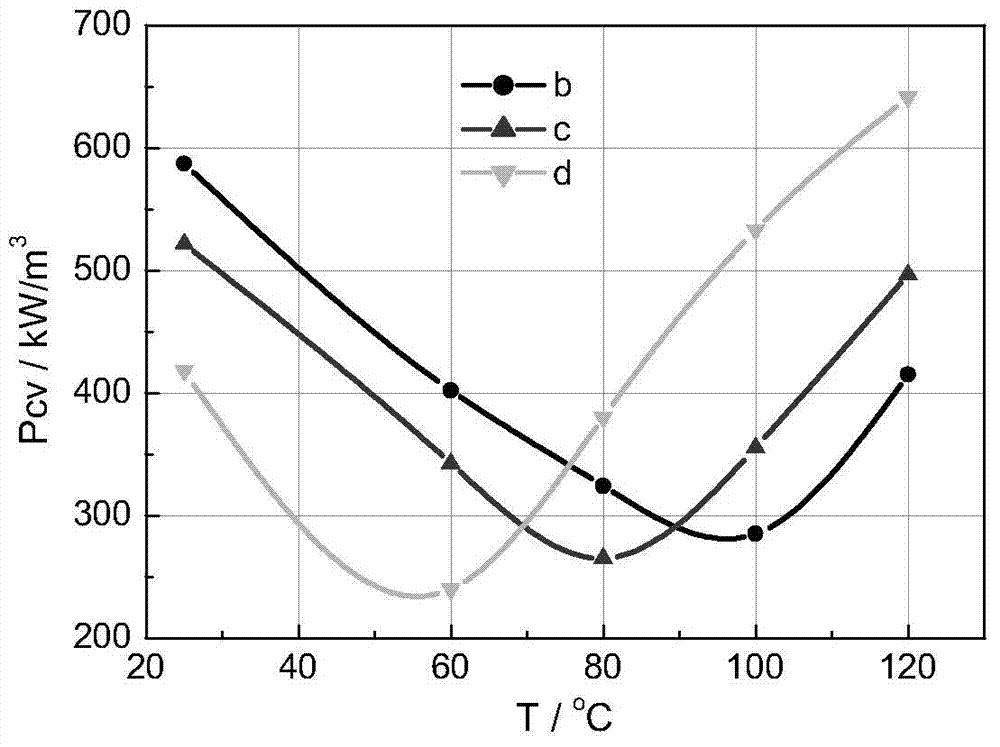

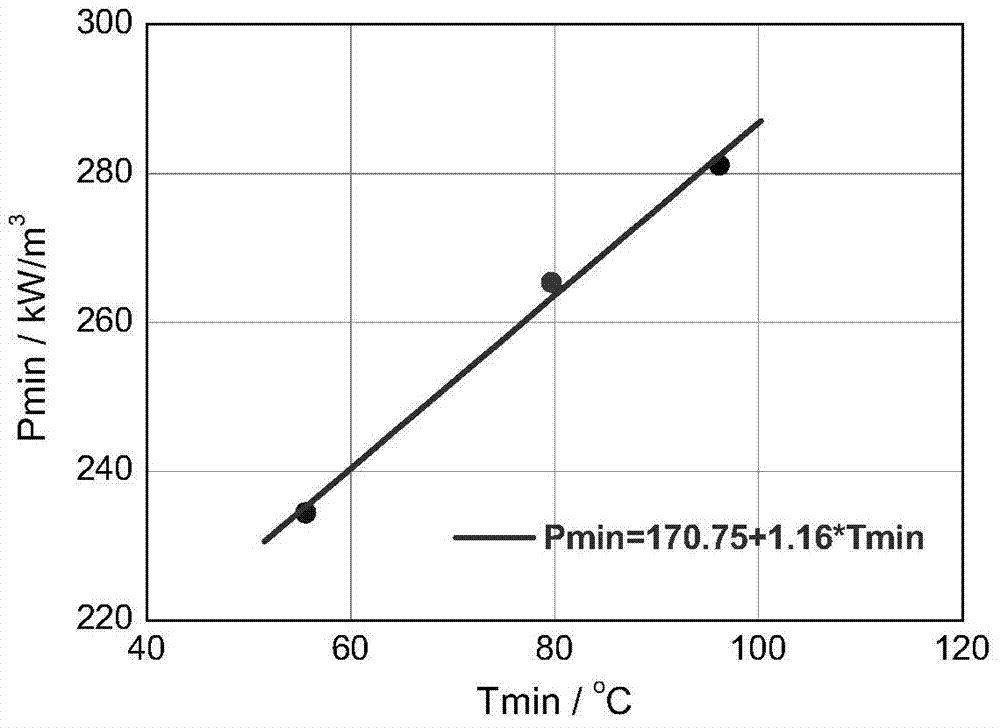

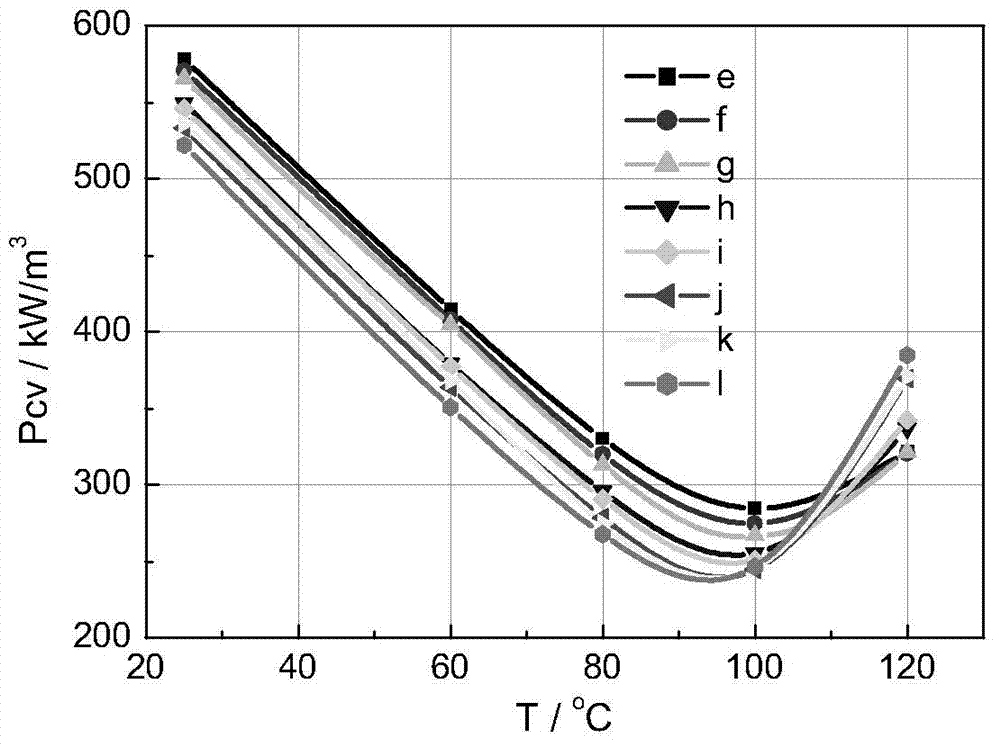

Preparation method of ultra-low-loss MnZn power ferrite material

The invention provides a preparation method of an ultra-low-loss MnZn power ferrite material. The method has ultra-low power consumption and is prepared by the method comprising the following steps of: getting 68 to 72wt% of Fe2O3, 6 to 9wt% of ZnO, and the balance of Mn3O4 in percentage by weight as the raw materials, and then performing batching, grinding for the first time, pre-sintering, grinding for the second time, granulating, molding, sintering and other processes. The manufacture method is innovated in that the bias of the prior art that increase of Fe2O3 leads to obvious lowering of two-peak temperature is removed, and little Fe2O3 is added during grinding for the second time so that the effect of obviously reducing the power consumption and slightly lowering the two-peak temperature is realized, and thus ultra-low loss at the temperature of 100 DEG C can be achieved.

Owner:江门安磁电子有限公司

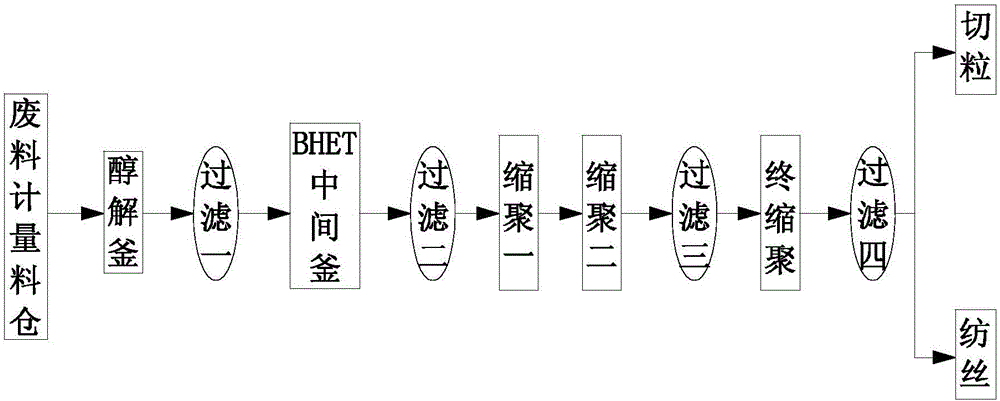

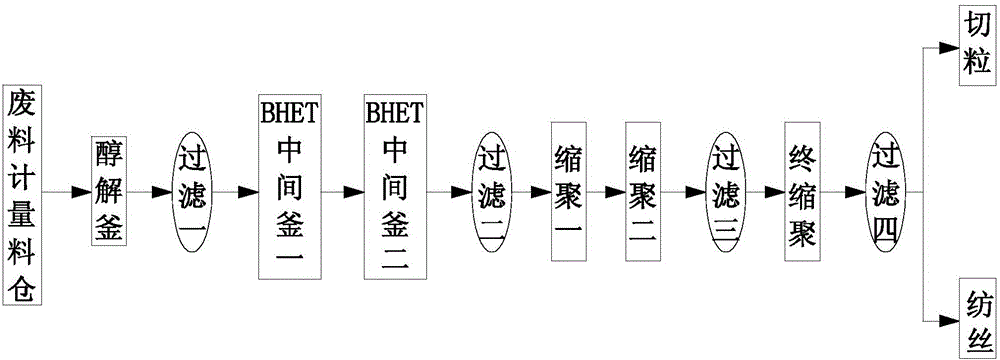

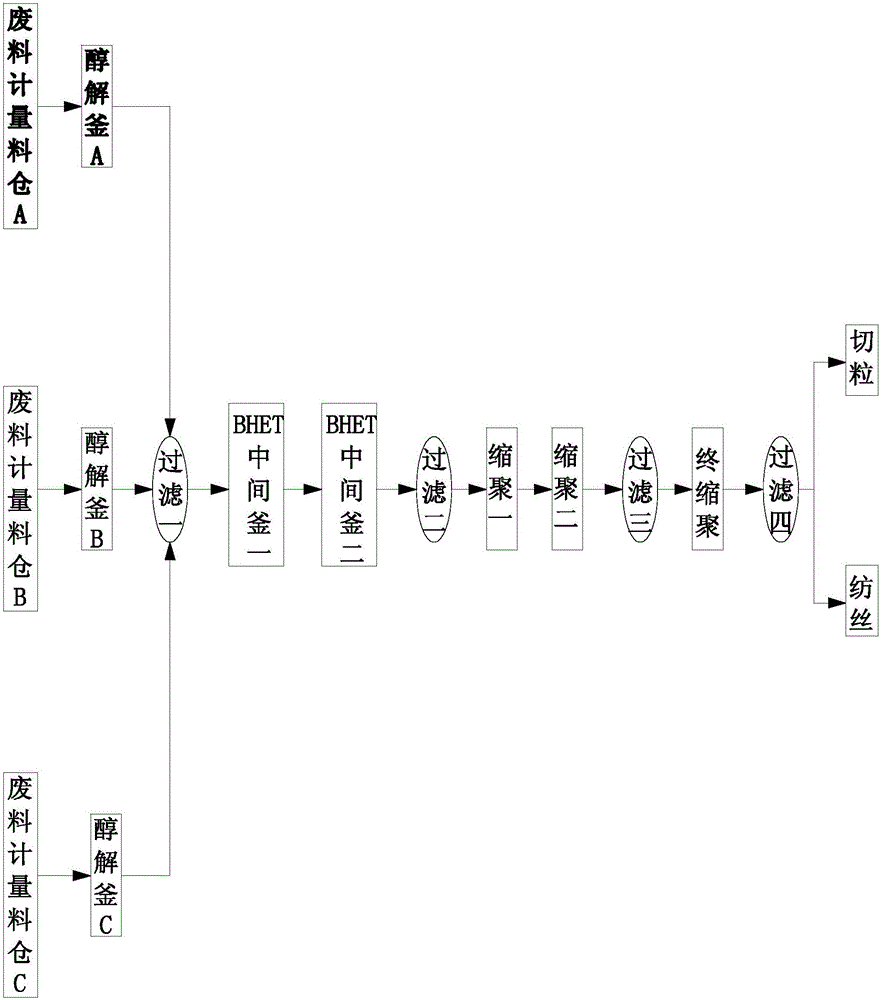

Recycling and regenerating process for waste textile containing polyester

The invention relates to a recycling and regenerating process for waste textile containing polyester and belongs to the technical field of polyester waste. The collected waste is smashed, rinsed, filtered, dried and metered so that finished products can be formed. The waste is dried after being smashed, rinsed and filtered, the waste is metered and conveyed into an alcoholysis kettle to complete alcoholysis and then is conveyed into a BHET middle kettle to react, then the waste is conveyed into a polycondensation kettle to complete polycondensation, and the finished products are formed through final polycondensation; and according to the alcoholysis process, the temperature of mother liquid ranges from 210 DEG C to 250 DEG C, and the reaction time ranges from 30 min to 5 h; the whole processing process is divided into four-stage filtering, the first-time filtering is completed after alcoholysis, the second-time filtering is completed after the reaction of the BHET middle kettle, the third-time filtering is completed after polycondensation, and the fourth-time filtering is completed after the final polycondensation, filter elements for four-stage filtering are 10-50 microns, and the filtering precision is sequentially improved from the first-time filtering to the fourth-time filtering. The recycling and regenerating process for the waste textile containing polyester is applied to waste silk and other polyester products and has the beneficial effects of being low in cost, short in process, high in quality, free of pollution and the like.

Owner:ZHEJIANG LUYU ENVIRONMENTAL PROTECTION

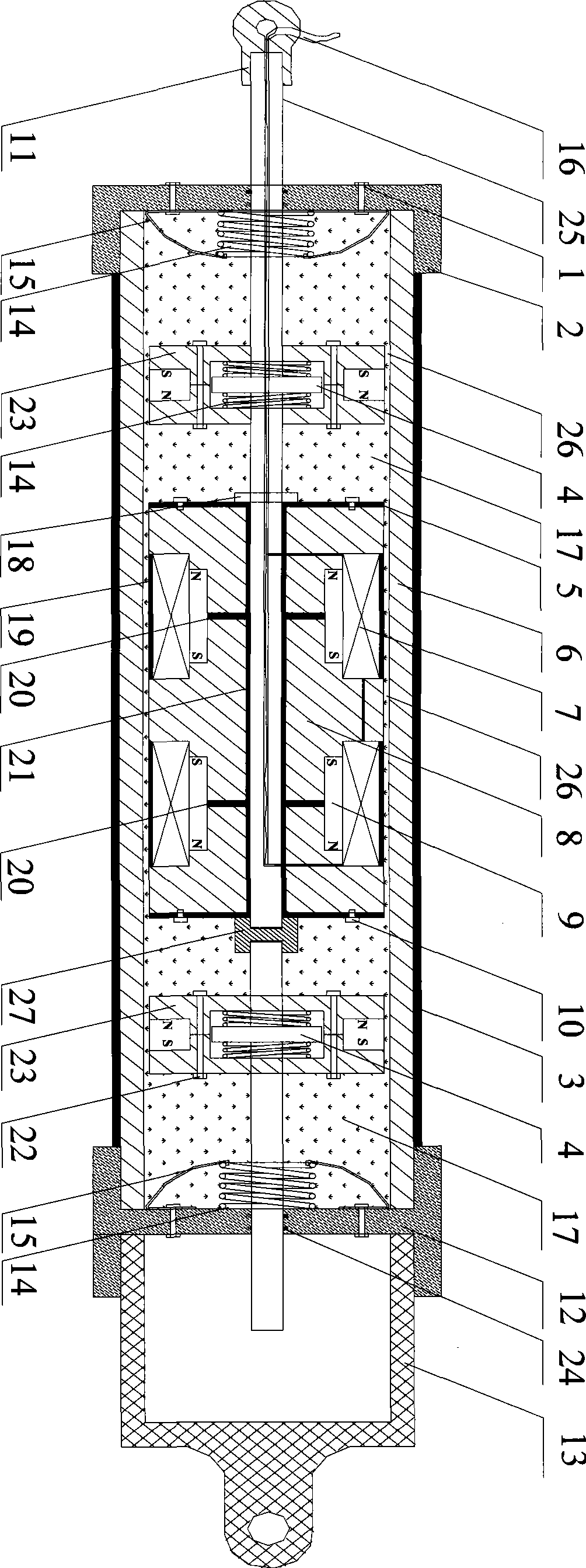

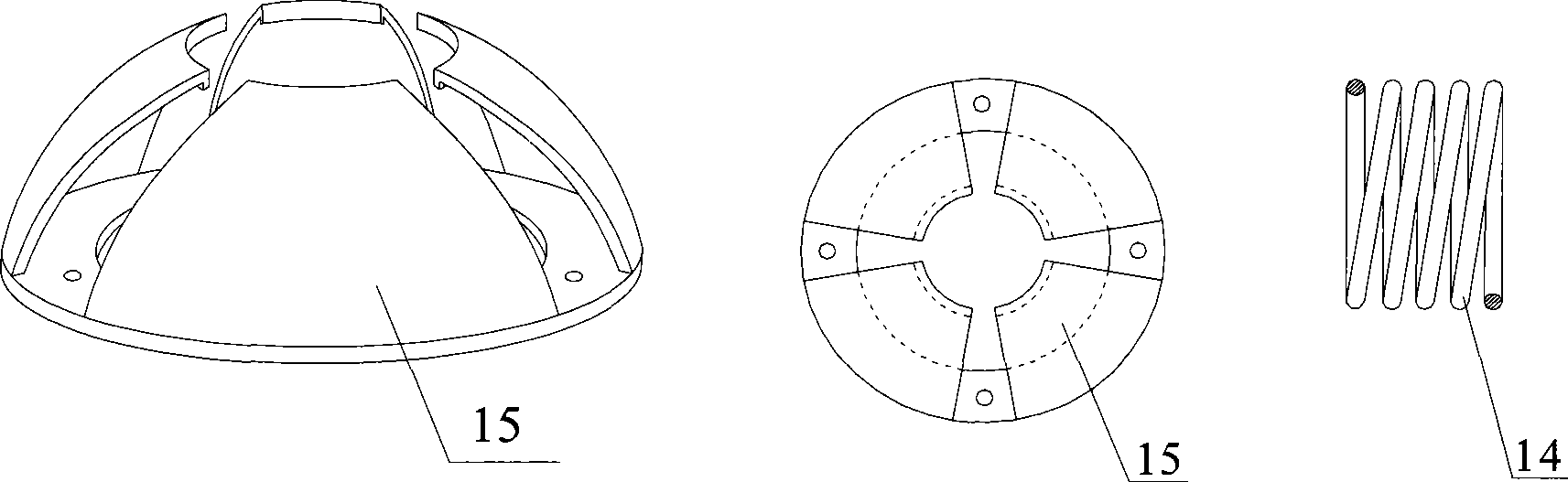

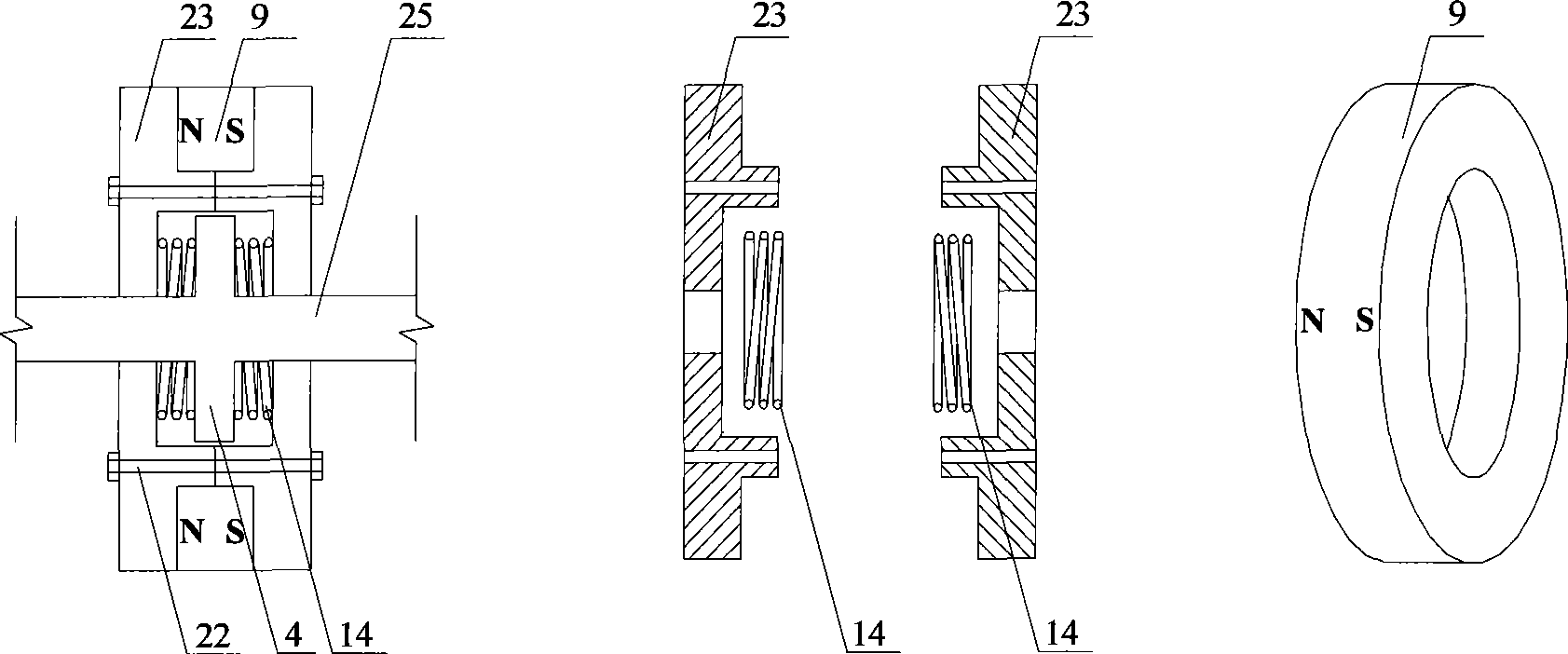

High-energy consumption self-decoupling magnetorheological damper

The invention relates to a high-energy consumption self-decoupling magnetorheological damper with damping force decoupling property and failure self-protection function. The damper not only has high energy consumption and output, but also can effectively prevent subsidence of magnetorheological fluid, therefore, the invention is suitable for civil engineering structures. The damper mainly comprises a master cylinder body (6), an auxiliary cylinder body (13), a main piston (8), two auxiliary pistons (23), a piston rod (25), and novel composite-structure energy accumulators (14 and 15). Permanent magnets (9) arranged in the main piston (8) and the two auxiliary pistons (23) can effectively prevent subsidence of magnetorheological fluid, and can still provide corresponding damping force under the condition of power supply failure to enhance the safety of the structure. Magnetic circuit guiding components improve the utilization factor of the magnetic field. A mechanical spring self-decoupling device is mainly operated on the condition that the damper is under low-frequency driving, thereby overcoming the disadvantage of low output of the damper under low-frequency driving.

Owner:HOHAI UNIV +1

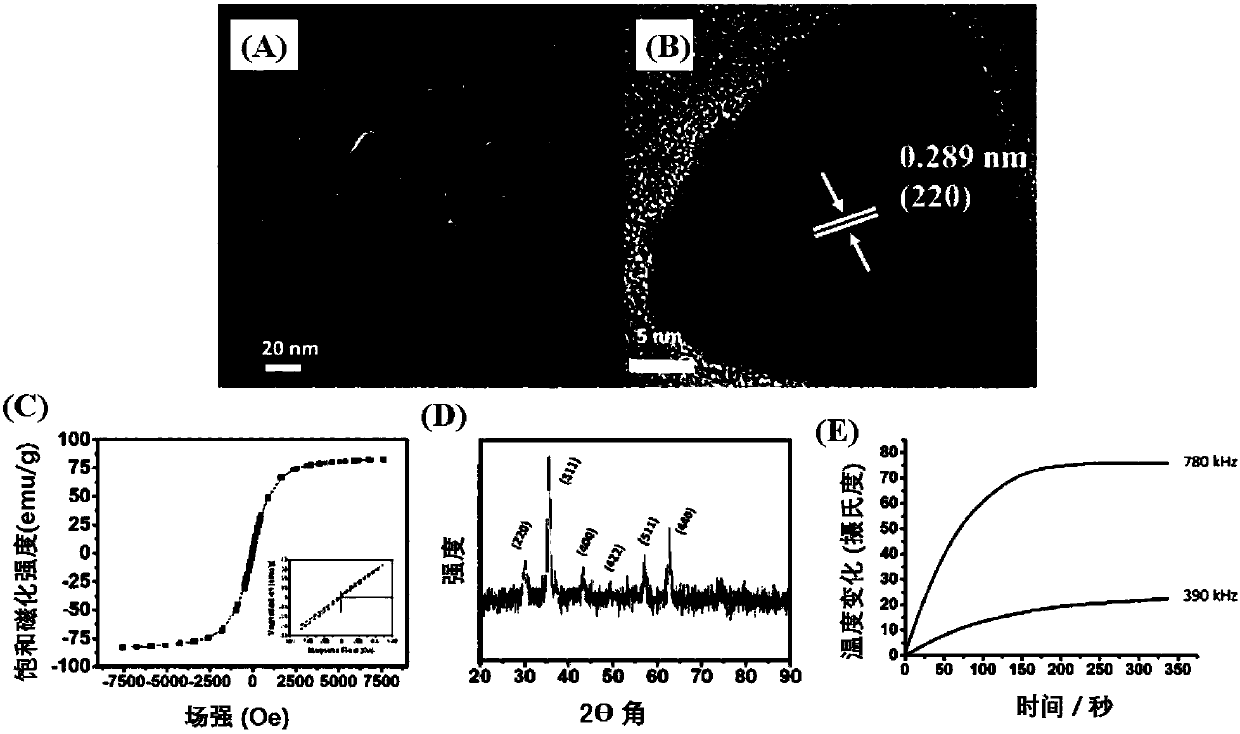

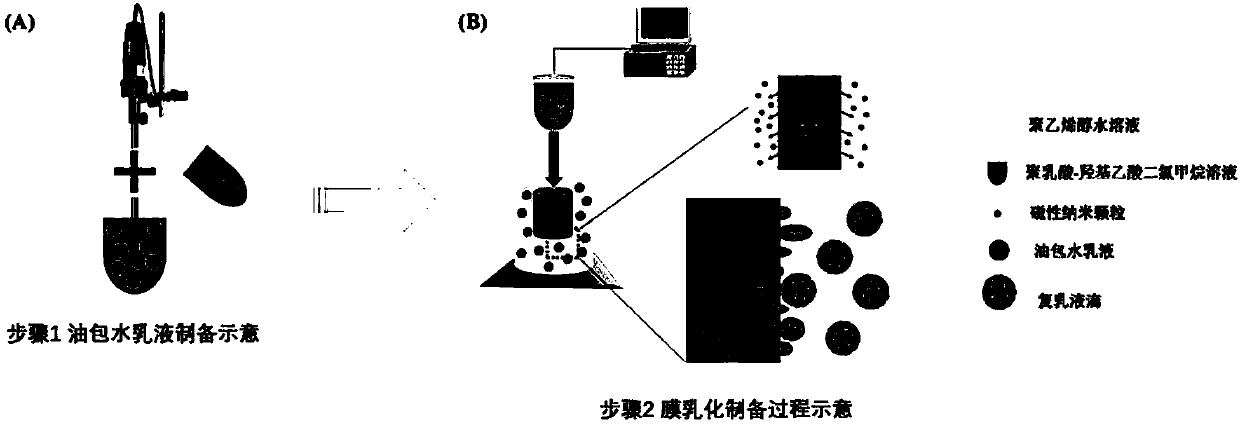

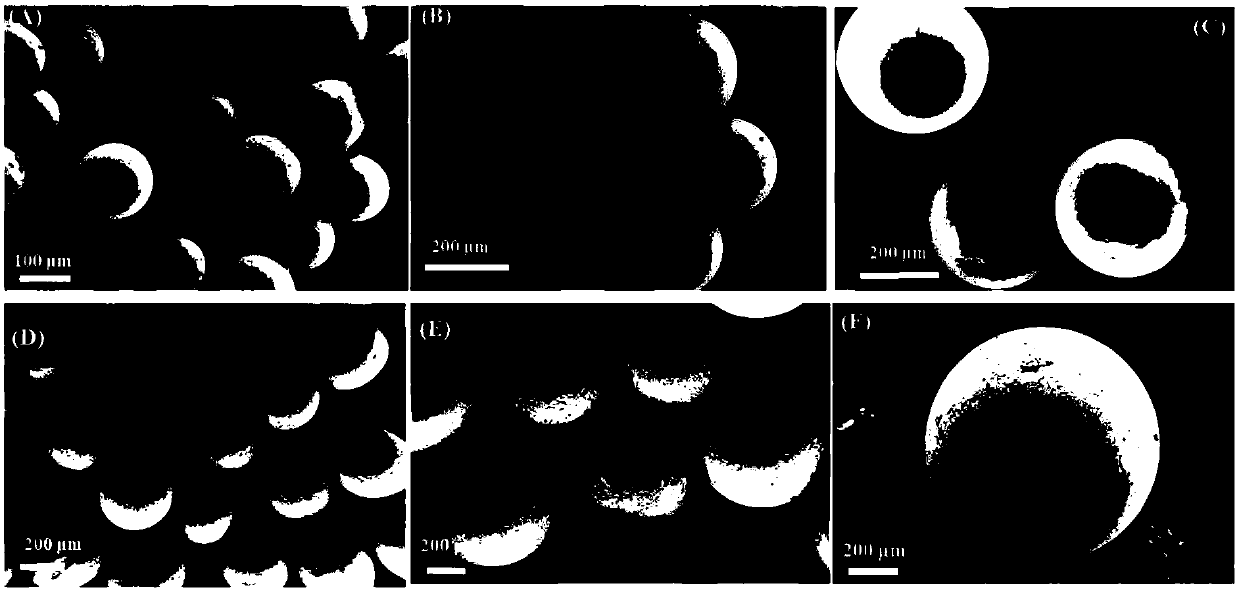

Preparation method of magnetic induction hyperthermia embolism microspheres

ActiveCN107661499ABlocking supportWon't leakEnergy modified materialsPharmaceutical non-active ingredientsPolyvinyl alcoholMicrosphere

The invention discloses a preparation method of magnetic induction hyperthermia embolism microspheres. The preparation method comprises the following steps of by taking a dissolved matter obtained bydissolving biodegradable high molecular polymers with low transition temperature and super paramagnetic Fe3O4 nano-particles into dichloromethane as an oil phase, Span 80 as a surfactant and an aqueous solution dissolved with polyvinyl alcohol (PVA) as an internal water phase, dropwise adding a water phase in the oil phase under the conditions with low temperature and high shearing to form primaryemulsion; placing the primary emulsion in a membrane emulsification instrument for membrane emulsification under the low temperature condition; forming multiple emulsion in a continuous phase of an external water phase PVA after the primary emulsion permeates a membrane, and performing low-temperature solidification to obtain the magnetic induction hyperthermia embolism microspheres which meet the demand for clinic size. The obtained microspheres are arbitrarily adjustable in size in a range from 100 microns to 1000 microns, can realize rabbit orthotopic liver cancer model embolism hyperthermia under guidance of iconography and have potential application in the interventional hyperthermia field of orthotopic tumors.

Owner:SOUTHEAST UNIV

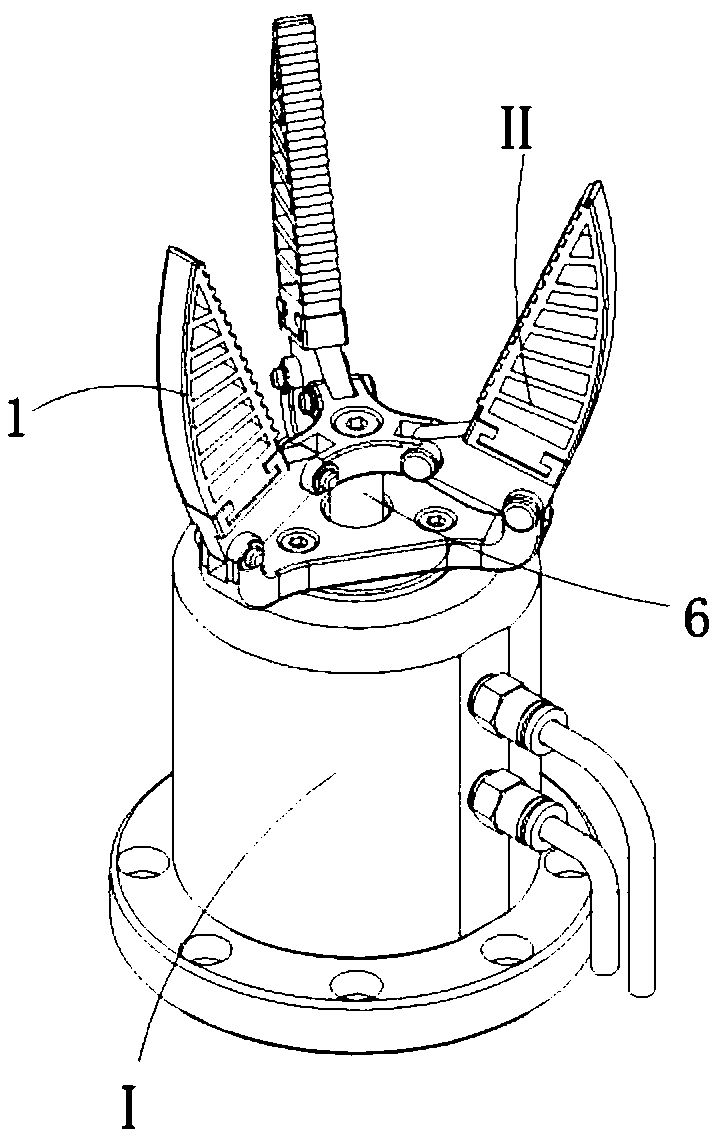

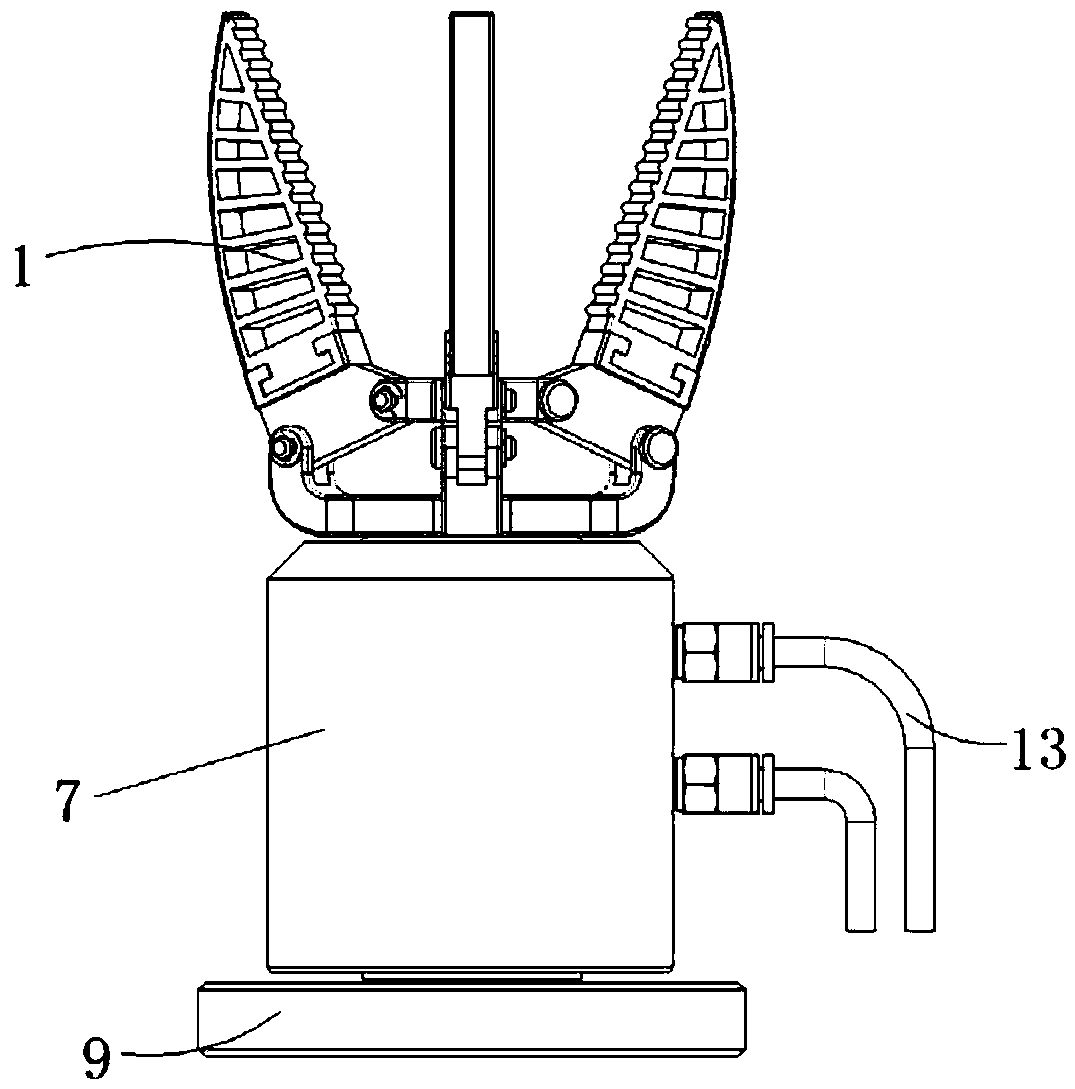

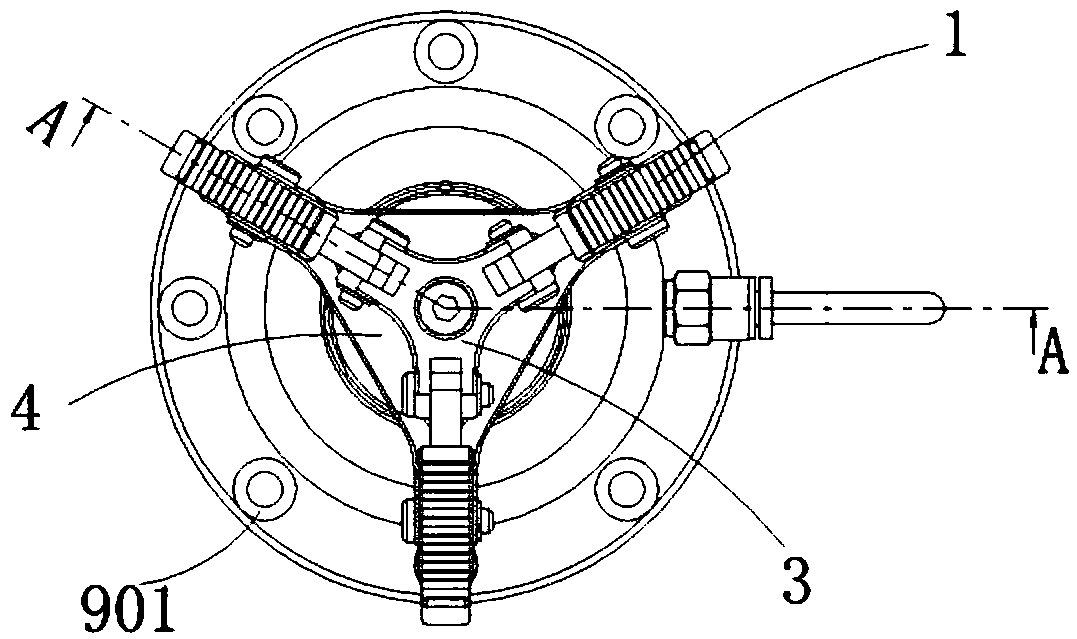

Flexible clamping jaw

The invention relates to a flexible clamping jaw comprising a cylinder driving mechanism and a clamping jaw assembly movably arranged on the cylinder driving mechanism. The cylinder driving mechanismcomprises a cylinder body and a gas guide ring rotationally arranged on the periphery of the cylinder body. A piston is arranged in the cylinder body. A support is arranged on the upper portion of thecylinder body, and the piston penetrates through the support. A connecting rod is connected to the upper end of the piston. The clamping jaw assembly comprises a clamping jaw fixing seat and clampingjaws. One end of the clamping jaw fixing seat is hinged to the support. The other end of the clamping jaw fixing seat is hinged to the connecting rod. An upper flow guide hole and a lower flow guidehole are formed in the cylinder body. The gas guide ring is provided with gas pipe connectors communicating with the upper flow guide hole and the lower flow guide hole. A valve-controlled gas channelis arranged outside the flexible clamping jaw to drive the clamping jaws to move, thus the rubber clamping jaws clamp an object, under the circumstance of extrusion, the clamping jaws generates self-adaptive deformation to be tightly attached to the surface of the grabbed object into a package state, meanwhile a pipeline on the gas guide ring is not wound due to rotation when the cylinder body rotates, and the original direction and state are maintained all the time.

Owner:SUZHOU QIAOYUE SOFTWARE

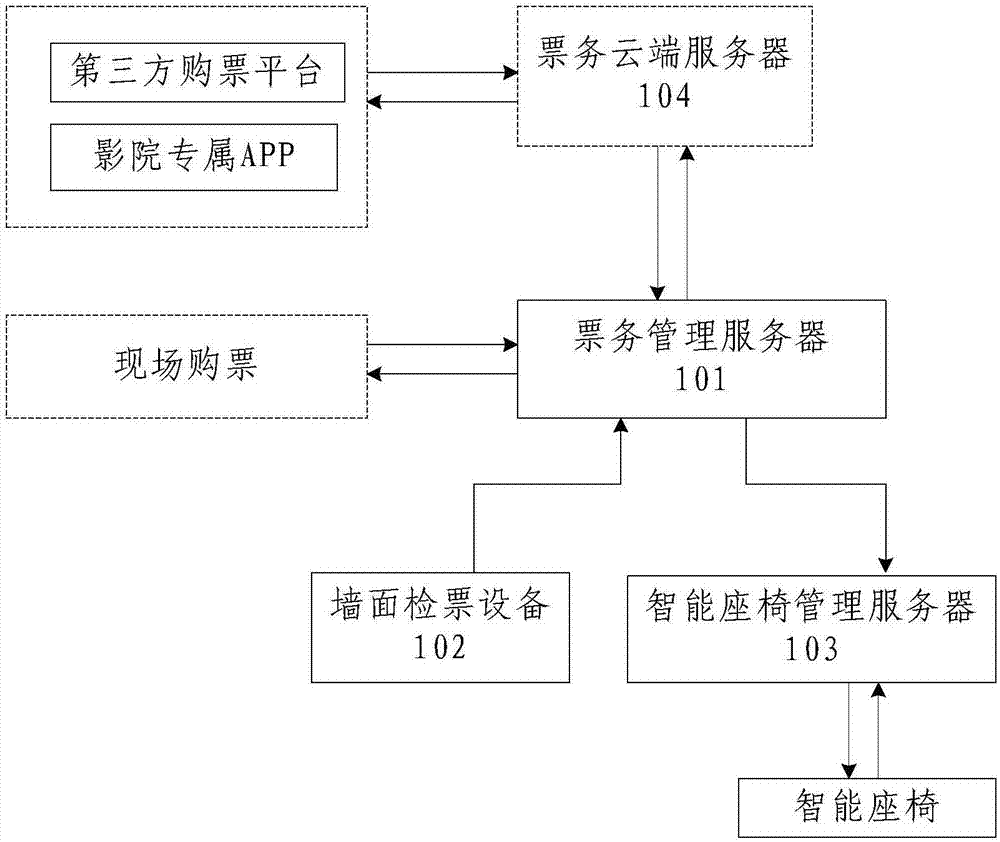

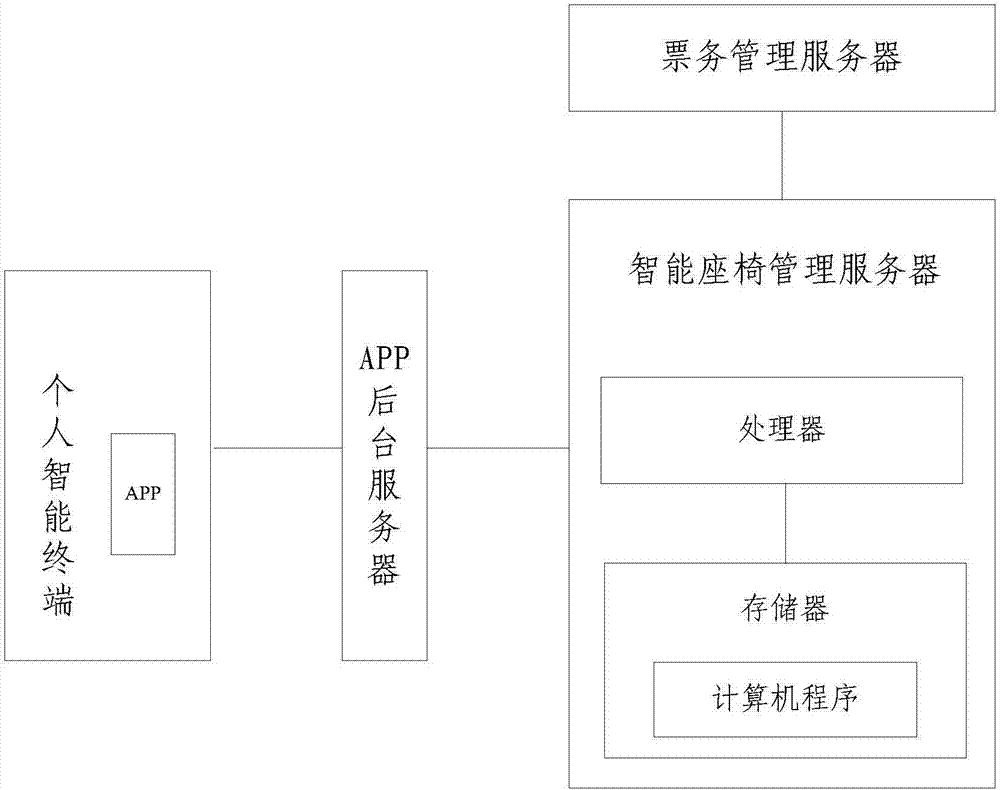

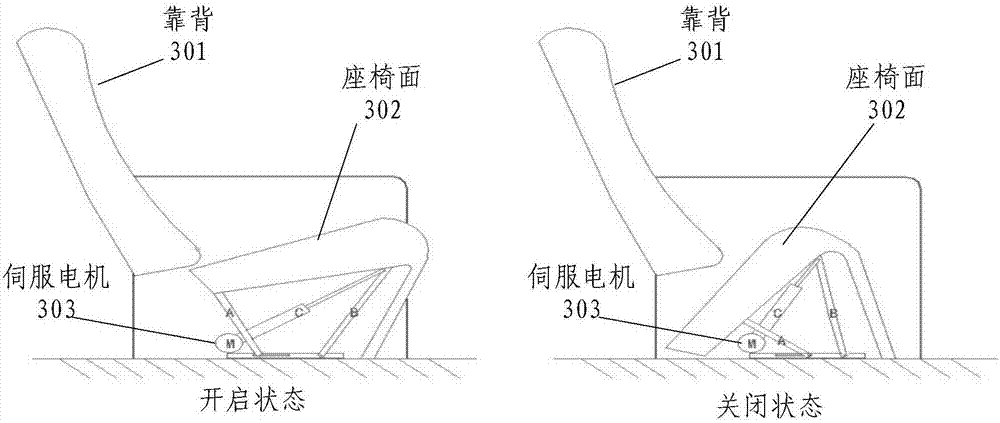

Intelligent seat, intelligent seat management server and control system

PendingCN107087919ASimple service modelService mode autonomyStoolsChairsControl systemControl engineering

The embodiment of the invention provides an intelligent seat which comprises a backrest, a seat face and a servo motor; support parts and a telescopic part are arranged under the seat face; and the support parts can support the seat face to bear weight, can also be mutually matched and acted with the telescopic part through mechanical connection and drives the seat face to carry out rotation drift motion relative to the backrest under the driving of the servo motor. Such structure form enables the starting and closing process of the intelligent seat to be finished within an own space of the seat face only without involving a space in which a user is located and harming the user; and in addition, the whole realization process is relatively soft, so that loss cannot be produced on the seat nearly. In addition, the embodiment of the invention also provides an intelligent seat management server and a control system, capable of changing the traditional service mode needing admission for watching by ticket only, realizing a self-service type watching mode of zero waiting without ticket checking by queuing and intelligent management and improving watching experience of the user.

Owner:北京中翰晟嘉文化传播有限公司

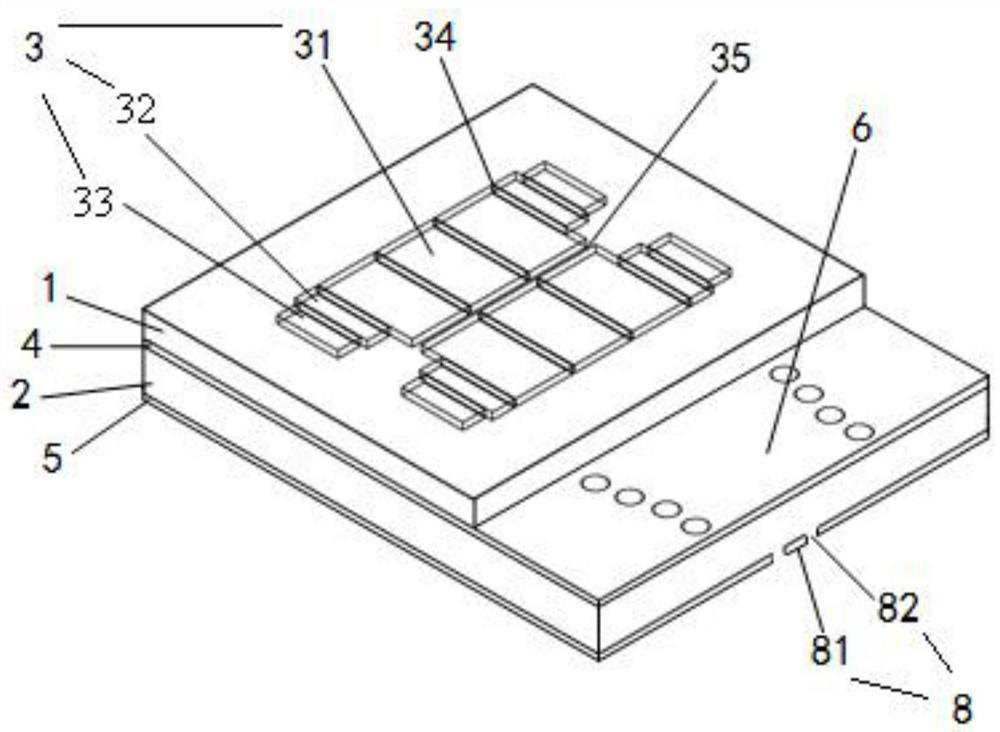

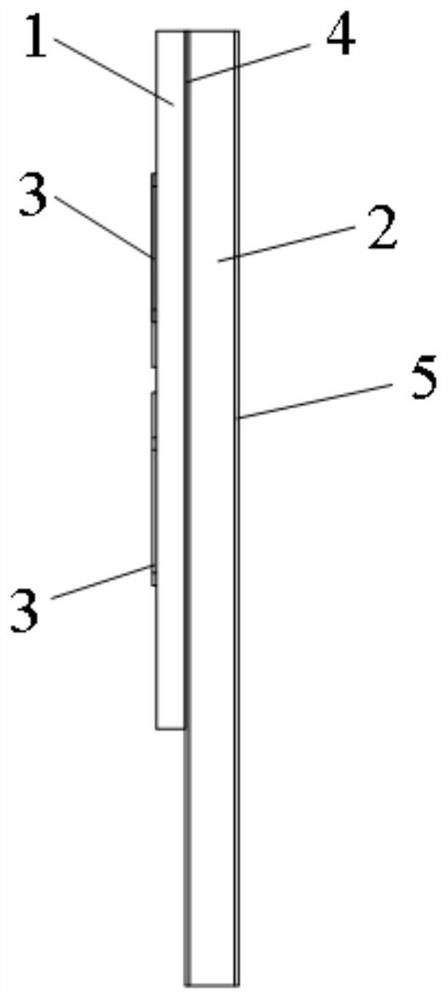

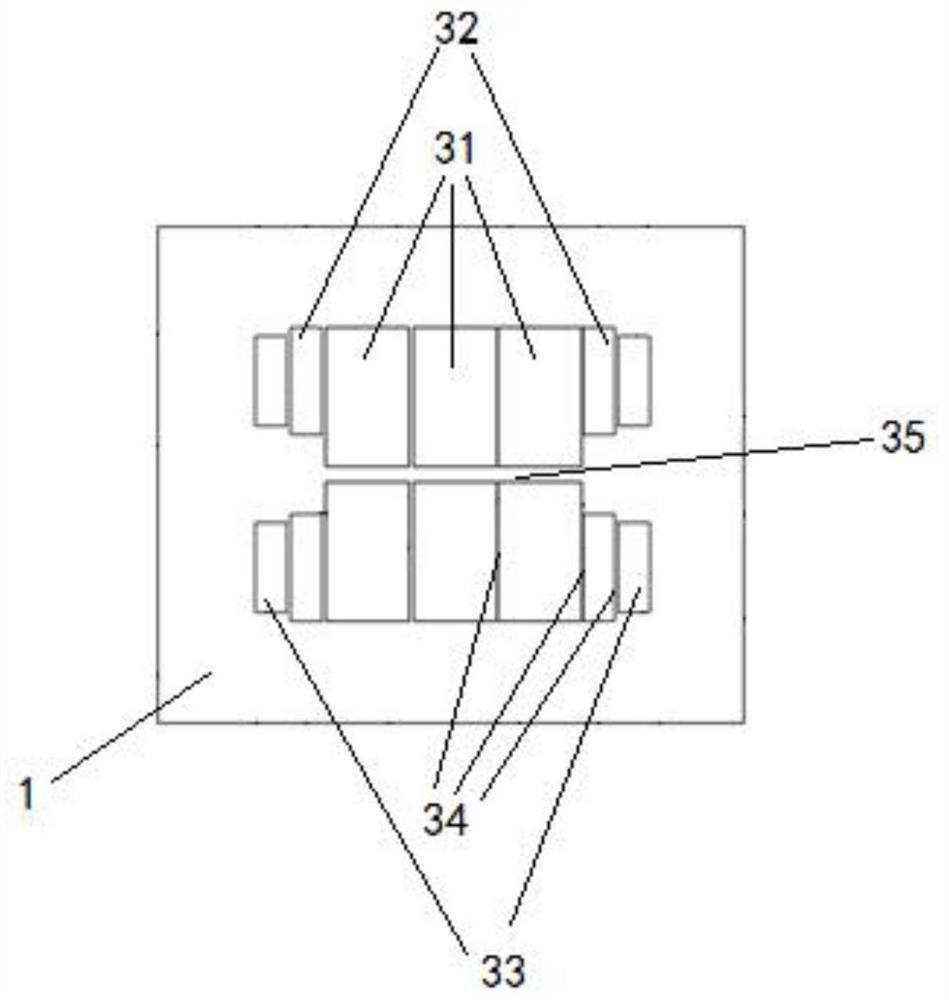

Electric vehicle power battery heat management device based on semiconductor refrigeration technology

PendingCN107732359AUnified functionReduce thermal management related componentsCell temperature controlBatteriesHeat transfer efficiencySemiconductor

The invention relates to an electric vehicle power battery heat management device based on a semiconductor refrigeration technology. The electric vehicle power battery heat management device is arranged in a battery cell module, and a gap is reserved between the heat management device and the battery cell. The electric vehicle power battery heat management device comprises a semiconductor chillingplate, two fixedly connected radiators, a controller and heat-conducting elements, wherein heat or cold produced by the semiconductor chilling plate is uniformly distributed on the radiators by virtue of the heat-conducting elements; the two radiators are respectively arranged at a heat end and a cold end of the semiconductor chilling plate; a plurality of heat-conducting elements are respectively connected between the heat ends or cold ends of the radiators and the semiconductor chilling plate in a pressing manner; and the controller is connected with the semiconductor chilling plate by a wire and controls the semiconductor chilling plate to be heated or chilled by switching the voltage polarity. According to the electric vehicle power battery heat management device disclosed by the invention, with the adoption of a semiconductor electronic technology, heating and cooling functions are realized by switching the voltage polarity, and the two radiators are respectively arranged on twoside faces of the semiconductor chilling plate, so that the heat transfer efficiency is improved. Moreover, the heat-conducting elements are respectively connected between the radiators and the semiconductor chilling plate in a pressing manner, and the heat-conducting efficiency between the semiconductor chilling plate and the radiators is improved.

Owner:BEIJING PRIDE NEW ENERGY BATTERY

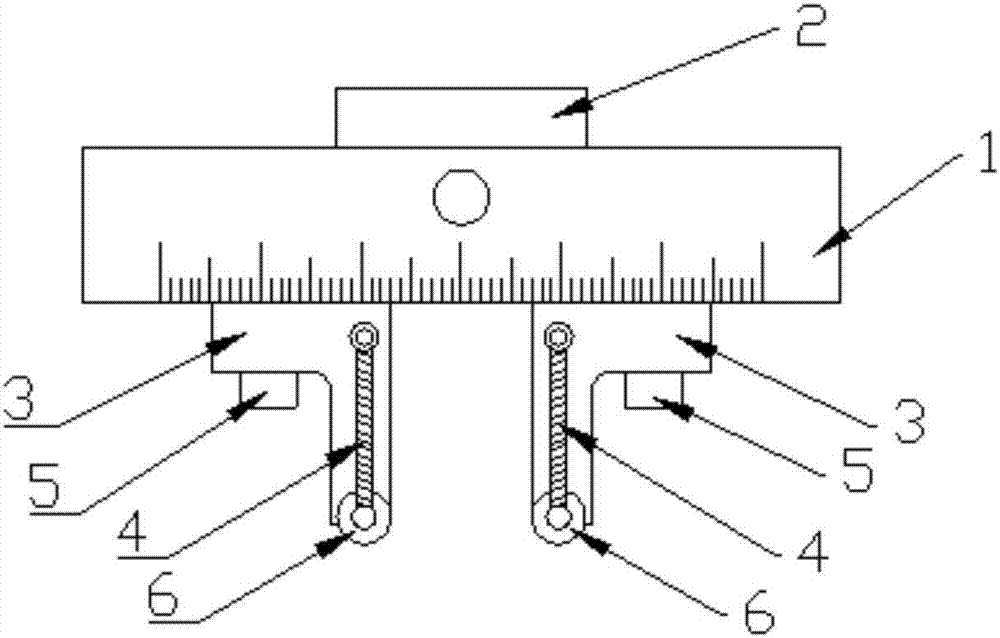

Clamp for bone fracture connecting plate bending intensity and equivalent bending rigidity determination and method

InactiveCN106885728AAdjustable distanceImprove versatilityMaterial strength using steady bending forcesElasticity measurementTest efficiencyFlexural strength

The invention discloses a clamp for bone fracture connecting plate bending intensity and equivalent bending rigidity determination and a method, and belongs to the technical field of bone fracture connecting plate quality inspection. The clamp comprises an upper clamp and a lower clamp which are used in a mutually matched way, wherein the upper clamp comprises an upper clamp body; two downwards projected inner side roller shafts are arranged on the lower surface of the upper clamp body; the lower surface of each inner side roller shaft is an arc-shaped surface; the lower clamp comprises a lower clamp body; two upwards projected outer side roller shafts are arranged on the upper surface of the lower clamp body; the upper surface of each outer side roller shaft is an arc-shaped surface; three displacement sensors are arranged between the two outer side roller shafts in parallel; the displacement sensors positioned at the two sides correspond to the two inner side roller shafts. The invention also discloses a method for determining the bone fracture connecting plate by using the clamp. The clamp and the method have the advantages that the test efficiency and the test result accuracy are improved; the test cost is reduced.

Owner:山东省医疗器械产品质量检验中心

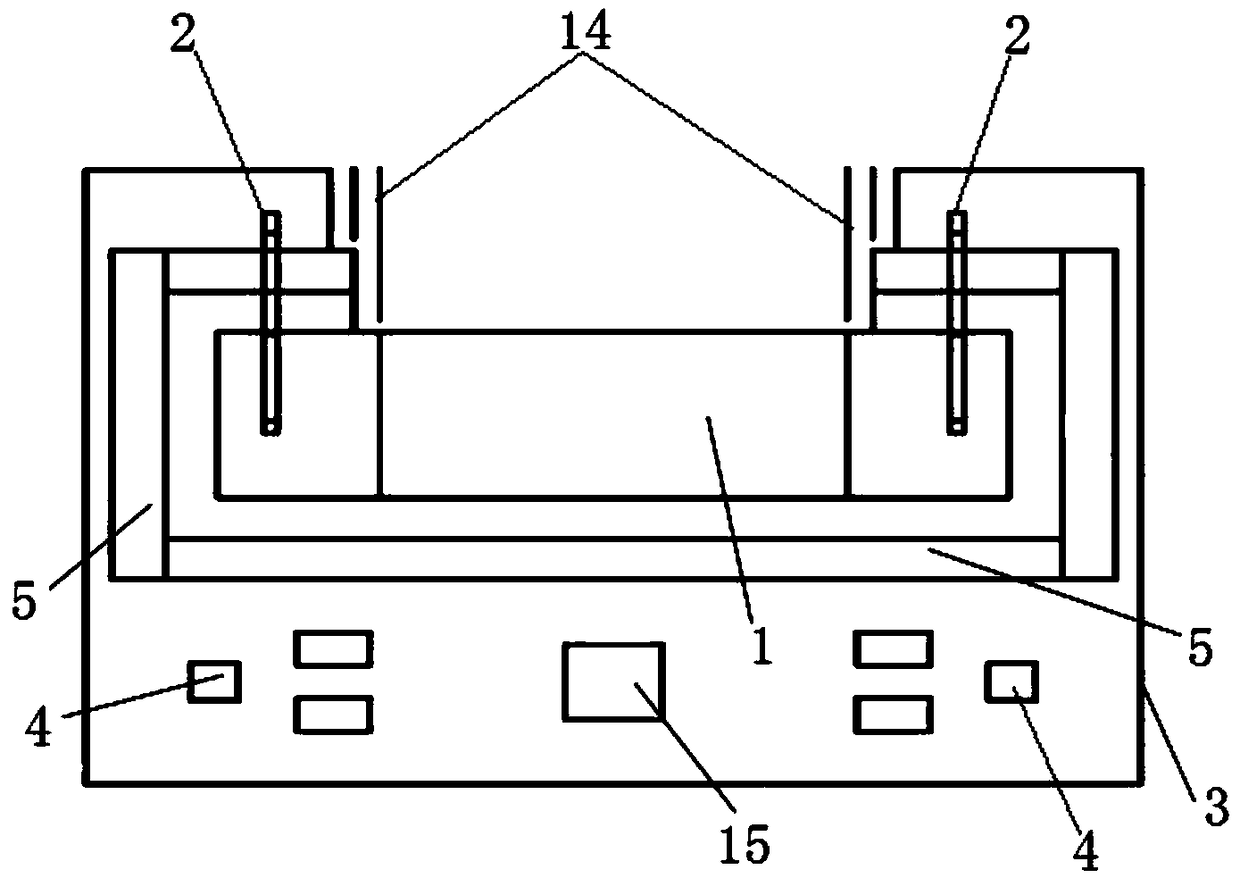

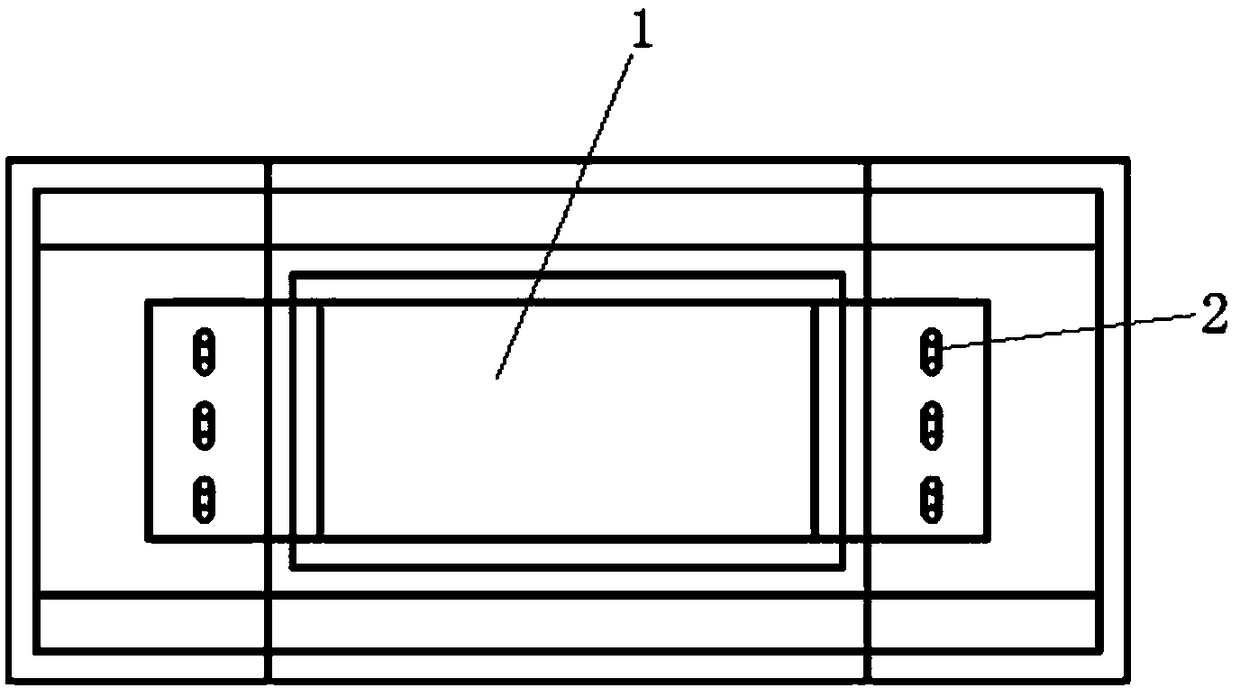

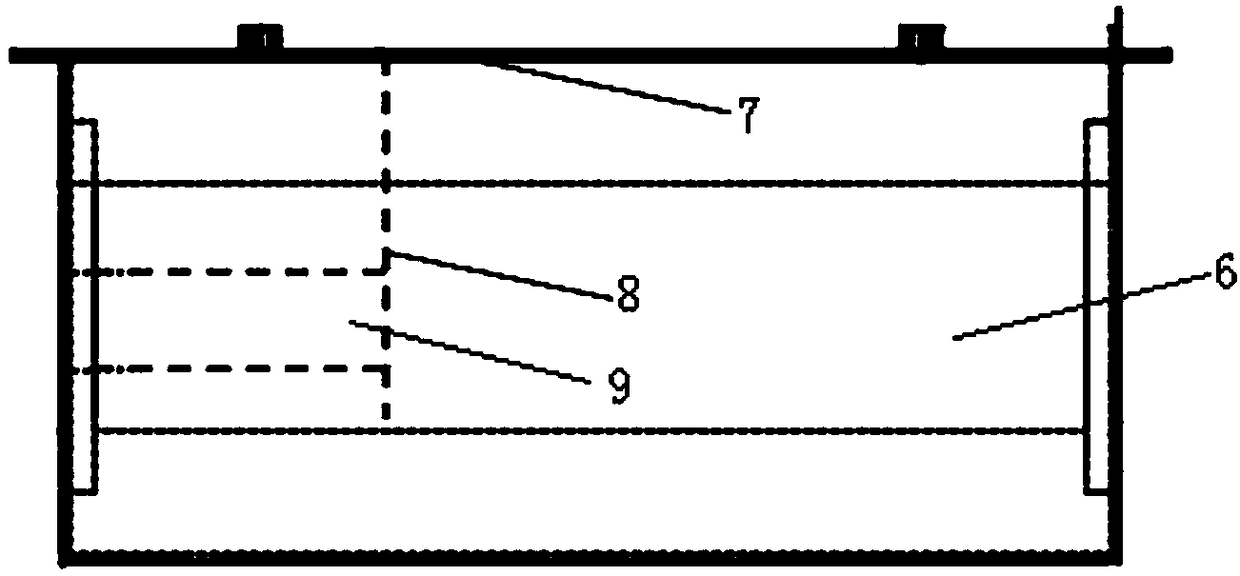

Experimental coke oven for small-scale production of coke and colloid layer samples and using method thereof

ActiveCN108398022ASimulation is accurateReal-time measurementCoke ovensFurnace typesCarbonizationColloid

The invention relates to an experimental coke oven for small-scale production of coke and colloid layer samples and a using method thereof. The experimental coke oven comprises a heating furnace, a reactor and a colloid layer sampler; the heating furnace is composed of a furnace shell, a heating furnace body, a carbonization chamber and a top split furnace door which are sequentially arranged fromoutside to inside; heating devices are arranged in the heating furnace body at the two ends of the carbonization chamber respectively; the reactor used for containing coal samples is arranged in thecarbonization chamber and is divided into a main reaction region and a colloid layer sampling region, and the main reaction region and the colloid layer sampling region are respectively close to two heating ends of the heating furnace body; and the colloid layer sampler is movably arranged in the colloid layer sampling region; and the top of the reactor is provided with a reactor upper cover, thereactor upper cover is provided with a gas outlet, a plurality of temperature sensors and a pressure sensor. The experimental coke oven can be used for accurately simulating the working conditions ofa large coke oven, and preparing the colloid layer samples and the coke samples for coking of single coal seed or coal blending; and meanwhile a colloid layer can be sampled at any time, and the experimental coke oven is simple in structure and convenient to operate.

Owner:UNIV OF SCI & TECH LIAONING

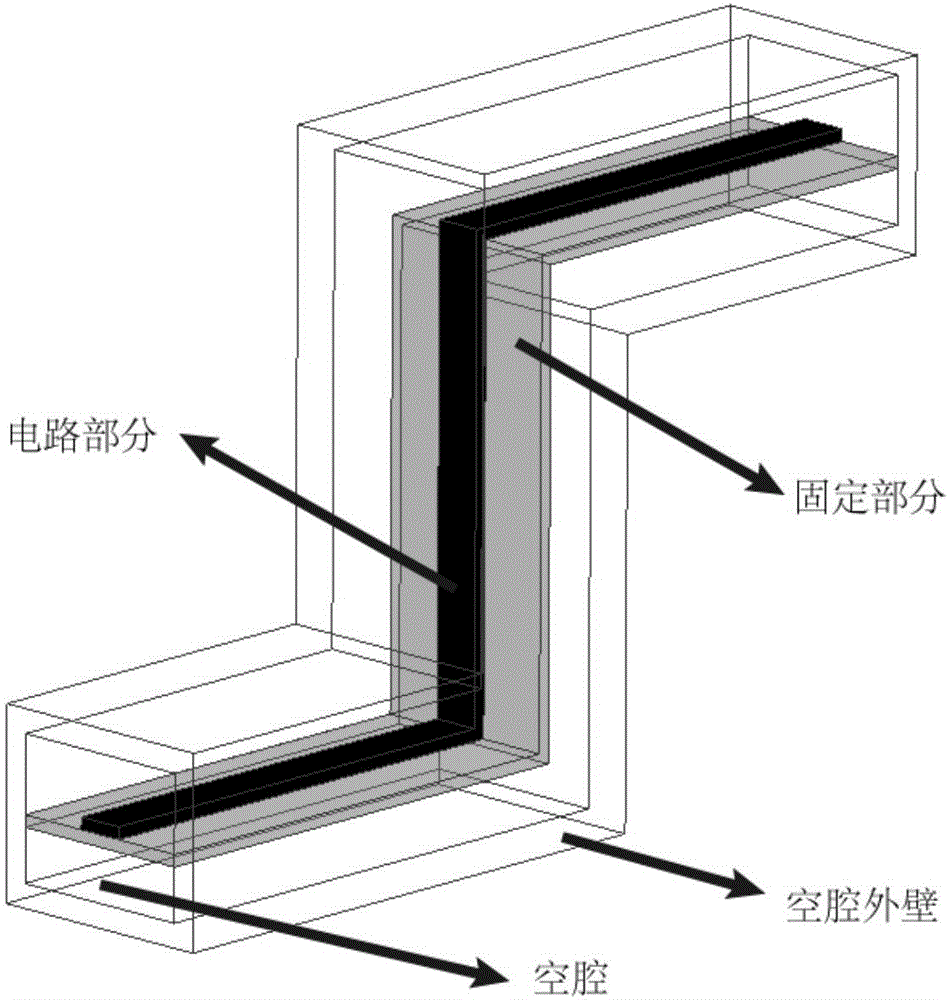

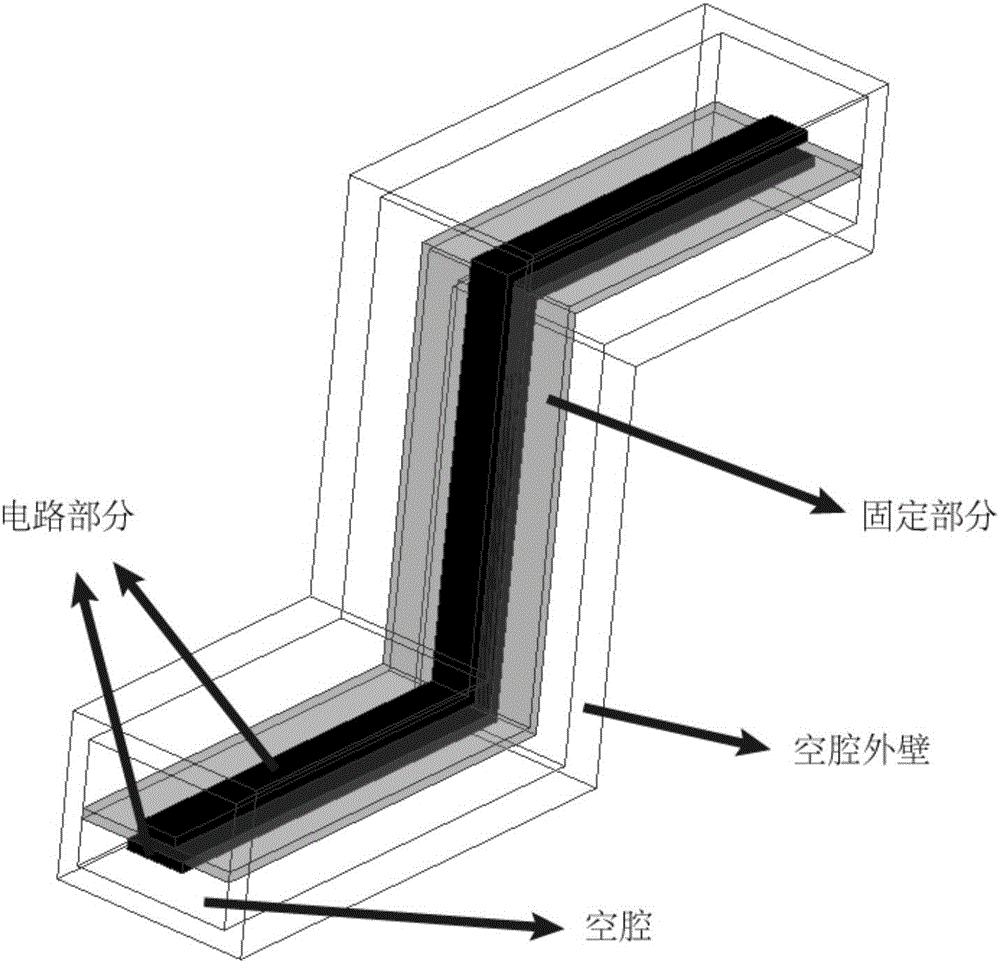

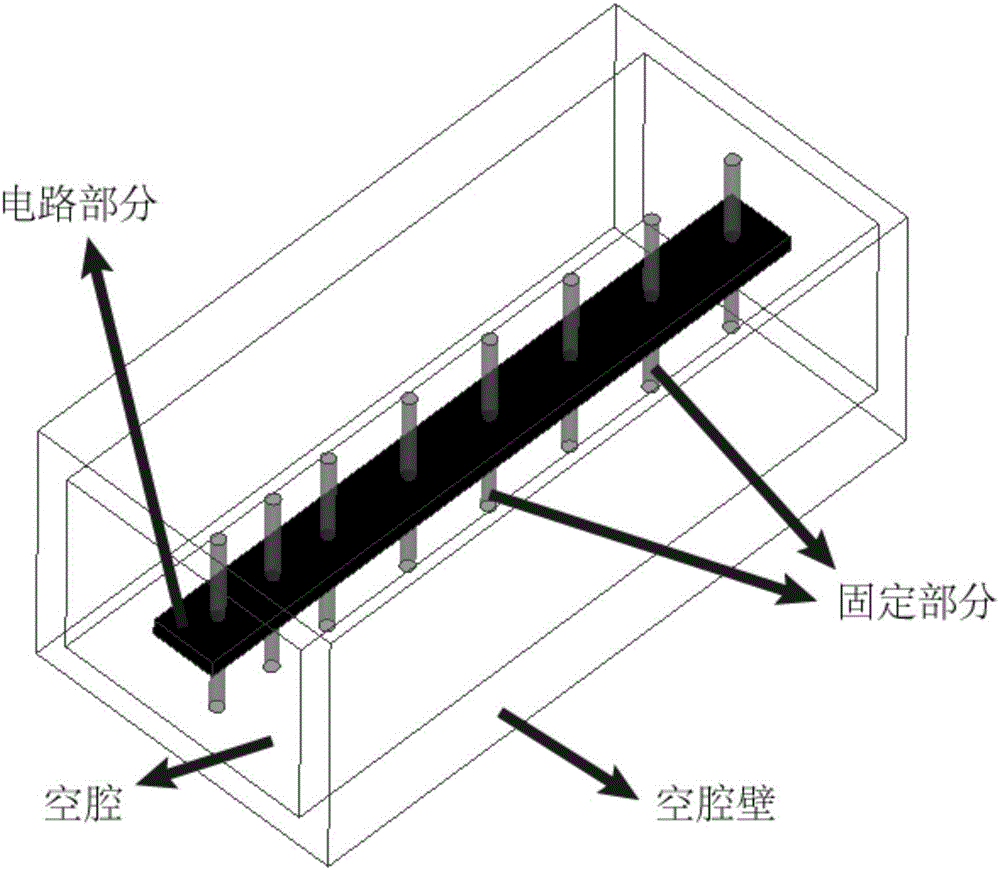

Medium integrated suspended line circuit structure based on 3D printing

ActiveCN107529274AImprove space utilizationSimple processingConductive pattern formationElectrical connection printed elementsCavity wallElectrical and Electronics engineering

The invention discloses a medium integrated suspended line circuit structure based on 3D printing, and the circuit structure comprises a circuit part which is used for designing a required circuit; a circuit fixing part which is used for connecting the circuit part and a cavity wall; a cavity part which is located between the circuit part and the cavity wall and is used for transmitting energy; and the cavity wall which is used for packaging the whole suspended line circuit. The structure solves technical problems that a conventional medium integrated suspended line is not high in space utilization rate and is complex in processing, achieves the high utilization rate of the space of the medium integrated suspended line, and is simple in processing.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

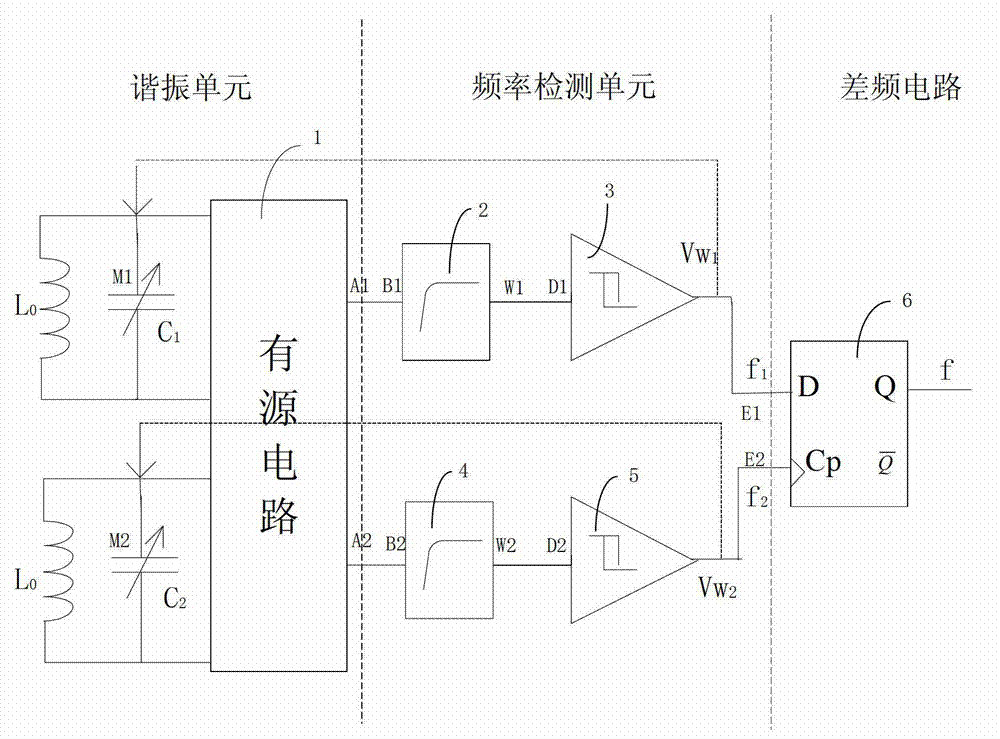

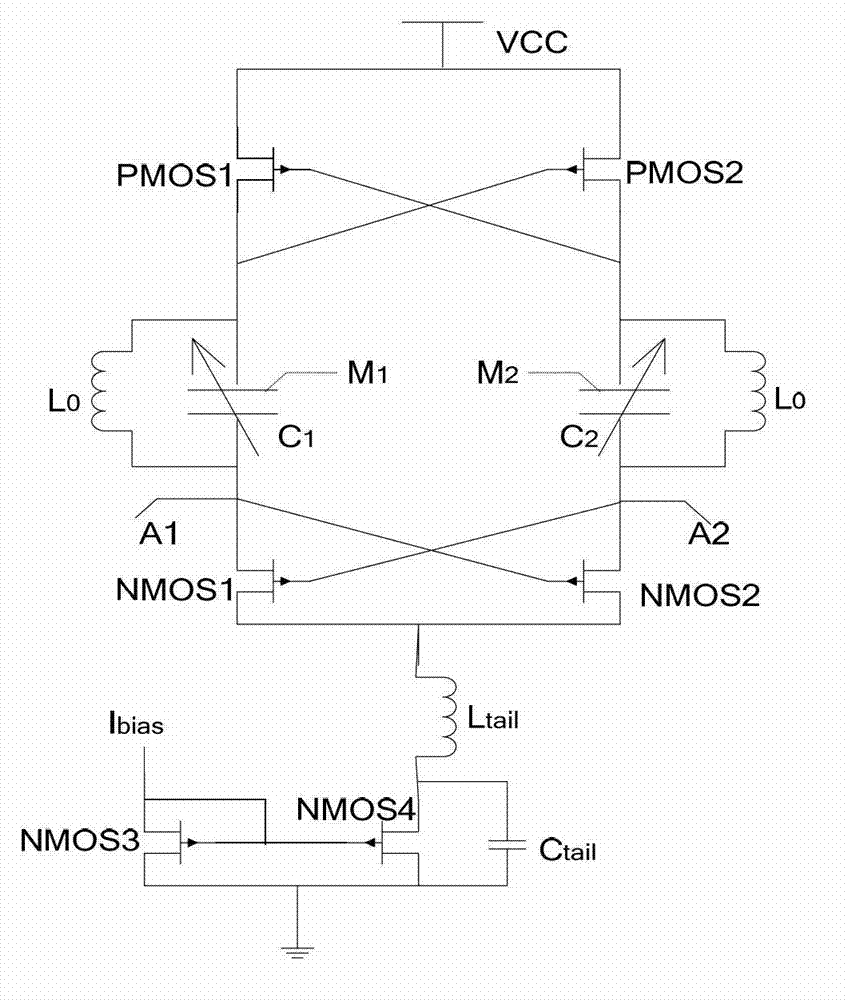

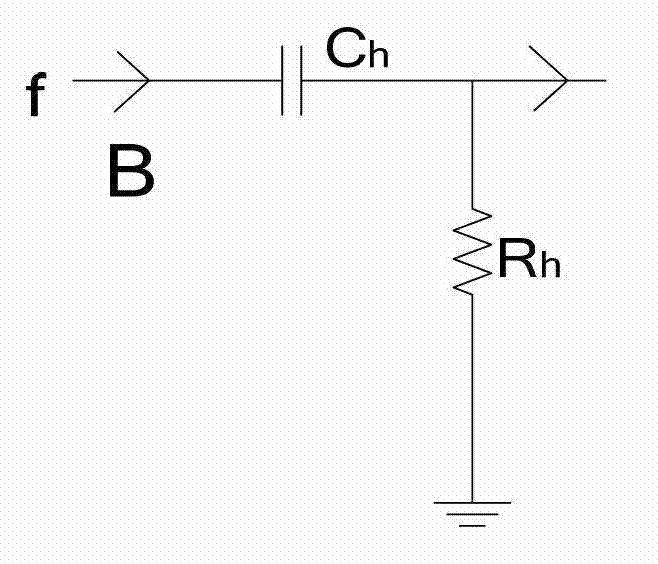

Detecting circuit of capacitance type MEMS (micro-electromechanical system) sensor

The invention relates to a detecting circuit of a capacitance type MEMS (micro-electromechanical system) sensor. The detecting circuit comprises a resonance unit which is formed after a first capacitor to be detected is connected with a second capacitor to be detected; the resonance unit is connected with a differential frequency circuit through a frequency detecting unit; an output end of the frequency detecting unit is respectively connected with a first movable pole plate of the first capacitor to be detected and a second movable pole plate of the second capacitor to be detected; the first capacitor to be detected and the second capacitor to be detected are correspondingly connected with each other to form the resonance unit; resonance frequency can be generated in the resonance unit; the resonance unit can compensate energy damped due to resonance; and the frequency detecting unit drives the differential frequency circuit to output corresponding frequency signals according to the resonance frequency outputted by the resonance unit. An active circuit is used for compensating energy loss of an energy storage device, an electrostatic feedback mechanism is utilized to form a closed-loop system to stably output frequency, anti-interference ability is increased, and the detecting circuit is simple and compact in structure and high in measurement accuracy and anti-interference ability, facilitates monolithic integration, overcomes energy loss and is stable and reliable.

Owner:中科芯未来微电子科技成都有限公司

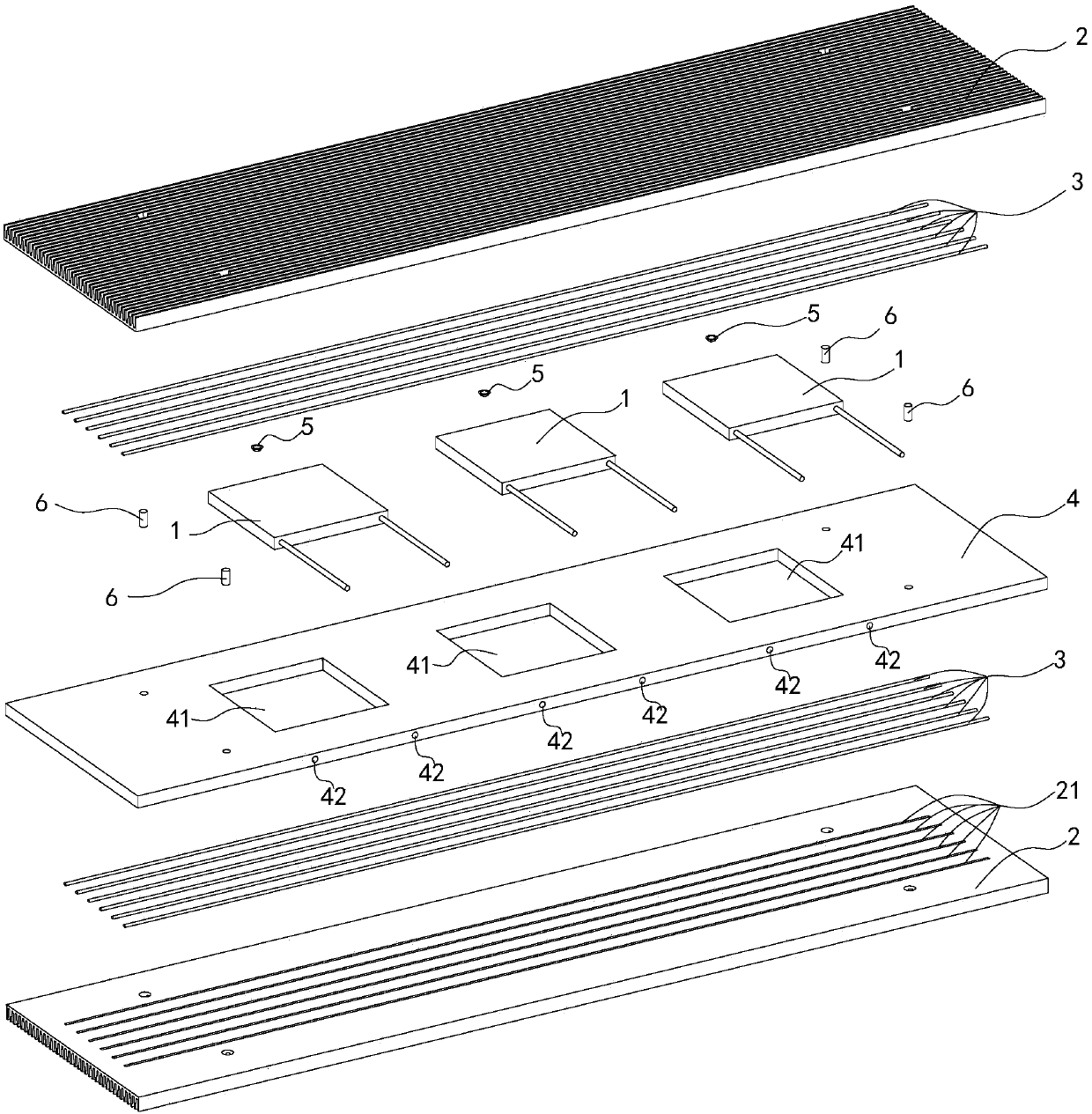

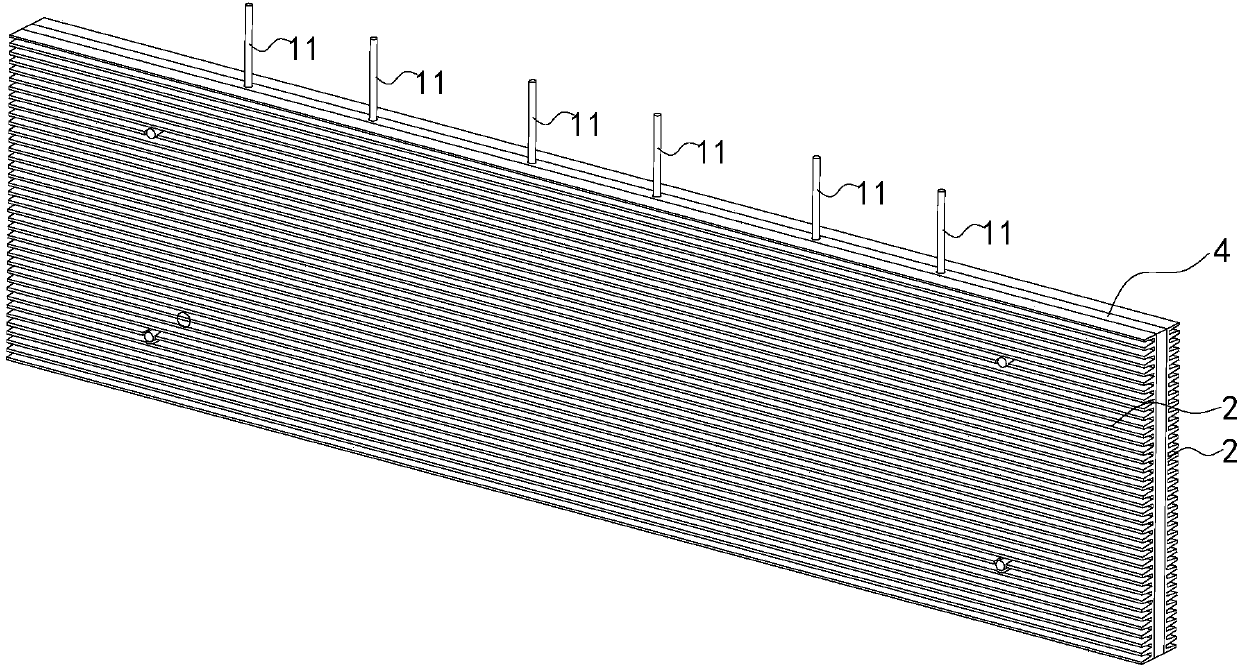

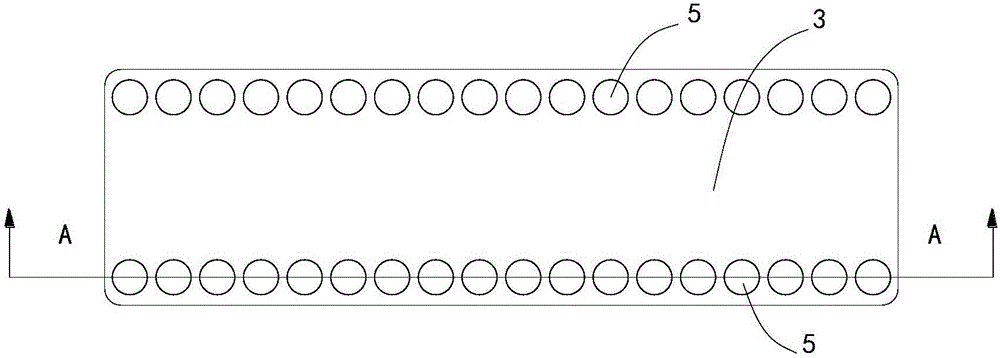

Millimeter wave band ultra wide band patch antenna based on substrate integrated waveguide feed

PendingCN112952372ALow profileEasy to integrateParticular array feeding systemsRadiating elements structural formsPhysicsDielectric substrate

The invention discloses a millimeter wave band ultra wide band patch antenna based on substrate integrated waveguide feed, which is characterized in that an upper layer dielectric substrate and a lower layer dielectric substrate are used as basic carriers, a first metal layer, a second metal layer and a third metal layer are attached, an SIW resonant cavity is formed in the lower layer dielectric substrate, a coupling slot is formed inthe upper surface of the SIW resonant cavity, the lower surface of the SIW resonant cavity is provided with back-to-ground coplanar waveguide feed, and the SIW resonant cavity and the back-to-ground coplanar waveguide are connected through a transition band to complete antenna design. The millimeter wave band ultra wide band patch antenna has the advantages of low profile, easy integration and easy processing, achieves the functions of low loss, high efficiency, high power capacity, relatively high gain and ultra-wide working frequency band, and solves the technical problems of narrow frequency band and large loss when a patch antenna in the prior art adopts a traditional planar transmission line as feed in a millimeter wave band.

Owner:GUILIN UNIV OF ELECTRONIC TECH

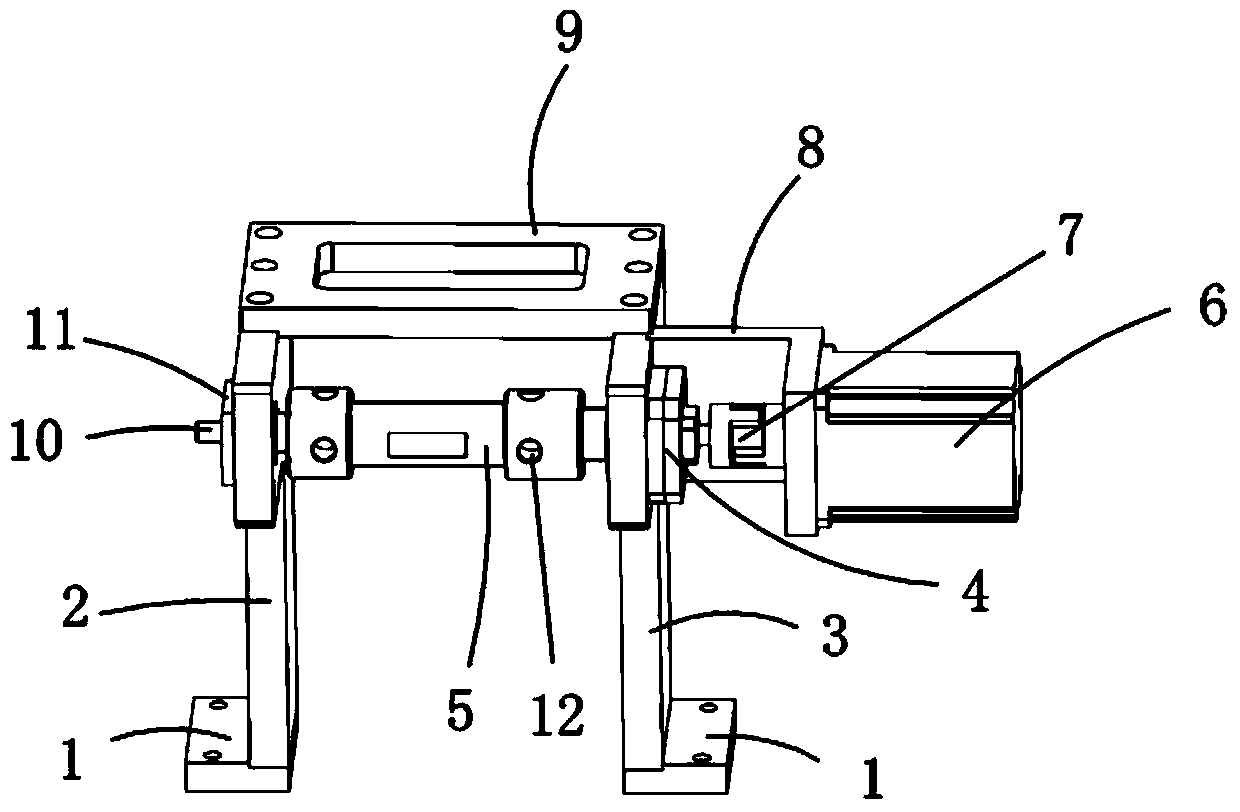

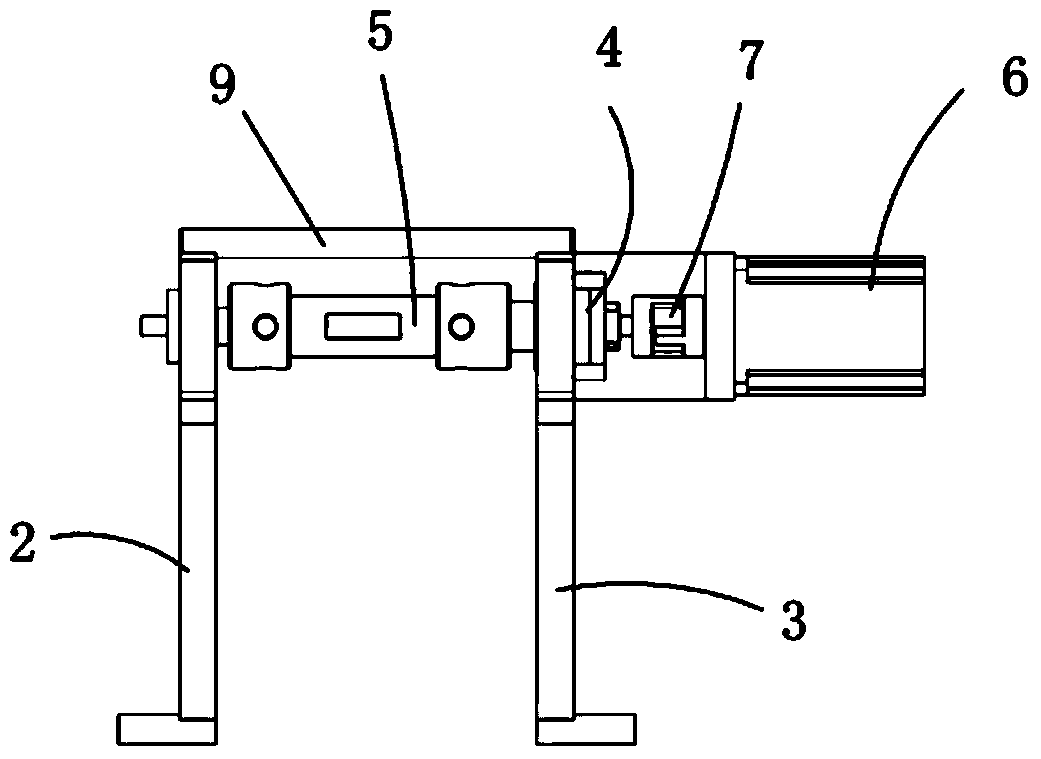

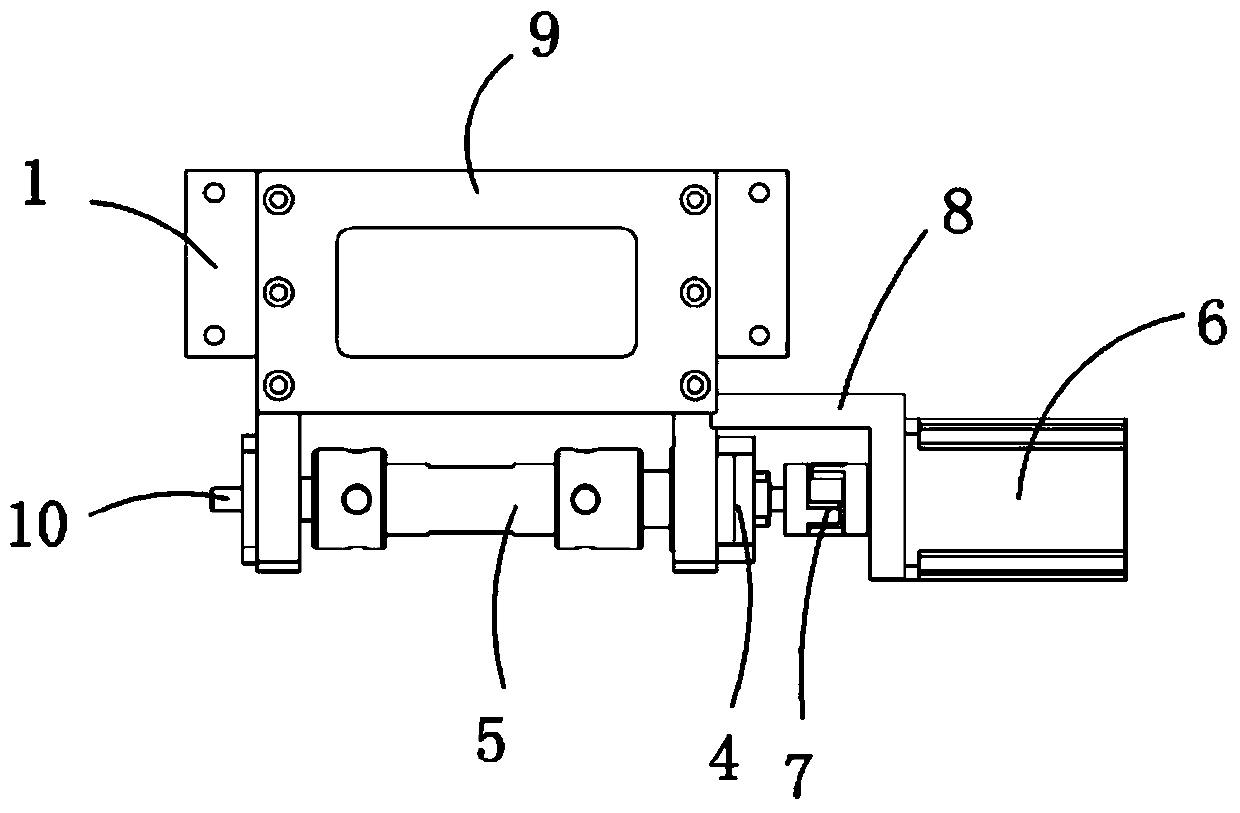

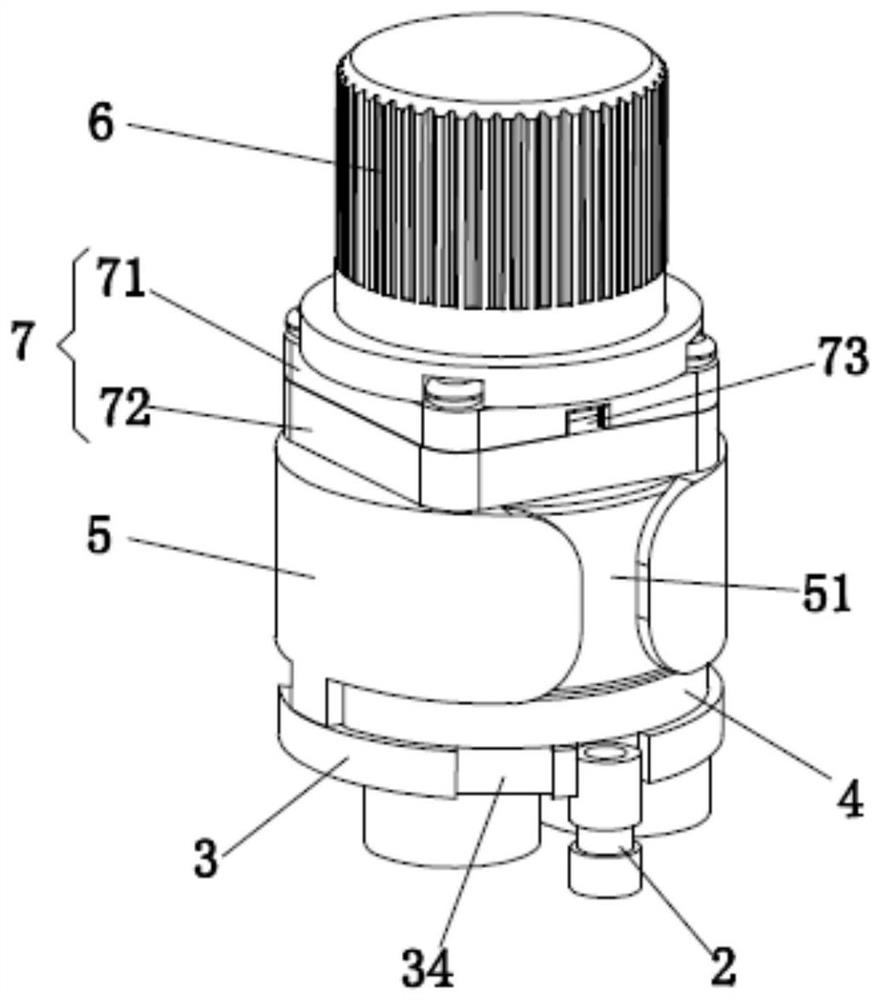

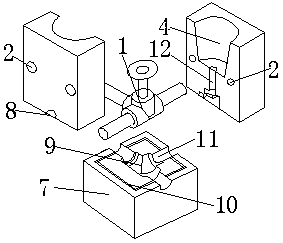

Rotary distributing mechanism

Owner:BOZHON PRECISION IND TECH CO LTD

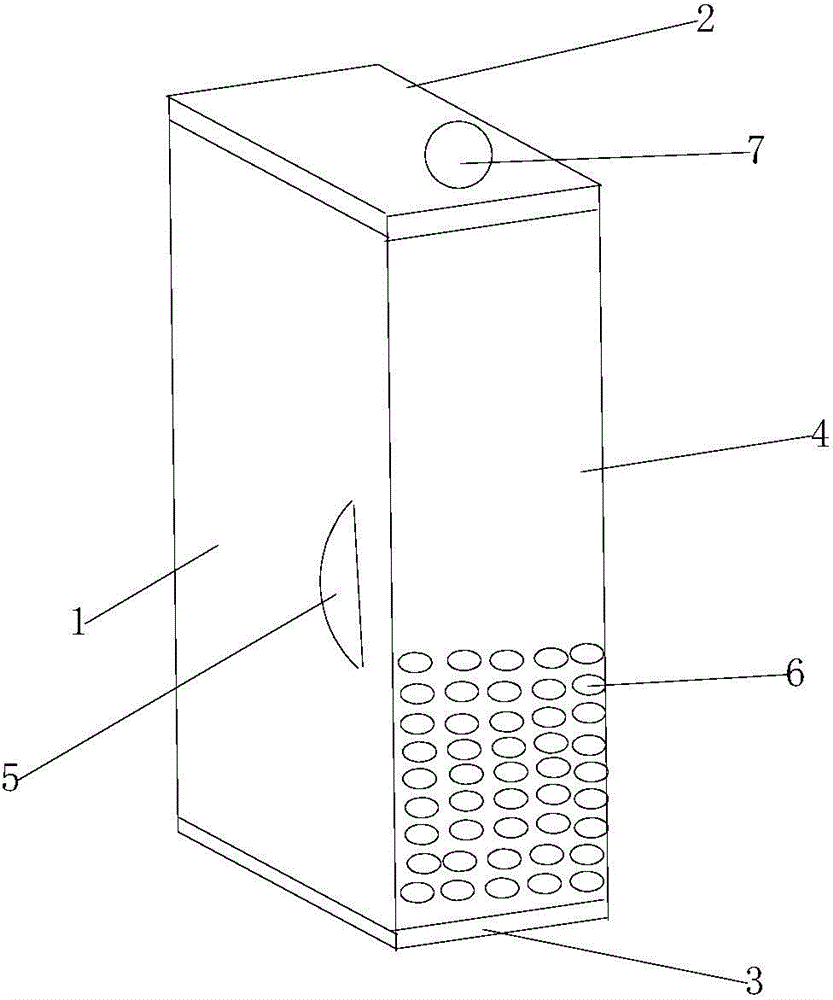

LED lamp

InactiveCN106016182AAvoid damageReduce wear outLighting support devicesProtective devices for lightingEngineeringLED lamp

The invention discloses an LED lamp. The LED lamp comprises an LED lamp body and a shell; the top of the shell is screwed with a top plate; a holding part is arranged in the shell; the LED lamp body is arranged in a cavity; the top plate is provided with a through hole communicated with the cavity; the tail end of the LED lamp body is inserted in the through hole; an elastic layer is arranged on the inner wall of the through hole; ventilation holes are uniformly distributed in the elastic layer; a clamping part includes two ejecting rods transversely penetrating through the shell; nuts are respectively screwed with the two ejecting rods, and are bonded on the outer side wall of the shell; the tail ends of the ejecting rods are positioned on the outer side of the shell; and the front ends of the two ejecting rods are oppositely arranged, and are both tightly bonded with the LED lamp body. The LED lamp is simple in structure, is provided with the shell for reducing the damage of the LED lamp body by external environment, is provided with the clamping part for fixing the LED lamp body in the shell, is convenient for use, can prolong the service life of the LED lamp body, and in particular, is suitable for production workshops with more dust and worse environment.

Owner:张祖宇

Seeding culture method for apricot

InactiveCN105475074AEasy to wear outAvoid infringementSeed and root treatmentCultivating equipmentsSodium diacetateZinc

A seeding culture method for apricot includes the steps that before seedlings are cultivated from apricot seeds, firstly, apricot seeds are refrigerated in an environment with the temperature of 0 DEG C to 3 DEG C at least twice; secondly, apricot seeds are sterilized and disinfected through a reagent; thirdly, a wooden softening mixture including acetic acid, zinc sulfate, ammonium phosphate, carboxymethyl chitosan, sodium citrate and sodium diacetate wraps the surface layers of apricot seeds.

Owner:SHANDONG INST OF POMOLOGY

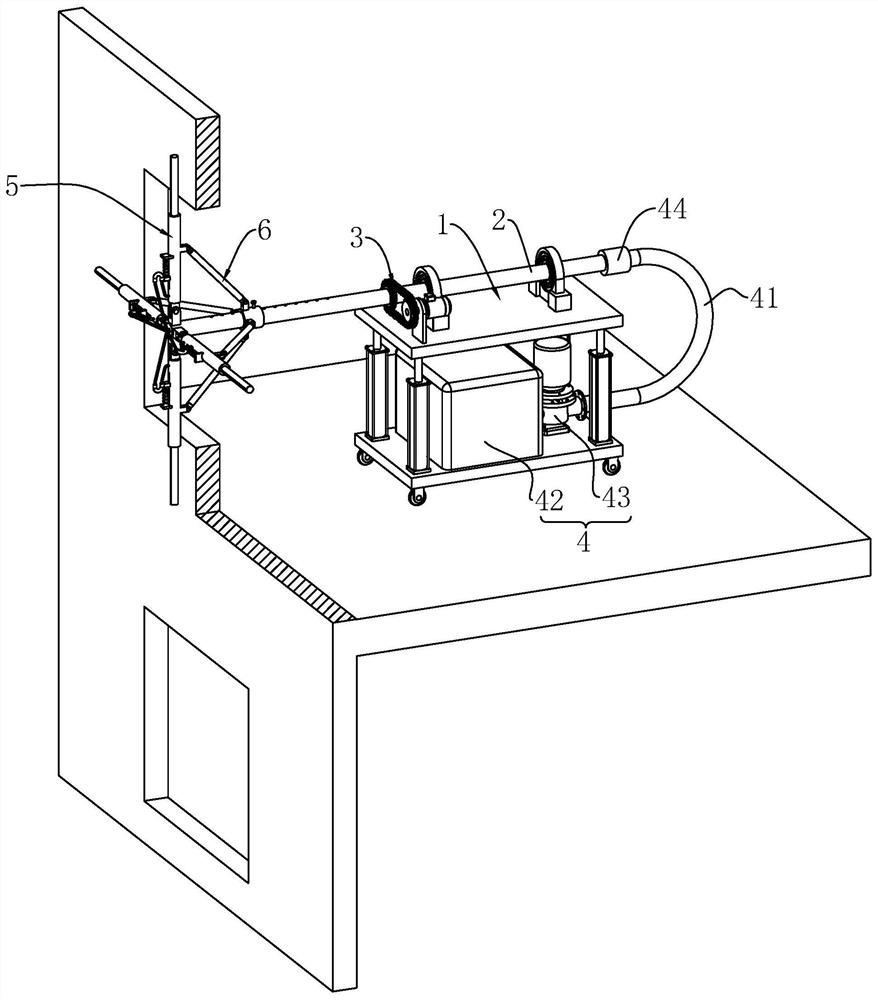

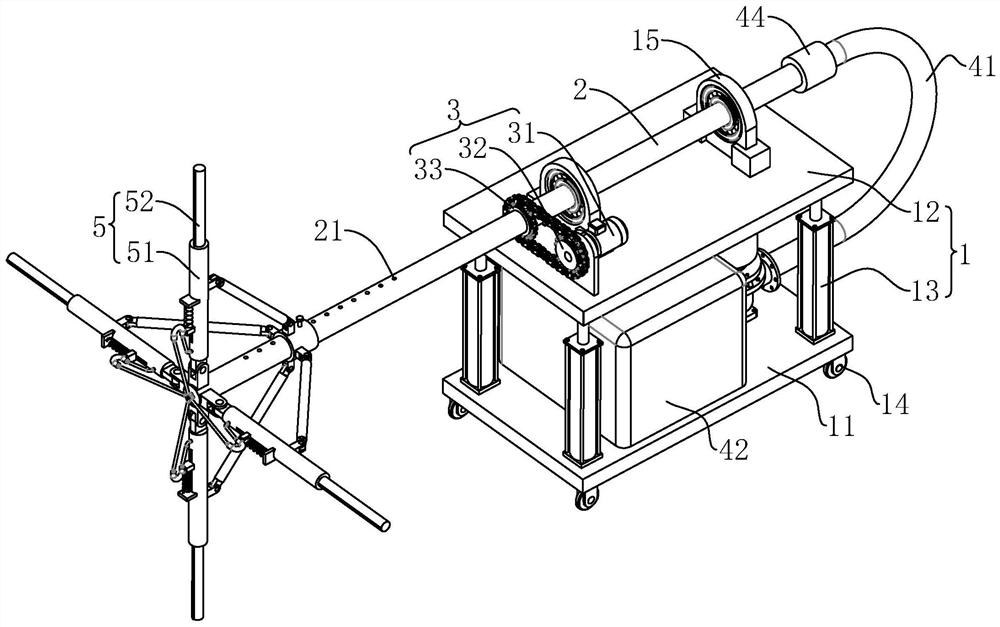

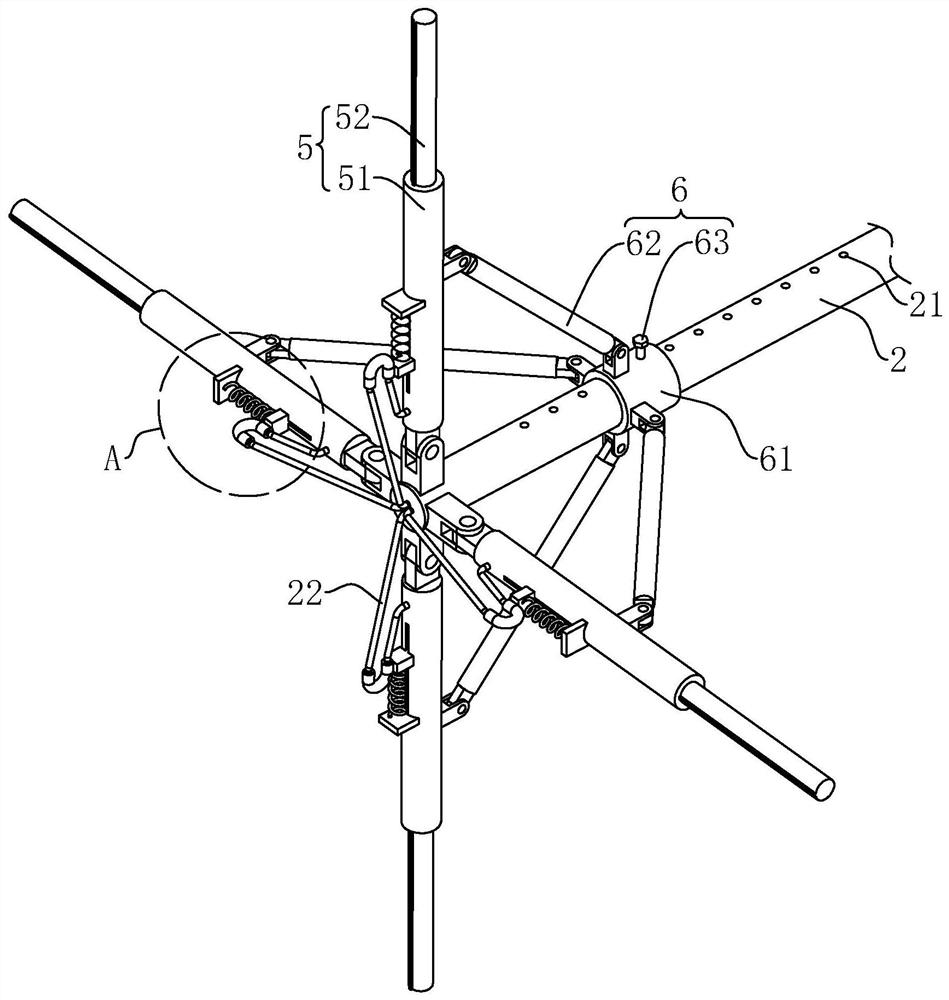

Window side wall water seepage detection device for constructional engineering

PendingCN112525796AEasy to wear outEasy to retractPermeability/surface area analysisClassical mechanicsStructural engineering

The invention relates to a window side wall water seepage detection device for constructional engineering. The device comprises a movable base, a rotating pipe rotationally connected to the movable base around the axis of the rotating pipe, a driving mechanism for driving the rotating pipe to rotate, a liquid conveying mechanism for conveying liquid into the rotating pipe, spraying pipes hinged toone end of the rotating pipe, and a folding and unfolding mechanism for adjusting the spraying pipes to be unfolded or folded, wherein the multiple spraying pipes are distributed around the axis of the rotating pipe. The window side wall water seepage detection device has the effect of reducing potential safety hazards existing when water seepage detection is conducted on the window side wall.

Owner:中核华辰工程管理有限公司

Method for recovering high-purity octafluorocyclobutane from difluoromonochloro methane cracking residual liquid

ActiveCN104529697AIncrease relative volatilityEfficient separationHalogenated hydrocarbon preparationBulk chemical productionChemistryRelative volatility

The invention relates to a method for recovering high-purity octafluorocyclobutane from difluoromonochloro methane cracking residual liquid. The method comprises the following steps: (1) difluoromonochloro methane cracking residual liquid is rectified, such that octafluorocyclobutane and azeotrope thereof are obtained; and (2) the octafluorocyclobutane and azeotrope thereof obtained in the step (1) are subjected to extractive distillation in an extractive distillation tower; octafluorocyclobutane is obtained from the top of the extractive distillation tower, and a mixed component of an extraction agent and impurities is obtained from the bottom of the extractive distillation tower; the mixed component is desorbed in an extractive desorption tower, and the obtained extraction agent is recycled and reused in the extractive distillation tower. According to the invention, a composite solvent composed of ionic liquid and organic solution is adopted as the extraction agent, such that the relative volatility of octafluorocyclobutane and azeotrope thereof can be substantially increased, and system high-efficiency separation is realized. With the method, octafluorocyclobutane purity is up to 99.999%.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

Wiping and dust removing device for flux-cored wires

InactiveCN107877040AWipe dust to achieveQuick and efficient wiping and dust removalWelding/cutting media/materialsSoldering mediaEngineeringFlux-cored arc welding

The invention discloses a wiping and dedusting device for flux-cored welding wire, which comprises a base plate, a box body is fixedly connected to the top of the bottom plate, and a partition plate is fixedly connected to both sides of the inner wall of the box body. Between the two sides of the inner wall and at the bottom of the partition plate, a rotating shaft is rotatably connected with a bearing. One end of the rotating shaft runs through the box and extends to one side of the box. The rotating shaft extends to one side of the box. The outer surface is sheathed with a worm gear, and the invention relates to the technical field of flux cored wire production facilities. The wiping and dust removal device for flux cored wire greatly enhances the dust removal effect, improves the dust removal efficiency very well, and realizes a good wiping and dust removal on the surface of the flux cored wire without spending a lot of time for the production personnel to clean the flux core. The repeated dust removal of the welding wire reduces the workload of the production personnel and realizes the rapid and efficient thorough wiping and dust removal of the flux-cored welding wire.

Owner:WUXI WEI KELAI TECH CO LTD

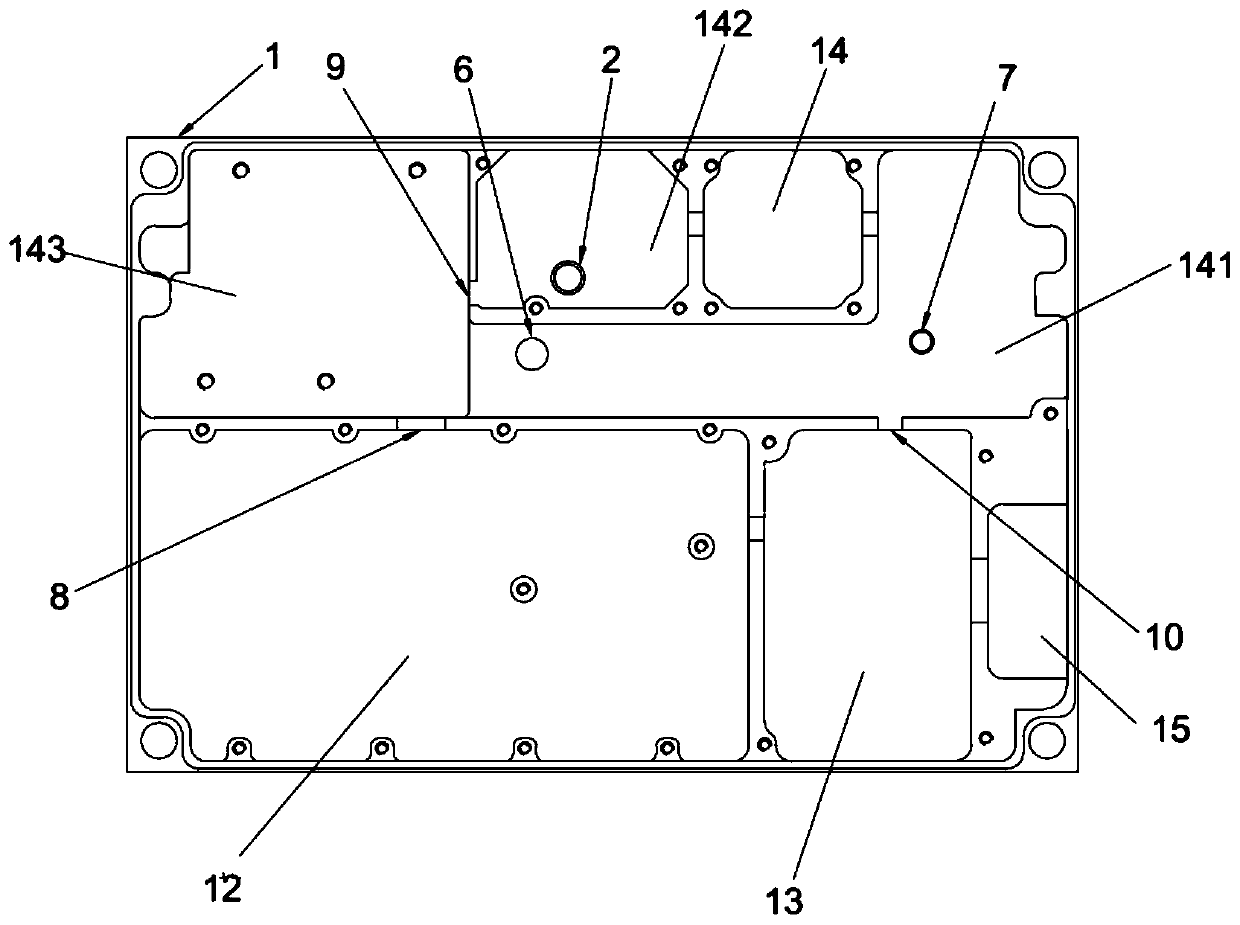

Filtering component

ActiveCN106209000AGood filtering effectEasy to use and maintainMultiple-port networksElectromagnetic compatibilityOpen structure

The invention discloses a filtering component comprising a shell provided with a chamber, wherein the top of the shell is of an open structure, and a first connector, a second connector, a third connector, a fourth connector, a fifth connector, a sixth connector and a seven connector are arranged on an outer surface of a side wall opposite to the open structure in sequence; the chamber of the shell is divided into a power supply filtering chamber and a signal filtering chamber by a division plate; a power supply filtering circuit board with a power supply filtering circuit integrated is arranged in the power supply filtering chamber; a signal filtering circuit board is arranged in the signal filtering chamber, a base is arranged right below the division plate, a grounding column is arranged at a position close to the base in the signal filtering chamber, a connecting sheet is arranged at the bottom of the division plate, and the connecting sheet is connected with the grounding column; and a conductive structure is arranged on the outer surface of the side wall where the connectors are mounted. By adopting the filtering component disclosed by the invention, the existing vehicle length terminal meets conduction CE102, radiation RE102 and other related electromagnetic compatibility requirements in GJB.

Owner:CHONGQING DAJI ELECTRONICS TECH

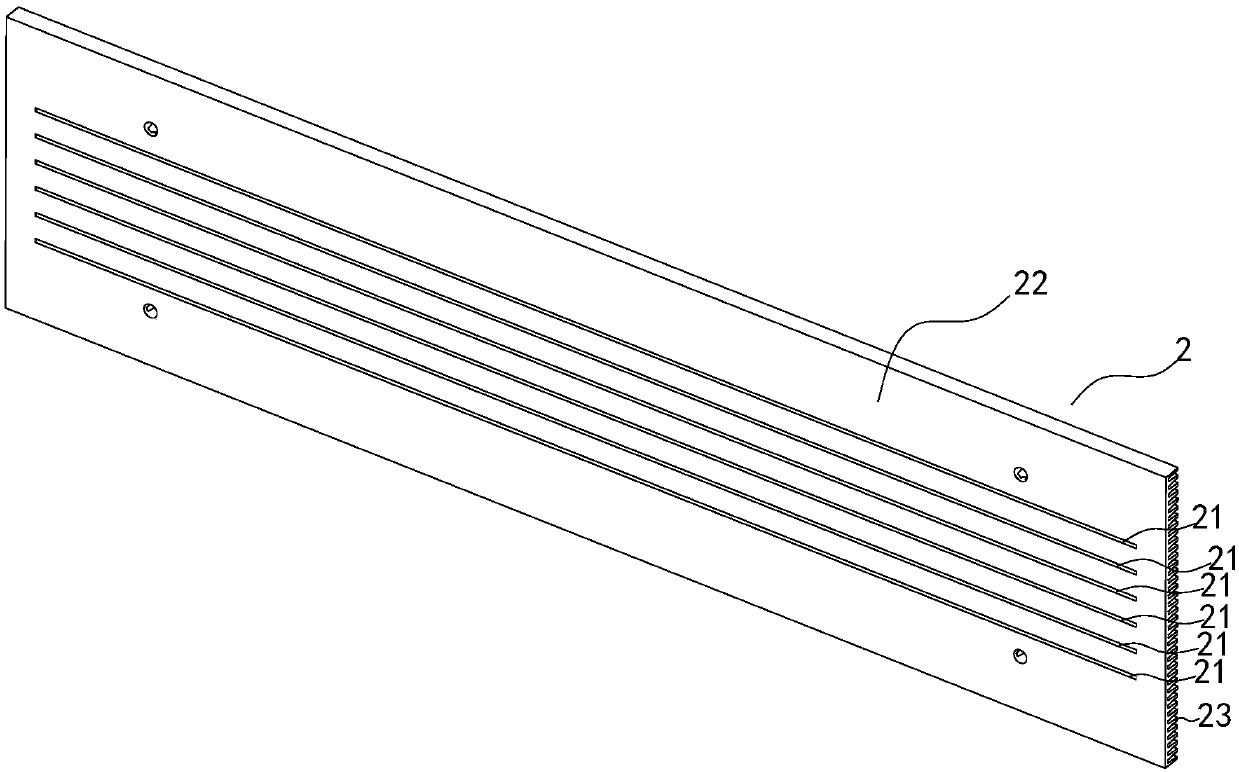

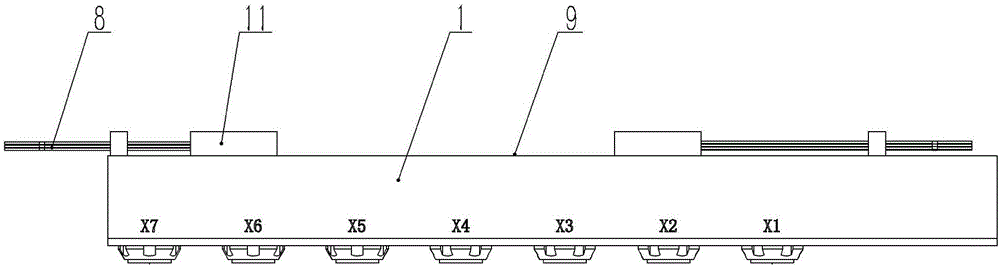

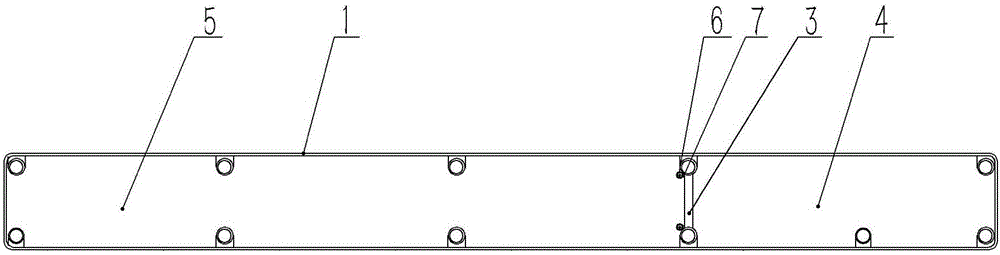

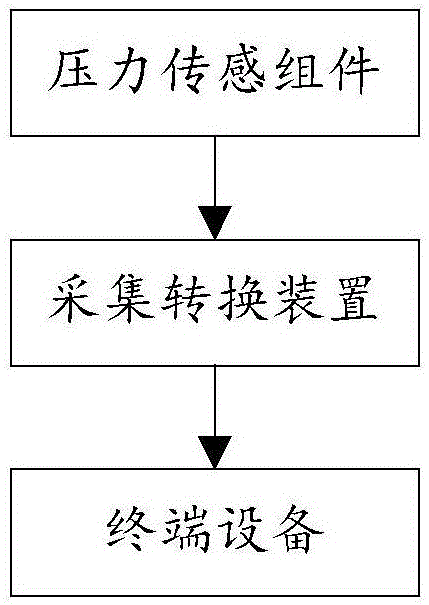

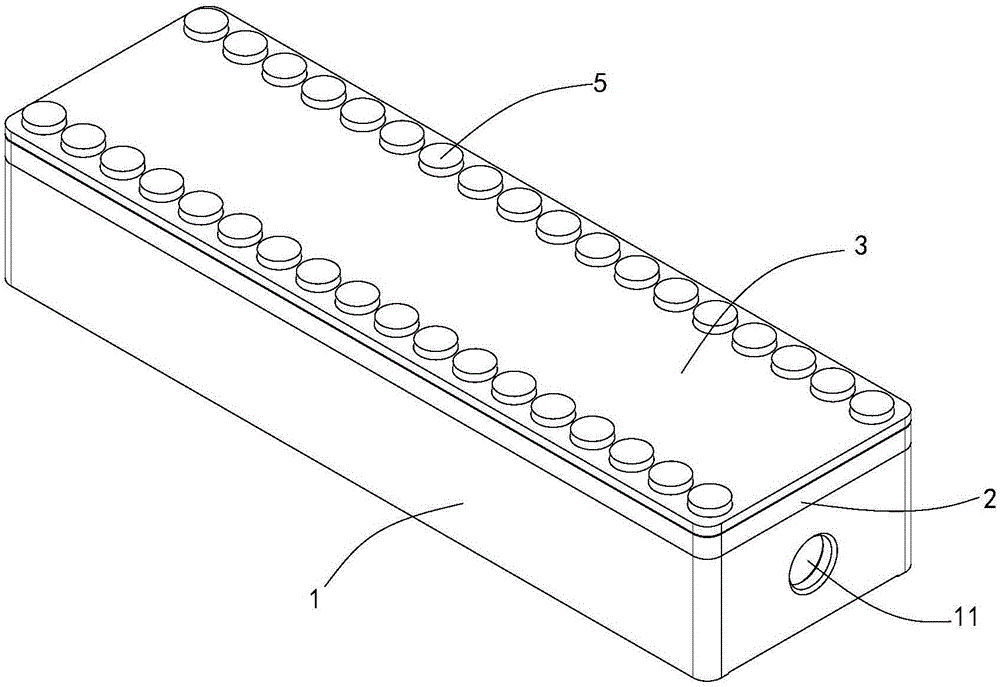

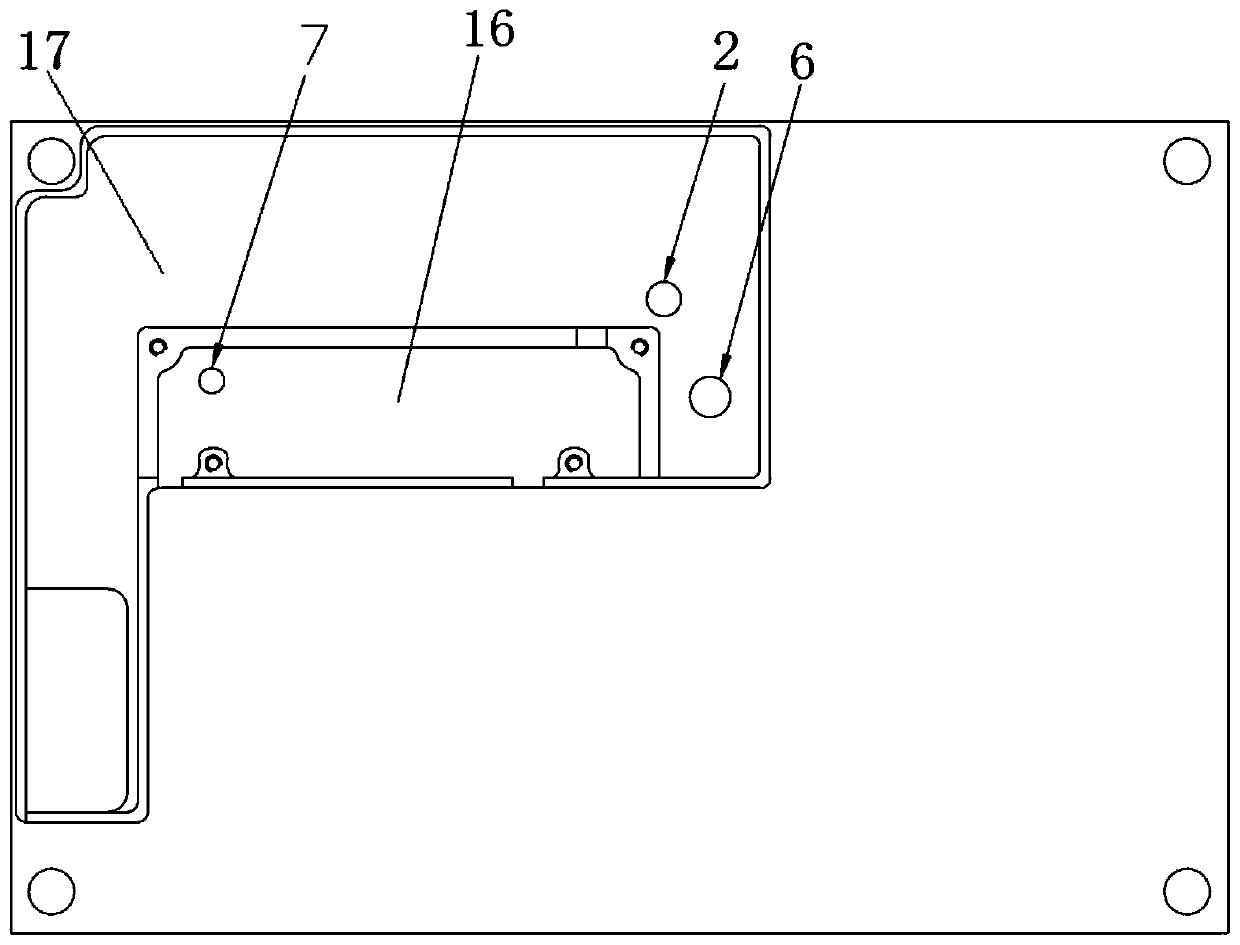

Pressing force detection device for laser welding clamp for power battery module

ActiveCN106825960ACheck the pressing forcePrecise pressing forceApparatus for force/torque/work measurementLaser beam welding apparatusElectricityPower battery

The invention relates to a pressing force detection device for a laser welding clamp for a power battery module. The pressing force detection device comprises terminal equipment, a collection and conversion device, multiple pressure sensing components and a detection tool, wherein the detection tool is adaptively connected into a clamp in a pressing manner; the multiple pressure sensing components are arranged on the detection tool, further, are connected with multiple spring sites in the clamp in one-to-one correspondence and pressing manners, and detect pressure signals of the corresponding spring sites; the collection and conversion device is electrically connected with the multiple pressure sensing components and the terminal equipment respectively, and is used for collecting the pressure signals and sending same to the terminal equipment; the terminal equipment is used for receiving and displaying the pressure signals. The detection tool of the pressing force detection device can be adaptively connected into the clamp in the pressing manner; the height of the detection tool is the same with the total height of a battery core and a bus bar; through connecting multiple pressure sensor components with the multiple spring sites in the clamp in the one-to-one correspondence and pressing manners, the pressure value of each spring site in the clamp can be detected; the pressing force of the laser welding clamp can be accurately detected; the measurement time is short; the measurement is precise; an observation result is intuitional and explicit.

Owner:江苏和中普方新能源科技有限公司

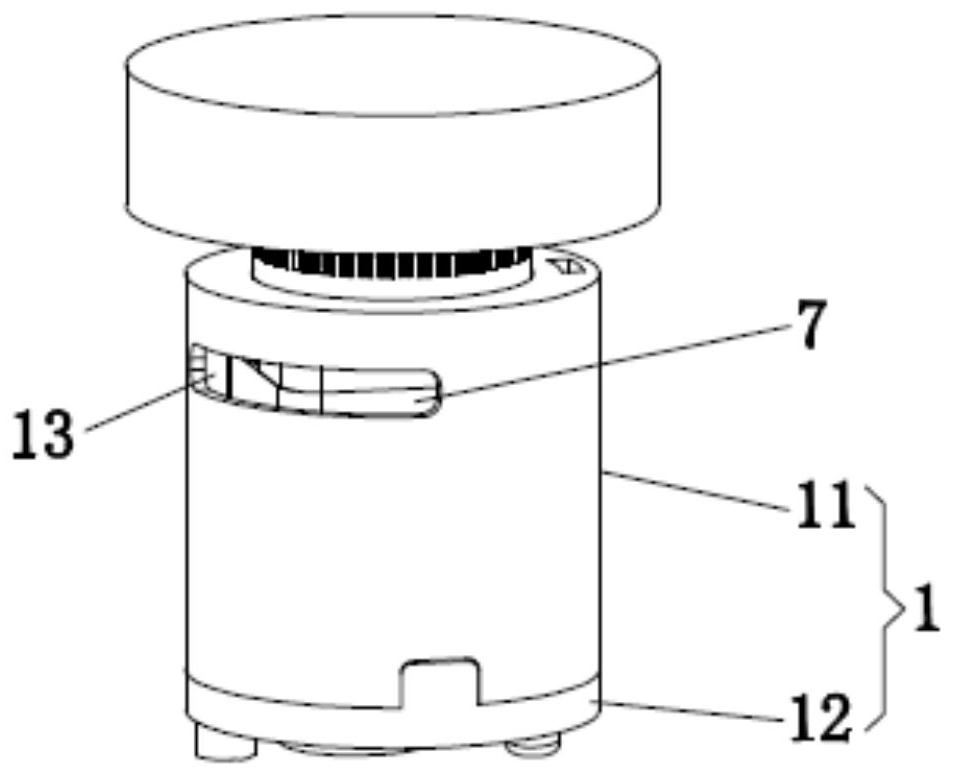

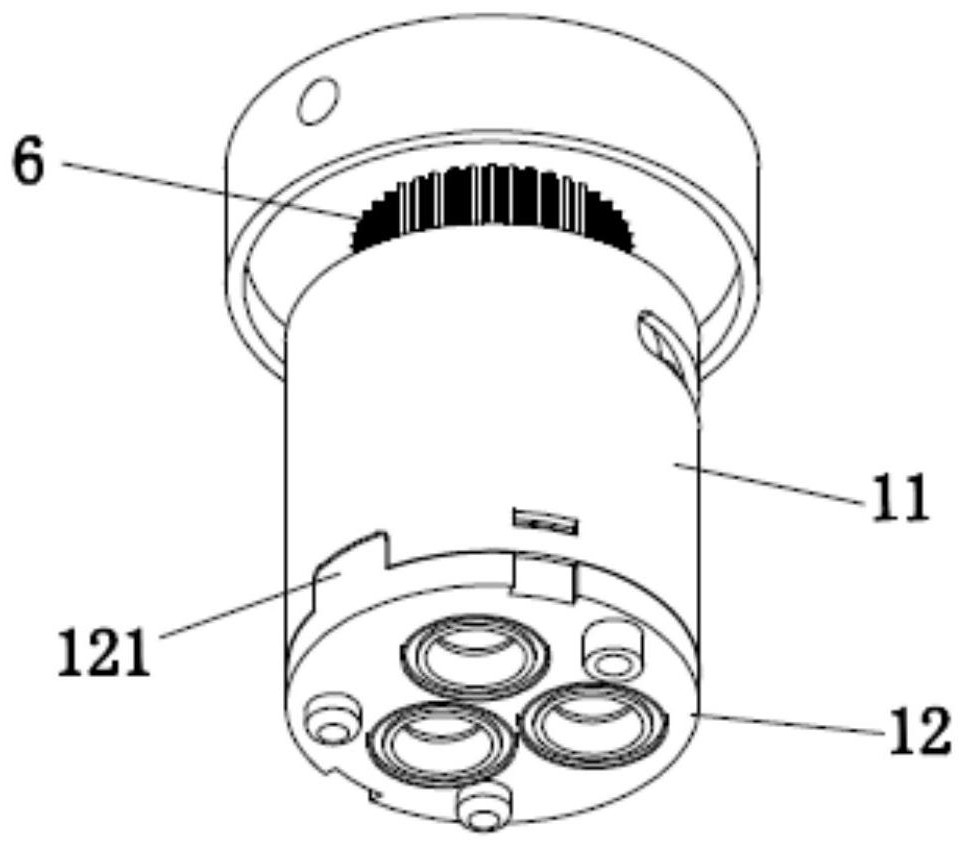

Sensing faucet valve element

PendingCN112833221AReduced housing cross-sectional dimensionsReduce volumeOperating means/releasing devices for valvesDomestic plumbingElectrical batteryEnvironmental engineering

The invention discloses a sensing faucet valve element. The element comprises a shell, a water passing channel and an electromagnetic valve which are sequentially arranged are arranged in the shell, a control panel is installed on the electromagnetic valve through an installation part, and the control panel is electrically connected with the electromagnetic valve; the control panel is provided with an inductor terminal and a battery terminal; one end of the shell is provided with a water inlet and a water outlet; the input end and the output end of the water passing channel are adjacent to the water inlet and the water outlet respectively; and the input end and the output end of the electromagnetic valve are connected to the middle of the water passing channel. The sensing faucet valve element provided by the invention is small in size and can be compatible with various types of faucets.

Owner:KAIPING JIANPAI SANITARY WARE CO LTD

Load distribution based method for calculating recently planned annual line loss of medium-voltage distribution network

ActiveCN102033999BEasy to wear outSolving complex and time-consuming problemsSpecial data processing applicationsLoad distributionComputer science

The invention relates to a load distribution based method for calculating recently planned annual line loss of a medium-voltage distribution network. The method comprises the following steps of: (1) calculating a load distribution coefficient of a typical load distribution line; (2) calculating a load distribution coefficient of an actual line; (3) virtualizing a return line, wherein parameters related to line loss calculation are all average parameters, and the loss of the return line is used as the average loss of the medium-voltage line of the planning area; (4) calculating the loss of a trunk line of the virtual line; (5) calculating the loss of a branch line of the virtual line; and (6) calculating the loss of the medium-voltage line in the planning area. The method has reasonable design, solves the problem that the failure of acquisition of the load data of a recently planned annual distribution network causes difficulty in line loss calculation, realizes the quick estimation ofthe line loss of the whole planning area and has the characteristics of simple operation, easier obtaining of collected data and short calculation time.

Owner:TIANDAQIUSHI ELECTRIC POWER HIGH TECH CO LTD

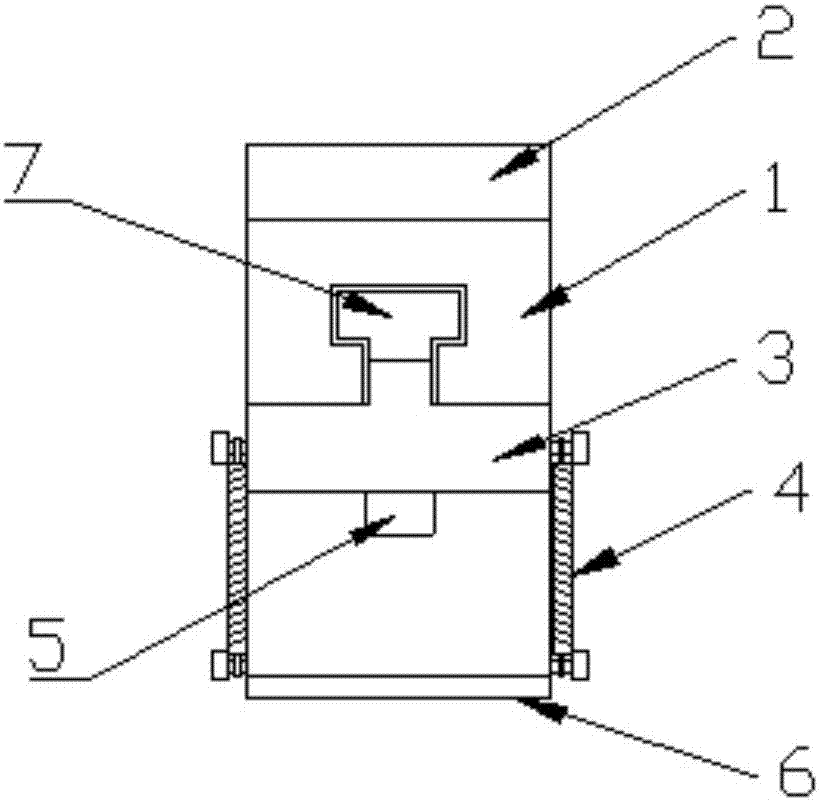

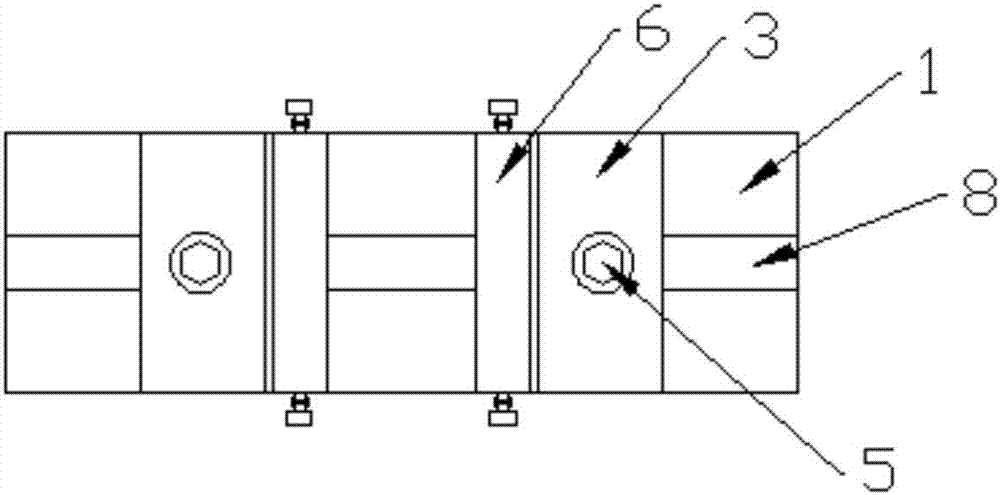

Heat-released welding die

PendingCN107627023AEasy to get inEasy to wear outAlumino-thermic welding apparatusExothermic weldingEngineering

The invention discloses heat-released welding die. The heat-released welding die comprises a left upper die and a lower die, wherein the interior of the upper die is provided with a reaction cavity used for welding and flow passages; welding cavities which are matched with each other are arranged on the contact surfaces of the upper die and the lower die respectively; the reaction cavity communicates with the welding cavities through the flow passages; strip-shaped grooves are formed in the peripheries of the welding cavities on the upper surface of the lower die; strip-shaped bulges corresponding to the strip-shaped grooves in positions are arranged on the peripheries of the welding cavities on the lower surface of the upper die; the upper die is formed by splicing at least two componentswhich are matched with each other; and the components which are matched with each other are detachable and fixedly connected mutually. In the welding process, when a welding flux is heated and expanded to enter into the reaction cavity, and after a structure that the upper die is difficult to take down from the upper die is formed through solidification, the upper die is split, the expanded welding flux in the reaction cavity and the welding cavities can be removed, and a workpiece is taken down.

Owner:CHENGDU KAILONG MACHINERY MAINTENANCE

Up-converter module structure

InactiveCN109921159ASimple structureCompact and reasonable layoutWaveguide type devicesFrequency mixingEngineering

The invention discloses an up-converter module structure, which is characterized in that the up-converter module structure comprises a large cavity, wherein a frequency mixing circuit board cavity isarranged on the front side of the large cavity, a first circuit board cavity for placing a first circuit board and a second circuit board cavity for mounting a second circuit board are arranged on thefront side of the large cavity, and a power supply circuit board cavity is arranged on the back side of the large cavity. The up-converter module structure is simple in structure, reasonable and compact in arrangement, small in space occupation, high in reliability and good in application prospect.

Owner:HUADONG PHOTOELECTRIC TECHN INST OF ANHUI PROVINCE

Cabinet

InactiveCN105451476AEnsure safetyImprove securityCasings/cabinets/drawers detailsEngineeringCable harness

The present invention provides a cabinet. The cabinet comprises a front cabinet door, a back cabinet door, a left side plate, a right plate, an upper top plate, a lower bottom plate, an upper beam, a lower beam and four upright wire ducts. The front cabinet door is provided with a handle; a punched hole is arranged at the position of the upper top plate close to the back cabinet door; an opening is arranged at the position of the lower bottom plate close to the front cabinet door; a wiring harness is able to pass through the punched hole or the opening; the front cabinet door is fixed on the left side plate through screws; the upper end and the lower end of each wire duct are respectively fixed at the upper top plate and the lower bottom plate through nuts; the wiring on the ducts is extended between the support pieces on the upper beam and the lower beam so that scrambled wiring harness is avoided in the cabinet, therefore the safety of the cabinet is greatly improved, and the adaptability is good.

Owner:XINJINWEI NETWORK TECH

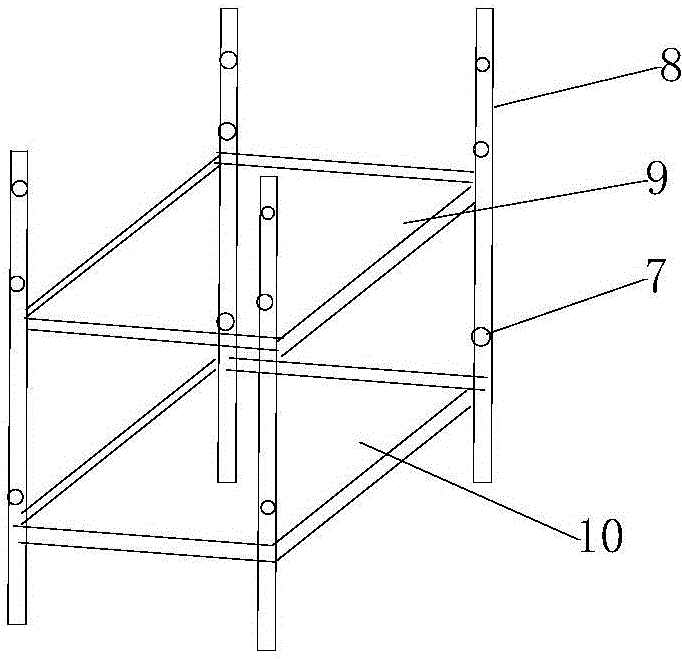

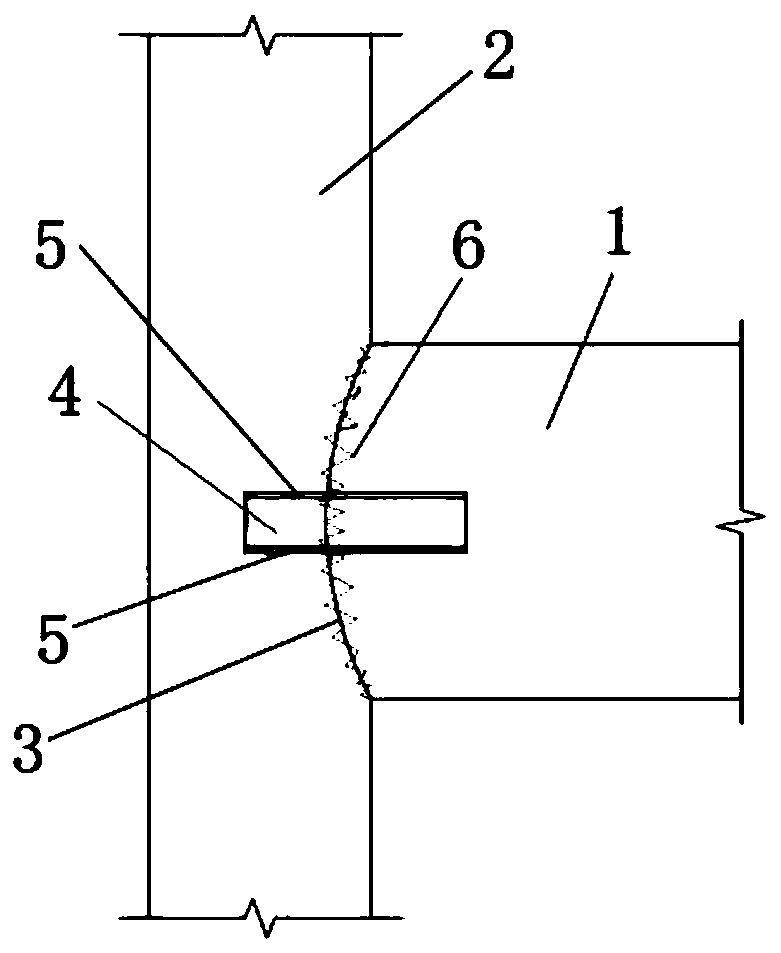

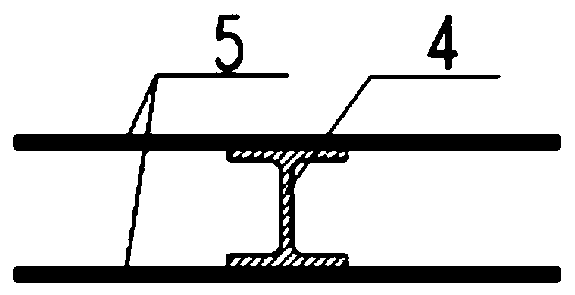

Concrete beam end and curved surface shear wall construction joint disposal device and method

PendingCN110528700ASolve the problem of retentionImprove adhesionBuilding insulationsAdhesion forceConcrete beams

The invention relates to a concrete beam end and curved surface shear wall construction joint disposal device. The concrete beam end and curved surface shear wall construction joint disposal device comprises a concrete beam and a concrete shear wall. A construction joint is formed in the junction of the end of concrete beam and the concrete shear wall. A section steel shear resisting key is pre-embedded in the construction joint and penetrates through the construction joint, one part of the section steel shear resisting key is located in the concrete shear wall, and the other part of the section steel shear resisting key is located in the concrete beam. The invention further relates to a concrete beam end and curved surface shear wall construction joint disposal method. According to the concrete beam end and curved surface shear wall construction joint disposal device and method, due to the fact that the section steel shear resisting key is embedded, the high shear resistance of the section steel shear resisting key and the feature that anchor bars are welded on the section steel shear resisting key are utilized to solve the problem of force transmission between beam-shear wall joints; and due to the fact that a dense-hole steel wire mesh serves as a formwork of pouring of the construction joint, the penetration of rebars of the concrete beam and the section steel shear resisting key is facilitated, the adhesion force of the construction joint is increased, the construction measure cost is saved, the construction period is shortened, and the concrete beam end and curved surface shear wall construction joint disposal device and method have certain engineering application value for spatial abnormally-shaped concrete beam construction.

Owner:SUZHOU INDAL PARK DESIGN & RES INST

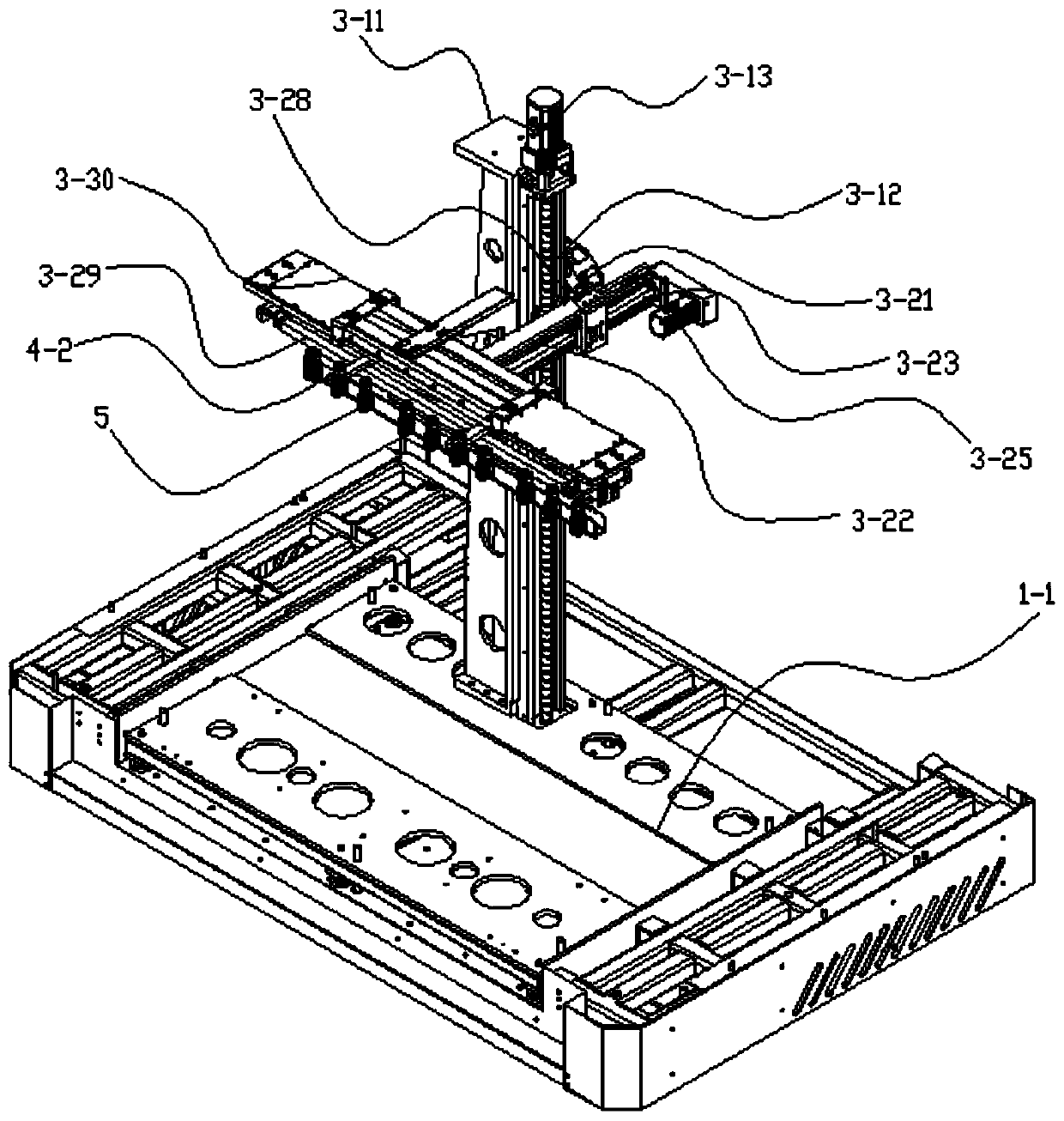

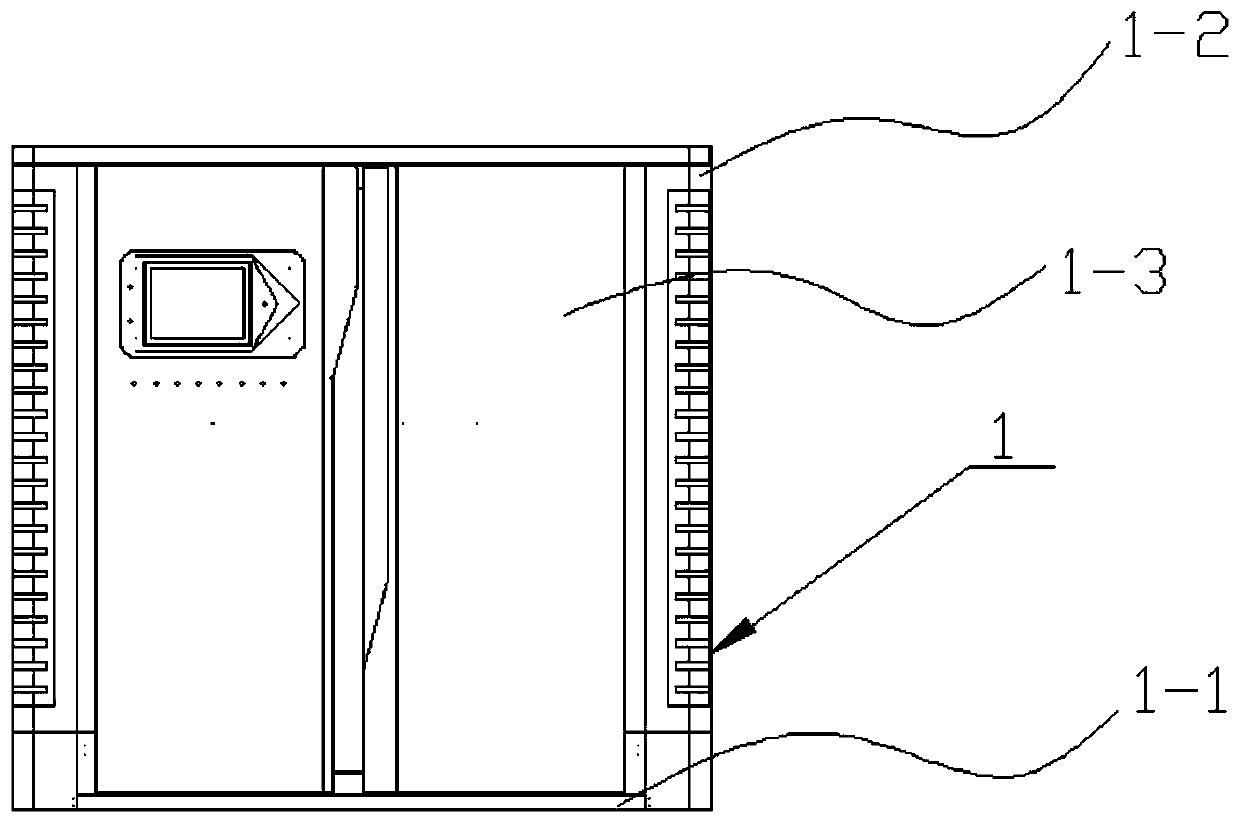

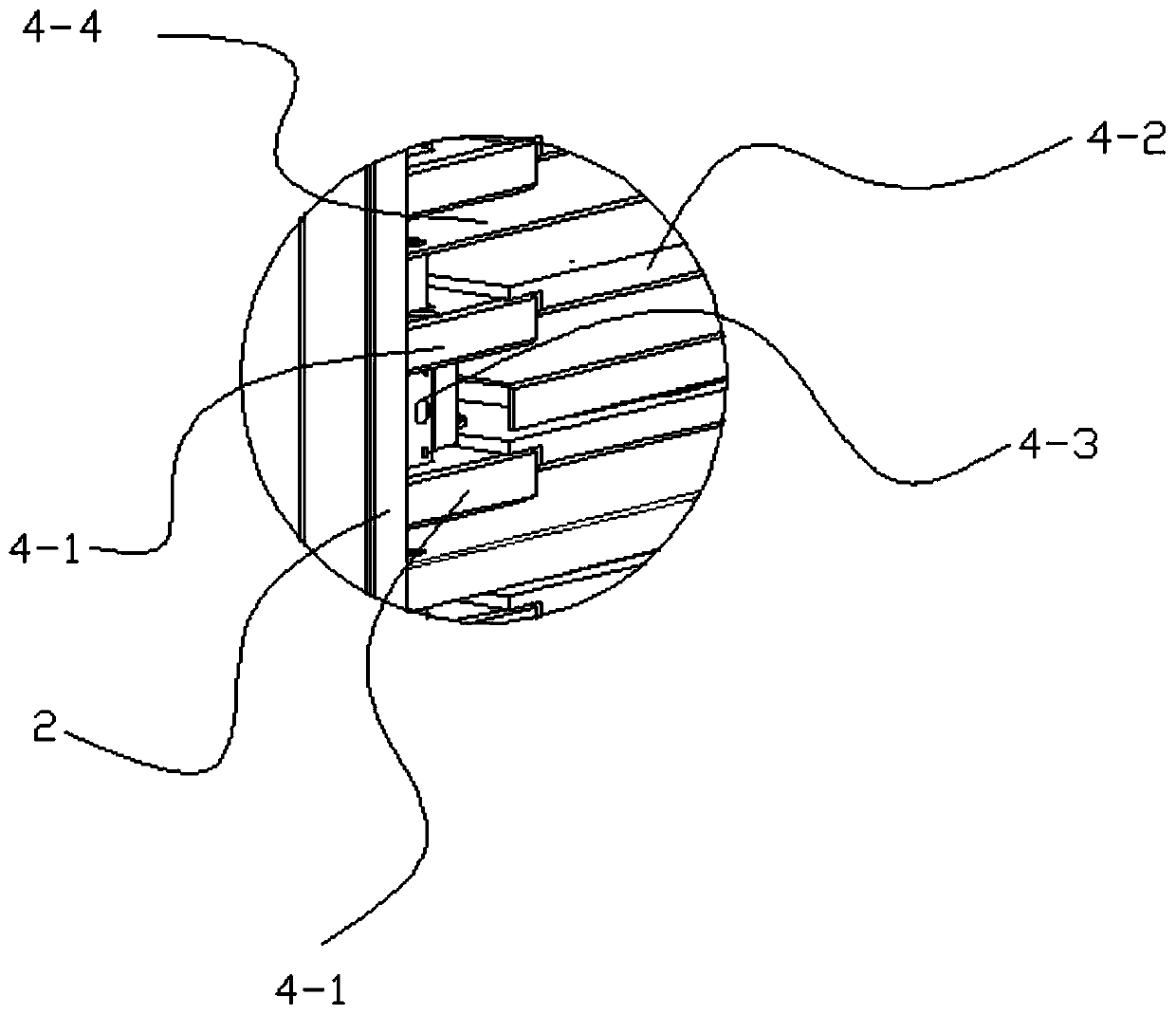

Automatic microbial culture mechanism

PendingCN110272817AEasy to heat individuallyAvoid displacementBioreactor/fermenter combinationsBiological substance pretreatmentsMicroorganismEngineering

The invention discloses an automatic microbial culture mechanism. The automatic microbial culture mechanism includes a culture box, the culture box includes a bottom plate and a box body, the box body is arranged above the bottom plate, and a box door is arranged at the side walls of the box body; a mounting frame and a monitoring platform are arranged in the culture box, the mounting frame is vertically arranged on the top of the bottom plate, and the mounting frame is close to the side of the box door; a plurality of layers of horizontally arranged culture dish placing devices are evenly distributed on two opposite side walls of the mounting frame; each culture dish placing device includes a placing plate, a tray, a mounting plate, a mounting piece, a cylinder and a heating plate; and the monitoring platform includes a vertical moving device and a horizontal moving device. The automatic microbial culture mechanism can realize a real-time automatic monitoring on the growth state of microorganisms in the culture dishes, and can greatly improve monitoring efficiency of the growth state of the microorganisms; meanwhile, the automatic microbial culture mechanism can also carry out rapid culture on the culture dishes in large batches and different temperature bands, greatly improving the efficiency of microbial culture.

Owner:张铁军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com