Medium integrated suspended line circuit structure based on 3D printing

A technology of circuit structure and medium integration, applied in printed circuits, printed circuit parts, electrical components, etc., can solve the problems of complex processing and low space utilization of medium-integrated suspension lines, and achieve simple processing and high space utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

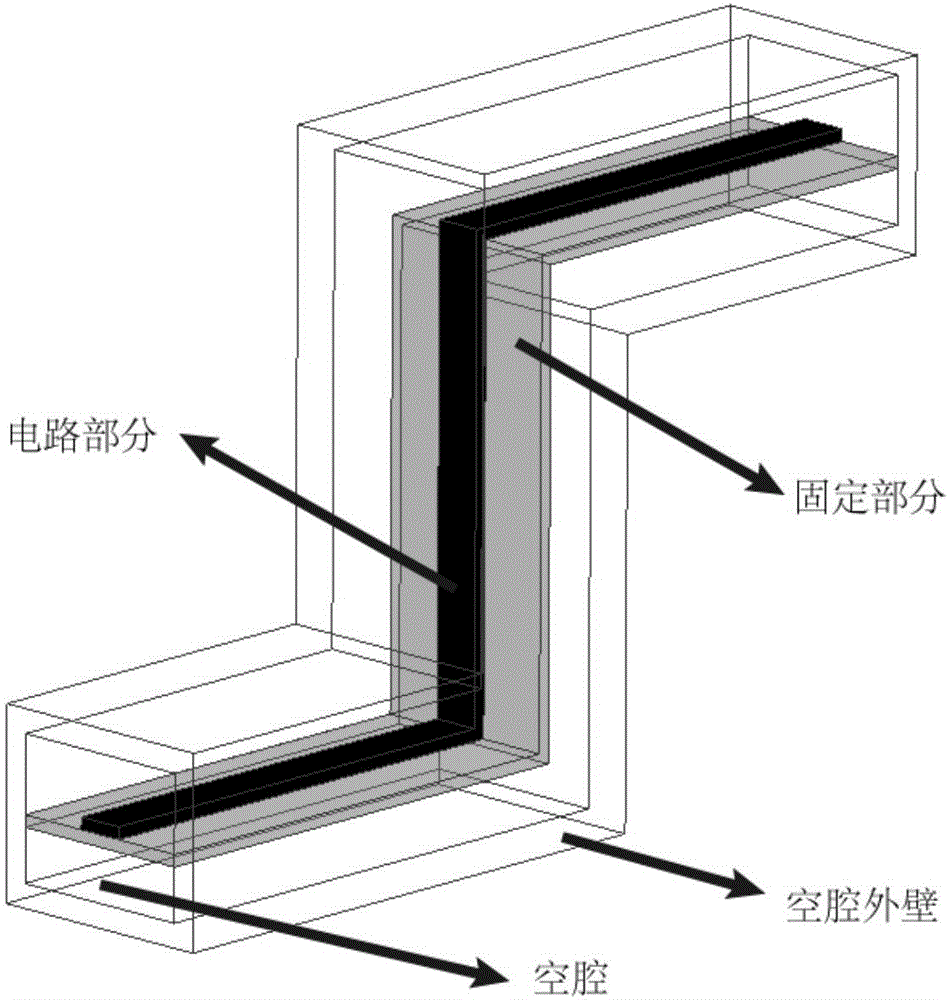

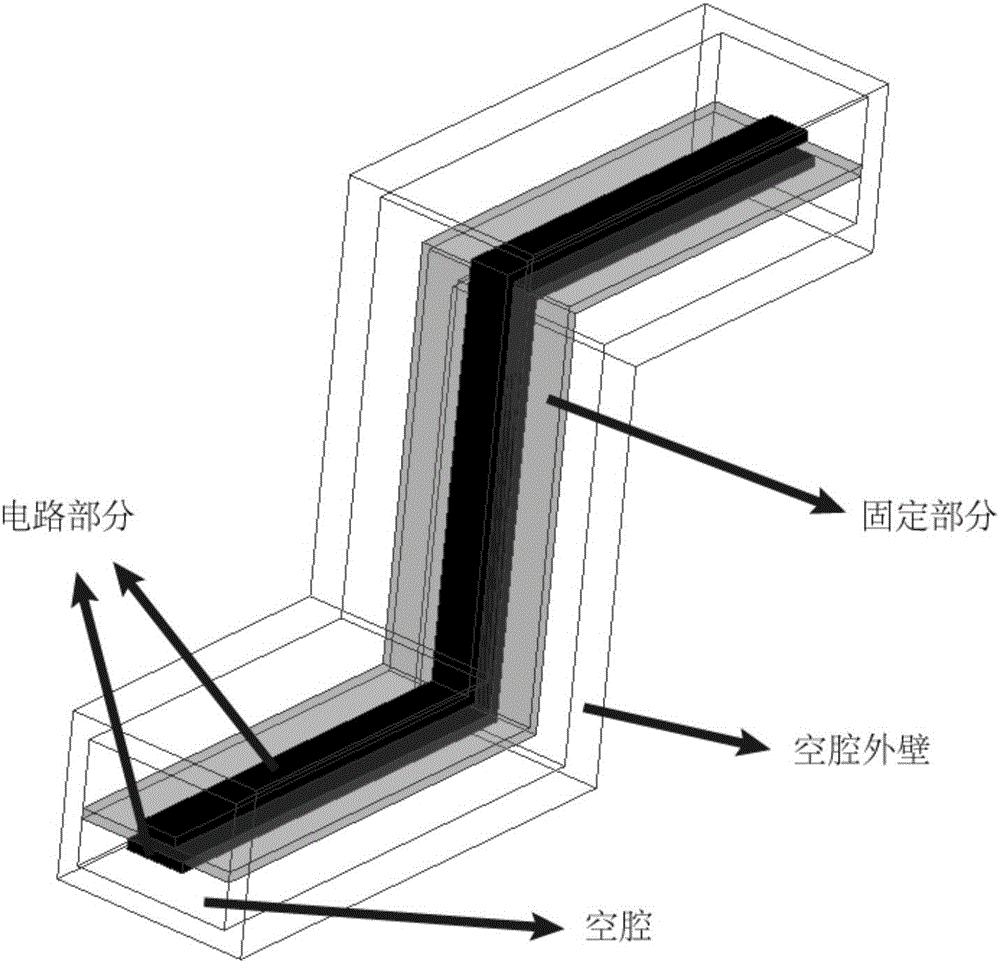

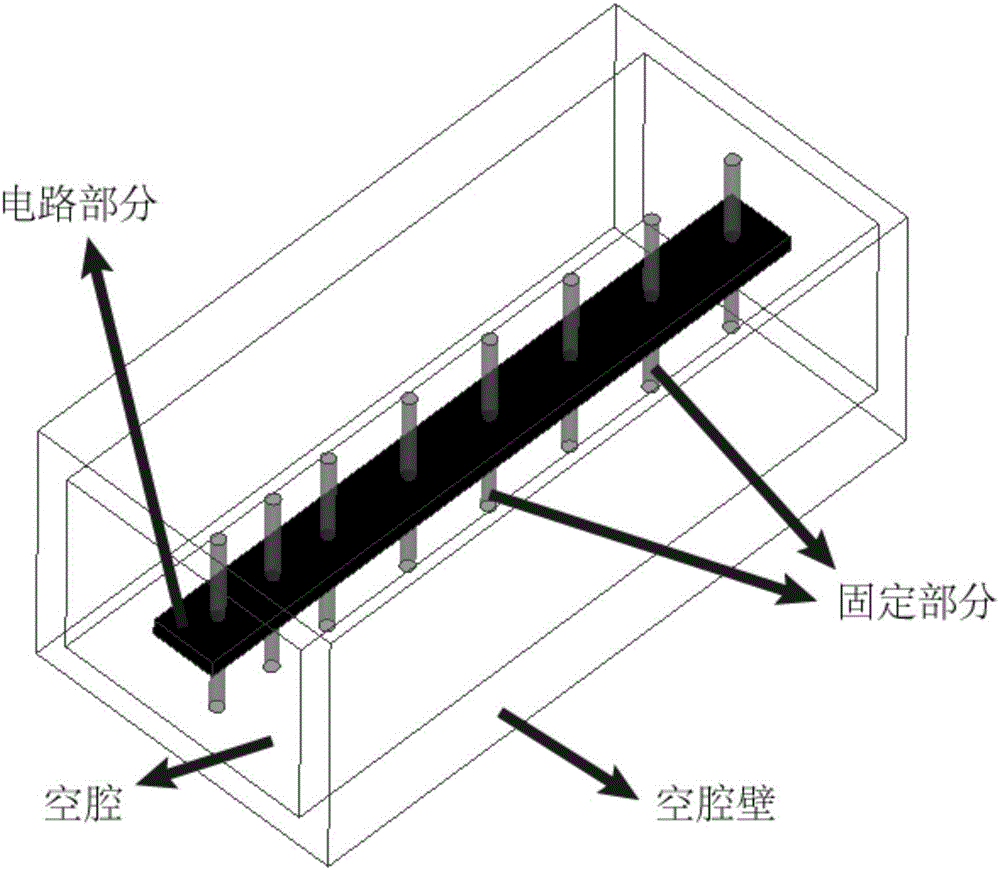

Embodiment 1

[0027] The medium-integrated suspension line circuit based on 3D printing technology mainly includes four parts: the circuit part, which is used to design the required circuit; the circuit fixing part, which is used to connect the circuit part with the cavity wall, so that the circuit part is fixed and has enough The mechanical strength; the cavity part, between the circuit part and the cavity wall, is used to transmit energy and reduce dielectric loss; the cavity wall is used to encapsulate the entire suspension line circuit, reduce radiation loss, and enhance the overall structure mechanical strength. Each part of the circuit part, the circuit fixing part, the cavity part and the cavity wall can be in any regular / irregular three-dimensional shape. The number of cavities in the cavity part can be 1 or more.

[0028] Further, the cavity wall, the circuit part, and the circuit fixing part can all be printed from non-conductive materials such as photosensitive resin, thermoplas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com