Detecting circuit of capacitance type MEMS (micro-electromechanical system) sensor

A detection circuit and sensor technology, applied in the direction of measuring resistance/reactance/impedance, instruments, measuring devices, etc., can solve problems such as constraints, no consideration of loss of electronic components, continuous weakening of energy, sensitivity to external interference, etc., and achieve enhanced anti-interference ability , Easy monolithic integration, strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below with reference to the specific drawings and embodiments.

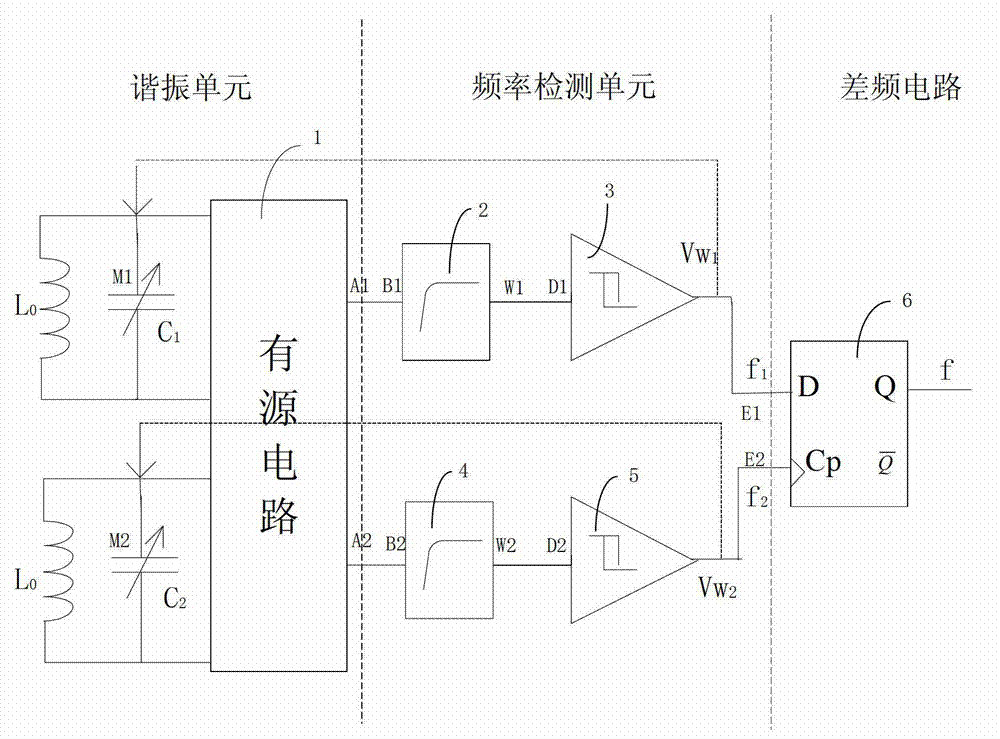

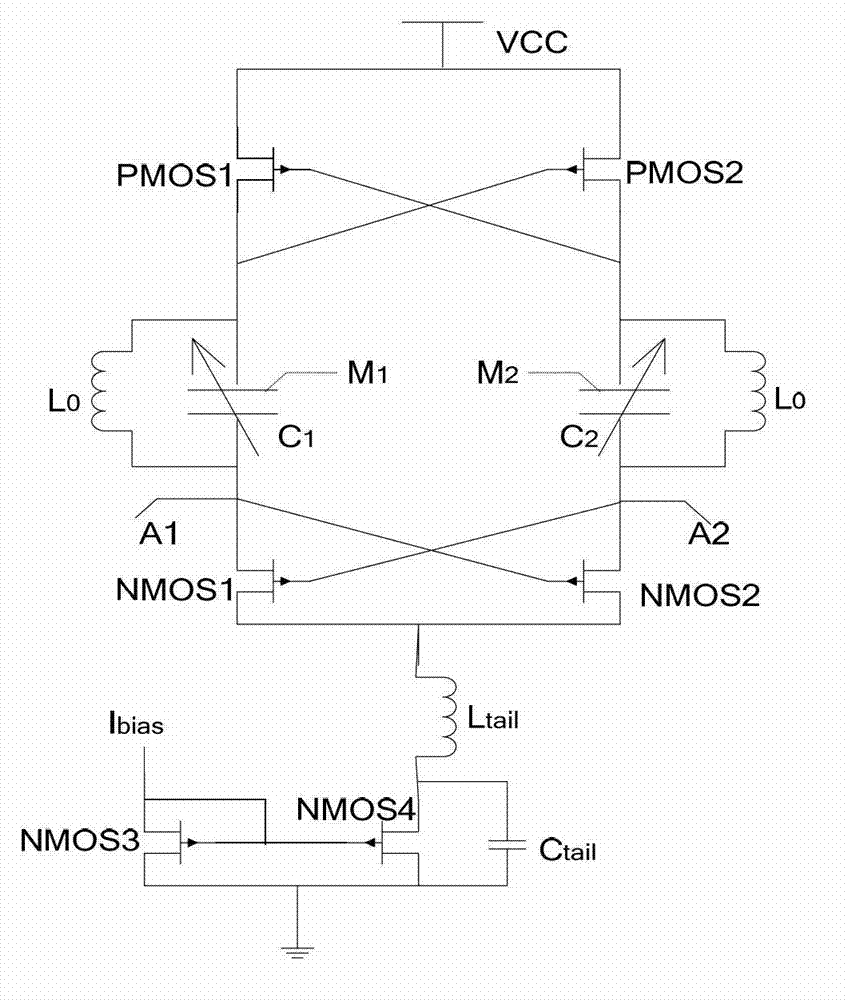

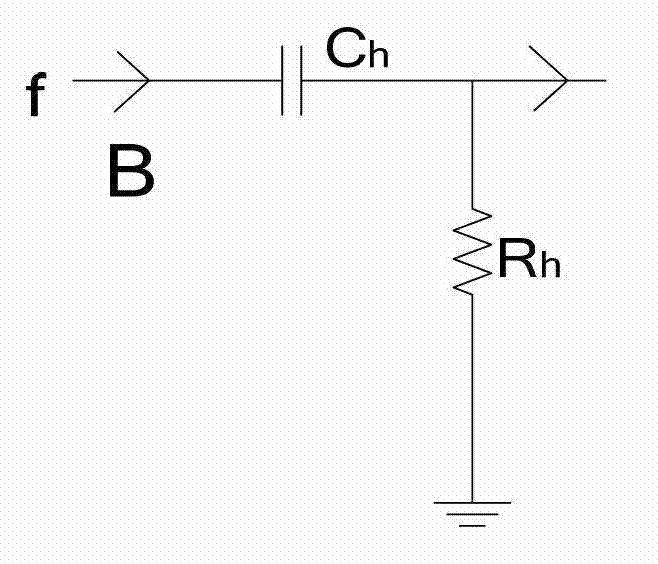

[0021] like figure 1 As shown: the detection circuit of the present invention includes a resonance unit formed after being connected with the first capacitor C1 to be measured and the second capacitor C2 to be measured, the resonance unit is connected to the difference frequency circuit through the frequency detection unit, and the frequency detection unit The output terminals are respectively connected with the first movable electrode plate M1 of the first capacitor C1 to be tested and the second movable electrode plate M2 of the second capacitor C2 to be tested; the first capacitor C1 to be tested and the second capacitor C2 to be tested are connected correspondingly A resonant unit is formed, the resonant frequency can be generated in the resonant unit, and the energy of resonance attenuation can be compensated; the frequency detection unit drives the diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com