Automatic microbial culture mechanism

A microbial and automatic technology, applied in the field of microbial cultivation, can solve the problems of low efficiency of microbial cultivation and monitoring, high professional requirements for operators, time-consuming and labor-intensive manual detection, etc., and achieve the effect of light weight, good insulation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

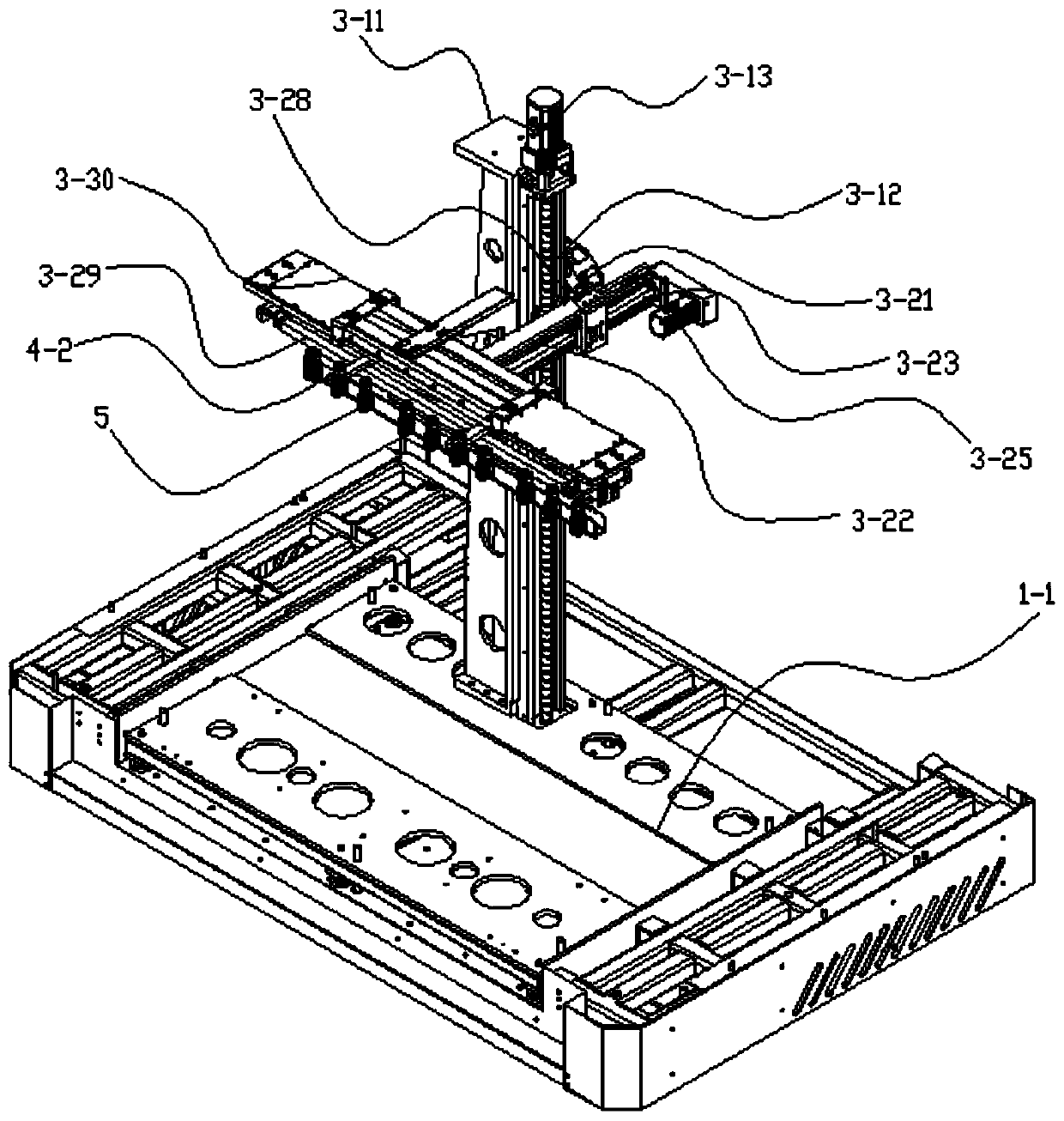

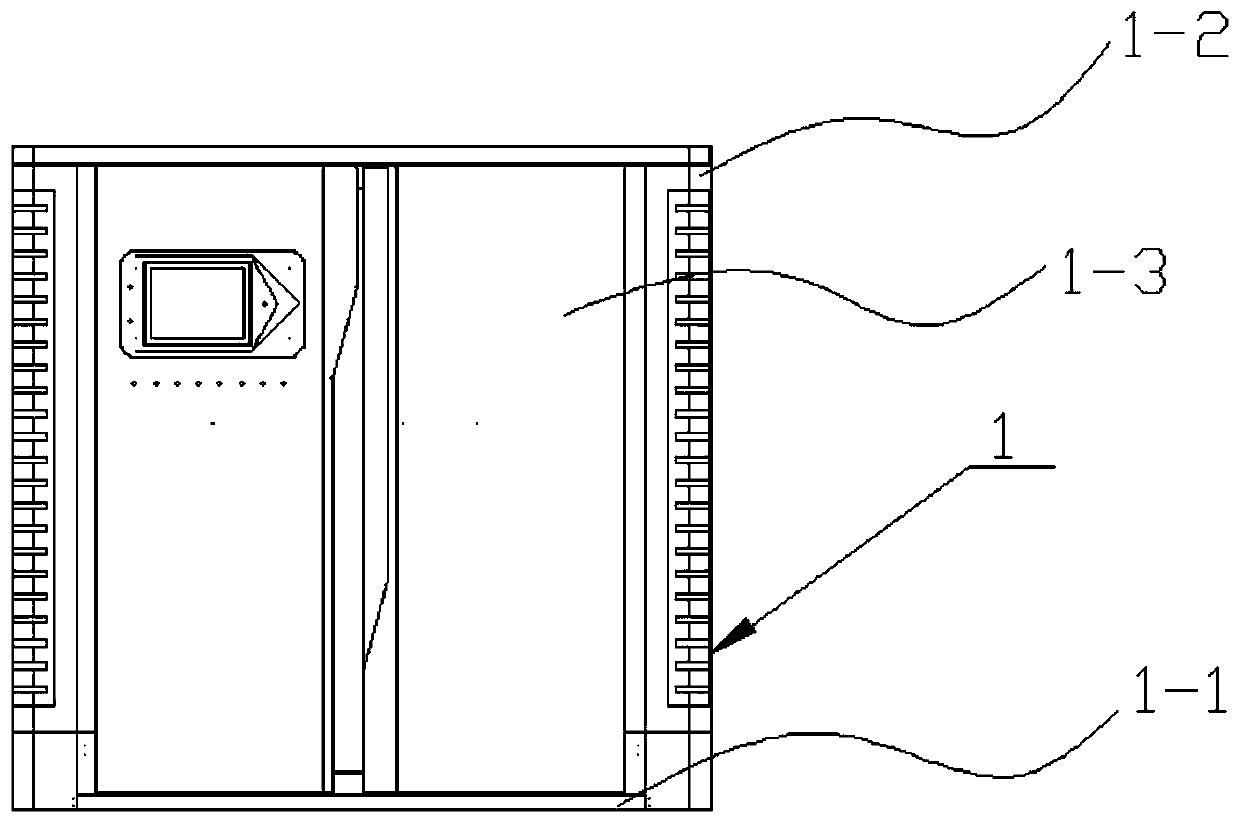

[0044] Such as Figure 1-8 Shown, a kind of microbial automatic culture mechanism, comprises bottom plate 1-1 and the box body 1-2 of bottom opening, and described box body 1-2 is arranged on described bottom plate 1-1 top, and described box body 1-2 A box door 1-3 is provided on the side wall; it is characterized in that a mounting frame 2 and a monitoring platform 3 are arranged inside the box body 1-2, and the mounting frame 2 is vertically arranged on the top of the bottom plate 1-1 On the side close to the box door 1-3, several layers of culture dish placement devices 4 arranged horizontally are evenly distributed on the mounting frame 2 from top to bottom;

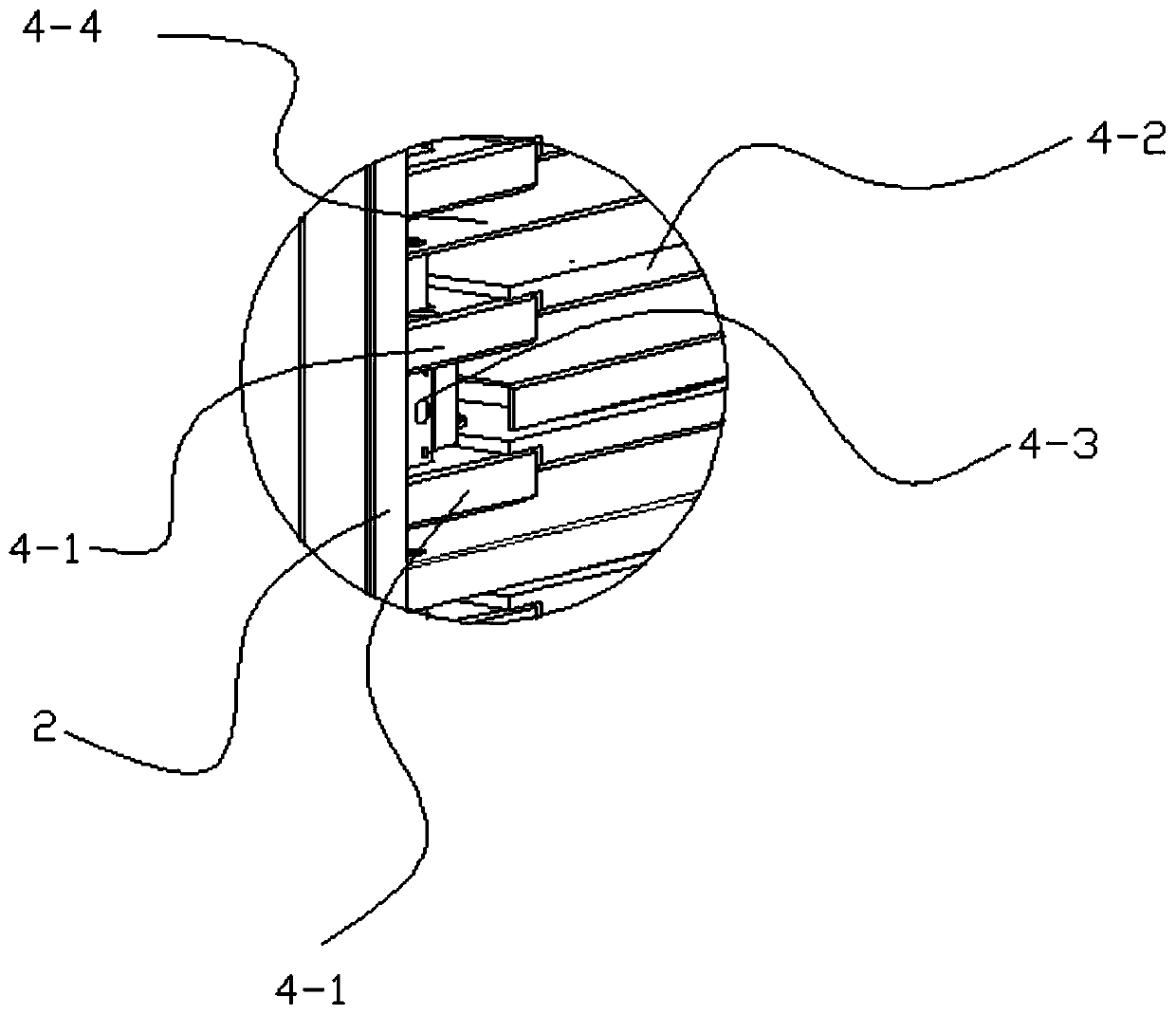

[0045] The culture dish placement device 4 includes a placement plate 4-1, a tray 4-2, a cylinder 4-3 and a heating plate 4-4; the placement plate 4-1 is arranged on the mounting frame 2, and the placement plate 4- 1 is provided with the cylinder 4-3, the piston rod of the cylinder 4-3 faces the placement plate 4-1 ...

Embodiment 2

[0053] Such as Figure 1-8 In this embodiment, on the basis of Embodiment 1, the two ends of the tray 4-2 are provided with positioning holes 4-21, and the placement plate 4-1 is provided with positioning pins 4-11 corresponding to the positioning holes 4-21. The tray 4-2 is provided with a number of petri dish placement holes 4-22, and the placement holes are arranged in rows; the camera 5 is set corresponding to one row of placement holes.

[0054] Positioning holes 4-21 are set at both ends of the pallet 4-2, and positioning pins 4-11 corresponding to the positioning holes 4-21 are set on the placement plate 4-1 at the same time, in order to prevent the pallet 4-2 from being placed Displacement occurs after the plate 4-1 is put on, and at the same time, the collection accuracy is improved during collection.

Embodiment 3

[0056] Such as Figure 1-8 In this embodiment, on the basis of Embodiment 1, the heating plate 4-4 has a four-layer structure, including a supporting plate layer 4-41, a heat insulating layer 4-42, a heat generating film layer 4-43 and a heat conducting layer 4-4. 44.

[0057] Set the heating plate 4-4 into a 4-layer structure, including the supporting plate layer 4-41, the heat insulation layer 4-42, the heating film layer 4-43 and the heat conduction layer 4-44, wherein the heat insulation plate insulates some heat, Prevent heat from being directly transmitted to the supporting plate layer 4-41, causing the user to be scalded after touching the supporting plate layer 4-41.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com