Experimental coke oven for small-scale production of coke and colloid layer samples and using method thereof

An experimental coke oven and colloidal layer technology, applied in the field of coking experiments, can solve the problems of not being able to prepare coke and colloidal layer samples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

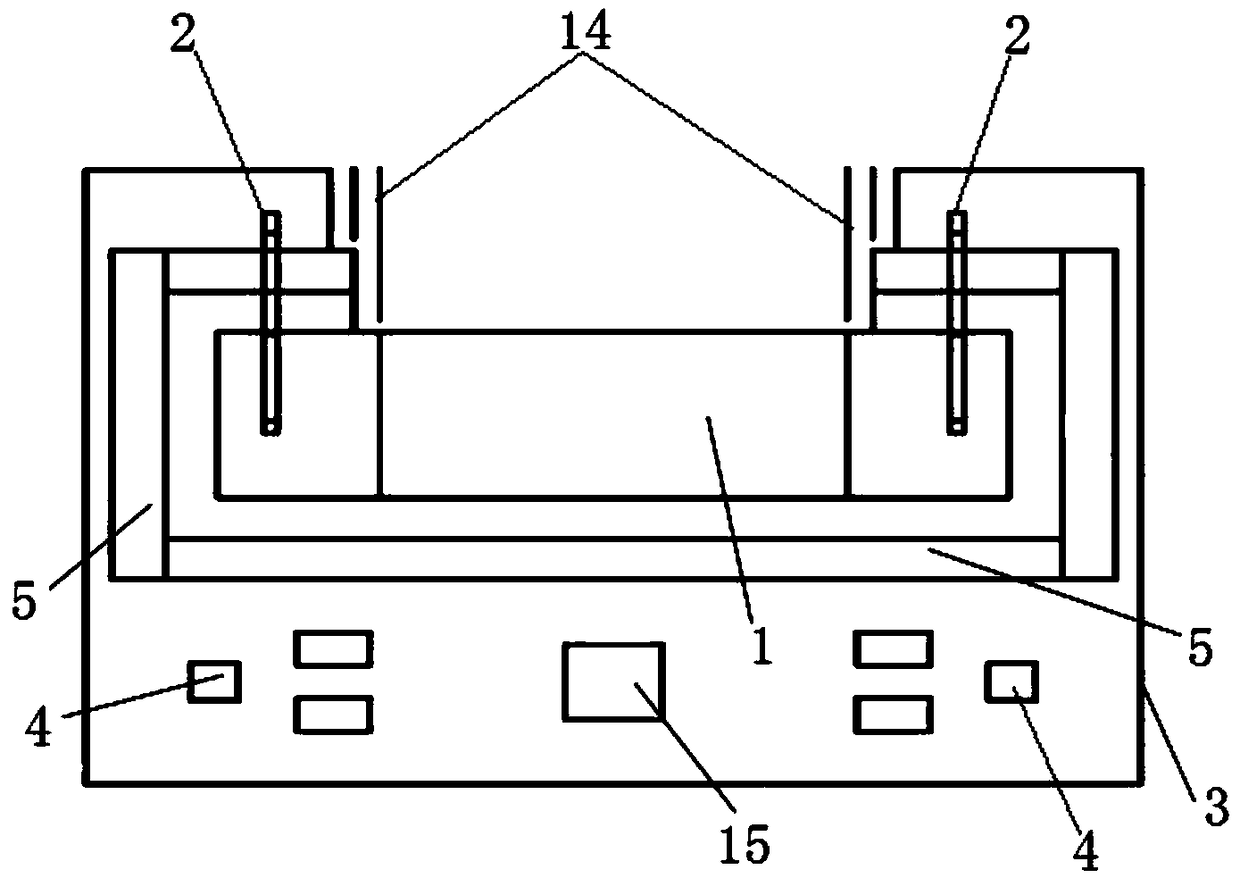

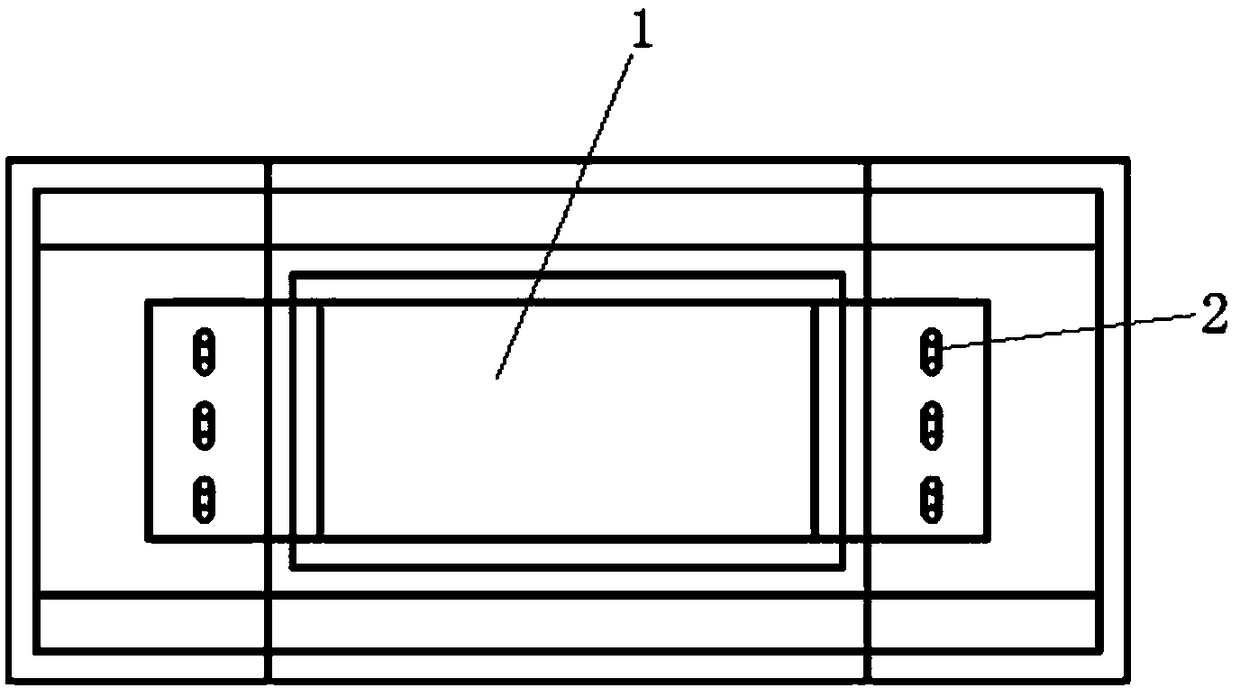

[0041] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

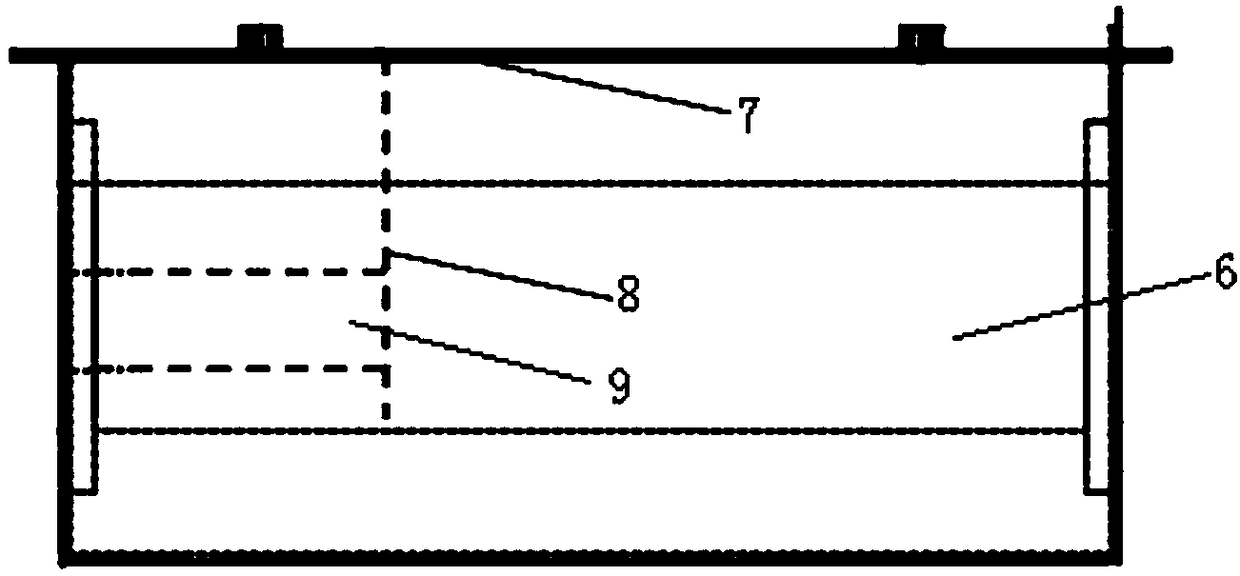

[0042] The experimental coke oven for small-scale production of coke and colloidal layer samples according to the present invention includes a heating furnace, a reactor 6 and a colloidal layer sampler 8; such as Figure 1a , 1b As shown in the figure, the heating furnace is composed of a furnace shell, a heating furnace body 3, a carbonization chamber 1 and a furnace door that opens at the top, which are arranged in sequence from the outside to the inside. The reactor 6 containing the coal samples is placed in the carbonization chamber 1, and is divided into a main reaction area and a colloidal layer sampling area, and the main reaction area and the colloidal layer sampling area are respectively close to the two heating ends of the heating furnace body 3; A colloidal layer sampler 8 (such as Figures 2a-2cshown), a cylindrical quartz tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com