Gas extraction and drilling cooperative drilling and protecting integrated system for soft coal seams and process

A technology for gas drainage and soft coal seam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

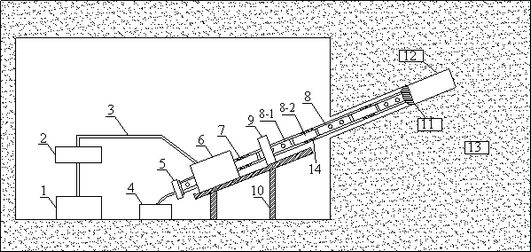

[0030] Example 1: Coal seam gas drainage hole coordinated drilling and protection integrated system for soft coal seams,

[0031] The system includes: console 2, hydraulic pump station 1, air compressor 4, feed device 6, drill rod 7, hole protection tube 8, polyurethane foam ring 14 and drill bit 11; hydraulic pump station 1 is controlled by high pressure hose 3 The table 2 is connected, and the feeding device 6 is located on the guide groove above the frame 10, and is connected to the console 2 through the high-pressure hose 3; the hole protecting pipe 8 is located inside the drill pipe 7, between the hole protecting pipe 8 and the drill pipe 7 A plurality of polyurethane foam rings 14 are provided, the drill rod 7 is located in the middle of the feeding device 6, a drill bit 11 is installed at the top of the drill rod 7, and a tray 5 is arranged at the tail of the drill rod 7, and the tray 5 is connected to an air compressor 4 through a high pressure hose 3.

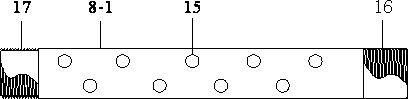

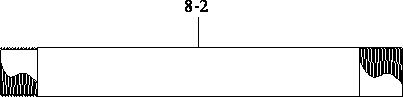

[0032] The hole pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com