Electric vehicle power battery heat management device based on semiconductor refrigeration technology

An electric vehicle and power battery technology, applied in the field of electric vehicle power battery thermal management devices, can solve problems such as reducing system reliability, increasing failure risk, and complex protection, so as to improve heat transfer efficiency, reduce thermal management related components, and improve The effect of thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

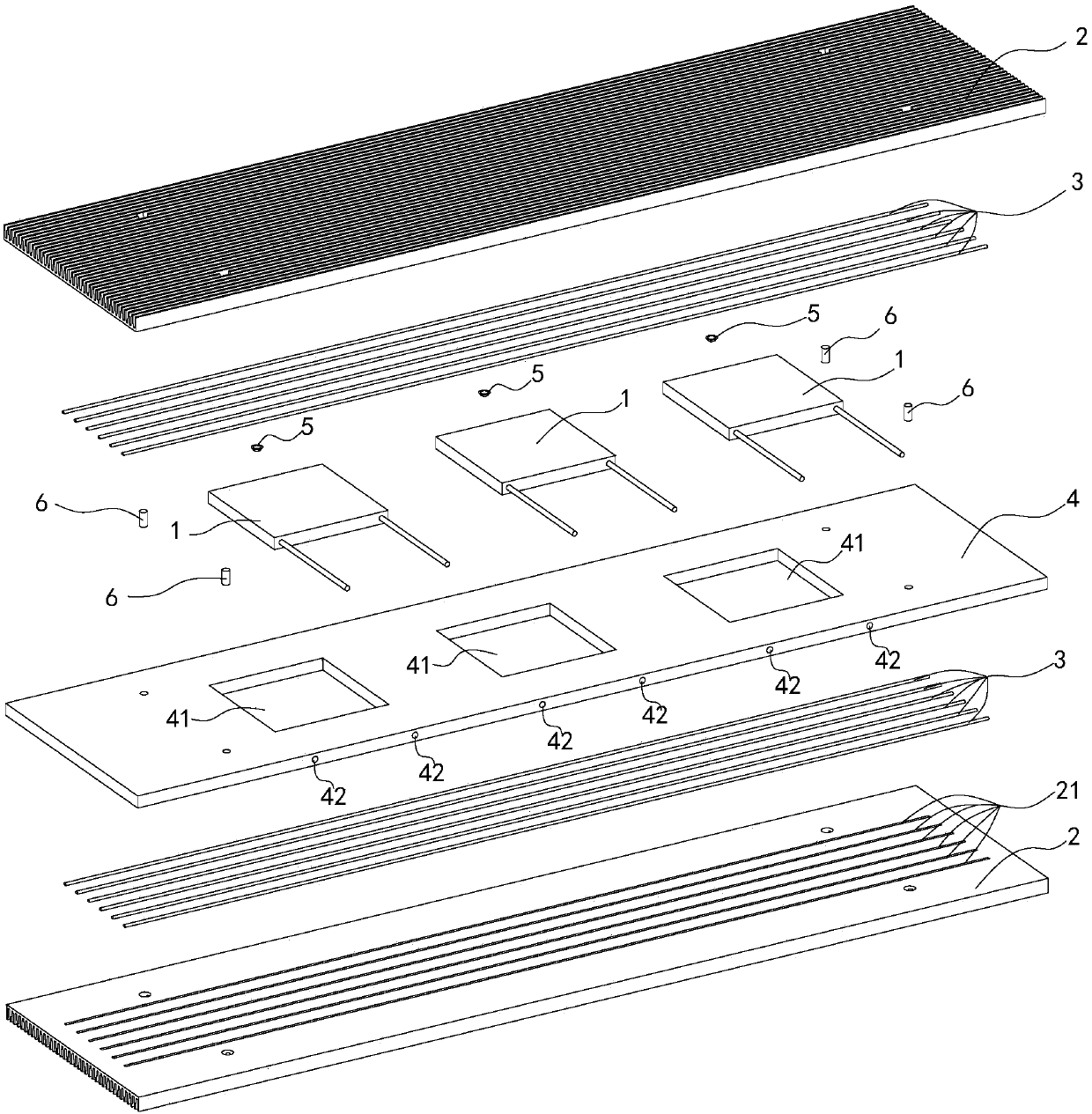

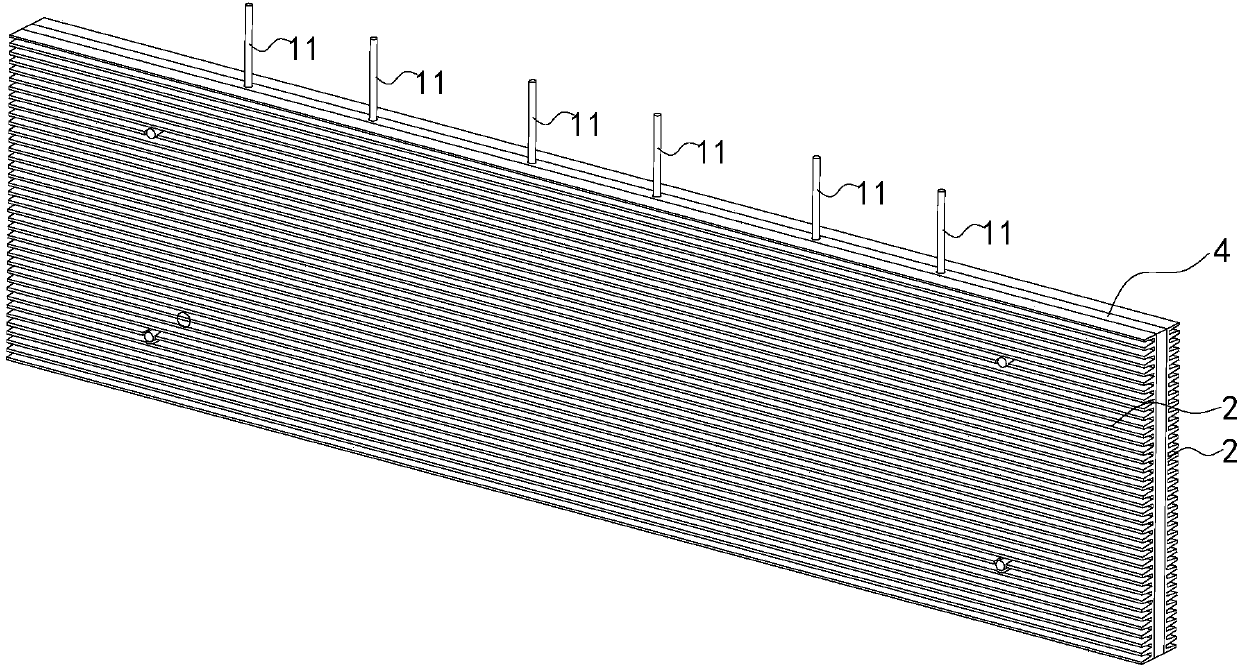

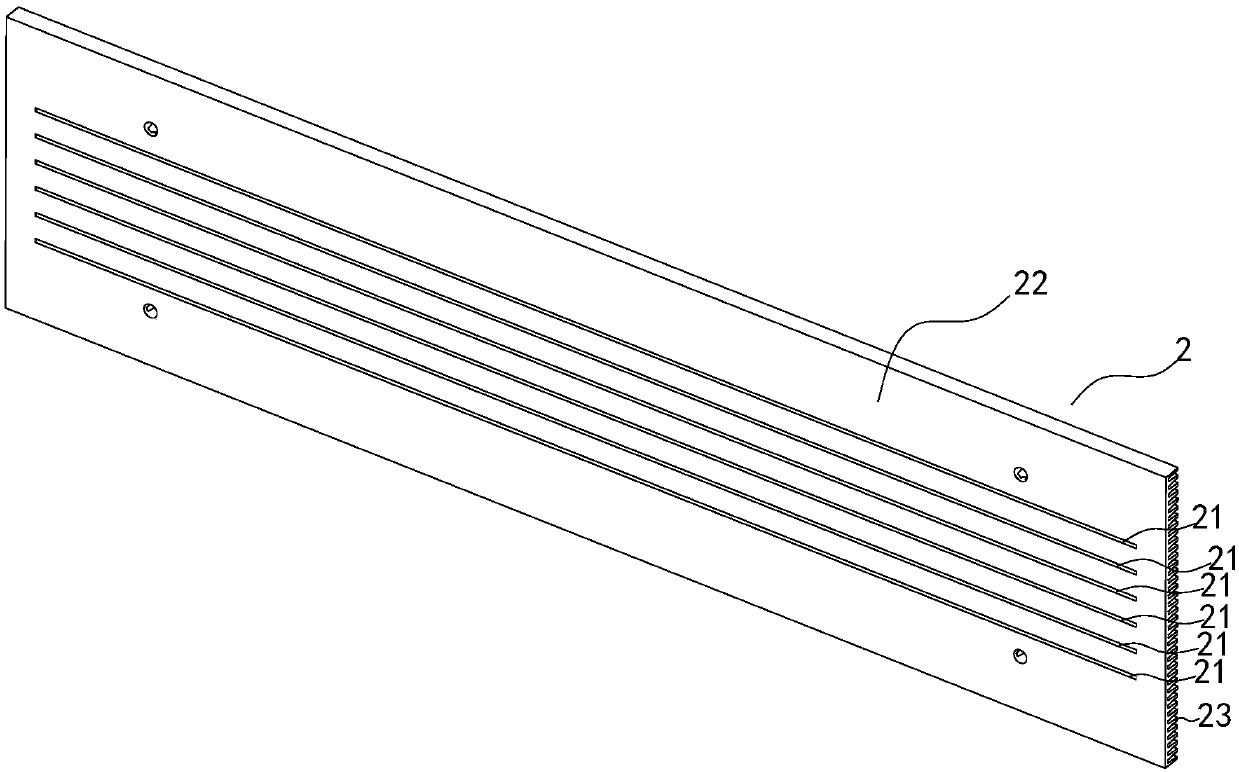

[0037] like Figure 1-Figure 5 As shown, the electric vehicle power battery thermal management device based on semiconductor refrigeration technology is set in the cell module with a gap between the cell and the cell; it includes a semiconductor cooling chip 1, two fixedly connected radiators 2, and a controller And the thermal conduction element 3 that uniformly distributes the heat or cold generated by the semiconductor cooling sheet 1 on the radiator 2; the two radiators 2 are respectively arranged at the hot end and the cold end of the semiconductor cooling sheet 1 , between the heat sink 2 and the hot end or cold end of the semiconductor refrigeration sheet 1, several heat conducting elements 3 are crimped; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com