Patents

Literature

68 results about "Octafluorocyclobutane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

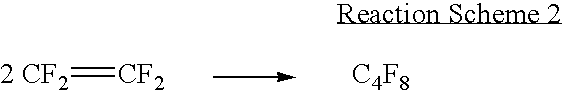

Octafluorocyclobutane, or perfluorocyclobutane, C₄F₈, is an organofluorine compound which enjoys several niche applications. It is related to cyclobutane by replacement of all C–H bonds with C–F bonds. Octafluorocyclobutane is produced by the dimerization of tetrafluoroethylene and the reductive coupling of 1,2-dichloro-1,1,2,2-tetrafluoroethane.

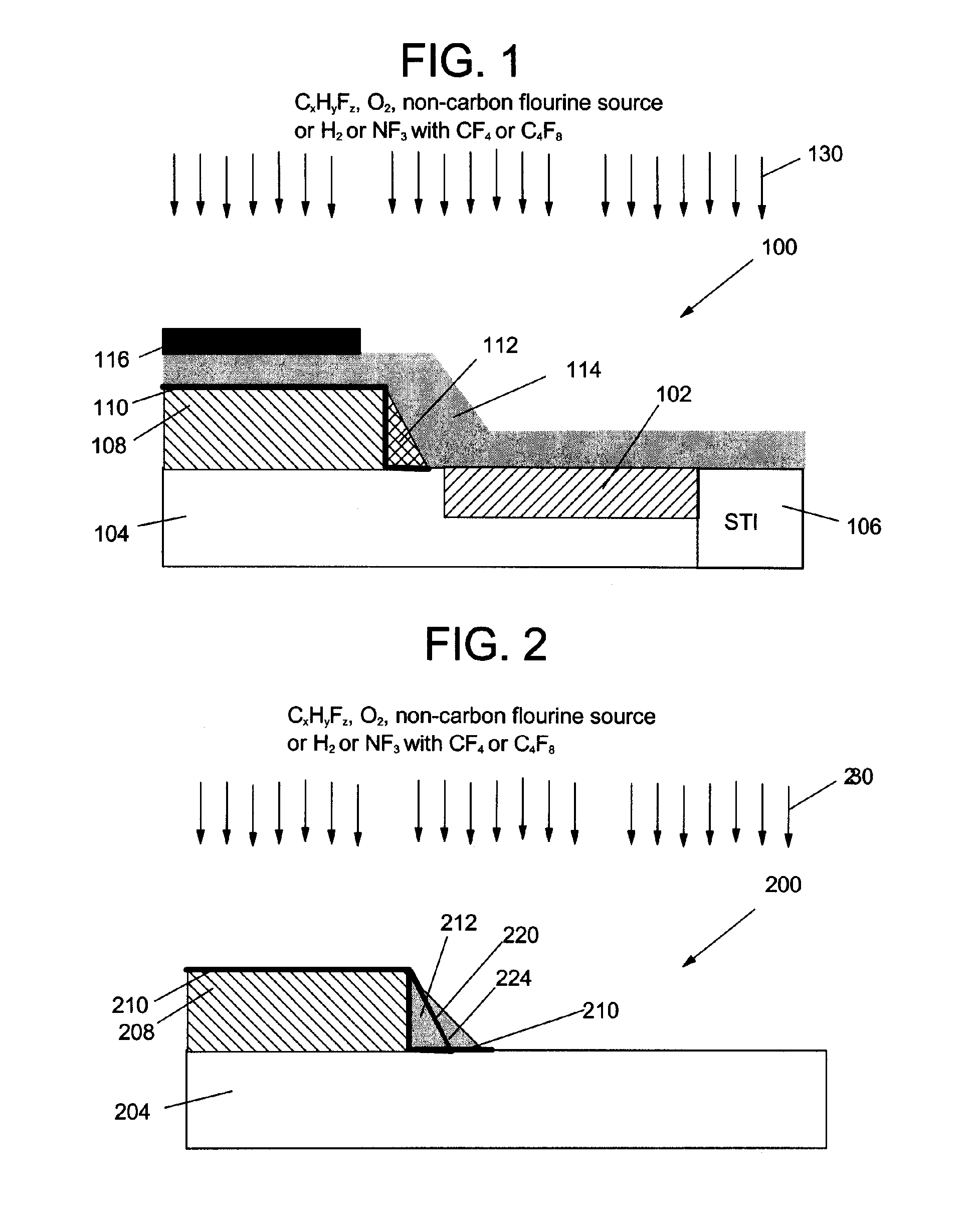

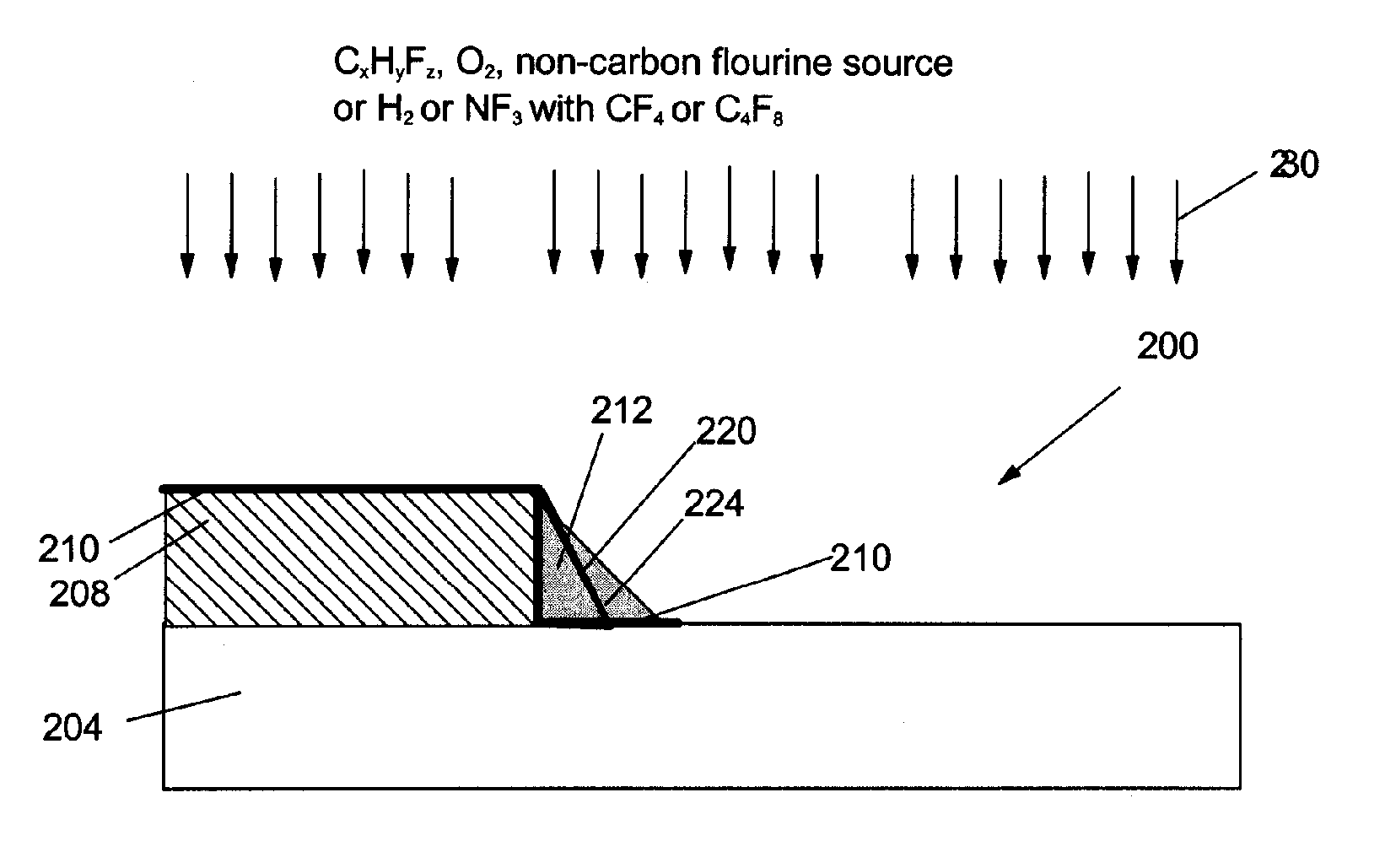

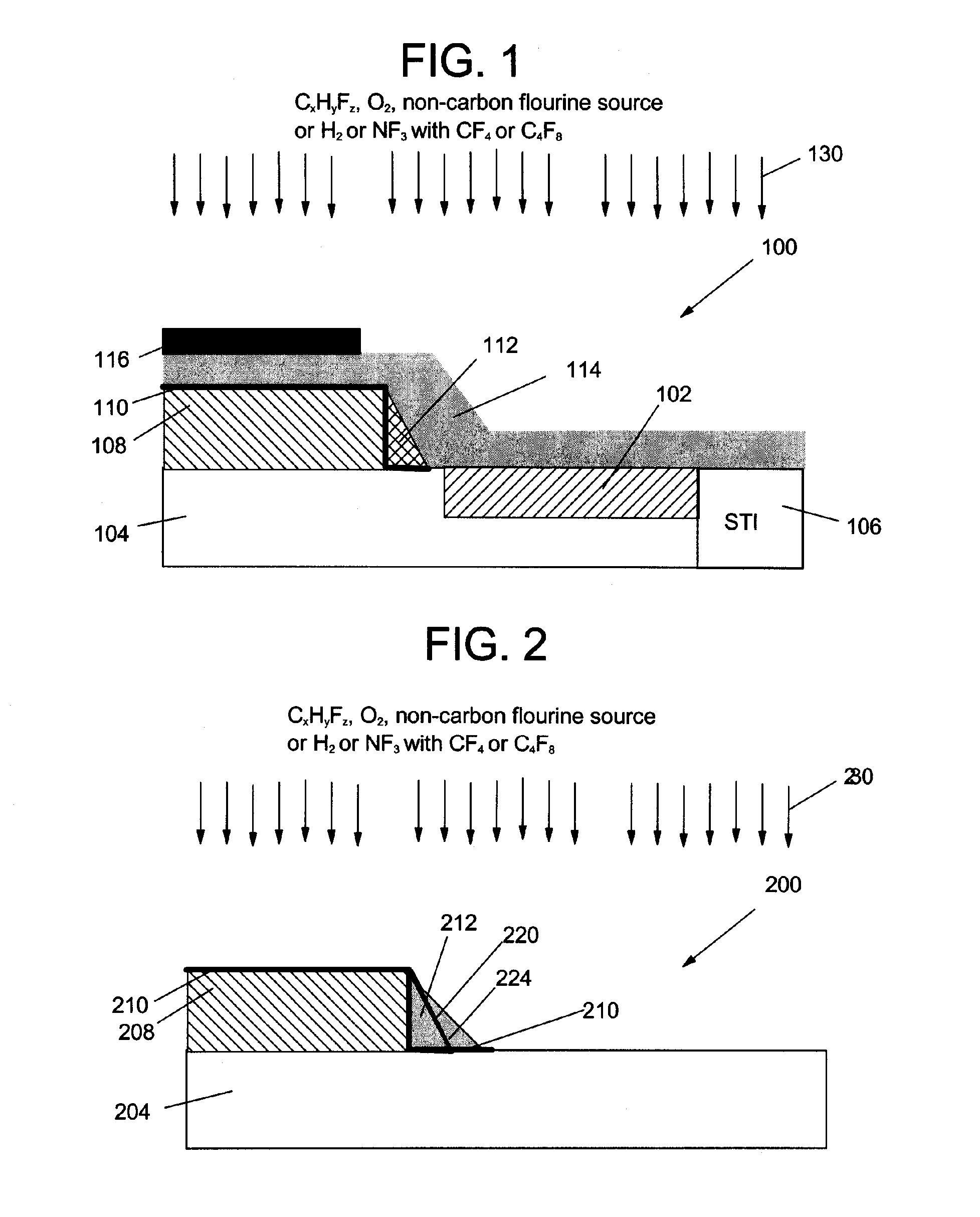

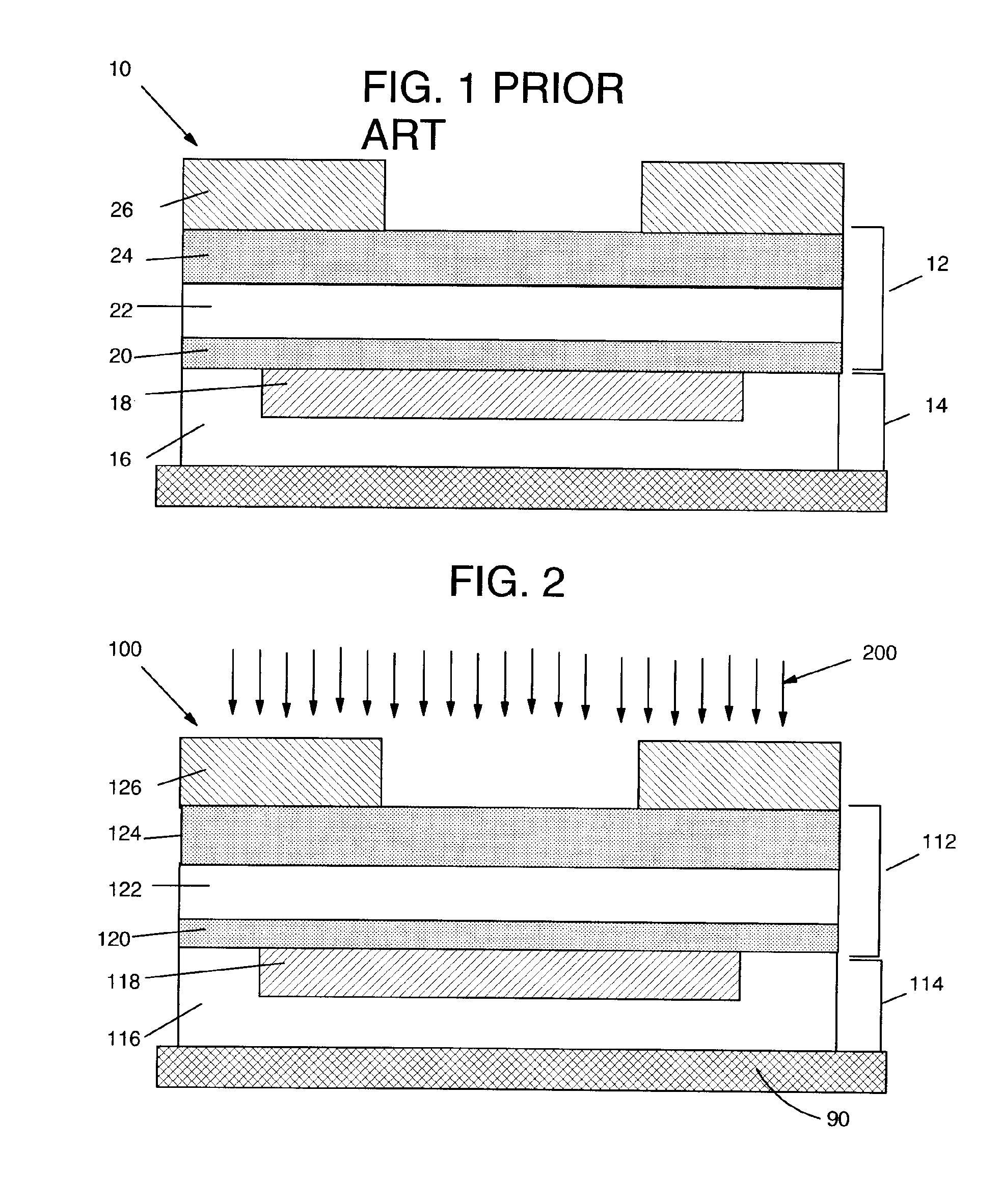

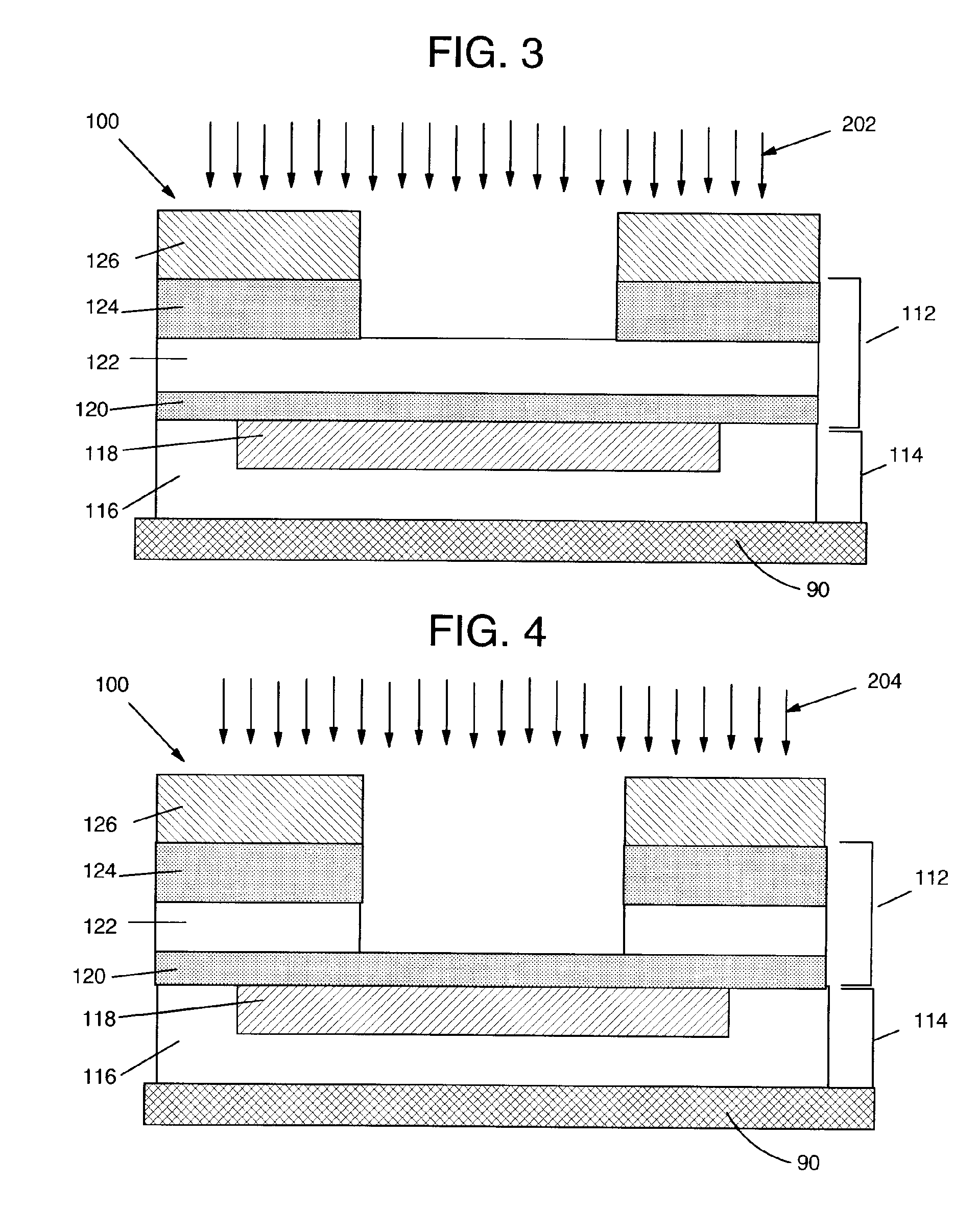

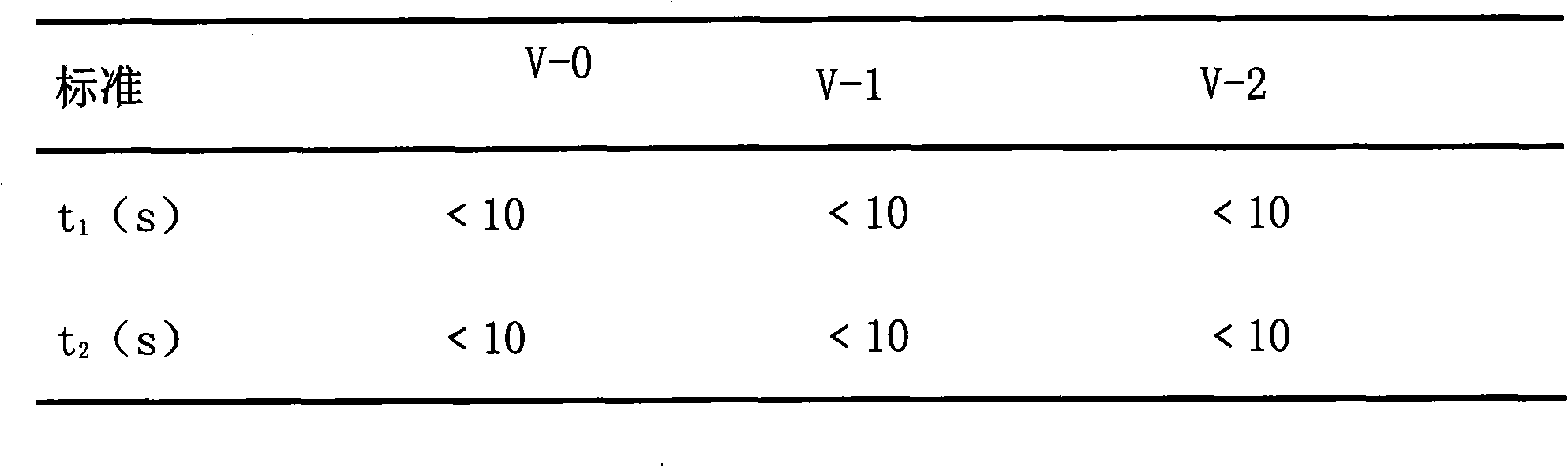

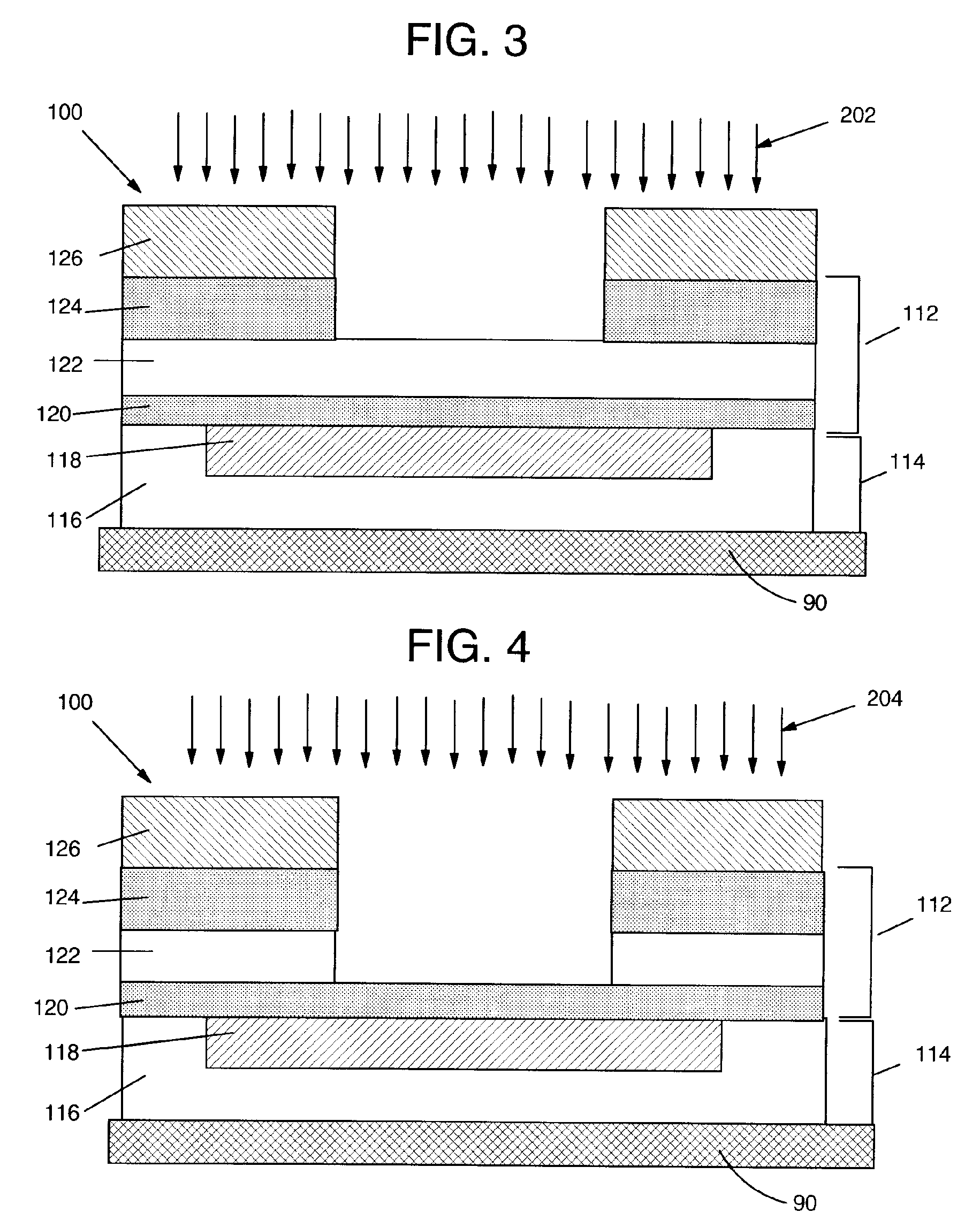

Silicon nitride etching methods

ActiveUS7288482B2Semiconductor/solid-state device manufacturingSulfur hexafluorideOctafluorocyclobutane

Methods of etching silicon nitride material, and more particularly, etching nitride selective to silicon dioxide or silicide, are disclosed. The methods include exposing a substrate having silicon nitride thereon to a plasma including at least one fluorohydrocarbon and a non-carbon containing fluorine source such as sulfur hexafluoride (SF6). The plasma may also include oxygen (O2) and the fluorohydrocarbons may include at least one of: trifluoromethane (CHF3), difluoromethane (CH2F2), and methyl fluoride (CH3F). In an alternative embodiment, the plasma includes one of hydrogen (H2) and nitrogen trifluoride (NF3) and one of tetrafluoromethane (CF4) and octafluorocyclobutane (C4F8). The methods are preferably carried out using a low bias voltage, e.g. <100 V.

Owner:IBM CORP +1

Coating process for lotus leaf-like diamond film

InactiveCN103469205AReduce stressToo much dopingSolid state diffusion coatingChemical vapor deposition coatingWear resistantGas phase

The invention relates to a coating process for a lotus leaf-like diamond film. According to the process, gases such as octafluorocyclobutane, monomethylsilane and dimethylsilane are introduced into a vacuum tank, denpending on plasma immersion ion deposition equipment; and the lotus leaf-like diamond film is coated on a workpiece surface by a plasma-enhanced chemical vapor deposition method. The coating process mainly comprises five steps of plasma cleaning, plasma nitriding, transition layer plating, diamond-like plating and lotus leaf-like film plating. The lotus leaf-like diamond film has very high hardness. Since the lotus leaf-like diamond film has a structure similar to the surface of the lotus leaf, the lotus leaf-like diamond film has extremely low surface energy. In consideration of high wear-resistant and hydrophobic properties of the lotus leaf-like diamond film, the lotus leaf-like diamond film can be successfully applied in the fields such as coal mine screen meshes, metal molds, aerospace aircraft wings and oil pipelines.

Owner:HEFEI YONGXIN PLASMA TECH

Adsorbent for purifying perfluorocarbon, process for producing same, high purity octafluoropropane and octafluorocyclobutane, and use thereof

To provide a purification adsorbent capable of effectively removing impurities contained in a perfluorocarbon and obtaining a perfluorocarbon reduced in the impurity content to 1 ppm by mass or less; a process for producing the adsorbent; high-purity octafluoropropane or octafluorocyclobutane; processes for purifying and for producing the octafluoropropane or octafluorocyclobutane; and uses thereof. Purification is performed using a purification adsorbent produced by a method comprising (1) washing an original coal with an acid and then with water, (2) deoxidizing and / or dehydrating the original coal, (3) re-carbonizing the original coal at a temperature of from 500 to 700° C. and (4) activating the original coal at a temperature of from 700 to 900° C. in a mixed gas stream containing an inert gas, carbon dioxide and water vapor.

Owner:SHOWA DENKO KK

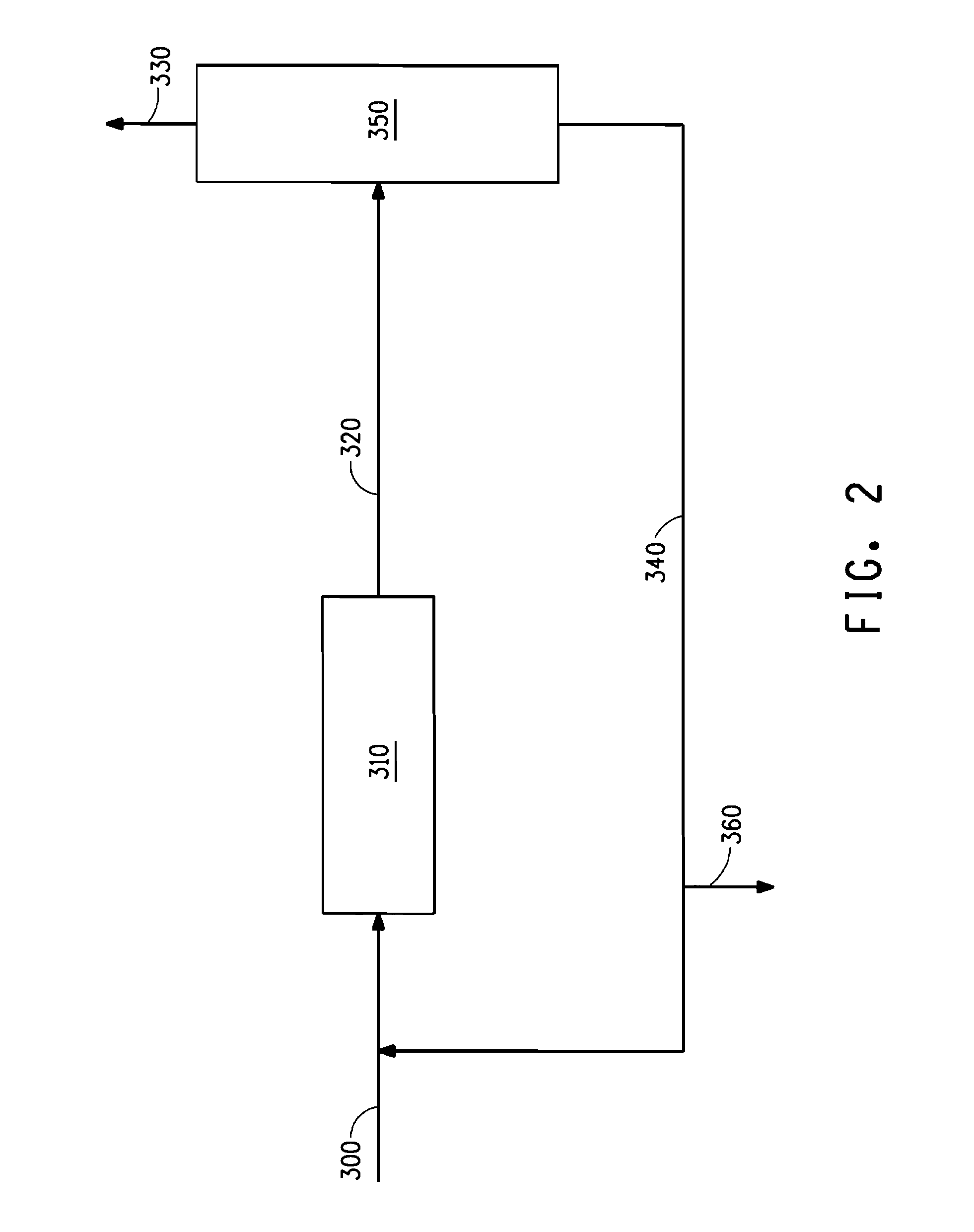

Hexafluoropropylene production method

InactiveCN1454883APrevent self-aggregationAvoid carbon formationHalogenated hydrocarbon preparationHexafluoropropyleneOctafluorocyclobutane

The production method of hexafluoropropylene includes the following steps: uniformly mixing raw material gas tetrafluoroethylene and octafluorocyclobutane according to a certain proportion, preheating and feeding them into stage heated tubular reactor for making cracking reaction, quenching reaction product, removing acid, drying and finally rectifying separation to obtain the invented hexafluoropylene whose purity is greater than or equal to 99.98%. Said invention adopts the octafluorocyclobutane as diluting agent and as reactant, at the same time adopts stage heated cracking process, so that it not only improves the thermal conductivity of cracking gas, but also can make the whole reaction process be implemented in optimum temp. range to inhibite the production of poor side reaction.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

Refrigerant mixture comprising difluromethane, pentafluroethane and 1,1,1-trifluoroethane

A novel refrigerant composition useful as a substitute for HCFC-22, comprising a first constituent of difluoromethane (CH2F2, HFC-32); a second constituent of pentafluoroethane (CHF2CF3, HFC-125); a third constituent of 1,1,1-trifluoroethane (CH3CF3, HFC-143a); a fourth constituent selected from the group consisting of cyclopropane (C3H6, RC-270), 1,1,1,2,3,3,3-heptafluoropropane (CF3CHFCF3, HFC-227ea), 1,1,1,2,2-pentafluoropropane (CH3CF2CF3, HFC-245cb), isobutane (CH(CH3)2CH3, R-600a), octafluorocyclobutane (C4F8, RC-318), 1,1,1,2,3,3-hexafluoropropane (CHF2CHFCF3, HFC-236ea), butane (C4H10, R-600), bis(difluoromethyl)ether (CHF2OCHF2, HFE-134) and pentafluoroethylmethylether (CF3CF2OCH3, HFE-245).

Owner:KOREA INST OF SCI & TECH

Silicon nitride etching methods

ActiveUS20060252269A1Reduce bias voltageSemiconductor/solid-state device manufacturingSulfur hexafluorideOctafluorocyclobutane

Methods of etching silicon nitride material, and more particularly, etching nitride selective to silicon dioxide or silicide, are disclosed. The methods include exposing a substrate having silicon nitride thereon to a plasma including at least one fluorohydrocarbon and a non-carbon containing fluorine source such as sulfur hexafluoride (SF6). The plasma may also include oxygen (O2) and the fluorohydrocarbons may include at least one of: trifluoromethane (CHF3), difluoromethane (CH2F2), and methyl fluoride (CH3F). In an alternative embodiment, the plasma includes one of hydrogen (H2) and nitrogen trifluoride (NF3) and one of tetrafluoromethane (CF4) and octafluorocyclobutane (C4F8). The methods are preferably carried out using a low bias voltage, e.g. <100 V.

Owner:IBM CORP +1

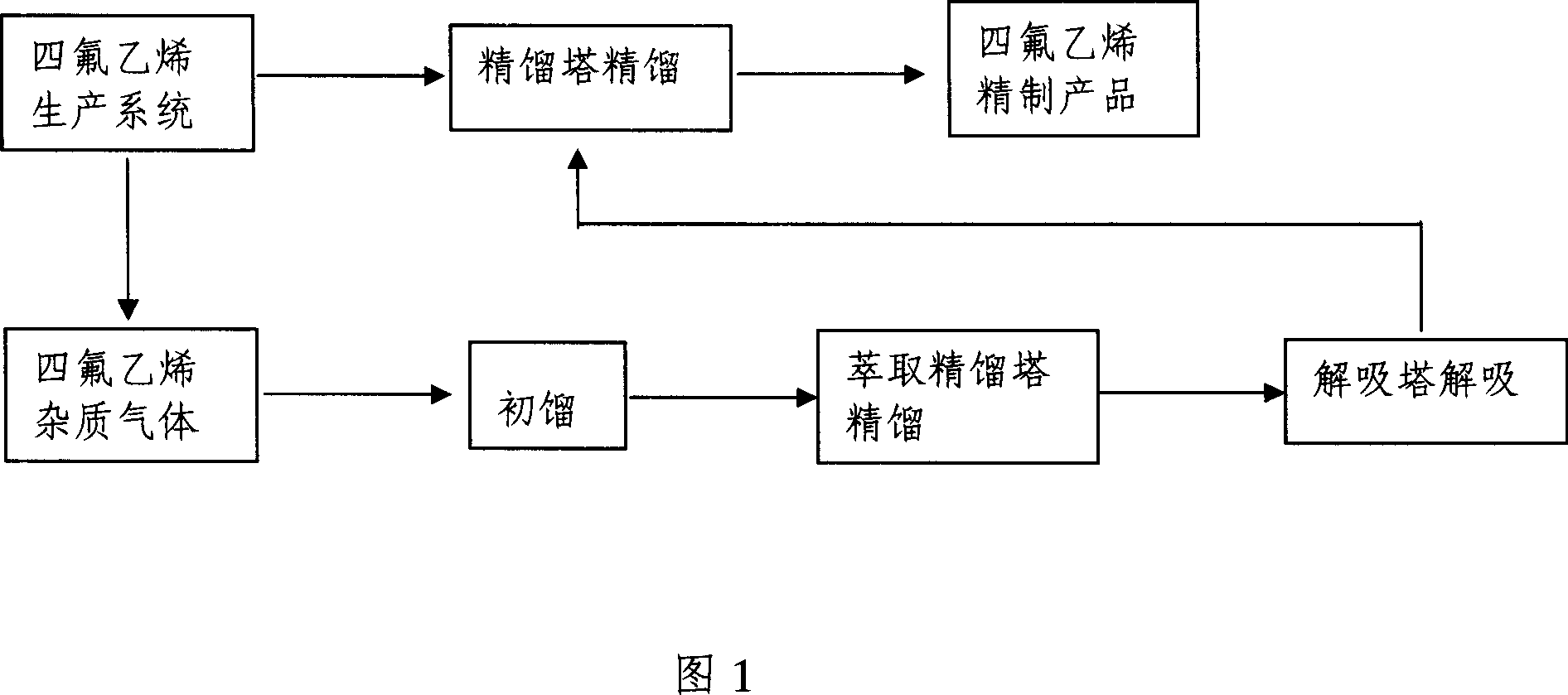

Method for removing impurity of tetrafluoroethylene

ActiveCN1962585ALow boiling pointLow priceHalogenated hydrocarbon separation/purificationOctafluorocyclobutaneKetone

The invention discloses an impurity removing method in the perfluoroethylene, which comprises the following steps: distilling perfluoroethylene gas with impurity in the degassing tower; controlling certain quantity to rectify in the extracting rectifying tower; adopting oligomer solvent of alcohols, ketones, chloroform and octafluorocyclobutane as extractant; combusting fluoride impurity gas on the top of rectifying tower; adsorbing the component from extracting rectifying tower autoclave; returning the component to rectifying unit directly to obtain the product.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

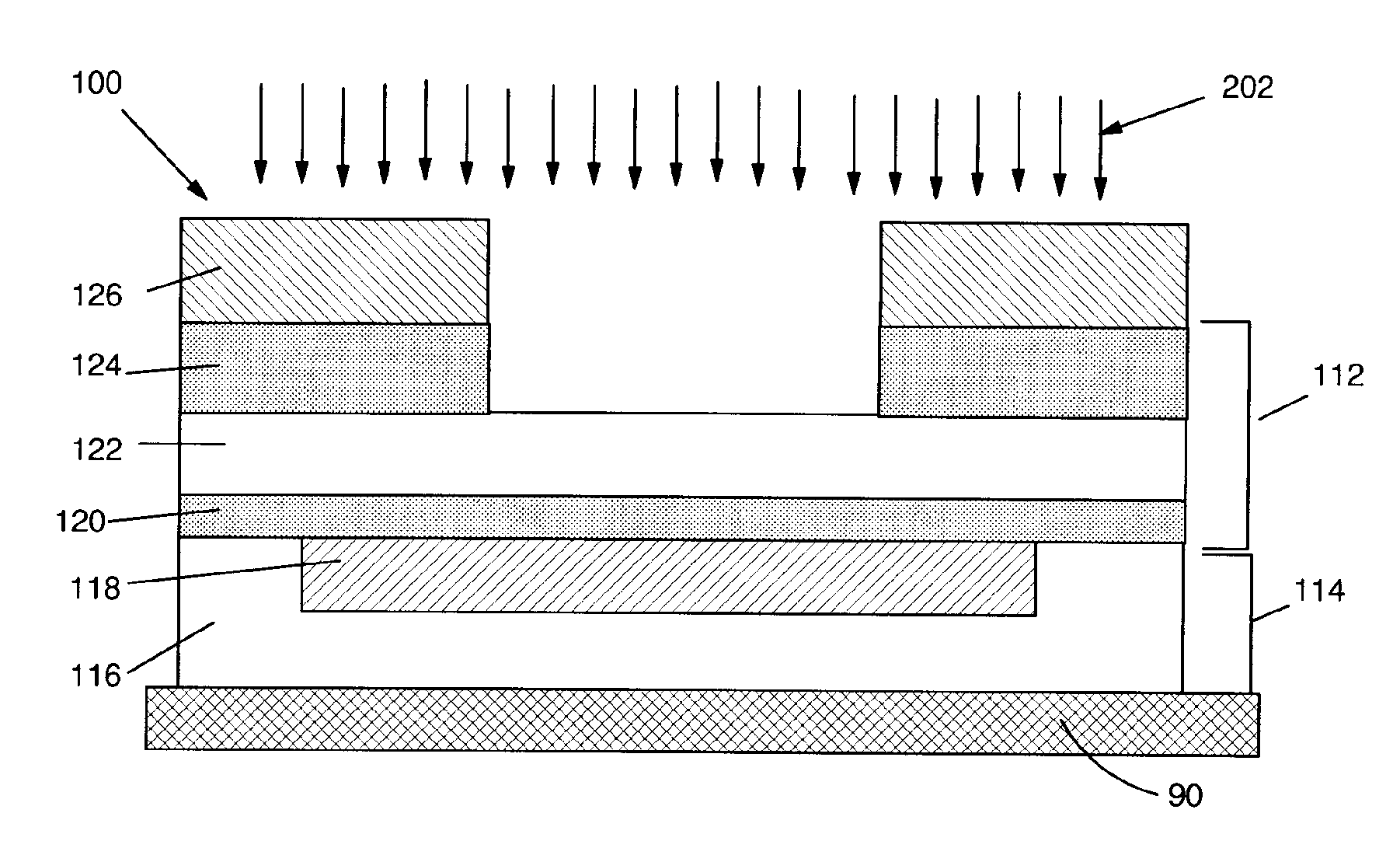

Etching processes using c4f8 for silicon dioxide

InactiveUS20070095787A1Reduced ESD defectReduce etch rateDecorative surface effectsSemiconductor/solid-state device manufacturingElectrical conductorTitanium nitride

Methods of etching a dielectric layer and a cap layer over a conductor to expose the conductor are disclosed. In one embodiment, the methods include the use of a silicon dioxide (SiO2) etching chemistry including octafluorocyclobutane (C4F8) and a titanium nitride (TiN) etching chemistry including tetrafluoro methane (CF4). The methods prevent etch rate degradation and exhibit reduced electro-static discharge (ESD) defects.

Owner:GOOGLE LLC

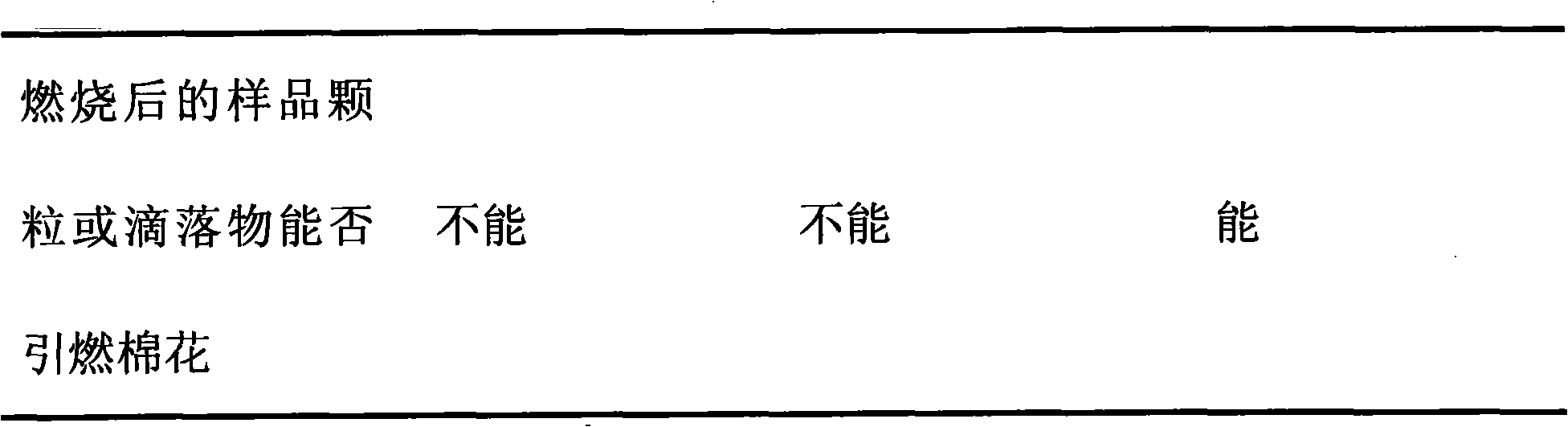

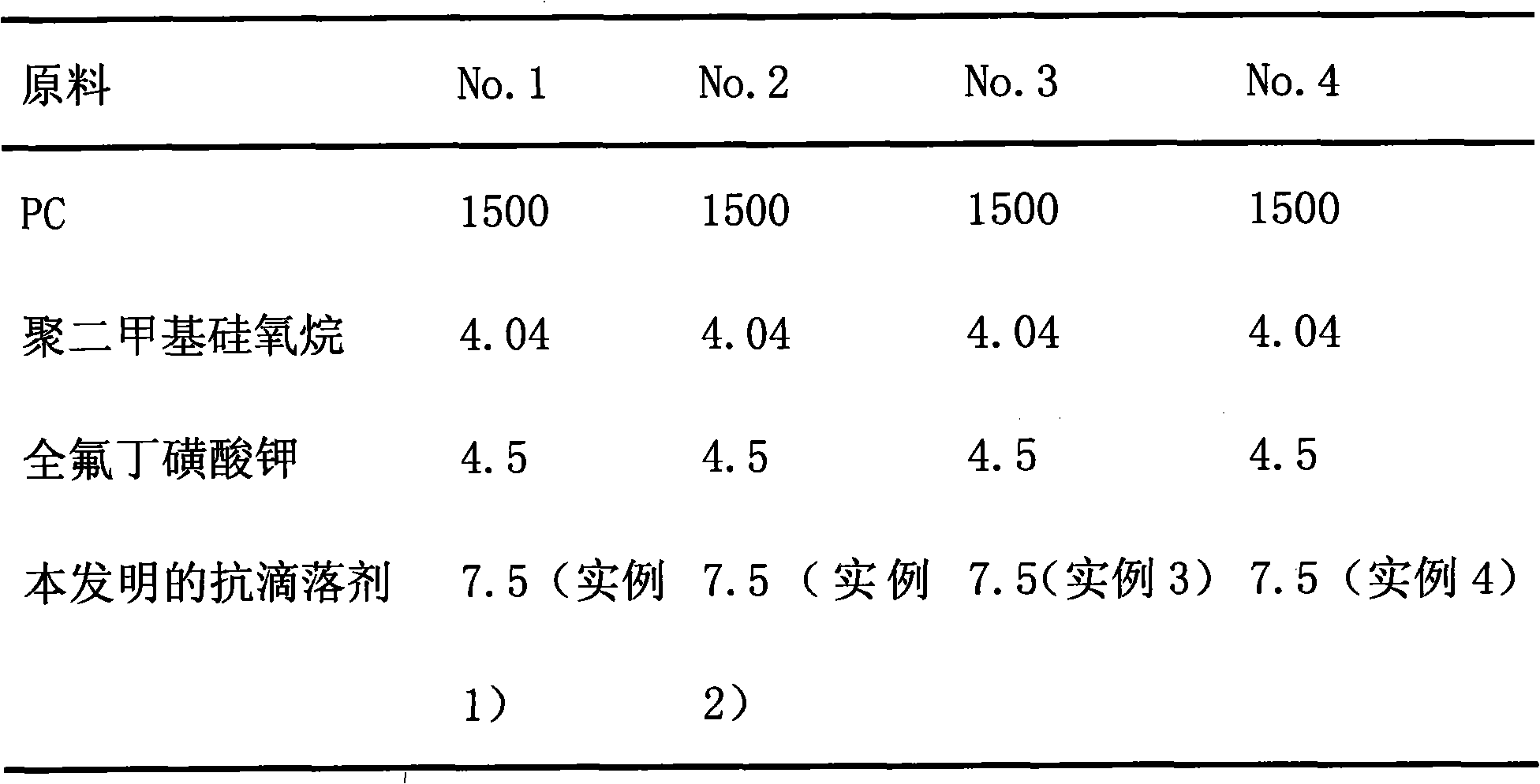

Anti-dripping agent preparation method

ActiveCN101628957AReduce energy consumptionImprove product qualityBulk chemical productionTetrafluoroethylenePolymer science

The invention discloses an anti-dripping agent preparation method; the anti-dripping agent comprises cores and shells, wherein, the cores are made from polytetrafluoethylene ultrafine powder which is prepared by mixing polytetrafluoethylene emulsion in high speed and centrifugalizing the emulsion, and the shells are prepared by adopting anionic initiator to initiate copolymerization in supercritical octafluorocyclobutane to one or more monomers of styrene, ethylene, propylene, butadiene, acrylonitrile, acrylic acid and methylacrylic acid. The specific preparation method comprises the following steps: 1. the preparation of the polytetrafluoethylene ultrafine powder: mixing polytetrafluoethylene emulsion in high speed in a condensation pot to agglomerate polytetrafluoethylene emulsion, then separating by high speed centrifugation to obtain the polytetrafluoethylene ultrafine powder; 2. the preparation of the anti-dripping agent: placing the polytetrafluoethylene ultrafine powder in a polymerizing pot and adding octafluorocyclobutane as solvent, heating to ensure that octafluorocyclobutane is in supercritical state, and mixing in high speed to keep the particle size of the polytetrafluoethylene ultrafine powder to 0.5mu m.

Owner:CHANGSHU 3F ZHENFU NEW MATERIALS CO LTD

Multicomponent mixture work medium suitable for fractional condensation type heat pump circulation system

InactiveCN1810914AFully consider the operating pressure ratio rangeConsider operating pressure ratio rangeFluid heatersHeat-exchange elementsDichlorodifluoromethaneOctafluorocyclobutane

The present invention discloses one kind of multicomponent mixture work medium suitable for fractional condensation type heat pump circulation system. The mixture work medium or mixed refrigeratant consists of two components, including one low boiling point component and one high boiling point component. The low boiling point component is one or several selected from difluro methane, trifluoro ethane, fluoro ethane, propylene, propane, pentafluoro ethane, etc. The high boiling point component is one or several selected from isobutane, n-butane, butene, isobutene, octafluoro isobutene, octafluoro cyclobutane, etc.

Owner:XI AN JIAOTONG UNIV

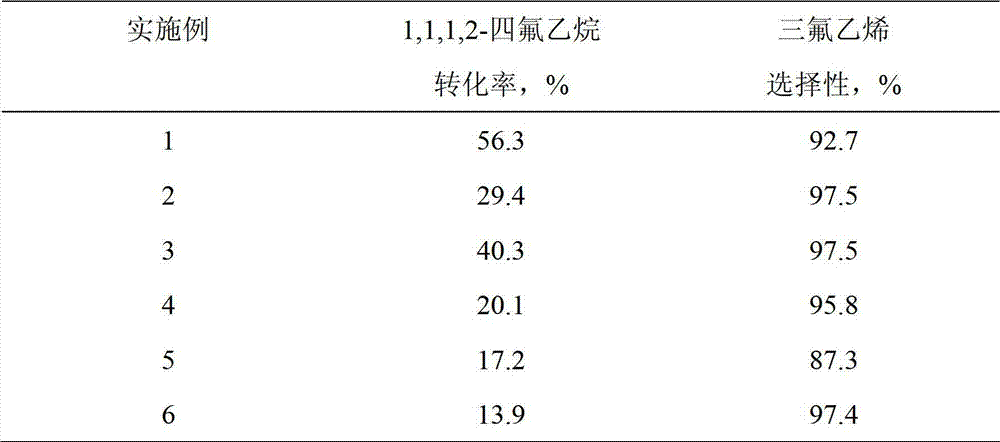

Preparation method of trifluoroethylene

ActiveCN103044190AImprove conversion rateLow reaction temperaturePreparation by hydrogen halide split-offOctafluorocyclobutaneReaction temperature

The invention discloses a preparation method of trifluoroethylene, which comprises the following steps: mixing 1,1,1,2-tetrafluoroethane with octafluorocyclobutane according to the molar ratio of 1:1-9 under the action of a cracking catalyst for reaction, controlling the reaction temperature to be 350-550 DEG C, the reaction airspeed to be 500-2000 hours-1 and the reaction pressure to be normal pressure and obtaining the trifluoroethylene after cracking gas generated by reaction is quenched, washed, alkali-cleaned, dried, compressed, rectified and purified. The preparation method has the advantages of low reaction temperature, simplicity in separation and purification and low cost, the maximum conversion rate of the 1,1,1,2-tetrafluoroethane is 56.3 percent, and the maximum selectivity of the trifluoroethylene is 97.5 percent.

Owner:JUHUA GROUP TECH CENT

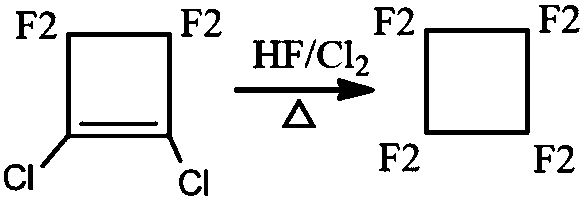

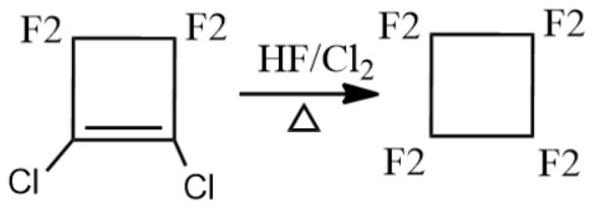

Method for synthesizing fire extinguishing agent octafluorocyclobutane

ActiveCN107721810ASave raw materialsConvenient sourcePreparation by halogen replacementCatalyst activation/preparationHydrogen fluorideChemical synthesis

The invention relates to a method for synthesizing a fire extinguishing agent octafluorocyclobutane, and belongs to the field of organic chemical synthesis. The method for synthesizing octafluorocyclobutane is characterized in that the octafluorocyclobutane is generated from dichlorotetrafluorocyclobutene, hydrogen fluoride and chlorine gas in the presence of a fluorination catalyst. FORMULA is shown in the description. According to the method, raw materials are cheap, the raw material source is convenient, product separating and purifying is simple, industrial production is easy, and a littlethree industrial wastes (waste solid, waste water and waste gas) is generated.

Owner:天津航大翼安科技发展有限公司

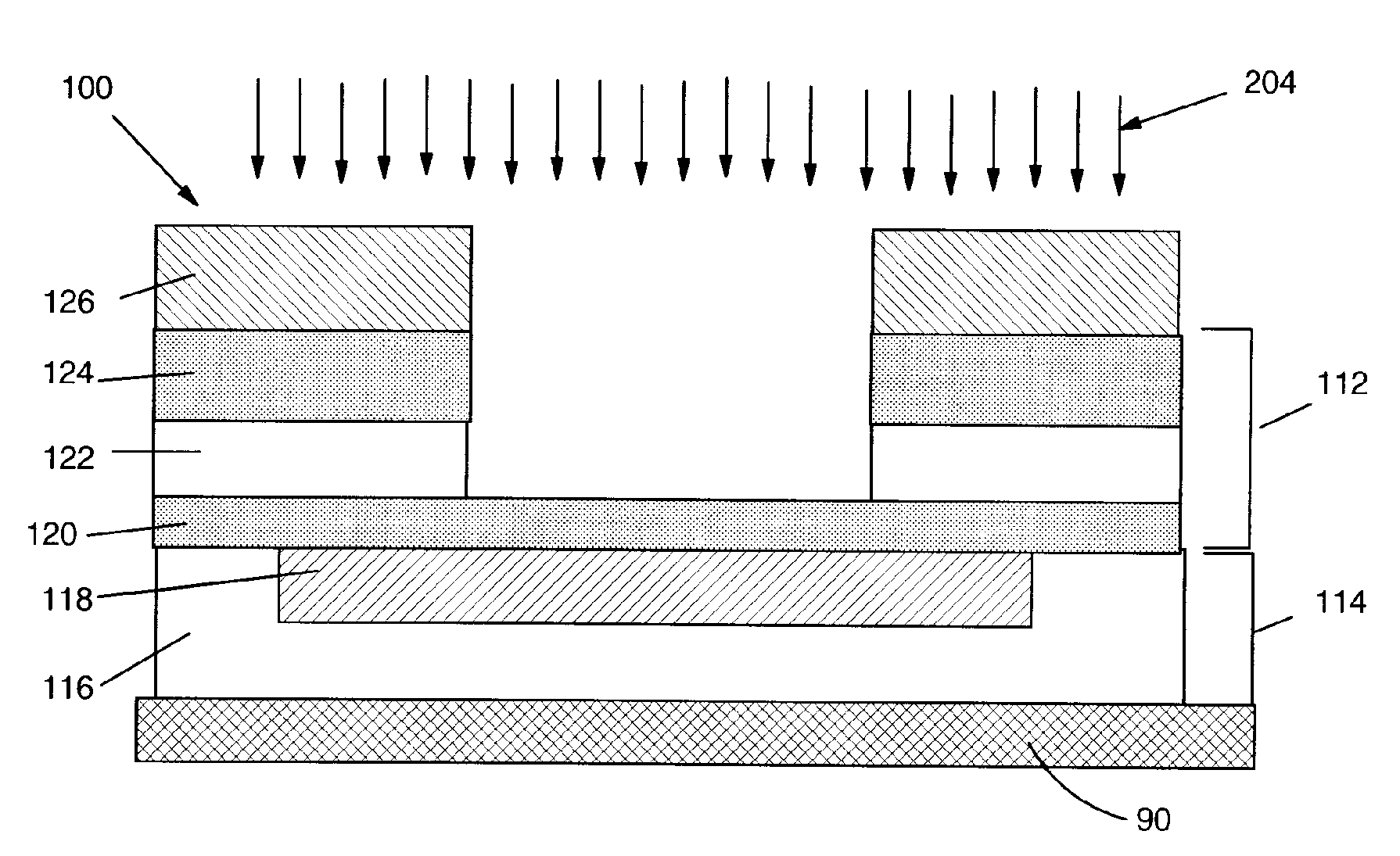

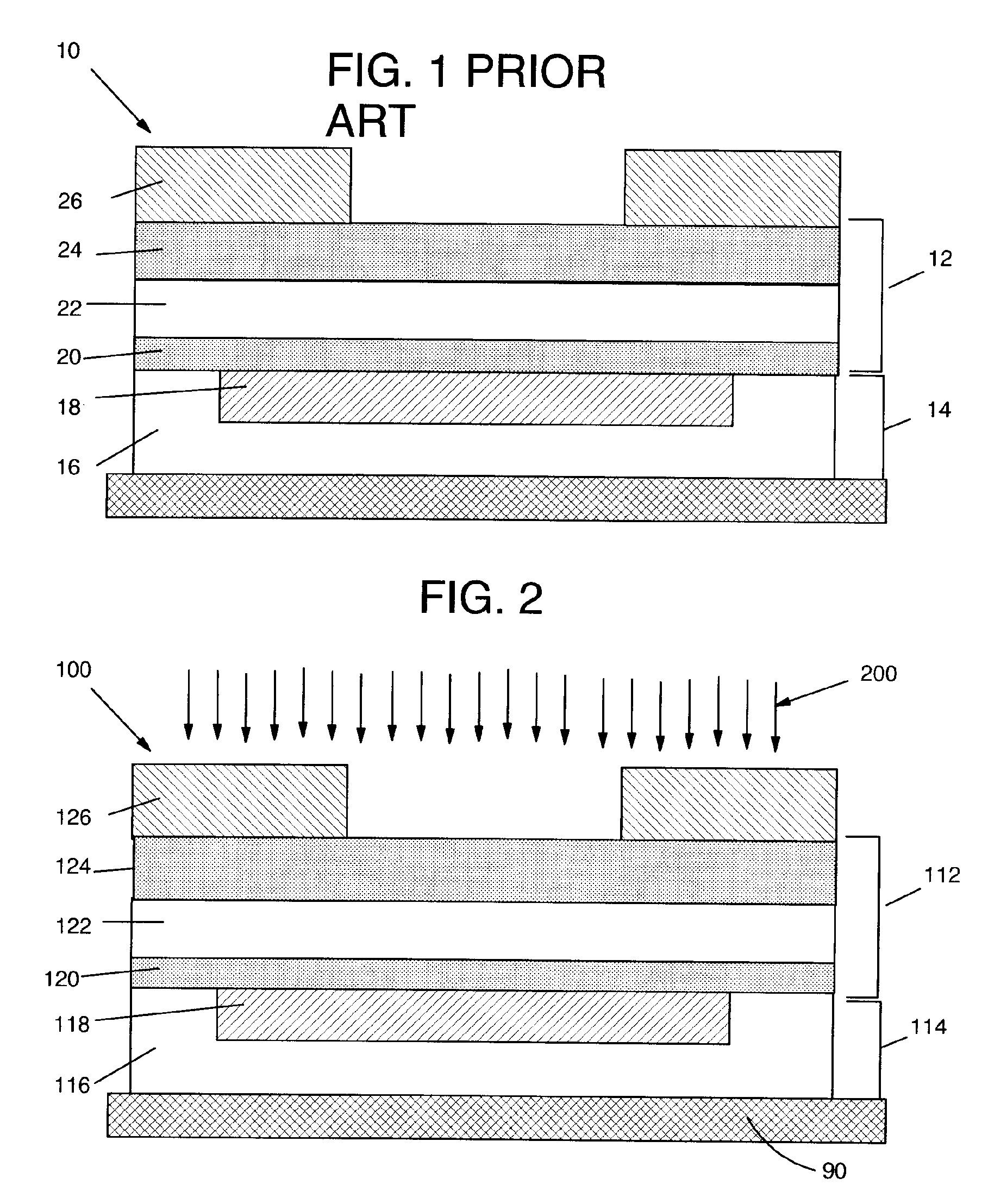

Etching processes using C4F8 for silicon dioxide and CF4 for titanium nitride

InactiveUS7276450B2Reduced ESD defectsDecorative surface effectsSemiconductor/solid-state device manufacturingElectrical conductorOctafluorocyclobutane

Methods of etching a dielectric layer and a cap layer over a conductor to expose the conductor are disclosed. In one embodiment, the methods include the use of a silicon dioxide (SiO2) etching chemistry including octafluorocyclobutane (C4F8) and a titanium nitride (TiN) etching chemistry including tetrafluoro methane (CF4). The methods prevent etch rate degradation and exhibit reduced electro-static discharge (ESD) defects.

Owner:GOOGLE LLC

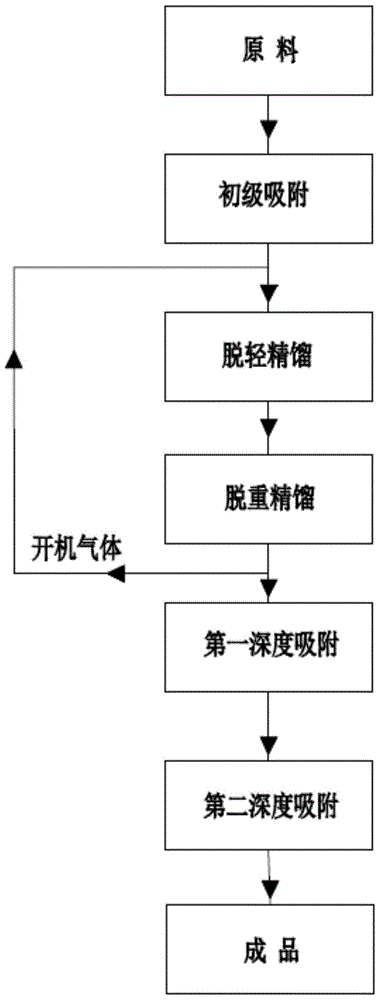

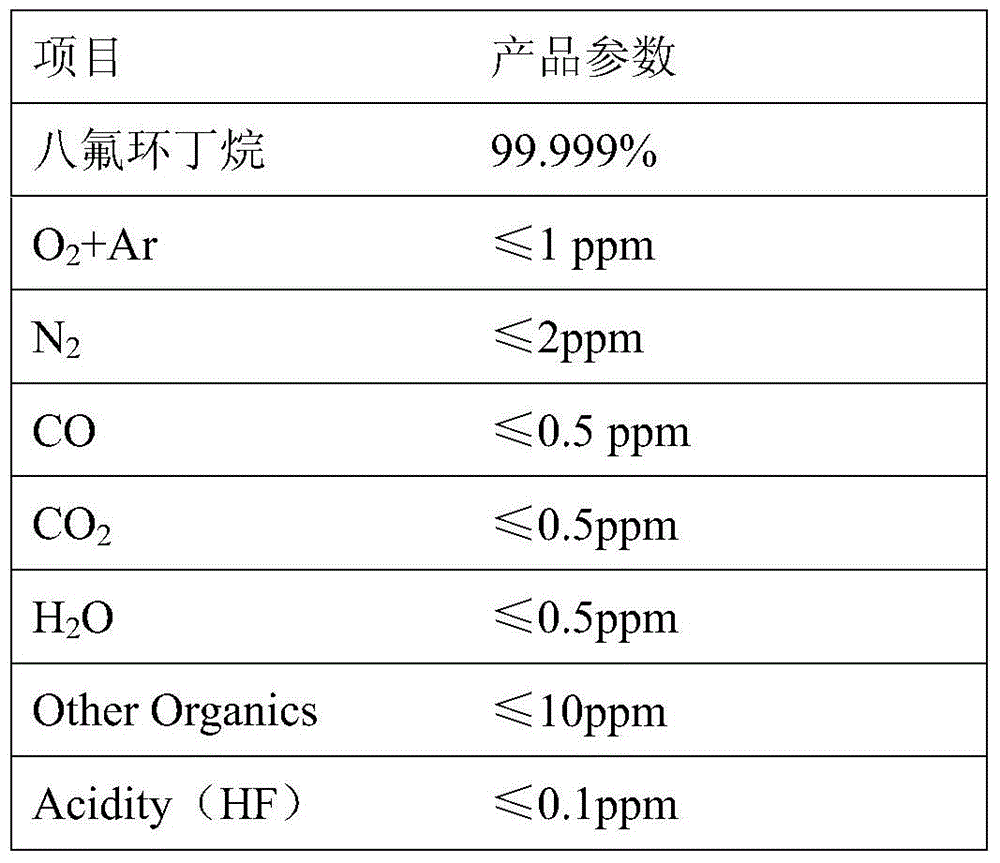

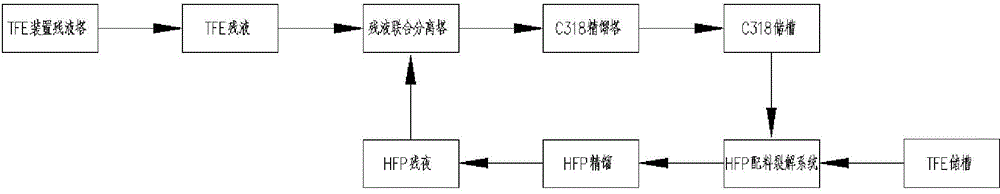

High-purity octafluorocyclobutane purification method and system

InactiveCN105777483AHigh puritySimple structureHalogenated hydrocarbon separation/purificationPurification methodsGas phase

The invention relates to a high-purity octafluorocyclobutane purification method, wherein the method comprises the following steps: step A, system cleaning: using nitrogen gas for purging a purification system, and after purging, vacuumizing the purification system; step B, low-boiling fraction removal and rectification; step C, high-boiling fraction removal and rectification; step D, finished production bottling: filling a preservation container with gas phase of a high-boiling fraction removal and rectification tower to obtain the finished product. The invention relates to a high-purity octafluorocyclobutane purification system including a primary adsorber, a low-boiling fraction removal and rectification tower, the high-boiling fraction removal and rectification tower, a membrane compressor, a first deep adsorber and a second deep adsorber. The high-purity octafluorocyclobutane purification method has simple and reliable process, and the finally obtained octafluorocyclobutane has high purity; the high-purity octafluorocyclobutane purification system has the advantages of simple structure, and has no need for large area reconstruction of conventional equipment.

Owner:FOSHAN HUATE GASES +1

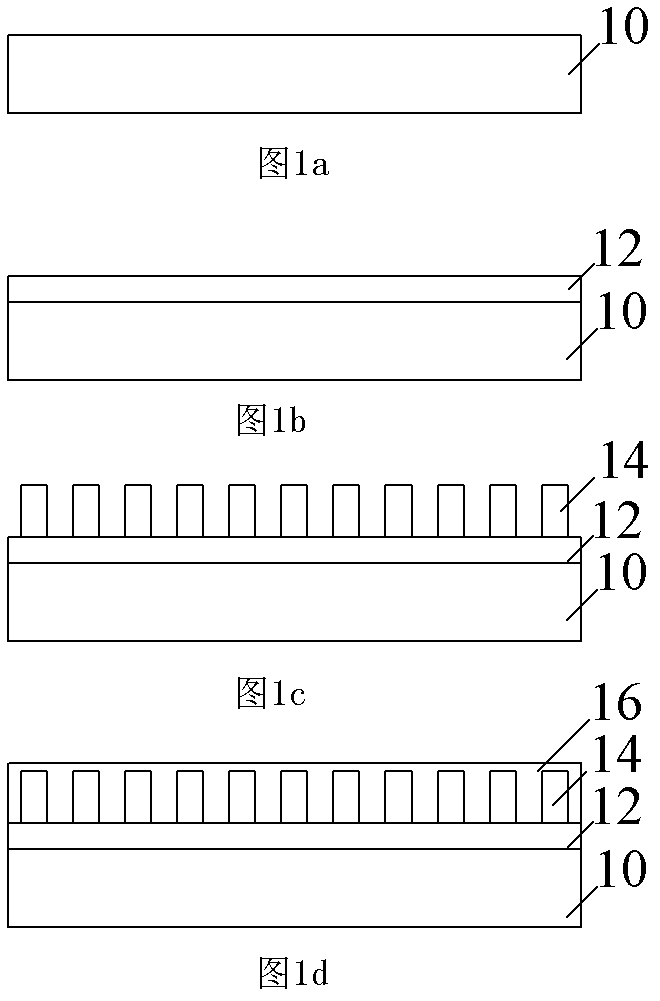

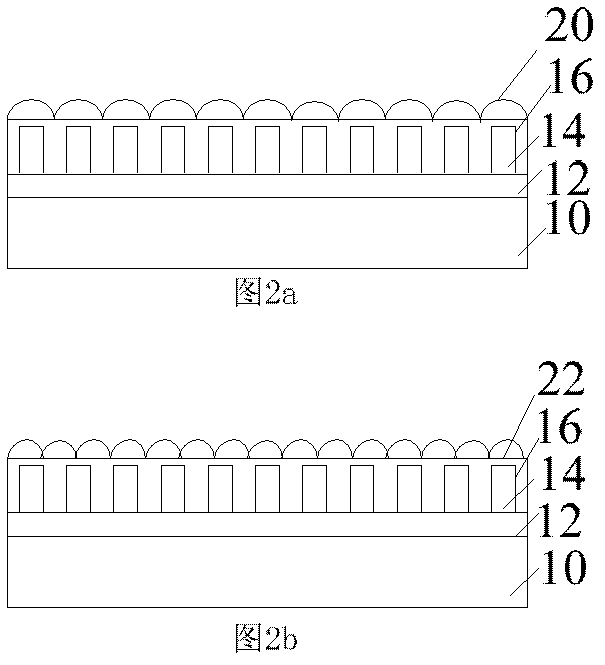

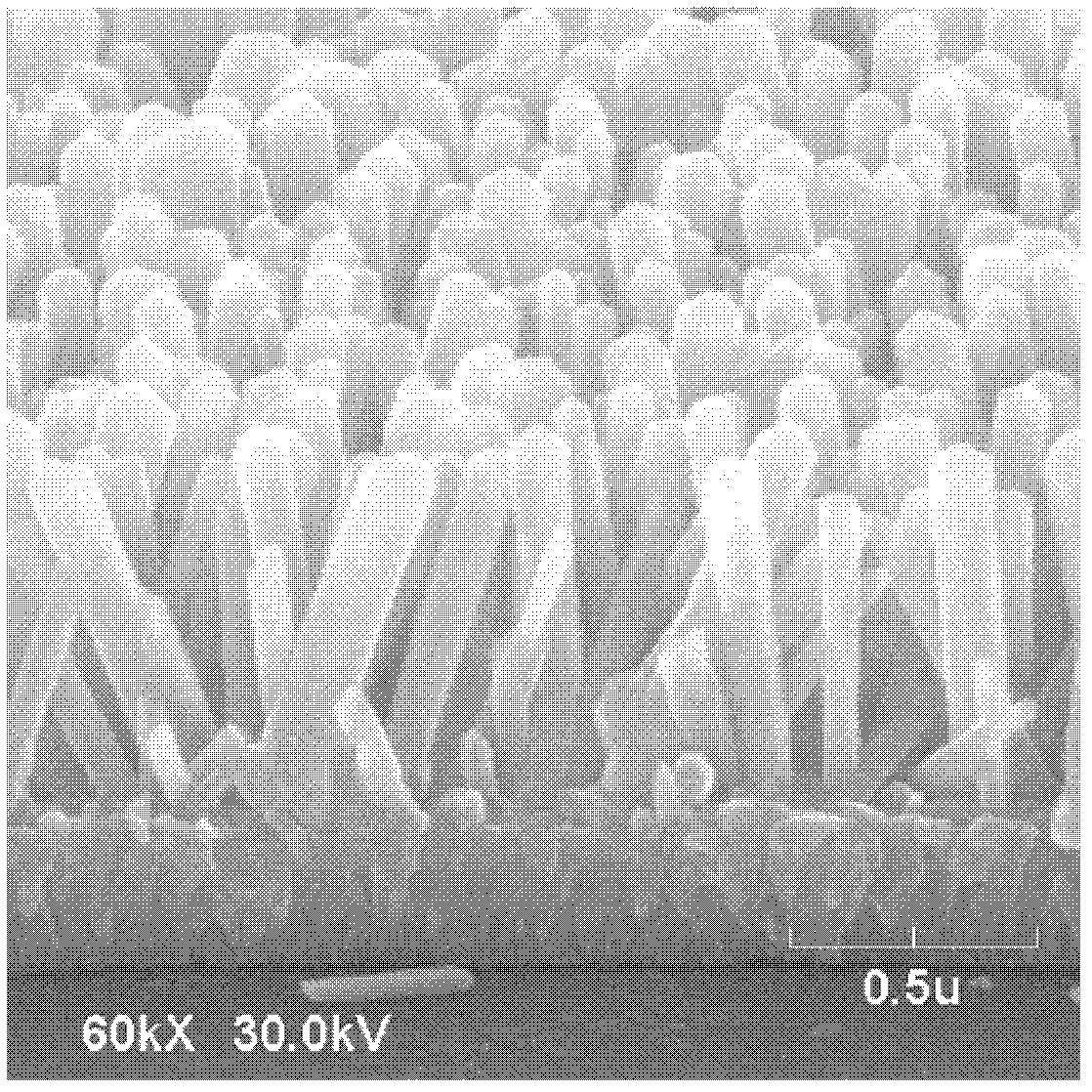

Process for manufacturing micro-lens array with large numerical aperture

The invention discloses a process for manufacturing a micro-lens array with a large numerical aperture, which comprises the following steps (a) manufacturing a zinc oxide nanometer column; (b) manufacturing an octafluorocyclobutane (C4F8) layer on the surface of the zinc oxide nanometer column; (c) manufacturing a micro-lens in a spray ink printing mode; and (d) curing the micro-lens and enabling the micro-lens array obtained in the step (b) to be cured through a mode of ultraviolet light source exposure and substrate heating. The method greatly reduces cost of the existing graphical technology, has potential of large-area manufacture simultaneously, and remarkably improves the numerical aperture of the micro-lens array. In addition, the spray ink printing is the process of natural dropping and forming of liquid drops, roughness of the surface of the manufactured lens is low, and errors including noises and the like can be removed when the lens is actually used.

Owner:XI AN JIAOTONG UNIV

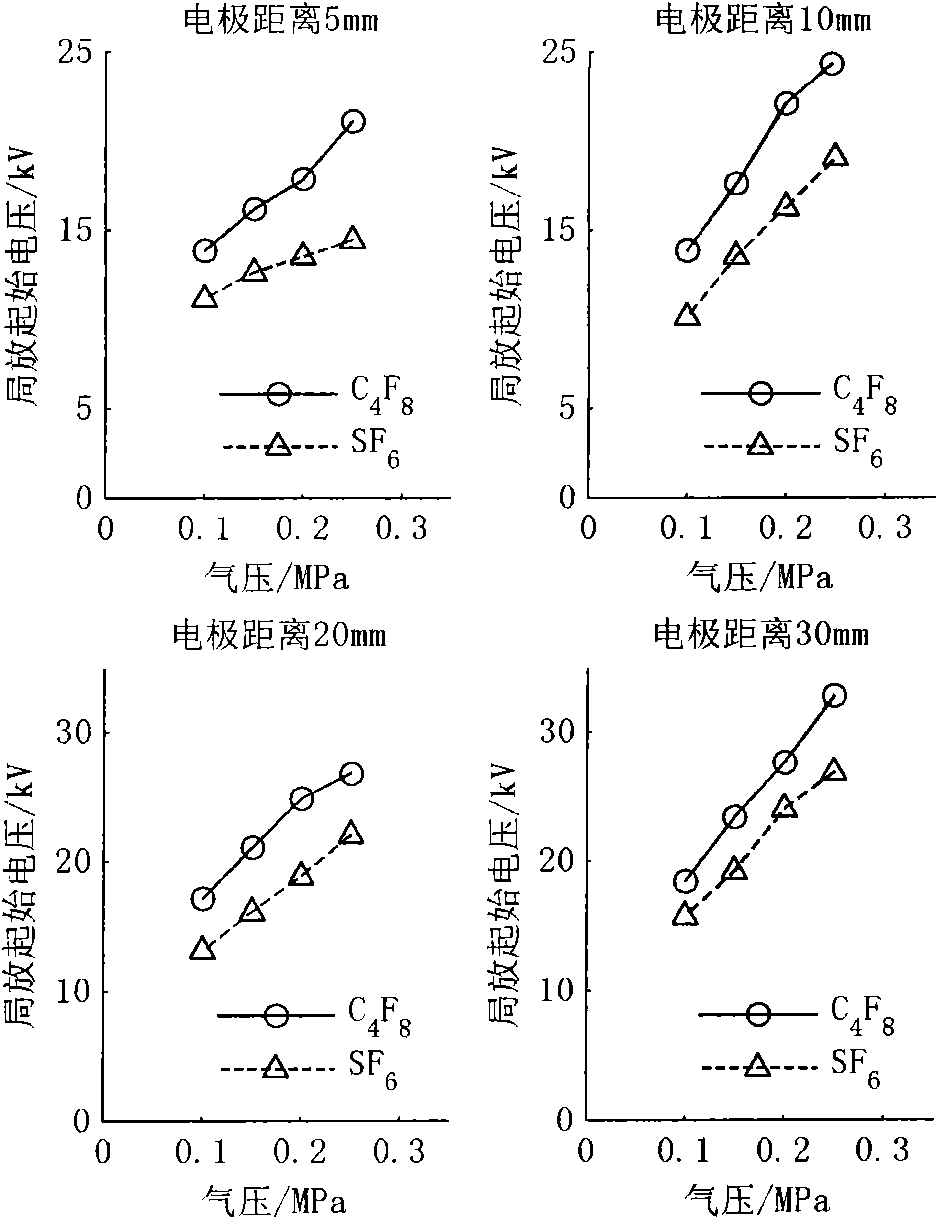

Mixed gas insulating medium

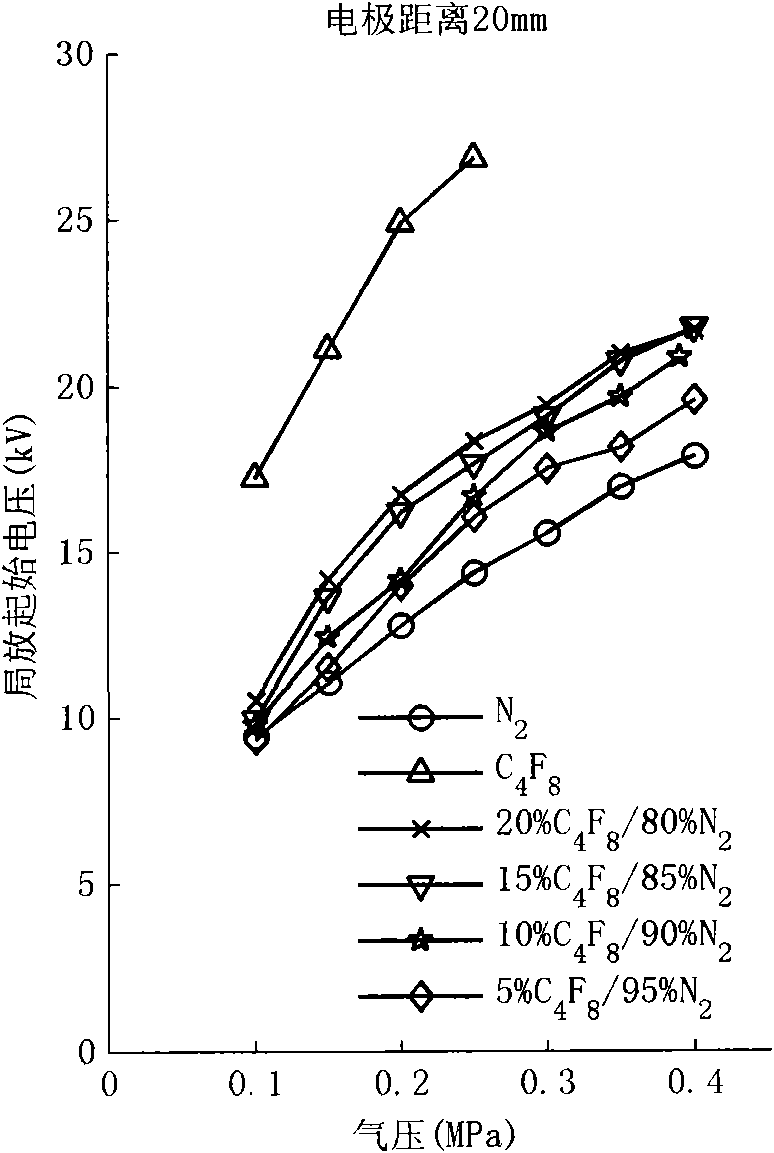

InactiveCN102136311AProcess environmental protectionFulfil requirementsInorganic gasesTransformerSulfur hexafluoride

The invention discloses a mixed gas insulating medium comprising the following components in percent by volume: 15-20 % of octafluorocyclobutane and 80-85% of nitrogen. The mixed gas insulating medium disclosed by the invention can serve as a new generation of gas insulating medium by replacing sulfur hexafluoride and can be widely applied to high-voltage power equipment, such as gas insulated transformers, gas insulated combined electrical appliances, gas insulated power transmission pipelines and the like.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

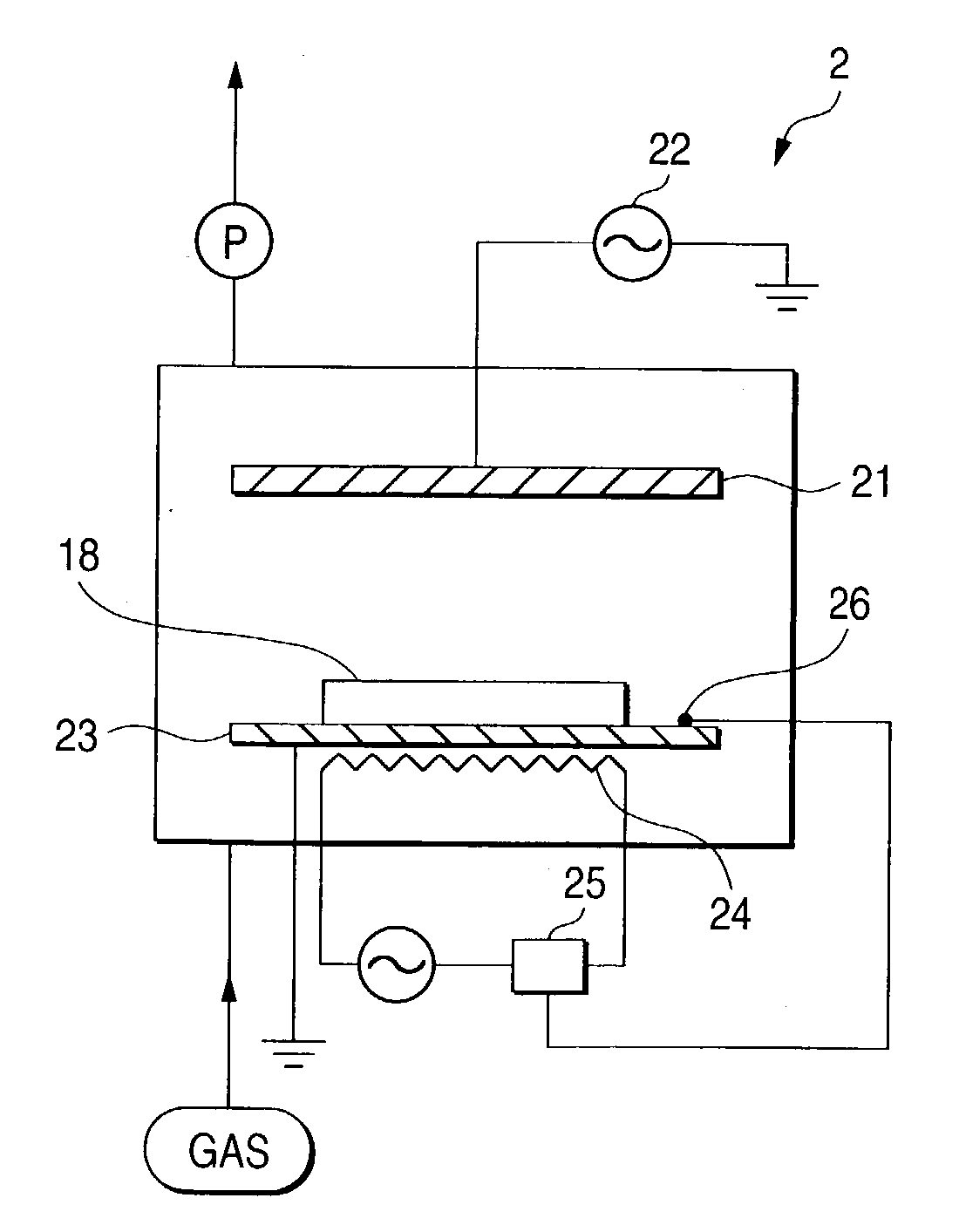

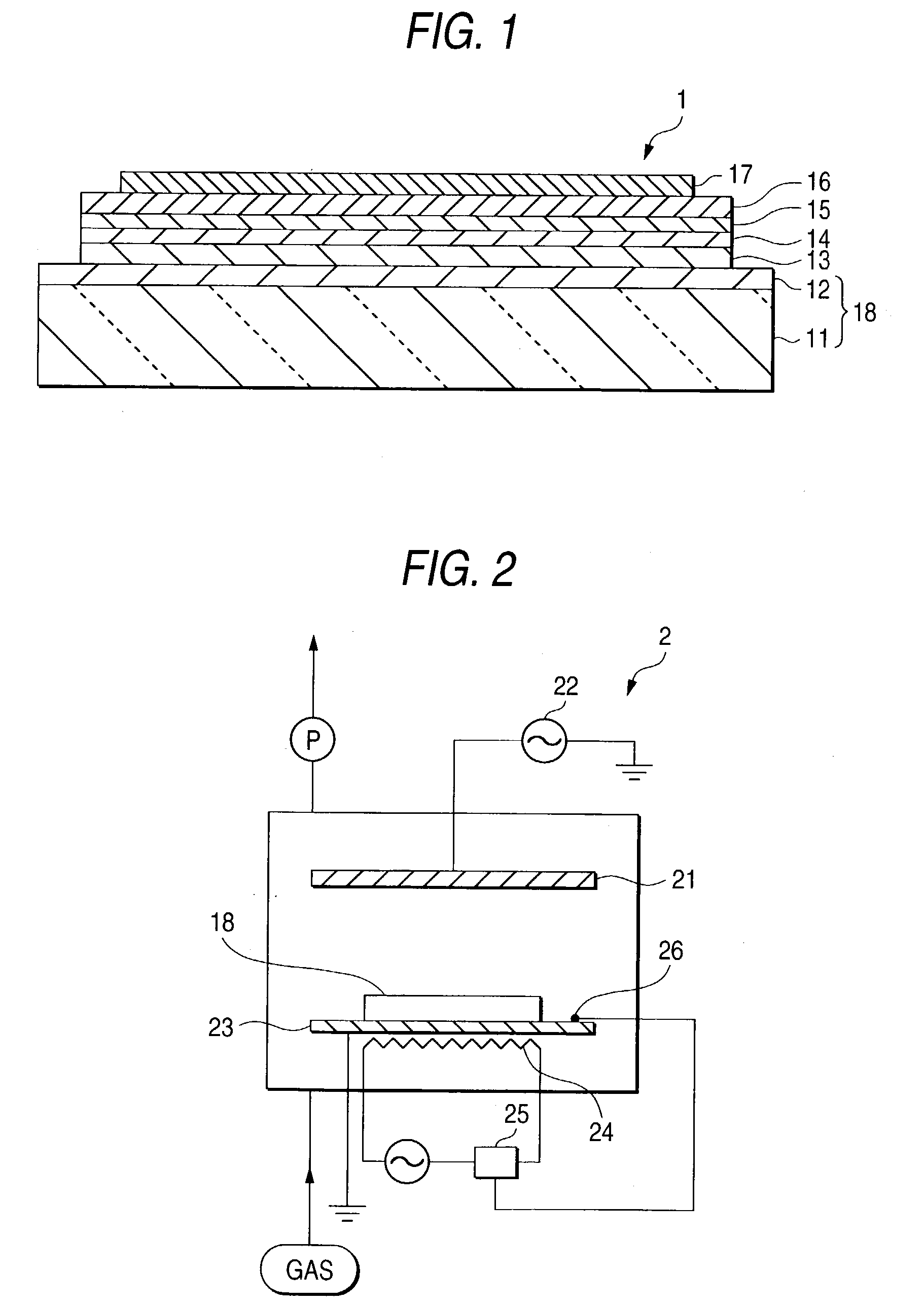

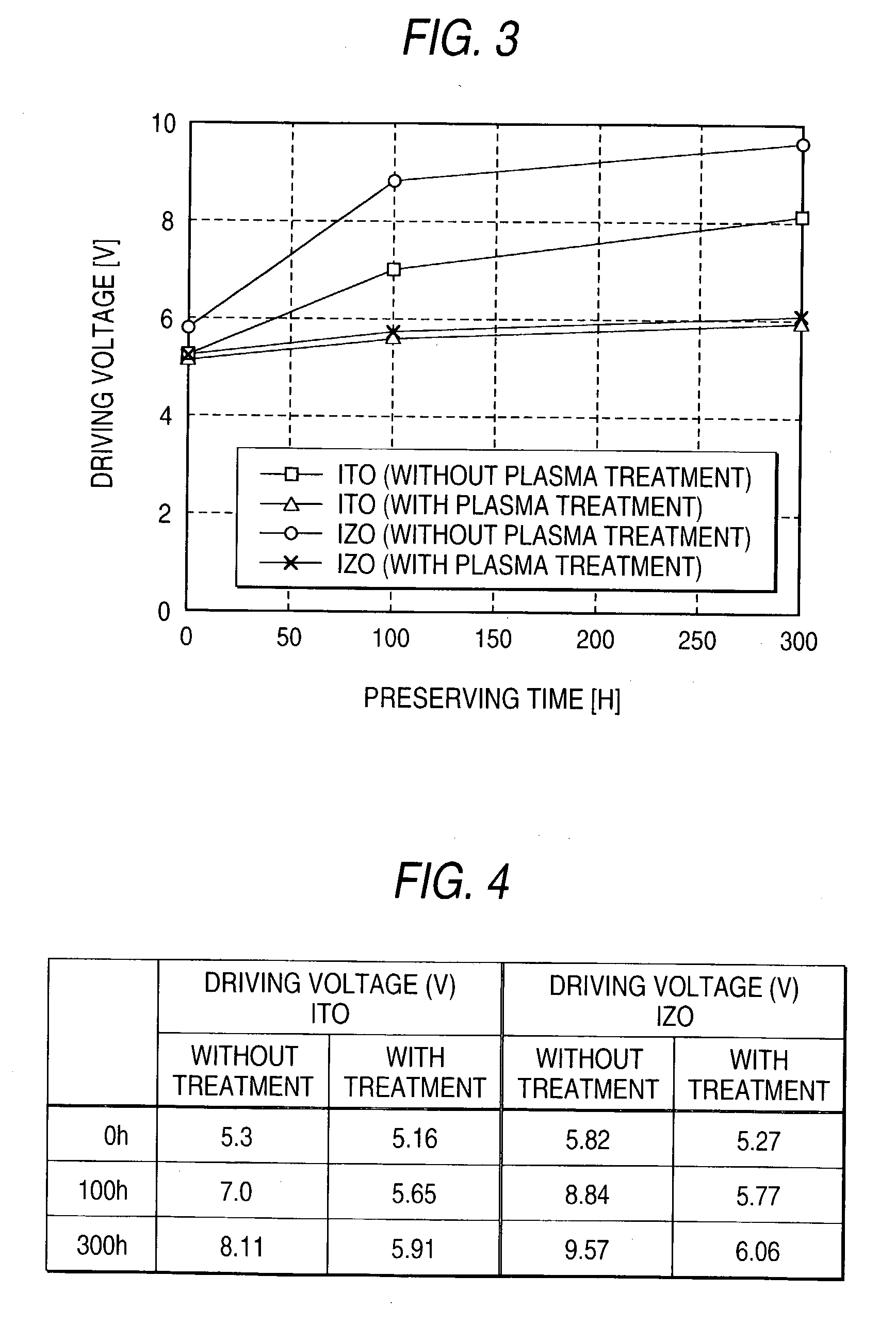

Manufacturing method of organic electroluminescent element

InactiveUS20030211233A1Low heat resistanceAvoid etchingElectroluminescent light sourcesSolid-state devicesHexafluoroethaneOctafluorocyclobutane

An electrode-equipped substrate includes a substrate portion of synthetic resin and a transparent electrode. The electrode-equipped substrate is subjected to heat treatment at a temperature of 200° C. or less as well as plasma treatment before organic layers are deposited. The plasma treatment is carried out within atmosphere of (A) a mixed gas of oxygen and any one of nitrogen, argon, helium, neon and xenon, with an oxygen density of 5% or less; (B) a mixed gas of oxygen and any one of carbon tetrafluoride, hexafluoroethane, octafluoropropane and octafluorocyclobutane; or (C) a sole gas of nitrogen, argon, helium, neon, xenon, carbon monoxide, carbon dioxide, nitrogen monoxide or nitrous oxide.

Owner:PIONEER CORP

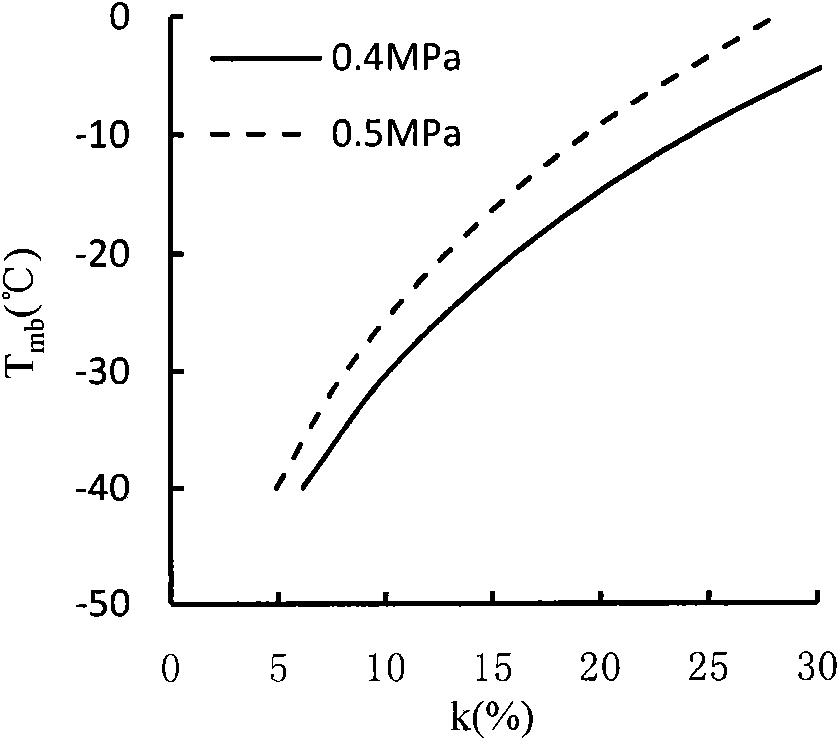

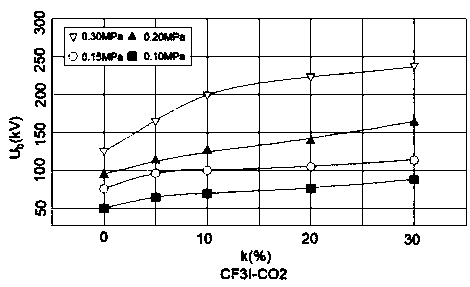

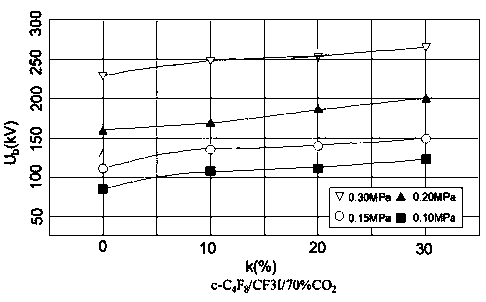

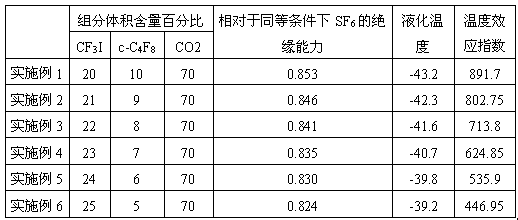

Mixed gas insulating medium containing environmentally friendly gaseous trifluoroiodomethane and preparation method of mixed gas insulating medium

InactiveCN109300575AMeet the use requirementsEnvironmental protection is goodInorganic gasesTransformerOctafluorocyclobutane

The invention relates to a mixed gas insulating medium containing environmentally friendly gaseous trifluoroiodomethane and a preparation method of the mixed gas insulating medium. The components of the mixed gas insulating medium comprise a trifluoroiodomethane gas, an octafluorocyclobutane gas and a carbon dioxide gas. The preparation method includes a vacuuming step and a mixing step. The mixedgas insulating medium can well meet the use requirements of high-voltage power equipment such as gas insulated transformers, gas-insulated combined electrical appliances and gas-insulated transmission pipelines, and has the advantages of excellent insulation performance and high environmental protection performance.

Owner:SHANGHAI JIAO TONG UNIV

Azeotrope Compositions of Octafluorocyclobutane and Uses Thereof

ActiveUS20090005618A1Other chemical processesHalogenated hydrocarbon separation/purificationHydrogen fluorideOctafluorocyclobutane

The present disclosure related to azeotrope and near-azeotrope compositions comprising PFC-C318 and HFC-236cb. The present disclosure further relates to processes for removing PFC-C318 from HFC-236cb. And the present disclosure further relates to azeotrope and near azeotrope compositions comprising hydrogen fluoride and PFC-C318.

Owner:THE CHEMOURS CO FC LLC

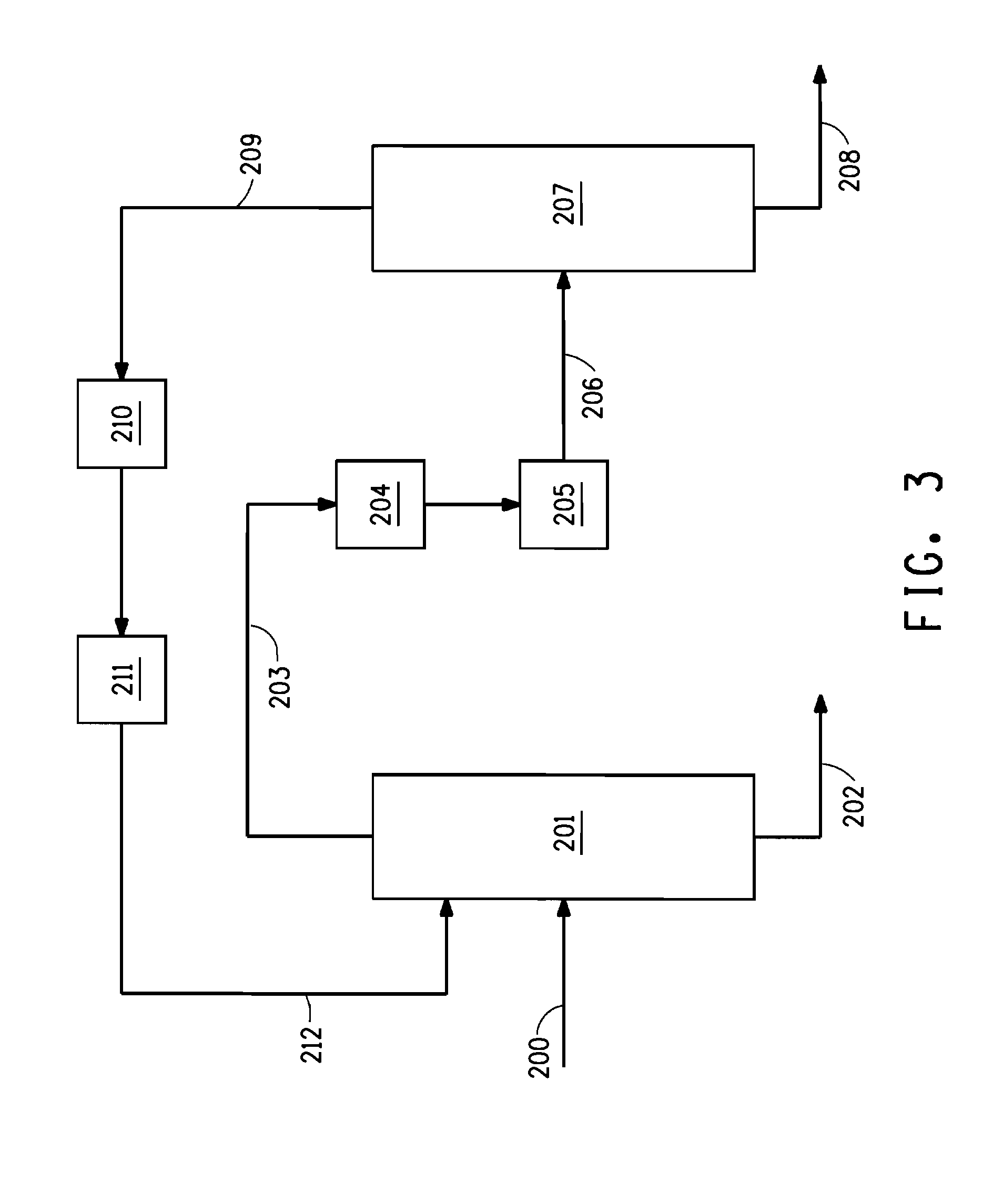

Jointly recycling method for production residual liquid of tetrafluoroethylene and hexafluoropropylene

ActiveCN104557447AQuality is not affectedAchieving perfect integrationPreparation by hydrogen halide split-offHexafluoropropyleneOctafluorocyclobutane

The invention relates to a jointly recycling method for a residual liquid in production of tetrafluoroethylene and hexafluoropropylene. According to the method, the residual liquid generated in production of tetrafluoroethylene is introduced to a production process of hexafluoropropylene and is rectified and recovered with the residual liquid generated in production of hexafluoropropylene to recover octafluorocyclobutane without independent equipment and process operations, so that octafluorocyclobutane in the tetrafluoro residual liquid can be recovered with a low cost. The recovered octafluorocyclobutane contains minute quantity of similar components. Being specially matched with a tetrafluoroethylene monomer, the quality of hexafluoropropylene is not affected, and the octafluorocyclobutane can be directly used for producing hexafluoropropylene, so that perfect fusion of the production process of hexafluoropropylene and the recovery process of the residual liquid is realized. Moreover, separation and recovery are more simplified and reliable.

Owner:福建三农新材料有限责任公司

Catalyst for catalytic conversion of impurities in octafluorocyclobutane, and preparation method and application thereof

ActiveCN111135842AHigh activityFor subsequent separationCatalyst activation/preparationHalogenated hydrocarbon separation/purificationActivated carbonCatalytic transformation

The invention discloses a catalyst for catalytic conversion of impurities in octafluorocyclobutane, and a preparation method and an application thereof. The catalyst is composed of an active carbon loaded active component and auxiliary agents, the active component is palladium, the auxiliary agents are X1 and X2, the content of the active component palladium is 0.2-1.5 wt%, the content of the auxiliary agent X1 is 0.1-2.5 wt%, and the content of the auxiliary agent X2 is 0.05-0.8 wt%. The content of alkene-containing fluorocarbon impurities in octafluorocyclobutane can be reduced to 1 ppmv orbelow. The catalyst has the advantages of good performances, high separation efficiency and simplicity in operation.

Owner:JUHUA GROUP TECH CENT

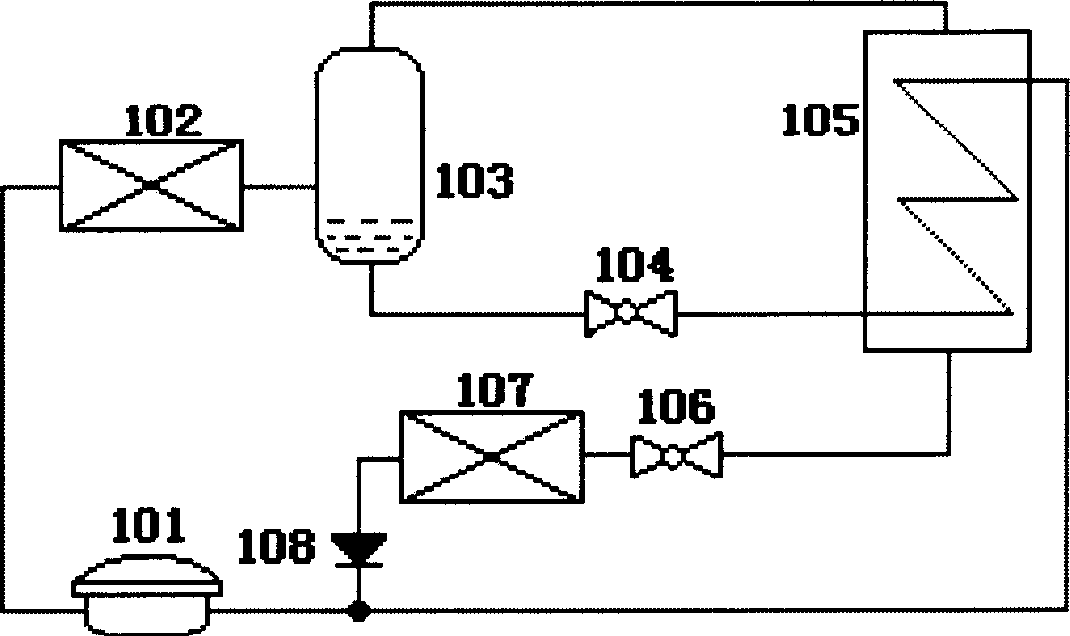

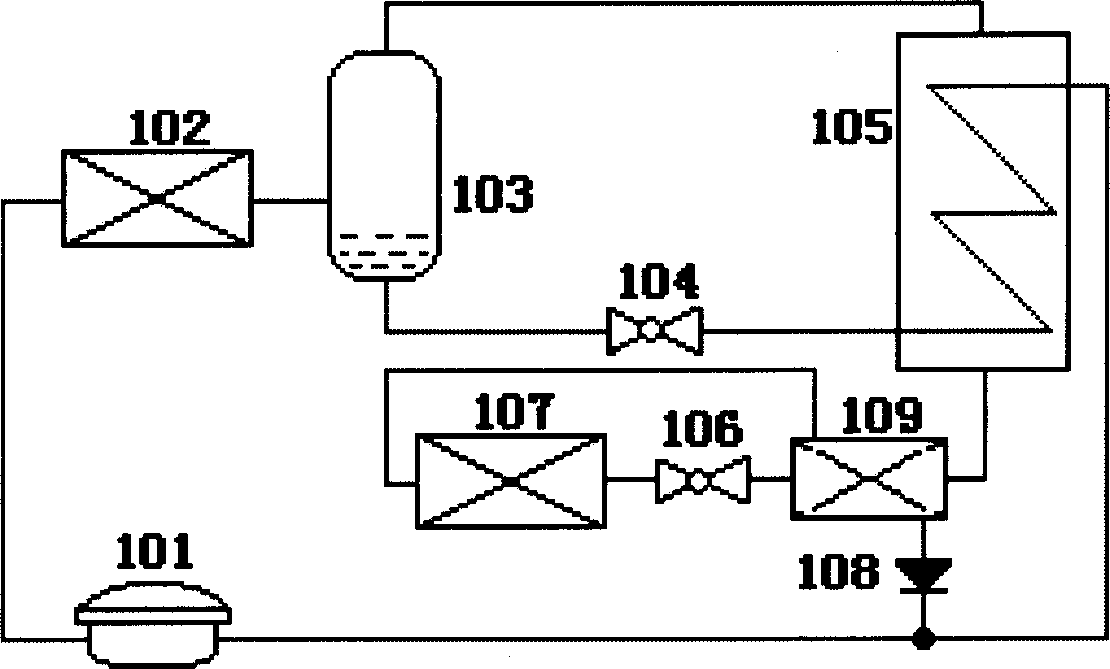

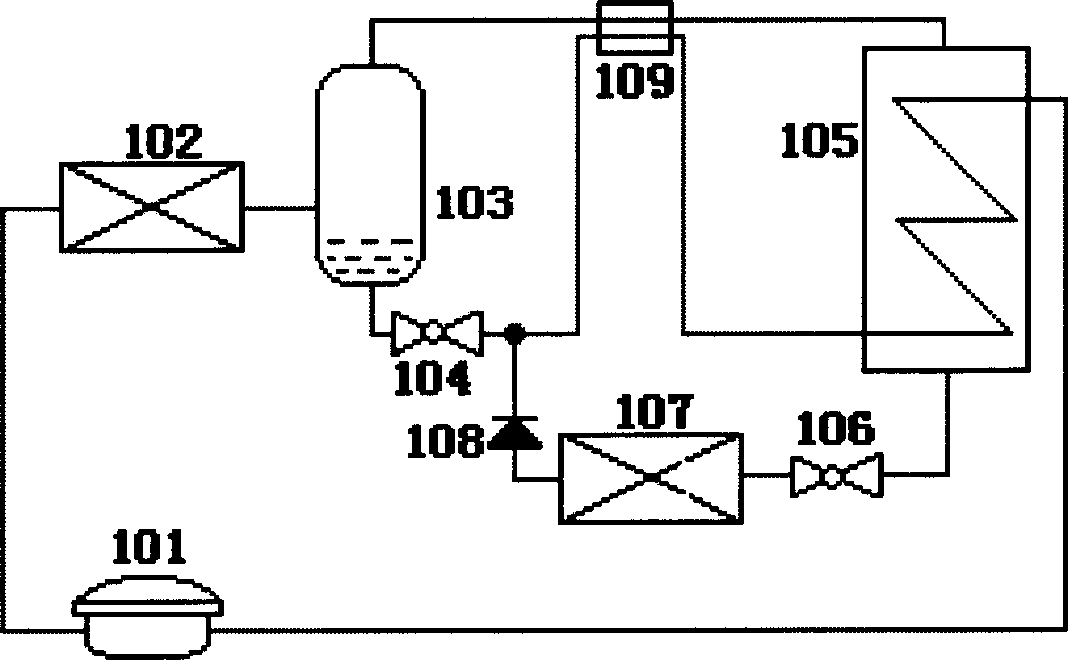

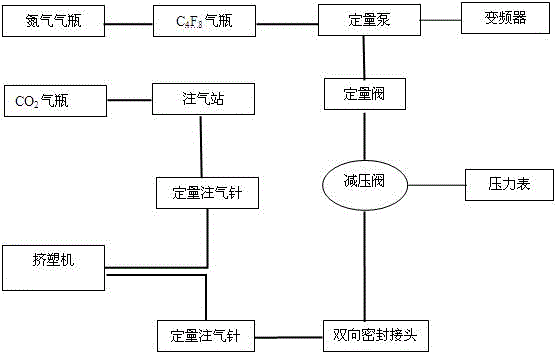

Dual-path gas injection system for physical foaming process and gas injection method thereof

The invention relates to a dual-path gas injection system for a physical foaming insulation process and a gas injection method of the gas injection method, aiming at improving the foaming degree of a leakage cable, ensuring the foaming stability and the foaming uniformity while achieving high foaming degree, improving the performances of a product and reducing the production cost. The dual-path gas injection system and the gas injection method of the gas injection method are particularly suitable for a physical foaming process of a polyethylene insulation material. The dual-path gas injection system comprises a carbon dioxide gas injection device and an octafluorocyclobutane gas injection device; the carbon dioxide gas injection device comprises a quantitative gas injection needle, a gas path, a gas injection machine and a gas bottle; the gas bottle is connected with the gas injection machine after being connected with a gas pipe, the gas injection machine stores gas until reaching the set pressure, the gas pipe is connected with the quantitative gas injection needle to inject the gas with the set pressure into a plastic extruding machine, the gas is dissolved in a polyethylene foam material in a molten state to form fine cell structures; and the octafluorocyclobutane gas injection device comprises a nitrogen gas bottle, an octafluorocyclobutane gas bottle, a frequency converter, a metering pump, a reducing valve, a gas pipe, a proportional valve, a dual-direction sealing joint and a quantitative gas injection needle.

Owner:ZHONGTIAN RADIO FREQUENCY CABLE CO LTD

Energy-saving environment-protecting zeotropic mixed refrigerant

InactiveCN1673308AAvoid separationReduce indirect global warming effectsChemical industryHeat-exchange elementsZeotropic mixtureAgricultural engineering

The present invention is one kind of energy-saving environment-protecting zeotropic mixture refrigerant consists of chlorobifluoromethane 43.0-46.5 wt%, 1, 1-difluorethane 6.0-9.0 wt%, 1-chloro-1, 1- difluorethane 4.0-6.0 wt%, and octafluorocyclobutane 41.0-44.0 wt%. The refrigerant has obvious energy saving effect, excellent environment protecting performance and excellent comprehensive performance, and may be used as new generation of refrigerant to replace CFC widely used in various refrigerator, heat pump and air conditioner.

Owner:顾雏军

Process for purifying octafluorocyclobutane, process for preparing the same, and use thereof

InactiveUS6815568B2Reduce impurityEasy to useSemiconductor/solid-state device manufacturingHalogenated hydrocarbon separation/purificationPurification methodsSorbent

A process for purifying octafluorocyclobutane according to the present invention is characterized by contacting a crude octafluorocyclobutane containing impurities with an impurity decomposing agent under elevated temperature and then with an adsorbent to substantially remove the impurities from the crude octafluorocyclobutane.According to the purification process or preparation process of octafluorocyclobutane of the present invention, the impurities such as fluorocarbon can be substantially removed and a high-purity octafluorocyclobutane can be easily obtained. The octafluorocyclobutane obtained by the purification process of the present invention is substantially free of impurities and therefore, can be used as an etching or cleaning gas for use in the production process of a semiconductor device or the like.

Owner:SHOWA DENKO KK

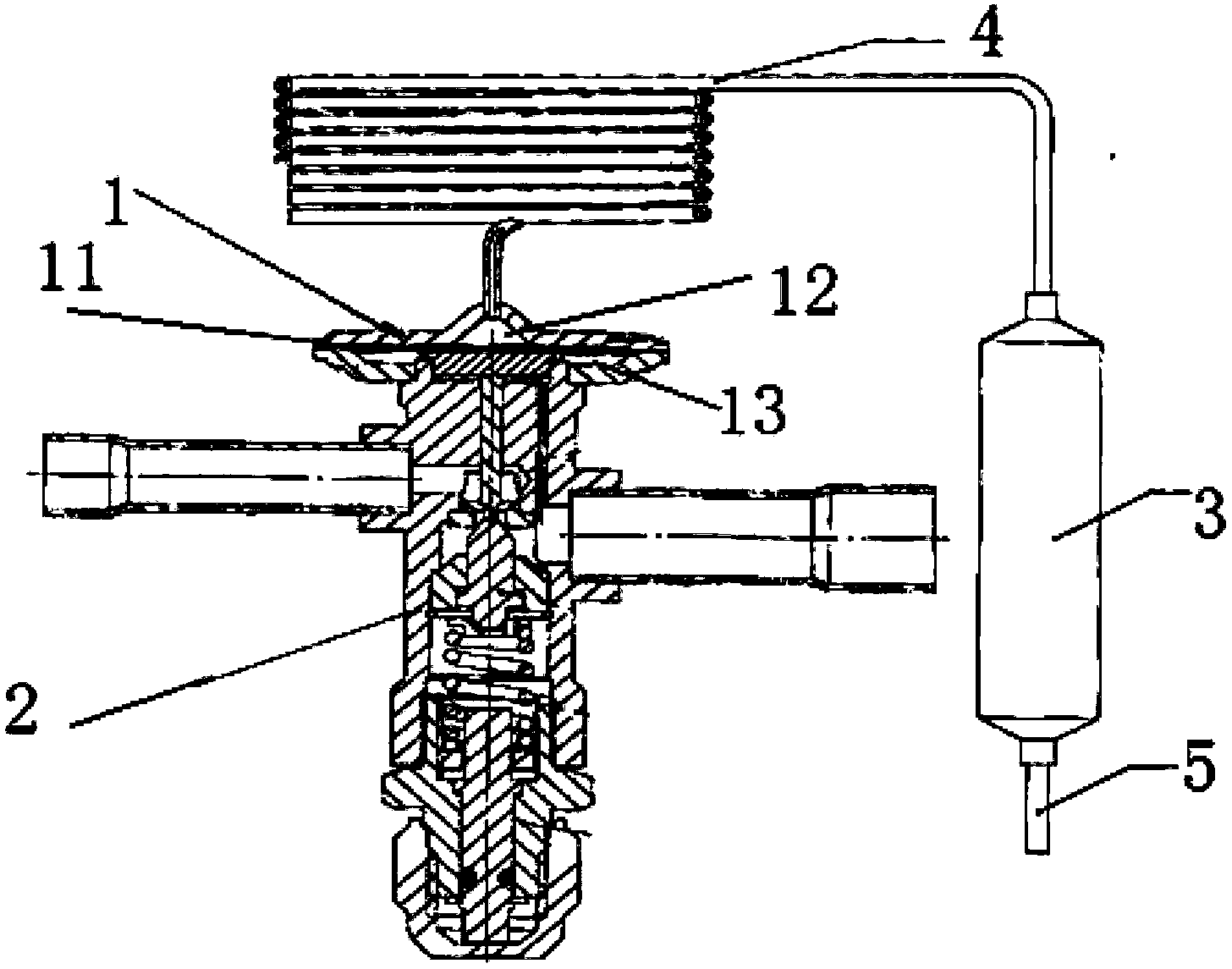

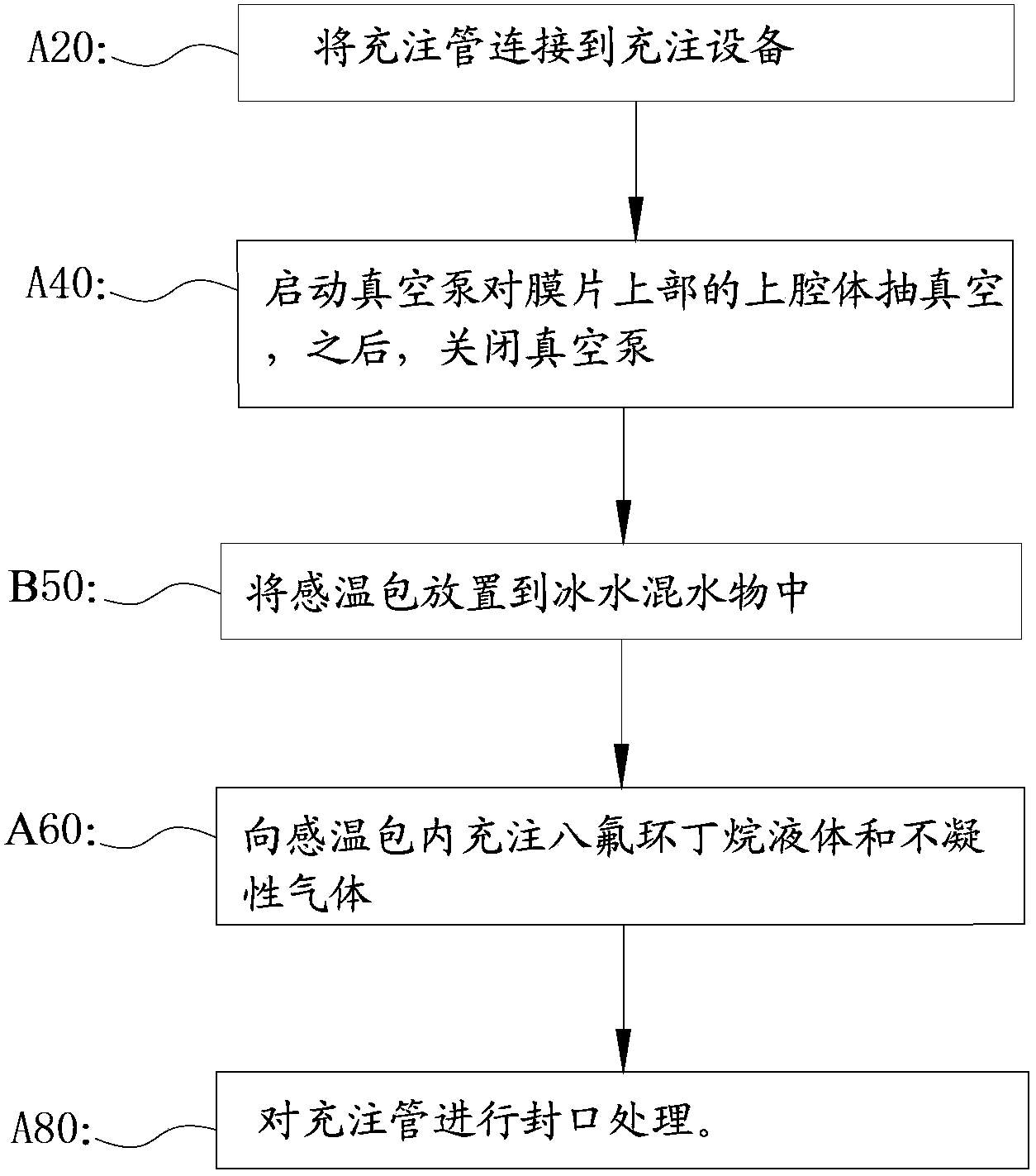

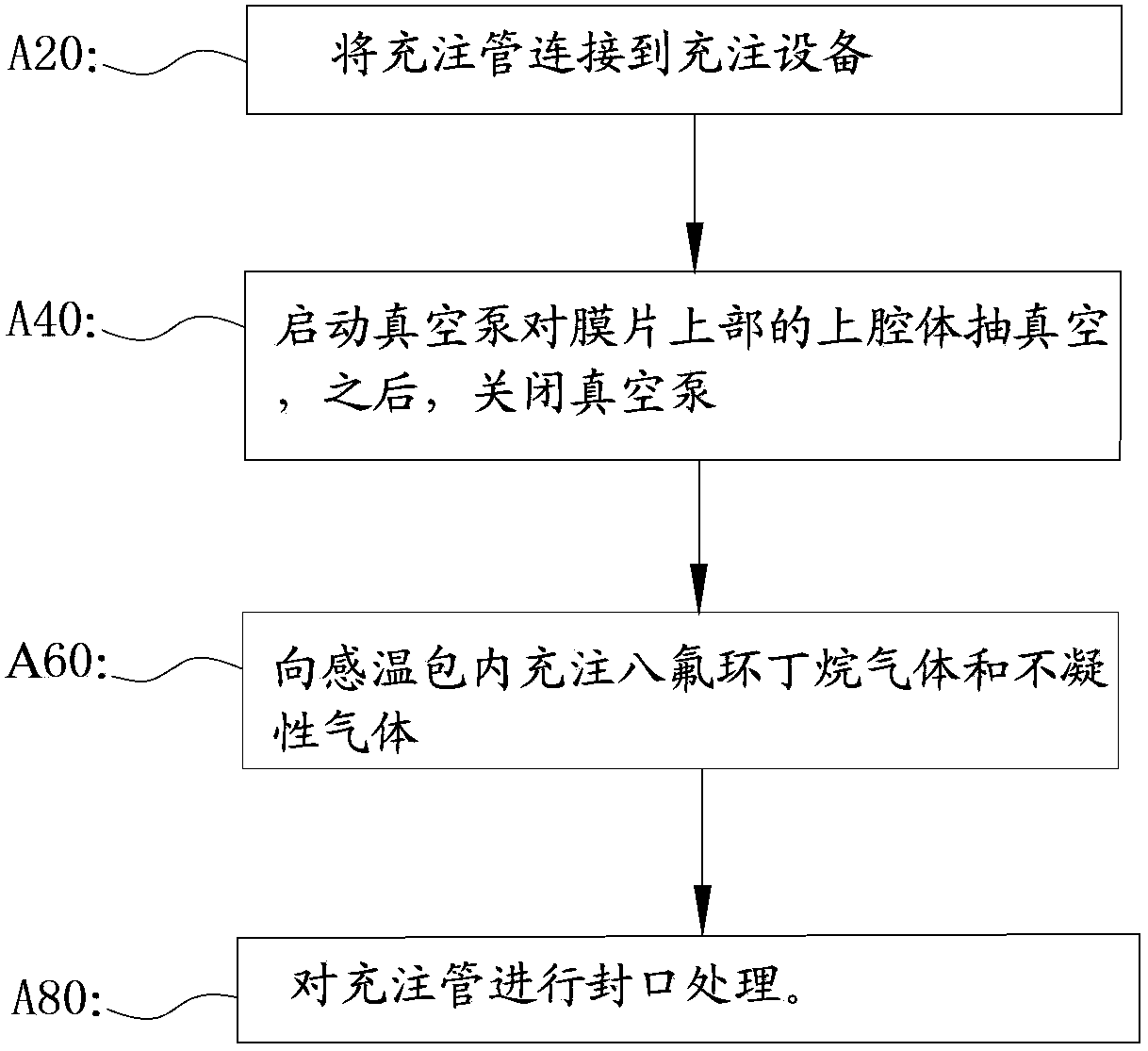

Thermal bulb of thermal expansion valve, filling method thereof and refrigerating system with same

InactiveCN103487154ALittle heat changeImprove energy efficiency ratioMechanical apparatusThermometers using material expansion/contactionBusiness efficiencyOctafluorocyclobutane

Owner:ZHEJIANG SANHUA CLIMATE & APPLIANCE CONTROLS GRP CO LTD

Process for purifying octafluorocyclobutane, process for preparing the same, and use thereof

InactiveUS20030132099A1Reduce impurityEasy to useSemiconductor/solid-state device manufacturingHydrocarbonsPurification methodsSorbent

A process for purifying octafluorocyclobutane according to the present invention is characterized by contacting a crude octafluorocyclobutane containing impurities with an impurity decomposing agent under elevated temperature and then with an adsorbent to substantially remove the impurities from the crude octafluorocyclobutane. According to the purification process or preparation process of octafluorocyclobutane of the present invention, the impurities such as fluorocarbon can be substantially removed and a high-purity octafluorocyclobutane can be easily obtained. The octafluorocyclobutane obtained by the purification process of the present invention is substantially free of impurities and therefore, can be used as an etching or cleaning gas for use in the production process of a semiconductor device or the like.

Owner:SHOWA DENKO KK

Adsorbent for removing hexafluoropropylene in octafluorocyclobutane and method for preparing adsorbent

ActiveCN107694509AEfficient removalLarge specific surface areaGas treatmentOther chemical processesHexafluoropropyleneSorbent

The invention discloses an adsorbent for removing hexafluoropropylene in octafluorocyclobutane. The adsorbent comprises, by weight, 10-25% of iron oxide, 5-20% of copper oxide, 60-80% of tin oxide, 0.05-0.5% of gallium, 0.05-0.3% of platinum, 0.1-1.5% of cadmium and 0.1-3% of molybdenum. The invention further discloses a method for preparing the adsorbent. The method includes steps of (1), addingsalt solution of the iron oxide, the copper oxide and the tin oxide into a hydrothermal reactor and uniformly stirring the salt solution of the iron oxide, the copper oxide and the tin oxide; (2), adding salt solution of the gallium, the platinum, the cadmium and the molybdenum into the hydrothermal reactor and carrying out doping modification; (3), adding metal mesh packing into the hydrothermalreactor, placing the hydrothermal reactor with the added metal mesh packing into a drying oven and carrying out reaction on solution in the hydrothermal reactor at the hydrothermal treatment temperatures of 110-160 DEG C for 40-70 min. The adsorbent and the method have the advantage that the hexafluoropropylene in the octafluorocyclobutane can be effectively removed by the adsorbent.

Owner:SUZHOU JINHONG GAS CO LTD

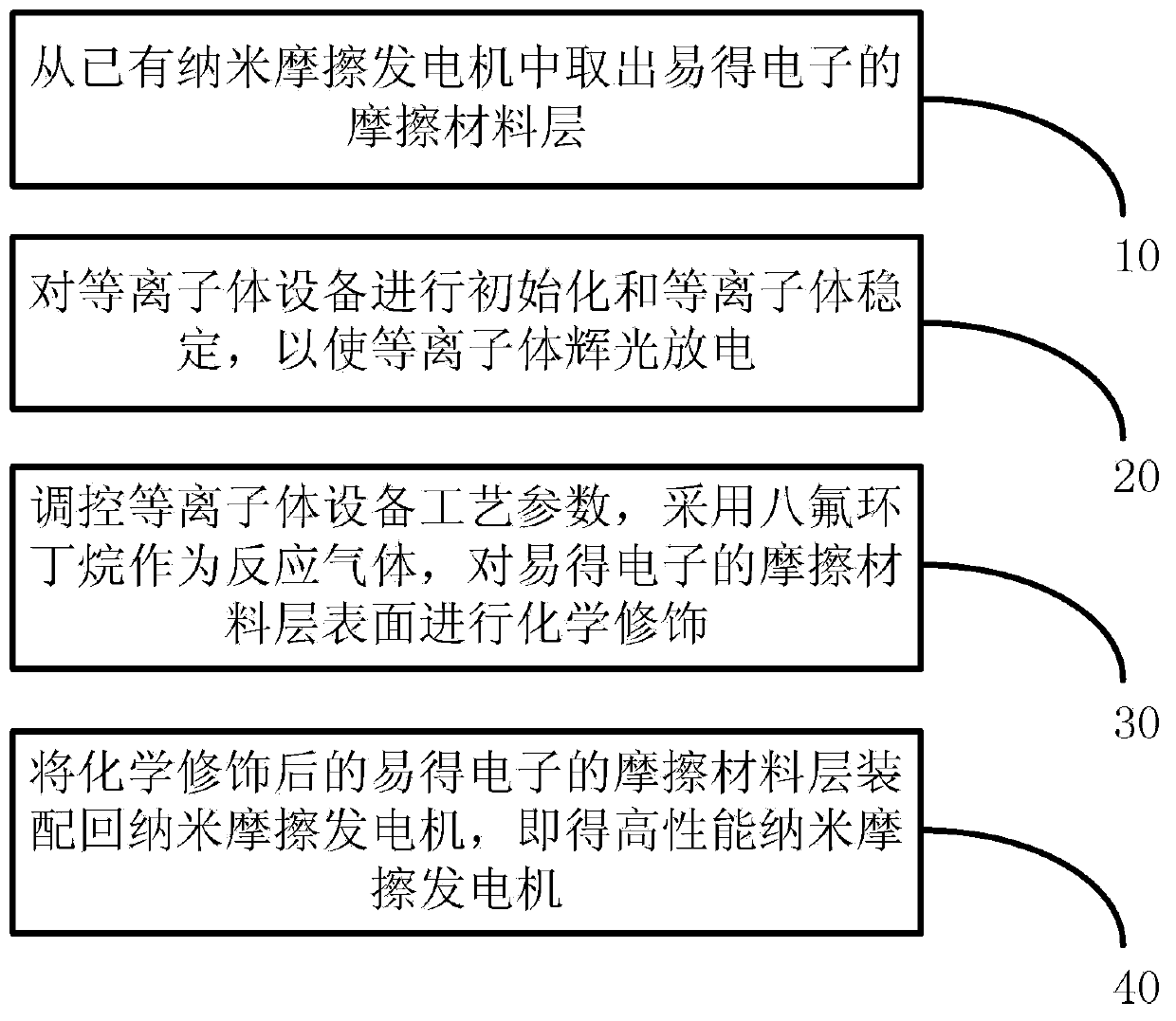

Method for manufacturing high-performance nano friction generator

InactiveCN103391021AUniversalSurface topography has no effectFriction generatorsNanogeneratorOctafluorocyclobutane

The invention relates to a method for manufacturing a high-performance nano friction generator. The method comprises the steps as follows: 1), a friction material layer easy to obtain electrons is taken from a conventional nano friction generator; 2), initialization and plasma stabilization are performed on plasma equipment, so that plasmas glow and discharge; 3), technological parameters of the plasma equipment are regulated, octafluorocyclobutane is taken a reaction gas, and the surface of the friction material layer easy to obtain electrons is subjected to chemical modification; and 4), the modified friction material layer easy to obtain electrons is assembled back to the nano friction generator, so that the high-performance nano friction generator is obtained. The method for manufacturing the high-performance nano friction generator is simple in process, low in cost and high in yield, the high-performance nano friction generator can be produced in batches, the process compatibility is excellent, the method is not limited to device structures, materials and the like and can be widely applied in the conventional nano friction generator, and the output performance is improved.

Owner:PEKING UNIV

A method for synthesizing fire extinguishing agent octafluorocyclobutane

ActiveCN107721810BSave raw materialsConvenient sourcePreparation by halogen replacementCatalyst activation/preparationChemical synthesisPtru catalyst

The invention relates to a method for synthesizing a fire extinguishing agent octafluorocyclobutane, and belongs to the field of organic chemical synthesis. The method for synthesizing octafluorocyclobutane is characterized in that the octafluorocyclobutane is generated from dichlorotetrafluorocyclobutene, hydrogen fluoride and chlorine gas in the presence of a fluorination catalyst. FORMULA is shown in the description. According to the method, raw materials are cheap, the raw material source is convenient, product separating and purifying is simple, industrial production is easy, and a littlethree industrial wastes (waste solid, waste water and waste gas) is generated.

Owner:天津航大翼安科技发展有限公司

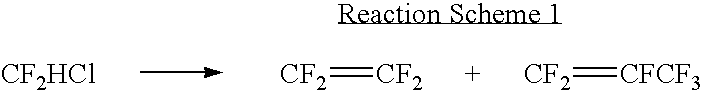

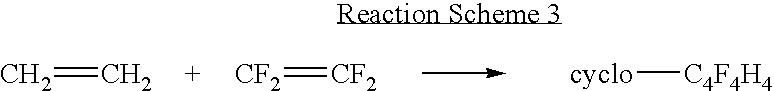

Method of a simultaneous preparation of hexafluoropropylene and octafluorocyclobutane

A method of simultaneous and selective perpararation of hexafluoropropylene and octafluorocyclebutane comprising the steps of: (a) thermally decomposing difluorochloromethane to obtain tetrafluoroethylene and then supplying the resulting tetrafluoroethylene into a bed reactor equipped with a distributor for supplying steam; and (b) supplying steam into a flow of tetrafluoroethylene supplied into the fluidized bed reactor, through a distributor for supplying steam at a certain molar ratio of tetrafluoroethylene / stream, and then performing dimerization of tetrafluoroethylene in the fluidized bed reactor under an atmospheric pressure.

Owner:KOREA INST OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com