Anti-dripping agent preparation method

A technology of anti-dripping agent and anion initiator, which is applied in the production of bulk chemicals, etc., can solve the problems of energy consumption and environmental pollution, and achieve the effects of reduced energy consumption, stable product quality and good anti-dripping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

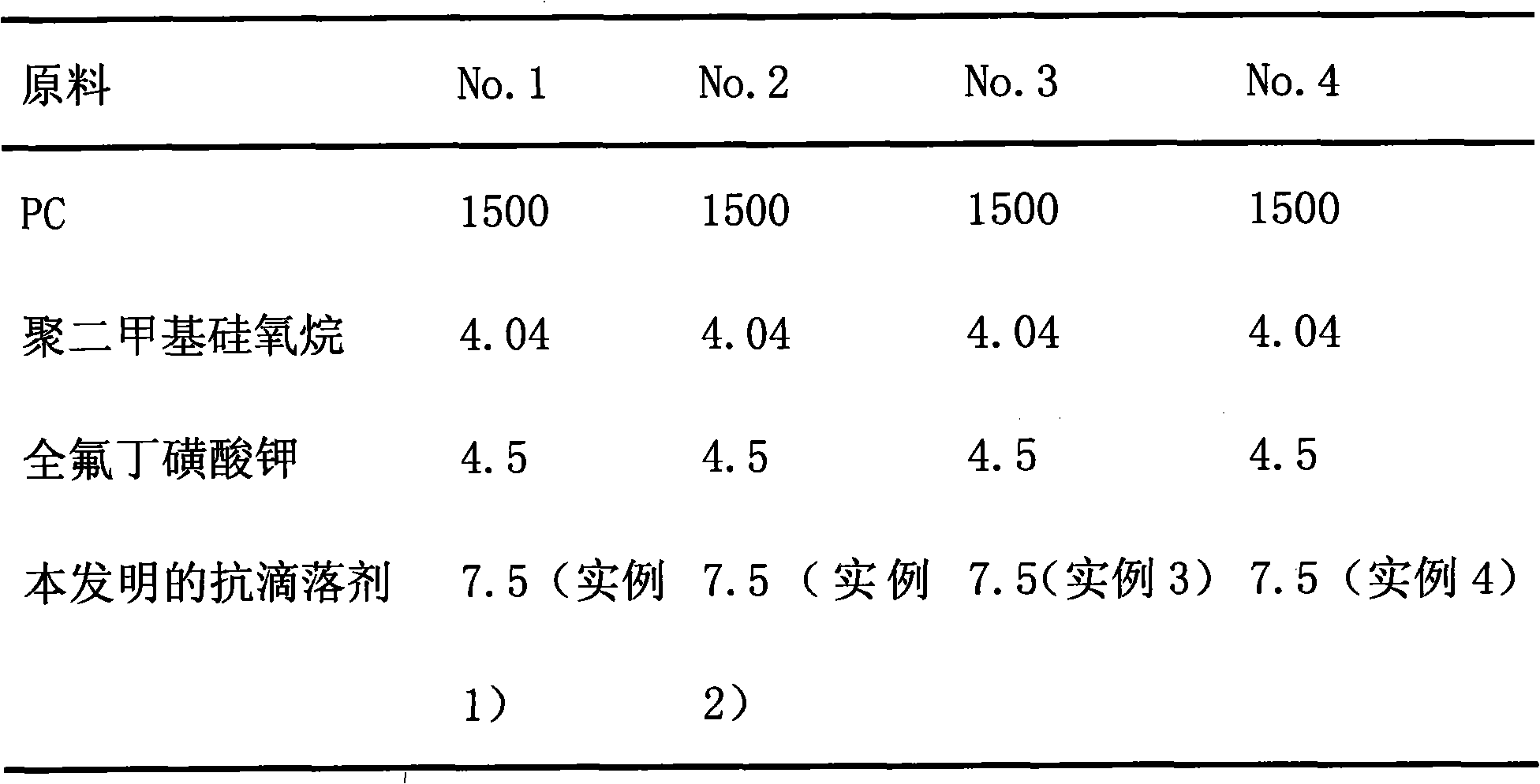

Embodiment 1

[0027] In a 200L stainless steel coagulation kettle, add 120 kg of 30% solid content polytetrafluoroethylene emulsion, start magnetic stirring, control the stirring speed at 100 rpm, and after stirring for 6 hours, put the material into the centrifugal separator , start the centrifugal separator to separate the PTFE particles from the water. Add 35.6 kg of polytetrafluoroethylene particles into a 500L stainless steel high-pressure polymerization kettle, add 200 g of n-butyllithium, and then add 200 kg of octafluorocyclobutane. Open the steam valve of the jacket of the autoclave, raise the temperature of the autoclave system to 115 degrees Celsius, and maintain the pressure of the system at 2.8Mpa. Start stirring, after mixing 3 kilograms of styrene with 7.68 kilograms of acrylonitrile, pump it into the polymerization kettle step by step with a pump, the time of adding is 1 hour, then under the conditions of the temperature and pressure, keep warm for 5 hours. Then lower the t...

Embodiment 2

[0029] In a 200L stainless steel coagulation kettle, add 120 kg of polytetrafluoroethylene emulsion with 40% solid content, start magnetic stirring, control the stirring speed at 150 rpm, and after stirring for 6 hours, put the material into the centrifugal separator , start the centrifugal separator to separate the PTFE particles from the water. Add 48 kg of polytetrafluoroethylene particles into a 500L stainless steel autoclave, add 300 g of n-butyllithium, and then add 250 kg of octafluorocyclobutane. Open the steam valve of the jacket of the autoclave, raise the temperature of the autoclave system to 120 degrees Celsius, and maintain the pressure of the system at 3.0Mpa. Start stirring, mix 10 kilograms of styrene, 5 kilograms of acrylonitrile and 5 kilograms of butadiene, and gradually pump them into the polymerization kettle with a pump. The adding time is 2 hours, and then keep the temperature and pressure for 7 Hour. Then lower the temperature to 60 degrees Celsius, ...

Embodiment 3

[0031] In a 200L stainless steel coagulation kettle, add 120 kg of polytetrafluoroethylene emulsion with 50% solid content, start magnetic stirring, control the stirring speed at 200 rpm, and after stirring for 6 hours, put the material into the centrifugal separator , start the centrifugal separator to separate the PTFE particles from the water. Add 60 kg of polytetrafluoroethylene particles into a 500L stainless steel autoclave, add 350 g of π-allyl nickel, and then add 300 kg of octafluorocyclobutane. The steam valve of the jacket of the autoclave was opened, the temperature of the autoclave system was raised to 125 degrees Celsius, and the pressure of the system was maintained at 3.5Mpa. Start stirring, and 30 kilograms of styrene are gradually pumped into the polymerization kettle with a pump, and the time of adding is 3 hours, and then under the conditions of this temperature and pressure, keep warm for 8 hours. Then lower the temperature to 60 degrees Celsius, open the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com