Patents

Literature

79results about How to "Improve anti-dripping performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flame-resistant polyester fiber and preparation method thereof

ActiveCN105463610ASmall coefficient of thermal degradationReduce generationElectrolysis componentsFlame-proof filament manufacturePolyesterFiber

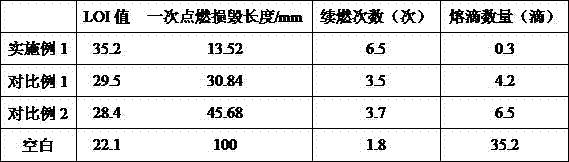

The invention relates to a flame-resistant polyester fiber and a preparation method thereof. The flame-resistant polyester fiber is prepared by spinning flame-resistant polyester and then carrying out ultraviolet irradiation. The limit oxygen index value of the flame-resistant polyester fiber is larger than 30, and the fiber has good molten drop resistance on the basis of flame resistance. Flame retardant 2-carboxyethyl(phenyl)phosphinicacid is used for improving the flame resistance of polyester, and unsaturated double bonds contained in polyester are opened to form crosslinking points under ultraviolet irradiation to form a certain quantity of network structures, so that the heat resistance temperature of the polyester fiber is increased, and the molten drop resistance of the polyester fiber is improved. The unsaturated double bonds are introduced into polyester and are effectively and safely controlled to be crosslinked after preparation of the polyester fiber is completed, the gel content of the fiber obtained after crosslinking is greatly increased, and therefore the mechanical performance, heat resistance, chemical resistance and flame resistance of the polyester fiber can be greatly improved.

Owner:JIANGSU HENGLI CHEM FIBER

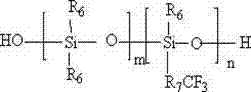

Preparation method for fluorine silicon phosphorus-containing anti-dropping flame-retardant polyethylene terephthalate

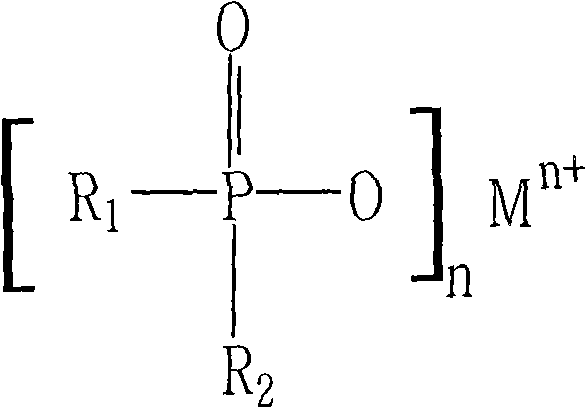

ActiveCN102391488AMechanical properties are not affectedReduce manufacturing costMonocomponent copolyesters artificial filamentFiberPolyethylene terephthalate glycol

The invention discloses a preparation method for fluorine silicon phosphorus-containing anti-dropping flame-retardant polyethylene terephthalate. The preparation method is characterized by comprising the following steps of: performing prepolymerization on a phosphorus-containing copolymerization flame retardant to synthesize phosphorus-containing copolymerization flame retardant prepolymer; performing dehydration reaction on trifluoalkyl siloxane and octaalkylcyclotetrasiloxane; adding dihydroxy siloxane and a catalyst, and reacting to synthesize dihydroxy fluorosiloxane; performing esterification on terephthalic acid and glycol; adding a catalyst B and a stabilizing agent; adding the phosphorus-containing copolymerization flame retardant prepolymer and the dihydroxy fluorosiloxane for polycondensation; and after the reaction is finished, cooling by using water and granulating to prepare the fluorine silicon phosphorus-containing anti-dropping flame-retardant polyethylene terephthalate. The product prepared by the method has high flame-retardant and anti-dropping properties and can serve as a raw material for producing films with the flame-retardant property of 94ULV-0 level or VTM-0 level, flame-retardant fibers and textiles with the flame-retardant level I and higher level, and V0-level flame-retardant plastic products.

Owner:四川东方绝缘材料股份有限公司

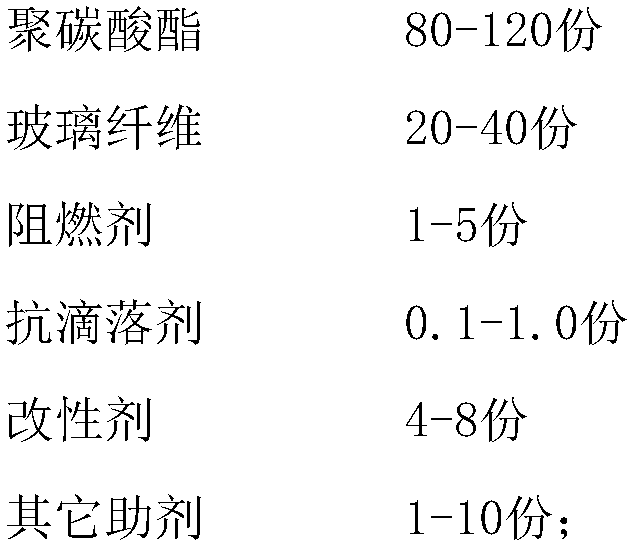

Laser markable high-shading polyester composite material for LED (Light Emitting Diode), and preparation method thereof

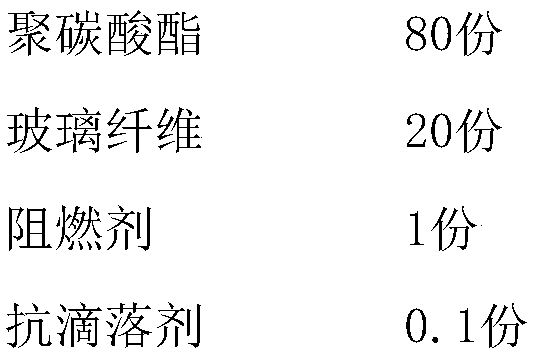

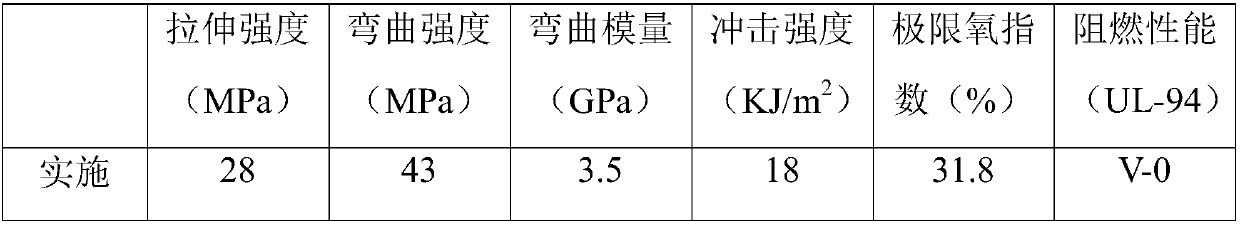

The invention relates to the technical field of high polymer materials, in particular to a laser markable high-shading polyester composite material for an LED (Light Emitting Diode), and a preparation method thereof. The laser markable high-shading polyester composite material for the LED comprises the following raw materials in parts by weight: 40-60 parts of polyester, 15-20 parts of glass fiber, 15-20 parts of main fire retardant, 3-5 parts of auxiliary fire retardant, 4-8 parts of flexibilizer, 0.1-0.2 part of antioxidant, 10-15 parts of opacifier, 0.3-1.0 part of laser marking powder and 0.5-1.0 part of other accessory ingredients. The laser markable high-shading polyester composite material for the LED has the advantages of good shading effect, good anti-flaming effect, good temperature tolerance and weather fastness, high intensity, excellent shock resistance, good processability and excellent overall performance, can be used for laser marking and can pass a high and low temperature (40DEG C below-120DEG C) impact test.

Owner:东莞市东翔塑胶有限公司

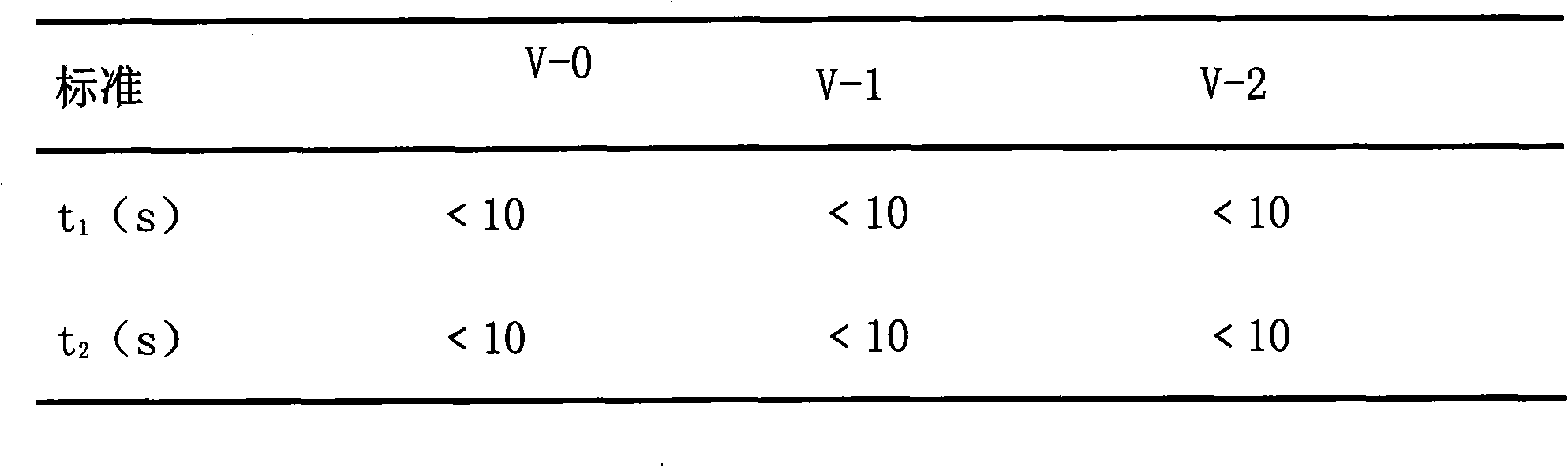

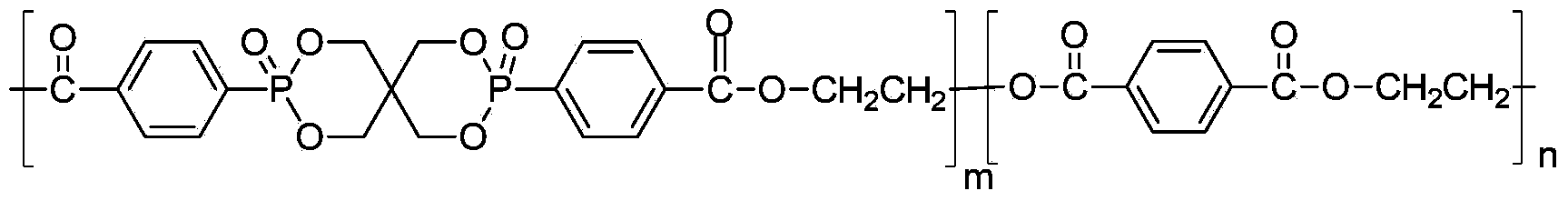

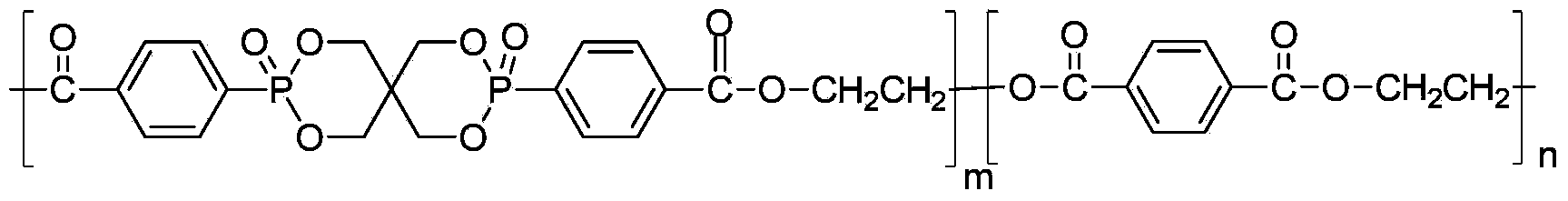

Branching, cross-linking, expanded, melt-dropping-resistant and flame-retardant copolyester based on triazine ring structure and preparation method of copolyester

ActiveCN104710604AIncrease melt viscosityImprove flame retardant performanceNitrogenNetwork structure

The invention discloses branching, cross-linking, expanded, melt-dropping-resistant and flame-retardant copolyester based on a triazine ring structure. The copolyester is prepared by conducting random copolymerization on structure units expressed as formulae I, II and III or structure units expressed as formulae I, II, III and IV according to a conventional method. The intrinsic viscosity [eta] of the prepared branching, cross-linking, expanded, melt-dropping-resistant and flame-retardant copolyester is 0.41-1.10 dL / g; the extreme oxygen index is 24.5-38.0%; the vertical combustion grade is between V-2 and V-0; the peak heat release rate p-HRR in a cone heat test is 247-643 kW / m<2>. According to the copolyester, a modified monomer of the triazine ring structure is introduced, and then copolymerized with polyester to form a unique ternary branched cross-linking network structure; the modified monomer of the triazine ring structure contains the flame-retardant element nitrogen, so that the melt viscosity of the copolyester in combustion can be improved; the copolyester is capable of releasing nitrogen and quickly forming an expanded char layer with excellent heat and oxygen insulation effects; especially, a phosphorus-nitrogen synergism effect can be generated when the copolyester is used together with the conventional phosphorus-containing flame-retardant agent; the flame-retardant performance and the melt-dropping-resistant effects can be more excellent; the selected monomer is low in price; the preparation process is mature; the operation is simple and convenient; the industrialized large-scale production is liable to implement.

Owner:SICHUAN UNIV

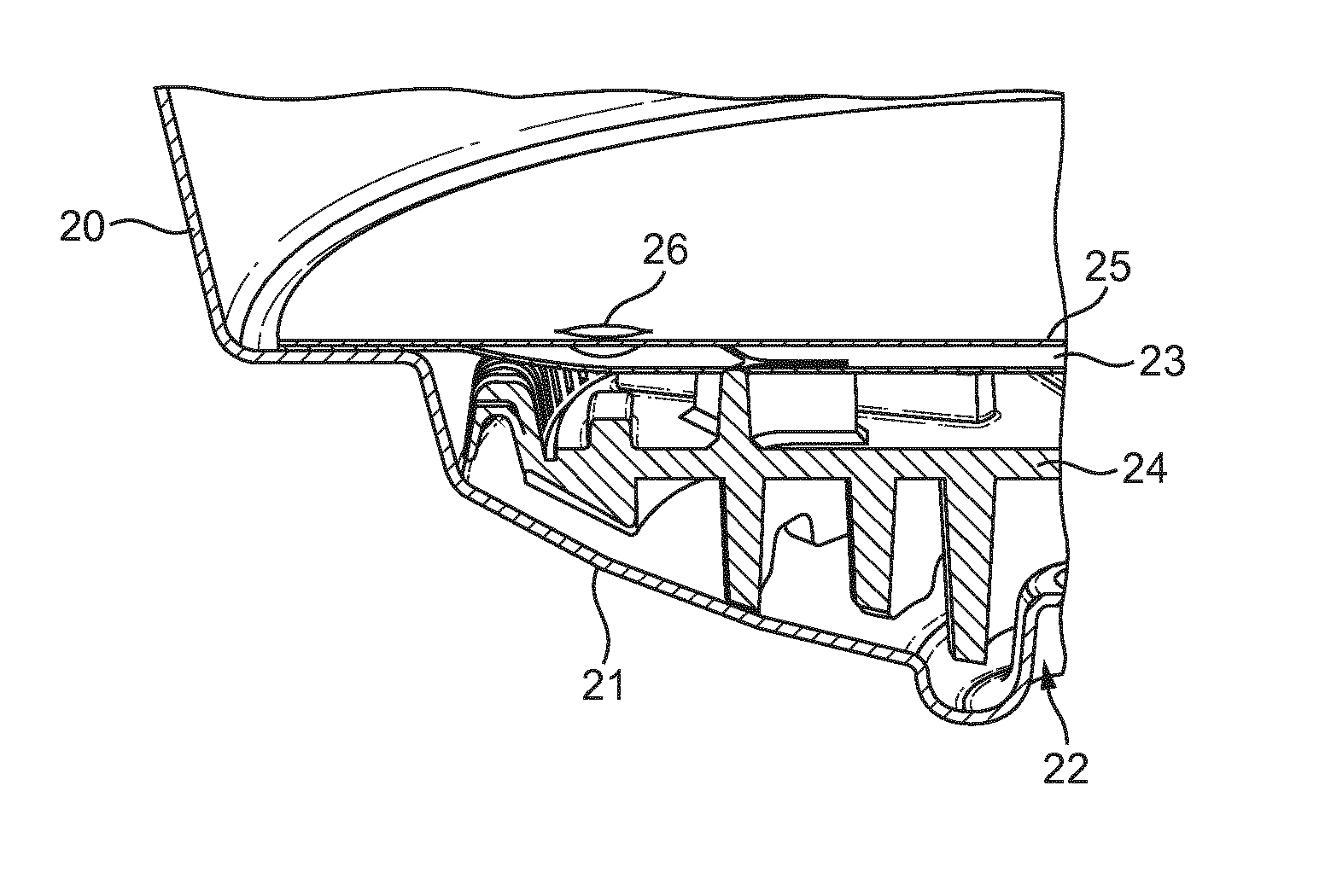

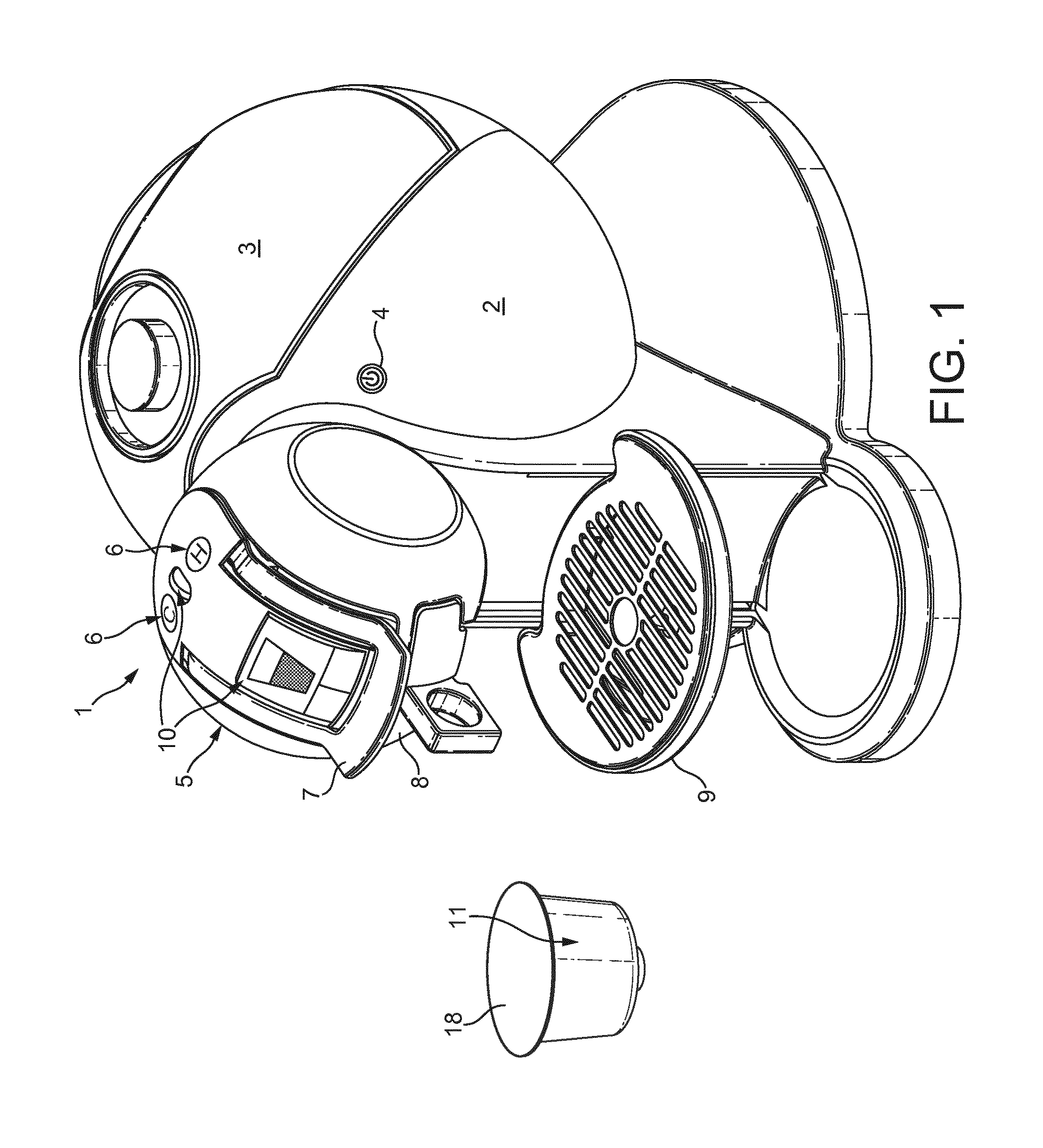

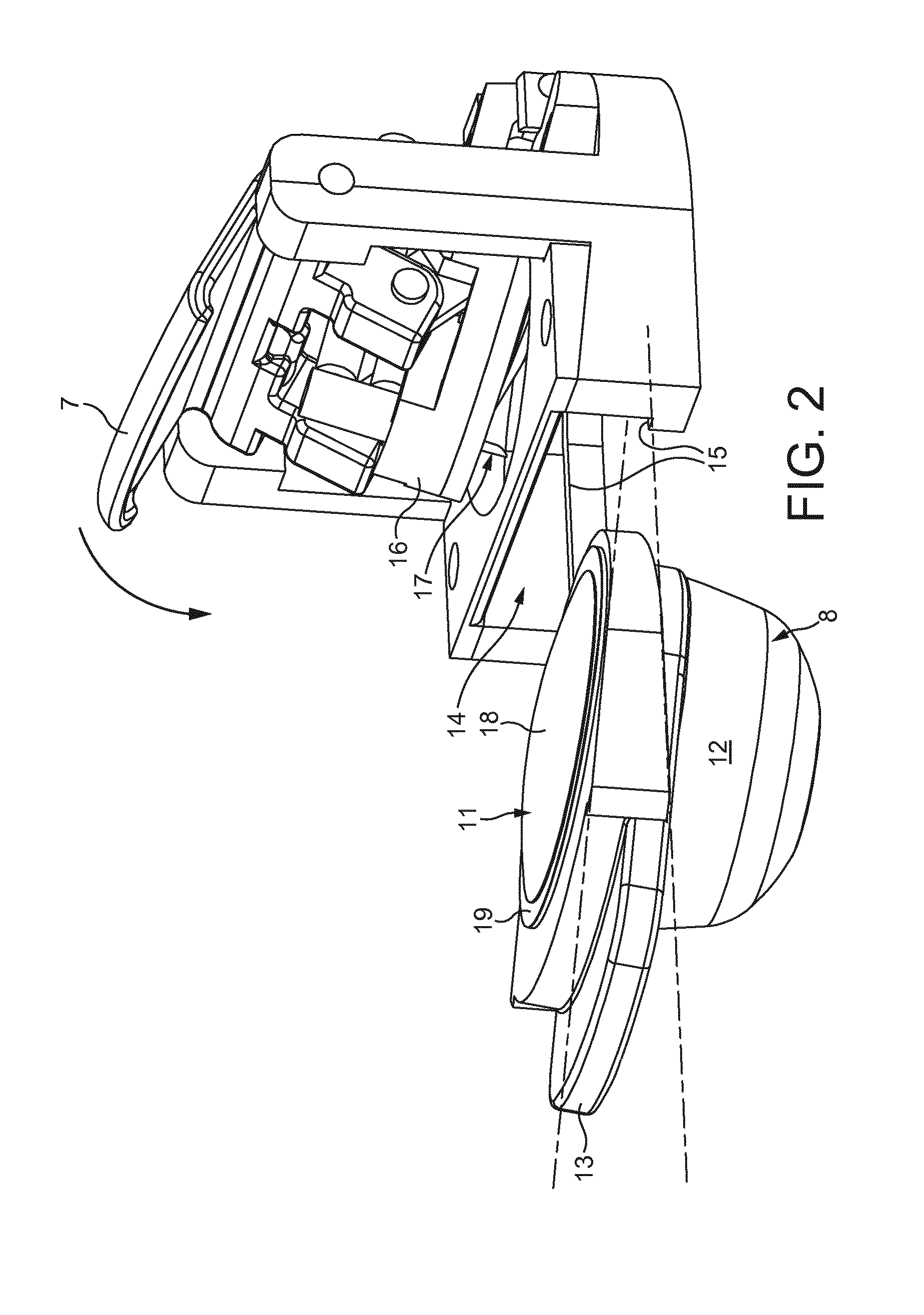

Beverage capsule with Anti-dripping membrane

InactiveUS20150232263A1Good anti drip propertyImprove anti-dripping performanceFlexible coversWrappersPressure sensitiveMembrane configuration

The present invention concerns a beverage capsule (11) comprising capsule side walls (20), a capsule top, and a capsule bottom (21) having a dispensing outlet (22), that define a chamber for containing a food or beverage precursor ingredient soluble and / or extractable when a fluid is injected inside said chamber under pressure, said capsule (11) further comprising a pressure-sensitive membrane (25), characterized in that said pressure-sensitive membrane (25) comprises at least one weakened or precut zone defining a non-reclosable opening (26) which: (i) elastically and plastically opens, respectively widens when the fluid pressure inside said capsule reaches a predetermined value between 0.5 and 20 bar relative pressure, and then (ii) maintains a widen configuration after the fluid pressure within the chamber is released to an atmospheric pressure value, such that the width of said at least one opening (26) does not exceed 1 mm.

Owner:NESTEC SA

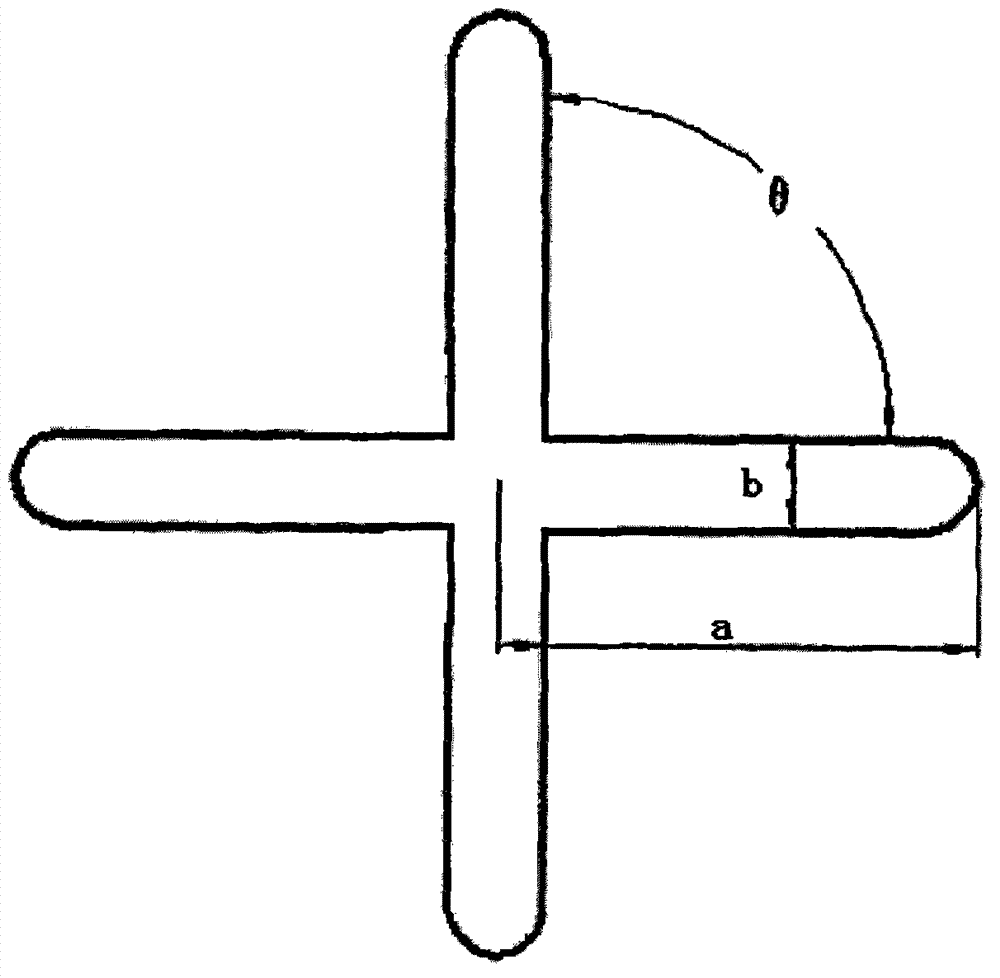

Uvioresistant, flame-retardant, anti-melt-drop, moisture absorption and sweat facilitating polyester monofilament and preparation method

ActiveCN103590134AAvoid damageImprove anti-dripping performanceFlame-proof filament manufactureMelt spinning methodsFiberPolyester

The invention relates to a uvioresistant, flame-retardant, anti-melt-drop, moisture absorption and sweat facilitating polyester monofilament and a preparation method. The raw materials are, by weight, 1-5% of uvioresistant, flame-retardant and anti-melt-drop polyester master batches, 1-10% of hydrophilic modified polyester chips, and the balance being polyester chips. Ammonium polyphosphate is coated with silane coupling agents, the compatibility of ammonium polyphosphate and polyesters is raised, and the anti-melt-drop performance of fire retardants is raised. Fabrics of fiber with four-leaf-shaped cross sections have moisture absorption and sweat facilitating characteristics and people feel comfortable.

Owner:FUJIAN JINJIANG HUAYU WEAVING +1

Anti-dripping agent preparation method

ActiveCN101628957AReduce energy consumptionImprove product qualityBulk chemical productionTetrafluoroethylenePolymer science

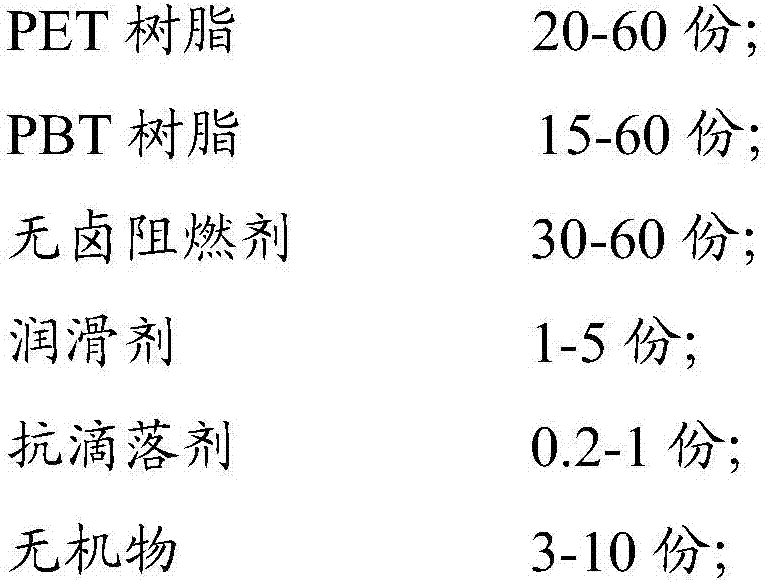

The invention discloses an anti-dripping agent preparation method; the anti-dripping agent comprises cores and shells, wherein, the cores are made from polytetrafluoethylene ultrafine powder which is prepared by mixing polytetrafluoethylene emulsion in high speed and centrifugalizing the emulsion, and the shells are prepared by adopting anionic initiator to initiate copolymerization in supercritical octafluorocyclobutane to one or more monomers of styrene, ethylene, propylene, butadiene, acrylonitrile, acrylic acid and methylacrylic acid. The specific preparation method comprises the following steps: 1. the preparation of the polytetrafluoethylene ultrafine powder: mixing polytetrafluoethylene emulsion in high speed in a condensation pot to agglomerate polytetrafluoethylene emulsion, then separating by high speed centrifugation to obtain the polytetrafluoethylene ultrafine powder; 2. the preparation of the anti-dripping agent: placing the polytetrafluoethylene ultrafine powder in a polymerizing pot and adding octafluorocyclobutane as solvent, heating to ensure that octafluorocyclobutane is in supercritical state, and mixing in high speed to keep the particle size of the polytetrafluoethylene ultrafine powder to 0.5mu m.

Owner:CHANGSHU 3F ZHENFU NEW MATERIALS CO LTD

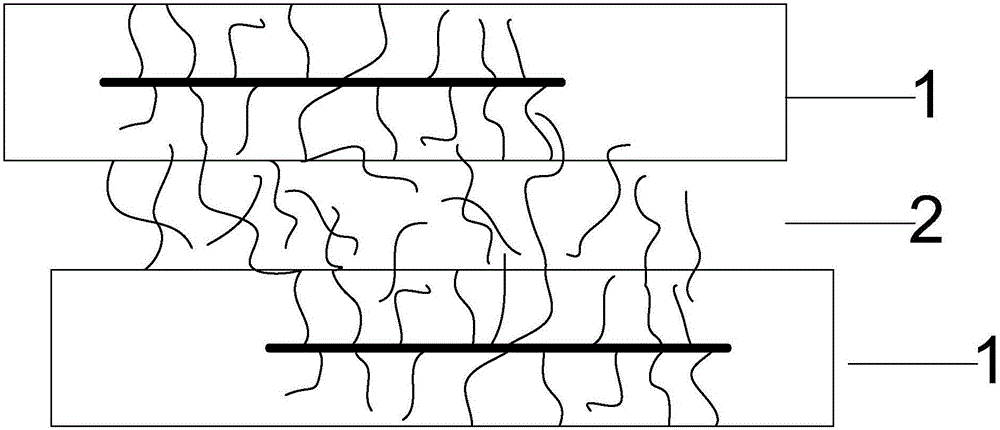

Double-layer fabric and camouflage clothing made thereof

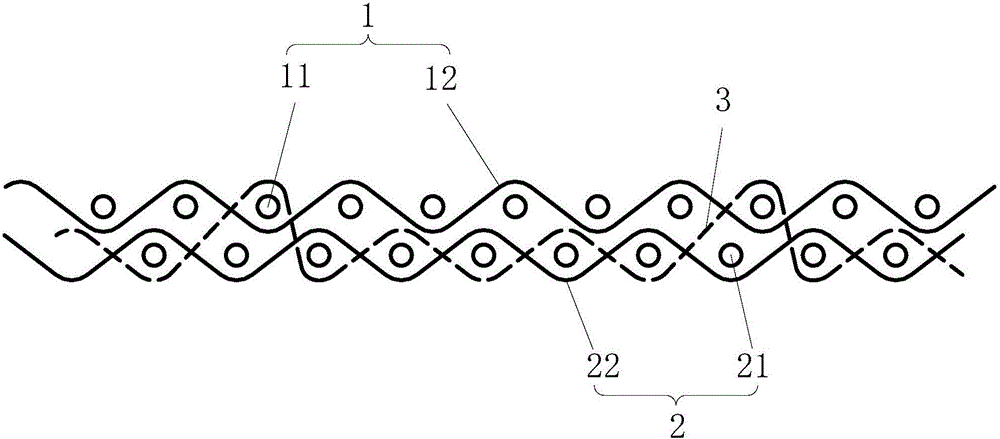

InactiveCN105755627AHigh strengthImprove anti-dripping performanceMulti-ply fabricsProtective garmentSurface layerViscose

The invention discloses a double-layer fabric and camouflage clothing made thereof.The double layer fabric comprises a surface fabric body formed by interweaving surface warp yarns and surface weft yarns, an inner fabric body formed by interweaving inner warp yarns and inner weft yarns, and a plurality of plated yarns enabling the surface fabric body and the inner fabric body to be connected.The surface warp yarns, the surface weft yarns and the plated yarns are first flame-retardant fiber yarns easy to print, and the first flame-retardant fiber yarns include 30-70wt% of flame-retardant viscose fibers and / or flame-retardant modacrylic fibers with chloride.The inner warp yarns and the inner weft yarns are second flame-retardant fiber yarns.On the premise that the double-layer fabric of the structure achieves high strength, high flame retardance and high molten drop resistance, the easy printing capability of the surface layer and the wearing comfort of the inner layer are improved, and the double-layer fabric is especially suitable for making camouflage clothing needing to be printed.

Owner:SHANGHAI IBENA TEXTILE PROD

Flame-retardant protective clothing polyester fabric

InactiveCN107385544AImprove flame retardant performanceWide applicabilityWeft knittingFlame-proof filament manufacturePolyesterCombustion

The invention discloses flame-retardant protective clothing polyester fabric. The flame-retardant protective clothing polyester fabric is prepared by cabling and twisting flame-retardant polyester fiber modified by polyphenylene sulfide with aramid fiber, basalt fiber and polyphenylene sulfide fiber, weaving, then finishing by using a softening agent, and drying. The flame-retardant protective clothing polyester fabric has the beneficial effects as follows: the flame-retardant protective clothing polyester fabric has excellent flame retardance, the advantages of various fibers complement one another to improve the flame retardance and the melt dripping resistance of a blended product, and during combustion, the flame-retardant protective clothing polyester fabric does not shrink and produce melt drips, so that the flame-retardant protective clothing polyester fabric is blended base fabric with relatively high cost performance; chemical substances harmful to a human body are not added, the preparation process causes a small environment impact and does no harm to the human body, and the flame-retardant protective clothing polyester fabric is high in softness and smooth in hand feel; the flame-retardant protective clothing polyester fabric is stable and long-lasting in flame retardance, an effective way of increasing product diversity is provided, an important method for improving product performance and expanding the application range is provided, and the commercial value is very high.

Owner:NINGBO HI TECH ZONE DAKANG IND TECH CO LTD

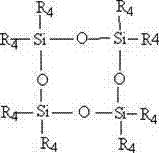

Novel fluorine-containing siloxane fire retardant, and preparation method and application thereof

The invention relates to the technical field of plastic assistants, and concretely relates to a novel fluorine-containing siloxane fire retardant, and a preparation method and an application thereof. The preparation method comprises the following steps: 1, uniformly mixing organosiloxane monomers, adding the obtained monomer mixture into a catalyst and emulsifier dissolved aqueous solution, and carrying out a reaction to obtain an organopolysiloxane emulsion; 2, adjusting the pH value of the organopolysiloxane emulsion by using an alkali liquid, adding a fluorine-containing styrene monomer and a copolymerization, adding an initiator, a crosslinking agent and a chain transfer agent, and carrying out a reaction to obtain an organosiloxane grafted fluorine-containing styrene polymer emulsion; and 3, diluting the polymer emulsion, adding a de-emulsifier to carry out demulsification, centrifuging the de-emulsified emulsion, and carrying out drying and crushing to prepare the novel fluorine-containing siloxane fire retardant. The novel fluorine-containing siloxane fire retardant prepared in the invention has excellent anti-dripping effect and fire-retardant property without affecting the mechanical properties of a high-molecular material polymer, and also can improve the mechanical properties and the heat resistance of matrix resin.

Owner:铨盛聚碳科技股份有限公司

Halogen-free flame-retarding polyester master batch specially used for simulative hairs and preparation method thereof

InactiveCN107286603AFeel goodGood shaping effectFlame-proof filament manufactureMonocomponent polyesters artificial filamentPolyesterSilicon dioxide

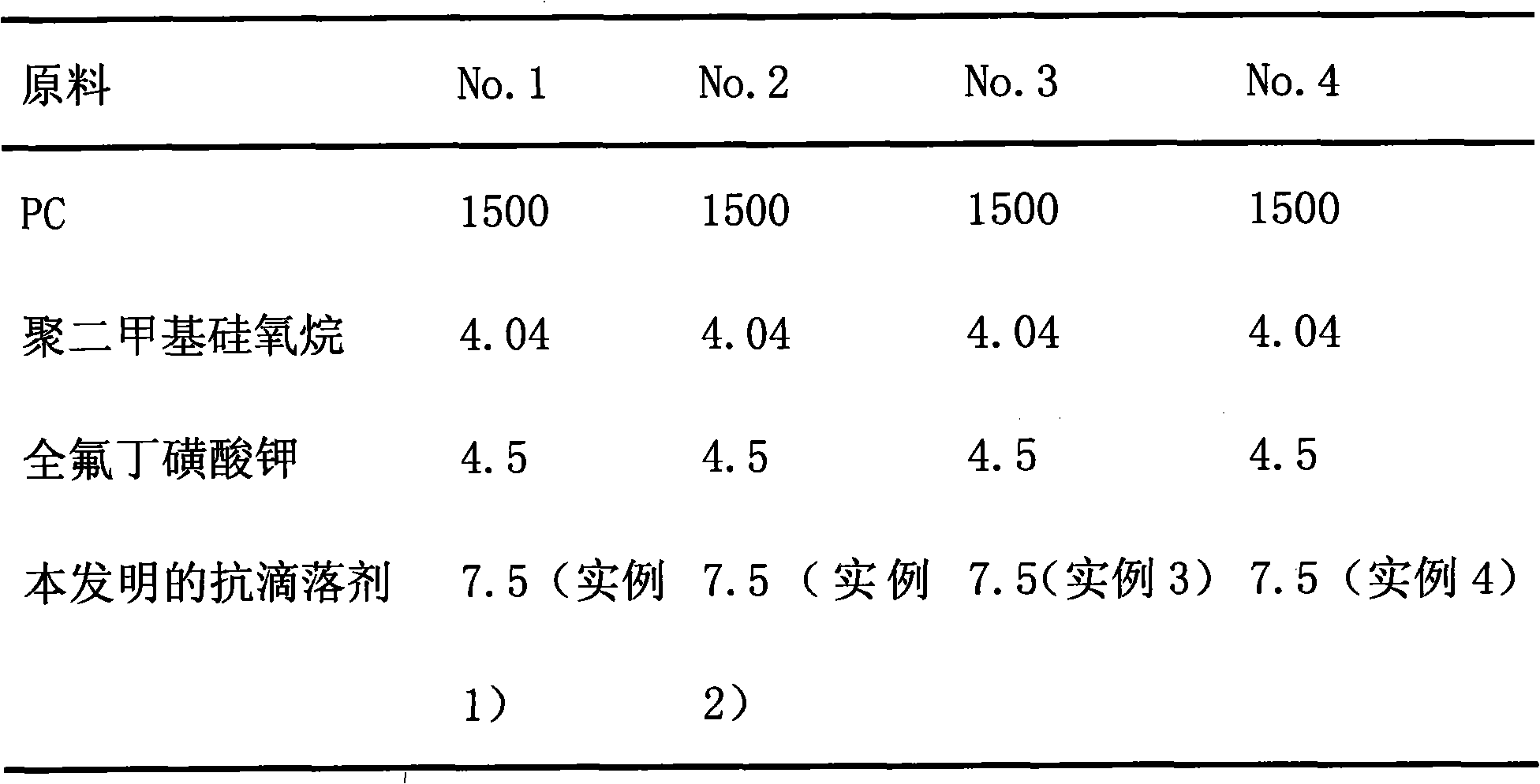

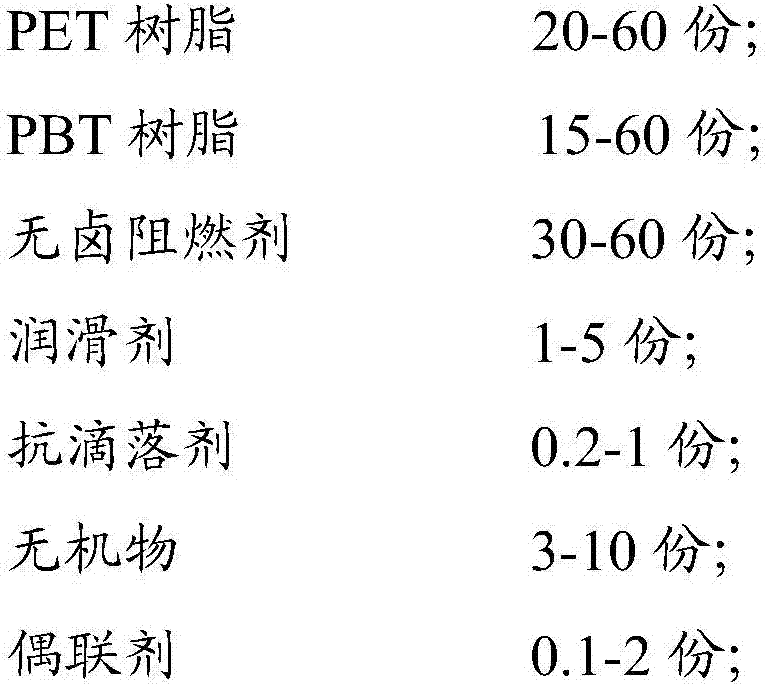

The invention provides a halogen-free flame-retarding polyester master batch specially used for simulative hairs, which includes 20-60 parts of PET resin, 15-60 parts of PBT resin, 30-60 parts of a halogen-free flame retardant, 1-5 parts of a lubricant, 0.2-1 part of an anti-dripping agent, 3-10 parts of an inorganic material, and 0.1-2 parts of a coupling agent. The inorganic material is one or more selected from SiO2, montmorillonoid, calcium carbonate and barium sulfate. The coupling agent is a silane coupling agent. The invention also provides a preparation method of the master batch, which includes the steps of: mixing the components in a high-speed mixer with material cylinder temperature being 60-120 DEG C; performing extrusive granulation to the mixed components through a twin-screw extruder. The preparation method is simple and is easy to carry out. The halogen-free flame-retarding polyester master batch, when being used for simulative hairs, especially high-temperature hairs, has excellent spinnability and combability, has good hand feel and shaping-ability, is good and durable in flame retarding effect, is low-smoke and toxic-free and has good charcoal-forming property.

Owner:郑宝胜 +1

Flame retardant anti-dripping blended fabric and preparation method thereof

InactiveCN102634896AImprove cohesionImprove flame retardant performanceFibre treatmentYarnYarnTemperature control

The invention discloses a flame retardant anti-dripping blended fabric and a preparation method of the blended fabric. The blended fabric is formed by blending aramid fiber and flame retardant terylene according to the mass ratio of (8-20): (80-92). The preparation method comprises the pretreatment process of aramid staple fiber and the blending process of the flame retardant terylene, wherein before blending, polar solvent is used for treating the aramid fiber for 60-90min at the temperature controlled within the range of 60-90 DEG C, and the flame retardant terylene is treated by 4-8g / L alkali for 30-90min at the temperature controlled within the range of 50-80 DEG C. Surface treatment is carried out on the aramid fiber and the flame retardant terylene, so that the fiber surface becomes appropriately rough, and blending can be better carried out. The prepared fabric woven by mixed yarn not only has good flame retardant property, but also has good dripping resistance.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

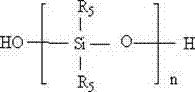

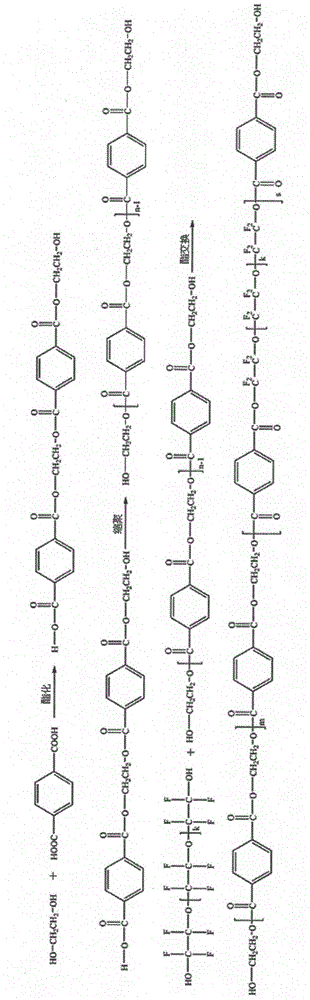

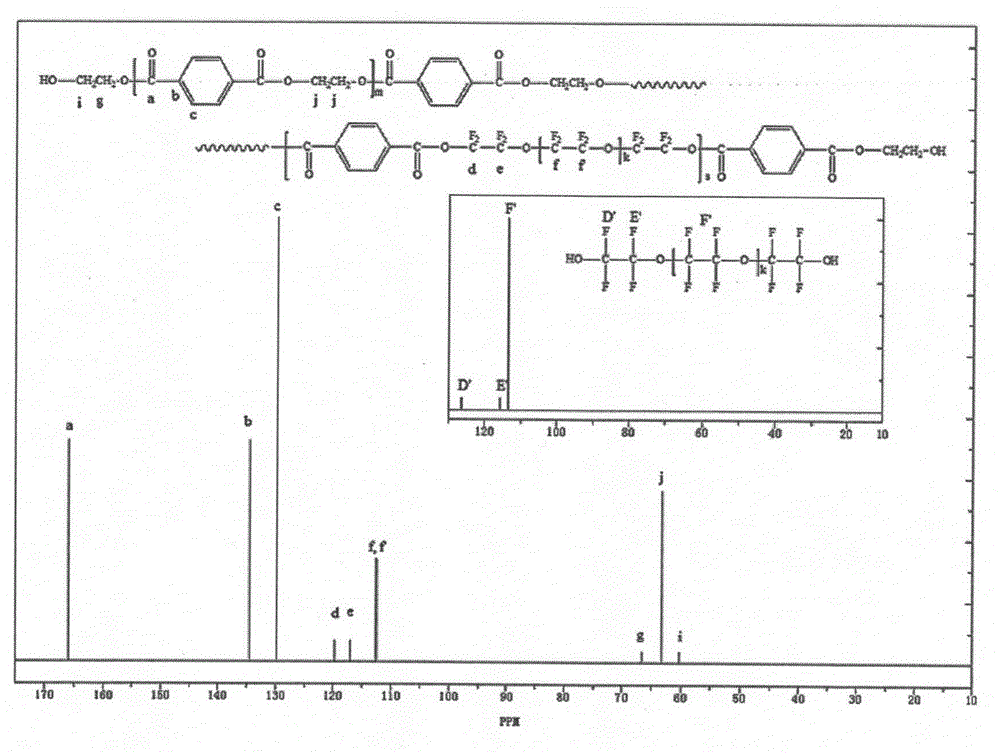

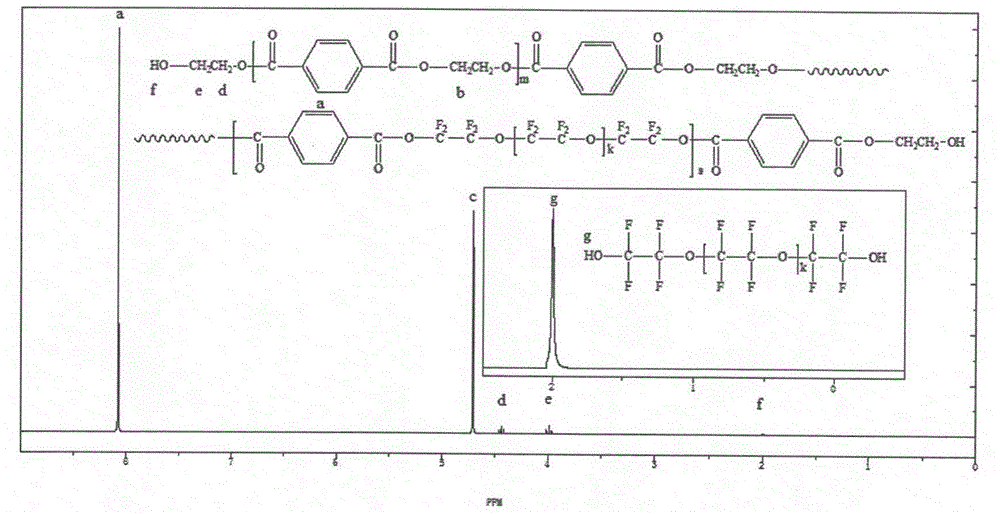

Perfluoropolyether modified antifouling droplet-preventing copolyester and preparation method thereof

InactiveCN104448277AImprove stain resistanceImprove flame retardant performanceMonocomponent copolyesters artificial filamentPolymer scienceIntrinsic viscosity

The invention discloses a perfluoropolyether modified antifouling droplet-preventing copolyester and a preparation method thereof. The surface energy of the copolyester is not more than 25mJ / cm<2>, the limiting oxygen index is more than 34, and the intrinsic viscosity is 0.50-0.65dL / g. The preparation method of the copolyester comprises the following steps of: (1) mixing ethylene glycol with terephthalic acid in proportion, and carrying out esterification reaction on ethylene glycol and terephthalic acid by pressurizing; and (2) adding terminal hydroxyl perfluoropolyether, carrying out pre-condensation at atmospheric pressure by heating, and carrying out post-condensation reaction in vacuum by heating to obtain the copolyester, wherein ethylene glycol, terephthalic acid and terminal hydroxyl perfluoropolyether serve as raw materials. The copolyester prepared by adopting the preparation method has excellent flame resisting performance, antifouling performance and droplet preventing performance and has a broad application prospect in the field of textiles.

Owner:DONGHUA UNIV

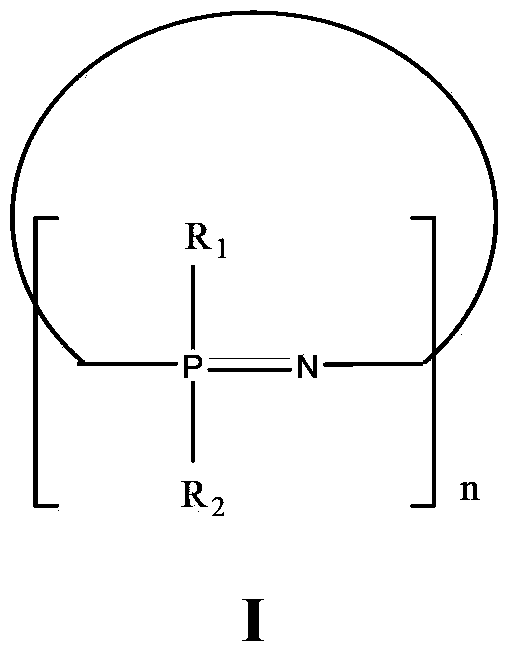

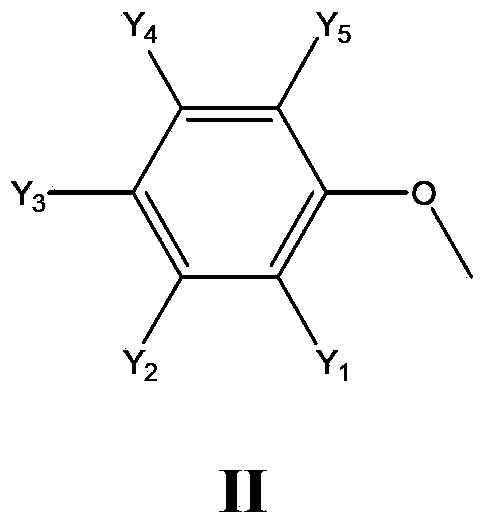

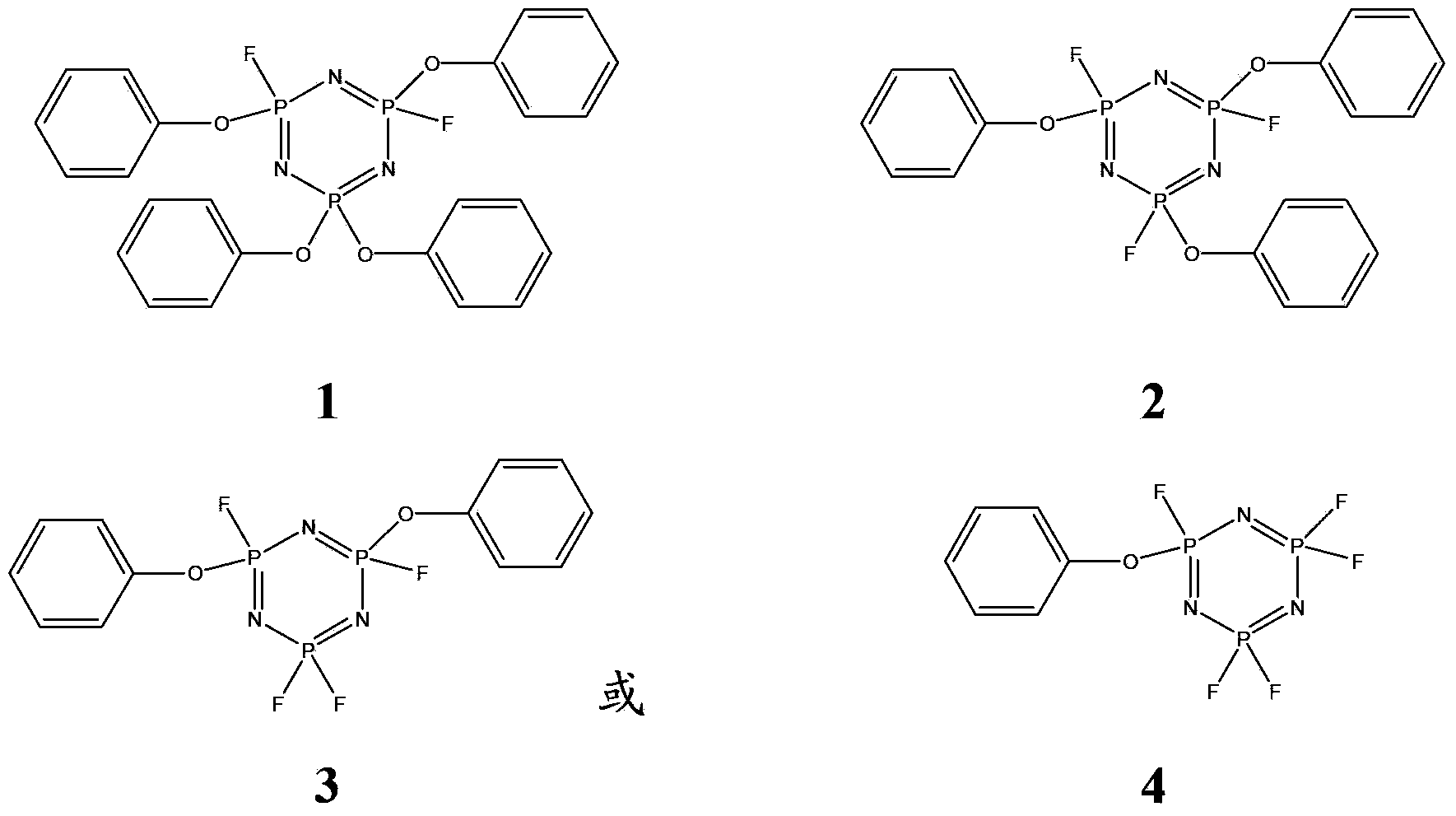

Application of cyclophosphazene compound in preparation of resin as antidrip agent

ActiveCN104140558AHas anti-dripping propertiesImprove mechanical propertiesGroup 5/15 element organic compoundsOrganic chemistry

Owner:CENWAY TECHNOLOGY CO LTD

Anti-dripping agent containing PTFE (polytetrafluoroethylene) and organic silicon and preparation method of anti-dripping agent

InactiveCN109320674AImprove flame retardant performanceImprove anti-dripping performanceAdjuvantEmulsion

The invention relates to the technical field of macromolecule adjuvants, in particular to an anti-dripping agent containing PTFE (polytetrafluoroethylene) and organic silicon and a preparation methodof the anti-dripping agent. The preparation method comprises the following steps: synthesis of organopolysiloxane core emulsion and preparation of the anti-dripping agent containing the PTFE and the organic silicon. By adding coated monomers into the organopolysiloxane core emulsion and PTFE emulsion to perform polymerization, the anti-dripping agent prepared by the preparation method not only hasrelatively good flame resistance but also has excellent anti-dripping performance, and is simple in process and low in cost.

Owner:铨盛聚碳科技股份有限公司

Preparation of polylactic acid composite material with flame-retardant function

InactiveCN104194292AHigh flame retardant levelImprove anti-dripping performancePhosphatePolymethyl methacrylate

The invention discloses preparation of a polylactic acid composite material with a flame-retardant function. The preparation comprises the following steps: mixing polylactic acid, core / shell-methyl polysiloxane / polymethyl methacrylate particles and polyarylate phosphate; carrying out melt blending by adopting torque rheology at the temperature of 168-180 DEG C to obtain the polylactic acid composite material with the flame-retardant function, wherein the weight percent of the core / shell-methyl polysiloxane / polymethyl methacrylate particles is 0%-25%, the weight percent of the polyarylate phosphate is 0%-25%, and the core / shell-methyl polysiloxane / polymethyl methacrylate particles and the polyarylate phosphate can not be 0 simultaneously. Compared with the traditional polylactic acid flame-retardant material, the polylactic acid composite material has the advantages of better flame-retardant property, mechanical property, crystallization property and heat-resistant property.

Owner:NANJING UNIV OF SCI & TECH

Method of surface grafting modification for nylon fabric

InactiveCN103074769AImprove anti-dripping performanceFacilitate the grafting reactionFibre treatmentNylon materialMicrowave method

The invention relates to a method of surface grafting modification for nylon fabric with a microwave irradiation method. The grafting reaction conducted with the microwave method has the advantages of short response time, uniform reaction and small influence on a property of the fabric. As hydroxyethyl methacrylate serves as a grafting monomer, the hygroscopicity of the grafted nylon fabric is improved obviously, and the dripping resistance is good; in addition, the reaction is combined with chemical bonds; an effect is stable and lasting; and the washing resistance is high.

Owner:BEIJING UNIV OF CHEM TECH

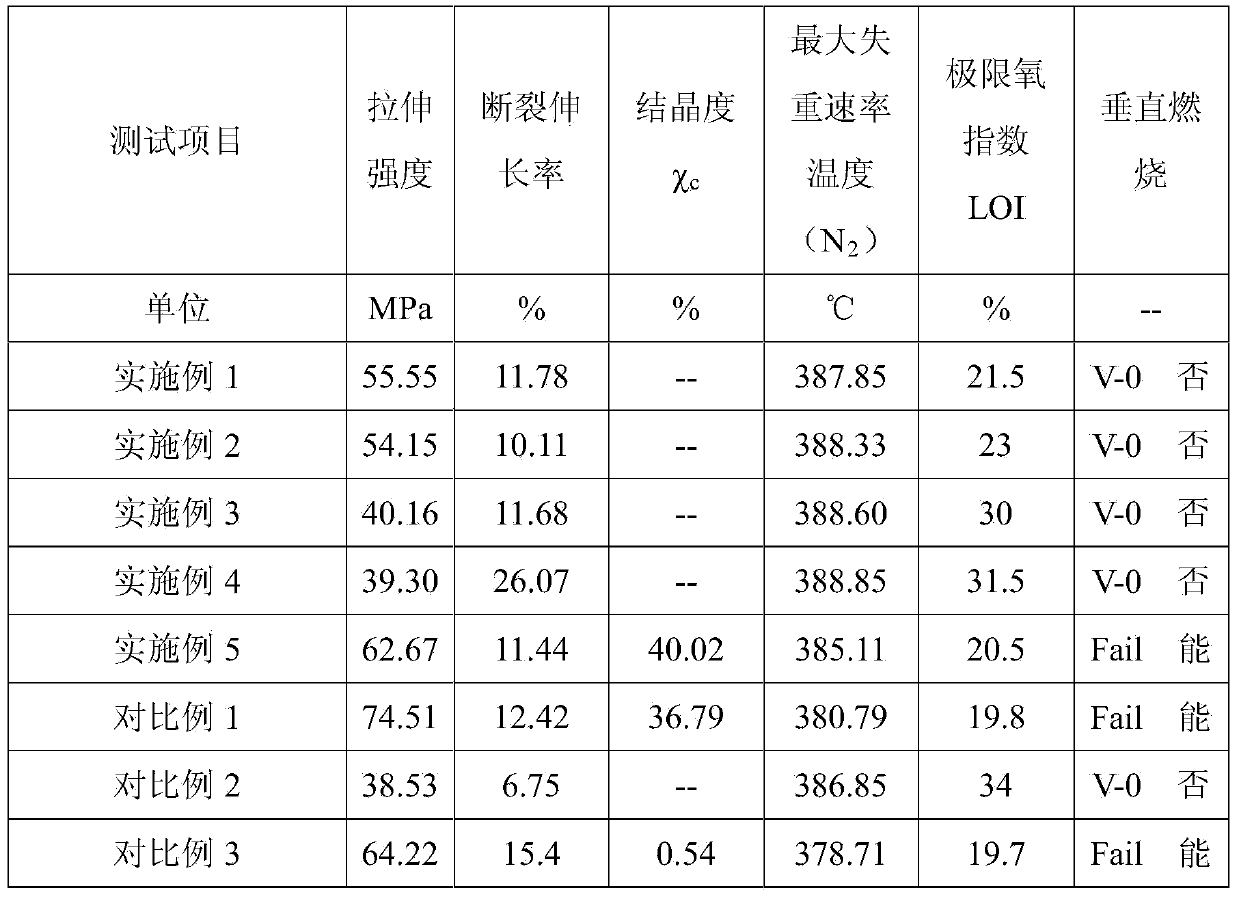

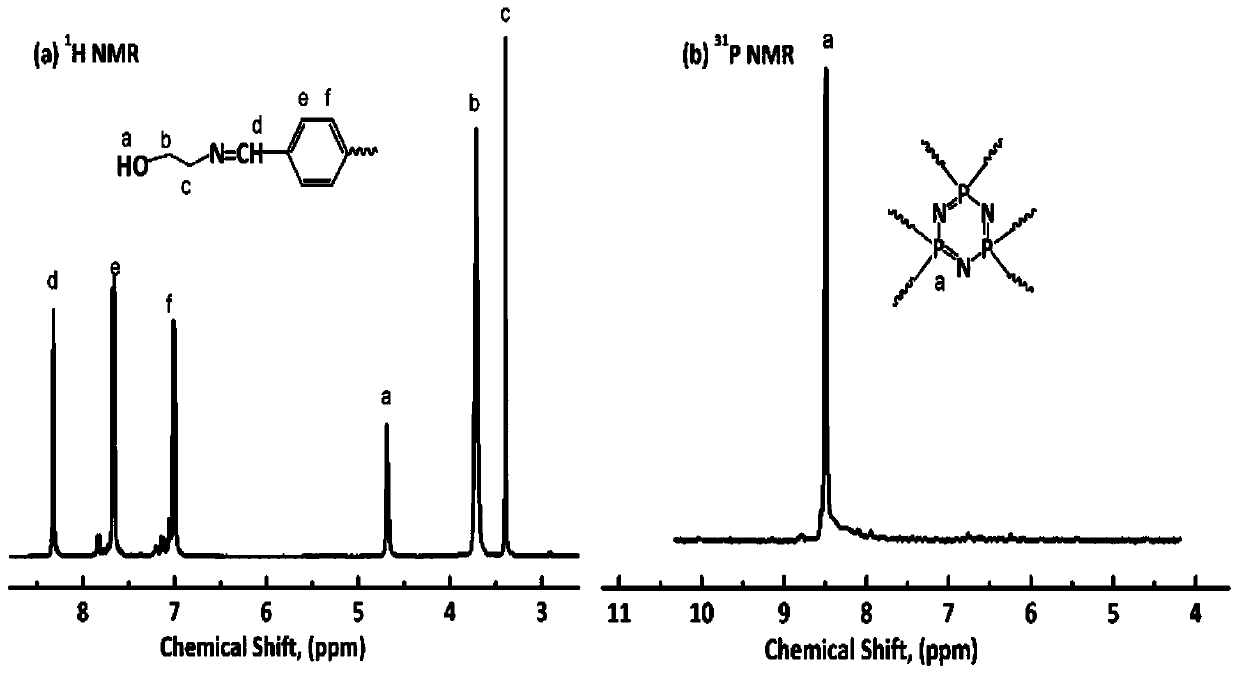

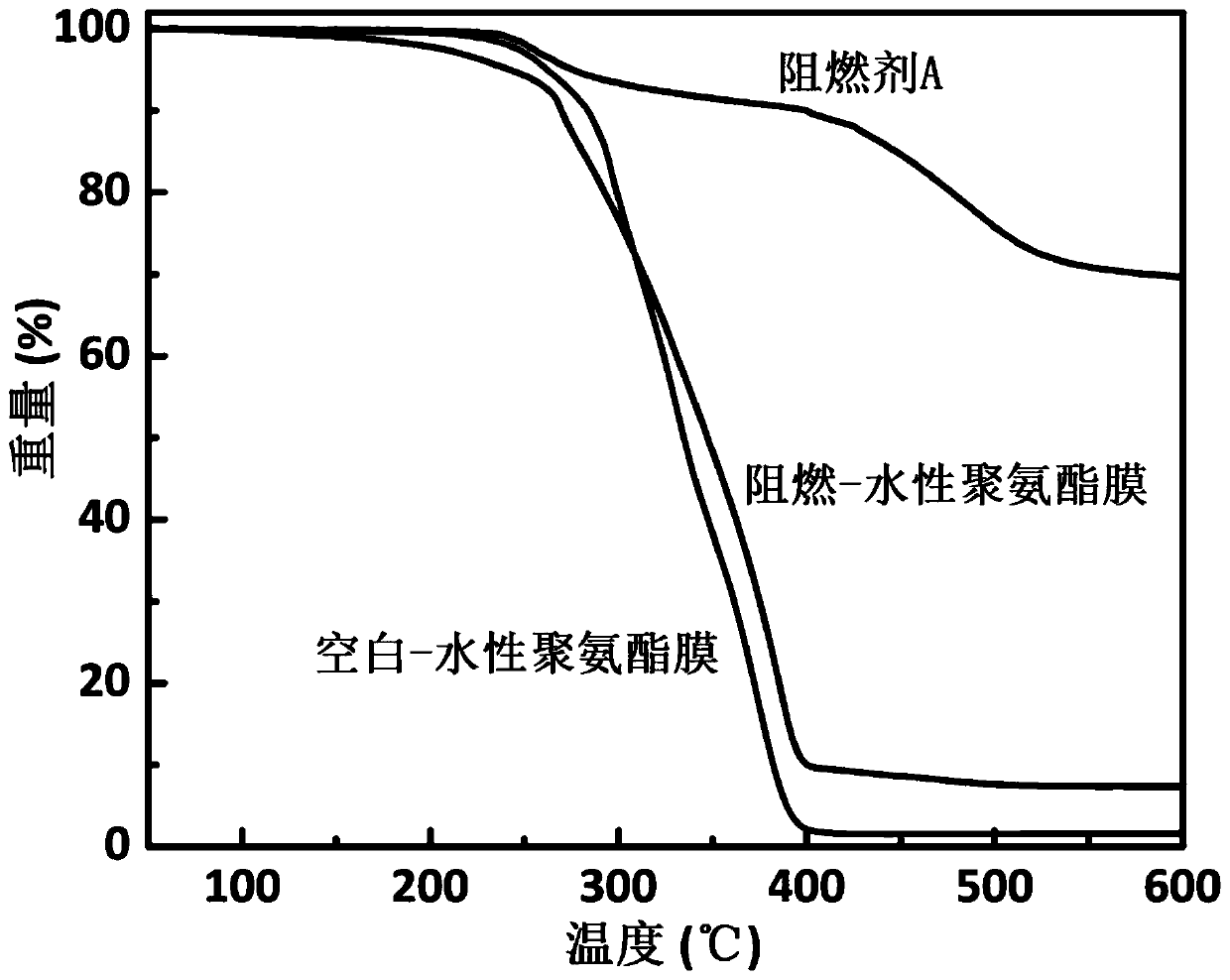

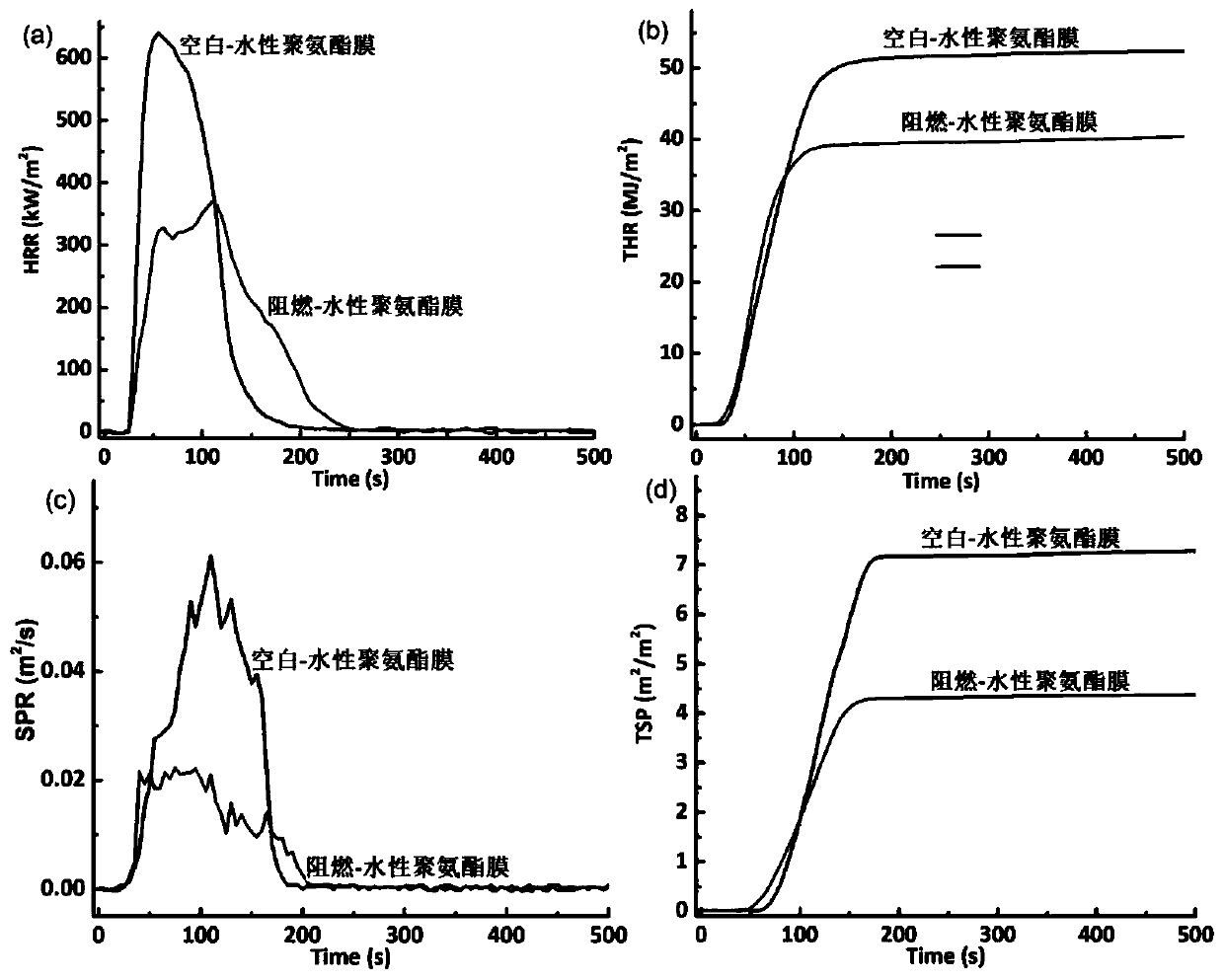

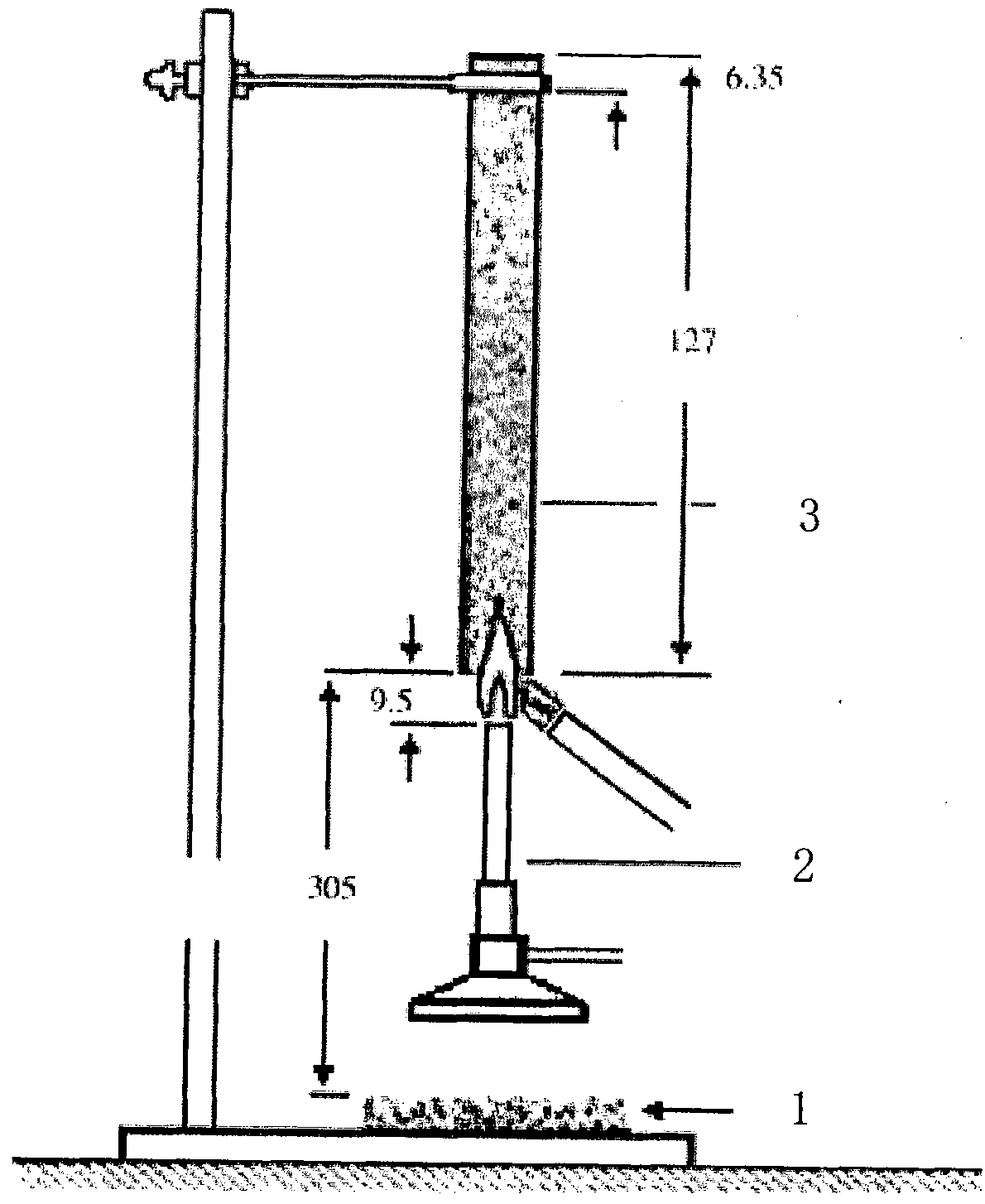

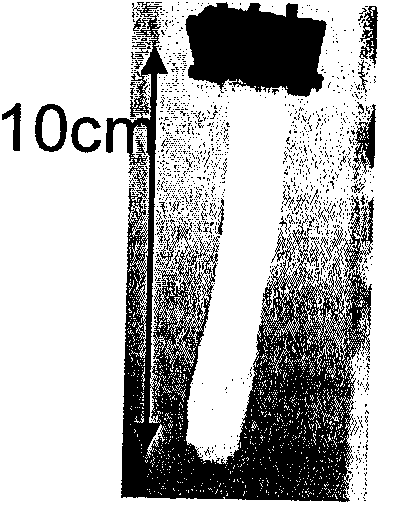

Synthesis methods of Schiff base phosphazene double-base structure flame retardant and modified polyurethane flame retardant

ActiveCN110563765AImprove flame retardant performanceImprove anti-dripping performanceGroup 5/15 element organic compoundsSynthesis methodsResidual carbon

The invention discloses a synthesis method of a Schiff base phosphazene double-base structure flame retardant. The synthesis method comprises the following steps: S1, reacting phosphonitrilic chloridetrimer with a compound containing hydroxyl and active carbonyl, a strong alkali and weak acid salt and a solvent to prepare a phosphazene-containing intermediate; S2, reacting the phosphazene-containing intermediate prepared in the step S1 with an alcohol amine compound and a solvent to prepare the Schiff base phosphazene double-base structure flame retardant. A synthesis method of a modified polyurethane flame retardant comprises the step of applying the prepared Schiff base phosphazene double-base structure flame retardant to waterborne polyurethane to prepare a waterborne polyurethane flame retardant containing the hydroxyl-terminated Schiff base phosphazene double-base structure. The Schiff base phosphazene double-base structure flame retardant can effectively improve the flame retardancy and molten drop resistance of a base material; a Schiff base structure contained in the structure of the modified polyurethane flame retardant has certain stability, crosslinking of melt and formation of residual carbon can be promoted, the molten drop resistance of a prepared flame-retardant material is improved, two elements including nitrogen and phosphorus in a phosphazene ring can achieve synergistic flame retardance, and a good flame-retardant effect is achieved.

Owner:青岛玉城科技有限公司

Non-halogen fire-retardant polyester, preparation method and application thereof

InactiveCN101921463AImprove anti-dripping performanceImprove flame retardant performanceMonocomponent polyesters artificial filamentFiberPolyester

The invention provides non-halogen fire-retardant polyester, a production method and application thereof. In the method, the polyester, hypophosphite, silicon-containing compound and other auxiliaries are melted and blended to prepare the non-halogen fire-retardant polyester with excellent fire redundancy and dripping resistance, which can be applied in the fields of fiber, films, resin and the like. The polyester is evaluated by UL 94 standard and achieves the V-0 standard of UL 94. The fire redundant used in the method does not contain halogen.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

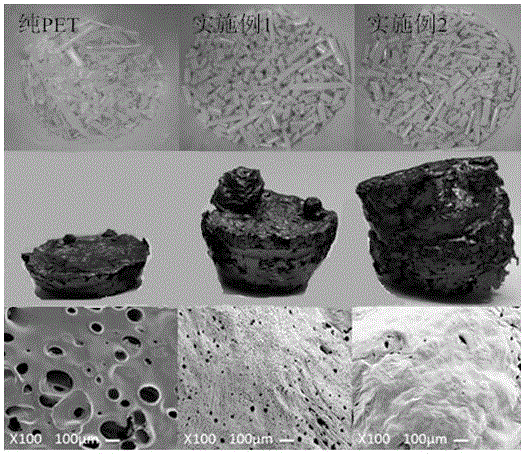

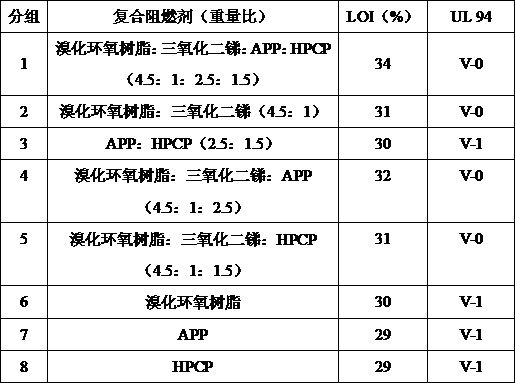

P-Br synergistic high-expansion and flame-retardation PET material and preparation method thereof

InactiveCN106554605AImprove flame retardant performanceImprove anti-dripping performanceHalogenPorous carbon

The invention discloses a P-Br synergistic high-expansion and flame-retardation PET material and a preparation method thereof, and belongs to the technical field of flame retardation. The flame-retardation composite material comprises, by weight, 80-90% of PET, 5-10% of aluminum diethylphosphinate and 5-10% of polypentabromobenzyl acrylate. The flame-retardation PET material prepared in the invention has excellent flame retardation performance and excellent droplet resistance; the flame-retardation PET material is sintered to form a porous carbon layer, and highly expands; and the use amount of halogens is greatly reduced, so negative influences of the halogens on environment are reduced.

Owner:CHANGZHOU UNIV

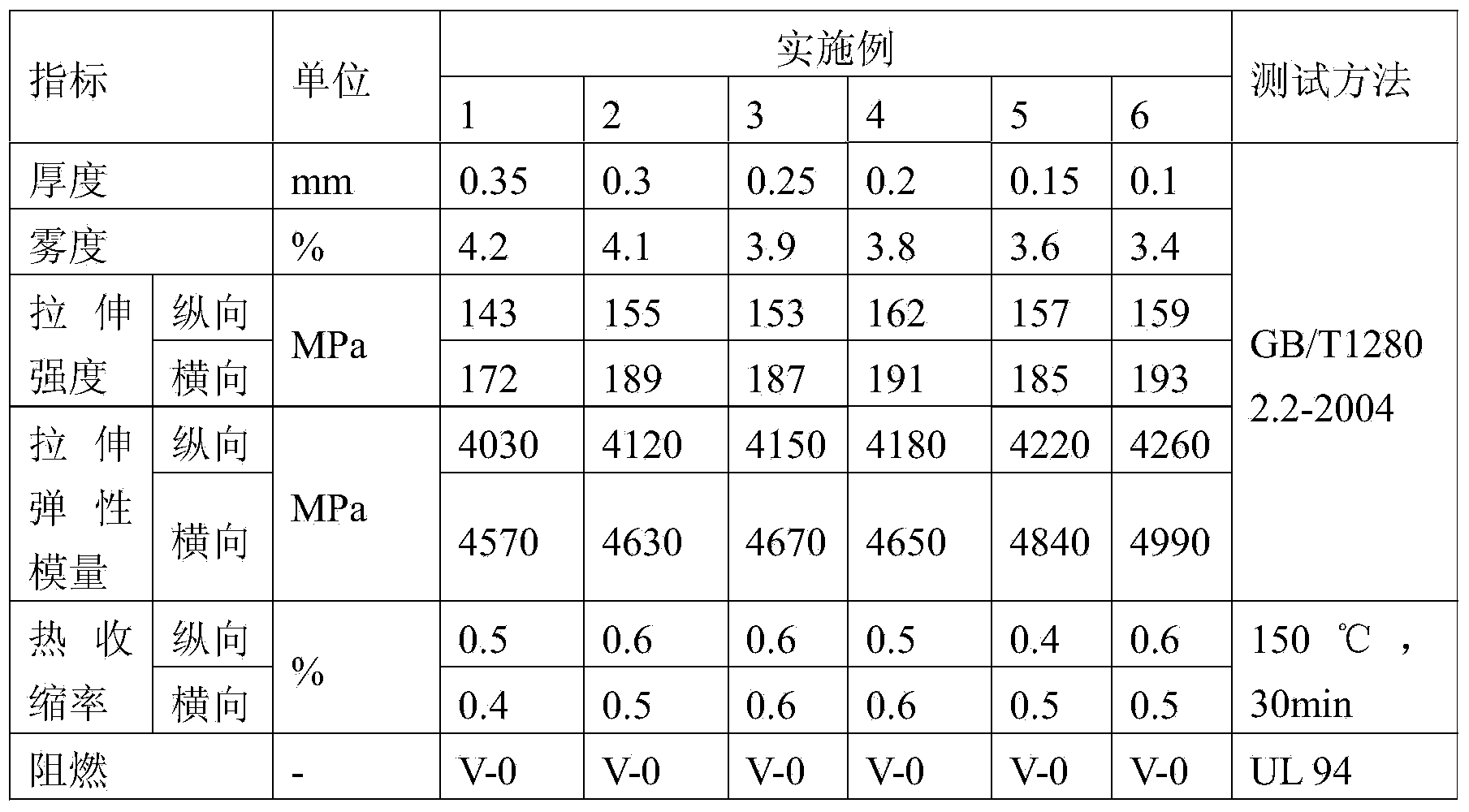

Halogen free flame-retardant polyester film and preparation method thereof

The invention relates to a halogen free flame-retardant polyester film, which comprises the following components in parts by mass: 100 parts of phosphorus-containing polyester slices, 0.1-1 part of inorganic nano particles, 0.5-1.5 parts of a crystallization nucleating agent and 0-5 parts of an antistat. The components are mixed, conveyed to an extruder for fusing and extrusion, bidirectionally stretched, loosened, shaped, subjected to corona treatment and finally rolled. According to the halogen free flame-retardant polyester film, the molecular structure is regular, and the polyester film has high crystallinity, a high fusing point, excellent flame-retardant performance and good comprehensive performance.

Owner:JIANGSU YUXING FILM TECH

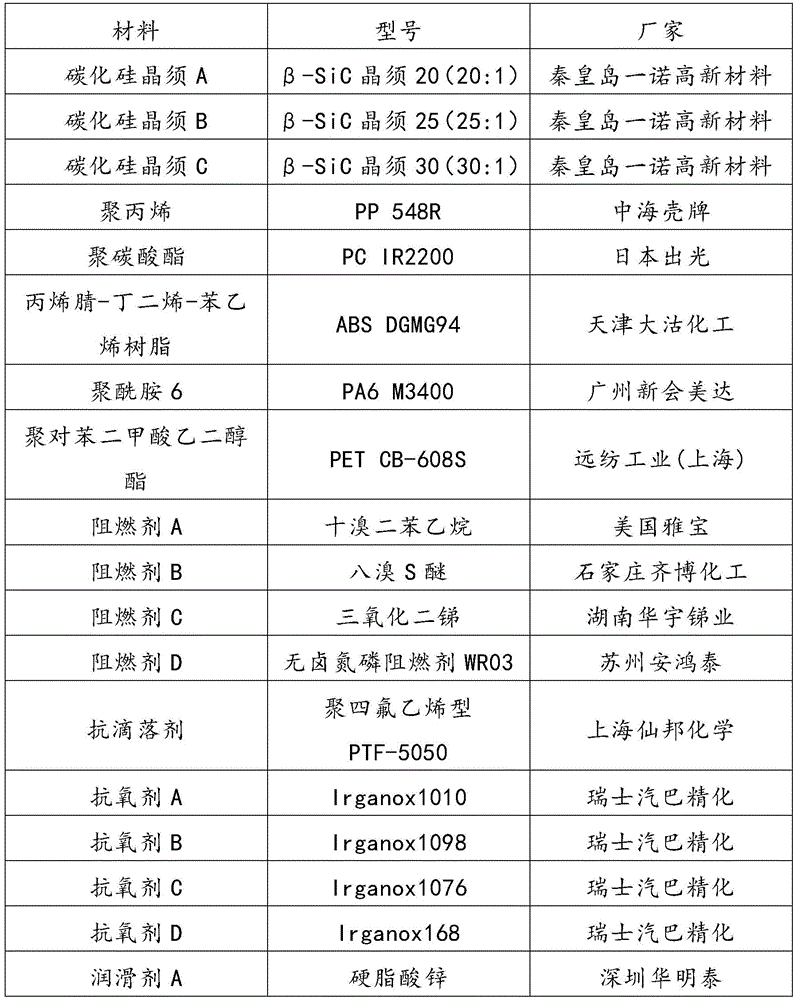

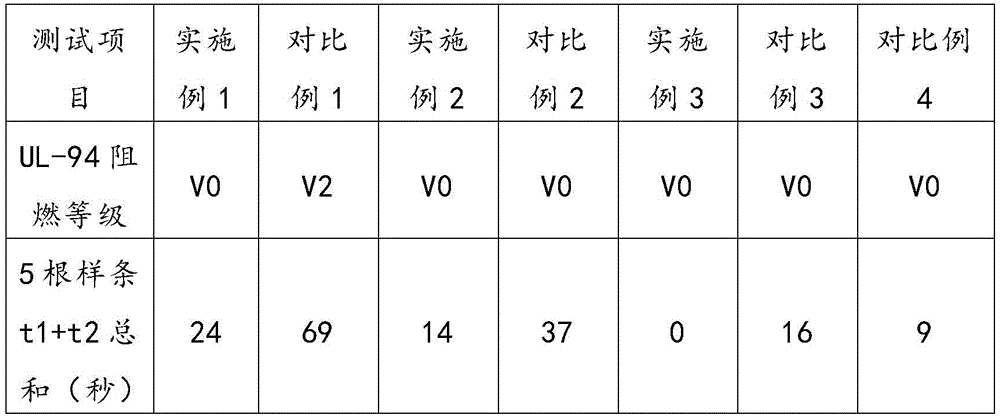

Application of silicon carbide whisker as flame-retardant anti-dripping agent of resin composition and resin composition containing silicon carbide whisker

The invention provides an application of a silicon carbide whisker as a flame-retardant anti-dripping agent of a composition and the resin composition containing the silicon carbide whisker. The diameter D of the silicon carbide whisker is smaller than 1.5mu m and the length-diameter ratio L / D of the silicon carbide whisker is (20 to 1)-(30 to 1). The silicon carbide whisker can be added to flame retardant materials as an anti-dripping agent instead of traditional polytetrafluoroethylene anti-dripping agents and has better effects than the polytetrafluoroethylene anti-dripping agents under the condition of the same content.

Owner:SHANGHAI KINGFA SCI & TECH

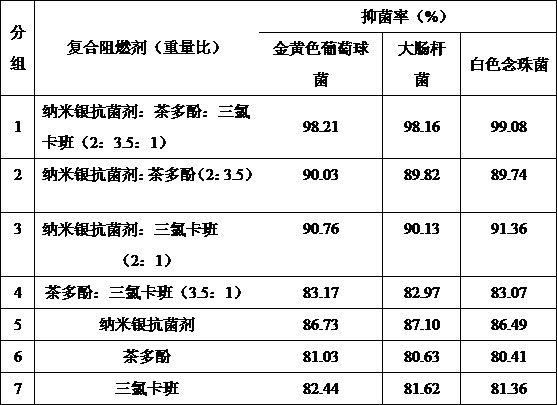

PLA-based degradable antibacterial flame-retardant wig fiber and preparation method thereof

PendingCN112030259AImprove universalityRelease stabilityFlame-proof filament manufactureMonocomponent polyesters artificial filamentEpoxyFiber

The invention provides a PLA-based degradable antibacterial flame-retardant wig fiber, and relates to the technical field of fibers for simulated wigs. The wig fiber is prepared from the following components in percentage by weight of 80-95 percent of PLA, 2-10 percent of composite flame retardant, 1.5-5 percent of a composite antibacterial agent, 0.4-0.8 percent of toner and pigment, 0.5-1.7 percent of an additive, 0.4-1.8 percent of a dispersing agent and 0.2-0.7 percent of a plasticizer. The composite flame retardant comprises brominated epoxy resin, antimonous oxide, polyphosphoric acid ammonia and hexaphenoxy cyclophosphazene, and the composite flame retardant can ensure that the wig fiber still has the excellent flame retardant property while reducing the addition amount of the brominated epoxy resin, so that the anti-dripping effect of the wig fiber is enhanced. The composite antibacterial agent comprises a nano-silver antibacterial agent, tea polyphenol and triclocarban, and the antibacterial rates of the wig fiber to staphylococcus aureus, escherichia coli and candida albicans can reach 98% or above through reasonable proportioning and common compounding, so that the wig fiber has excellent antibacterial performance; and the wig fiber has the advantages of being environmentally friendly, degradable, antibacterial, flame-retardant, anti-dripping and the like.

Owner:XUCHANG HONGYANG BIOCHEM IND DEV

Organic silicon toughening agent with anti-drip effects and synthetic method of toughening agent

InactiveCN109438633AImprove impact resistanceImprove waterproof performanceStrength of materialsToughening

The invention relates to the technical field of high-molecular additives, in particular to an organic silicon toughening agent with anti-drip effects and a synthetic method of the toughening agent. The synthetic method includes the steps: synthesizing organic polysiloxane nuclear emulsion; synthesizing the organic silicon toughening agent with the anti-drip effects. According to the synthetic method, organic silicon and PTFE (polytetrafluoroethylene) are polymerized and then sequentially wrapped with a soft monomer and a hard monomer, and the prepared organic silicon toughening agent improvesimpact strength of materials, has excellent drip resistance and is simple in process and low in cost.

Owner:铨盛聚碳科技股份有限公司

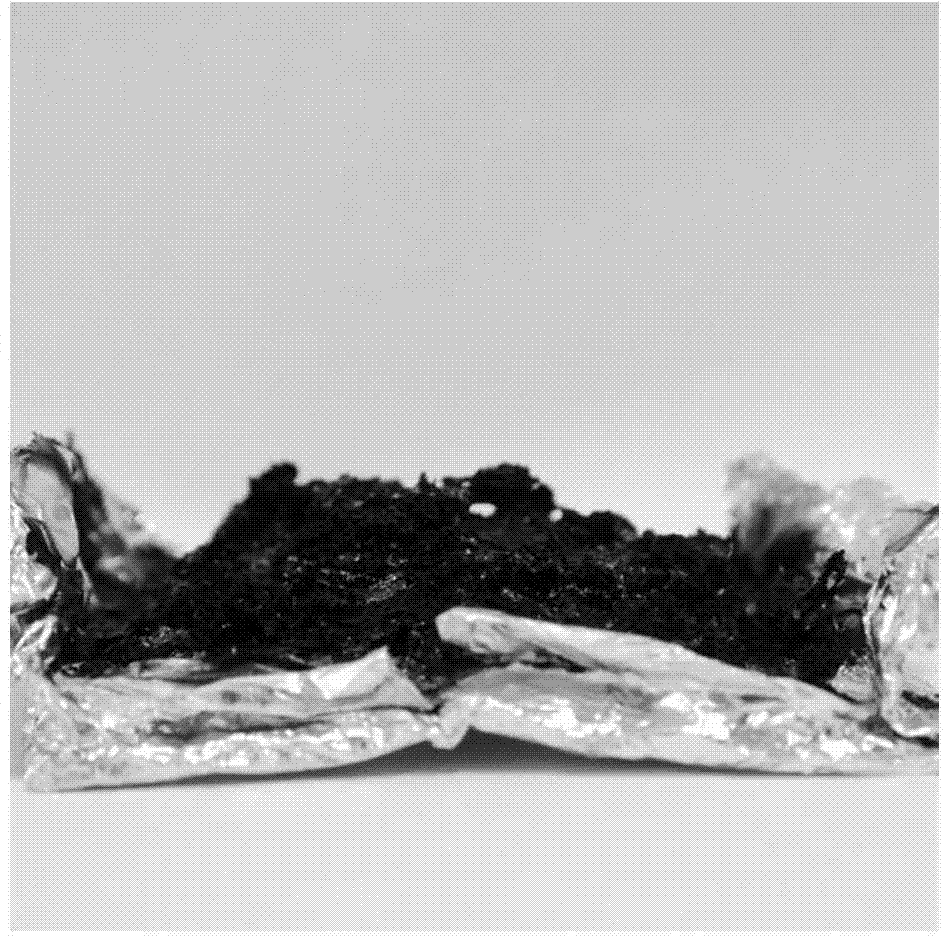

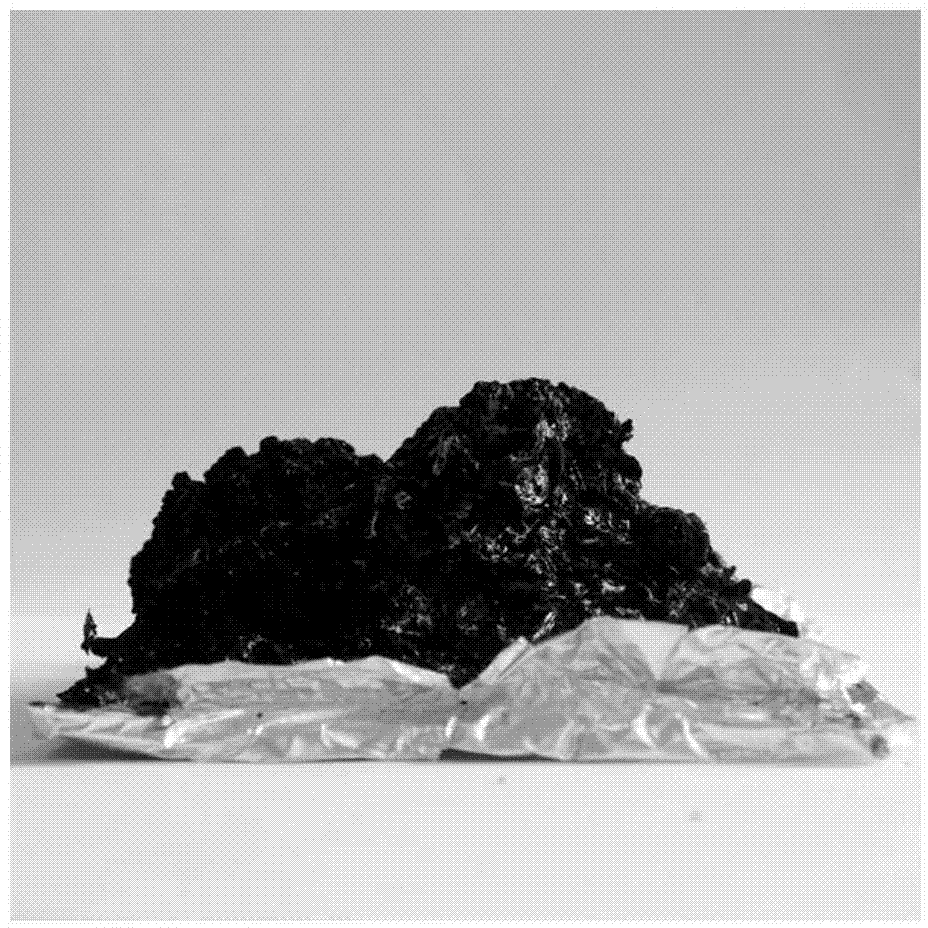

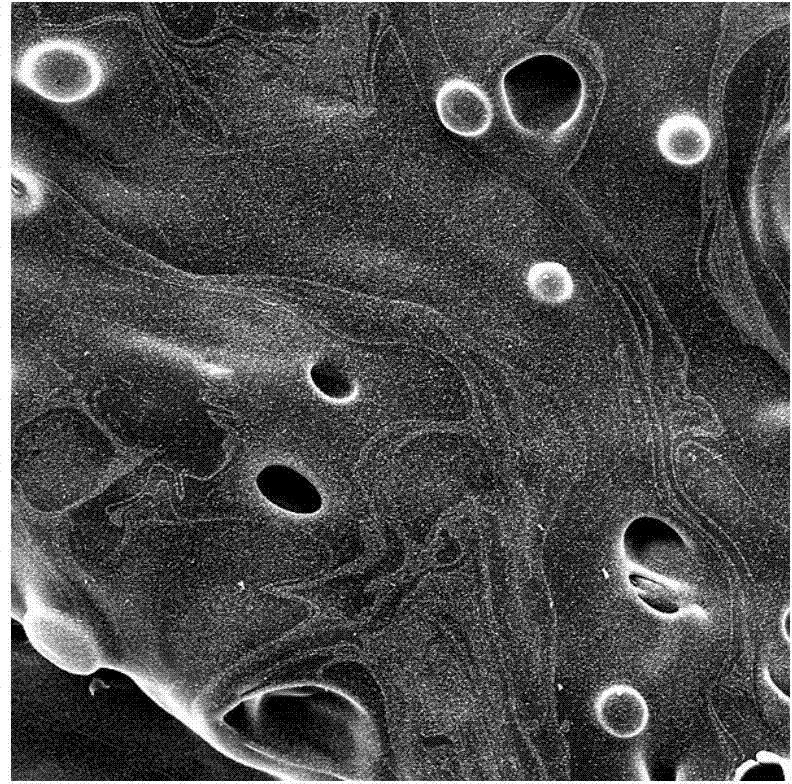

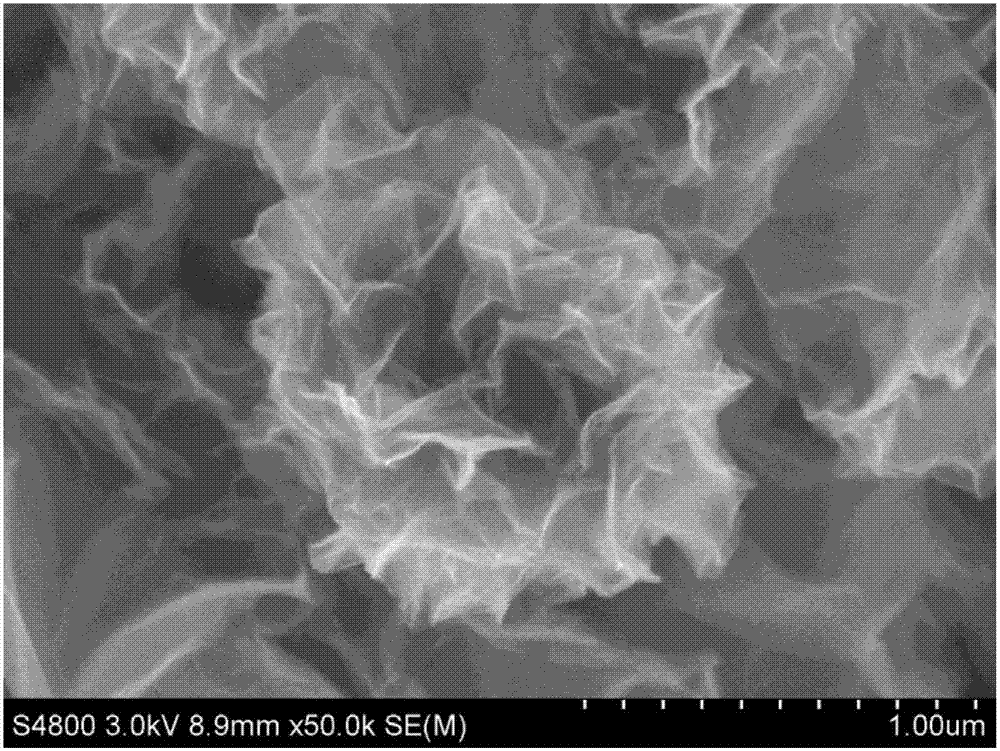

High-strength melt dripping resistant graphene/PET composite plate and production method thereof

The invention discloses a high-strength melt dripping resistant graphene / PET composite plate and a production method thereof. The graphene / PET composite plate is produced through melt-extrusion of a graphene / PET composite nano-material, and the graphene / PET composite nano-material is obtained through adding plicated spherical grpahene oxide and a catalyst into a PET precursor and carrying out in situ polycondensation. The method avoids stacking of the graphene oxide in the esterifying stage, greatly saves the cost, and increases the production efficiency. Obtained graphene is well dispersed in a polymer matrix, and a small amount of the graphene is added to significantly improve the melt dripping resistance, the yield strength and high-temperature yield strength of the composite plate. The production method is simple and effective, and the obtained composite plate has superior performances, and can be applied to the fields of building materials, refractory materials and heating kitchen tools.

Owner:HANGZHOU GAOXI TECH CO LTD

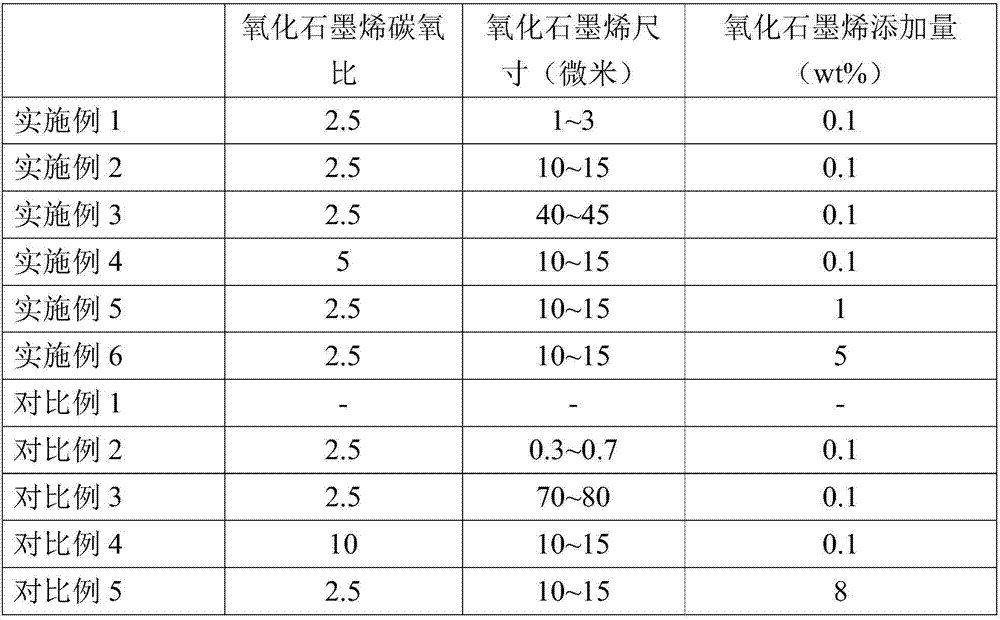

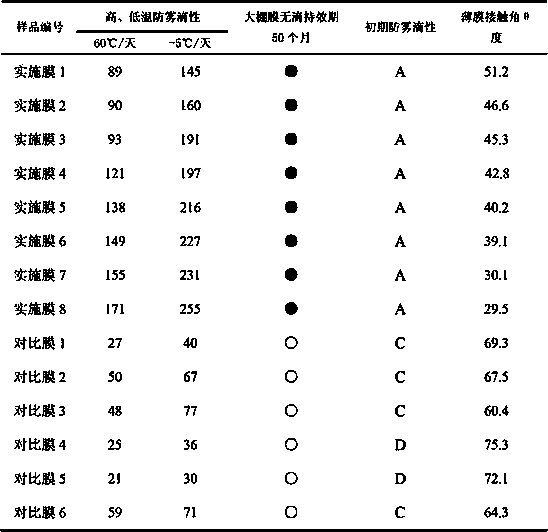

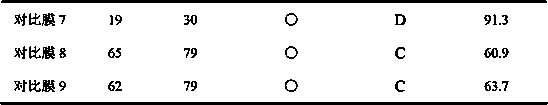

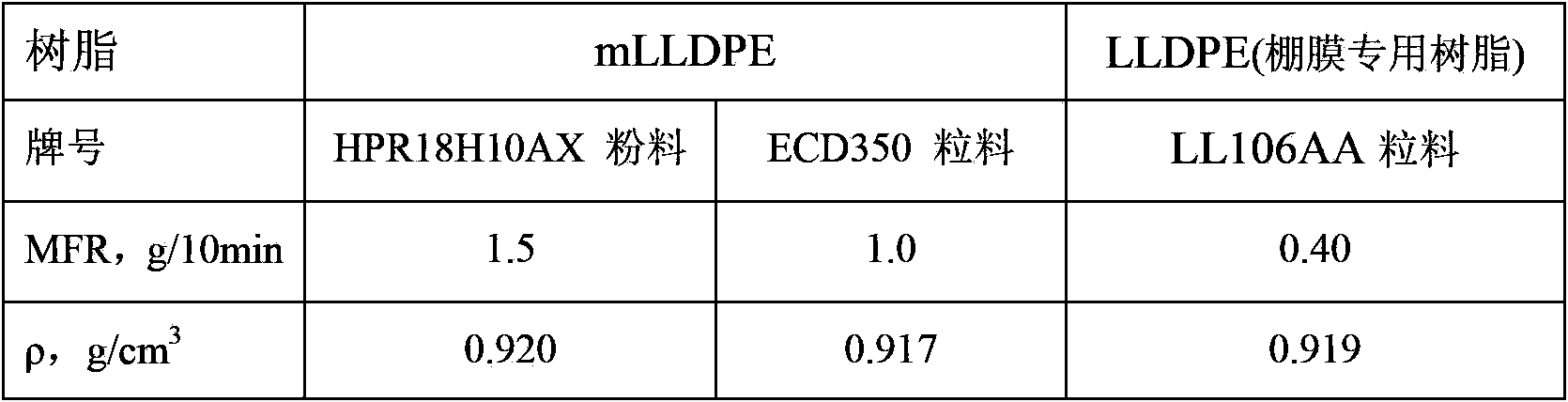

Lasting type anti-fogging polyolefin film master batch

The present invention provides a polyethylene anti-fogging film master batch and a preparation method thereof. The polyethylene anti-fogging film master batch comprises, by weight of mLLDPE, (1) 100% of mLLDPE, (2) 5-15% of a diatomite / anti-fogging agent complex, and (3) 3-7% of an mLLDPE-g-AM graft. According to the present invention, with the diatomite and the mLLDPE-g-AM graft in the master batch, absorption, migration and slow-release channels for the dripping agent are easily formed so as to solve rapid migration and precipitation of the small molecule anti-fogging agent in the polyethylene greenhouse film and significantly increase utilization efficiency of the dripping agent; and the anti-fogging lasting period of the master batch can be prolonged to more than 50 months from about 3-10 months of the general inner addition type blow molding agricultural polyethylene greenhouse film, the anti-fogging performance of the agricultural polyethylene greenhouse film is significantly increased, and good market application prospects are provided.

Owner:PETROCHINA CO LTD

A montmorillonite composite flame retardant material and a preparing method thereof

A montmorillonite composite flame retardant material and a preparing method thereof are disclosed. The montmorillonite composite flame retardant material includes, by weight, 60-80 parts of polypropylene resin, 1-3 parts of modified montmorillonite, 2-5 parts of a phosphorus containing flame retardant, 1-2 parts of a flame retardant synergistic, 1-5 parts of a compatilizer and 0.1-0.5 part of an antioxidant. Through specific component composition, the components are synergistic. The montmorillonite composite flame retardant material does not generate toxic or harmful gas after combustion, is free of harm to human bodies and is free of environment pollution. A preparing process is simple and convenient, the cost is low and the method is suitable for industrial production.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP

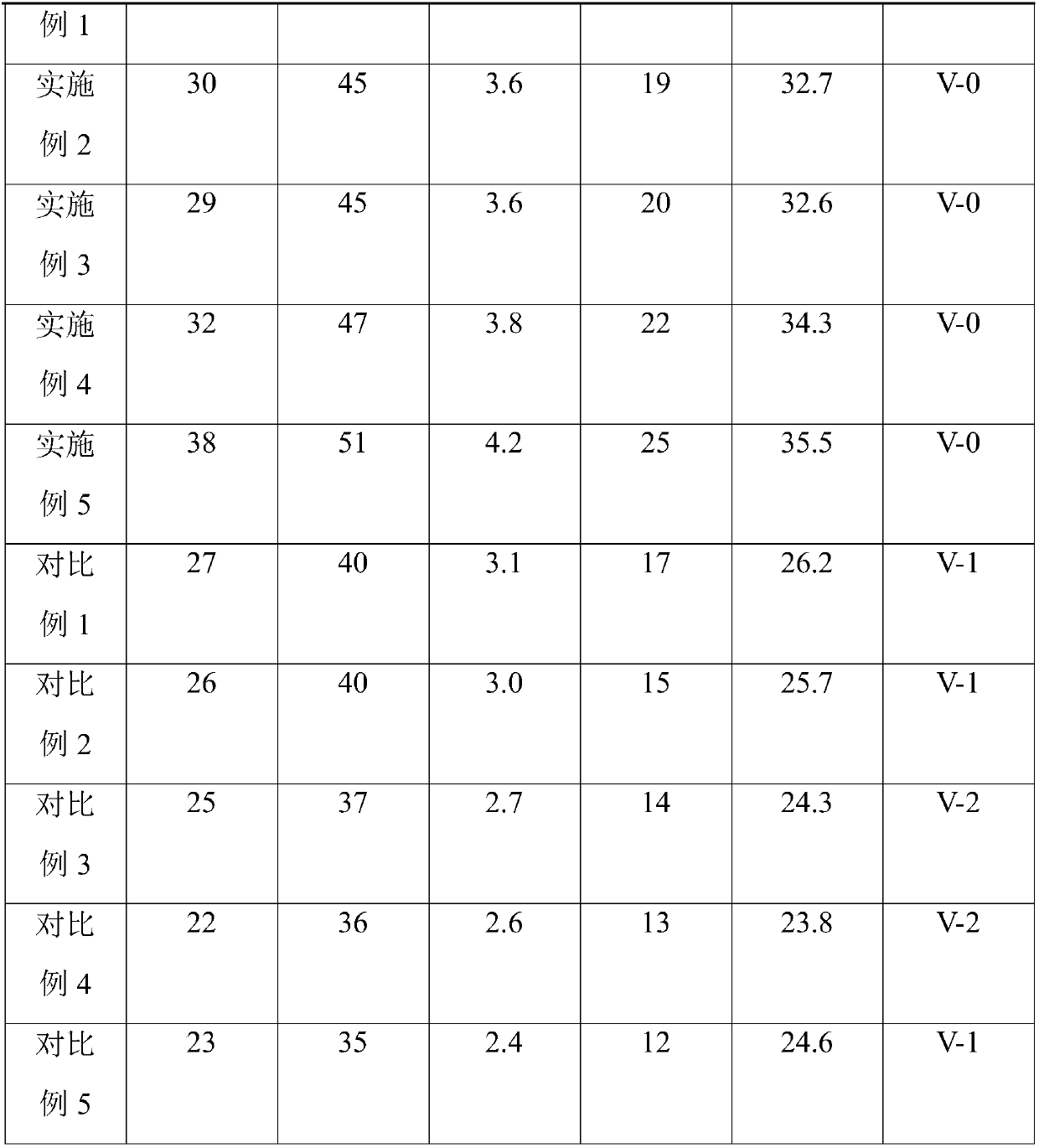

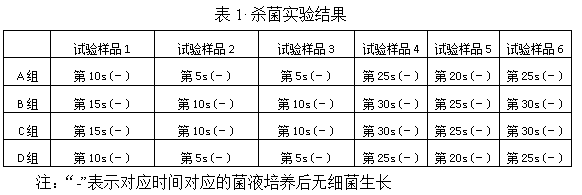

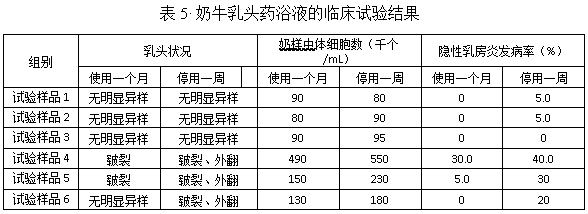

Composite dairy cow nipple dip and preparation method thereof

ActiveCN110420257AGood antibacterial effectDisrupt normal metabolismOrganic active ingredientsPharmaceutical delivery mechanismSide effectPolyethylene glycol

The invention belongs to the technical field of dairy cow mastitis prevention and treating, and particularly discloses composite dairy cow nipple dip and a preparation method thereof. The composite dairy cow nipple dip is prepared from water, a biguanide sterilizing agent, an emollient, a thickener, alcohol, polyglycol, a radix notoginseng extracting solution, a fructus mume extracting solution, aflos caryophylli extracting solution, a velvet antler extracting solution, pigment and a non-ionic surfactant. According to the composite dairy cow nipple dip, the Chinese herbal medicine extractingsolutions are compounded with other components for composite sterilization, the high efficiency and broad spectrum are achieved, the effect is lasting, safety is achieved, no side effect exists, drugresistance is not prone to being generated, the viscosity of the dip is proper, the anti-drop performance is excellent, layers of protective films can be formed on dairy cow nipples, the effect is lasting, disinfection and skin care can be achieved, and the problem that traditional dip is short in moisturizing time, and consequently the dairy cow nipples are subjected to suncrack is solved.

Owner:陕西汉隆清洁消毒产品有限公司

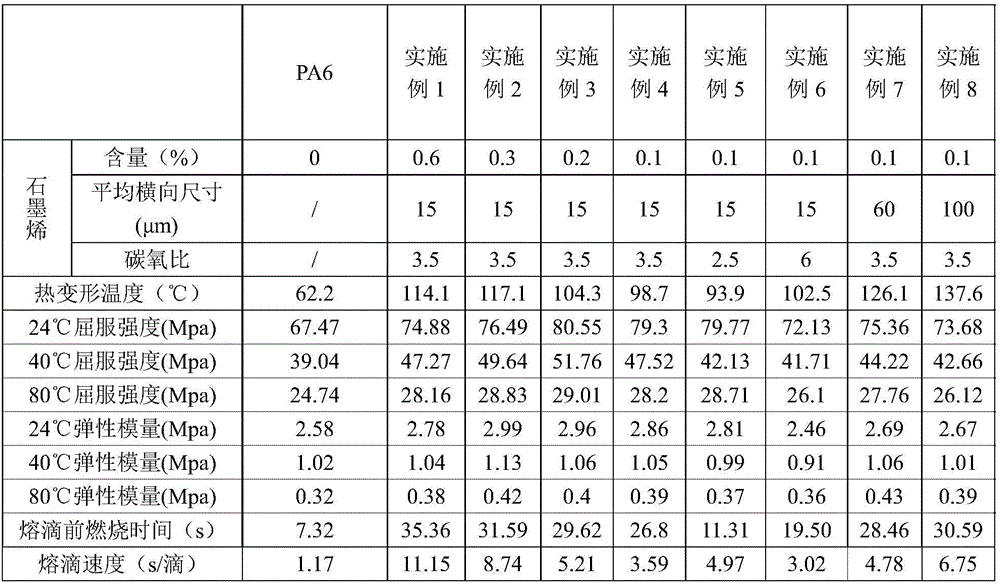

High temperature and molten droplet resistant graphene/ nylon-6 composite board and preparation method thereof

ActiveCN106751781AImprove high temperature performanceHigh heat distortion temperatureHeat deflection temperatureIn situ polymerization

The invention discloses a high temperature and molten droplet resistant graphene / nylon-6 composite board and a preparation method thereof, and belongs to the field of polymer composites. The graphene / nylon-6 composite board is obtained by melt extrusion of a graphene / nylon-6 composite material. The graphene / nylon-6 composite material is obtained by in-situ polymerization of nylon-6, graphene and aids. The composite board prepared by the method has excellent physical and mechanical properties, and the thermal deformation temperature, molten droplet resistance and high-temperature yield strength are significantly improved as compared with an uncompounded pure nylon-6 body board. The graphene / nylon-6 composite board prepared by the method is simple in manufacturing process and low in cost, has good high temperature and molten droplet resistance, and can be used as high temperature resistant engineering pieces, flame-retardant building materials, etc.

Owner:HANGZHOU GAOXI TECH CO LTD

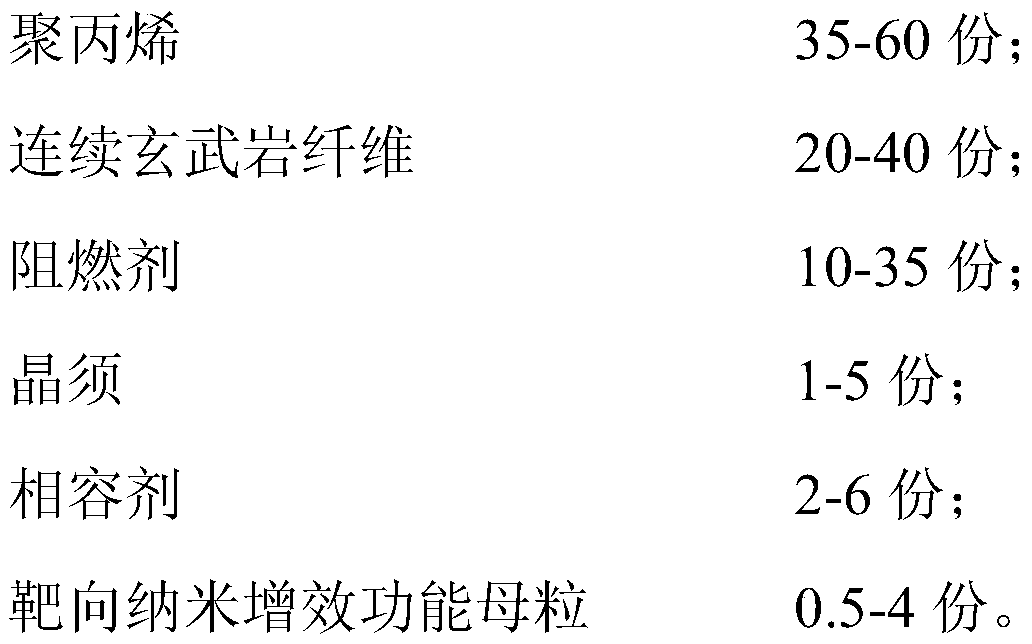

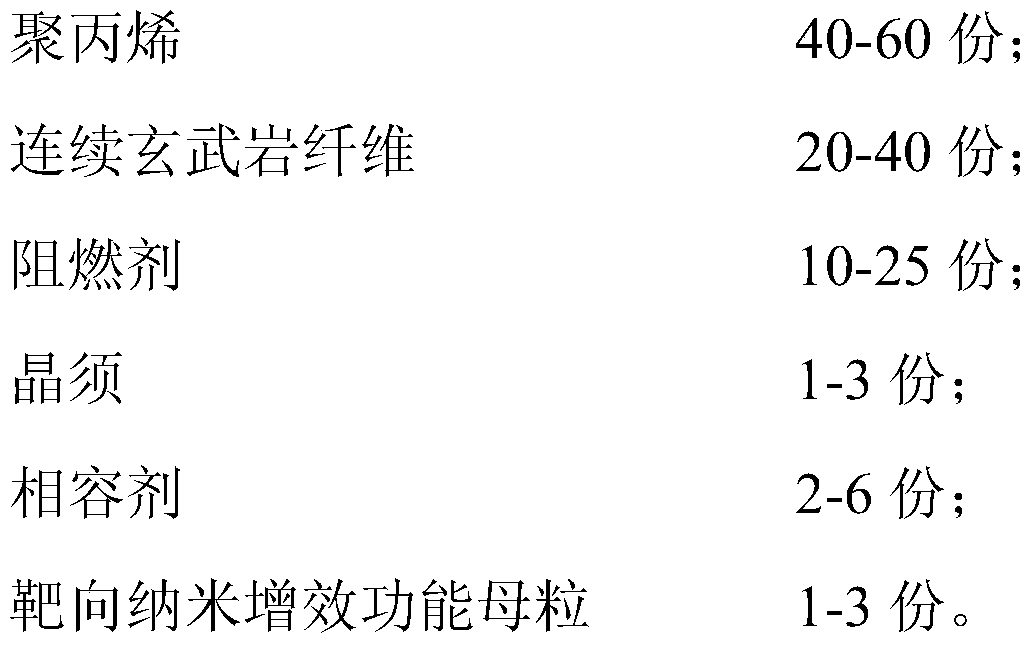

Continuous basalt fiber reinforced polypropylene composite material and preparation method and application thereof

The invention relates to the field of high polymer materials, and discloses a continuous basalt fiber reinforced polypropylene composite material. The continuous basalt fiber reinforced polypropylenecomposite material comprises the following raw materials in parts by weight: 35 to 60 parts of polypropylene, 20 to 40 parts of continuous basalt fibers, 10 to 35 parts of a flame retardant, 1-5 partsof whiskers, 2-6 parts of a compatilizer, and 0.5-4 parts of a targeting nanometer synergistic functional master batch. The preparation method of the material comprises the following steps: uniformlymixing the raw materials, adding the obtained mixture into blending equipment for melt blending, extruding the mixture into an impregnation mold, and drawing the continuous basalt fibers into the impregnation mold for impregnation to obtain the polypropylene composite material. According to the invention, the impregnation effect of the flame retardant and the continuous basalt fibers is improvedby adding the targeting nanometer synergistic functional master batch, and the stability of a carbon layer is improved through combination with the whiskers, so the polypropylene composite material with excellent mechanical properties and flame retardancy is obtained and has wide application prospects in the fields of new energy automobiles and the military industry.

Owner:中广核俊尔(浙江)新材料有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com