Halogen-free flame-retarding polyester master batch specially used for simulative hairs and preparation method thereof

A technology of flame-retardant polyester masterbatch and hair, which is applied in the manufacture of fire-resistant and flame-retardant filaments, single-component polyester artificial filaments, etc., can solve the problems of lack of matte elasticity and flame retardancy of hair, Achieve excellent combability, high flame retardant efficiency and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

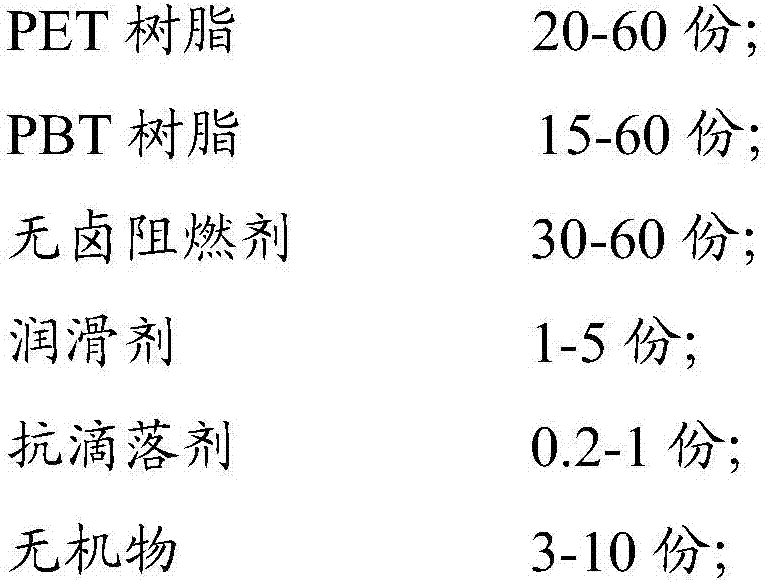

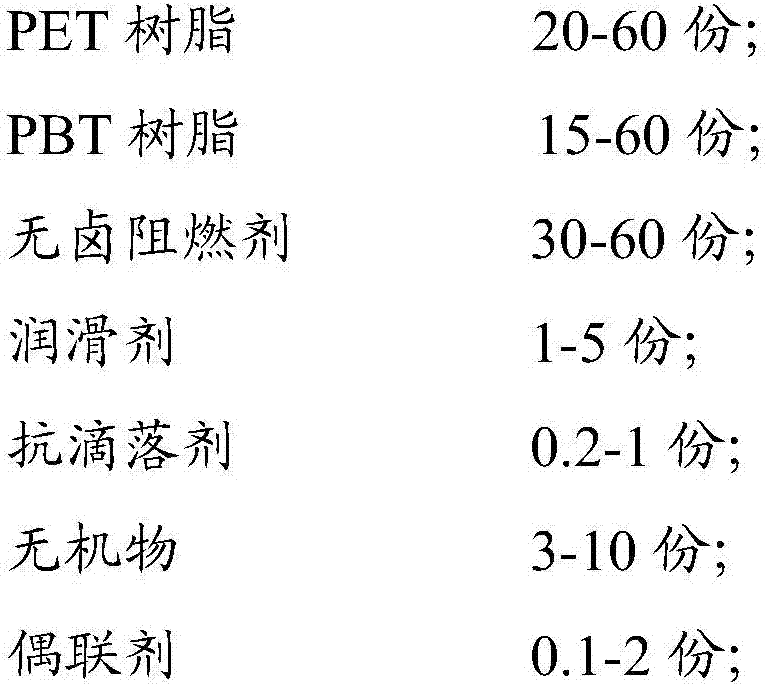

[0028] A kind of halogen-free flame-retardant polyester masterbatch specially used for imitating hair, its components are proportioned by mass percentage as follows:

[0029] PET: 20%, PBT: 17%, Halogen-free flame retardant: 55%, Lubricant: 2%, Anti-dripping agent: 0.5%, Inorganic: 5%, Coupling: 0.5%,

[0030] The PET is polyethylene terephthalate, PBT is polybutylene terephthalate, the halogen-free flame retardant is polyphenylsulfone diphenyl phosphonate oligomer, and the lubricant is talc powder, the anti-dripping agent is coated polytetrafluoroethylene, the inorganic substance is silicon dioxide, and the coupling agent is silane coupling agent.

[0031] Preparation:

[0032] (1) Take each component by weight, add the high-speed mixer and mix evenly before discharging;

[0033] (2) Add the mixture obtained in step (1) into a twin-screw extruder, plasticize, mix, extrude and granulate at 220°C to 260°C, then dry and pack to obtain the finished product.

Embodiment 2

[0035] A special halogen-free flame-retardant polyester masterbatch for artificial hair, the proportion of its components by mass percentage is:

[0036] PET: 25%, PBT: 17%, halogen-free flame retardant: 50%, lubricant: 2%, anti-dripping agent: 0.5%, inorganic substance: 5%, coupling agent: 0.5%.

[0037] The PET is polyethylene terephthalate, PBT is polybutylene terephthalate, the halogen-free flame retardant is zinc diethyl hypophosphite, and the lubricant is silicone powder, which is anti-dripping The agent is coated polytetrafluoroethylene, the inorganic substance is barium sulfate, and the coupling agent is silane coupling agent.

[0038] Preparation:

[0039] (1) Take each component by weight, add the high-speed mixer and mix evenly before discharging;

[0040] (2) Add the mixture obtained in step (1) into a twin-screw extruder, plasticize, mix, extrude and granulate at 220°C to 260°C, then dry and pack to obtain the finished product.

Embodiment 3

[0042] A kind of halogen-free flame-retardant polyester masterbatch specially used for imitating hair, its components are proportioned by mass percentage as follows:

[0043] PET 20%, PBT 17%, halogen-free flame retardant 55%, lubricant 2%, anti-dripping agent 0.5%, inorganic matter 5%, coupling agent 0.5%,

[0044] Among them, PET is polyethylene terephthalate with an intrinsic viscosity of 0.8dl / g, PBT is polybutylene terephthalate with an intrinsic viscosity of 1.0dl / g, and the halogen-free flame retardant is Zinc diethyl hypophosphite, melamine cyanurate, talcum powder as lubricant, coated polytetrafluoroethylene as anti-dripping agent, silicon dioxide as inorganic substance, and silane coupling agent as coupling agent.

[0045] Preparation method: (1) Weigh each component according to the weight ratio, add it into a high-speed mixer, mix it evenly, and then discharge;

[0046] (2) Put the mixture in step (1) into a twin-screw extruder, plasticize, mix, extrude and granul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com