Preparation of polylactic acid composite material with flame-retardant function

A composite material and polylactic acid technology, applied in the field of preparation of flame retardant composite materials, can solve the problems of material mechanics, poor processing performance, low oxygen index, high flame retardant addition amount, and achieve good anti-melting performance and improve Mechanical properties, effect of high flame retardant grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

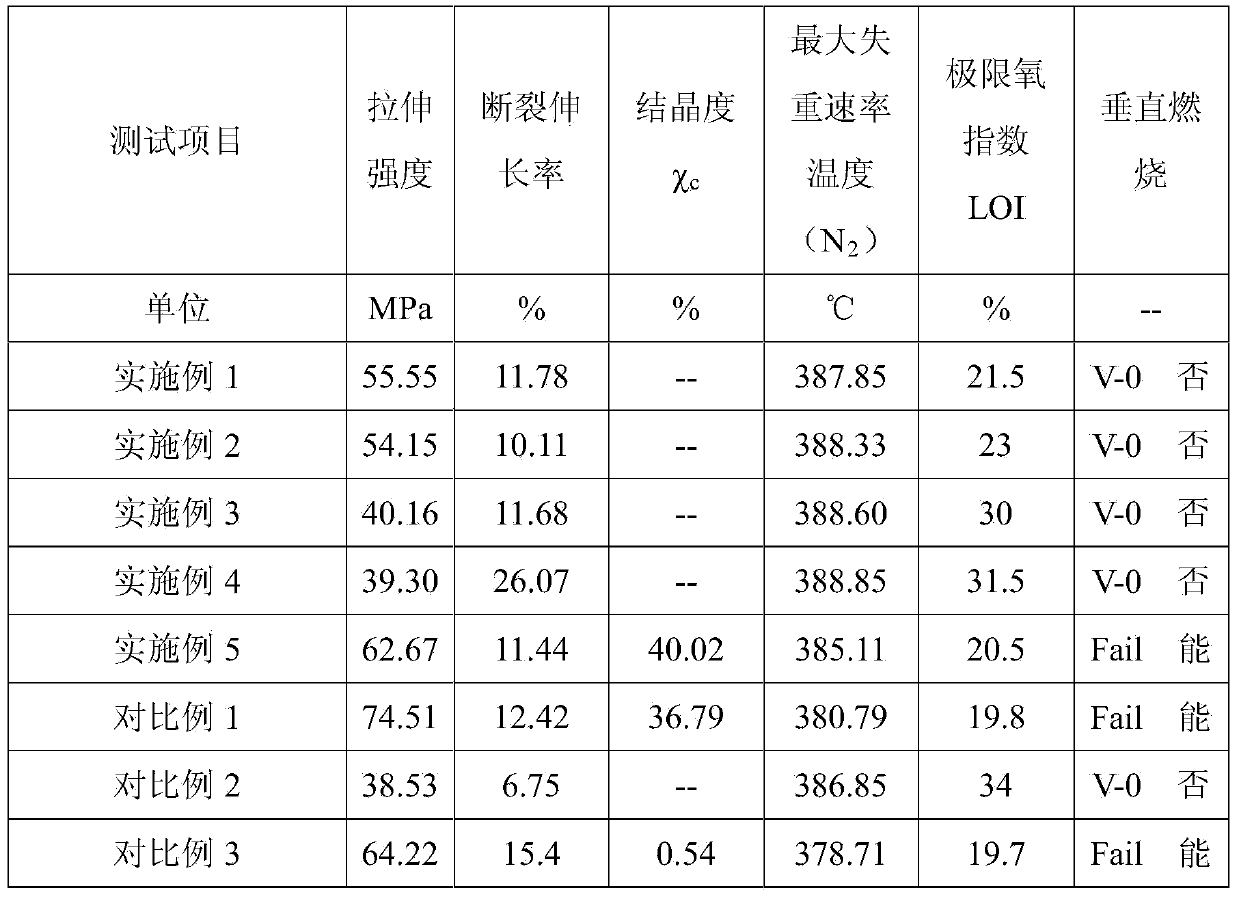

[0028] Take the obtained core / shell structure polymethylsiloxane / polymethyl methacrylate nanoparticles 6g, polyaryl phosphate 6.5g, dry at 70°C for 8 hours; polylactic acid 37.5g, dry at 60°C Dry for 7 hours. Put the three into the torque rheometer after physical blending, the temperature of the three sections are: 168-174°C, 170-175°C, 170-175°C; rotation speed 30rpm; blending 5-8min. Get the target material. The tensile strength and elongation at break are tested according to GBT1040.2-2006, the limiting oxygen index is tested according to GB / T2046.2-2009, and the vertical combustion is tested according to GB / T2408-2008. The mechanical, crystallization, heat resistance, and combustion properties of the new polylactic acid / polyaryl phosphate composite are shown in Table 1

Embodiment 2

[0030] Get the obtained core / shell structure polymethylsiloxane / polymethyl methacrylate nanoparticles 4.5g, polyaryl phosphate 8g, dry at 70°C for 8 hours; polylactic acid 37.5g, at 60°C Dry for 7 hours. Put the three into the torque rheometer after physical blending, the temperature of the three sections are: 168-174°C, 170-175°C, 170-175°C; rotation speed 30rpm; blending 5-8min. Get the target material. The tensile strength and elongation at break are tested according to GBT1040.2-2006, the limiting oxygen index is tested according to GB / T2046.2-2009, and the vertical combustion is tested according to GB / T2408-2008. The mechanical, crystallization, heat resistance, and combustion properties of the new polylactic acid / polyaryl phosphate composite are shown in Table 1

Embodiment 3

[0032] Take the obtained core / shell structure polymethylsiloxane / polymethyl methacrylate nanoparticles 3g, polyaryl phosphate 9.5g, dry at 70°C for 8 hours; polylactic acid 37.5g, dry at 60°C Dry for 7 hours. Put the three into the torque rheometer after physical blending, the temperature of the three sections are: 168-174°C, 170-175°C, 170-175°C; rotation speed 30rpm; blending 5-8min. Get the target material. The tensile strength and elongation at break are tested according to GBT1040.2-2006, the limiting oxygen index is tested according to GB / T2046.2-2009, and the vertical combustion is tested according to GB / T2408-2008. The mechanical, crystallization, heat resistance, and combustion properties of the new polylactic acid / polyaryl phosphate composite are shown in Table 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com