Double-layer fabric and camouflage clothing made thereof

A double-layer fabric and surface layer technology, which is applied in clothing, clothing, textiles, etc., can solve the problems of camouflage fabrics with insufficient flame retardancy and droplet resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

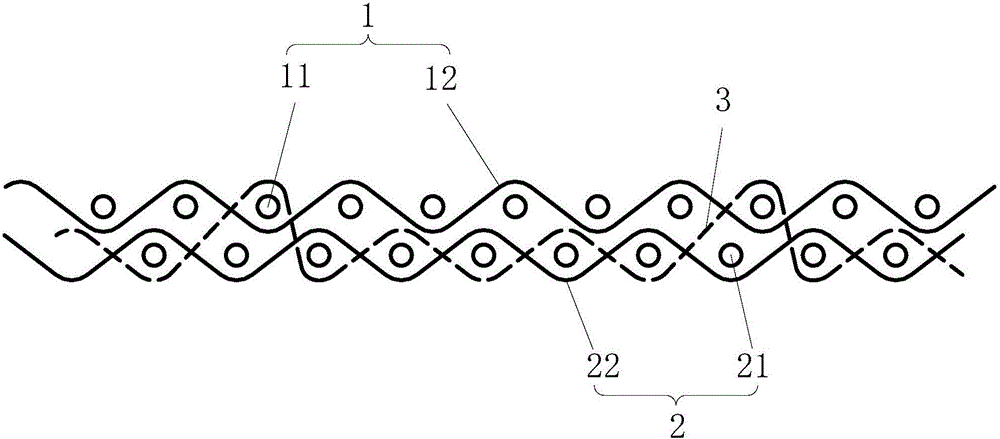

[0022] figure 1 It is a structural diagram of Embodiment 1 of a double-layer fabric. Such as figure 1 As shown, the double-layer fabric provided in this embodiment includes a surface layer fabric 1 , an inner layer fabric 2 , and a binding thread 3 .

[0023] Wherein, the surface layer fabric 1 surface layer warp thread 11 and the surface layer weft thread 12 are interwoven to form, the inner layer fabric 2 is formed by the inner layer warp thread 11 and the inner layer weft thread 12 interweaving, and several binding threads 3 are used to connect the surface layer fabric 1 and the inner layer fabric 2.

[0024] Specifically, the surface layer warp thread 11, the surface layer weft thread 12, and the binding thread 3 are the first flame-resistant fiber yarns that are easy to print, and the first flame-resistant fiber yarn contains 30 (wt)% to 70 (wt)% of Flame-retardant adhesive fiber or 30(wt)%~70(wt)% flame-retardant acrylic fiber, also can be in the first flame-resistant ...

Embodiment 2

[0039] In this embodiment, the parts that are the same as in the first embodiment are given the same reference numerals, and the same text descriptions are omitted.

[0040] Compared with Embodiment 1, the double-layer fabric provided by this embodiment mainly has the following differences:

[0041] Wherein, the binding thread 3 includes a binding warp thread and a binding weft thread.

[0042] Specifically, in the inner layer fabric 2, a binding warp is arranged every interval of at least two inner layer warp threads 21, and a binding weft thread is arranged every interval of at least two inner layer weft threads 22, and the binding warp thread and the surface layer weft thread 12 phases are interwoven, and the binding weft is interwoven with the surface layer warp 11.

[0043]Compared with the first embodiment, the double-layer fabric provided by this embodiment has better bonding strength. The double-layer fabric of this kind of structure can improve the structural intens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com