Lasting type anti-fogging polyolefin film master batch

A polyethylene film and anti-fogging technology, which is applied in the field of polyethylene resin composition, can solve the problems of anti-fogging agent loss, maintenance for about 3 to 10 months, and poor compatibility of anti-fogging agents, so as to improve the utilization efficiency and improve the effect of long-term anti-fog droplet effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

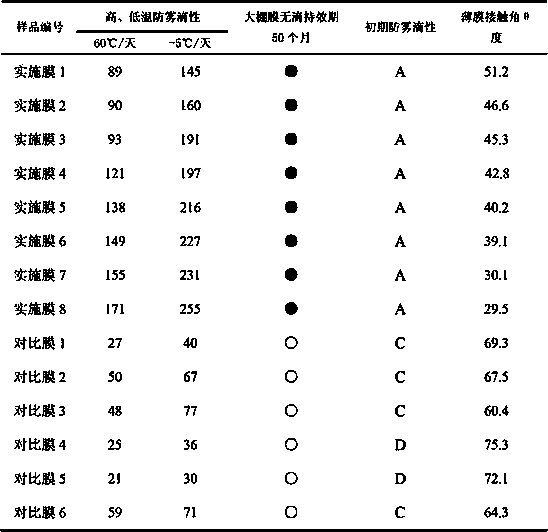

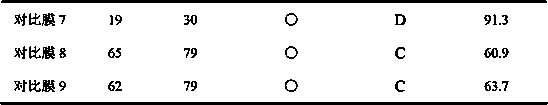

Examples

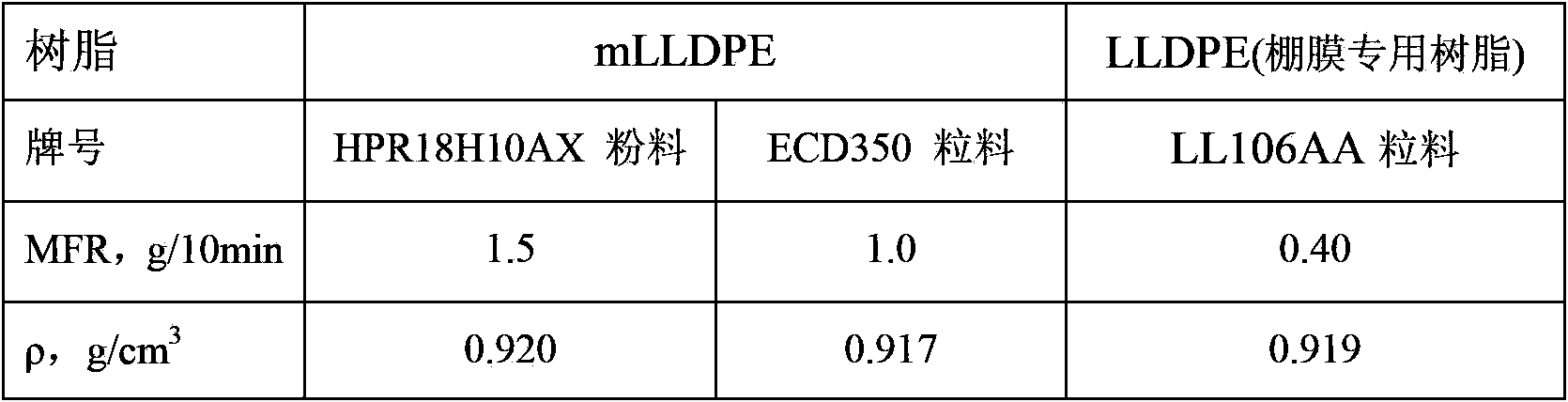

Embodiment 1

[0046] (1) Preparation of mLLDPE-g-AM grafts: Prepare a mixed solution of 7 parts of acrylamide (AM) and 5 parts of xylene, then mix the mixed solution with 100 parts of mLLDPE at high speed for 5 minutes, and mix well Place the material in a closed container for 12 hours; then take 0.03 parts of DTBP and 0.1 part of acetone to prepare a mixed solution, then put the mixed solution and the placed mixture into a 10L high-speed mixer, and mix at a high speed for 5 minutes; finally mix well The material is added to the Φ67 twin-screw extruder, and the reaction temperature (°C) of each section of the screw is: 150, 155, 160, 170, 185, 190, 190, 180, 170; the melt grafting reaction is carried out, and after 7 minutes of reaction , extruded, cooled, and granulated to obtain mLLDPE-g-AM grafts (grafting rate: 1.4%).

[0047] (2) Preparation of diatomite / anti-fogging and dripping agent compound: According to the weight percentage of polyoxyethylene sorbitan monostearate (T-60), 25 part...

Embodiment 2

[0050] (1) Preparation of mLLDPE-g-AM graft: Same as Example 1.

[0051] (2) Preparation of diatomaceous earth / anti-fogging agent compound: Same as Example 1.

[0052] (3) Preparation of mLLDPE anti-fogging film masterbatch: put 100 parts of mLLDPE (HPR18H10AX) and 4 parts of mLLDPE-g-AM grafts with a graft rate of 1.4% into a 10-liter high-speed mixer, and Mix for 3 minutes; then add 7 parts of diatomaceous earth / polyoxyethylene sorbitan monostearate compound, 0.15 parts of antioxidant 1010, 0.15 parts of calcium stearate, and mix at high speed for 5 minutes; add the mixed material To the Φ67 twin-screw extruder, the reaction temperature (°C) of each section of the screw is: 160, 170, 180, 190, 200, 210, 200, 190, 180; after 4 minutes of reaction, extrude, cool, and granulate to obtain mLLDPE anti-fogging film masterbatch.

Embodiment 3

[0054] (1) Preparation of mLLDPE-g-AM graft: Same as Example 1.

[0055] (2) Preparation of diatomaceous earth / anti-fogging agent compound: Same as Example 1.

[0056] (3) Preparation of mLLDPE anti-fogging film masterbatch: put 100 parts of mLLDPE (HPR18H10AX) and 5 parts of mLLDPE-g-AM grafts with a graft rate of 1.4% into a 10-liter high-speed mixer, and Mix for 3 minutes; then add 9.0 parts of diatomaceous earth / polyoxyethylene sorbitan monostearate compound, 0.15 parts of antioxidant 1010, 0.15 parts of calcium stearate, and mix at high speed for 5 minutes; add the mixed material To the Φ67 twin-screw extruder, the reaction temperature (°C) of each section of the screw is: 160, 170, 180, 190, 200, 210, 200, 190, 180; after 4 minutes of reaction, extrude, cool, and granulate to obtain mLLDPE anti-fogging film masterbatch.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com