Organic silicon toughening agent with anti-drip effects and synthetic method of toughening agent

A synthesis method and silicone technology, applied in the field of polymer additives, can solve the problems of easy aging, notch toughness limitation, notch sensitivity, etc., and achieve the effect of improving impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

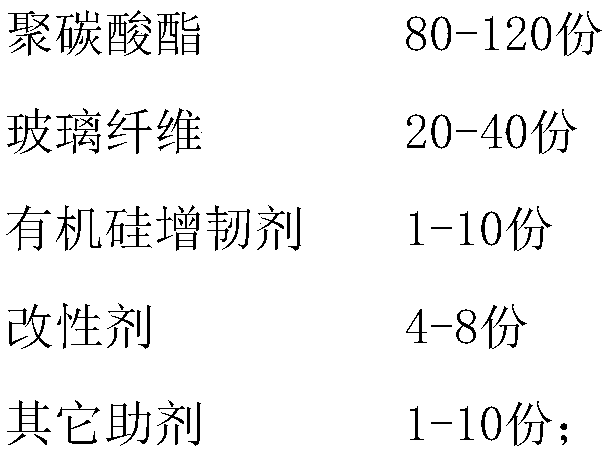

Method used

Image

Examples

Embodiment 1

[0071] A kind of synthetic method of the organosilicon toughening agent with anti-dripping effect, comprises the steps:

[0072] A. Synthesis of organopolysiloxane core emulsion:

[0073] A1. Mix the organosiloxane monomer evenly, and use a homogenizer to shear at a high speed of 8000 rpm for 20 minutes to obtain a mixed solution;

[0074] A2. Add the mixed liquid to the aqueous solution in which the catalyst and emulsifier are dissolved, and react at 85°C for 12 hours to obtain an organopolysiloxane core emulsion; wherein, the total mass of the organosiloxane monomer is 40% of the water mass %, the amount of the catalyst is 1% of the mass of the organosiloxane monomer, and the amount of the emulsifier is 1% of the mass of the organosiloxane monomer;

[0075] B. Synthesis of silicone toughening agent with anti-dripping effect:

[0076] B1. Add organopolysiloxane core emulsion, PTFE emulsion, dispersant and distilled water into the reaction kettle together, and stir at high s...

Embodiment 2

[0107] A kind of synthetic method of the organosilicon toughening agent with anti-dripping effect, comprises the steps:

[0108] A. Synthesis of organopolysiloxane core emulsion:

[0109] A1. Mix the organosiloxane monomer evenly, and use a homogenizer to shear at a high speed of 9000 rpm for 15 minutes to obtain a mixed solution;

[0110] A2. Add the mixed solution to the aqueous solution dissolved with catalyst and emulsifier, and react at 88°C for 10 hours to obtain an organopolysiloxane core emulsion; wherein, the total mass of the organosiloxane monomer is 45% of the water mass %, the consumption of the catalyst is 2% of the mass of the organosiloxane monomer, and the consumption of the emulsifier is 5% of the mass of the organosiloxane monomer;

[0111] B. Synthesis of silicone toughening agent with anti-dripping effect:

[0112] B1. Add the organopolysiloxane core emulsion, PTFE emulsion, dispersant and distilled water into the reaction kettle together, and stir at a ...

Embodiment 3

[0143] A kind of synthetic method of the organosilicon toughening agent with anti-dripping effect, comprises the steps:

[0144] A. Synthesis of organopolysiloxane core emulsion:

[0145] A1. Mix the organosiloxane monomer evenly, and use a homogenizer to shear at a high speed of 10,000 rpm for 12 minutes to obtain a mixed solution;

[0146] A2. Add the mixed solution to the aqueous solution dissolved with catalyst and emulsifier, and react at 92°C for 9 hours to obtain an organopolysiloxane core emulsion; wherein, the total mass of the organosiloxane monomer is 50% of the water mass %, the consumption of the catalyst is 3% of the mass of the organosiloxane monomer, and the consumption of the emulsifier is 10% of the mass of the organosiloxane monomer;

[0147] B. Synthesis of silicone toughening agent with anti-dripping effect:

[0148] B1. Add the organopolysiloxane core emulsion, PTFE emulsion, dispersant and distilled water into the reaction kettle together, and stir at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com