Application of silicon carbide whisker as flame-retardant anti-dripping agent of resin composition and resin composition containing silicon carbide whisker

A technology of resin composition and silicon carbide whiskers, which is applied in the field of flame retardant modification of polymer materials, can solve problems such as secondary combustion and dripping, achieve wider application range, improve anti-dripping effect, and break singleness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

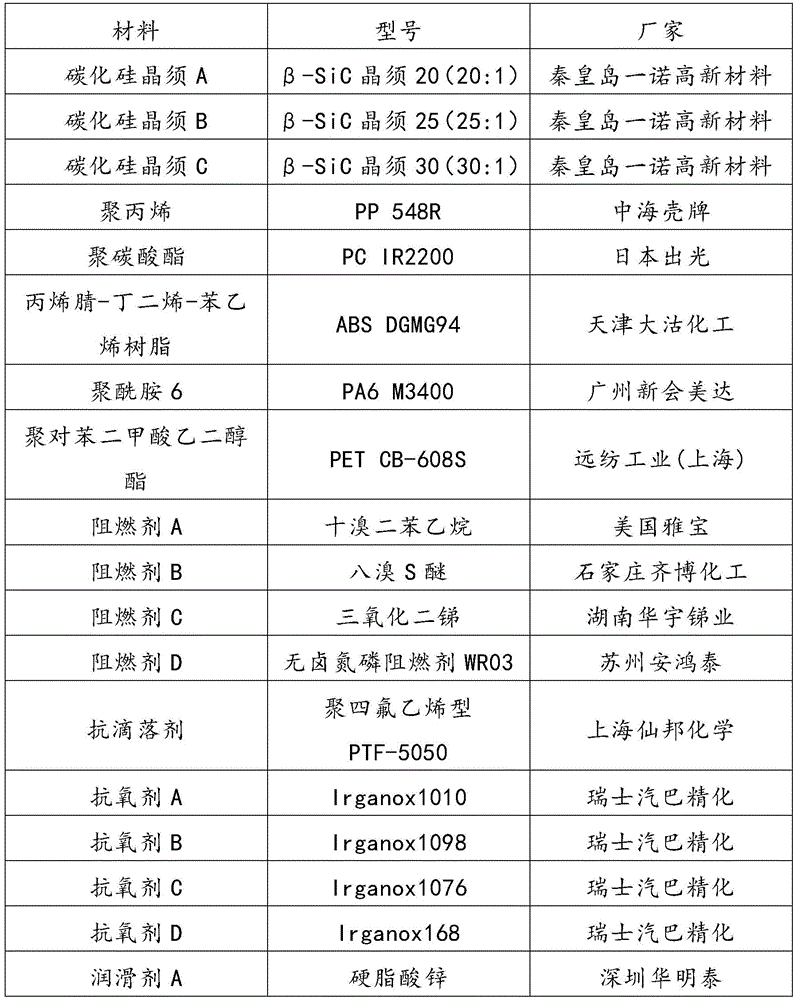

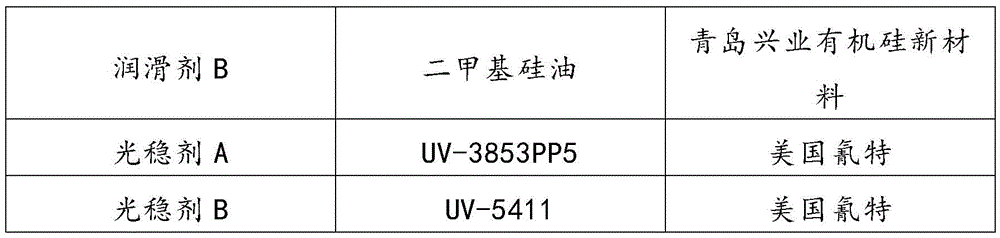

Method used

Image

Examples

Embodiment 1

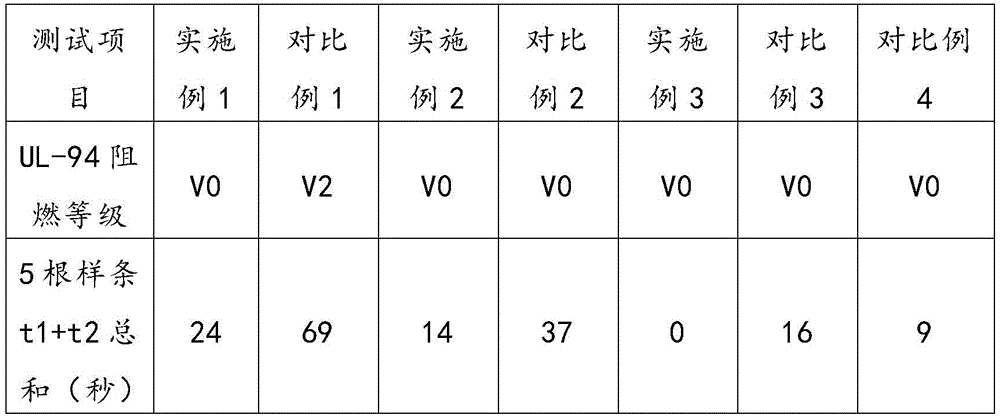

[0032] The parts by weight are 100 parts of polypropylene, 21 parts of flame retardant A, 7 parts of flame retardant C, 0.32 parts of silicon carbide whiskers A, 0.12 parts of antioxidant A, 0.1 part of antioxidant D, 0.12 parts of Add lubricant A, 0.07 parts of light stabilizer A, and 0.05 part of light stabilizer B into a high-speed mixer for uniform mixing. Wherein, the temperature of the high-speed mixer is 63° C., and the speed of the high-speed mixer is 130 rpm. Then put the mixed material into a twin-screw extruder for extrusion, cooling, granulation, and packaging. The temperature of the extruder is 180°C, 195°C, 195°C, 190°C, 190°C, 190°C, 185°C, 185°C from the feeding section to the machine head, the screw speed is 180 rpm, and the screw length-to-diameter ratio for 36. Its flame retardant properties are shown in Table-1.

Embodiment 2

[0036] The parts by weight are 100 parts of polypropylene, 23 parts of flame retardant B, 7 parts of flame retardant C, 0.65 parts of silicon carbide whiskers B, 0.2 parts of antioxidant A, 0.25 parts of antioxidant D, 0.28 parts of Add lubricant A, 0.15 parts of light stabilizer A, and 0.13 parts of light stabilizer B into a high-speed mixer for uniform mixing. Wherein, the temperature of the high-speed mixer is 63° C., and the speed of the high-speed mixer is 130 rpm. Then put the mixed material into a twin-screw extruder for extrusion, cooling, granulation, and packaging. The temperature of the extruder is 180°C, 195°C, 195°C, 190°C, 190°C, 190°C, 185°C, 185°C from the feeding section to the machine head, the screw speed is 180 rpm, and the screw length-to-diameter ratio for 36. Its flame retardant properties are shown in Table-1.

Embodiment 3

[0040] 100 parts by weight of polypropylene, 30 parts of flame retardant D, 0.93 parts of silicon carbide whiskers C, 0.15 parts of antioxidant A, 0.25 parts of antioxidant D, 0.2 parts of lubricant A, 0.1 part of light stabilizer Add agent A and 0.1 part of light stabilizer B into a high-speed mixer and mix evenly. Wherein, the temperature of the high-speed mixer is 60° C., and the speed of the high-speed mixer is 120 rpm. Then put the mixed material into a twin-screw extruder for extrusion, cooling, granulation, and packaging. The temperature of the extruder is 180°C, 195°C, 195°C, 190°C, 190°C, 190°C, 185°C, 185°C from the feeding section to the machine head, the screw speed is 180 rpm, and the screw length-to-diameter ratio for 40. Its flame retardant properties are shown in Table-1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com