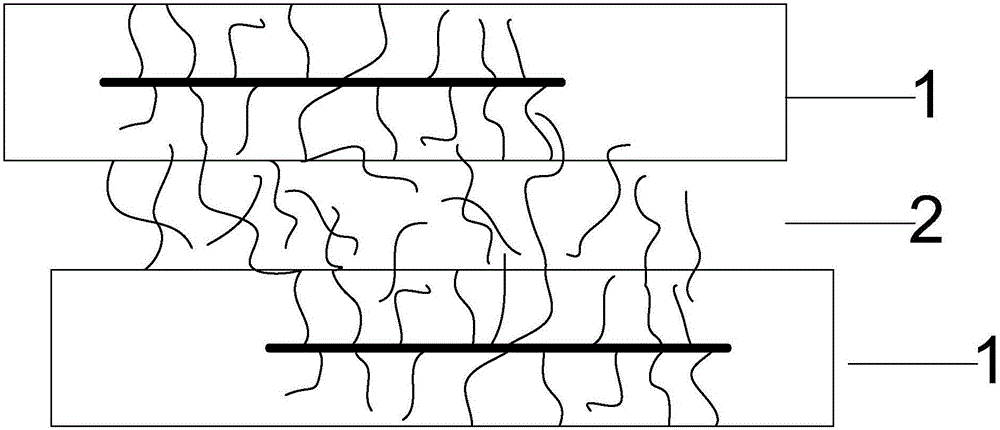

High temperature and molten droplet resistant graphene/ nylon-6 composite board and preparation method thereof

A composite sheet and graphene technology, applied in the field of polymer composite materials, can solve the problems of nylon resin degradation and oxidation, high energy consumption, large dosage, etc., to improve high-temperature performance, reduce dripping speed, and add less Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

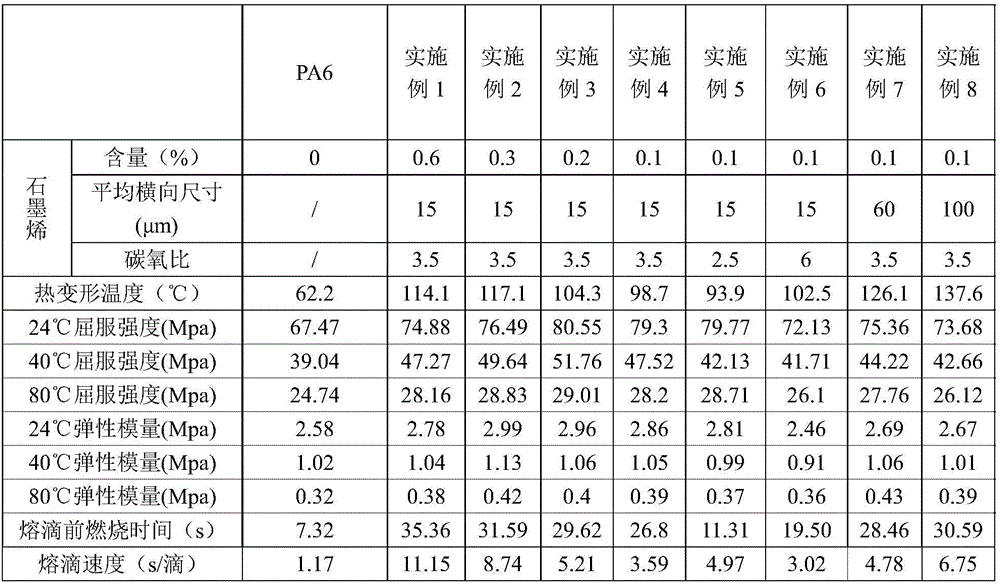

Embodiment 1

[0023] 100 parts by mass of caprolactam salt are heated and melted, and 0.6 parts by mass of graphene are added while stirring. The lateral size of the graphene used is 15 microns, the carbon-to-oxygen ratio is 3.5, and the oxygen-containing functional groups are mainly composed of carboxyl groups and hydroxyl groups. After mixing evenly, add it to the reactor, and react for 2-3 hours under the protection of nitrogen atmosphere at a temperature of 250°C and a pressure of 0.6-0.9MPa. Then react in vacuum for 4h. The resulting melt is cooled in a water tank and then granulated. Then add 0.2 parts by mass of additives containing antioxidants and antistatic agents to melt and extrude the sheet. The melt temperature during extrusion is 275° C., the screw speed is 60 rpm, and the pulling speed is 2 m / min. The relevant properties of the obtained graphene / nylon 6 composite sheet are shown in Table 1.

Embodiment 2

[0025] 100 parts by mass of caprolactam salt were heated and melted, and 0.3 parts by mass of graphene was added while stirring. The graphene used had a lateral size of 15 microns, a carbon-to-oxygen ratio of 3.5, and oxygen-containing functional groups mainly composed of carboxyl groups and hydroxyl groups. After mixing evenly, add it to the reactor, and react for 2-3 hours under the protection of nitrogen atmosphere at a temperature of 250°C and a pressure of 0.6-0.9MPa. Then react in vacuum for 4h. The resulting melt is cooled in a water tank and then granulated. Then add 0.2 parts by mass of additives containing antioxidants and antistatic agents to melt and extrude the sheet. The melt temperature during extrusion is 275° C., the screw speed is 60 rpm, and the pulling speed is 2 m / min. The relevant properties of the obtained graphene / nylon 6 composite sheet are shown in Table 1.

Embodiment 3

[0027] 100 parts by mass of caprolactam salt are heated and melted, and 0.2 parts by mass of graphene are added while stirring. The graphene used has a transverse dimension of 15 microns, a carbon-to-oxygen ratio of 3.5, and oxygen-containing functional groups mainly composed of carboxyl groups and hydroxyl groups. After mixing evenly, add it to the reactor, and react for 2-3 hours under the protection of nitrogen atmosphere at a temperature of 250°C and a pressure of 0.6-0.9MPa. Then react in vacuum for 4h. The resulting melt is cooled in a water tank and then granulated. Then add 0.2 parts by mass of additives containing antioxidants and antistatic agents to melt and extrude the sheet. The melt temperature during extrusion is 275° C., the screw speed is 60 rpm, and the pulling speed is 2 m / min. The relevant properties of the obtained graphene / nylon 6 composite sheet are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com