Continuous basalt fiber reinforced polypropylene composite material and preparation method and application thereof

A technology of basalt fiber and composite material, which is applied in the field of high-strength, high-flame-retardant continuous basalt fiber-reinforced polypropylene composite material, and can solve the problem of destroying the continuity of polypropylene matrix, failing to form a stable skeleton structure, and reducing mechanical properties, etc. problems, to achieve excellent flame retardant properties and mechanical properties, good mechanical properties and dimensional stability, and reduce the effect of adding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

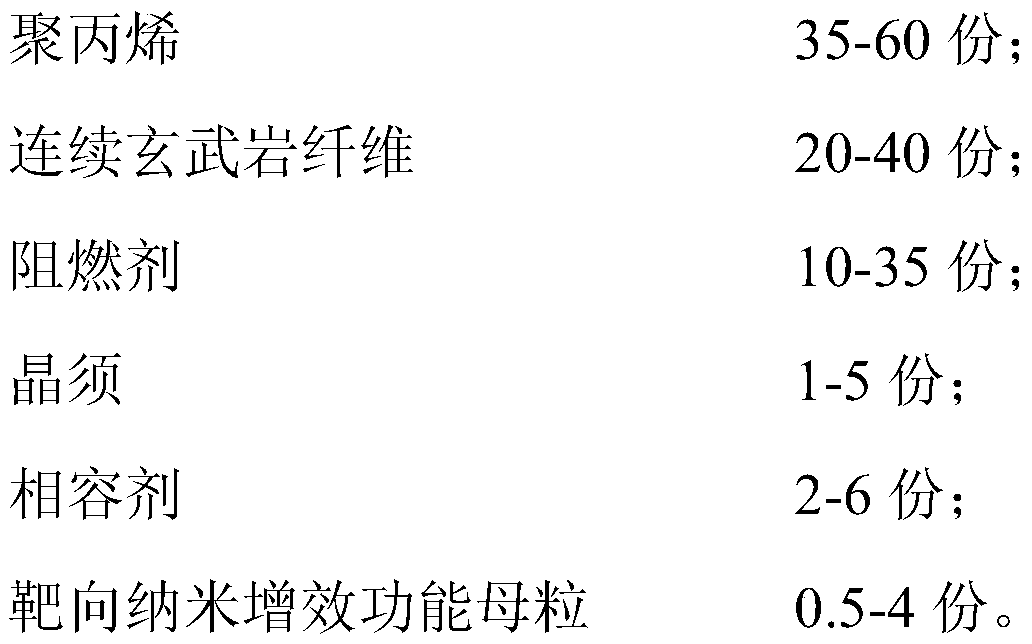

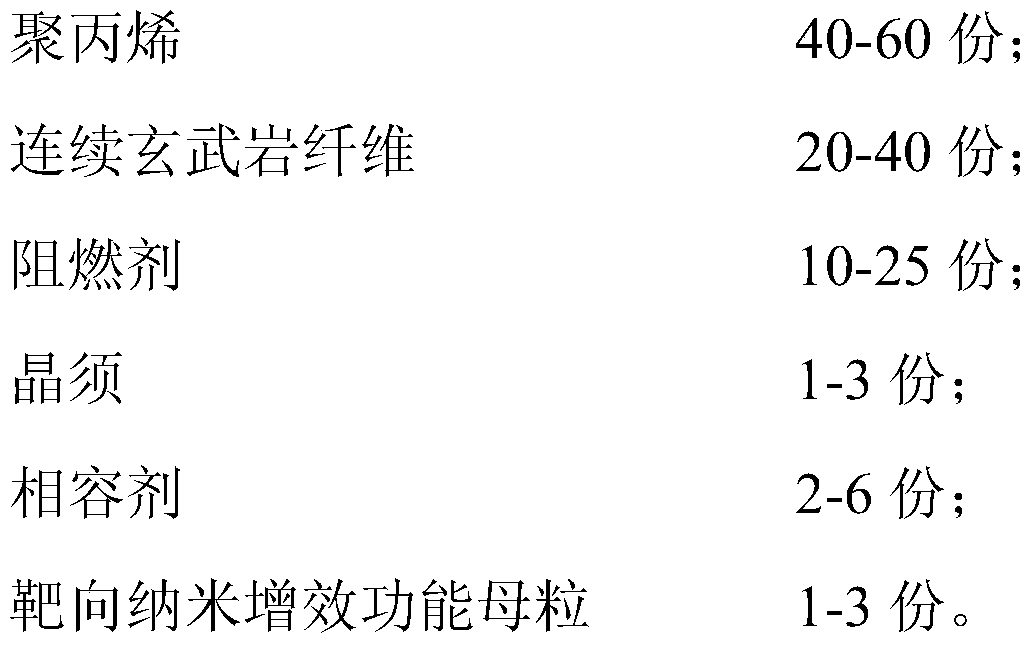

Method used

Image

Examples

Embodiment 2

[0050] Example 2 Compared with Example 3, the addition of flame retardant was reduced in Example 3, while the addition of 2 parts of whiskers was increased, but it did not cause its flame retardant effect to decline. On the other hand, 15 parts of retardant were added In the comparative example 2 of the flame retardant, because no targeted nano-synergy functional masterbatch and whiskers are added, the vertical combustion has no grade, and the flame retardant effect is poor. Reanalyzing the mechanical properties, compared with Example 2, in Example 3, because the addition of flame retardant was reduced and the addition of whiskers was increased, its mechanical properties, especially tensile strength and impact strength, were greatly improved, while Compared with Comparative Example 2 with the same flame retardant added, the mechanical properties of the two are even more different. It can be seen that whiskers and targeted nano-synergistic functional masterbatch have outstanding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com