Method for producing chemical fiber pomace with fiber as raw material

A plant fiber and chemical fiber pulp technology, which is applied in fiber raw material processing, cellulose pulp post-processing, raw material separation, etc., can solve the problems that pulp cannot meet the requirements of chemical fiber pulp, consume tree resources, and the environment, and achieve the goal of cooking The effect of shortening time, shortening time, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

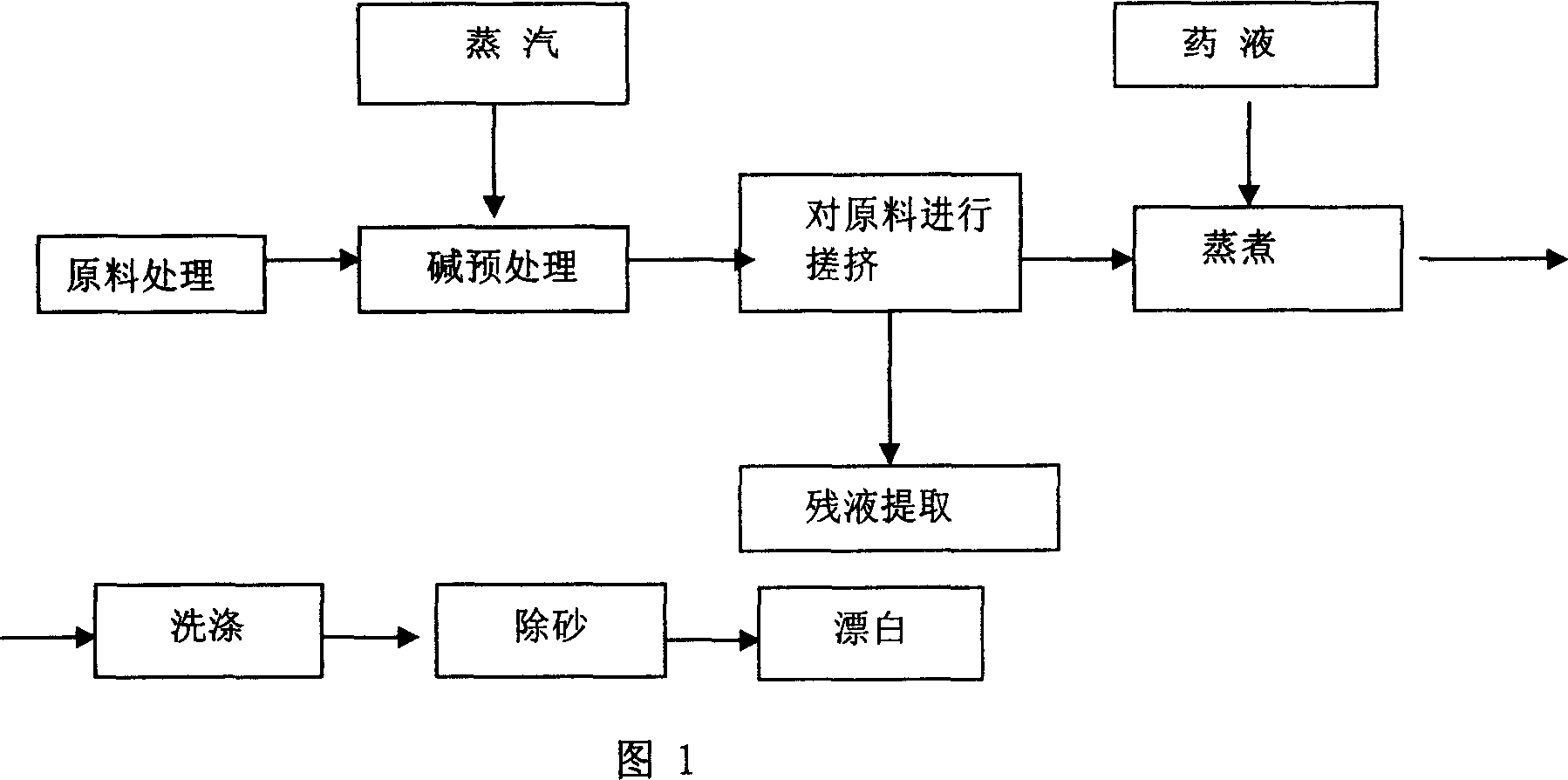

[0046] The plant fiber raw material used is bamboo. The processing steps of the preparation method are as follows:

[0047] (1) Raw material processing: the bamboo is cut into a specified size;

[0048] (2) Lye pre-impregnation: fully mix the bamboo material with the lye, the amount of alkali in the lye is 8% of the absolute dry raw material in terms of NaOH. The liquid ratio is 1:3, the pre-impregnation time is 3 hours, and the temperature is 60°C;

[0049] (3) Extrude the raw materials: use a double-helix variable-pitch squeezer. The ratio of the average value of the forward helical pitch to the reverse helical pitch is 1.75, and the product obtained in step (2) enters from the feed inlet of the rubbing squeeze machine, and the discharge temperature of the slurry after rubbing is 100 ° C. The number of pulp machines connected in series is 3;

[0050] (4) Cooking the pulp after rubbing and extrusion: adopt oxygen-alkali method for cooking. The amount of alkali added in t...

Embodiment 2

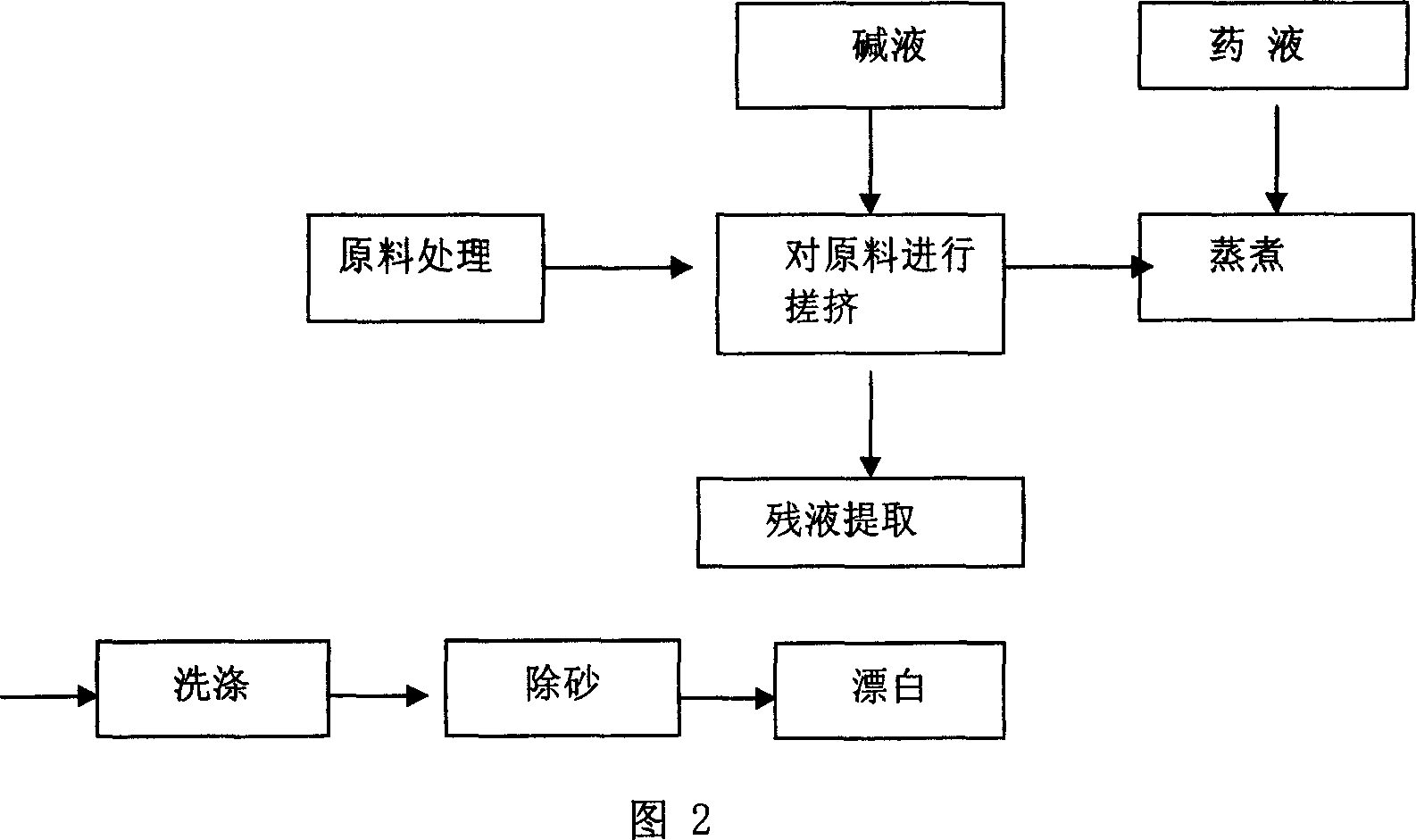

[0058] The used plant fiber raw material is bamboo, and all the other conditions are the same as in Example 1. The difference is that the lye pre-soaking process is completed in the process of rubbing and squeezing in the present embodiment, and the liquid ratio is 1: 1. In the lye The amount of alkali is 12% of the absolute dry raw material in terms of NaOH; the ratio of the average value of the forward helical pitch to the reverse helical pitch is 1.8, the number of presses connected in series is 2, and the output of the slurry after rubbing and squeezing is 1.8. The temperature is 80°C, and the oxygen-alkali method is used for cooking. The amount of alkali added in the vertical steamer is 18% of the absolute dry pulp in terms of NaOH, and the liquid ratio is 1:2. 2 o 2 The dosage is 3% of the absolute-dry slurry, and the temperature is raised to 120°C for cooking and kept for 70 minutes. The quality of the prepared chemical fiber pulp fully meets the requirements of the fi...

Embodiment 3

[0060] Used plant fiber raw material is bamboo, and all the other conditions are identical with embodiment 2, in rubbing the pulp, liquid ratio 1: 4, the consumption of alkali in the described lye is 20% to absolute dry raw material in NaOH, forward spiral The ratio of the average value of the screw pitch to the reverse screw pitch is 1.5, the number of presses in series is 4, the discharge temperature of the slurry after rubbing is 140°C, and the alkali method is used for cooking, and the amount of alkali used is calculated by NaOH. Dry pulp 8%, cook and heat up to 160 ° C for 120 minutes. The quality of the prepared chemical fiber pulp fully meets the requirements of the first-class product in FZ / T51002-1998.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com