A montmorillonite composite flame retardant material and a preparing method thereof

A composite flame retardant and montmorillonite technology, applied in the field of montmorillonite composite flame retardant materials and their preparation, can solve the problems of producing a large amount of toxic smoke, poor flame retardant effect, unfriendly environment, etc., and achieves improved mechanical properties, enhanced Flame retardancy and mechanical properties, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

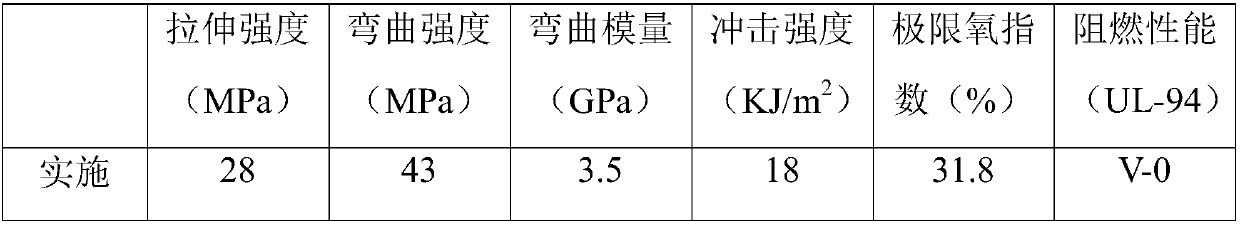

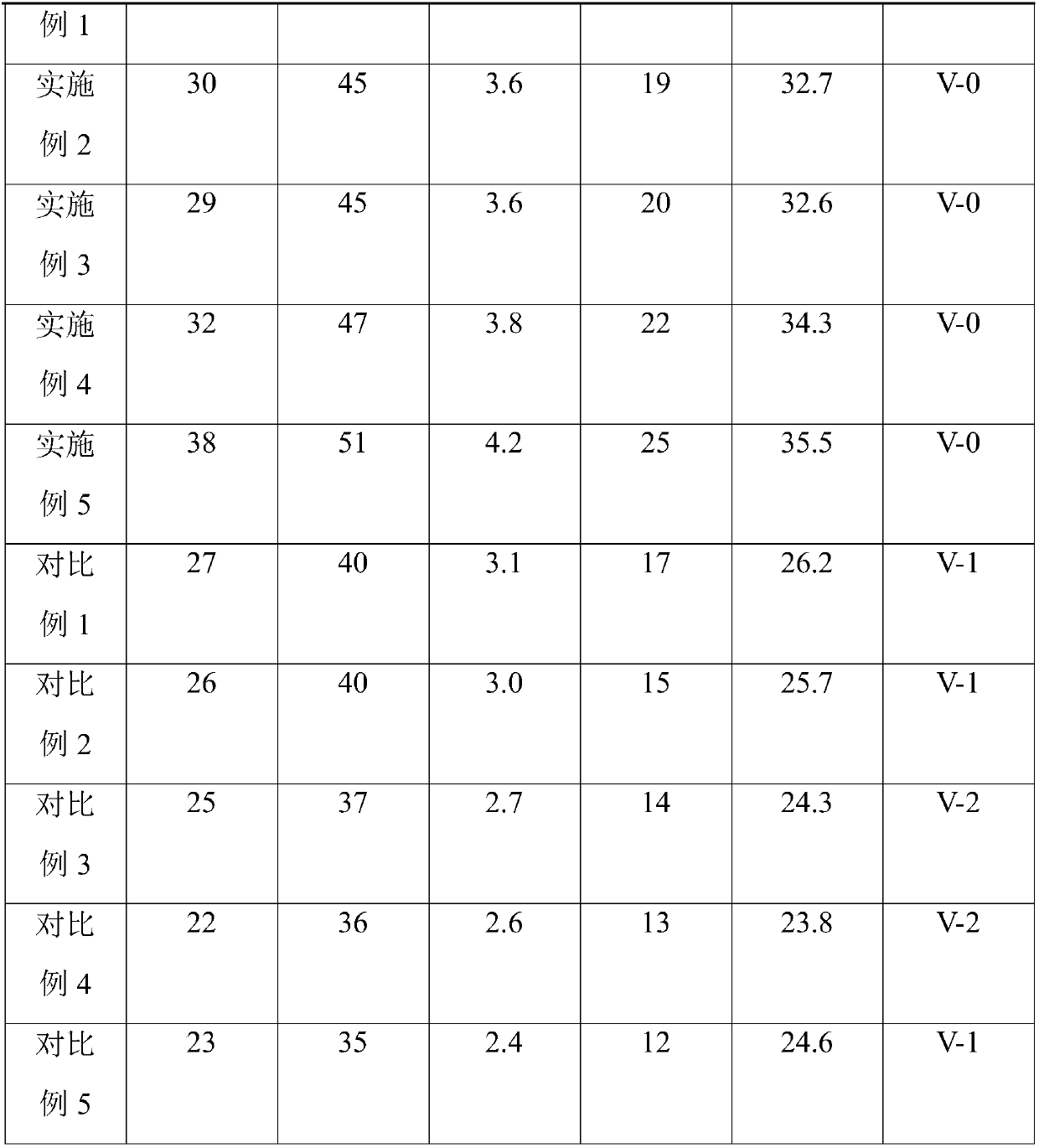

Examples

Embodiment 1

[0028] A montmorillonite composite flame retardant material, comprising the following components by weight:

[0029] 60 parts of polypropylene resin, 1 part of modified montmorillonite, 2 parts of phosphorus-containing flame retardant, 1 part of flame retardant synergist, 1 part of compatibilizer and 0.1 part of antioxidant.

[0030] Wherein, modified montmorillonite is prepared by the following method:

[0031] Add montmorillonite to 90°C water, ultrasonically disperse for 0.5h to prepare a montmorillonite dispersion with a concentration of 5wt%, then add intercalation agent and protonating agent, control the temperature to 90°C, continue ultrasonically dispersing for 0.5h, then Filter to get the first precipitate, put the first precipitate in a beaker, add 90°C water, stir for 0.5h, filter to get the second precipitate, put the second precipitate in a beaker, add 90°C water, stir for 0.5h, Filter to obtain the third precipitate, put the third precipitate in a beaker, add 90...

Embodiment 2

[0037] A montmorillonite composite flame retardant material, comprising the following components by weight:

[0038] 80 parts of polypropylene resin, 3 parts of modified montmorillonite, 5 parts of phosphorus-containing flame retardant, 2 parts of flame retardant synergist, 5 parts of compatibilizer and 0.5 part of antioxidant.

[0039] Wherein, modified montmorillonite is prepared by the following method:

[0040] Add montmorillonite to water at 80°C, ultrasonically disperse for 1 hour to obtain a montmorillonite dispersion with a concentration of 10 wt%, then add intercalation agent and protonating agent, control the temperature at 80°C, continue ultrasonically dispersing for 1 hour, and then filter. To obtain the first precipitate, put the first precipitate in a beaker, add 80°C water, stir for 0.5h, filter to obtain the second precipitate, put the second precipitate in a beaker, add 80°C water, stir for 0.5h, filter, To obtain the third precipitate, put the third precipit...

Embodiment 3

[0046] A montmorillonite composite flame retardant material, comprising the following components by weight:

[0047] 65 parts of polypropylene resin, 1.5 parts of modified montmorillonite, 3 parts of phosphorus-containing flame retardant, 1.3 parts of flame retardant synergist, 2 parts of compatibilizer and 0.2 part of antioxidant.

[0048] Wherein, modified montmorillonite is prepared by the following method:

[0049]Add montmorillonite to water at 80°C, ultrasonically disperse for 1 hour to obtain a montmorillonite dispersion with a concentration of 6 wt%, then add intercalation agent and protonating agent, control the temperature at 80°C, continue ultrasonic dispersion for 1 hour, and then filter. To obtain the first precipitate, put the first precipitate in a beaker, add 80°C water, stir for 0.5h, filter to obtain the second precipitate, put the second precipitate in a beaker, add 80°C water, stir for 0.5h, filter, To obtain the third precipitate, put the third precipitat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com