Patents

Literature

43results about How to "Not produced" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

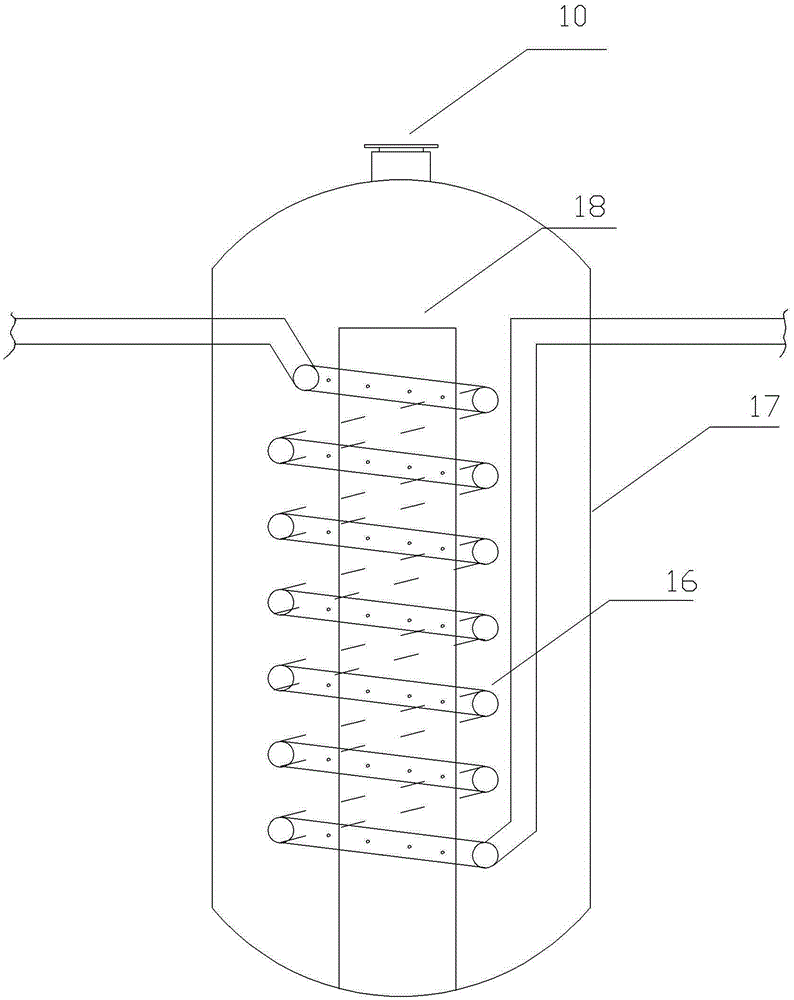

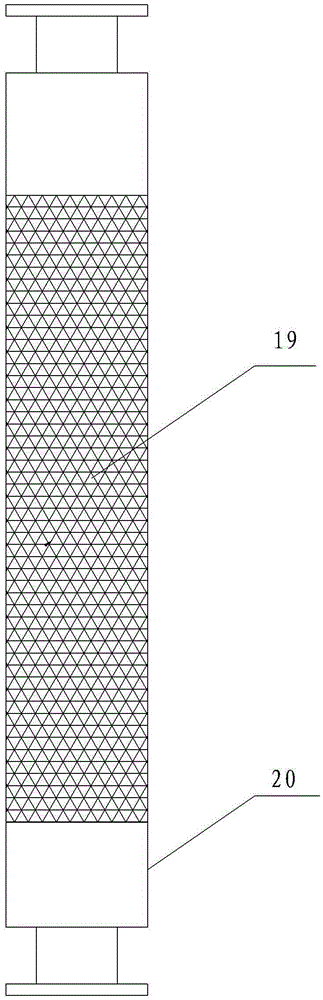

Microporous aluminum-salt lithium adsorbent, preparation method therefor, filler and lithium ion enriching method

ActiveCN106076243AOvercome the problem of high dissolution rateControl areaOther chemical processesAlkali metal oxides/hydroxidesLithiumSorbent

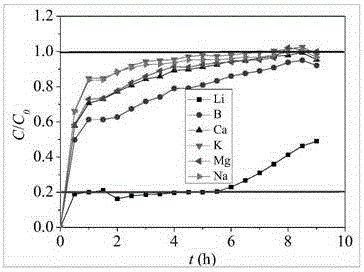

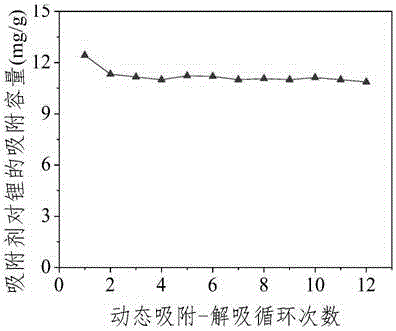

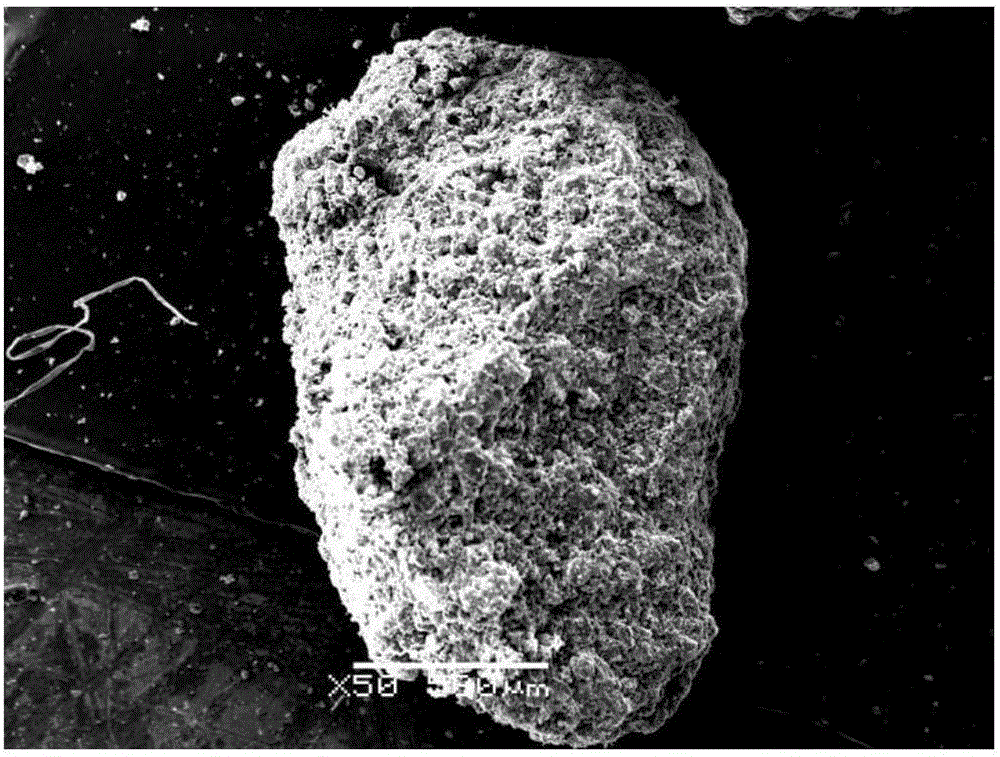

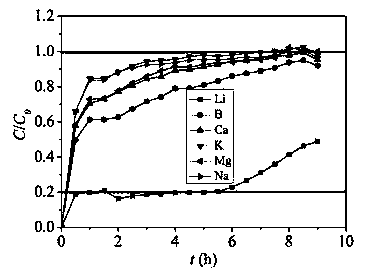

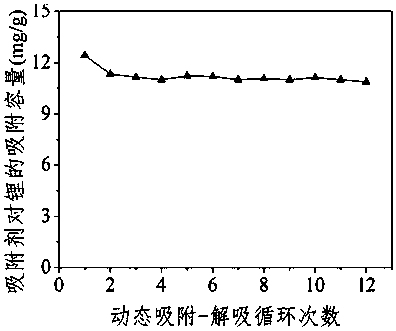

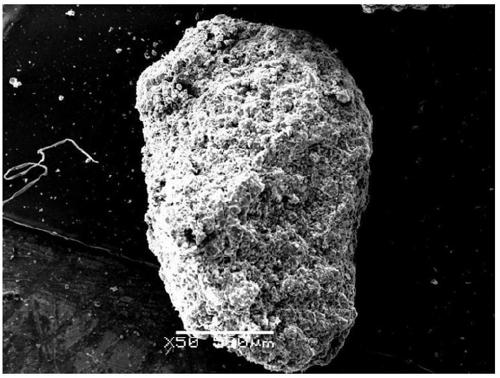

The invention discloses a microporous aluminum-salt lithium adsorbent, a preparation method therefor, filler containing the microporous aluminum-salt lithium adsorbent and a lithium ion enriching method. The microporous aluminum-salt lithium adsorbent disclosed by the invention has the molecular formula of LiCl.aAl(OH)3.bH2O and has micropores, of which the average pore size is smaller than 2nm, wherein a is greater than 1 and smaller than 3, and b is greater than 0.5 and smaller than 2. The preparation method disclosed by the invention is simple, and the obtained adsorbent is large in lithium ion adsorption capacity, high in selectivity, simple in eluting regeneration and long in cycle life and can be applied to the separation and extraction of lithium from lithium-containing saline lake brine, salt-field concentrated lithium-containing senescent brine, lithium-containing medicinal wastewater and a lithium-containing solution with the mineralization degree lower than 50g / L.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

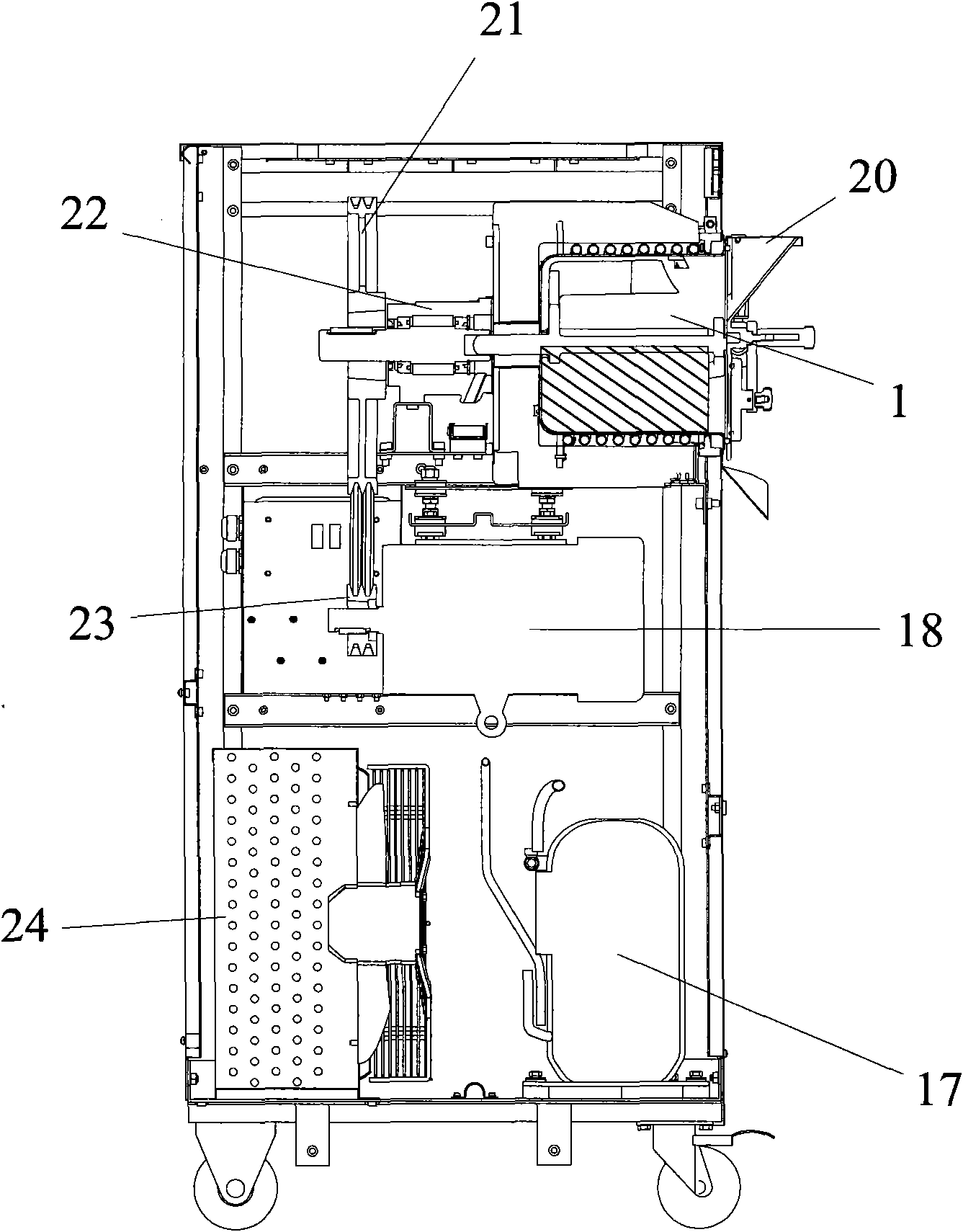

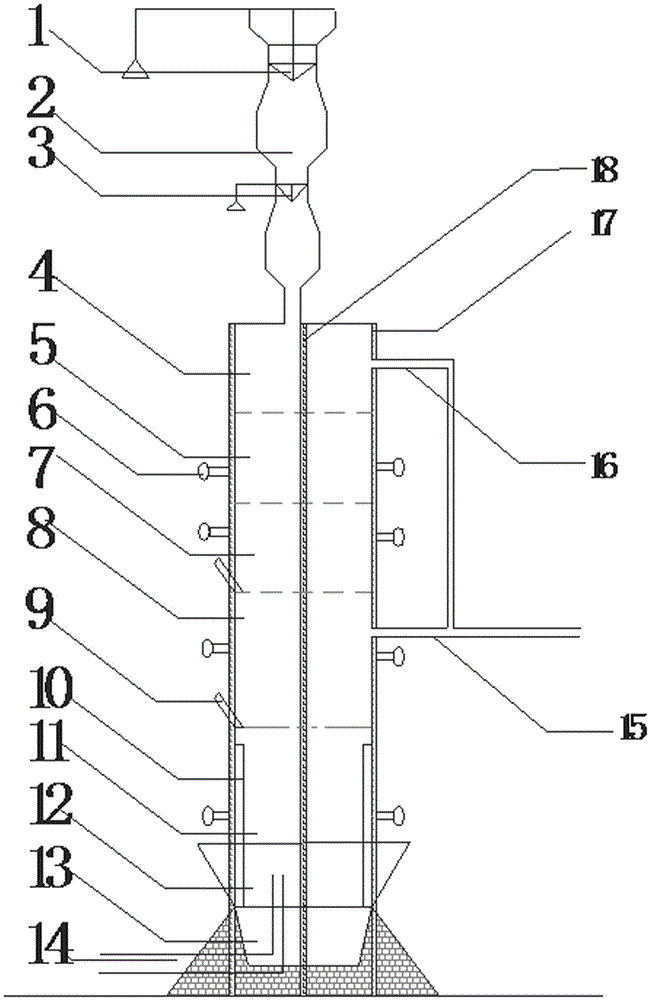

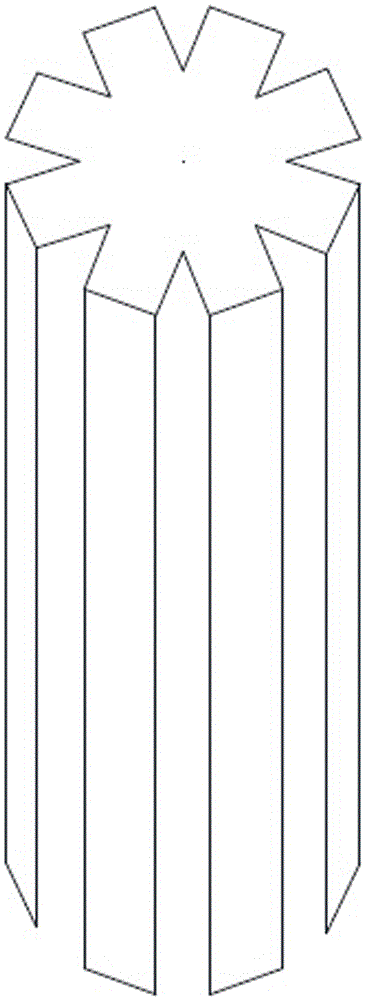

Process for generating combustible gas by virtue of sludge gasification

ActiveCN104031687ASignificant reductionNot producedCombustible gas productionCombustible gasProcess engineering

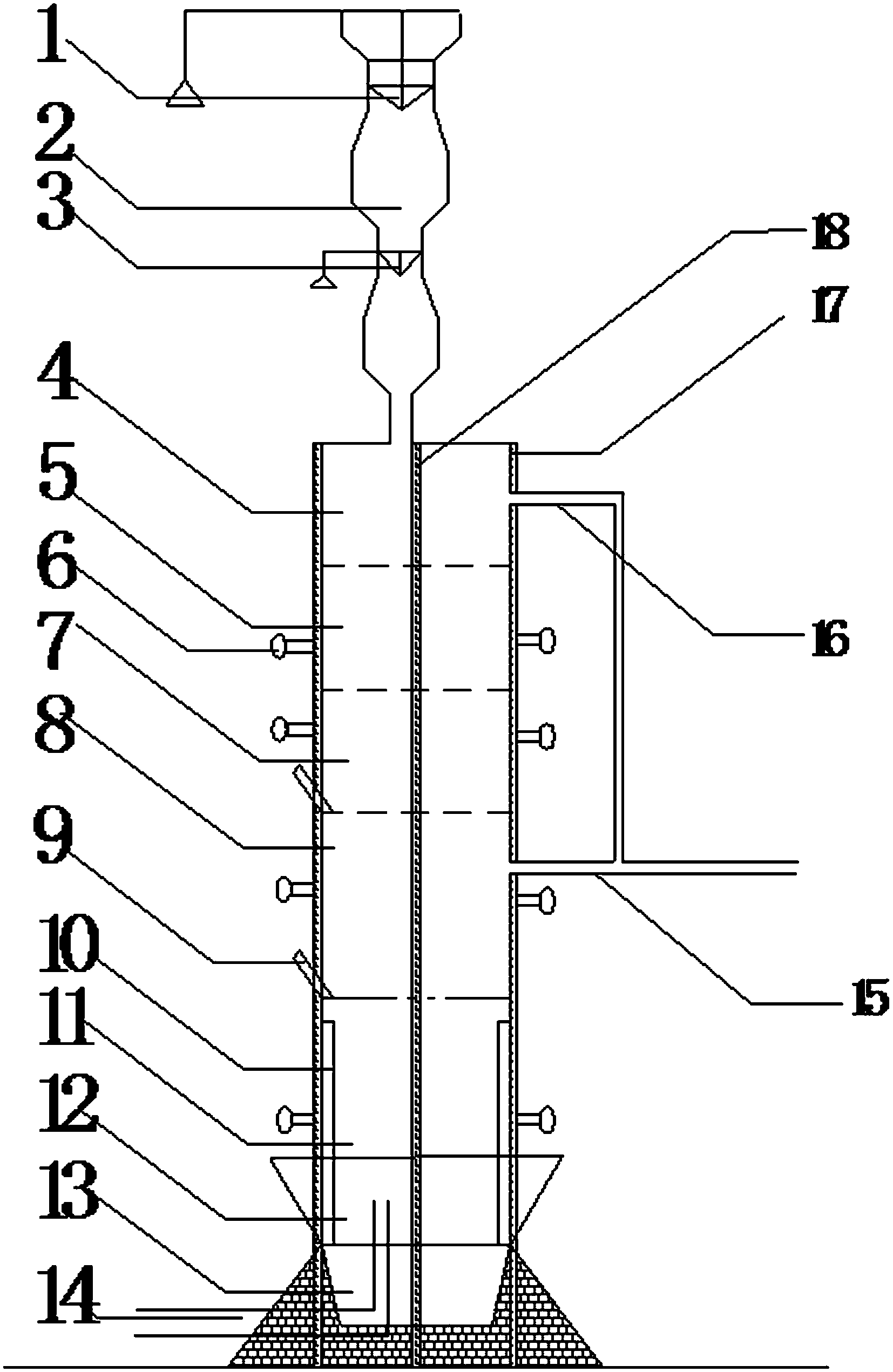

The invention discloses a process for generating combustible gas by virtue of sludge gasification. The process comprises the following steps: 1, dewatering sludge; 2, granulating the dewatered sludge, airing and drying; 3, feeding dried sludge granules into an integrated sealed pyrolysis gasification device, and gradually drying, drily distilling, carbonizing, gasifying and combusting the sludge granules from top to bottom in the integrated sealed pyrolysis gasification device; and finally discharging gas generated in the device through a pipeline, collecting the gas, combusting organic matter residues and inorganic matters at high temperature to obtain harmless molten slag, and discharging the molten slag through a slag outlet. According to the process, 200 tons of sludge with the water content of less than 60% can be treated by a monomer gasification device each day; the reduction, the harmlessness and the energization of the sludge treatment are realized; the dioxin generation conditions are avoided; the operating cost is low, namely a large quantity of manpower cost can be reduced due to automated operation and management; 1 ton of sludge with the water content of less than 30% can be averagely gasified to generate 1600Nm<3> of combustible gas.

Owner:河南华天环保科技有限公司

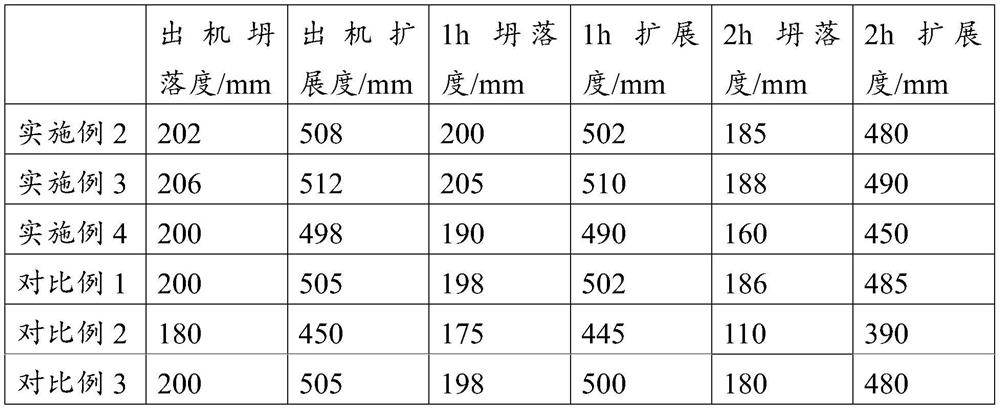

Machine-made sand regulator for concrete, concrete and preparation method thereof

The invention relates to the technical field of building materials, and discloses a machine-made sand regulator for concrete, which comprises polycarboxylic acid mother liquor, diethanolisopropanolamine, triisopropanolamine, glycerol and sodium sulfate. Water is used as a solvent. The machine-made sand regulator disclosed by the embodiment of the invention has rich hydroxyl, is weakly alkaline, does not contain chloride ions, is non-toxic and non-corrosive, and is a high-performance green and environment-friendly material. The components are simple, and the excellent performance is achieved byregulating and controlling the reasonable ratio of the components. By using the machine-made sand regulator as an admixture of concrete, all sand in the concrete can adopt machine-made sand. No wasteliquid is generated, no cleaning is needed after stirring, no production wastewater is generated, and no waste gas is generated. The invention further discloses concrete and a preparation method thereof.

Owner:广州砼奇杰建材科技有限公司

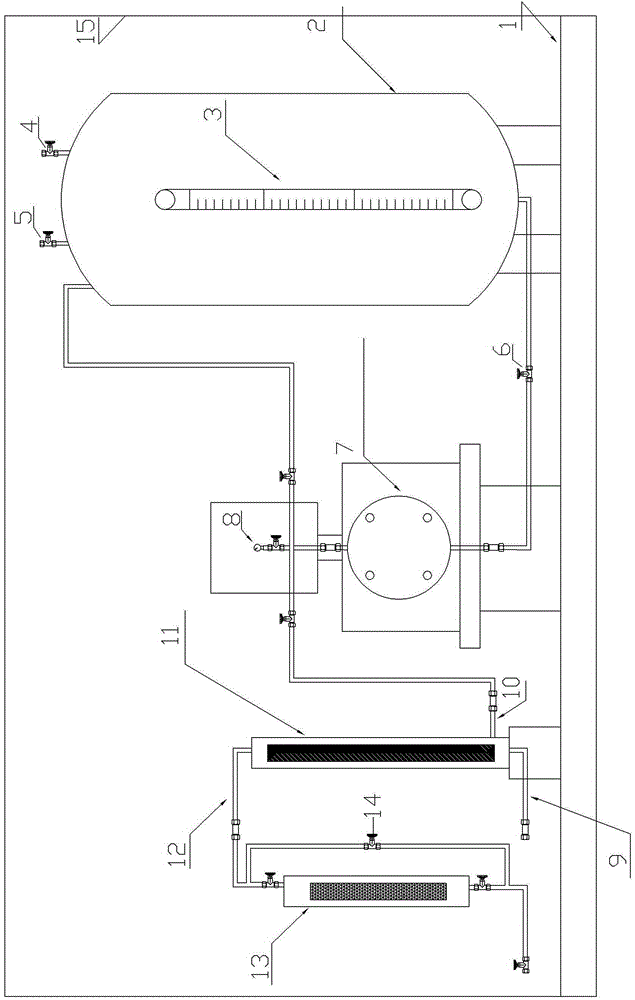

Energy-saving apparatus used for catalytic synergy of natural gas

The invention especially relates to an energy-saving apparatus used for catalytic synergy of natural gas, which belongs to the technical field of catalytic synergy of natural gas. The energy-saving apparatus used for catalytic synergy of natural gas can greatly improve energy efficiency of natural gas and reduce cost. The apparatus comprises a base. Structural main points of the apparatus are as follows: the base is provided with a vertical synergist storage tank, an electromagnetic metering pump and a mixer; the upper end of the synergist storage tank is provided with a vertical liquid feeding pipe and a vertical evacuation pipe, the upper end of the liquid feeding pipe is connected with a liquid feeding valve, and the upper end of the evacuation pipe is connected with an evacuation valve; a lower outlet of the synergist storage tank is connected with a lower inlet of the electromagnetic metering pump; a first pipeline is provided with a first stop valve; and an upper inlet of the electromagnetic metering pump is connected with one end of a second pipeline, one end of a third pipeline and one end of a fourth pipeline.

Owner:锦州安燃高能切割气有限公司

Liquid fuel and preparation method thereof

InactiveCN101619245AWide variety of sourcesLow priceLiquid carbonaceous fuelsMethyl carbonateKerosene

The invention discloses a liquid fuel and a preparation method thereof. The liquid fuel consists of the following raw materials in portion by weight: 0.6 to 2 weight percent of cosolvent, 5 to 50 weight percent of water, 1.2 weight percent of carbon deposition preventer, 2.5 weight percent of flavoring agent, 3.5 to 25 percent of additive, and the balance of an alcohol-containing compound. The alcohol-containing compound is one of the following compounds or the combination thereof: methanol, ethanol, waste methanol, and waste ethanol; and the additive is a C5 additive or No.70 gasoline or isooctyl nitrate or methyl carbonate. The fuel cannot produce harmful gas during the combustion, and has the advantages of sanitary, convenient and safe use, broad source of the raw materials, low cost, low pollution, and convenient transportation and keeping. The liquid fuel can completely substitute diesel oil, kerosene, liquefied petroleum gas, natural gas, coal and the like, and is used on cookers.

Owner:王明海

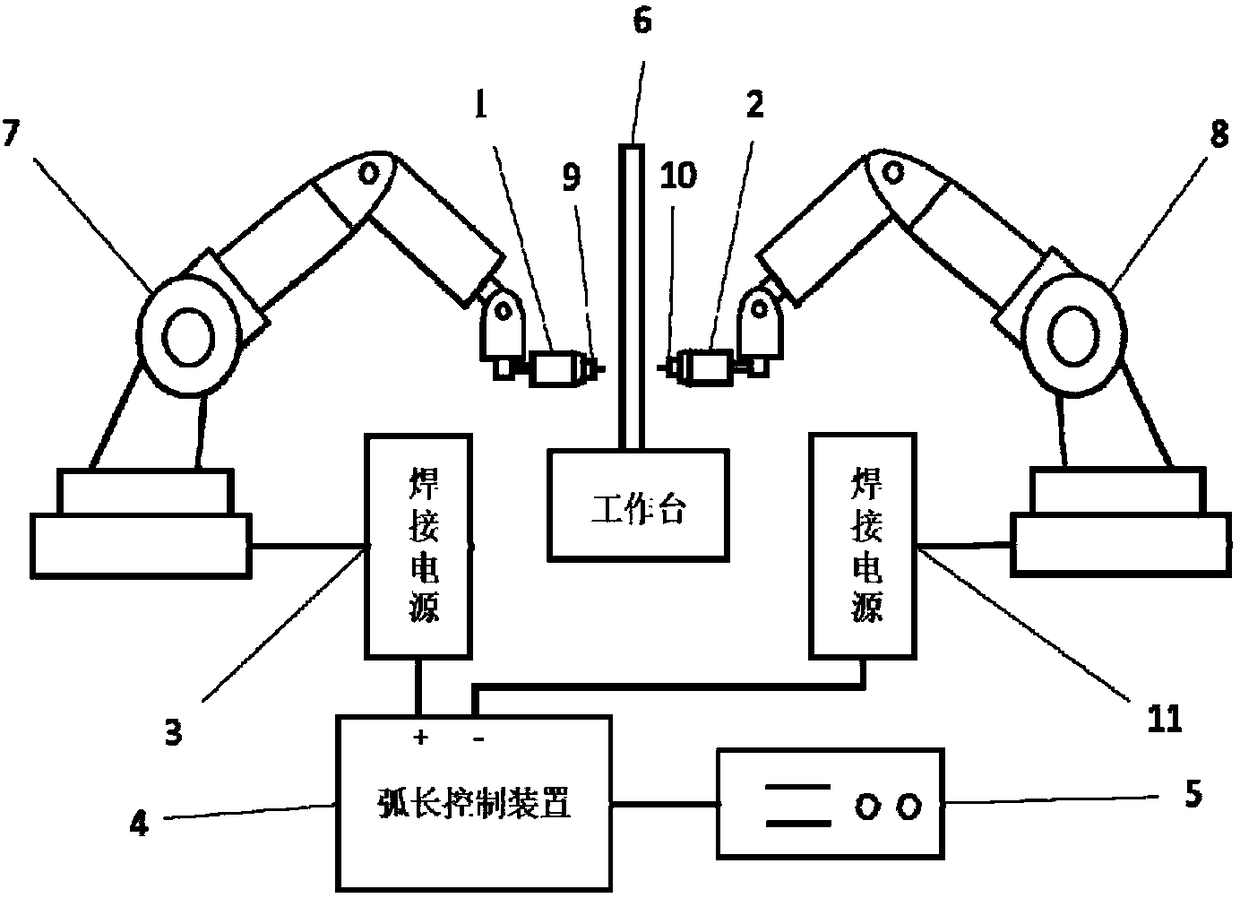

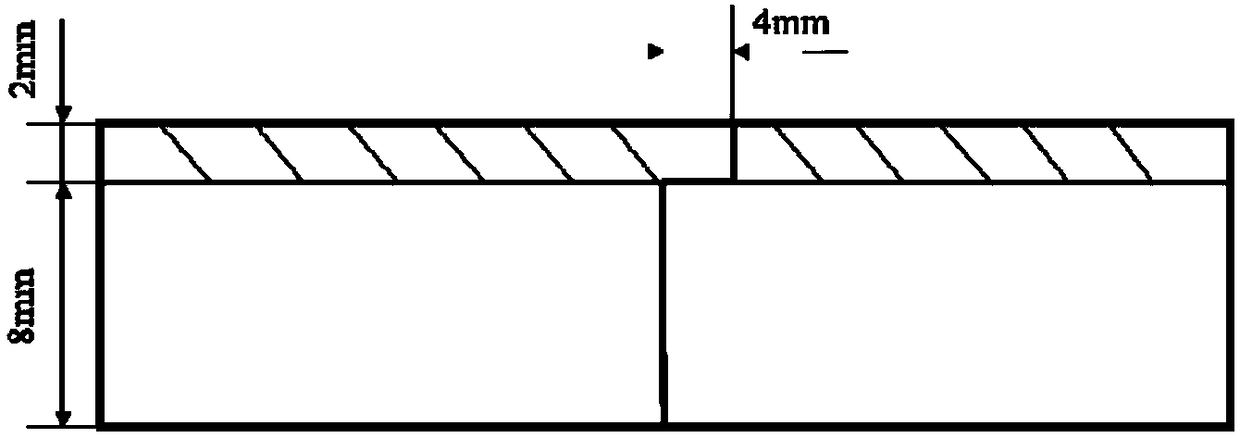

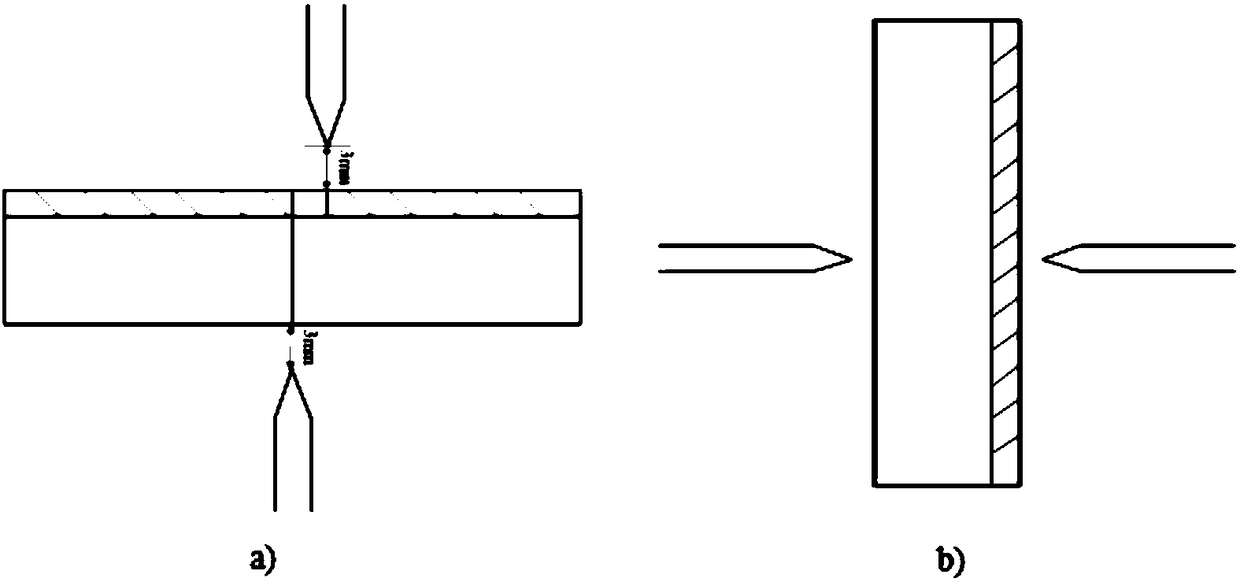

Double-side double-arc vertical welding fusion depth control device and welding method thereof

The invention discloses a double-side double-arc vertical welding fusion depth control device and method for a composite board. The double-side double-arc vertical welding fusion depth control devicecomprises dual robots, a welding power supply, an arc-length control device, an industrial personal computer and the like. The fusion depth control method mainly adopts the combination of double-sideddouble-arc vertical welding and a self-developed arc-length control device, electric-arc parameters on both sides are independently adjusted in the welding process, voltage data are collected and adjusted through the arc-length control device, and accurate control over the fusion depth on the front side and the back side of the composite board is realized. Through the double-side double-arc vertical welding fusion depth control method, one-time through welding on 5-10mm composite boards made of titanium-steel, stainless steel-steel and the like can be realized, adding of a transition layer isnot needed, the efficiency is improved, the welding deformation is small, and the generation of intermetallic compounds is reduced.

Owner:NANJING UNIV OF SCI & TECH

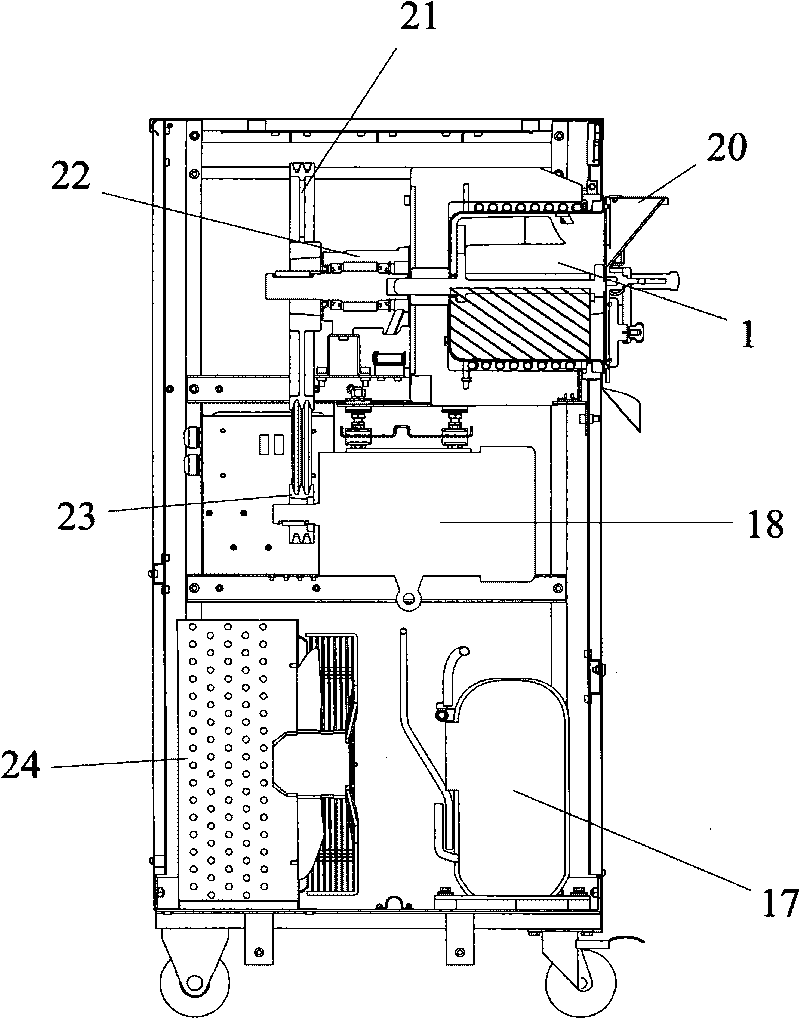

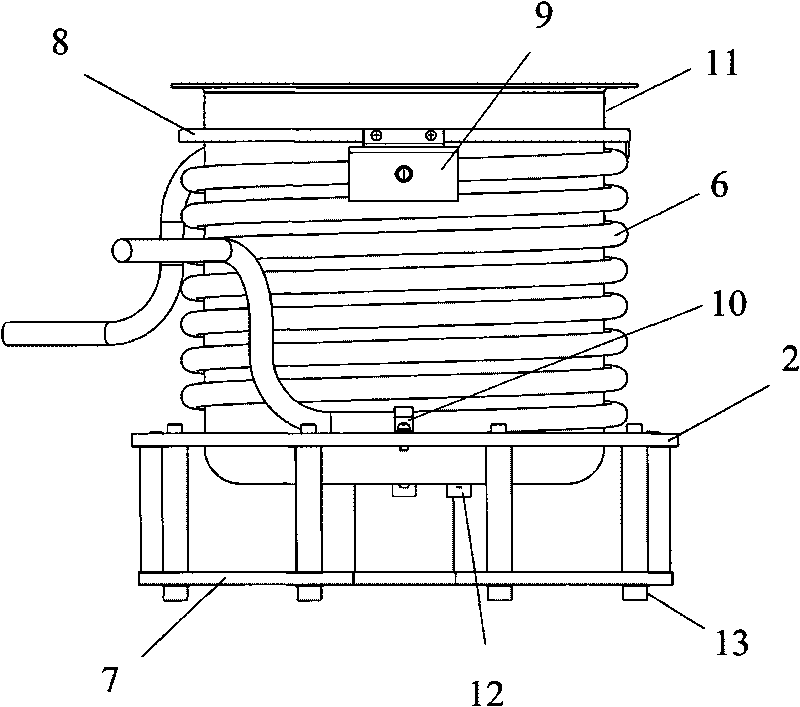

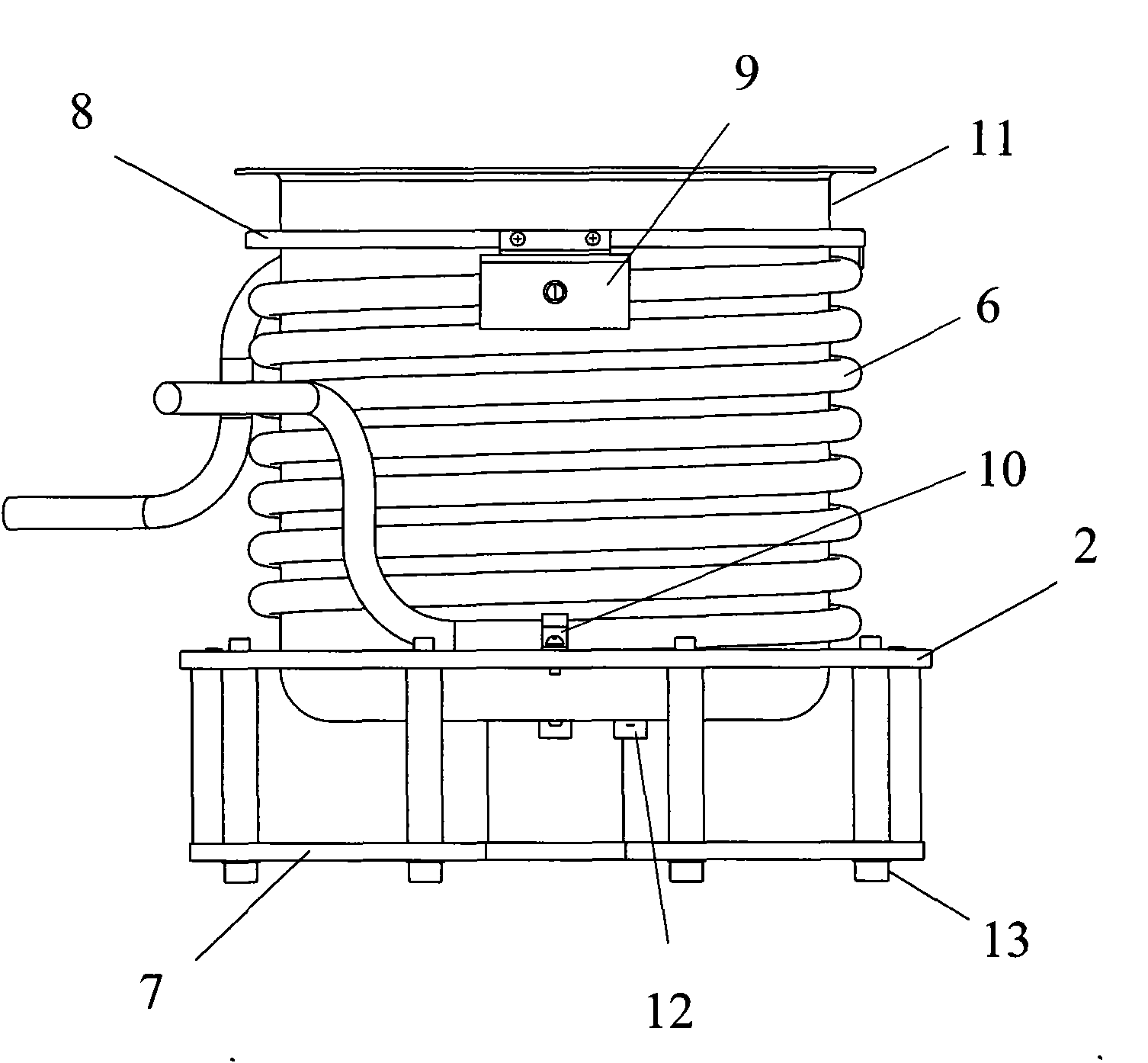

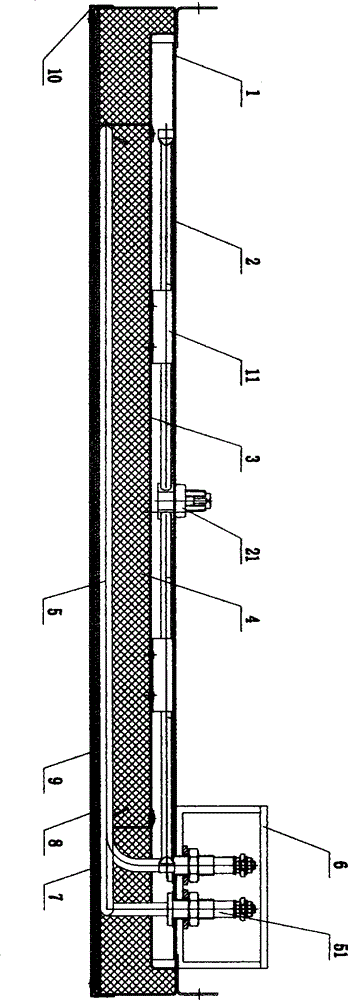

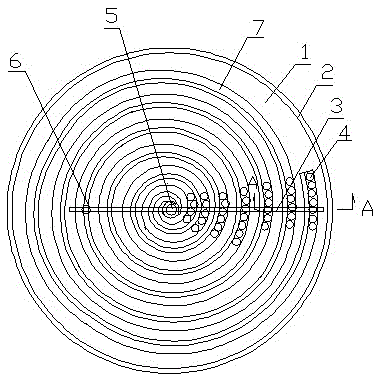

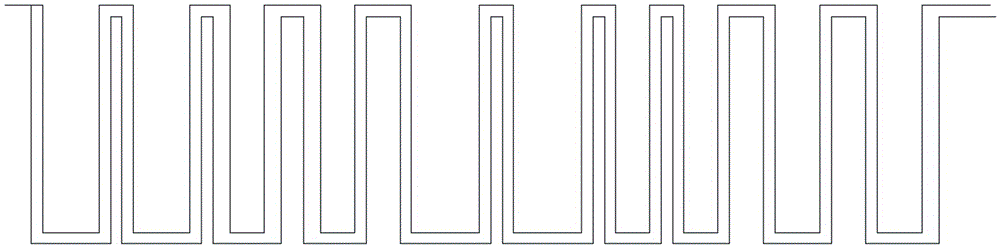

Hard ice cream machine evaporator, fixture and method for winding copper condensation tube

InactiveCN101749894ASimple structureImprove cooling effectEvaporators/condensersManufacturing technologyEngineering

The invention discloses a hard ice cream machine evaporator with copper condensation tubes and additionally discloses a fixture and a method for winding copper condensation tubes. A copper condensation tube is placed on the winding fixture, the winding fixture is sheathed on a cylinder, an adjusting bolt is turned, a sliding block moves in a guide block to enable the copper condensation tube to be closely attached onto the periphery of the cylinder, the winding fixture rotates around the cylinder and the copper condensation tube is wound on the periphery of the cylinder. The manufacturing technology of the hard ice cream machine evaporator is simple, the production efficiency is high, not lots of people but only one people is required to operate the relevant mechanisms and devices for manufacturing the hard ice cream machine evaporator, the cost is greatly saved, no harmful gas is produced and no environmental pollution is caused because no argon arc welding is conducted when in manufacturing the hard ice cream machine evaporator, no large worksite is occupied, the production efficiency of the evaporator is high and the intermediate link is omitted because the manufactured evaporator can be immediately installed on the hard ice cream machine.

Owner:SHENZHEN OCEAN POWER INDUSTRIAL CO LTD +3

Calcium carbide used as water phosphorus removal filter material and preparation method thereof

ActiveCN106219692ASolving Passivation ProblemsSolve the cost problemEnergy based wastewater treatmentWater/sewage treatment apparatusUranium carbideMixed materials

The invention relates to calcium carbide used as a water phosphorus removal filter material and a preparation method of the calcium carbide. The calcium carbide is prepared from, by volume, 0.5-30% of metal materials, 0.5-80% of binding agent, 1-40% of activating agent and 0.5-15% of catalyst. The preparation method of the filter material comprises the steps that the components of the filter material are subjected to micronization and nanocrystallization treatment, and the fineness of the components is not smaller than 300 mesh after micronization and nanocrystallization treatment; the components subjected to micronization and nanocrystallization treatment are mixed to be uniform; the evenly-mixed material is subjected to sintering-free extrusion (hydraulic) molding; the molded product is maintained, dried and packaged. Compared with the prior art, the problems of metal passivation, high cost and lack of timeliness in phosphorus removal methods are well solved.

Owner:上海润溪环保科技有限公司

Hard ice maker evaporator, winding clamp for condensation copper pipe and winding method thereof

InactiveCN101849602ASimple structureImprove cooling effectFrozen sweetsEvaporators/condensersConductor CoilCopper tubing

The invention discloses a hard ice maker evaporator with a condensation copper pipe, and discloses a winding clamp special for the condensation copper pipe and a winding method thereof. The condensation copper pipe is placed on the winding clamp; and after the winding clamp is sleeved on a cylinder, an adjusting bolt is rotated, a slide block moves in a guide block so that the condensation copperpipe is tightly attached to the periphery of the cylinder, and the winding clamp rotates around the cylinder to wind the condensation copper pipe on the periphery of the cylinder. The method for manufacturing the hard ice maker evaporator has simple manufacturing process and high production efficiency, does not need many persons to operate related mechanism and equipment to manufacture the hard ice maker evaporator, and only needs one person to manufacture the hard ice maker evaporator so as to greatly save the cost; meanwhile, the method does not burn argon arc for welding during manufacturing, does not produce harmful gas, does not pollute the environment, and does not occupy much working site; and the method has higher production efficiency, and the manufactured evaporator can be arranged on a hard ice maker so as to save a middle link.

Owner:SHENZHEN OCEAN POWER INDUSTRIAL CO LTD +3

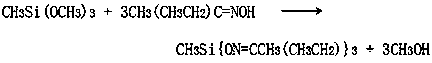

A kind of preparation method of methyl tributylketoxime base silane

The invention belongs to the technical field of fine chemistry and relates to a methyltris(methylethylketoxime)silane preparation method.Methyltrimethoxysilane, diacetylmonoxime and p-toluenesulfonic acid which serves as a catalyst react according to a certain proportion, excessive diacetylmonoxime in the reaction process serves as a solvent to make the reaction more thorough and easier, and methanol is recovered during reaction. After reaction is finished, the diacetylmonoxime which serves as the solvent is recovered by reduced pressure distillation, and the recovered diacetylmonoxime can be recycled.Products obtained by distillation are washed and filtered to obtain high-purity methyltris(methylethylketoxime)silane. The methyltris(methylethylketoxime)silane preparation method has the advantages that product yield is above 97%, product content is above 98%, materials can be recycled completely, no waste liquid is generated, and accordingly environment pollution is avoided.

Owner:JINGZHOU JIANGHAN FINE CHEM

Coating for aluminium plated paper and spraying technology for aluminium plated paper

A disclosed coating for aluminium plated paper is characterized by comprising the following compositions in parts by weight: 15-25 parts of an acrylate, 20-40 parts of nitro cellulose, 15-25 parts of polyurethane, 5-10 parts of acrylic acid, 20-30 parts of an acrylate emulsion, and 90-110 parts of an alcohol solution. According to the technology, alcohol is employed as a solution and can be completely reacted with the acrylate, no toxic solvent is generated and environment is not polluted. The acrylate emulsion and the acrylate are employed at the same time as glue materials, are further reacted with the solution while the binding purpose is reached, and no toxic solution is left in the binder.

Owner:JIANGSU KINGHENG PACKAGE MATERIAL CO LTD

Low-temperature catalysis type infrared gas heater and catalyst preparation process thereof

InactiveCN104100974AAvoid lostReduce consumptionGaseous fuel burnerMetal/metal-oxides/metal-hydroxide catalystsExcited stateGas heater

The invention discloses a low-temperature catalysis type infrared gas heater comprising a shell, a gas conduit, a gas homogenizing component, a dry type preheating electrical-heating pipe and an activated aluminum catalyst layer. The inside of the shell is of cavity structure. The gas conduit is arranged in the cavity structure of the shell, the gas homogenizing component is arranged on the lower portion of the gas conduit so as to homogenize gas released from the gas conduit, the dry type preheating electrical-heating pipe is arranged in the gas homogenizing component so as to preheat the catalyst layer and activating catalyst on the catalyst layer, the activated aluminum catalyst layer is arranged on the lower portion of the gas homogenizing component, the homogenized gas is catalyzed and combusted in the activated aluminum catalyst layer, a low-energy base is formed on the surface of the catalyst layer to generate vibrational-state products, and energy is released by infrared radiation. The low-temperature catalysis type infrared gas heater is energy saving, environment friendly, low in noise and high in efficiency.

Owner:王荣根

Danxiyupingfeng drip pill and its preparation method

A Chinese medicine in the form of pill for nourishing Qi and treating sweating and weakness is prepared from astragalus root, ledebouriella root, white atractylodes rhizome and ginger. Its preparing process is also disclosed.

Owner:北京博智绿洲医药科技有限公司

Coating slow-release fertilizer production method

InactiveCN104446852AStrong adsorptionImprove the sustained release effectSuperphosphatesAlkali orthophosphate fertiliserFertilizerPre treatment

The present invention discloses a coating slow-release fertilizer production method, which is characterized by comprising: (1) material pre-treatment, (2) conditioning, (3) fertilizer dissolving, (4) controlled release fertilizer production, (5) composite coupling agent production, (6) composite fertilizer production, and (7) coating. According to the present invention, straws and other crops have excellent adsorption so as to significantly improve the slow-release effect of the fertilizer and solve the problem of soil hardening caused by long term fertilizer application, and become the complement components of the long-acting fertilizer; the coupling method is adopted, and waste gas, waste water and waste are not produced so as not to pollute the environment; and the production process is simple, the special equipment is not required, the period is short, the cost is low, the product price is equivalent to the urea price, the fertilizer utilization rate is high, the fertilizer saving effect is significant, and the slow control efficiency of the fertilizer is improved through the coating.

Owner:SHANDONG ENBAO BIOTECH

Compound liver-benefiting dropping pill for treating hepatitis and its preparing method

The present invention discloses a Chinese medicine composition with the actions of boosting liver, enriching kidney, removing toxic material and dispelling dampness for curing the diseases of hypochondriac pain, reduced food intake, obdominal distention, aching lumbus, lack of strength and yellow urine, etc. due to deficiency of liver-yin and kidney-yin and noxious dampness. Said Chinese medicine composition can be made into compound Yiganling dripping pills, and is made up by using Chinese medicine Yiganling powder and Wurenchun extract as raw material and medicinal carrier as matrix through a certain preparation process.

Owner:北京博智绿洲医药科技有限公司

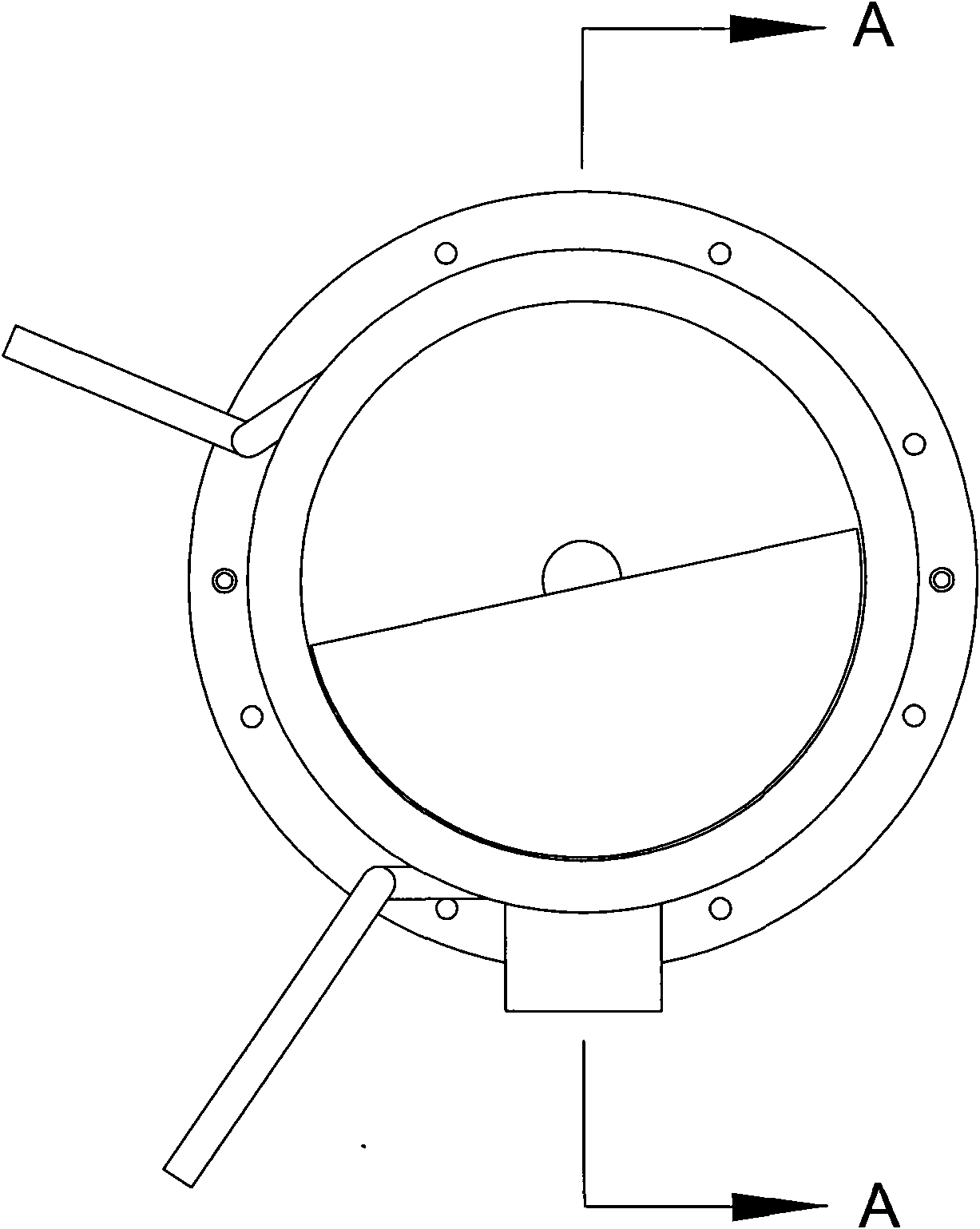

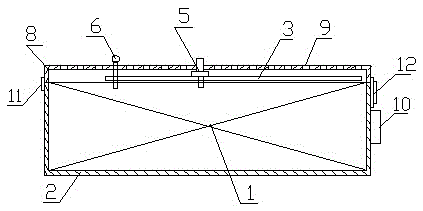

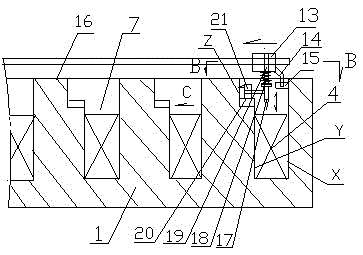

Environmentally friendly imitation firecrackers

ActiveCN104729363BImprove aestheticsIncrease joyFirework simulationsFirecrackerEnvironmental profile

The invention discloses an environment-friendly profiling firecracker. The environment-friendly profiling firecracker comprises a mold cake (1), an outer box (2) and a cover (8), the outer box (2) is used for packaging the mold cake, the mold cake is provided with a spiral groove (7), bubble bags (4) are arranged in the spiral groove successively and continuously, the mold cake is provided with a rotating rod (3), a spring mechanism (5) connected with the rotating rod is arranged in the middle of the mold cake, and the cover is provided with a safety bolt (6) capable of limiting rotation of the rotating rod; a concave-convex face (20) having the same motion direction as the spiral groove is arranged on the inner side face of the spiral groove, a sliding sleeve (13) is arranged at one end of the rotating rod, the sliding sleeve is connected with a backing wheel (15) through a cantilever (14), the backing wheel (15) can be attached to the outer side face of the spiral groove, the sliding sleeve is provided with a lifting rod (19) capable of moving vertically, the lower end of the lifting rod is connected with a pricking needle (17), and the concave-convex face is provided with a guide wheel (21). The environment-friendly profiling firecracker does not pollute the environment, can save resources, cannot cause safety accidents and can achieve the effect of simulating firecracker setting-off.

Owner:欧阳文亮

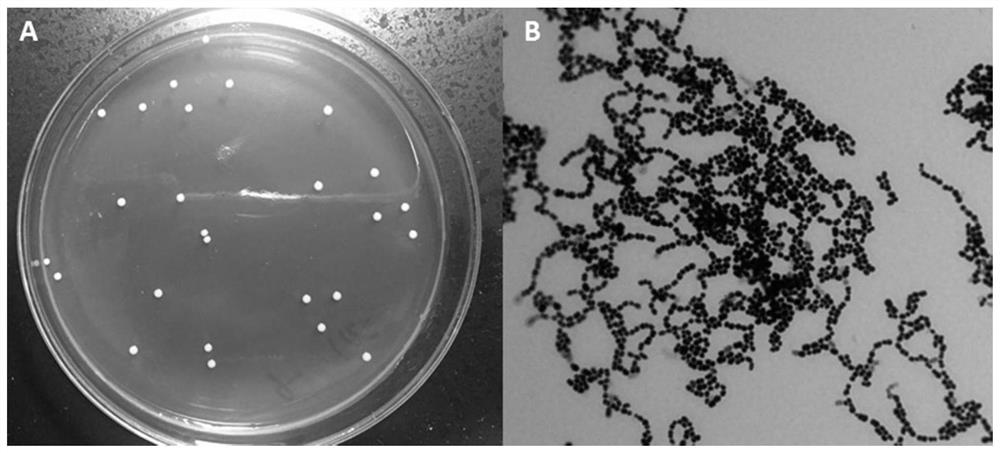

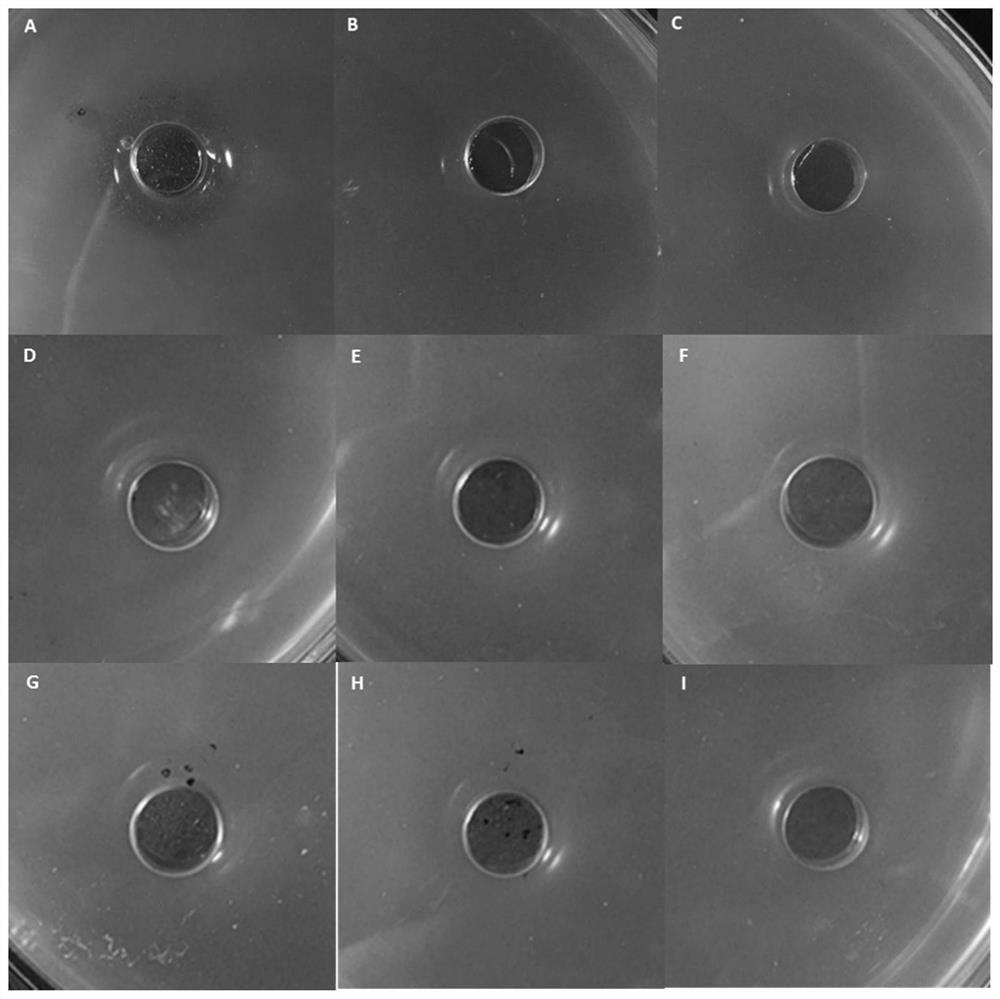

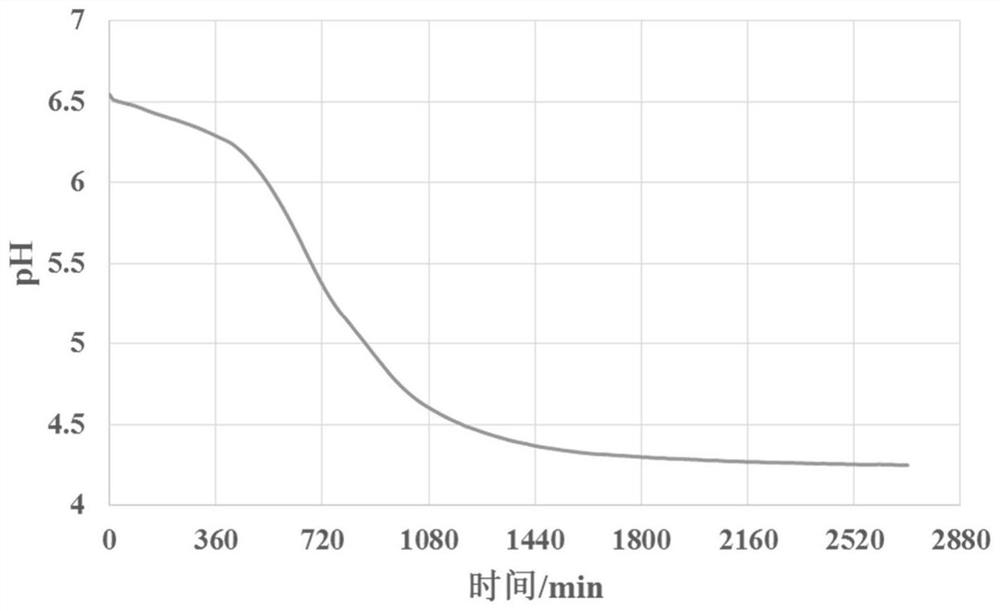

Lactococcus lactis capable of improving oral health and application of lactococcus lactis

ActiveCN112481155AGood antagonistic propertiesStrong gathering abilityMilk preparationBacteriaBiotechnologyOral health

The invention relates to the field of microorganisms, and discloses lactococcus lactis capable of improving oral health and application thereof, the lactococcus lactis is named as 2311 and is preserved in China General Microbiological Culture Collection Center on May 25th, 2018, and the preservation number is CGMCC No. 15812; wherein the microorganisms are classified and named as Lactococcus lactis subsp. Lactis. The strain disclosed by the invention has special characteristics in the aspect of oral health related application, and particularly has the characteristics of good antagonism to oralharmful bacteria, good aggregation capability, no generation of volatile sulfide and low acidification; therefore, the strain is suitable for being applied to various oral cavity improvement foods, medicines, dietary supplements, oral care products and the like.

Owner:HANGZHOU WAHAHA TECH

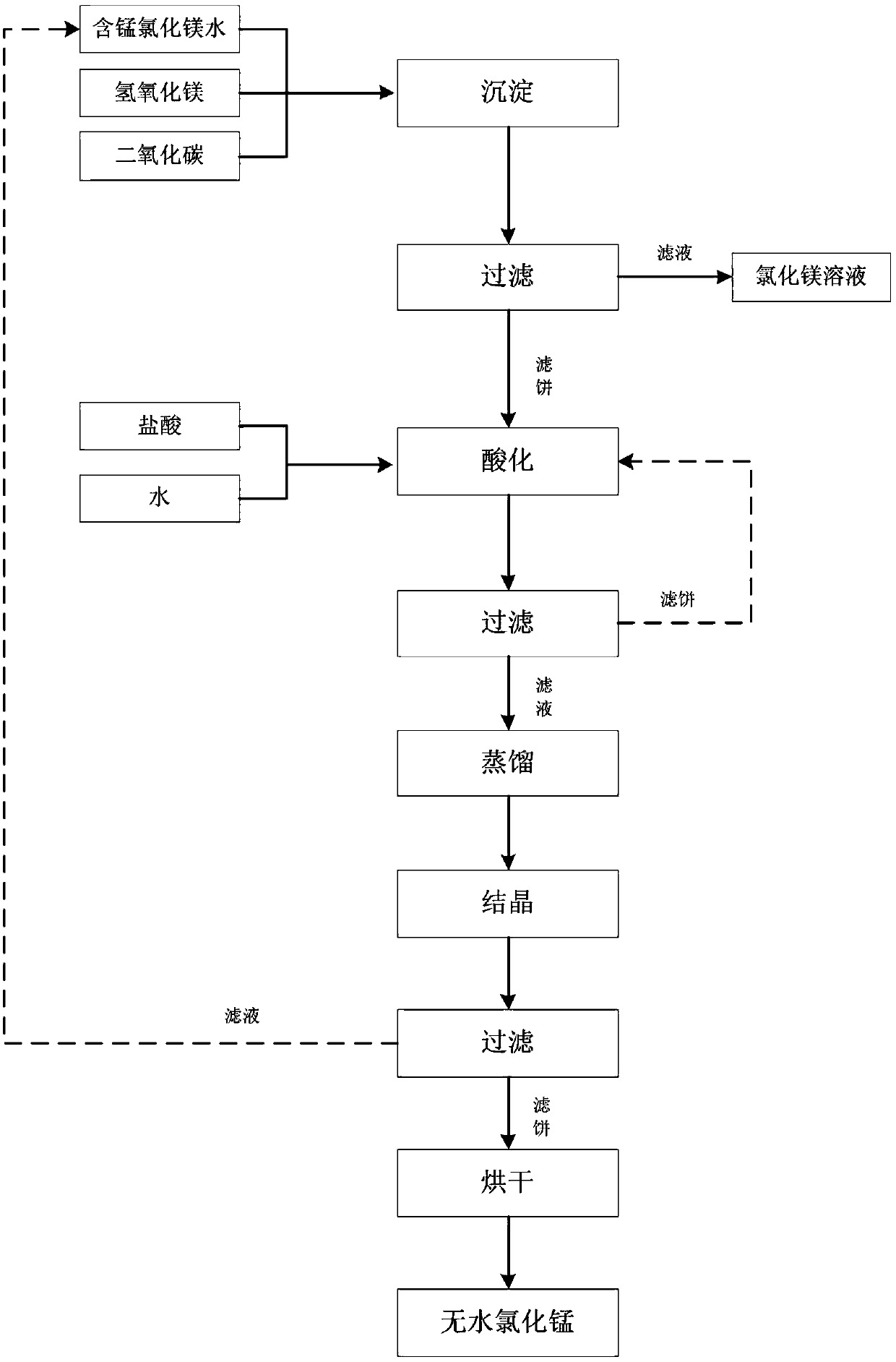

Process for recovering magnesium and manganese elements in industrial waste water

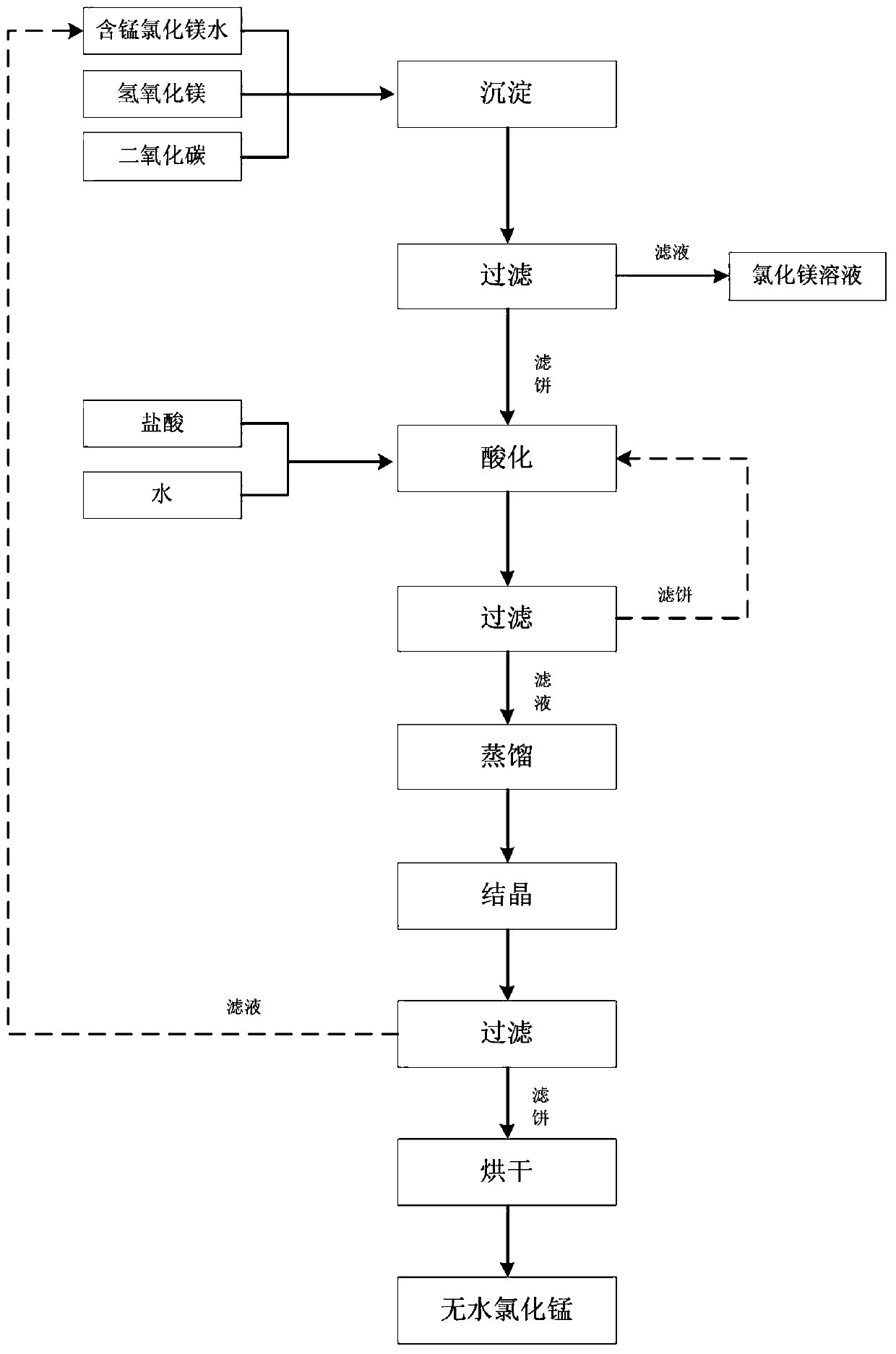

ActiveCN108046329AHigh purityReduce pollutionMagnesium chloridesManganese halidesIndustrial waste waterDistillation

The invention relates to a process for recovering magnesium and manganese elements in industrial waste water. The process comprises the following steps: step 1, determining elements in the waste water; step 2, precipitating manganese chloride; step 3, performing acidification for precipitating salts; step 4, performing distillation crystallization: performing reduced-pressure distillation on a filtrate obtained in the step 3, performing cooling to the temperature of 55 DEG C at the speed of 8-12 DEG C / h, performing heat preservation for 0.9-1.1h at the temperature of 55 DEG C, and continuing to perform cool to the temperature of 0-10 DEG C at the speed of 8-12 DEG C / h, so as to obtain a pulp; step 5, performing centrifugation and drying: pressing the pulp prepared in the step 4 into a centrifugation machine, performing centrifugation drying until no mother liquid is centrifuged out from a centrifugation outlet, so as to obtain a mother liquid and a wet product material, putting the wetproduct material into an oven, performing first drying at the temperature of 205-215 DEG C, taking out the dried material, performing smashing, and continuing to perform second drying at the temperature of 205-215 DEG C, so as to obtain anhydrous manganese chloride; and step 6, performing recovery. The process provided by the invention has the advantages of low costs, high purity and a high yield.

Owner:甘肃东港药业有限公司

Microporous aluminum salt lithium adsorbent and preparation method thereof, filler and method for enriching lithium ions

ActiveCN106076243BControl areaLarge specific surface areaOther chemical processesAlkali metal oxides/hydroxidesLithiumSorbent

The invention discloses a microporous aluminum-salt lithium adsorbent, a preparation method therefor, filler containing the microporous aluminum-salt lithium adsorbent and a lithium ion enriching method. The microporous aluminum-salt lithium adsorbent disclosed by the invention has the molecular formula of LiCl.aAl(OH)3.bH2O and has micropores, of which the average pore size is smaller than 2nm, wherein a is greater than 1 and smaller than 3, and b is greater than 0.5 and smaller than 2. The preparation method disclosed by the invention is simple, and the obtained adsorbent is large in lithium ion adsorption capacity, high in selectivity, simple in eluting regeneration and long in cycle life and can be applied to the separation and extraction of lithium from lithium-containing saline lake brine, salt-field concentrated lithium-containing senescent brine, lithium-containing medicinal wastewater and a lithium-containing solution with the mineralization degree lower than 50g / L.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

A process for recovering magnesium and manganese elements from industrial wastewater

ActiveCN108046329BHigh purityReduce pollutionMagnesium chloridesManganese halidesIndustrial waste waterCentrifugation

The invention relates to a process for recovering magnesium and manganese elements in industrial waste water. The process comprises the following steps: step 1, determining elements in the waste water; step 2, precipitating manganese chloride; step 3, performing acidification for precipitating salts; step 4, performing distillation crystallization: performing reduced-pressure distillation on a filtrate obtained in the step 3, performing cooling to the temperature of 55 DEG C at the speed of 8-12 DEG C / h, performing heat preservation for 0.9-1.1h at the temperature of 55 DEG C, and continuing to perform cool to the temperature of 0-10 DEG C at the speed of 8-12 DEG C / h, so as to obtain a pulp; step 5, performing centrifugation and drying: pressing the pulp prepared in the step 4 into a centrifugation machine, performing centrifugation drying until no mother liquid is centrifuged out from a centrifugation outlet, so as to obtain a mother liquid and a wet product material, putting the wetproduct material into an oven, performing first drying at the temperature of 205-215 DEG C, taking out the dried material, performing smashing, and continuing to perform second drying at the temperature of 205-215 DEG C, so as to obtain anhydrous manganese chloride; and step 6, performing recovery. The process provided by the invention has the advantages of low costs, high purity and a high yield.

Owner:甘肃东港药业有限公司

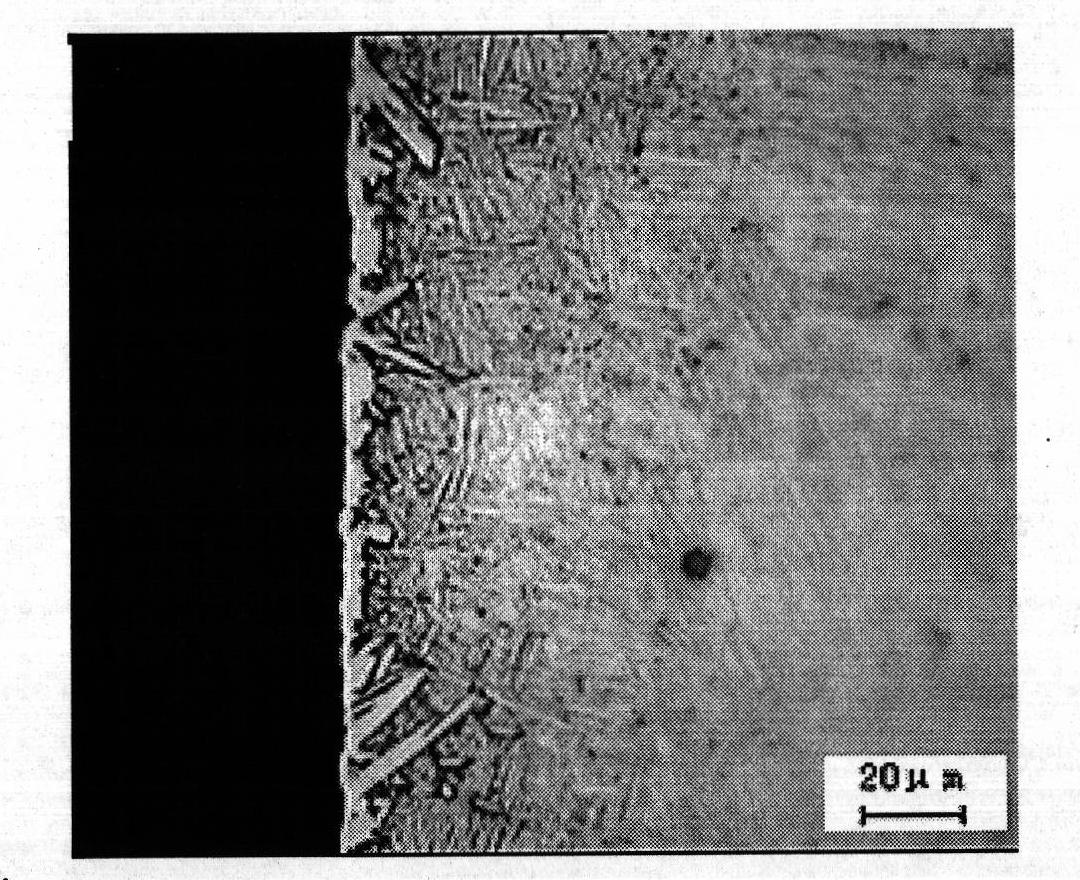

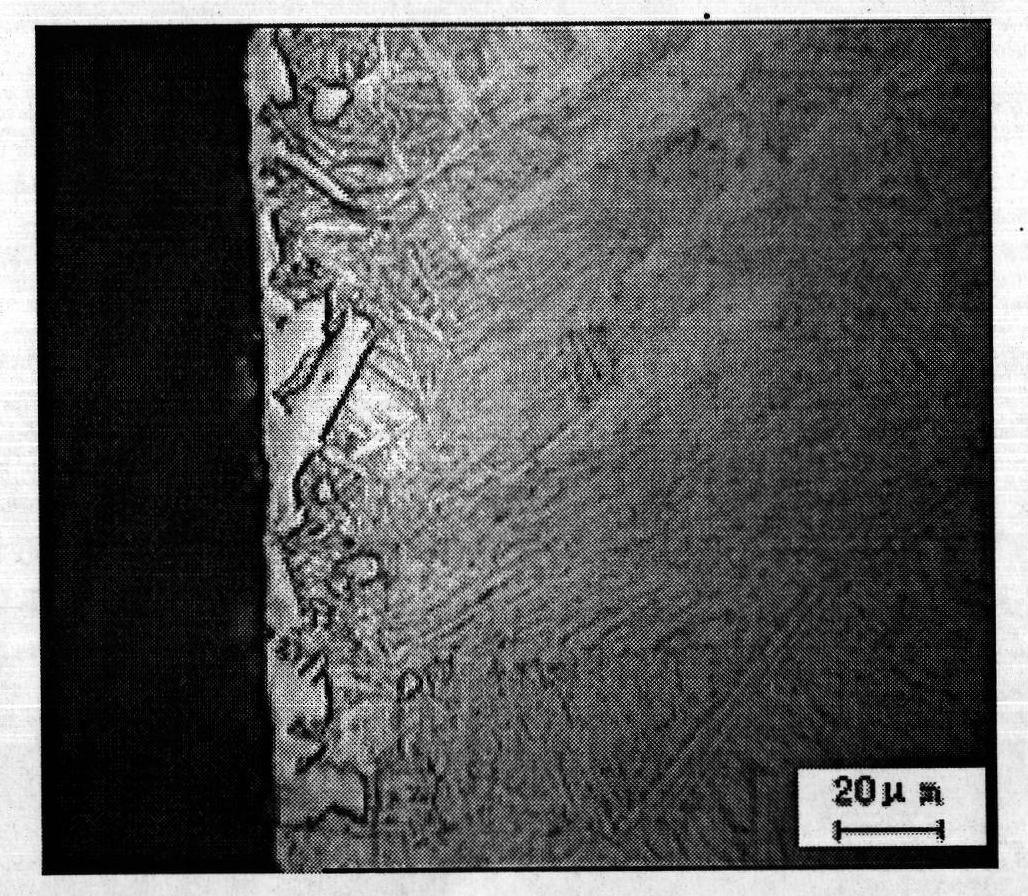

Titanium alloy surface boronizing method

InactiveCN101608296BSimple compositionEasy to manufactureSolid state diffusion coatingAdhesiveBoron carbide

The invention relates to a titanium alloy surface boronizing method belonging to the technical field of metal surface treatment. The method comprises the following steps: performing the degreasing, water washing and surface polishing pretreatment on a titanium alloy surface, pressing boron carbide powder penetrating agents with the granularity of less than or equal to 0.1 mm and the pretreated titanium alloy material into sectional materials by using a pressing machine, putting the sectional materials into a crucible and covering the crucible with a cover, sealing gaps between the cover and the crucible by using adhesives, drying the crucible, performing the heating, heat preservation and cooling treatment on the crucible at the condition of raising the temperature with the increase rate of 8-10 DEG C / min to 1000-1200 DEG C in heating and the heat preservation time of 5-20 hours, and taking out the crucible and cooling the crucible to the room temperature. The method can reduce the varieties of composition materials of bornizing agents, thereby simplifying the titanium alloy surface boronizing technology and reducing the operation conditions so as to obtain an ideal alloying thickness of titanium alloy such as TC4 and the like under the air condition, and the boronizing agent of single composition can avoid the pollution of harmful gases to the environment.

Owner:NORTHEASTERN UNIV LIAONING

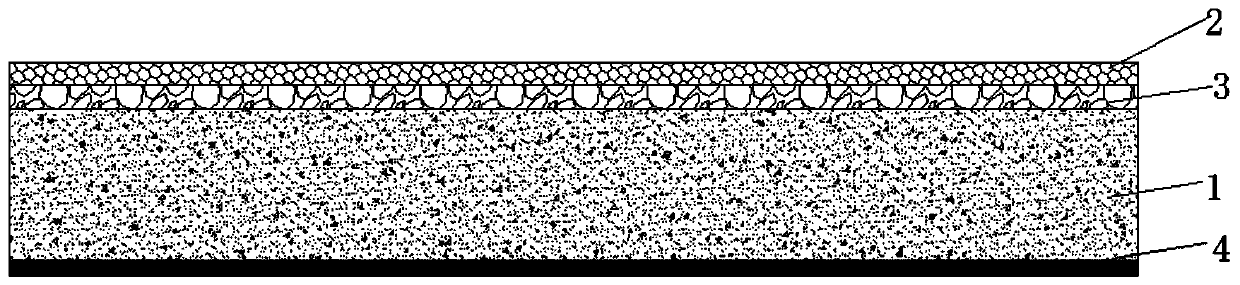

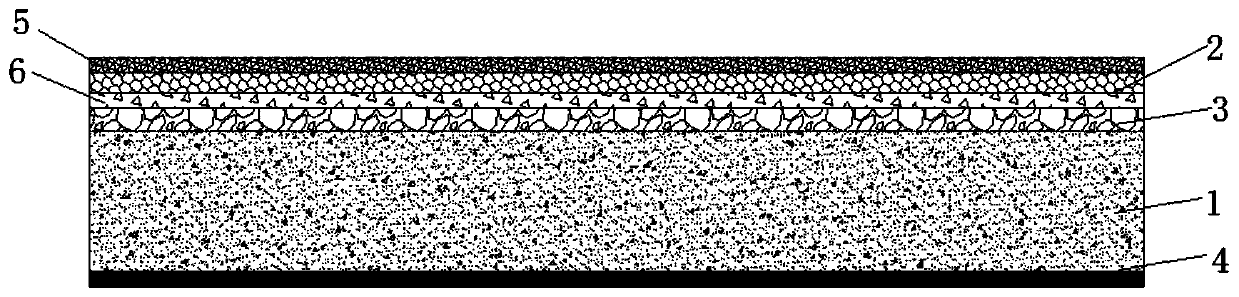

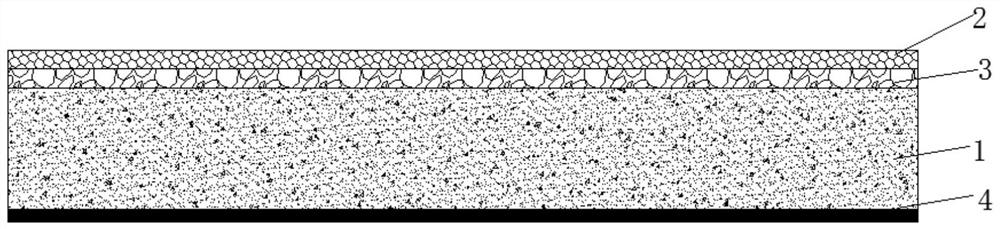

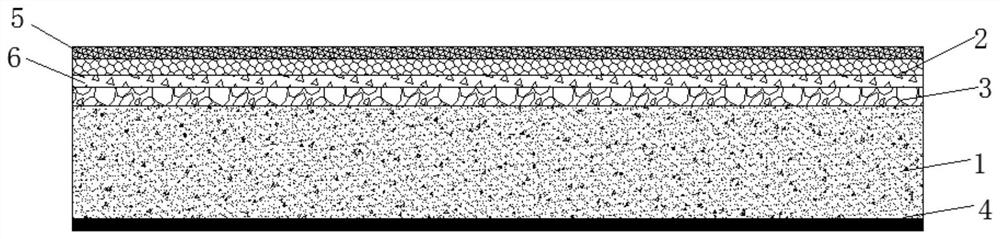

Metal and asphalt composite tile for special-shaped roof and preparation method of metal and asphalt composite tile

ActiveCN109878179ASolve installation difficultiesSolve the problem of heavy roof loadRoof covering using tiles/slatesLamination ancillary operationsFlangingAsphalt

The invention relates to a metal and asphalt composite tile for a special-shaped roof, comprising an asphalt base layer and a metal layer provided with a surface coating, wherein a bonding layer usedfor bonding the metal layer provided with the surface coating and the asphalt base layer is arranged between the asphalt base layer and the metal layer provided with the surface coating, and a protective film is arranged on the lower portion of the asphalt base layer. The metal and asphalt composite tile has the beneficial effects that the metal and asphalt composite tile has great advantages in the aspects of flexibility, a fixing mode, light weight and rich colors, and is very suitable for being applied to special-shaped roofs, such as spherical roofs and conical roofs; the bonding layer isarranged between the asphalt base layer and the metal layer provided with the surface coating, so that the metal layer provided with the surface coating is firmly bonded with the asphalt base layer; by arranging the surface coating, the effects of protecting the metal layer provided with the surface coating and decorating are achieved; a flanging used for wrapping the asphalt base layer is arranged on the metal layer provided with the surface coating, so that the waterproof material is prevented from being directly exposed in the sun and rainwater to accelerate the aging of the waterproof material.

Owner:科肯绿色(北京)科技有限公司

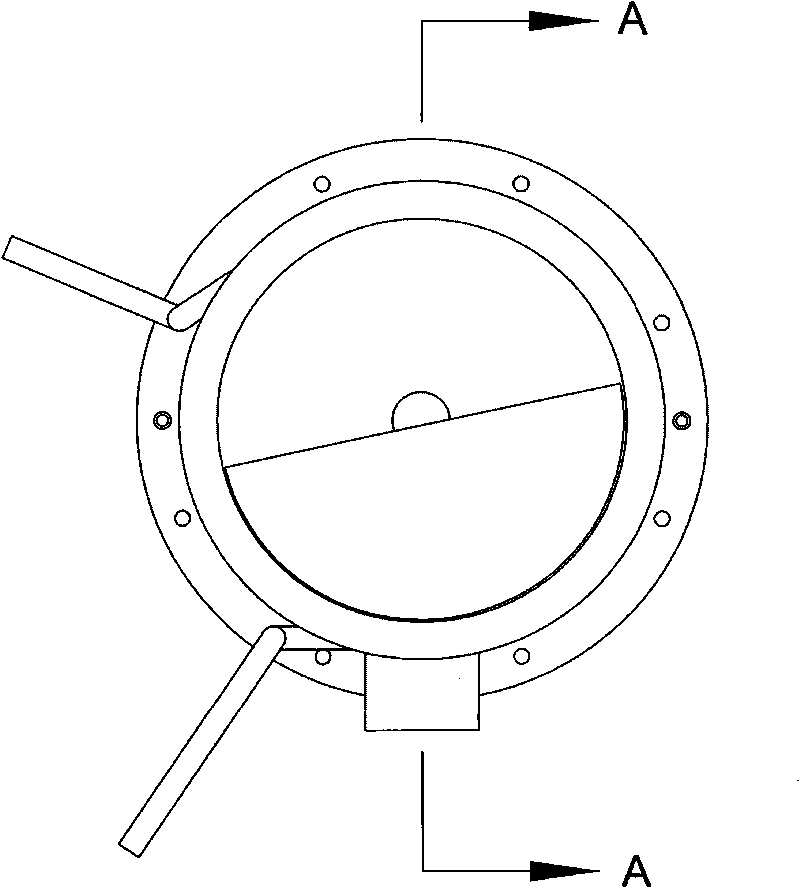

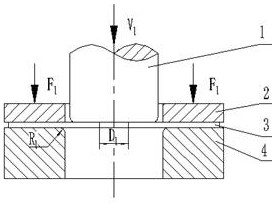

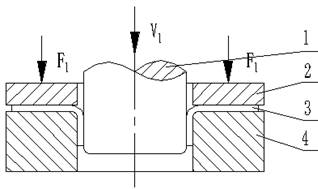

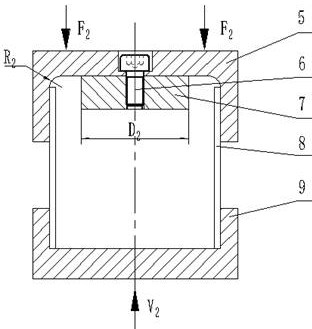

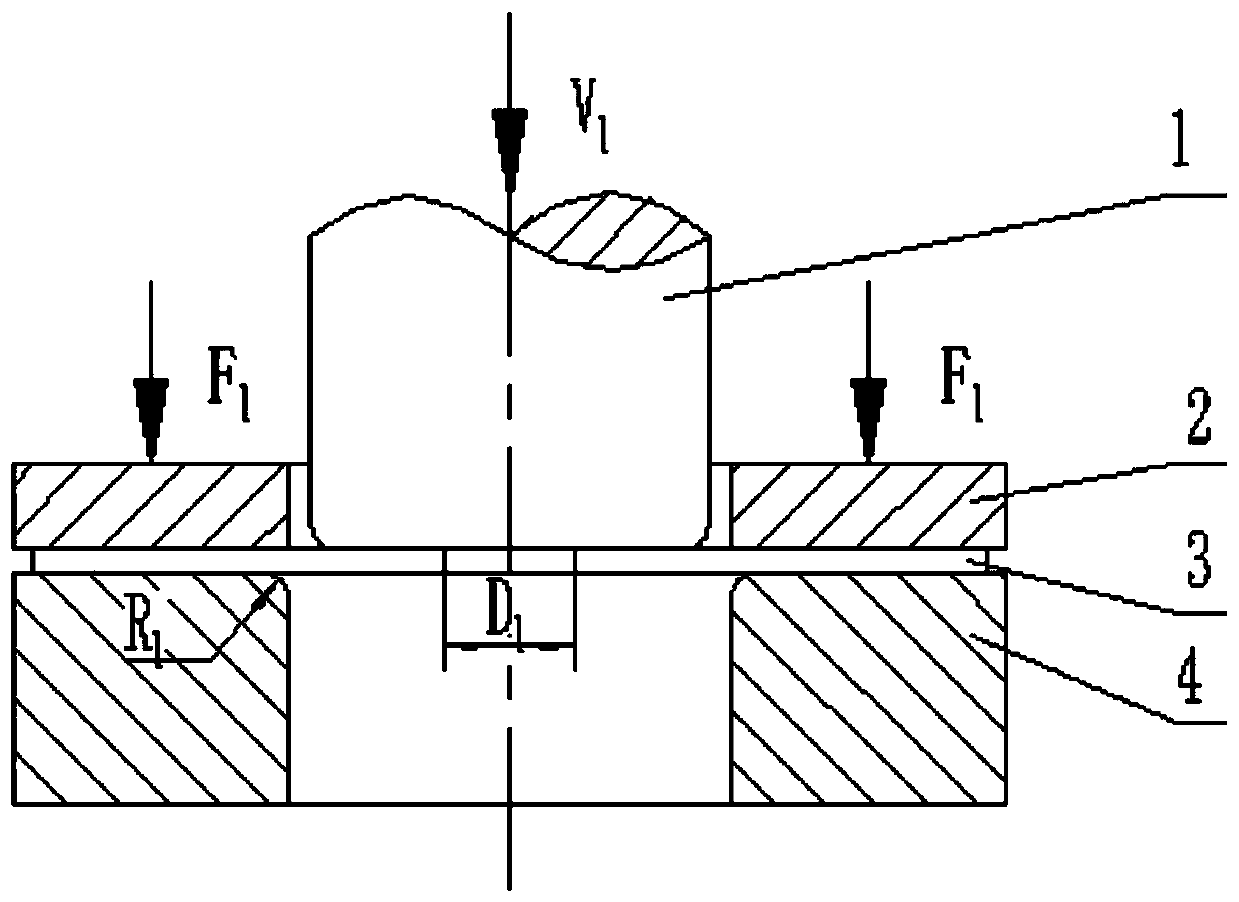

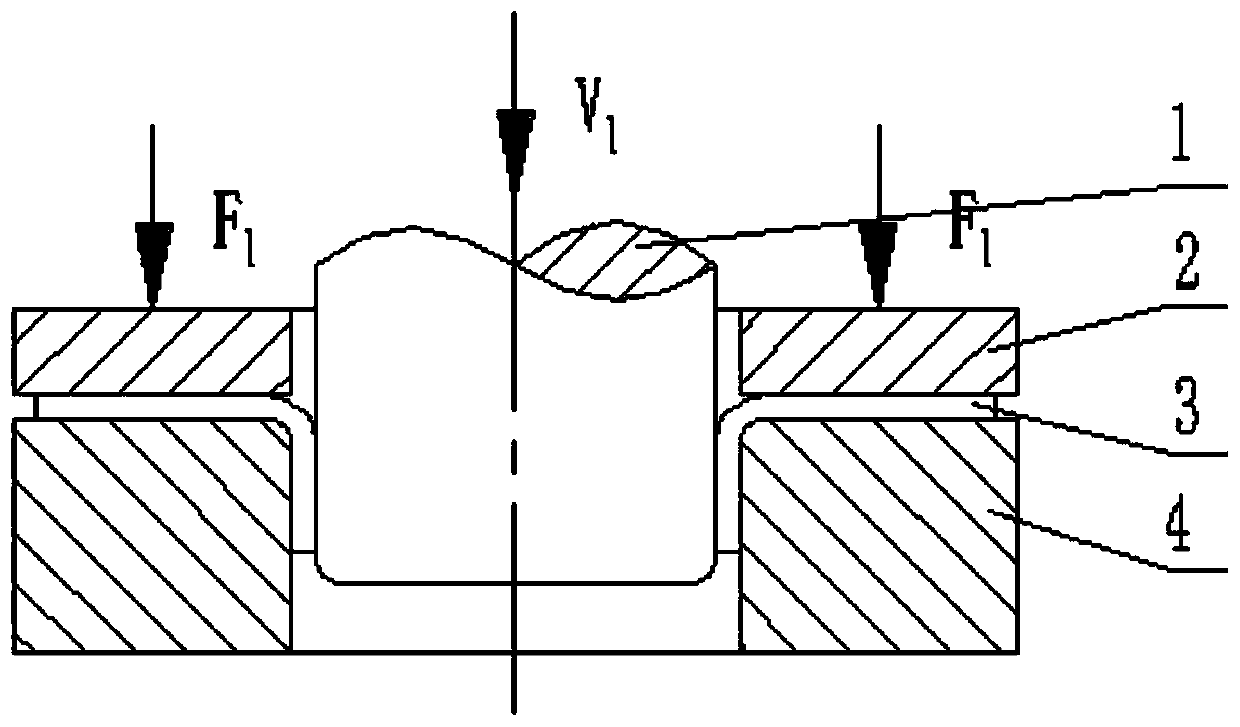

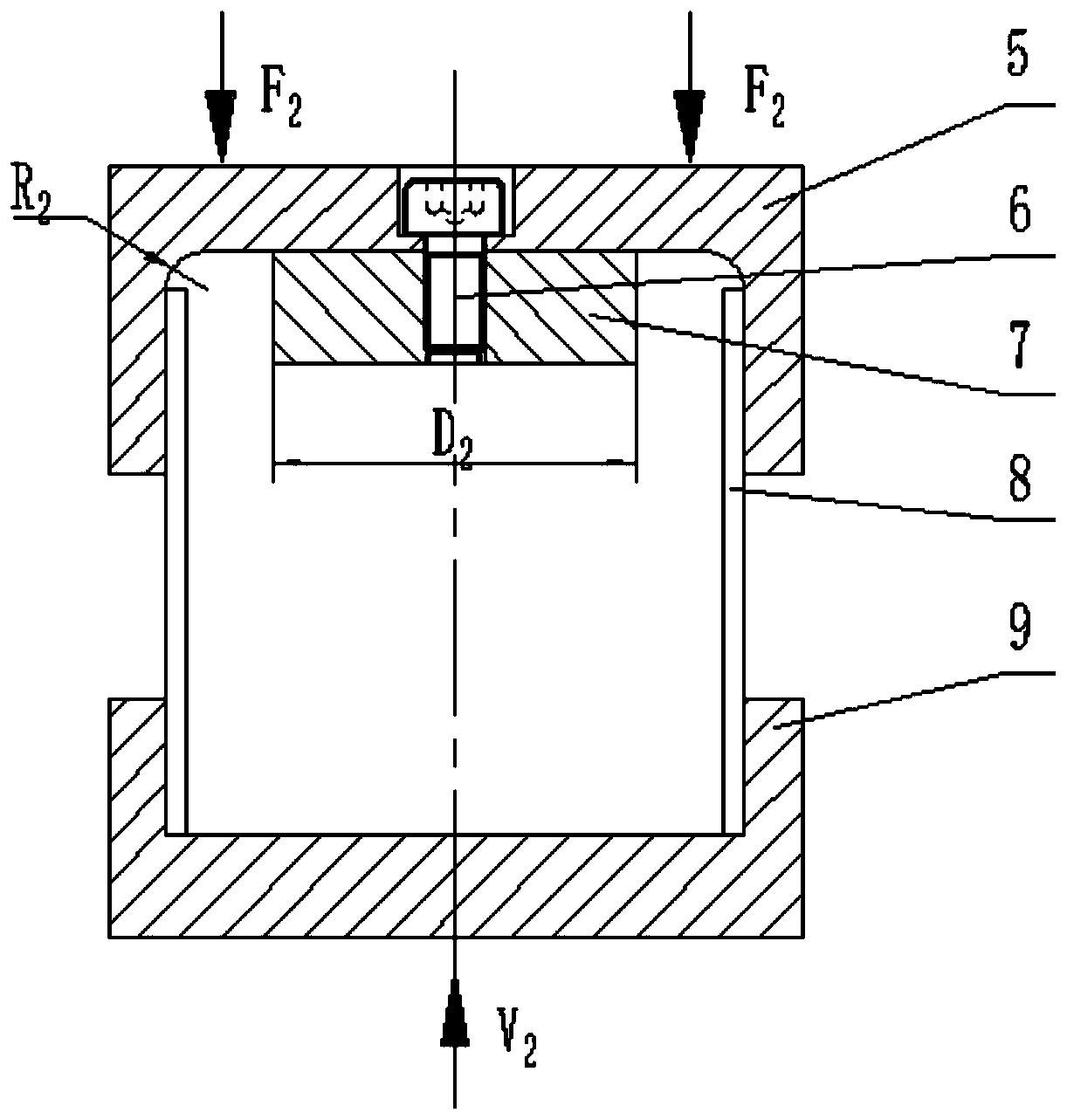

A method and device for connecting pipes and plates using plastic deformation of pipes

ActiveCN111054830BHigh strengthNo pollutionShaping toolsHigh volume manufacturingHazardous substance

The invention discloses a method and a device for realizing the connection between a pipe and a plate by utilizing the plastic deformation of the pipe, and belongs to the technical field of material connection. Combining the pre-flanging of the plate with the shrinkage cavity of the pipe, the plastic deformation of the flanging part of the plate is used to realize the plastic connection between the plate and the end of the pipe. The method is simple to operate, can use existing equipment to construct corresponding devices, has low requirements on power sources, simple steps, is suitable for mass production, molds ensure forming accuracy, high repeatability, high production efficiency, and does not pollute the environment. Plastic deformation is adopted, so that no harmful substances are produced during the entire connection process, which is environmentally friendly. The device for realizing the method has simple structure, reasonable design, convenient installation and good compatibility with conventional equipment.

Owner:SHAANXI UNIV OF SCI & TECH

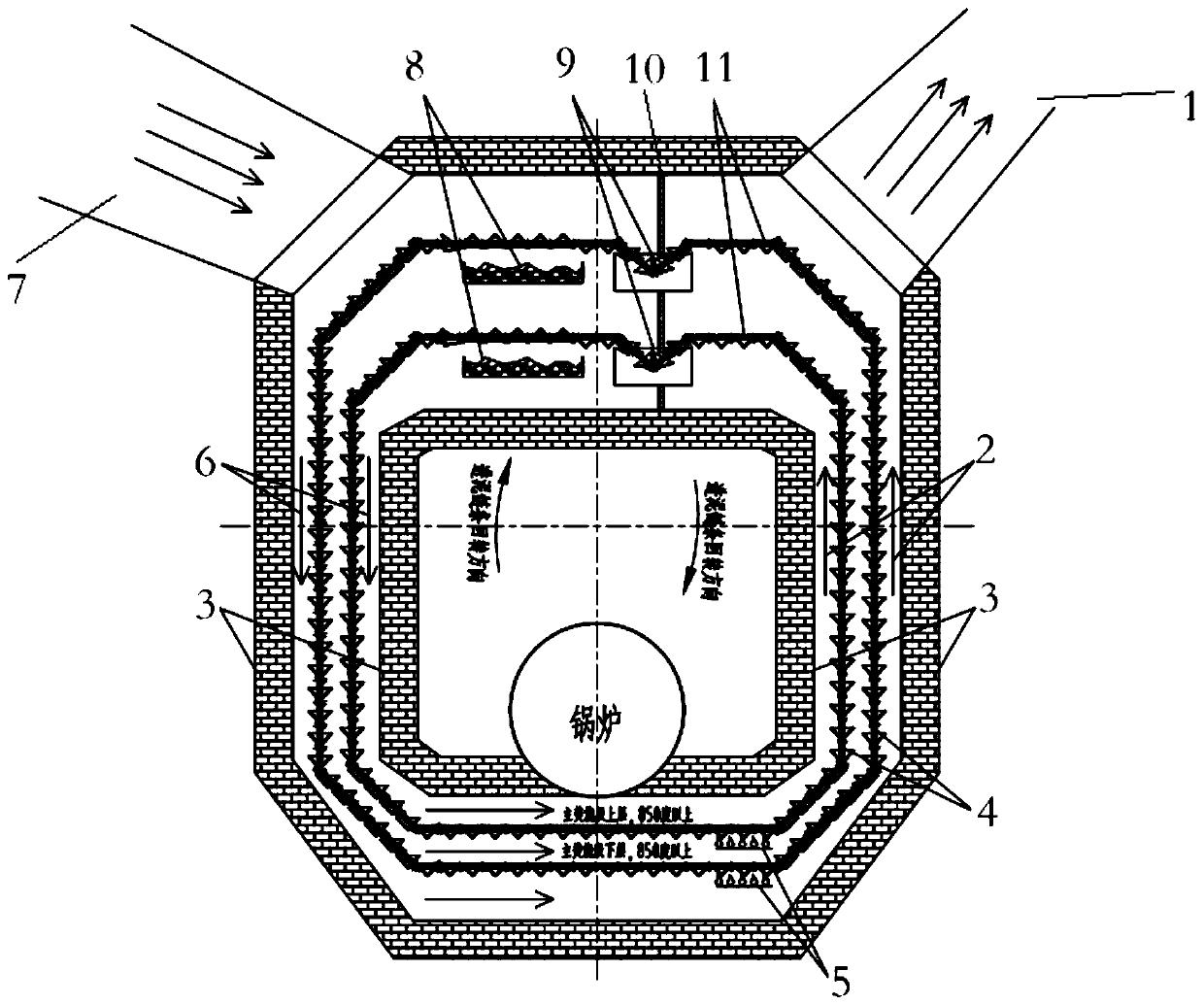

A rotary incinerator and rotary incineration method

The invention relates to the technical field of sludge drying and incineration devices and methods, in particular to a rotary incinerator and a rotary incineration method. The rotary incinerator comprises an inner wall and an outer wall. A loop-shaped working space is defined by the inner wall and the outer wall. Sludge inlet chains closed in a loop shape are arranged in the working space. A gas inlet and a gas outlet are correspondingly formed in the two sides of the top end of the working space. The upper part of the working space is provided with a discharging opening at the side the same with the gas inlet. The upper part of the working space is provided with a feeding opening at the side the same with the gas outlet. The bottom of the working space is a main incineration section. Compared with the prior art, the rotary incinerator and the rotary incineration method have the beneficial effects that no or less fly ash and dust are generated; inlet sludge is dried by high-temperatureexhaust gas after incineration, the sludge and chain buckets after the incineration are cooled by inlet air, meanwhile the inlet air is heated, preheating is fully used, and a high degree of energy saving is realized; and the application range is wide, and the rotary incinerator and the rotary incineration method not only can be used for sludge incineration, but also can be used for incinerationof other granulated combustible materials.

Owner:上海仁创环境科技有限公司

Method and device for realizing connection of pipe and plate by utilizing plastic deformation of pipe

ActiveCN111054830AHigh strengthNo pollutionShaping toolsHigh volume manufacturingHazardous substance

The invention discloses a method and a device for realizing connection of a pipe and a plate by utilizing plastic deformation of the pipe, and belongs to the technical field of material connection. The pre-flanging of the plate is combined with the shrinkage cavity of the pipe, and the plastic deformation of the flanging part of the plate is utilized to realize the plastic connection of the plateand the end part of the pipe. The method is easy to operate, capable of adopting existing equipment to construct corresponding devices, low in requirement for a power source, simple in step, suitablefor mass production, moreover, the forming precision is guaranteed through a mold, repeatability is high, production efficiency is high, and environment pollution is free. A plastic deformation modeis adopted, so that no harmful substance is generated in the whole connection process, and environmental friendliness is achieved. The device for implementing the method is simple in structure, reasonable in design, convenient to install and good in compatibility with conventional equipment.

Owner:SHAANXI UNIV OF SCI & TECH

Compound drop pills of dahurian rhododendron leaf and preparation method

InactiveCN100364509CIncrease surface areaHas a wetting effectPill deliveryRespiratory disorderDiseaseBronchitis

Owner:北京博智绿洲医药科技有限公司

Metal and asphalt composite tile for special-shaped roof and preparation method thereof

ActiveCN109878179BImprove the decorative effectAccelerated agingRoof covering using tiles/slatesLamination ancillary operationsBase courseSurface coating

The invention relates to a metal and asphalt composite tile for special-shaped roofs, comprising an asphalt base and a metal layer with a surface coating, and a surface for bonding is provided between the asphalt base and the metal layer with a surface coating. The bonding layer between the metal layer of the coating and the asphalt base, and the lower part of the asphalt base is provided with a protective film. Its beneficial effects are: the present invention has great advantages in terms of flexibility, fixing method, light-weight property and rich colors, and is very suitable for the application of special-shaped roofs, such as curved roofs such as spherical surfaces and conical surfaces; An adhesive layer is provided between the metal layers with surface coating to make the metal layer with surface coating and the asphalt base firmly bonded; by providing a surface coating, the metal with surface coating can be protected The role of layer and decoration; through the metal layer with surface coating, there is a flange for wrapping the asphalt base layer, so as to avoid the waterproof material from being directly exposed to the sun and rain to accelerate its aging.

Owner:科肯绿色(北京)科技有限公司

Process of generating combustible gas by gasification of sludge

ActiveCN104031687BSignificant reductionNot producedCombustible gas productionCombustible gasProcess engineering

The invention discloses a process for generating combustible gas by virtue of sludge gasification. The process comprises the following steps: 1, dewatering sludge; 2, granulating the dewatered sludge, airing and drying; 3, feeding dried sludge granules into an integrated sealed pyrolysis gasification device, and gradually drying, drily distilling, carbonizing, gasifying and combusting the sludge granules from top to bottom in the integrated sealed pyrolysis gasification device; and finally discharging gas generated in the device through a pipeline, collecting the gas, combusting organic matter residues and inorganic matters at high temperature to obtain harmless molten slag, and discharging the molten slag through a slag outlet. According to the process, 200 tons of sludge with the water content of less than 60% can be treated by a monomer gasification device each day; the reduction, the harmlessness and the energization of the sludge treatment are realized; the dioxin generation conditions are avoided; the operating cost is low, namely a large quantity of manpower cost can be reduced due to automated operation and management; 1 ton of sludge with the water content of less than 30% can be averagely gasified to generate 1600Nm<3> of combustible gas.

Owner:河南华天环保科技有限公司

Method for preparing biological powder fuel by using peony pods and seed coats

The invention relates to a biological powder fuel and a preparation method thereof. According to the invention, pods and seed coats of a reproducible perennial woody plant peony are prepared into the biological powder fuel. The preparation method comprises the steps that: (1) material selecting is carried out, wherein impurities such as sand, stone, and metal should be removed from selected raw materials; and the raw materials are boxed or bagged for layer use; (2) crushing is carried out, wherein the raw materials peony pods and seed coats are crushed in a crusher, until required particle sizes are reached; (3) material blending is carried out, wherein peony pod powder and seed coat powder are well mixed according to a certain ratio; and (4) detection is carried out, wherein each ton of the product is detected 5 times for ensuring that the particle size reaches a requirement. During the preparation process, no additive is adopted, the process is simple, and energy consumption is low. With the fuel, no harmful gas is generated during combustion, and the fuel is economical and practical. With the method, the prepared peony pod and seed coat biomass powder fuel has an average heat value of approximately 4000Kcal / kg, which is equivalent to that of medium-heat-value coal. The peony pod and seed coat biomass powder fuel assists in supplementing conventional energy shortage, and has good economic and social benefits.

Owner:NORTHEAST FORESTRY UNIVERSITY +1

Compound liver-benefiting dropping pill for treating hepatitis and its preparing method

InactiveCN1315470CIncrease surface areaHas a wetting effectDigestive systemAntiviralsDiseaseDrug content

The present invention discloses a Chinese medicine composition with the actions of boosting liver, enriching kidney, removing toxic material and dispelling dampness for curing the diseases of hypochondriac pain, reduced food intake, obdominal distention, aching lumbus, lack of strength and yellow urine, etc. due to deficiency of liver-yin and kidney-yin and noxious dampness. Said Chinese medicine composition can be made into compound Yiganling dripping pills, and is made up by using Chinese medicine Yiganling powder and Wurenchun extract as raw material and medicinal carrier as matrix through a certain preparation process.

Owner:北京博智绿洲医药科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com