Hard ice maker evaporator, winding clamp for condensation copper pipe and winding method thereof

A winding method and evaporator technology, which is applied to evaporators/condensers, refrigerators, frozen desserts, etc., can solve the problems of poor refrigeration effect, complicated production process, and many operators, and achieve excellent refrigeration effect and preparation The process is simple and the effect of not polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

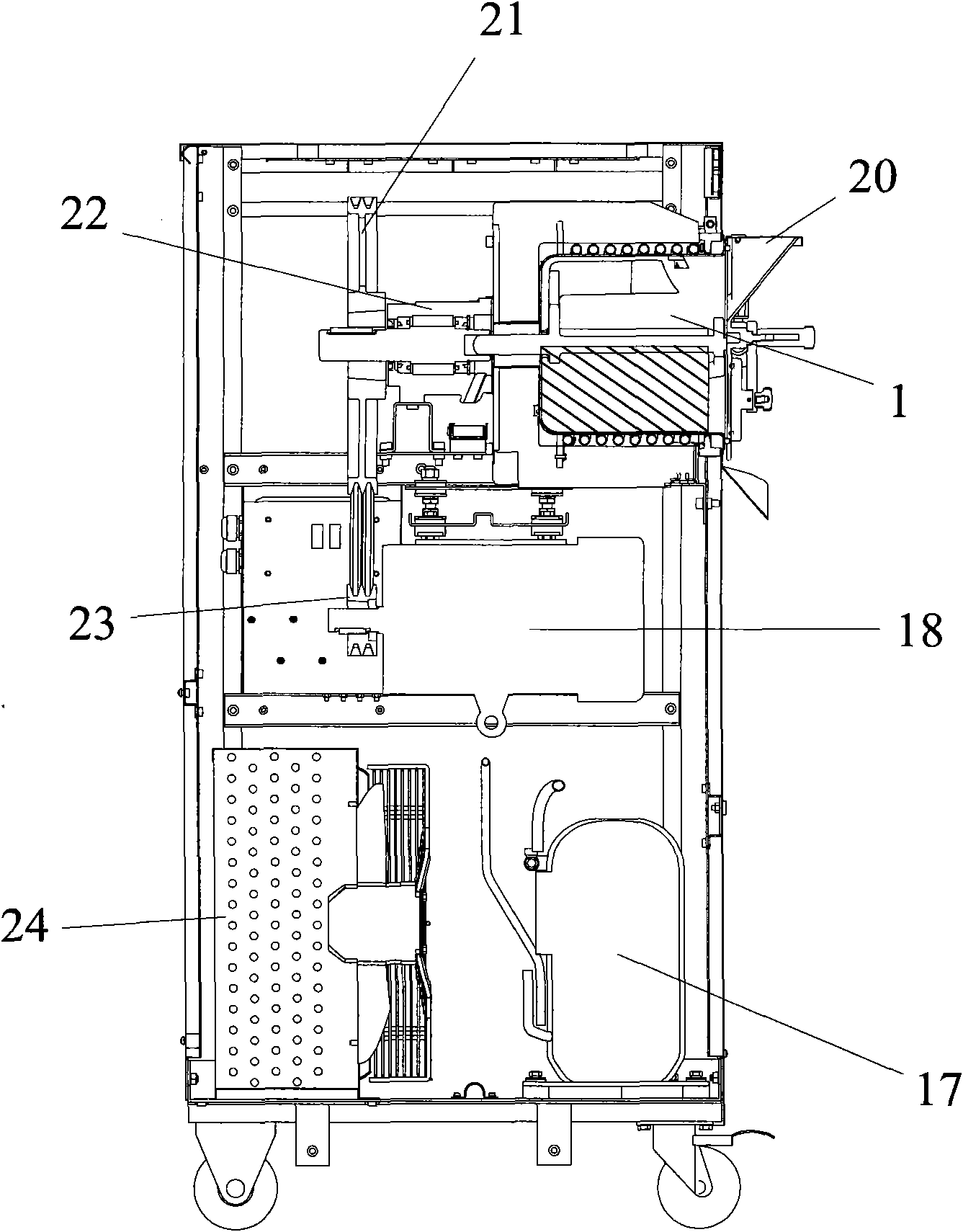

[0026] see figure 1 , as shown in the figure, the hard ice cream machine has a body, a discharge door assembly 20 is installed on the body, and a motor 18, a compressor 17, a condenser 24, a large pulley 21, a small pulley 23, and a discharge door assembly 20 are built in the body. The connected evaporator 1 and the base 22 connected with the evaporator 1 .

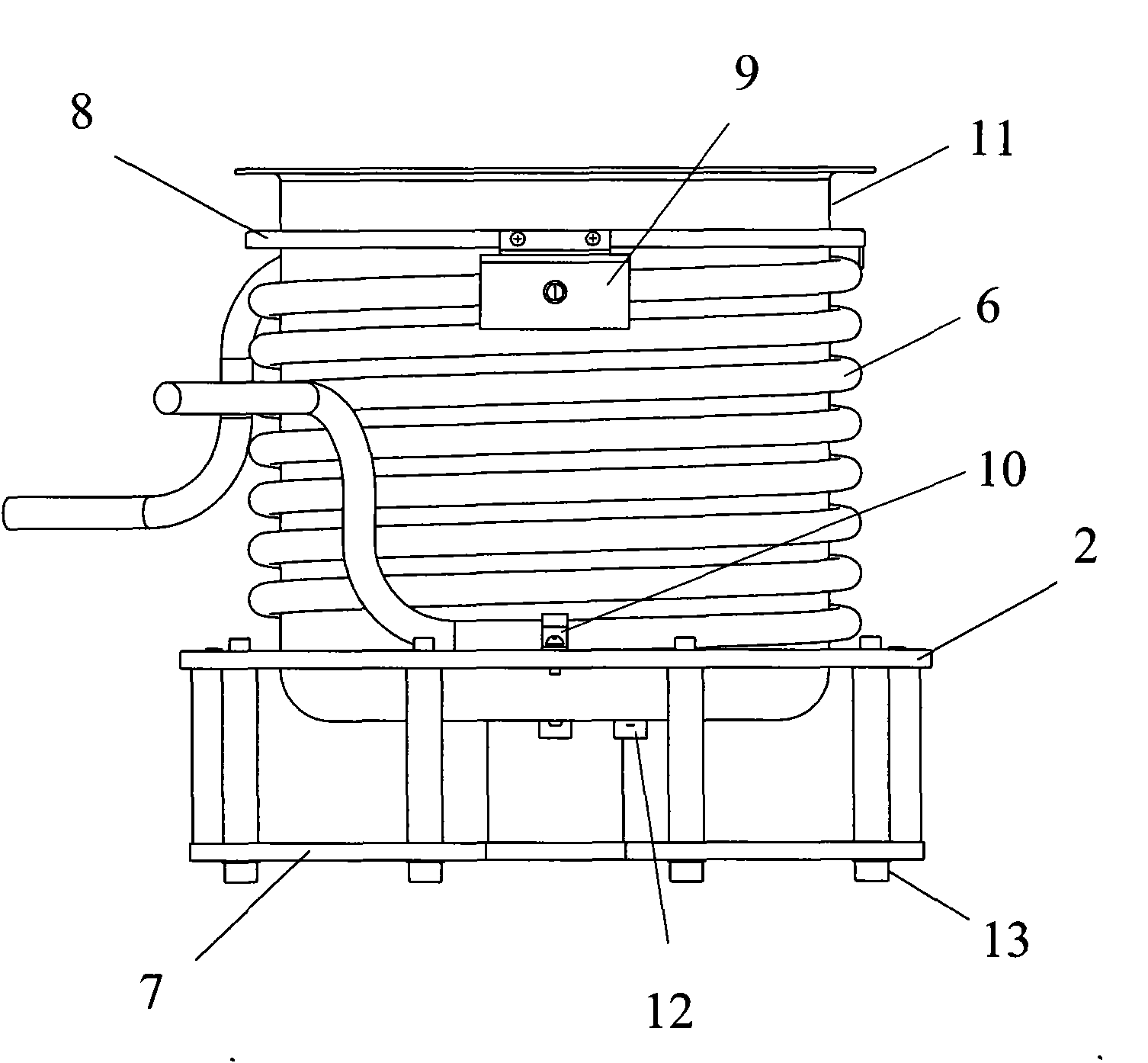

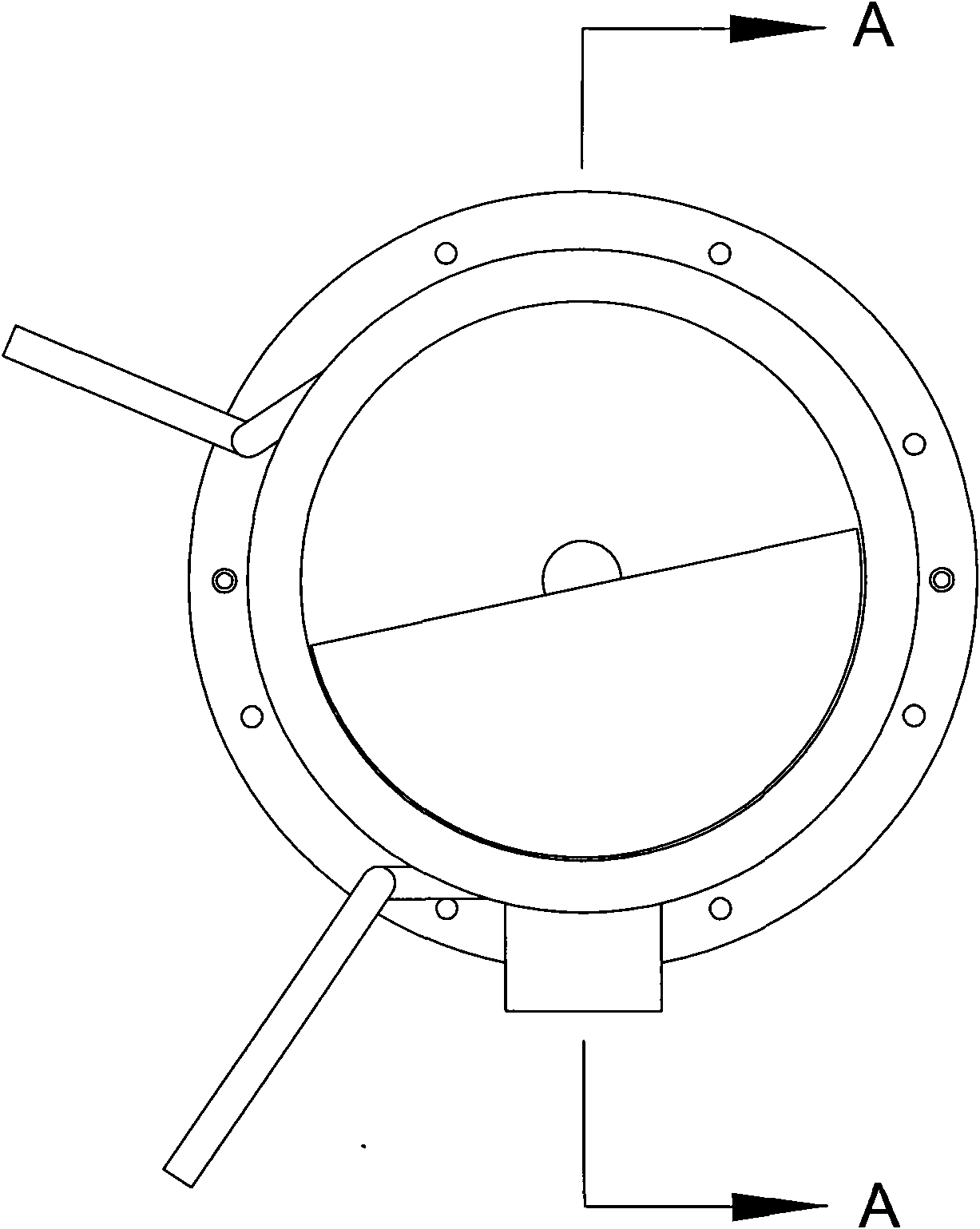

[0027] Please also refer to Figure 2 to Figure 4 , as shown in the figure, the hard ice machine evaporator further includes: a cylinder body 11, a front welding plate 8 installed at the front end of the cylinder body 11, a rear welding plate 2 installed at the rear end of the cylinder body 11, and the rear welding plate 2 passes through Several locking pieces are connected to the bottom plate 7, the rear welding plate 2 has a certain height interval from the bottom plate 7, the short sleeve 5 at the bottom of the cylinder body 11 abuts against the bottom plate 7, and condensed copper is tightly wound on the periphery of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com