A kind of preparation method of methyl tributylketoxime base silane

A technology of methyl tributyl ketone oxime and methyl trimethoxysilane, which is applied in the field of preparation of methyl tributyl ketone oxime silane, can solve the problems that the process cannot be carried out continuously, easy to produce filter residue, unsafe process, etc., and achieves Easy to separate and purify, increase product yield, optimize process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

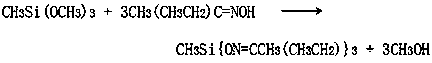

Method used

Image

Examples

Embodiment 1

[0021] Put 340g of methyltrimethoxysilane, 1305g of butanone oxime and 3g of p-toluenesulfonic acid into a 2000ml three-necked reaction flask, turn on the magnetic stirring, control the magnetic stirring at 300 revolutions per minute, and adopt the temperature programming method for the reaction temperature, and the reaction temperature is controlled at 65°C-153°C, the reaction time is 6 hours, that is, the average temperature rises 14.7°C per hour. During the reaction, methanol is recovered while reacting, and a semi-finished product is obtained after the reaction. The semi-finished product recovers excess butanone oxime through vacuum distillation, washes and filters the methyl tributylketoxime silane product obtained at the bottom of the bottle, and finally obtains 737g of methyl tributylketoxime silane product, which has 10 colors. The rate reaches 97.9%, and the product content is 98.7%.

Embodiment 2

[0023] Put 340g of methyltrimethoxysilane, 1305g of butanone oxime and 2g of p-toluenesulfonic acid into a 2000ml three-necked reaction flask, turn on the magnetic stirring, control the magnetic stirring at 300 revolutions per minute, and adopt the temperature programming method for the reaction temperature, the reaction temperature is controlled at 65°C-135°C, the reaction time is 7 hours, that is, the average temperature rises by 10°C per hour. During the reaction, methanol is recovered while reacting, and a semi-finished product is obtained after the reaction. The semi-finished product recovers excess butanone oxime through vacuum distillation, washes and filters the methyl tributylketoxime silane product obtained at the bottom of the bottle, and finally obtains 730g of methyl tributylketoxime silane product, which has 10 colors. The rate reaches 97.0%, and the product content is 98.5%.

Embodiment 3

[0025] Put 340g of methyltrimethoxysilane, 1305g of butanone oxime and 3.4g of catalyst p-toluenesulfonic acid into a 2000ml three-necked reaction flask, turn on the magnetic stirring, control the magnetic stirring at 300 revolutions per minute, and adopt the temperature programming method for the reaction temperature. The temperature is controlled at 85°C-153°C, and the reaction time is 7 hours, that is, the average temperature increase is 9.7°C per hour. During the reaction, methanol is recovered while reacting, and a semi-finished product is obtained after the reaction. The semi-finished product recovers excess butanone oxime through vacuum distillation, washes and filters the methyl tributylketoxime silane product obtained at the bottom of the bottle, and finally obtains 740g of methyl tributylketoxime silane product, the product is 10 colors, and the product is collected The rate reaches 98.3%, and the product content is 99.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com