Patents

Literature

176results about How to "Significant reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

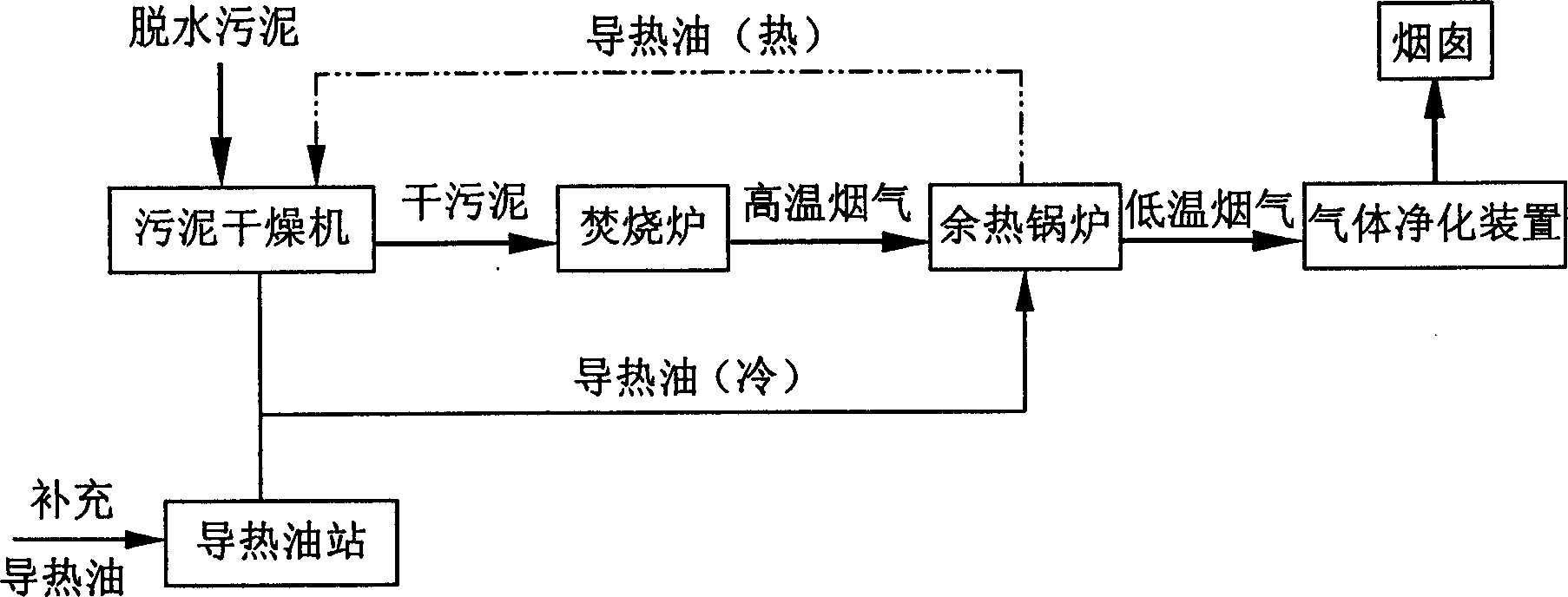

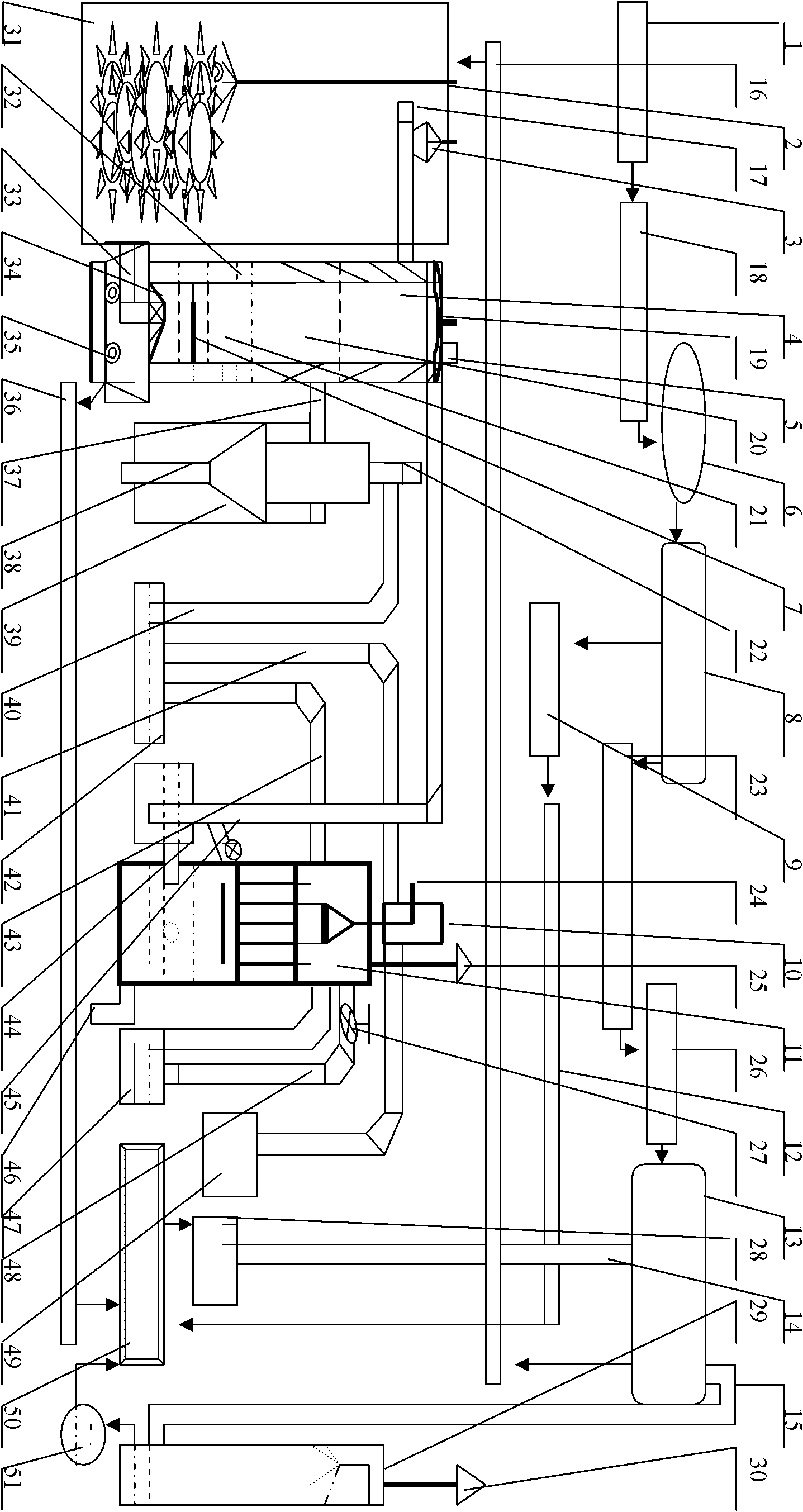

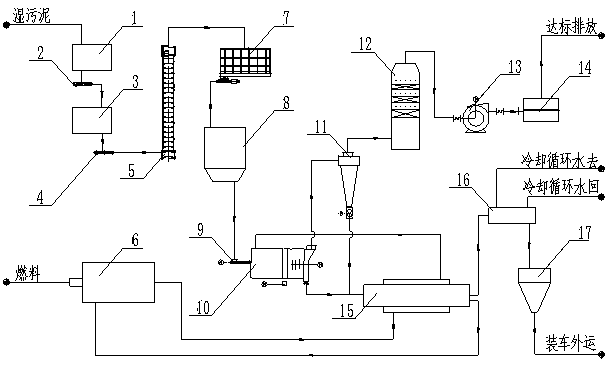

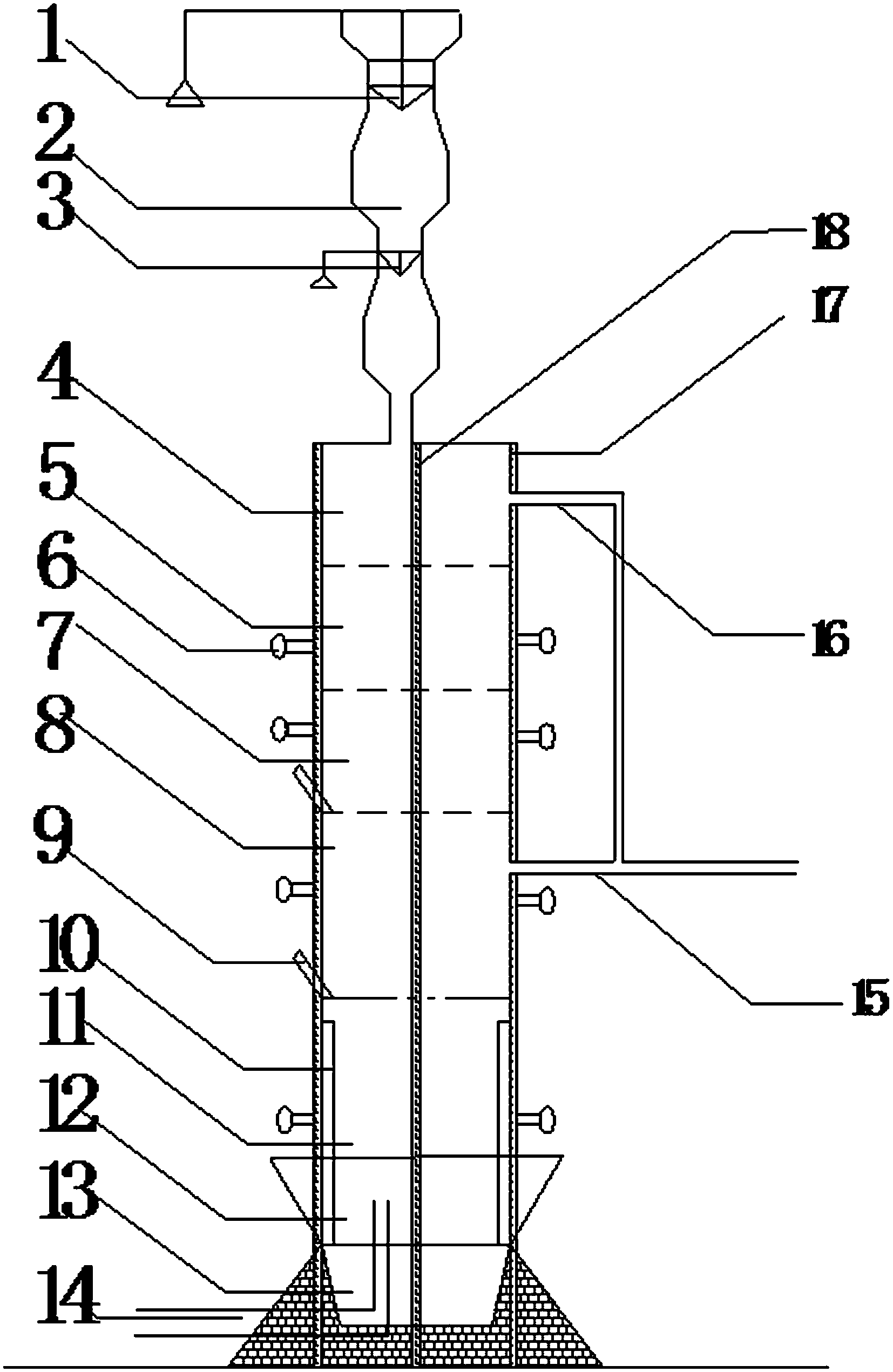

Sludge anhydration and burning process, and its systematic device

ActiveCN1800062ALow investment costLow running costSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationAir preheaterHeat conducting

The invention relates to a sludge drying and burning technique and its system devices, applying to the handling of active sludge in urban sewage treatment plants, its process flows through: wet sludge stock house, measuring bin, sludge mixer, sludge dryer, granular splitter, cooler, drying products storage bin, incinerator, smoke gas cleaning devices, which is characterized by: said incinerator is bubbling fluid bed incinerator with coal economizer, air heater fixed in its end part, high-heat smoke gas generated by burning is used to heat heat-conducting oil and cool air individually, and heat-conducting oil after being heated is transferred to sludge dryer through the circulating pump to dry wet-sludge. The invention is characterized by: take heat-conducting oil as heating medium, use the heat generated by burning dry sludge to heat heat-conducting oil and then dry wet-sludge to make full use of resources; the volume-reducing quantity after drying and burning could reach over 90%; the percentage of desulphurization in incinerator could reach 75% as a result of adopting two stage technology of sulfur removal, and the gross percentage of desulphurization meets national environmental legislation requirements. The invention accomplishes the resources, volume reduction, and innocence of sludge.

Owner:贵州筑信水务环境产业有限公司

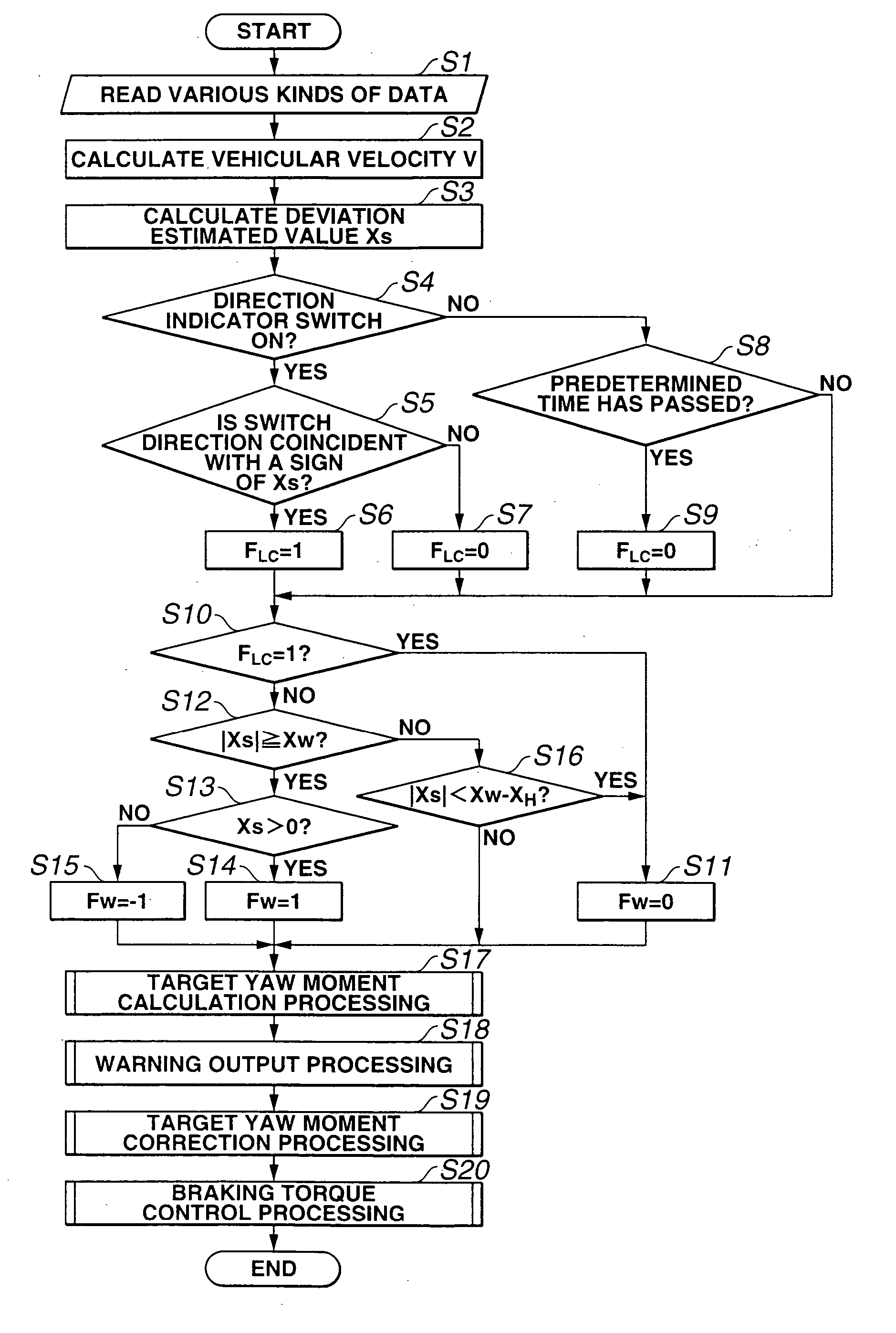

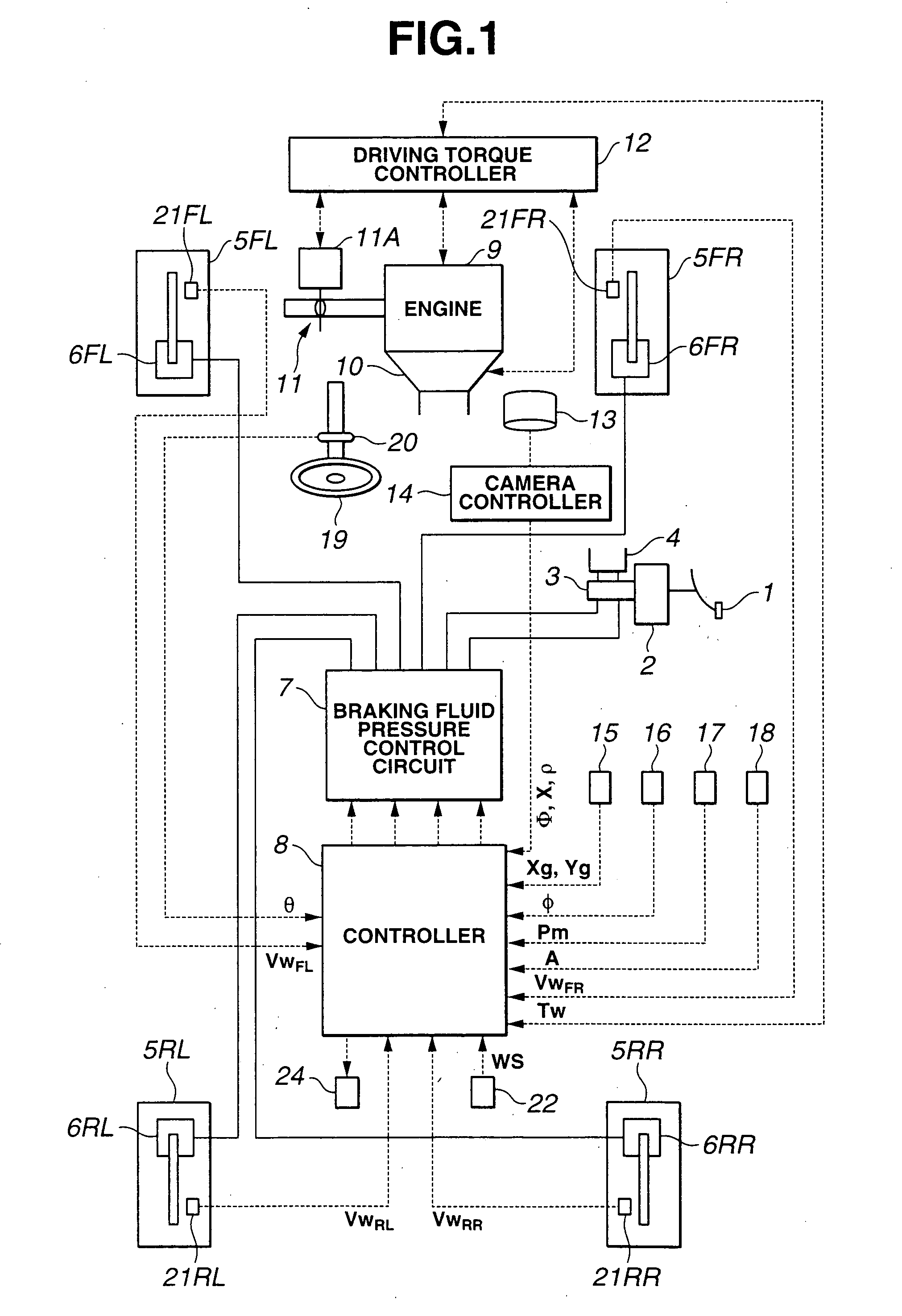

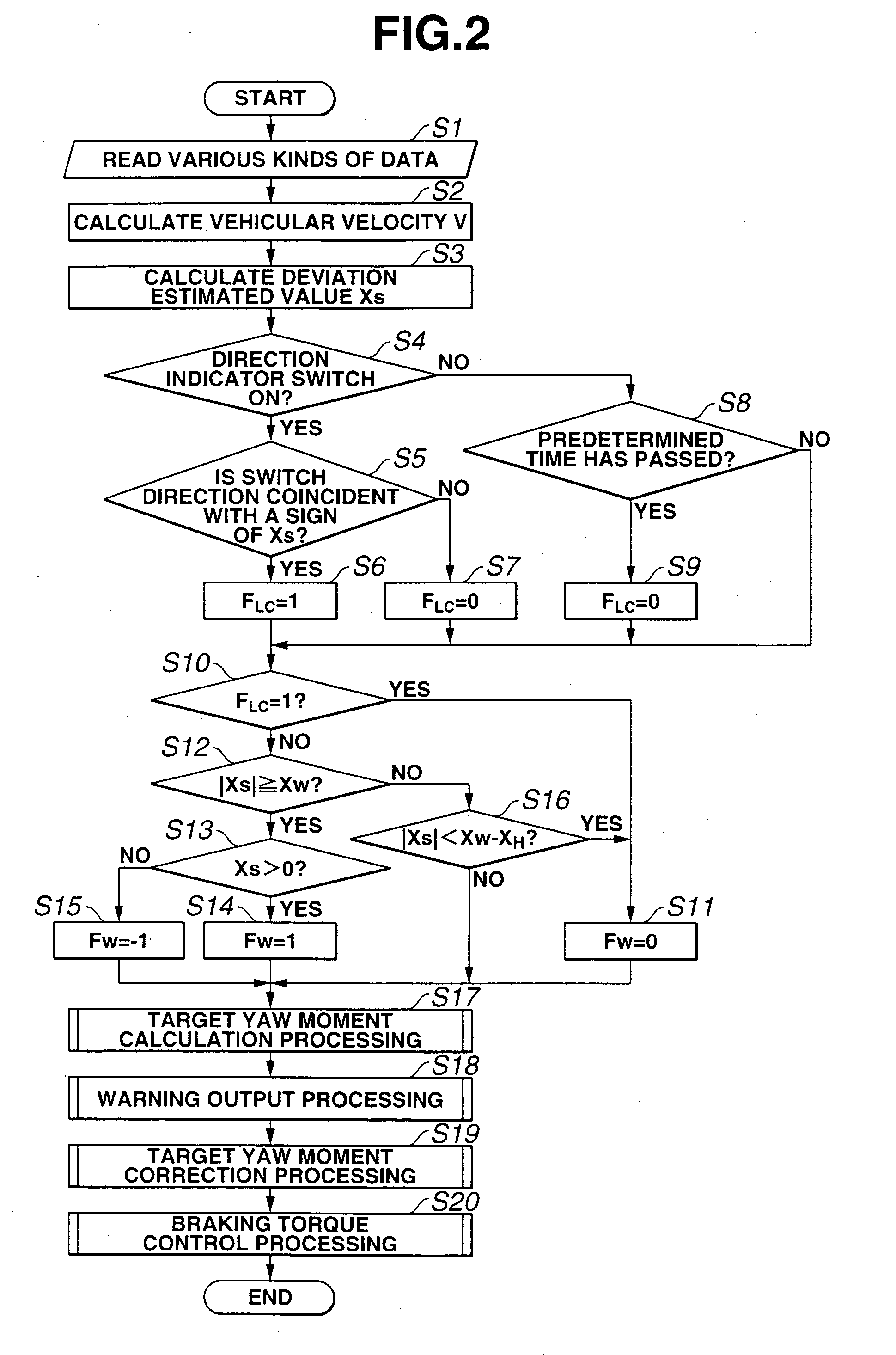

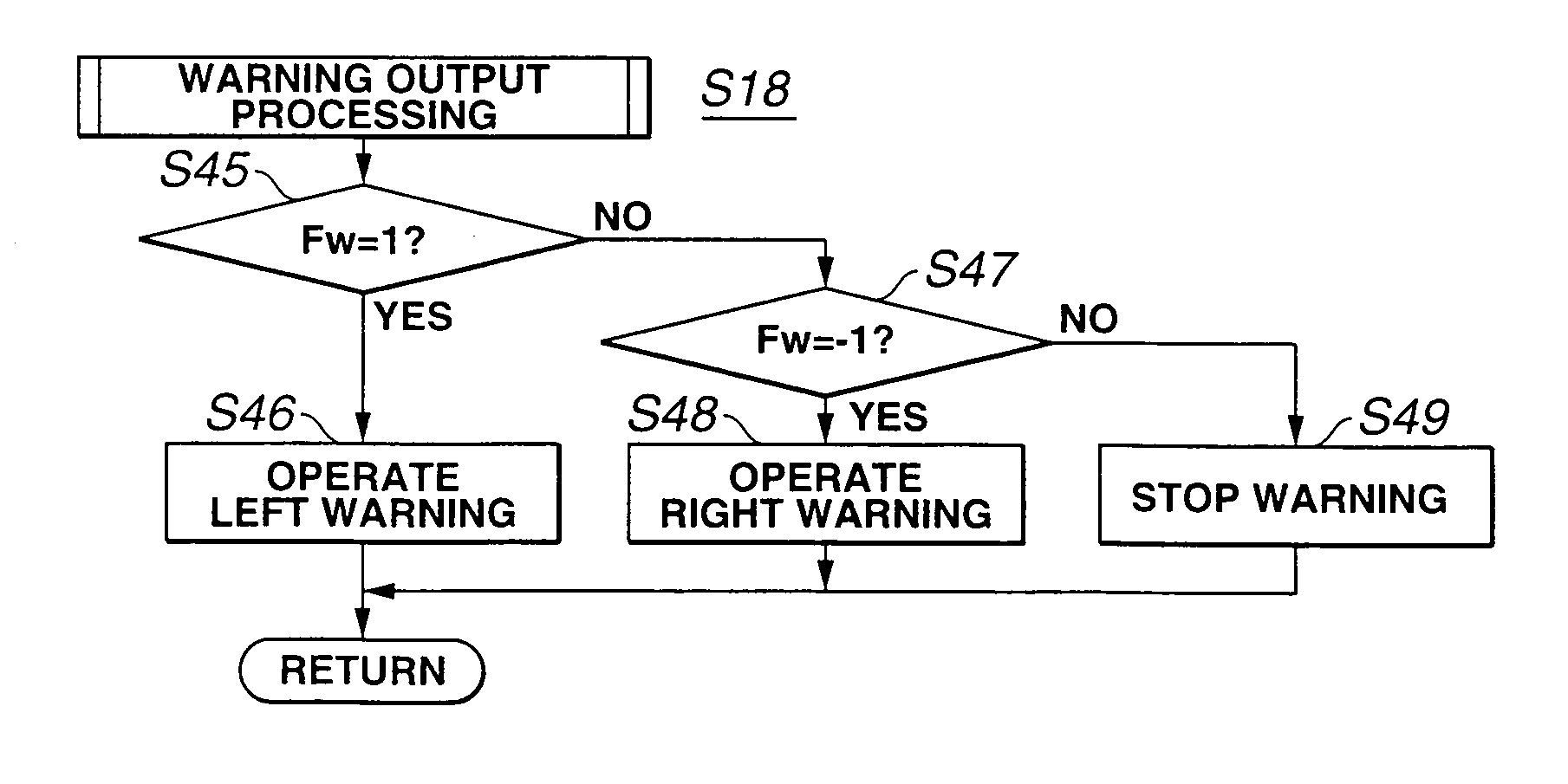

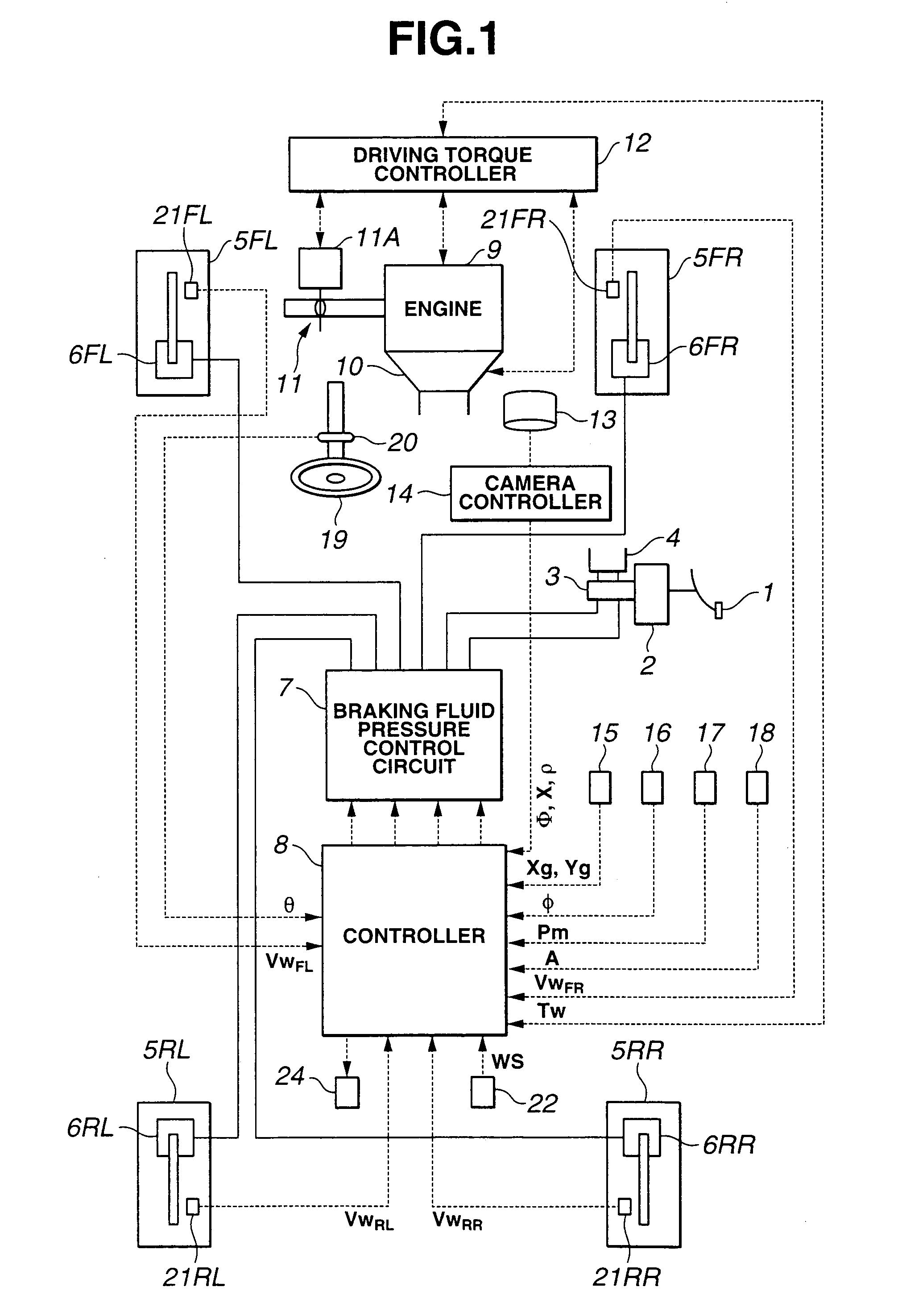

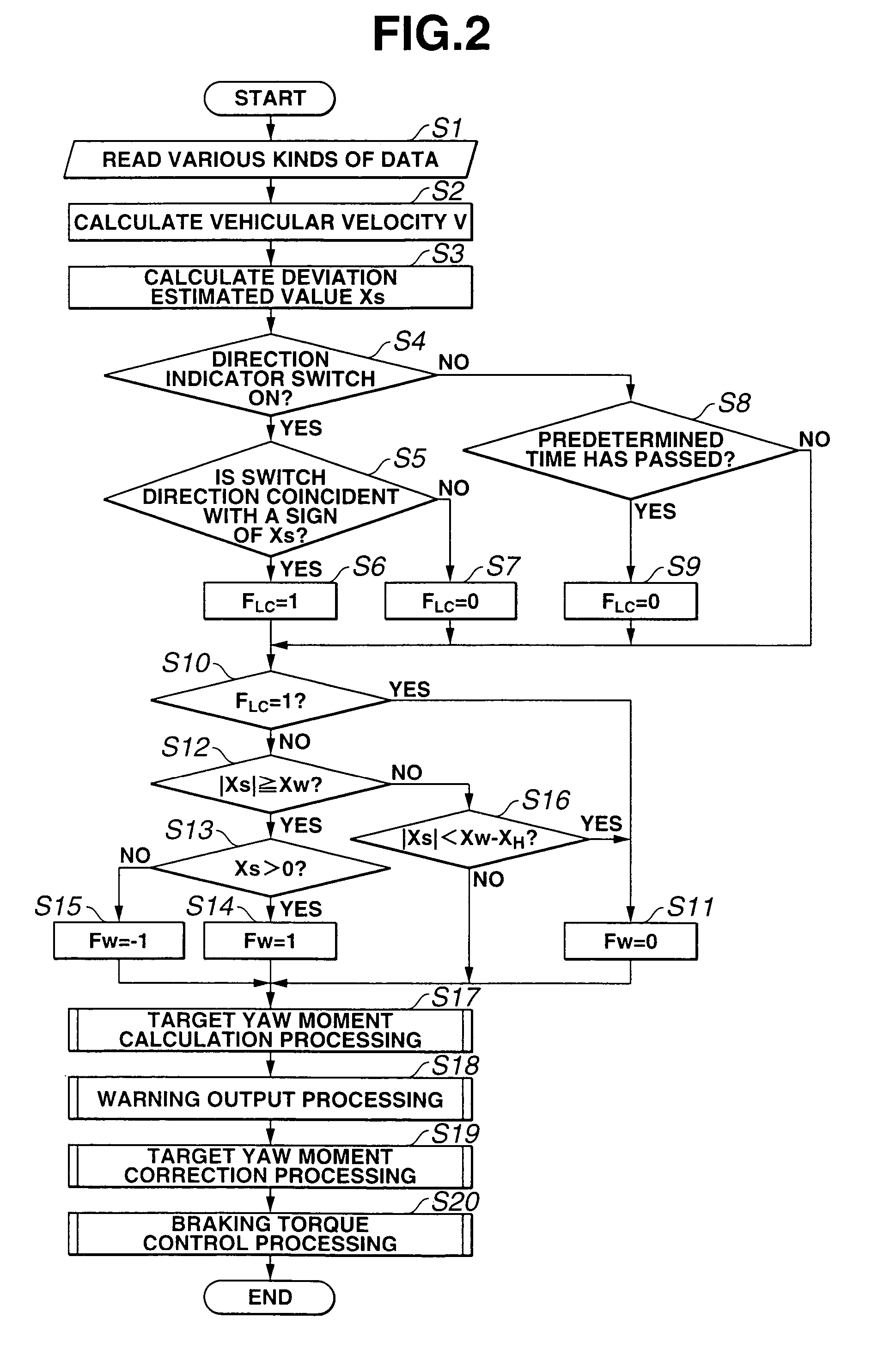

Lane keep control apparatus and method for automotive vehicle

ActiveUS20050107931A1Vehicle speed largeLane deviation can be preventedDigital data processing detailsAnti-collision systemsSteering angleMotorized vehicle

In lane keep control apparatus and method for an automotive vehicle, a traveling state of the vehicle is detected, a determination is made on whether the vehicle has a tendency of a deviation from the traveling traffic lane according to the detected traveling state, a deviation avoidance control is executed for the vehicle in a direction to avoid the deviation according to the traveling state, steering angles before and after a start of the deviation avoidance control are detected, and a controlled variable of the deviation avoidance control is detected on the basis of a deviation between a steering angle before the start of deviation avoidance control and that after the start of deviation avoidance control when a determination is made that the vehicle has the tendency of the deviation.

Owner:NISSAN MOTOR CO LTD

Method for producing highly purified, granular silicium

InactiveUS7001579B2Minimum formation of dustMinimizing reactionSiliconChemical/physical processesHydrogen halideHydrogen

The invention relates to a method for producing granular silicon by thermal decomposition of a gas containing silicon in a fluidized bed, said decomposition occurring in the presence of free-flowing mobile elements. Preferably, said free-flowing mobile elements become devoid of silicon in a separate procedural step, said silicon being deposited during decomposition of gas containing silicon, by reacting with hydrogen halides, halogens, alkyl halogenides, aryl halogenides or combinations of halogen and / or hydrogen halide and / or oxidized mineral acids and / or by thermal treatment of said elements.

Owner:SOLARWORLD

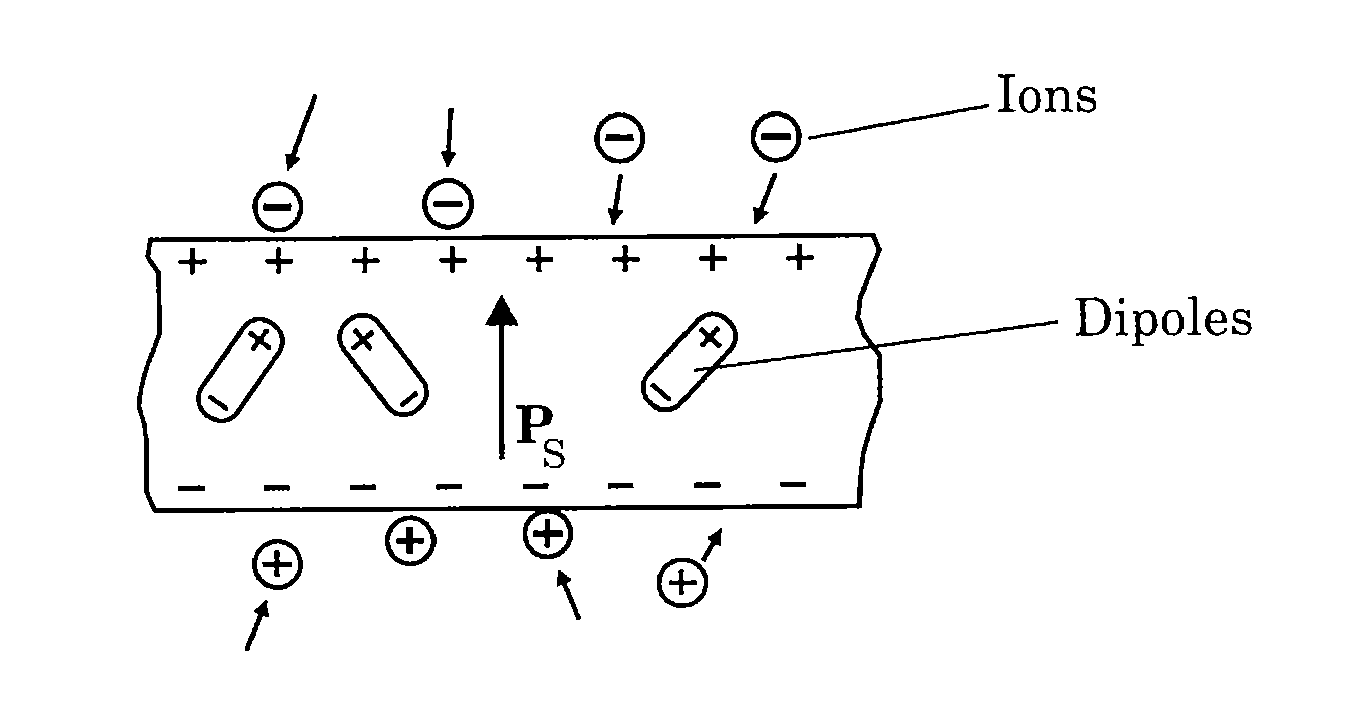

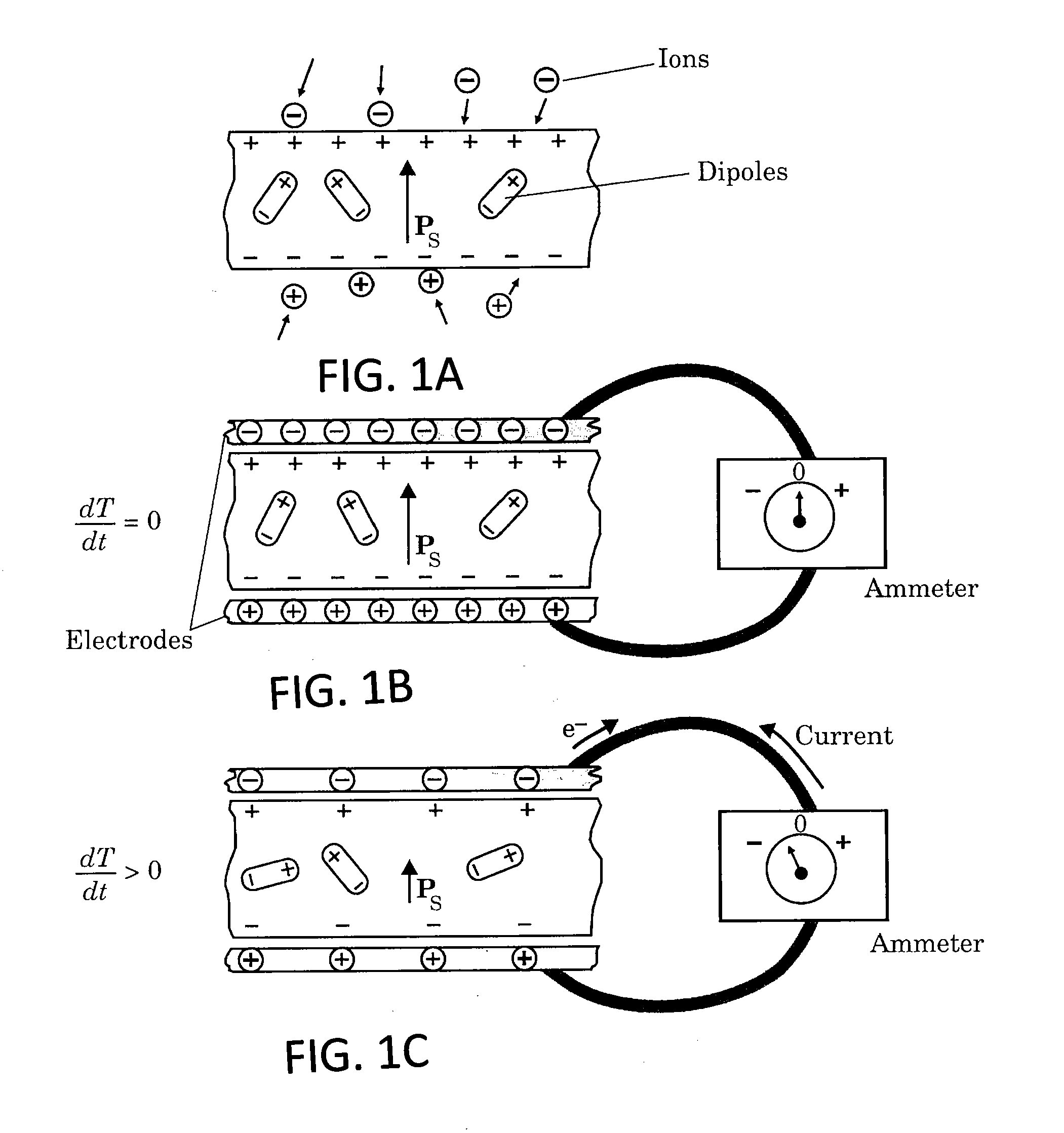

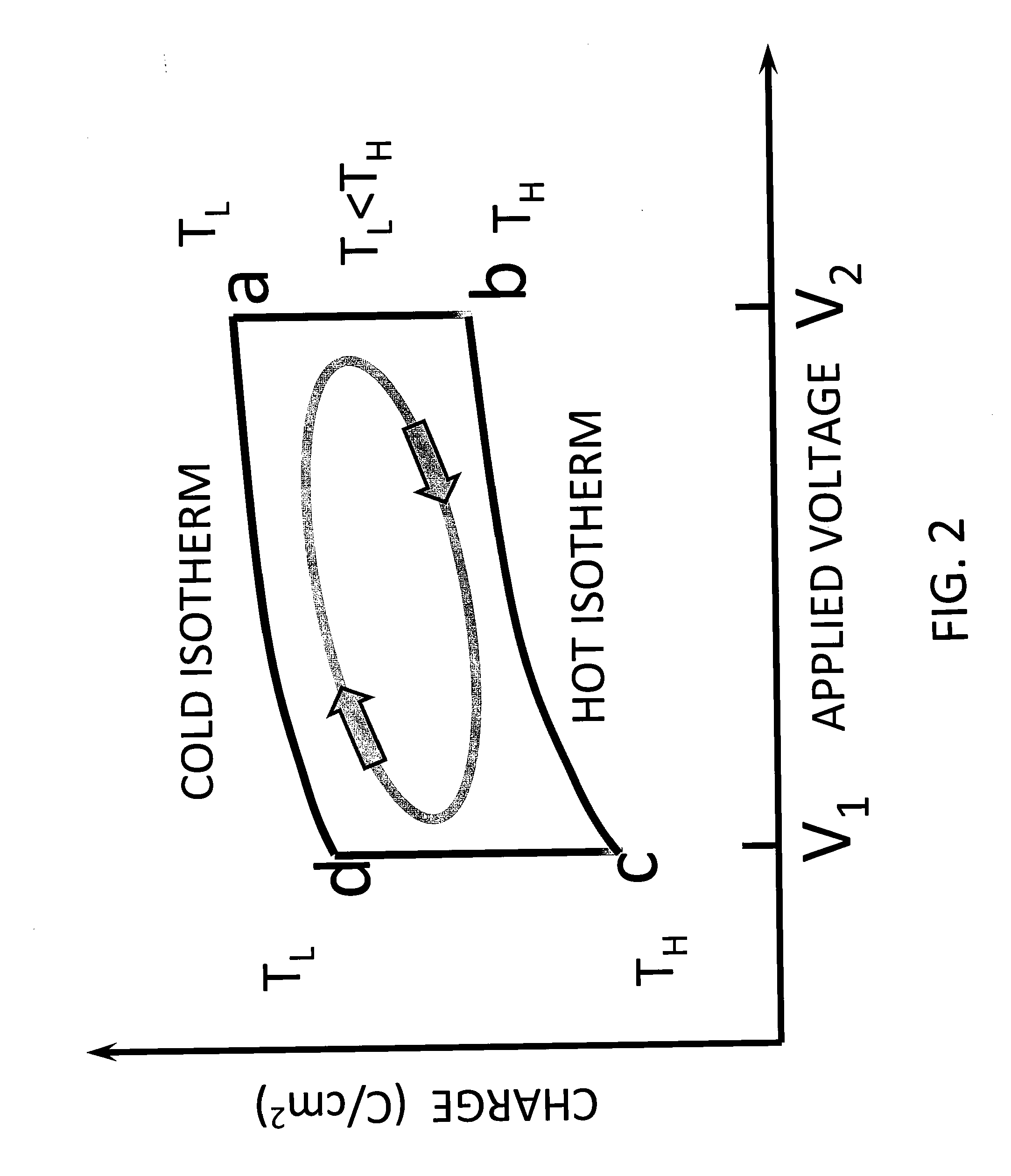

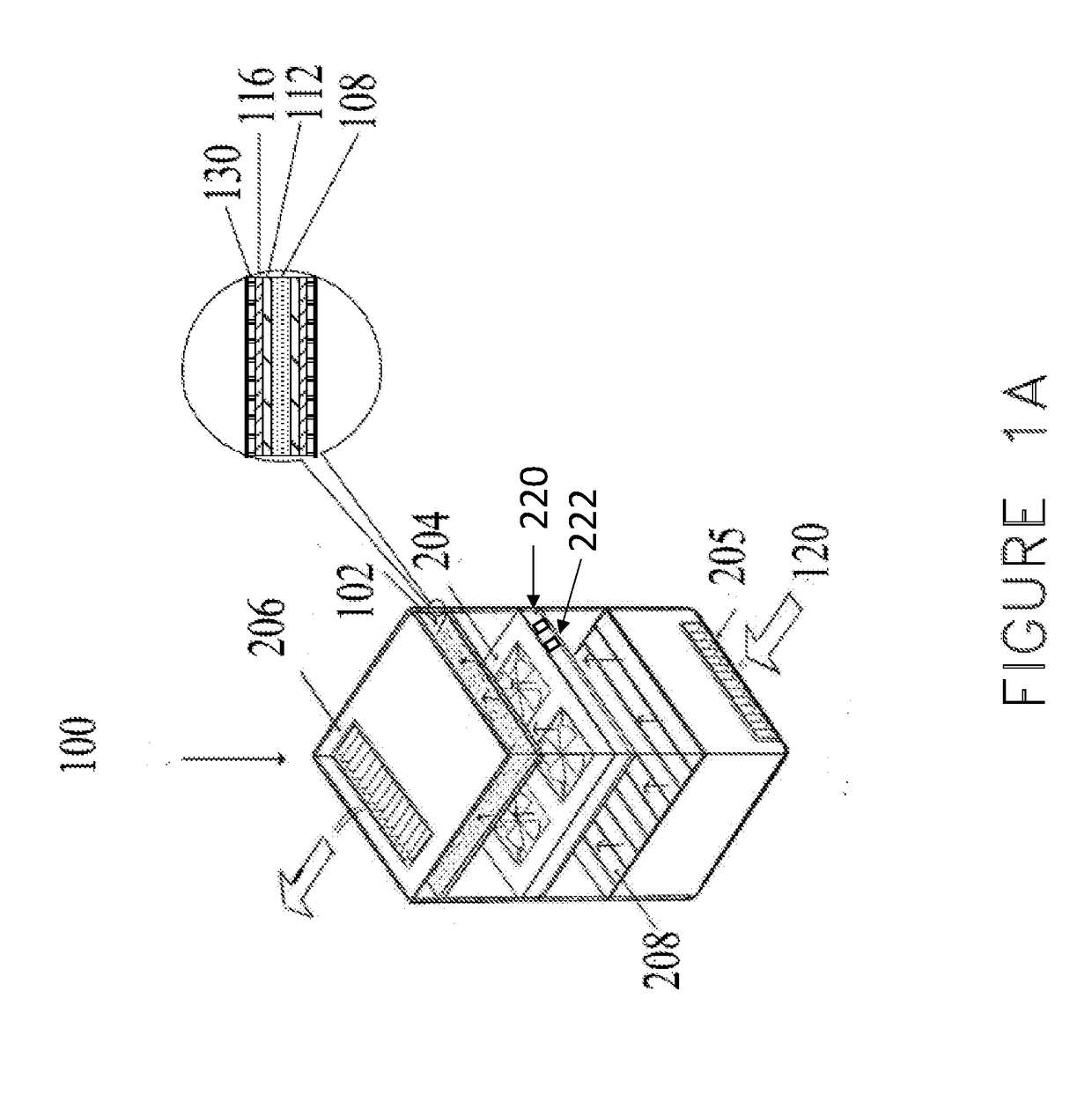

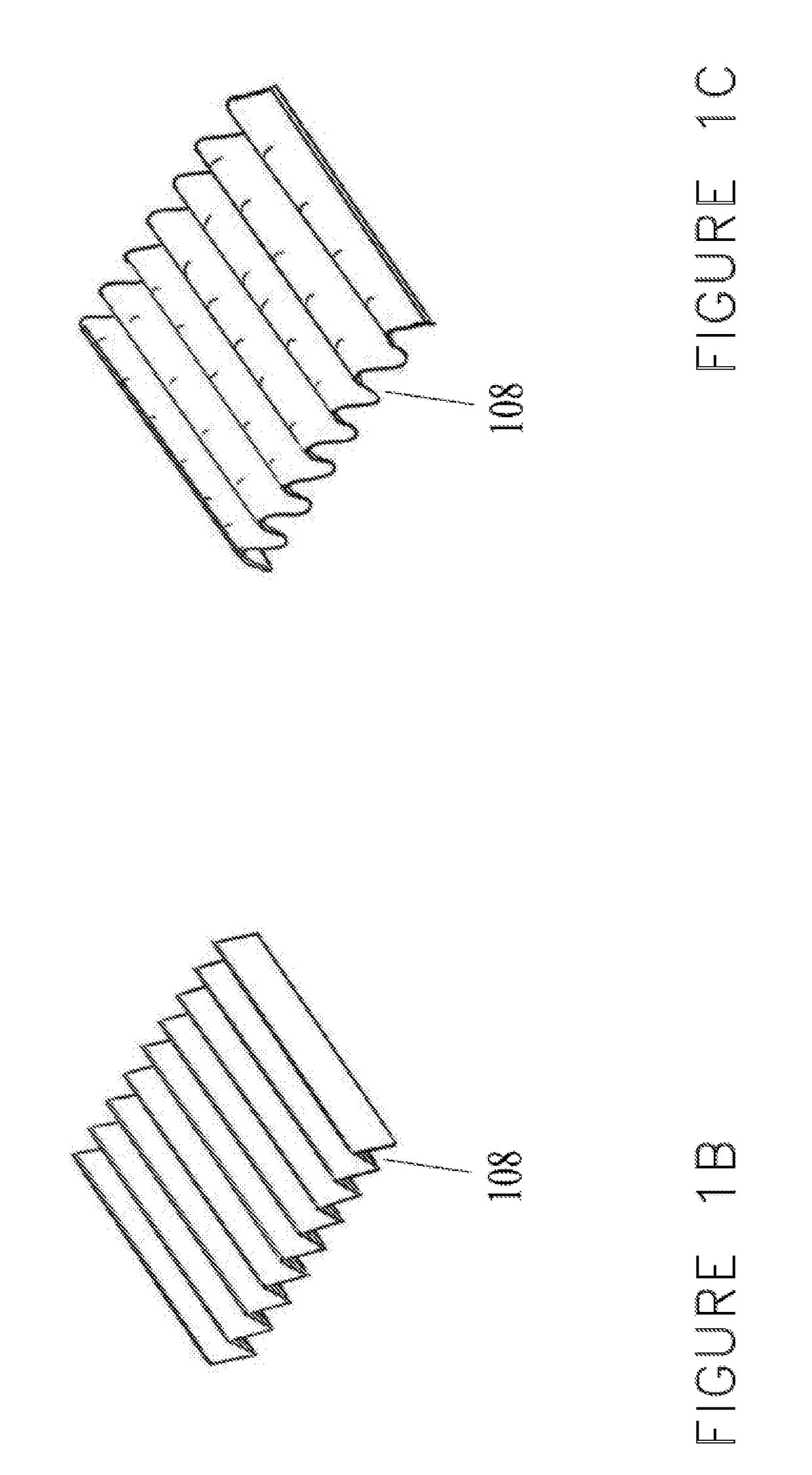

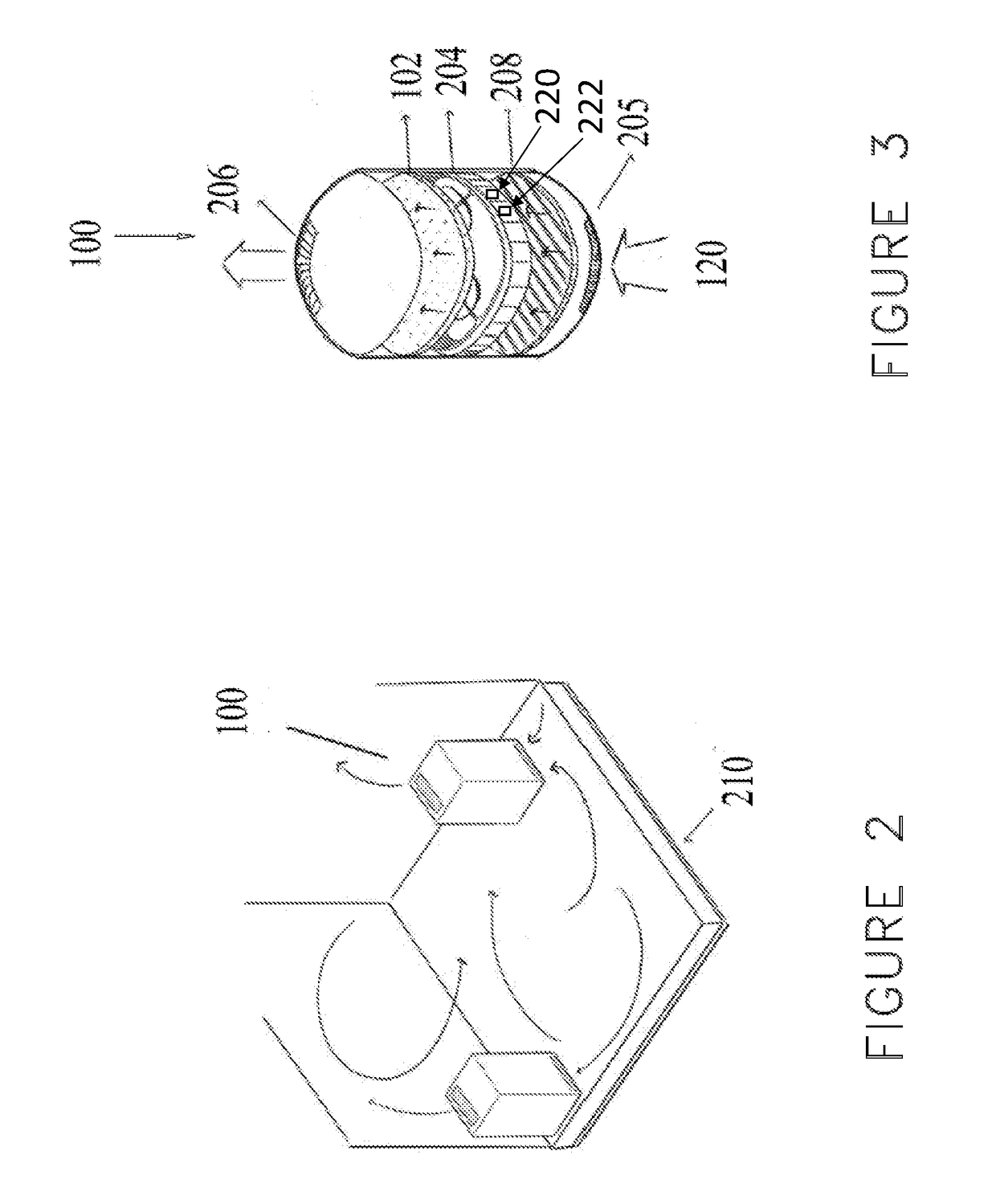

MEMS based pyroelectric thermal energy harvester

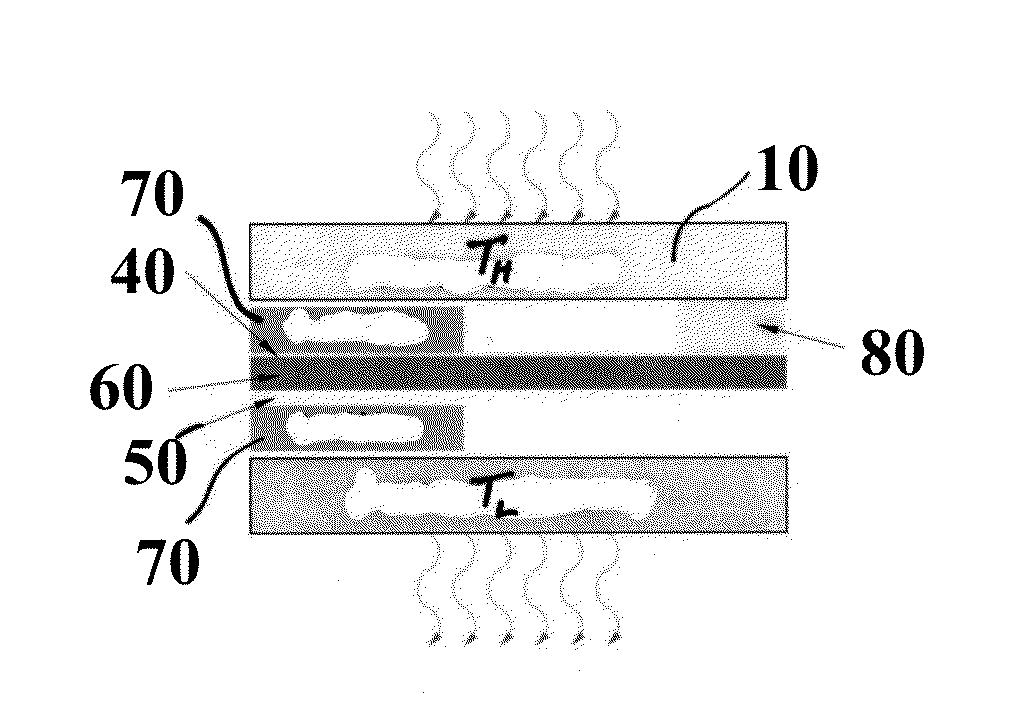

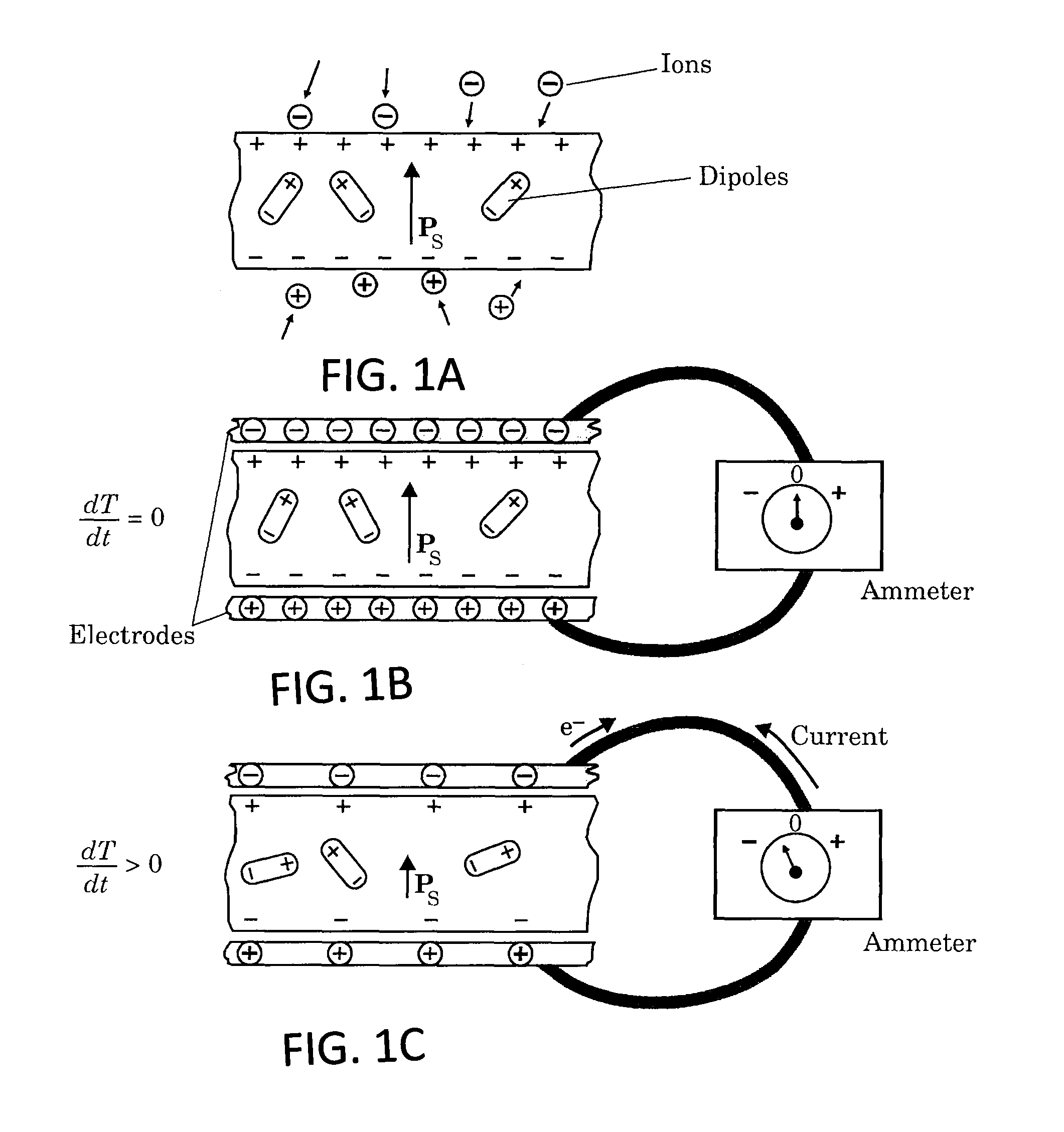

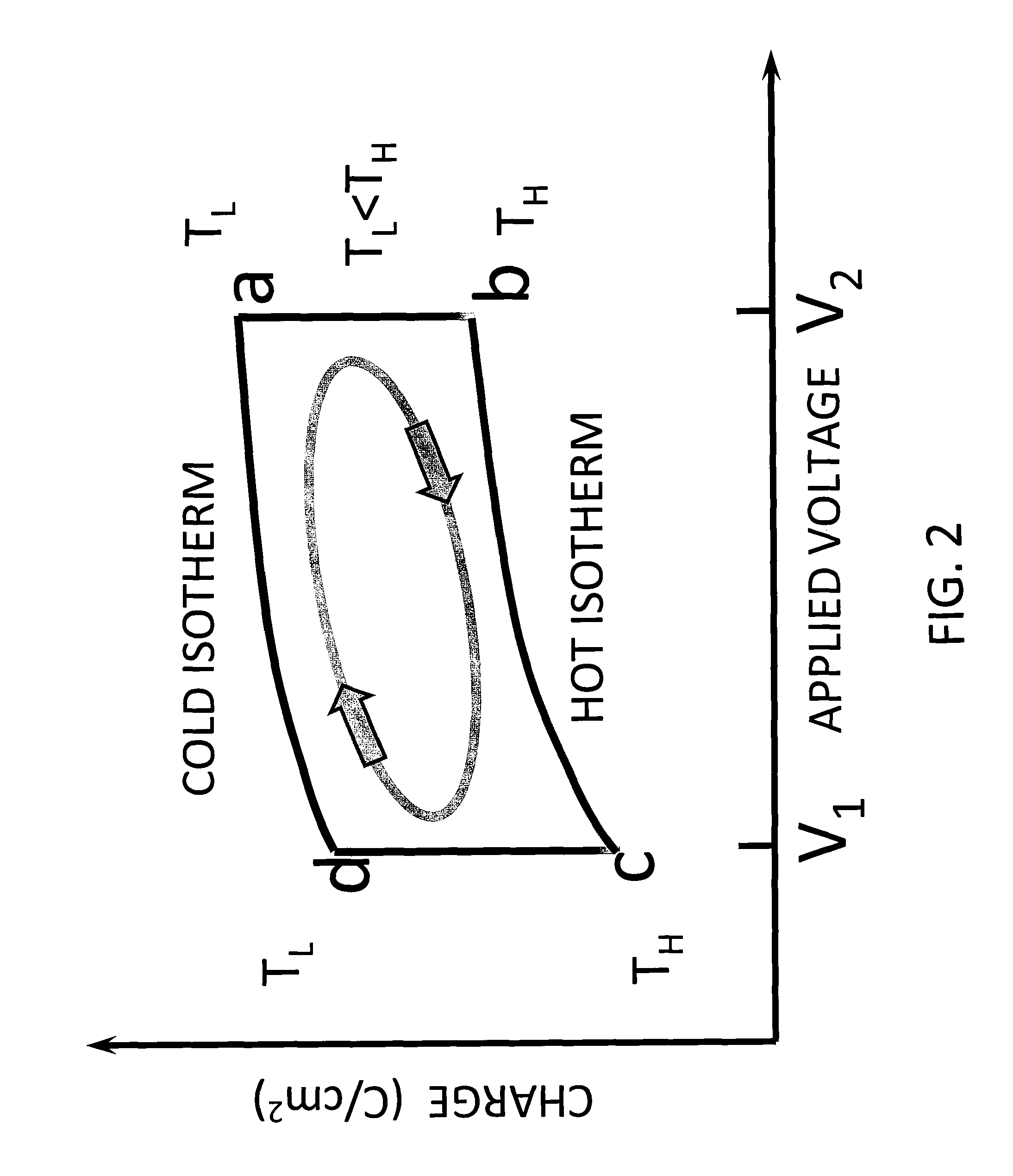

InactiveUS20120056504A1High quality electrical energySignificant reductionThermoelectric device with dielectric constant thermal changeThermal electric motorTemperature differenceDielectric layer

A pyroelectric thermal energy harvesting apparatus for generating an electric current includes a cantilevered layered pyroelectric capacitor extending between a first surface and a second surface, where the first surface includes a temperature difference from the second surface. The layered pyroelectric capacitor includes a conductive, bimetal top electrode layer, an intermediate pyroelectric dielectric layer and a conductive bottom electrode layer. In addition, a pair of proof masses is affixed at a distal end of the layered pyroelectric capacitor to face the first surface and the second surface, wherein the proof masses oscillate between the first surface and the second surface such that a pyroelectric current is generated in the pyroelectric capacitor due to temperature cycling when the proof masses alternately contact the first surface and the second surface.

Owner:UT BATTELLE LLC

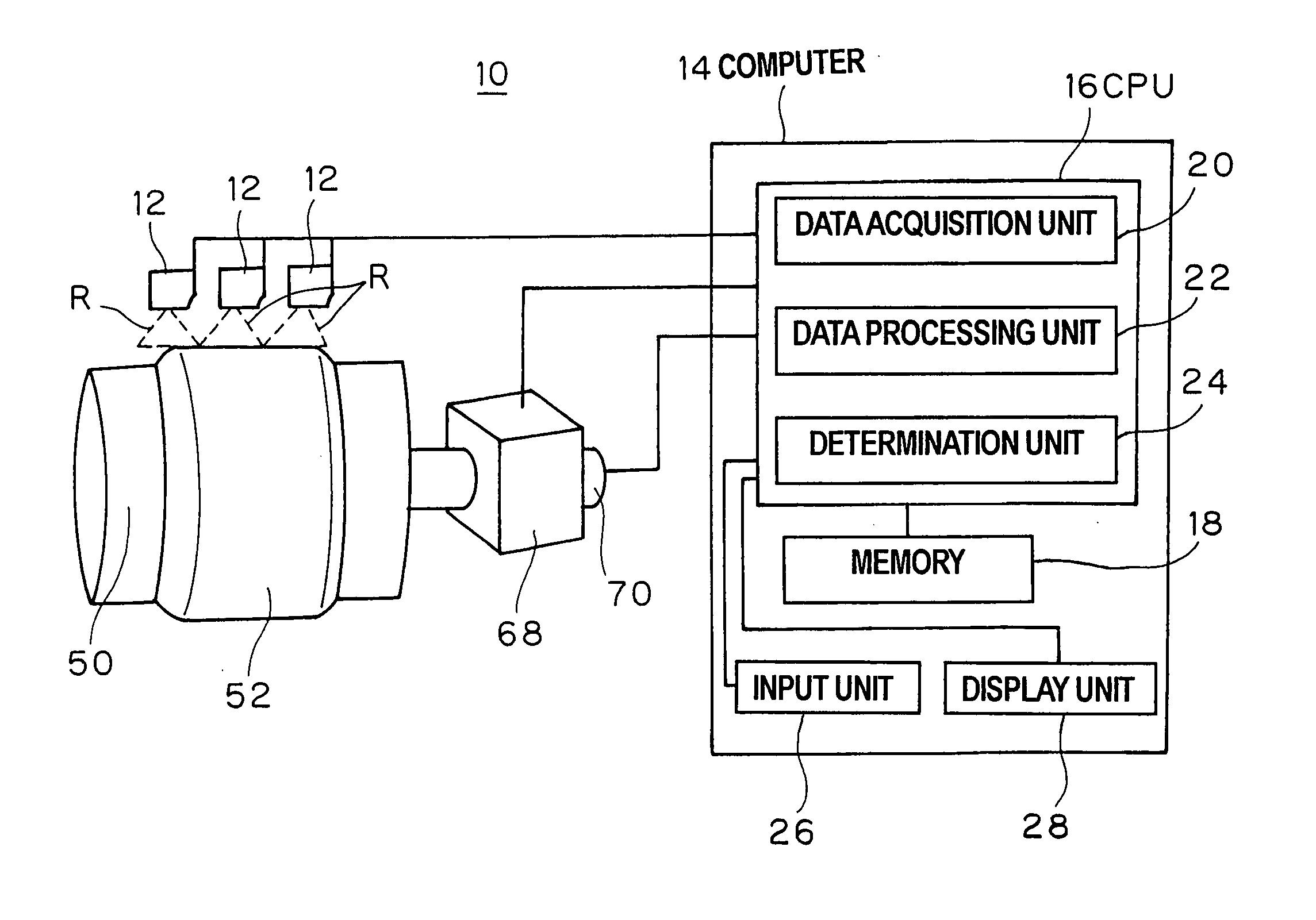

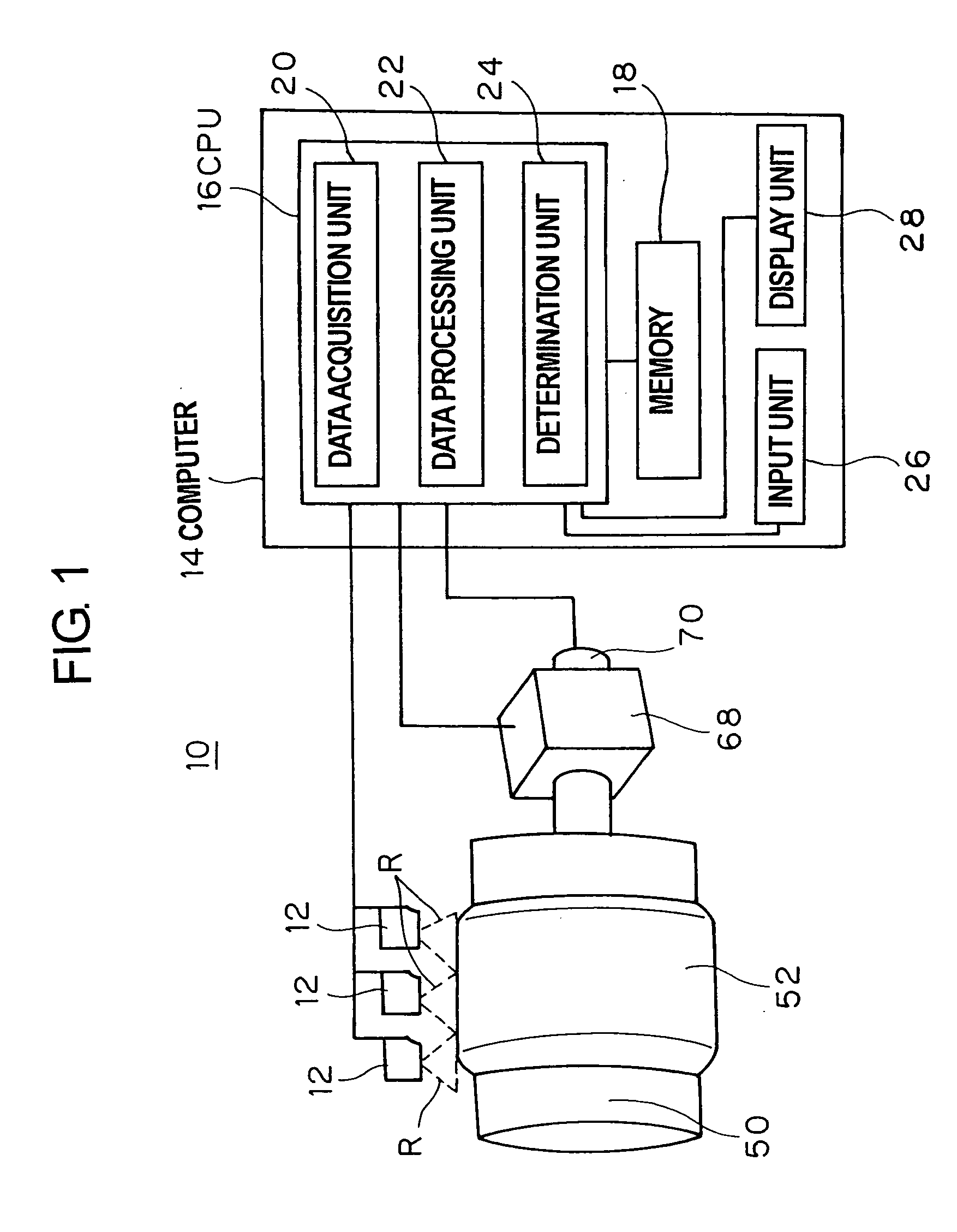

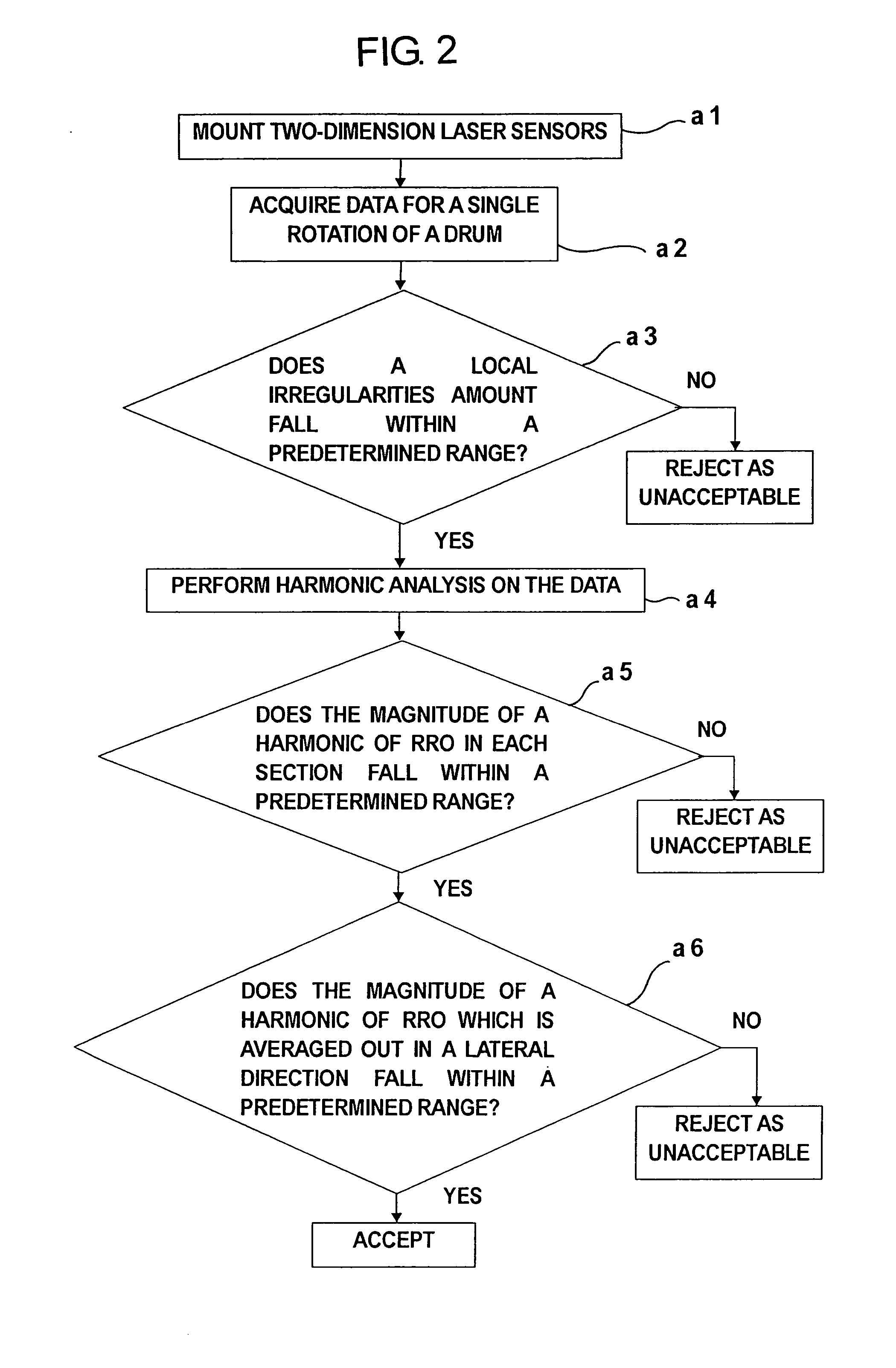

Method and apparatus for inspecting pneumatic tire during production

InactiveUS20070084541A1Reduce defectsReduce material costsLamination ancillary operationsLaminationHarmonic analysisEngineering

There is provided an inspection method for inspecting an object built on a tire building drum to make up a pneumatic tire with respect to profile thereof in process of production of the tire includes, in which data with respect to a profile of the object for a single rotation of the tire building drum is acquired by a two-dimension laser sensor having a detection range along a lateral direction of the object while rotating the drum. Then, using the data so acquired, a radial run-out (RRO) in a circumferential direction of the tire is averaged out in a lateral direction of the object for harmonic analysis, and whether or not the magnitude of the harmonic obtained as a result of the analysis falls within a predetermined range is determined.

Owner:TOYO TIRE & RUBBER CO LTD

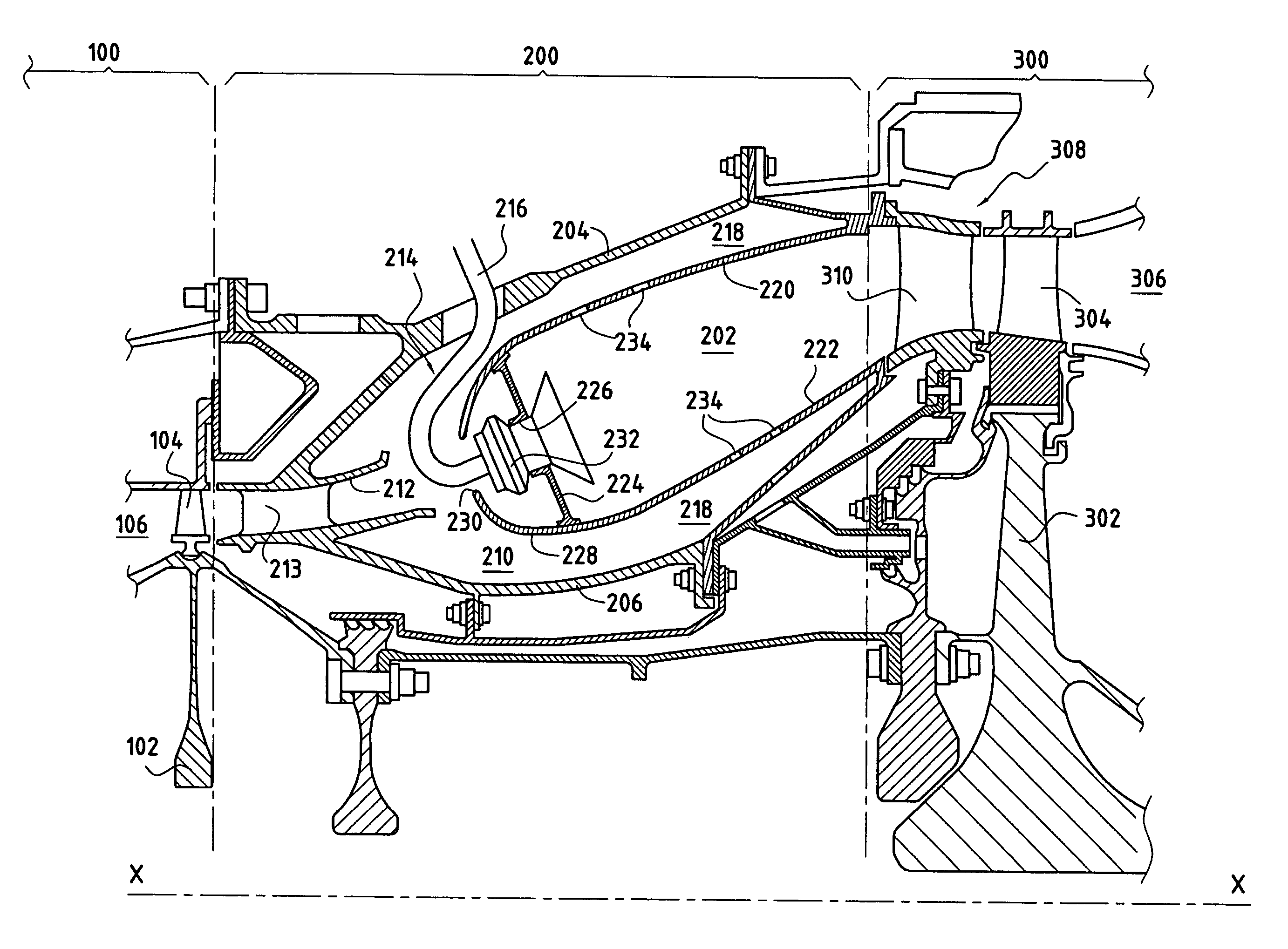

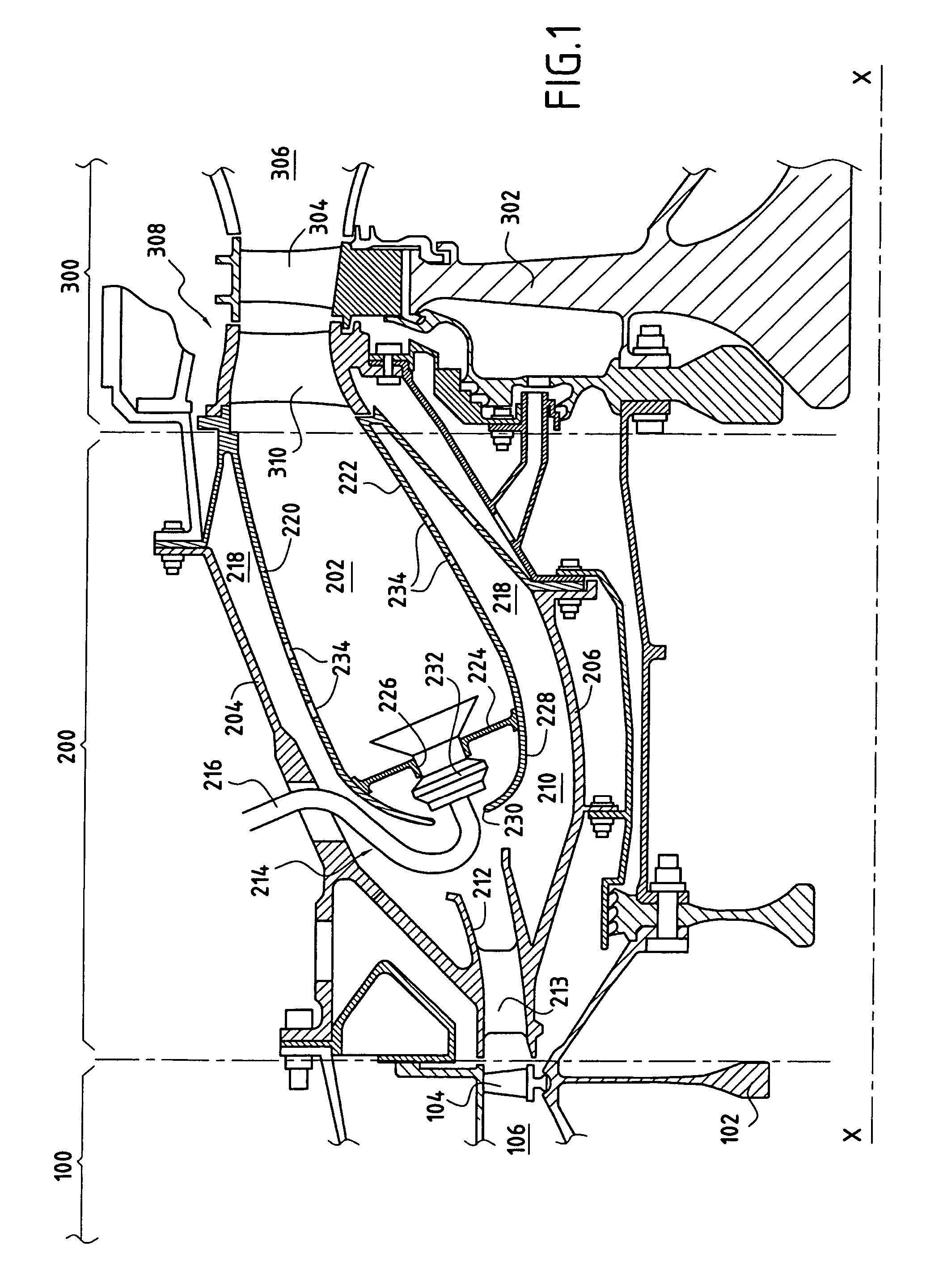

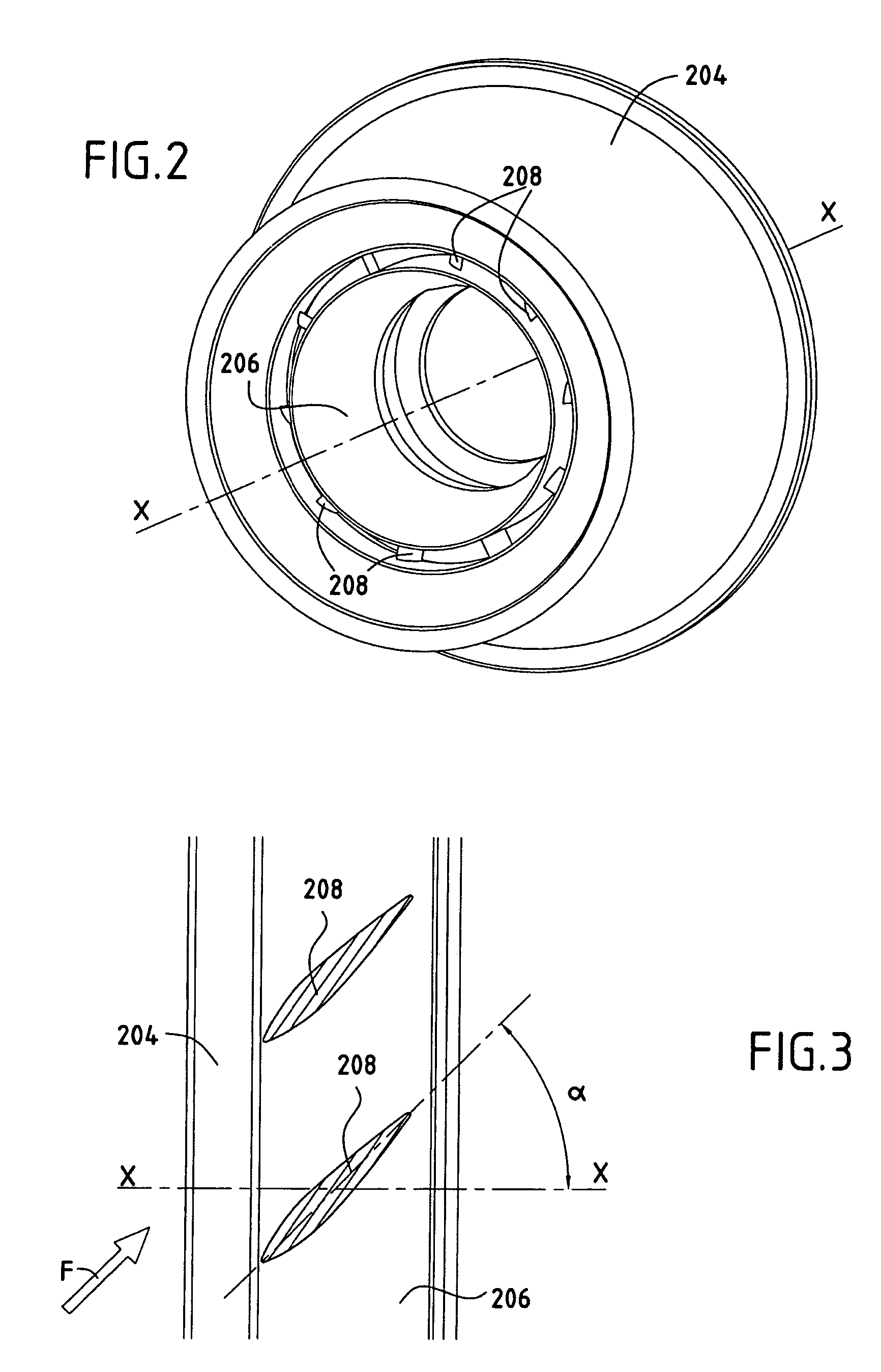

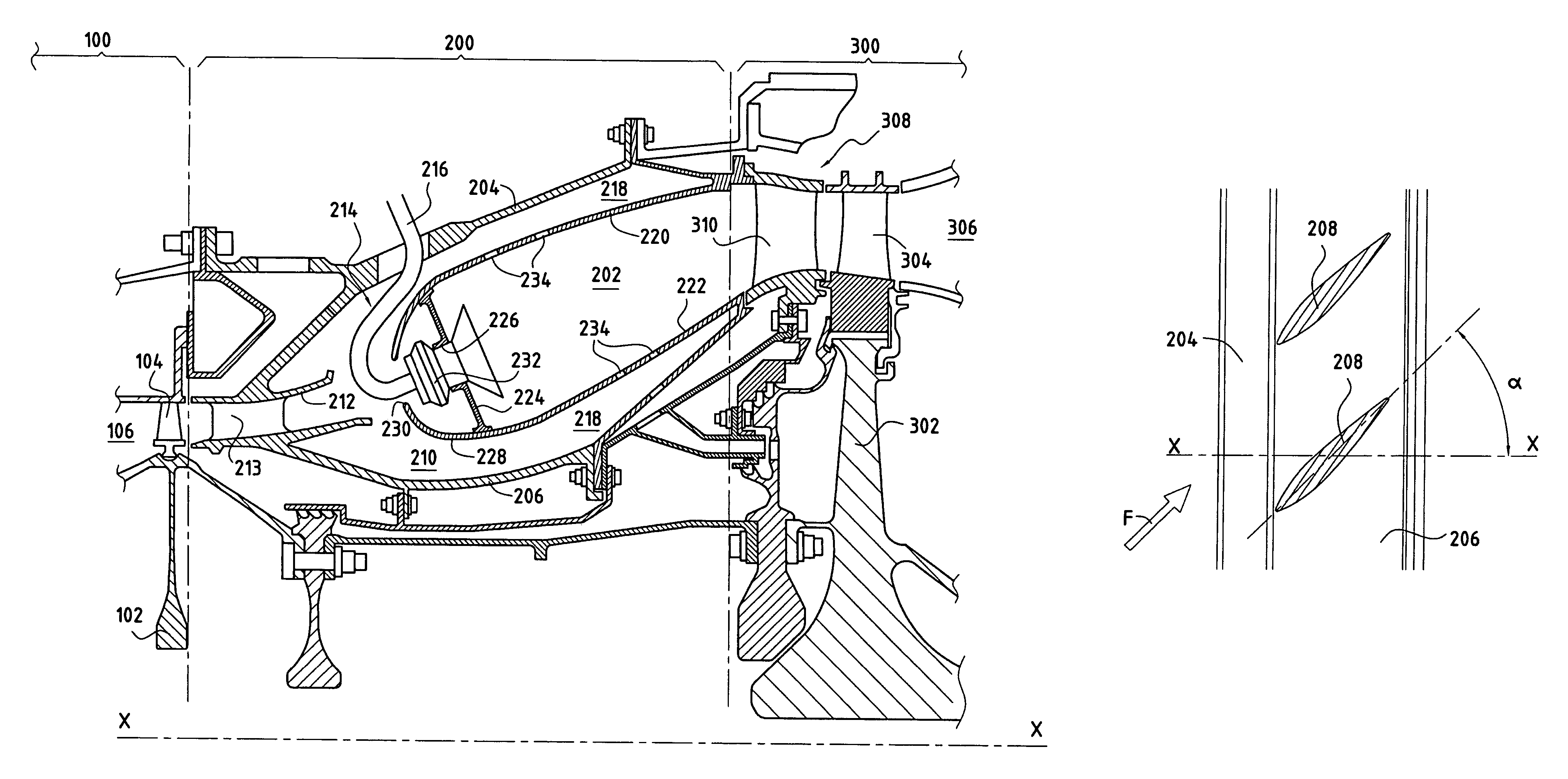

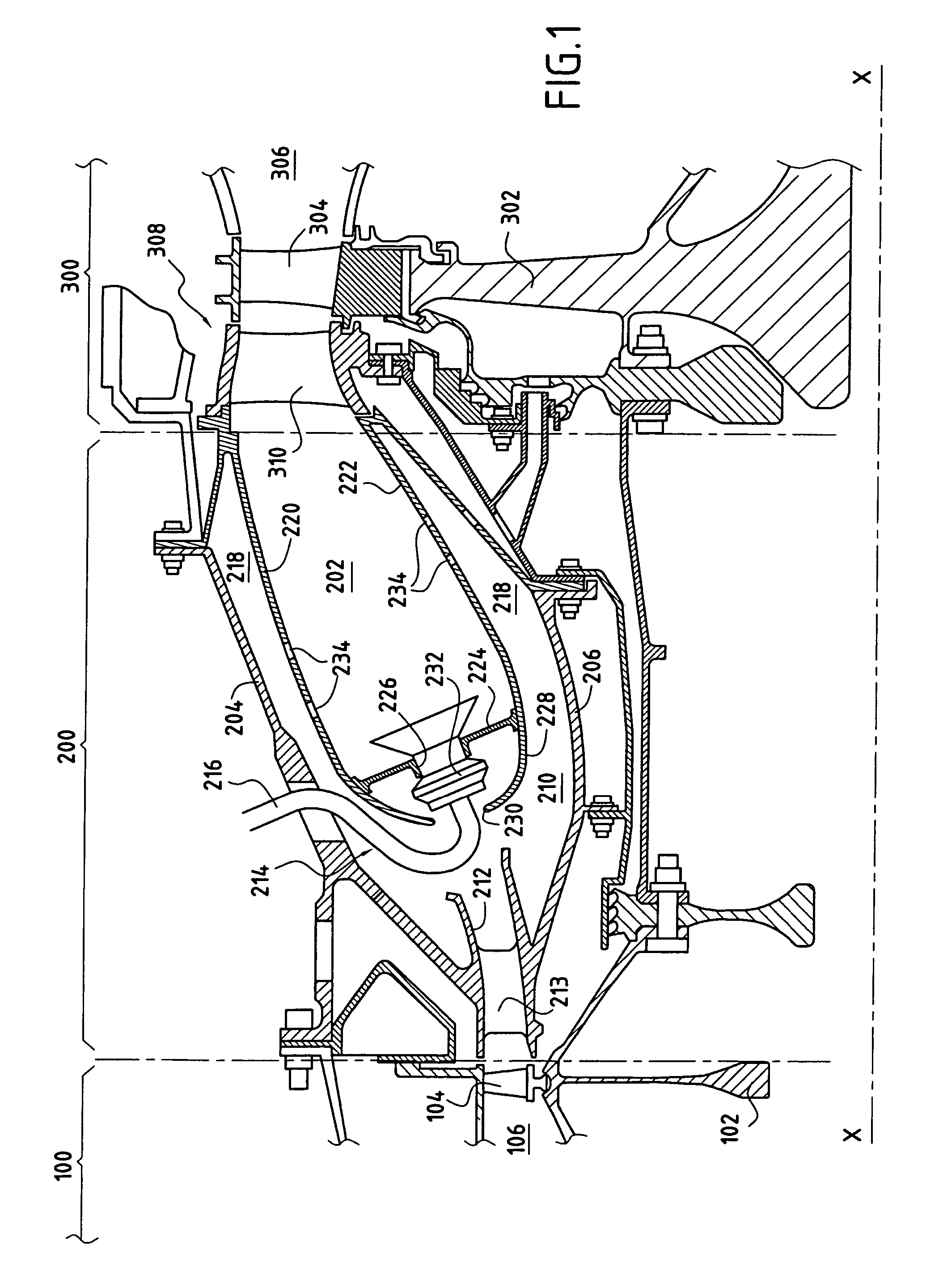

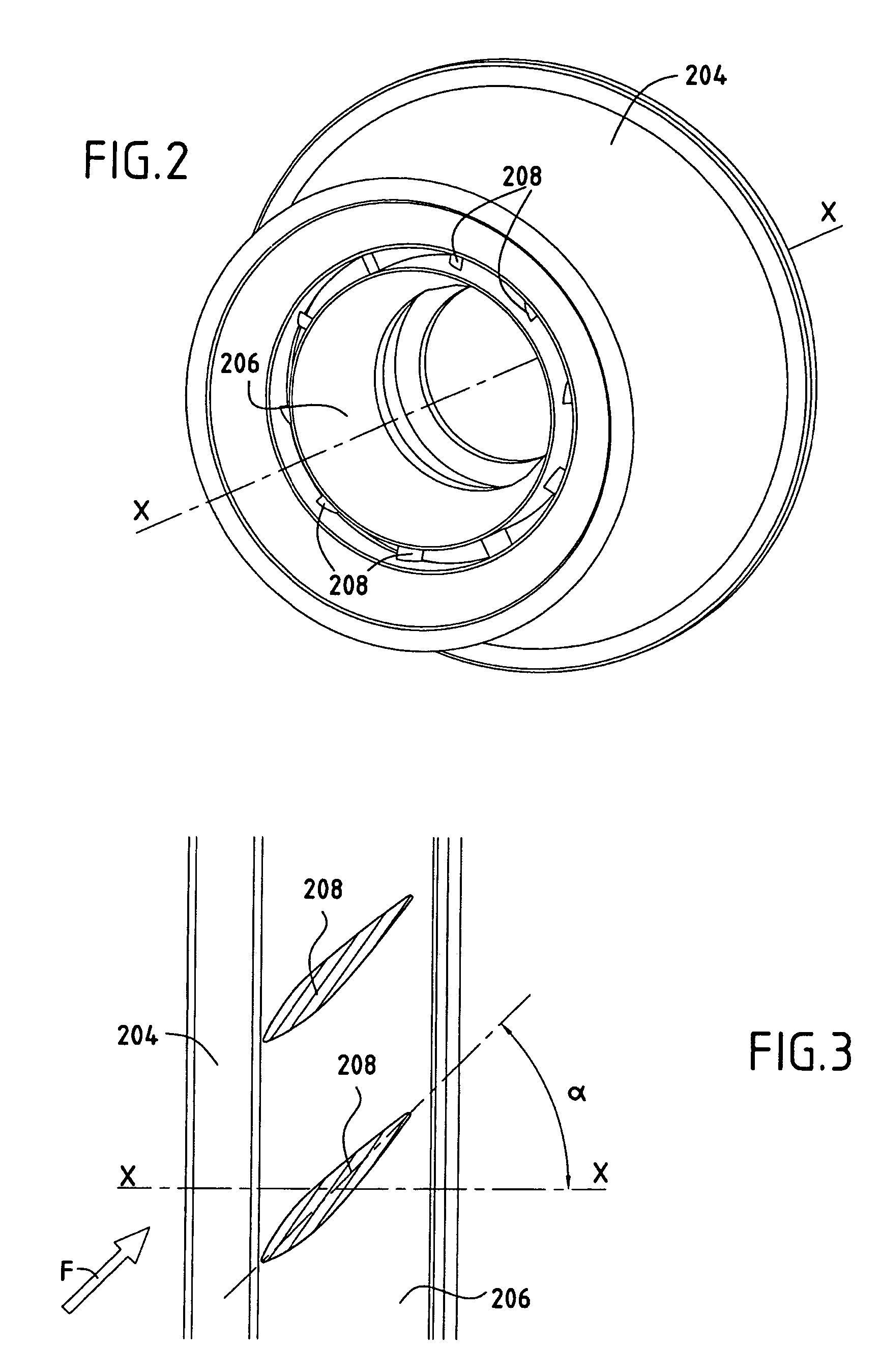

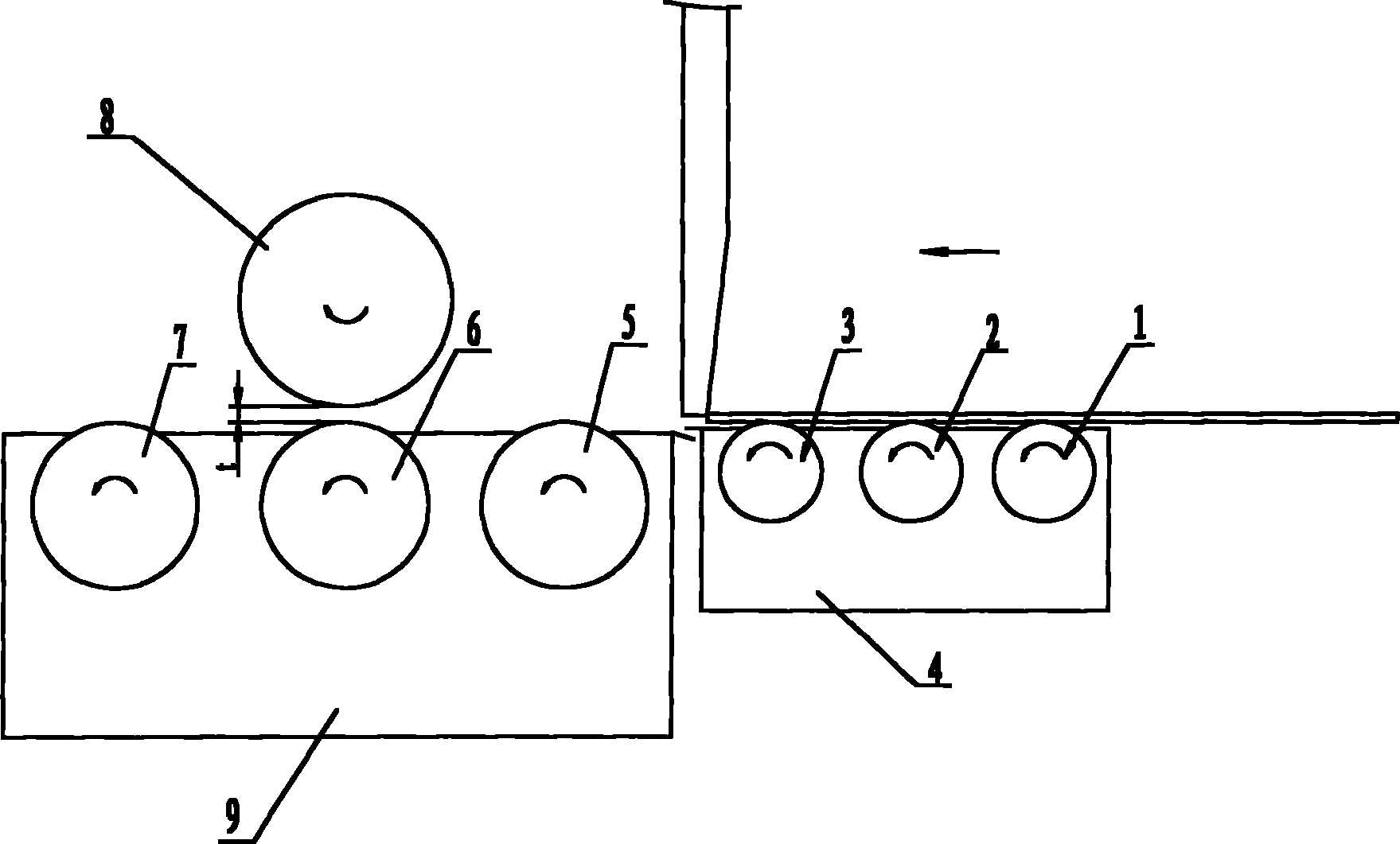

Turbomachine with angular air delivery

ActiveUS20070012048A1Mitigate such drawbackSignificant reductionContinuous combustion chamberGas turbine plantsCombustionTurbine

A turbomachine assembly comprising: an annular compression section; a casing formed by an outer annular shell (204) and an inner annular shell (206) secured inside the outer shell by means of a plurality of radial support arms (208); an annular combustion section housed inside the casing; and an annular turbine section. The air coming from the compression section presents rotary motion with an angle of inclination relative to a longitudinal axis (X-X) of the turbomachine, and the combustion section includes angular distribution means for determining air flow direction so as to impart on the gas leaving the combustion section rotary motion with an angle of inclination that is equal to or greater than the angle of inclination of the air leaving the compression section, said angular distribution means being formed by the support arms (208), each of which presents an angle of inclination relative to the longitudinal axis (X-X) of the turbomachine that is greater than or equal to the angle of inclination of the air leaving the compression section.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Lane keep control apparatus and method for automotive vehicle

ActiveUS7117076B2Vehicle speed largeEliminate the effects ofDigital data processing detailsAnti-collision systemsSteering angleMotorized vehicle

Owner:NISSAN MOTOR CO LTD

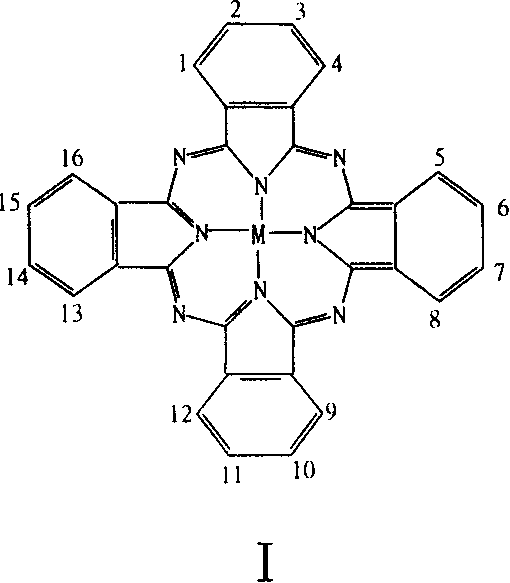

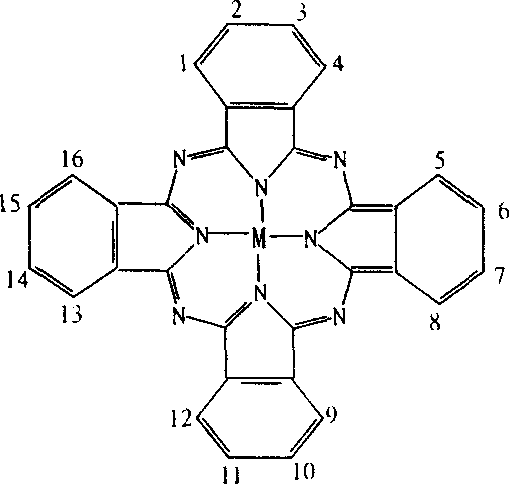

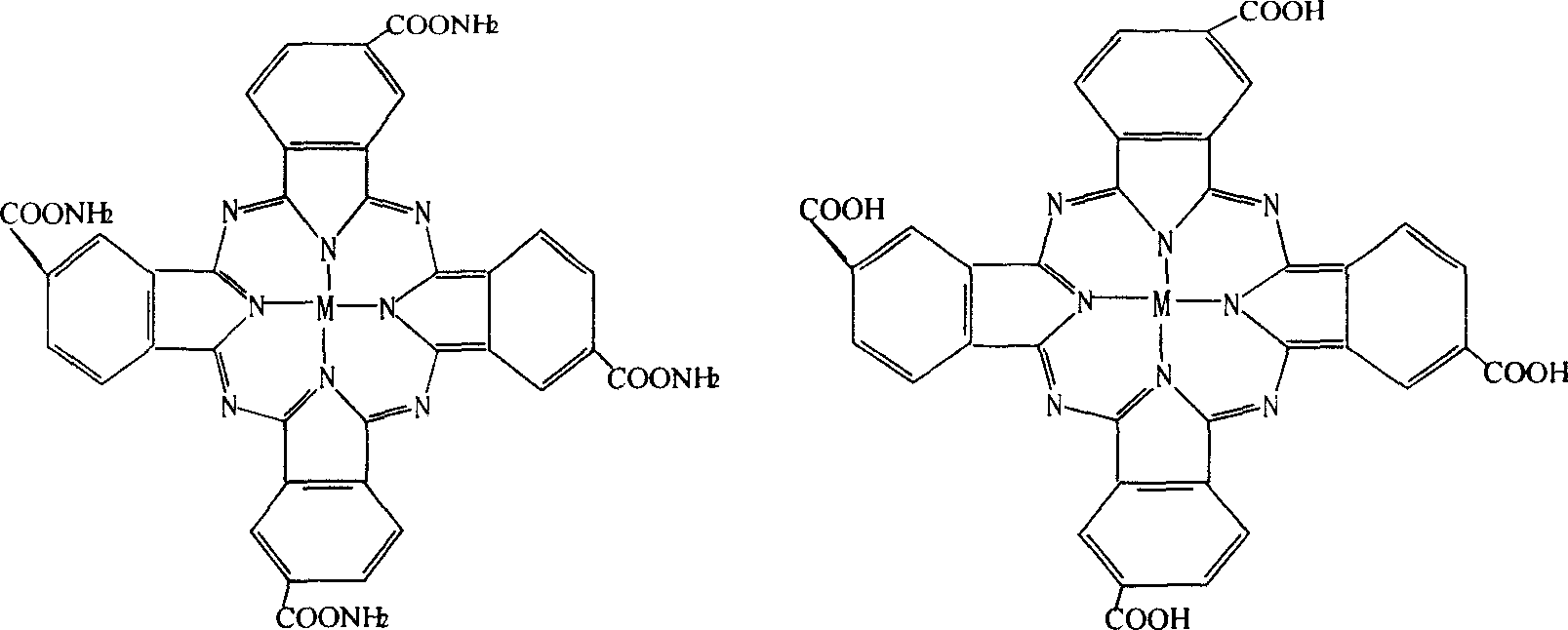

Use of phthalocyanin compound as cigarette harm-reducing agent

The present invention relates to an application of phthalocyanin compound as harm-reducing agent of cigarette. Said phthalocyanin compound can obviously reduce harmful substances of CO, nitrogen oxide, aldehydes and amines in the smoke, and also can remove noble metal ions and eliminate free radical.

Owner:NANJING NORMAL UNIVERSITY

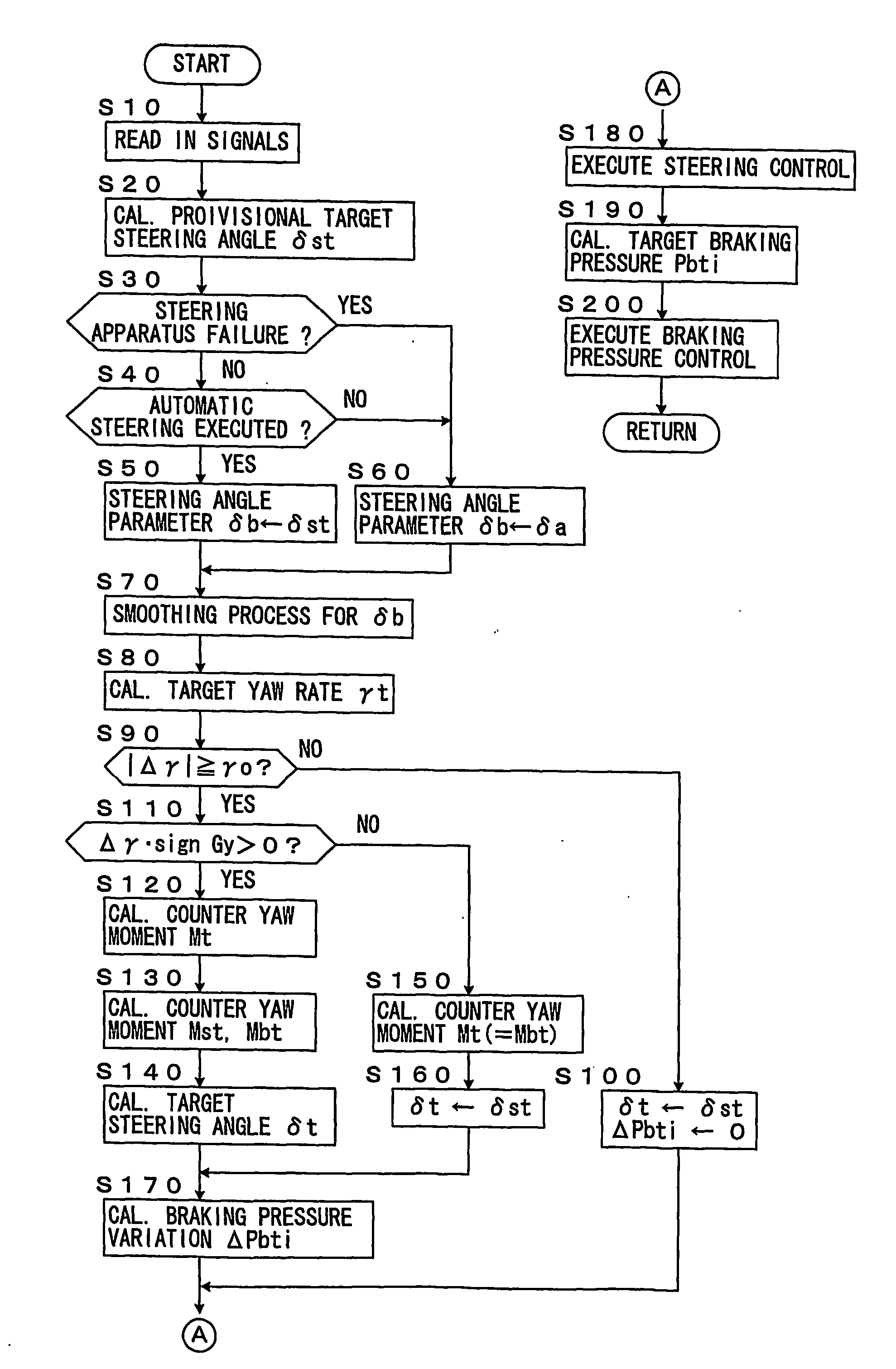

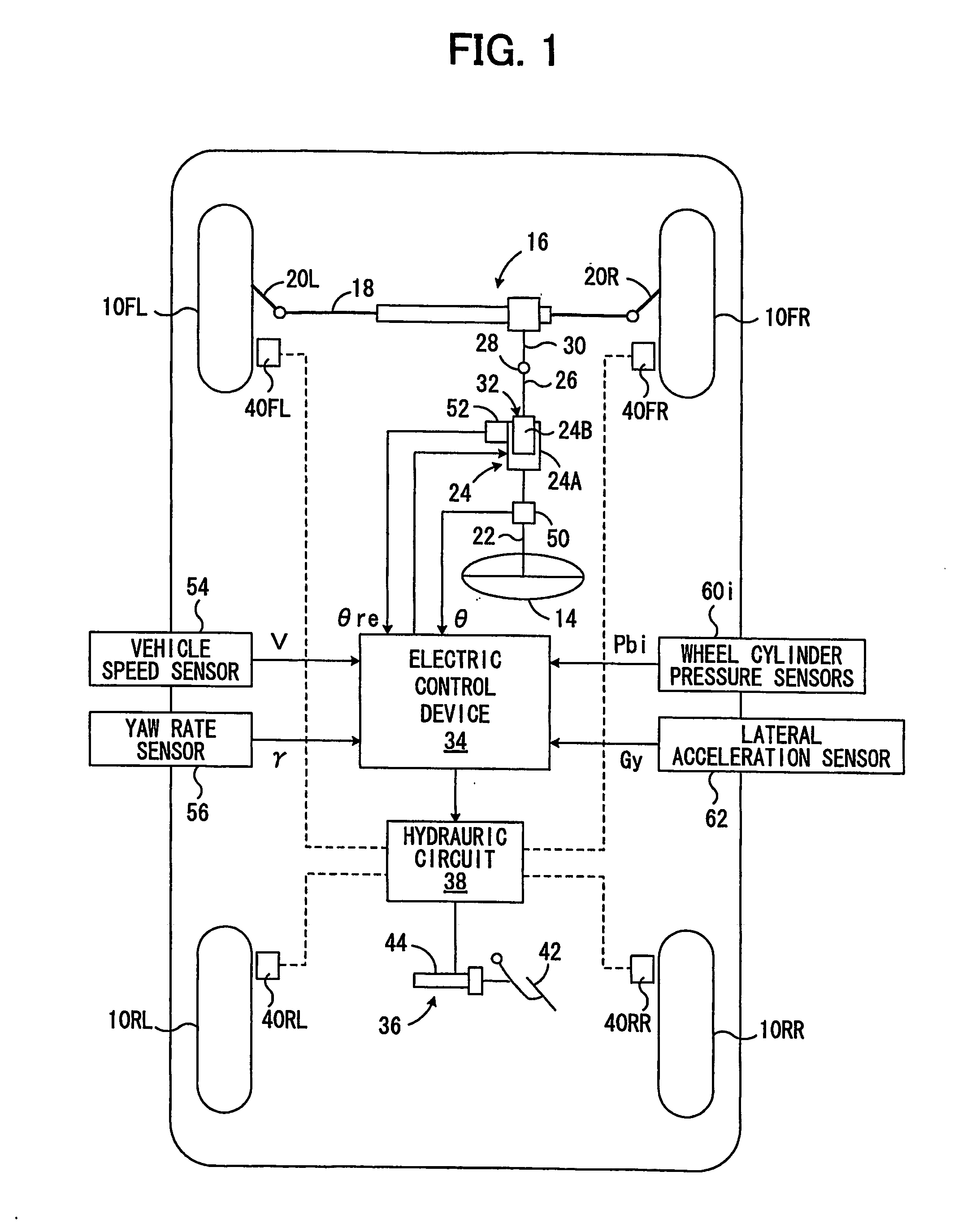

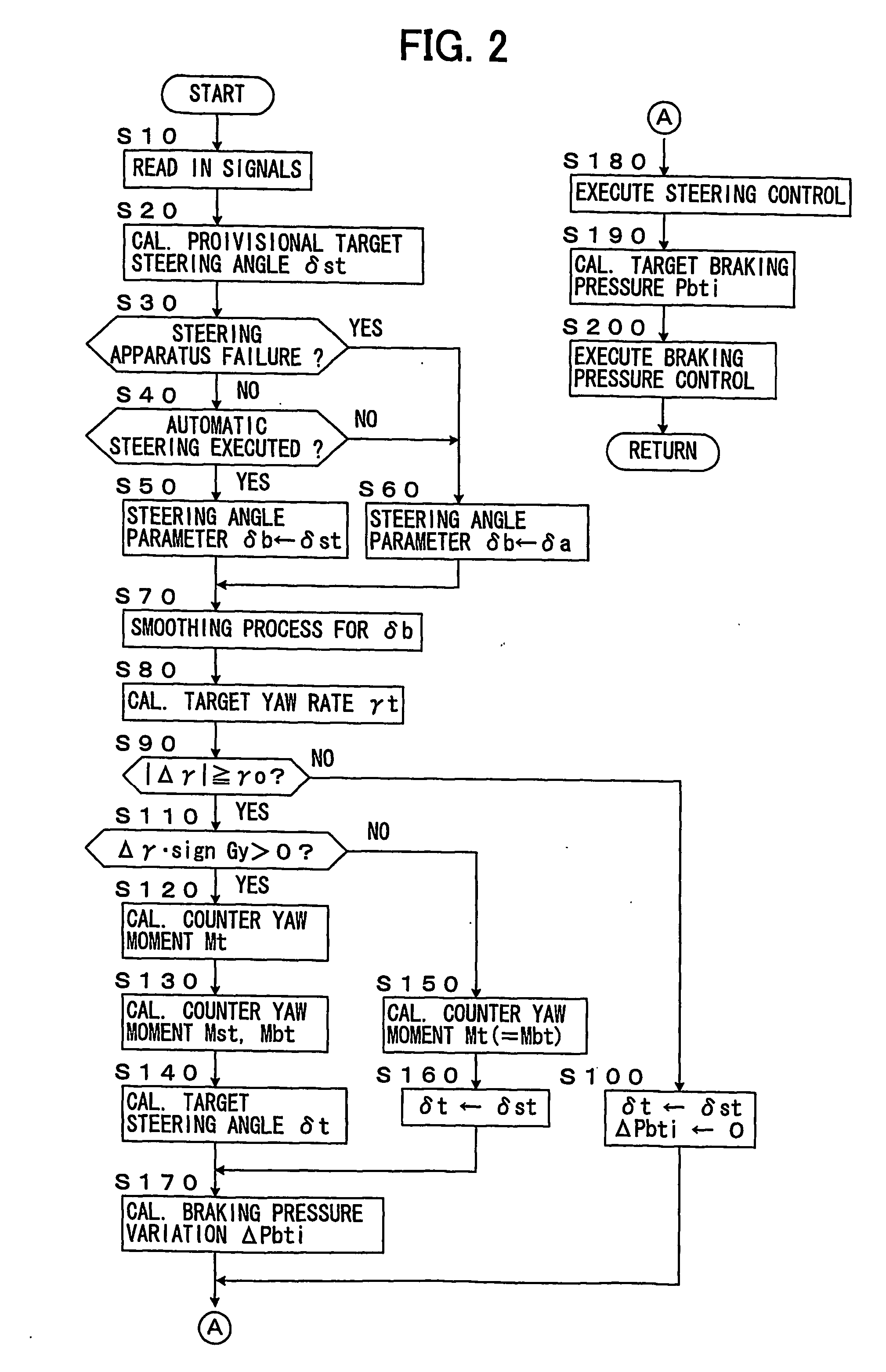

Vehicle stability control device

InactiveUS20060149445A1Suppressing oversteering and understeering tendenciesAppropriately executedSteering initiationsDigital data processing detailsSteering wheelSteering angle

A novel vehicle stability control device through steering wheels independently of the driver's handling operation is provided, in which a suitable steering angle parameter in determining a target value for a turning state parameter is selected. The control device calculates a provisional target steering angle for wheels based upon an amount of an operation of a driver and a predetermined steering characteristic; a target value for the turning state parameter; and a target steering angle for wheels for reducing a magnitude of a deviation of the actual turning state parameter from its target value when the magnitude of the deviation is at a reference value or above, and thereby controlling a steering angle based upon the target steering angle. During execution of controlling the steering angle based upon the target steering angle, the target value of the turning state parameter is calculated based upon the provisional target steering angle.

Owner:TOYOTA JIDOSHA KK

MEMS based pyroelectric thermal energy harvester

InactiveUS8519595B2Significant reductionImprove powerThermoelectric device with dielectric constant thermal changeElectric discharge tubesPower flowTemperature difference

A pyroelectric thermal energy harvesting apparatus for generating an electric current includes a cantilevered layered pyroelectric capacitor extending between a first surface and a second surface, where the first surface includes a temperature difference from the second surface. The layered pyroelectric capacitor includes a conductive, bimetal top electrode layer, an intermediate pyroelectric dielectric layer and a conductive bottom electrode layer. In addition, a pair of proof masses is affixed at a distal end of the layered pyroelectric capacitor to face the first surface and the second surface, wherein the proof masses oscillate between the first surface and the second surface such that a pyroelectric current is generated in the pyroelectric capacitor due to temperature cycling when the proof masses alternately contact the first surface and the second surface.

Owner:UT BATTELLE LLC

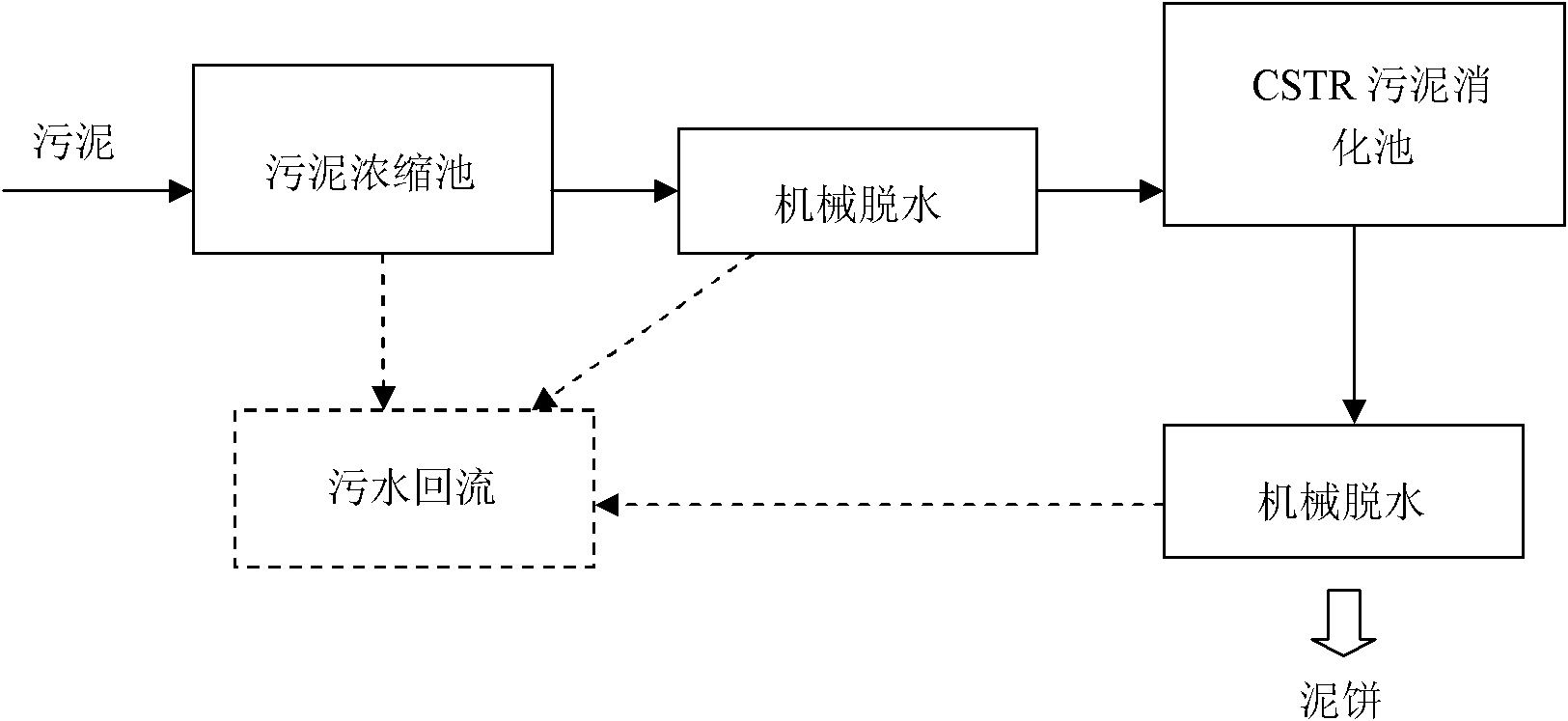

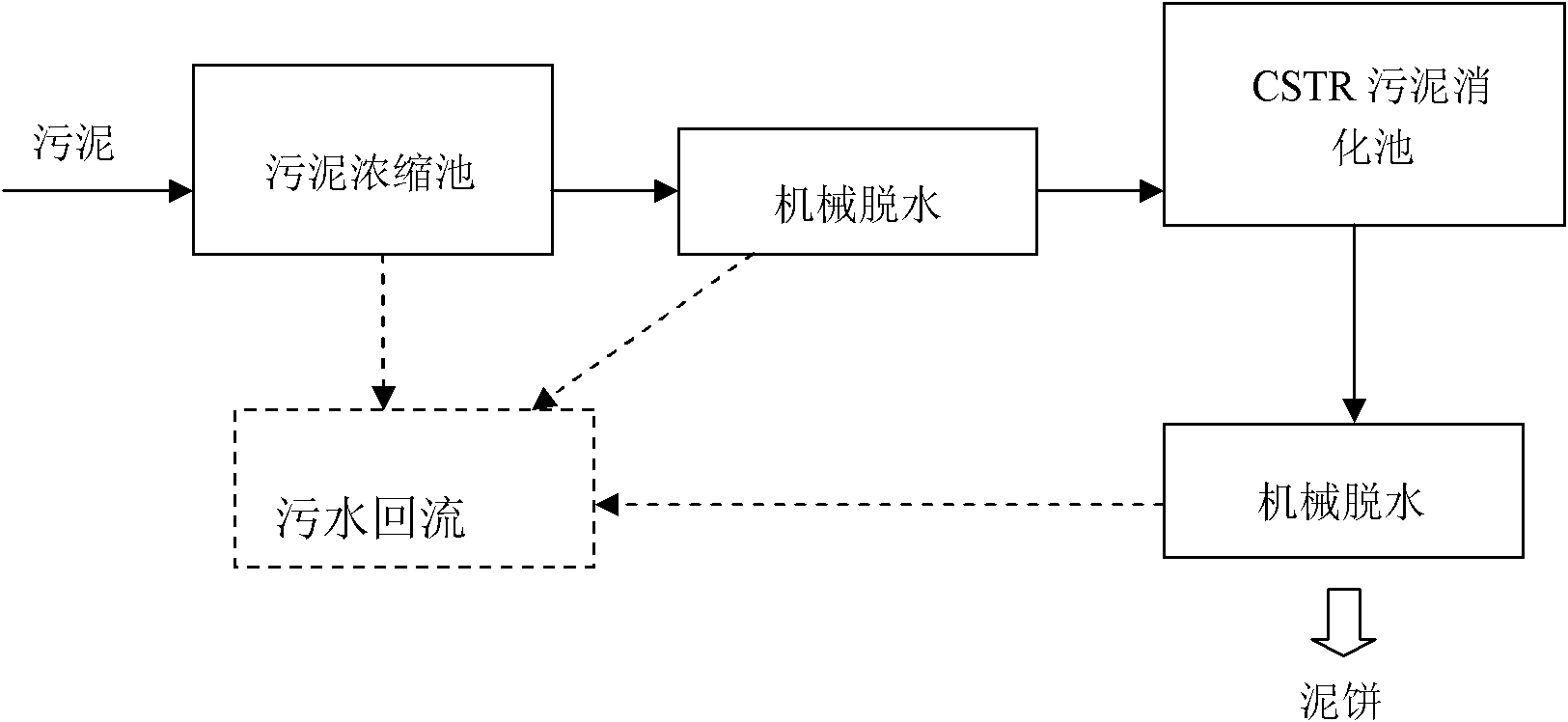

High-concentration anaerobic sludge digestion treatment process for carrying out mechanical dewatering on sludge

ActiveCN101948231AReduce moisture contentReduce volumeSludge treatment by de-watering/drying/thickeningBiological sludge treatmentHigh concentrationSludge cake

The invention relates to a high-concentration anaerobic sludge digestion treatment process for carrying out mechanical dewatering on sludge, comprising the following steps of: conveying sludge with high water content into a concentration tank, wherein the water content of the concentrated sludge is reduced to 97 percent, and a supernate reflexes to a sludge treatment system; carrying out mechanical pre-dewatering on the concentrated sludge, wherein the water content is about 88-90 percent after the mechanical pre-dewatering; then carrying out anaerobic digestion on the pre-dewatered sludge under the high concentration condition by adopting a CSTR (Continuous Stirred-Tank Reactor); and further dewatering the sludge after anaerobic digestion, wherein the water content of a treated sludge cake is about 75 percent. The invention has following advantages and positive effects: by adopting the technical scheme, the dewatering effect of the sludge is favorable, the volume of an anaerobic sludge digestion tank is greatly shortened, and the capital construction investment and the operation cost of a sewage treatment plant are reduced; the load of organic matters in the sludge can be effectively improved by carrying out pre-dewatering on the sludge; and the CSTR anaerobic sludge digestion which is suitable for the high-concentration solid materials is used for treatment, which is beneficial to sludge resource utilization.

Owner:NANJING YANJIANG ACAD OF RESCOURCES & ECOLOGY SCI CO LTD

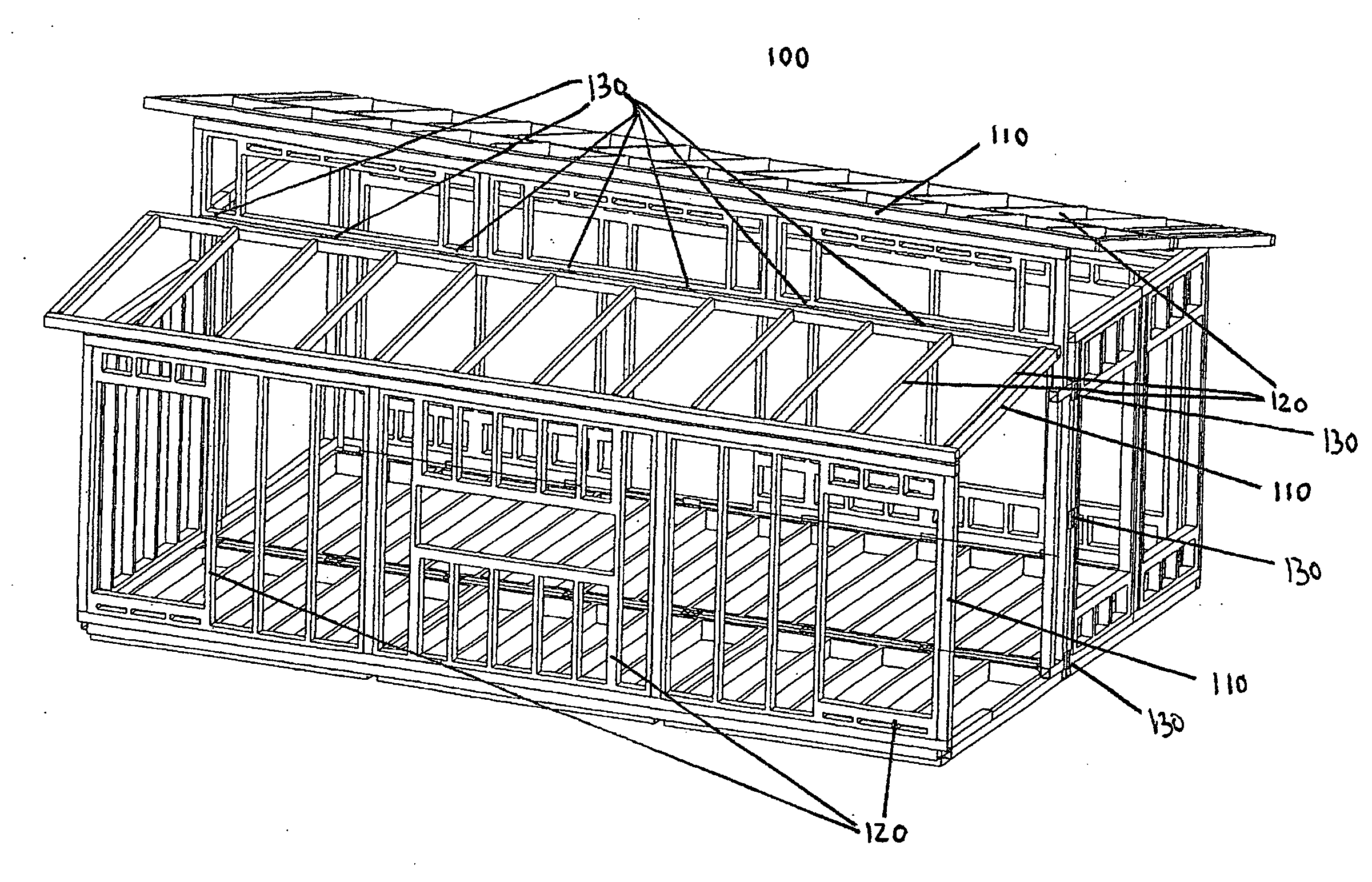

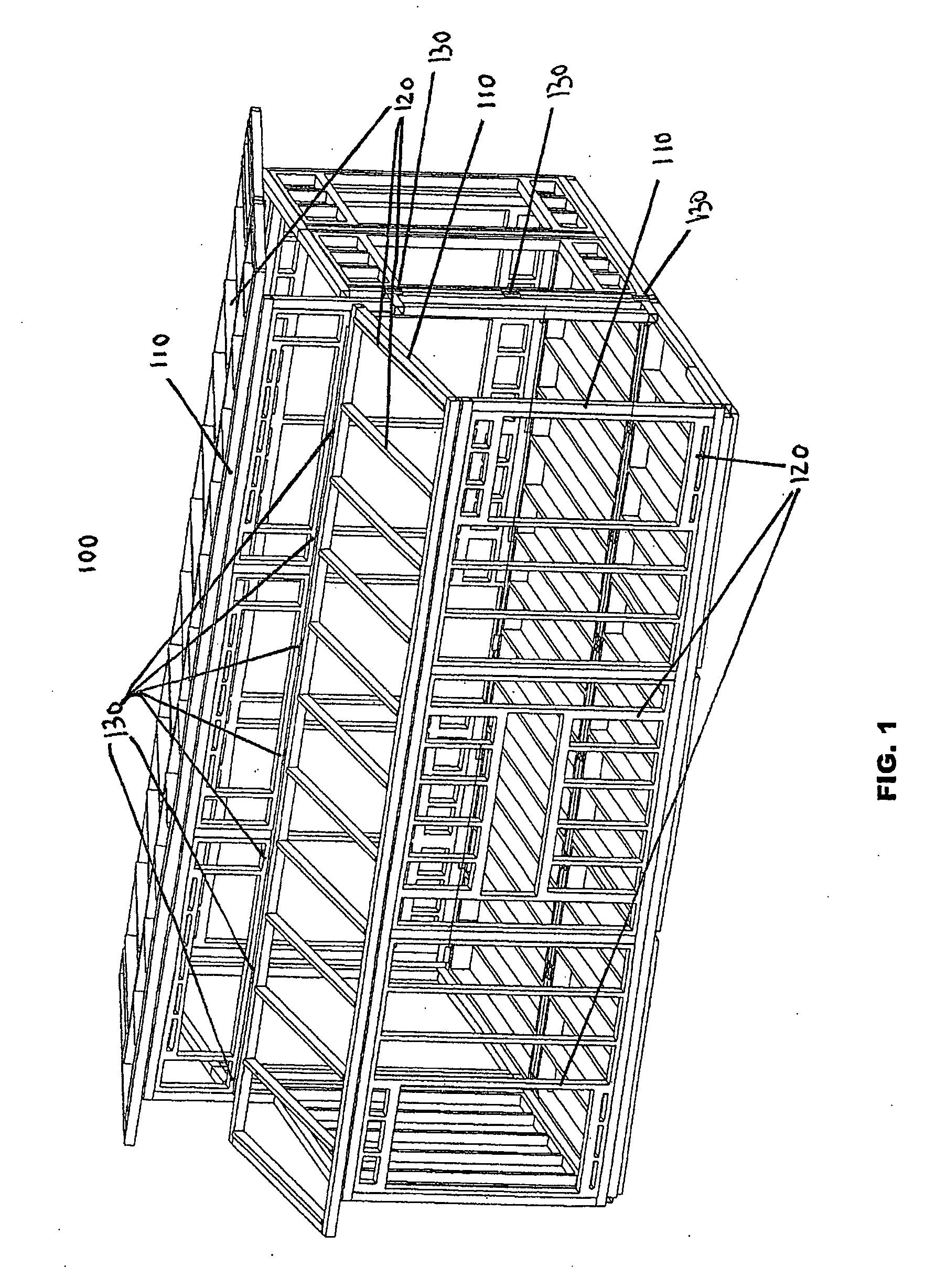

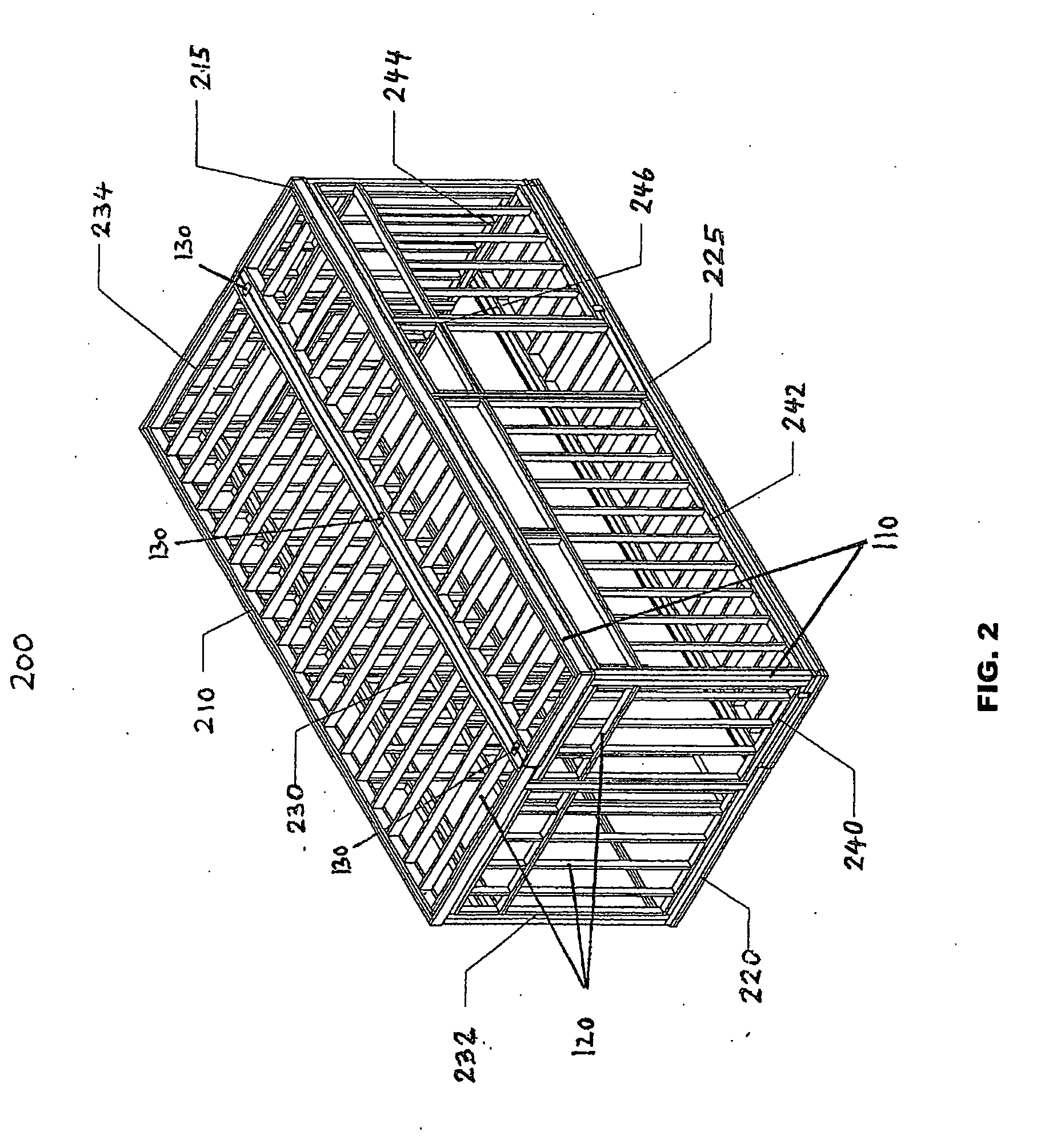

Foldable building units

InactiveUS20120279142A1Easy to prefabReduce and eliminate material damageBuilding roofsPublic buildingsArchitectural engineeringBuilding unit

Owner:BLU HOMES

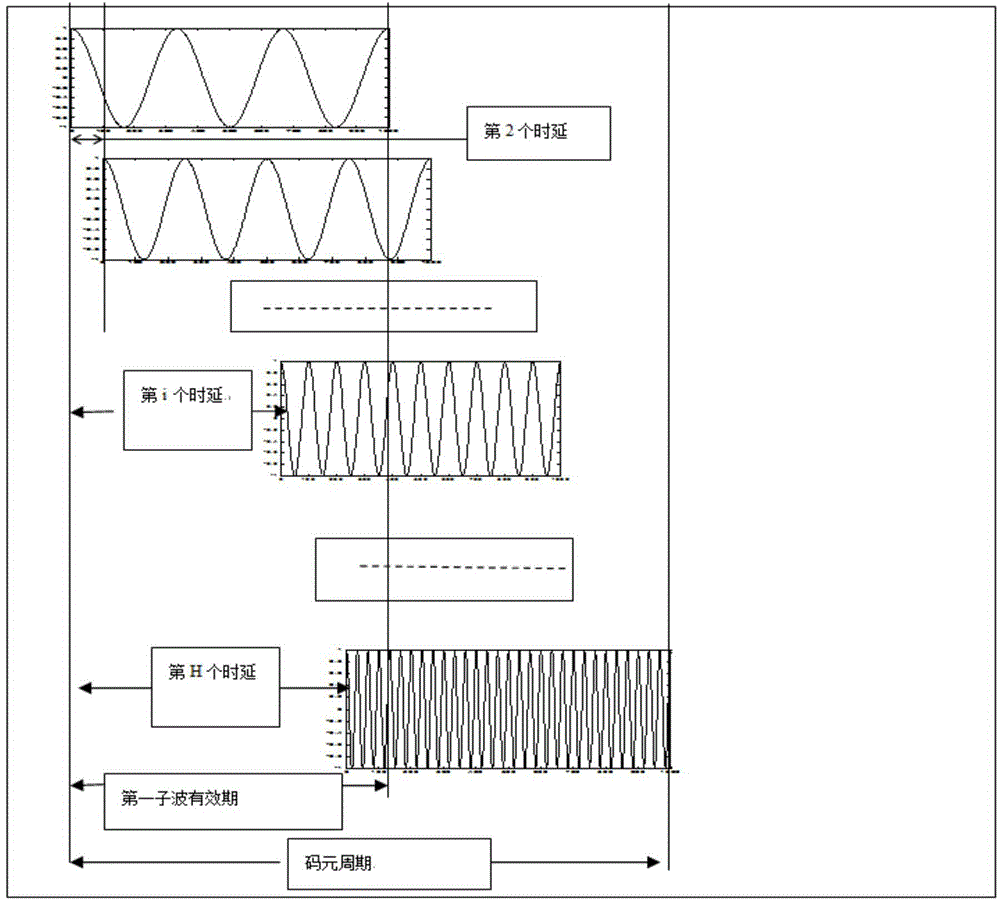

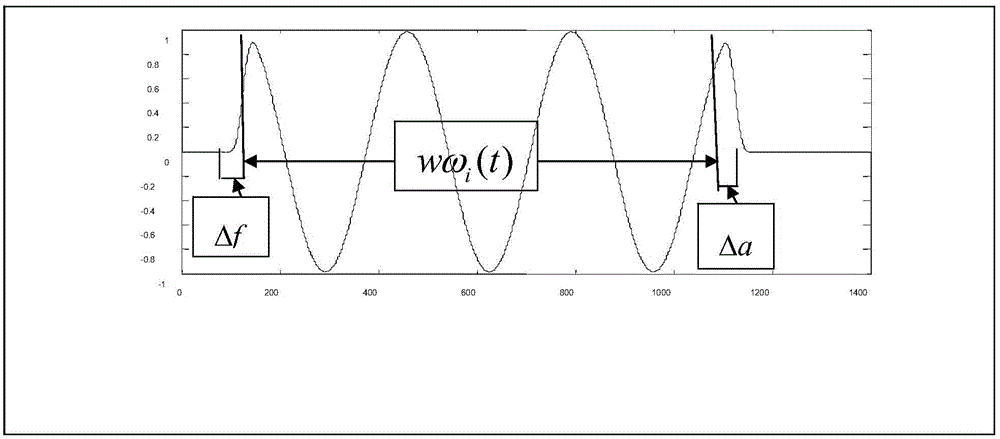

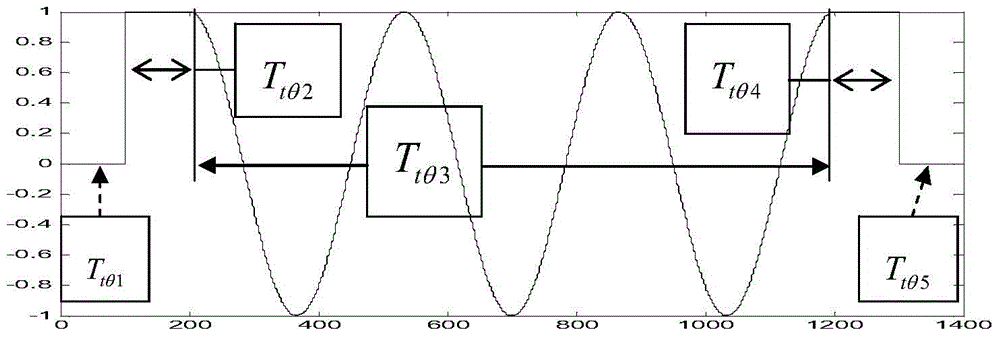

Time-delay multi-carriers modulation and demodulation method

ActiveCN104601517AWavelet number increasedIncrease the number of subchannelsMulti-frequency code systemsTime delaysCarrier signal

The invention discloses a time-delay multi-carriers modulation and demodulation method. The code element waveform structure is composed of H cosine wavelets, all wavelets have different time delays sequentially, and various wavelets are linearly superposed to form a non-orthogonal composite wave code element waveform; the wavelets are amplitude-variable basic wavelets, and the basic wavelets are standard cosine waves with amplitude at 1 constantly. Meanwhile, the basic wavelets of a transmission end are transmitted finishing basic wavelets with a trailing area 0 and a trailing area 1 added at two ends of the standard cosine waves, and a receiving end is partially balanced to obtain received finishing basic wavelets with trailing to form non-orthogonal composite waves. The modulation adopts three methods including (1) an equilateral-triangle equation set method formed by an equilateral-triangle coefficient matrix; (2) an inverted-triangle equation set method formed by an inverted-triangle coefficient matrix; (3) an optimization method. The time-delay multi-carriers modulation and demodulation method reserves the advantages of high efficiency of a time-frequency mixing multi-carriers modulation method and reduces complexity as well as error bit rate.

Owner:DALIAN MARITIME UNIVERSITY

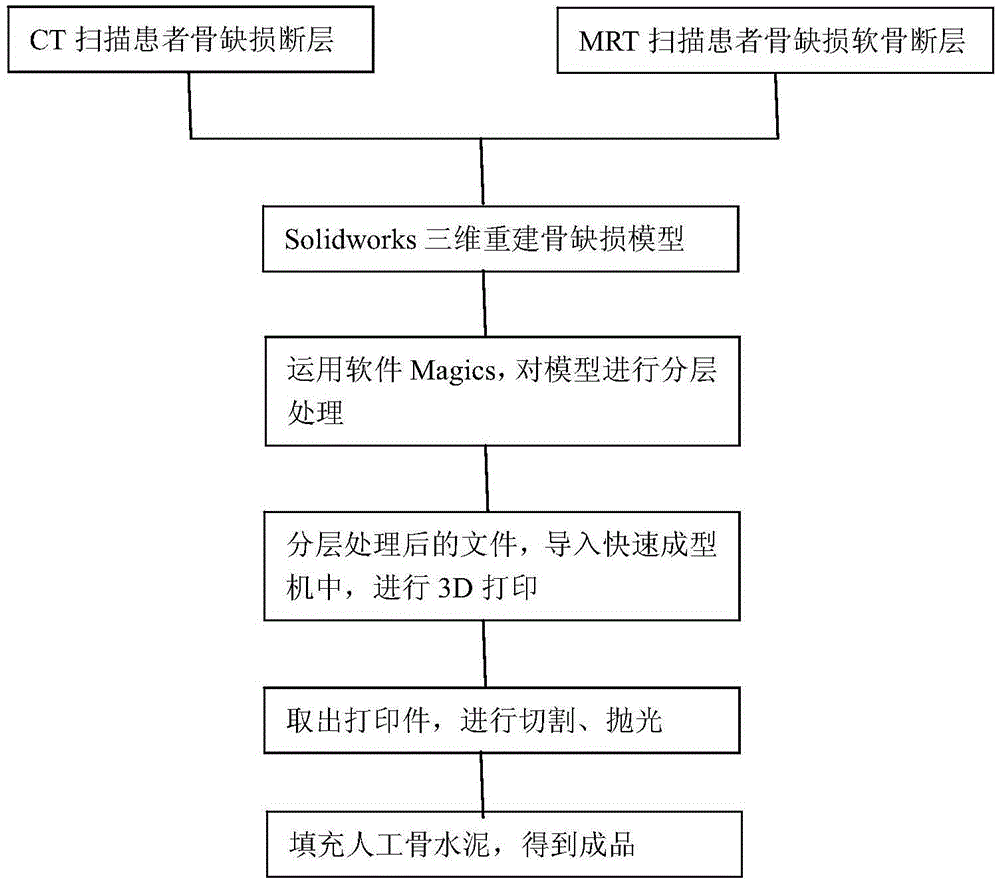

Large bone defect assist bone graft magnesium alloy stent and production method thereof

InactiveCN104688387AMake up for the shortcomings of failureImprove matchBone implantBone defectArtificial bone

The invention discloses a massive bone defect assist bone graft magnesium alloy stent and a production method thereof. The production method includes the steps of (1) performing three-dimensional reconstruction according to the CT and MRT imaging technology to simulate the size and the shape of a large bone defect portion; (2) printing a biomedical orthopedic material through the 3D printing technology to produce the assist bone graft magnesium alloy stent; (3) treating the outside and edges of the assist bone graft magnesium alloy stent to enable the assist bone graft magnesium alloy stent to adapt to the large bone defect portion; (4) filling the assist bone graft magnesium alloy stent with appropriate amount of artificial bone cement to complete the overall assist bone graft magnesium alloy stent. The massive bone defect assist bone graft magnesium alloy stent and the production method of the massive bone defect assist bone graft magnesium alloy stent are based on CT and MRT data of a patient to maximally repair the defect portion of the patient, effectively improve the matching degree of the bone stent with the patient and use the 3D printing technology for achieving personalized customization, shortening the production time of the bone stent and reducing costs.

Owner:SOUTH CHINA INST OF COLLABORATIVE INNOVATION

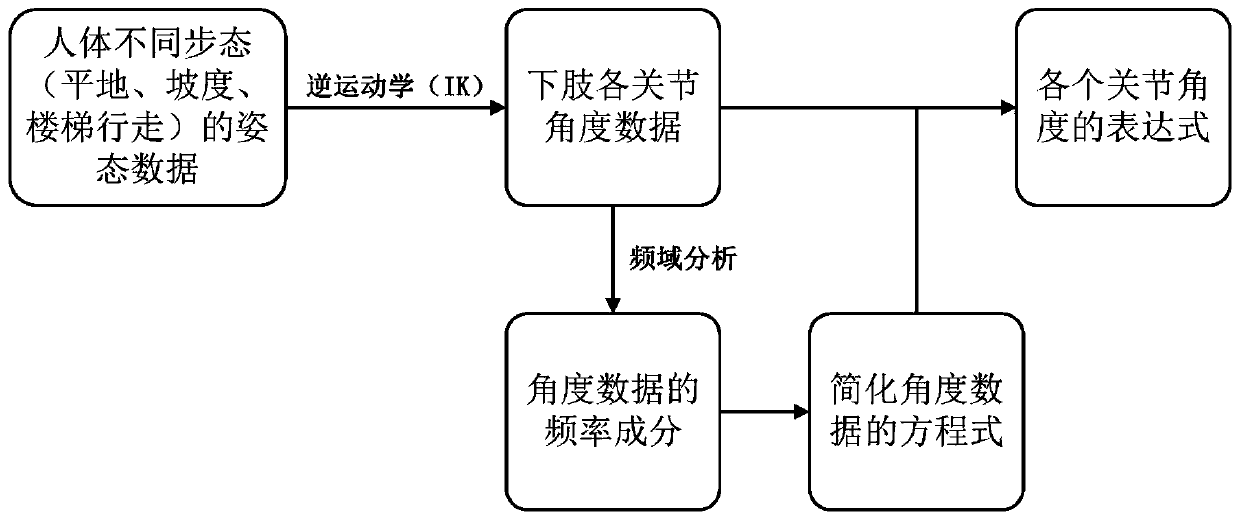

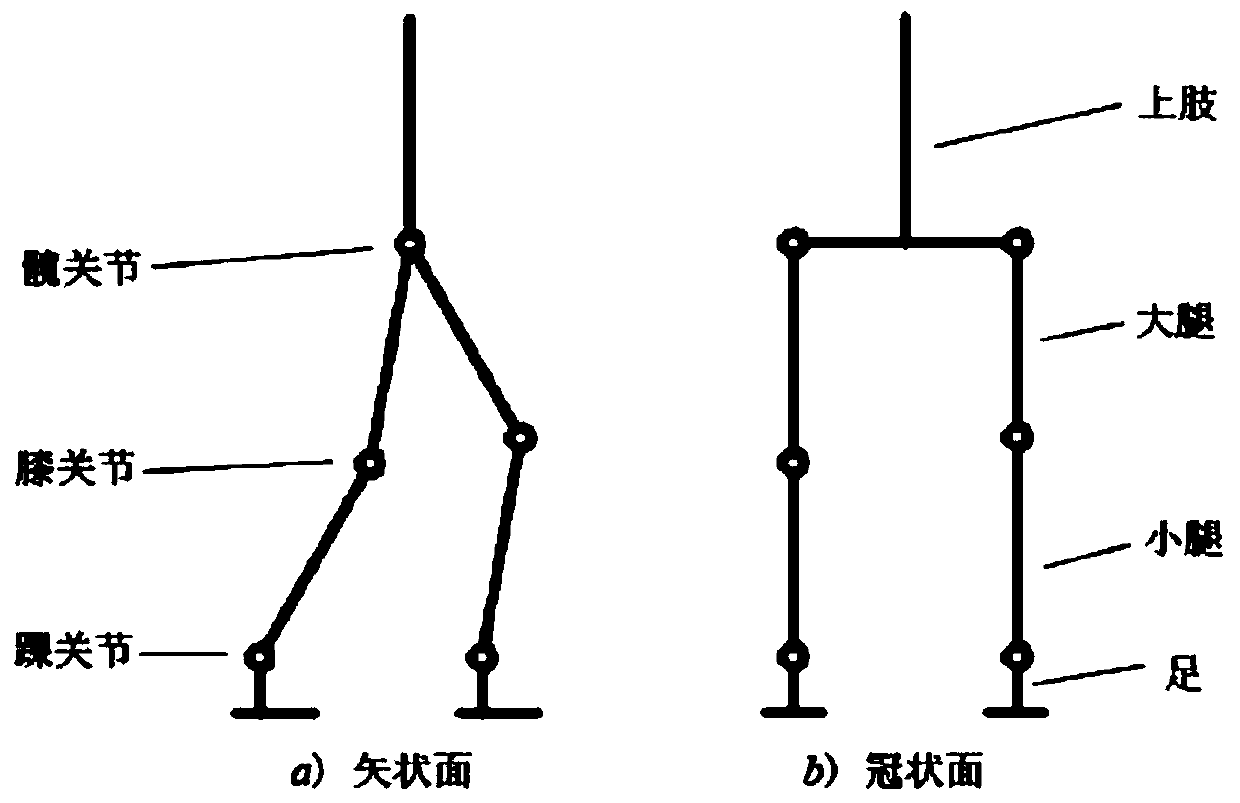

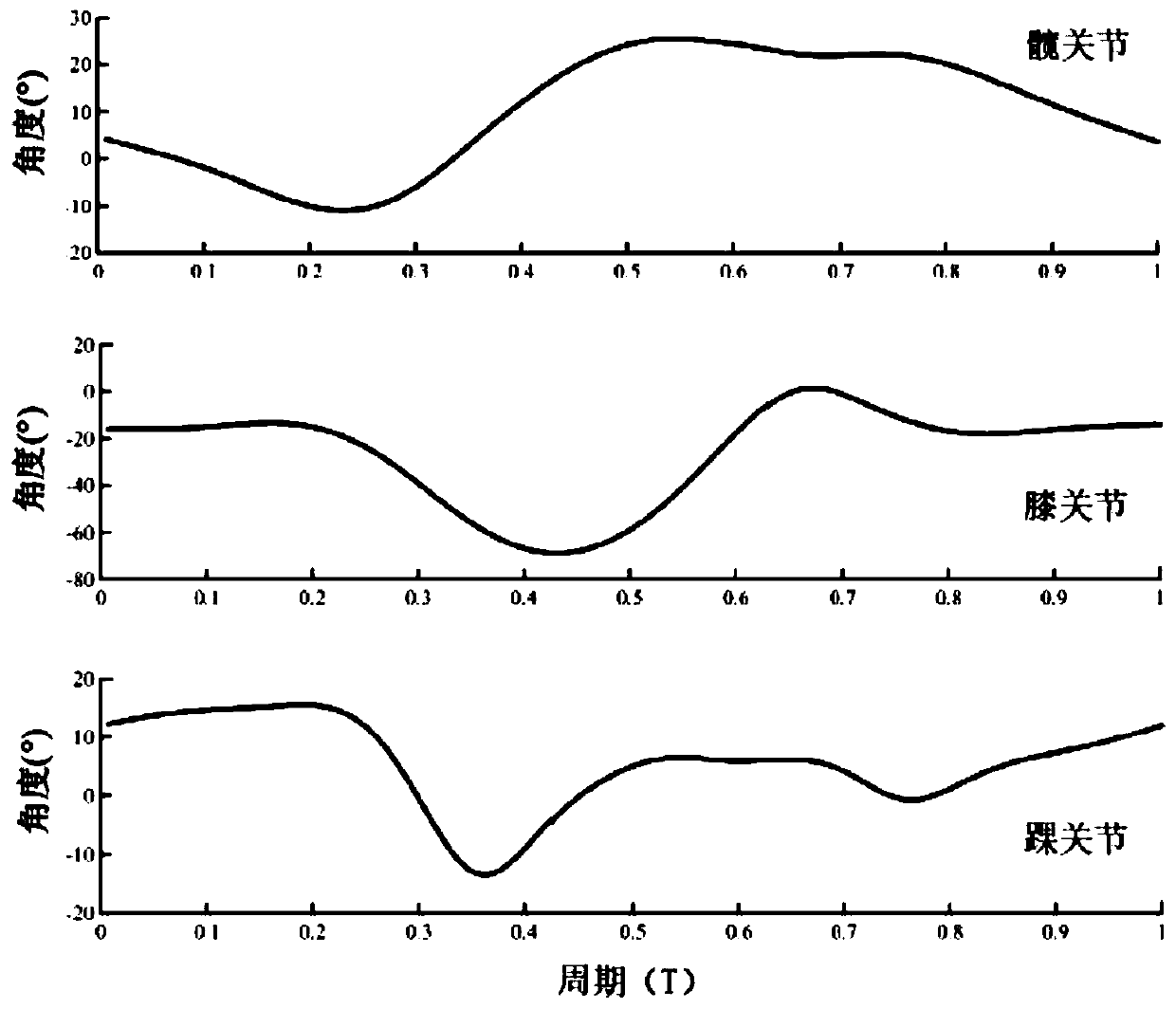

Complex environment-oriented lower limb robot gait planning method

ActiveCN109991979AGood fitSignificant reductionPosition/course control in two dimensionsVehiclesHuman bodyGait planning

The invention belongs to the field of robots, and specifically discloses a complex environment-oriented lower limb robot gait planning method. The method comprises the steps of: setting mark points onthe lower limbs of a human body, and obtaining static posture data and moving posture data of the human body through a motion capture system; carrying out inverse kinematic calculation on a human body model according to the moving posture data so as to obtain angle data of each joint in the moving process; and establishing a fitting function according to a relationship between the angle data of each joint and a period, and carrying out lower limb robot gait planning according to the fitting function. According to the method, the discrete joint angle data is serialized, so that the change of the joint angle data in the gait period can be basically restored; experiences prove that the method has relatively fitting results, is capable of enabling the lower limb robots to restore the motionsof the human bodies to the greatest extent, and can be suitable for complex walking environments such as walking, climbing hills and climbing stairs.

Owner:HUAZHONG UNIV OF SCI & TECH

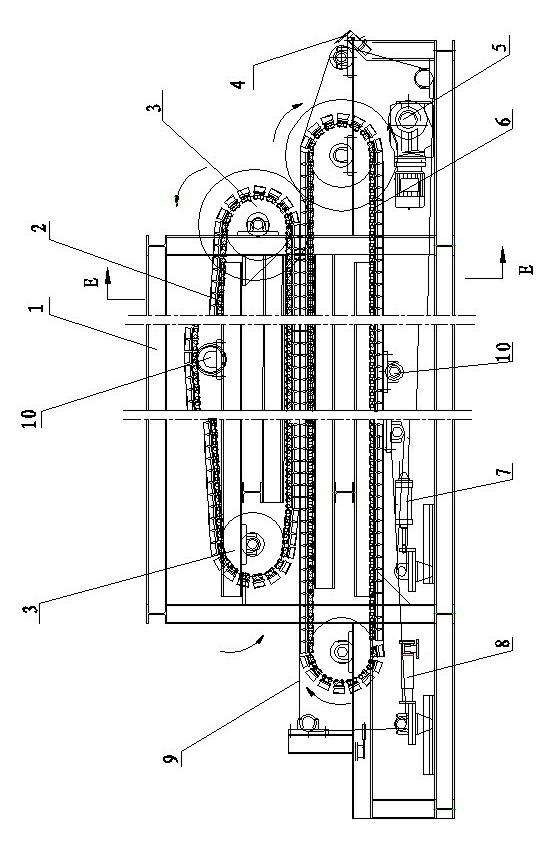

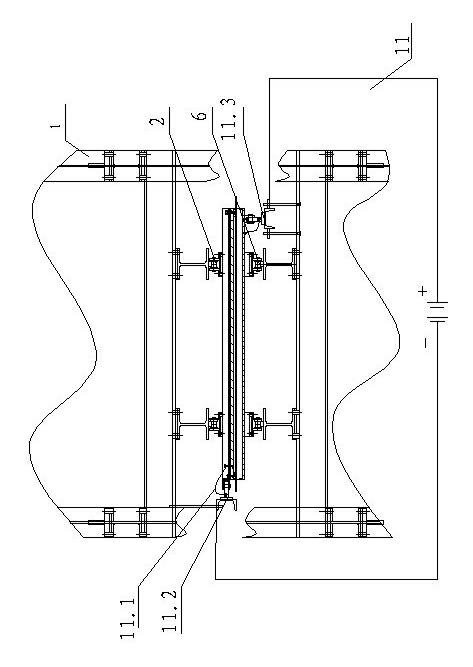

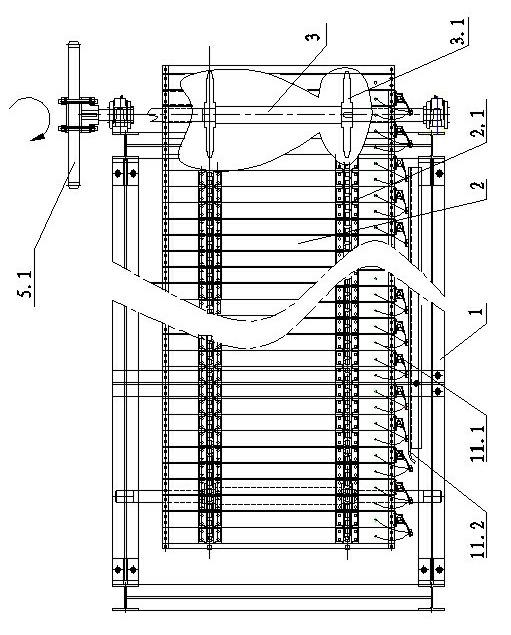

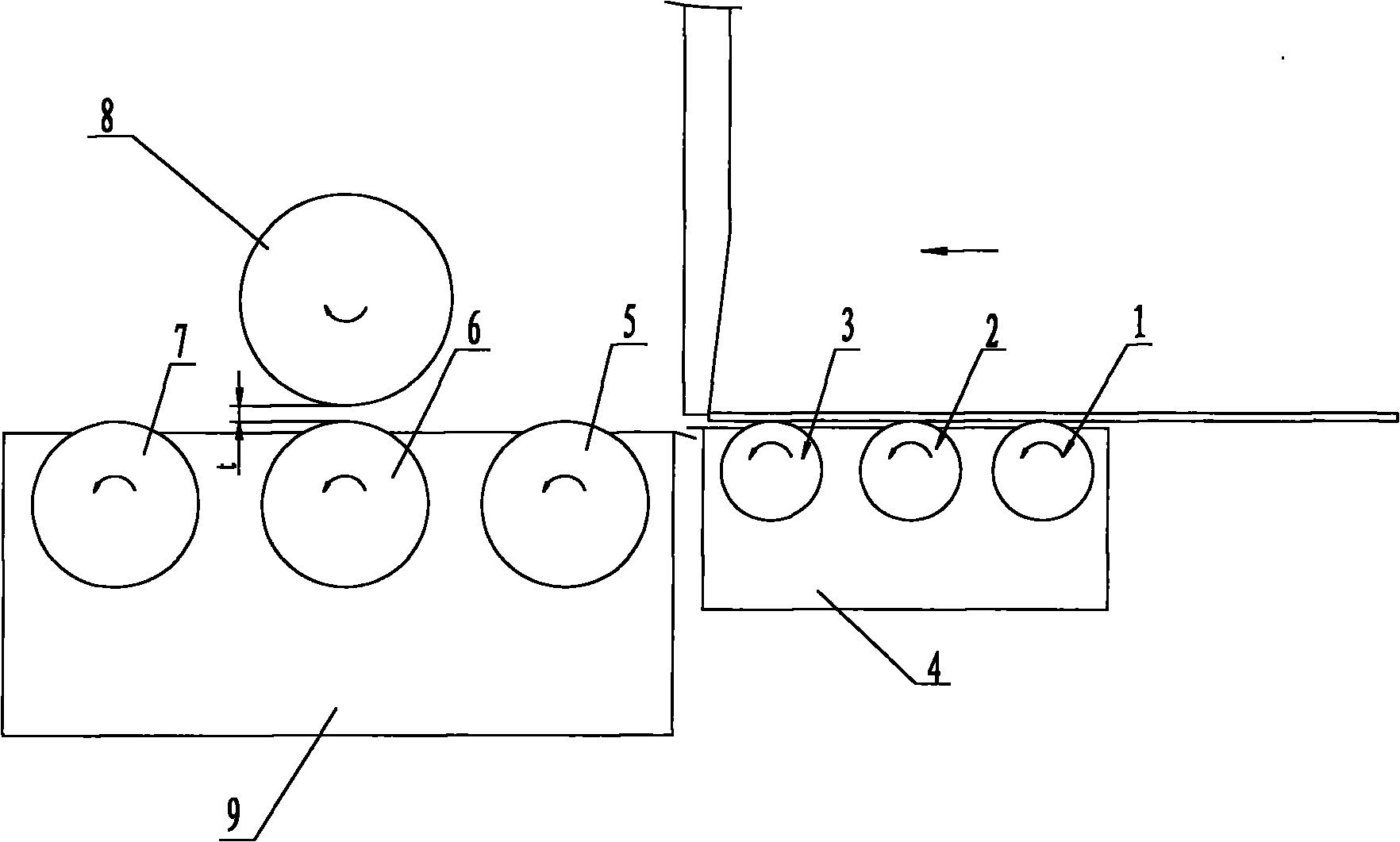

Electroosmosis belt type squeezing sludge dehydration equipment

ActiveCN102653438ASignificant reductionFacilitate flowSludge treatment by de-watering/drying/thickeningSludge cakeDrive shaft

The invention discloses electroosmosis belt type squeezing sludge dehydration equipment, which comprises a stander, an upper squeezing belt, transmission shafts, a scraper blade, power machinery, a lower squeezing belt, a tension device, a rectification device, a filter belt, supporting wheels and a power supply, wherein the upper squeezing belt and the lower squeezing belt which are supported and driven by the transmission shafts have the same structure, namely a track type structure which consists of two chains arranged at an interval and an upper bridge plate and / or a lower bridge plate which are / is transversely arranged according to pitches of the chains; the upper squeezing belt and the lower squeezing belt are respectively connected with the positive electrode and the negative electrode of the direct current power supply and clamp the filter belt to enter a wedged flat groove of the stander, namely a squeezing region under an electrophoresis condition, so that water molecules in sludge flow towards the lower bridge plates with negative levels; and therefore, the squeezing dehydration efficiency is greatly improved, the sludge is reduced obviously, and the produced high-dryness sludge cake is favorable for later-stage recycling application.

Owner:江苏百新环境工程有限公司

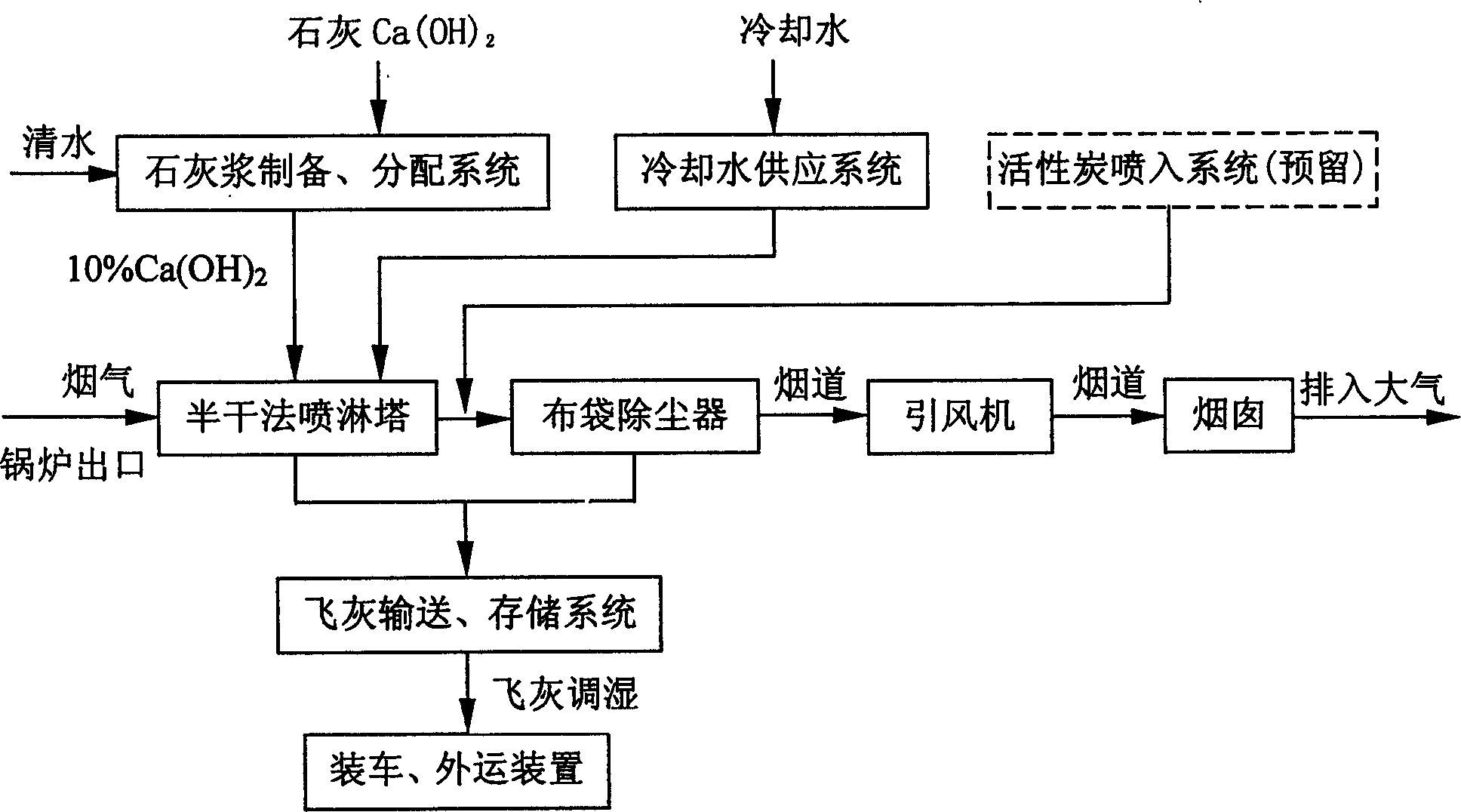

Integrated garbage treatment and utilization method for effectively controlling dioxin

InactiveCN102145343AInhibitionContainment hazardWaste processingSolid waste disposalRefuse DisposalsPollution

The invention discloses an integrated garbage treatment and utilization method for effectively controlling dioxin, which comprises a garbage sorting, drying and storing method, a garbage dry distillation, pyrolysis and gasification method, an integrated treatment and utilization method for garbage ash and combustible gas and an integrated treatment and utilization method for exhaust gas and wastewater, belonging to the field of environmental protection. The method comprises how to effectively control the dioxin and solve the pollution problem of reducing waste water, exhaust gas, waste residue and the like in the garbage treatment process. The solution comprises the steps of sorting and drying the garbage, turning the garbage into renewable resources like combustible gas, tar and the like through integrated treatment of dry distillation, pyrolysis and gasification, comprehensively utilizing the waste residue and waste water for brick making and emitting the exhaust gas up to the standard after treatment. By adopting the technique for garbage treatment, the generation and damage of the dioxin can be effectively controlled, the emission of no waste water, no waste residue and no wastes can be achieved, and the better effect of complete harmlessness, reduction and recycling approximate to 100% can be realized.

Owner:ZHENGREN ENVIRONMENTAL PROTECTION TECH

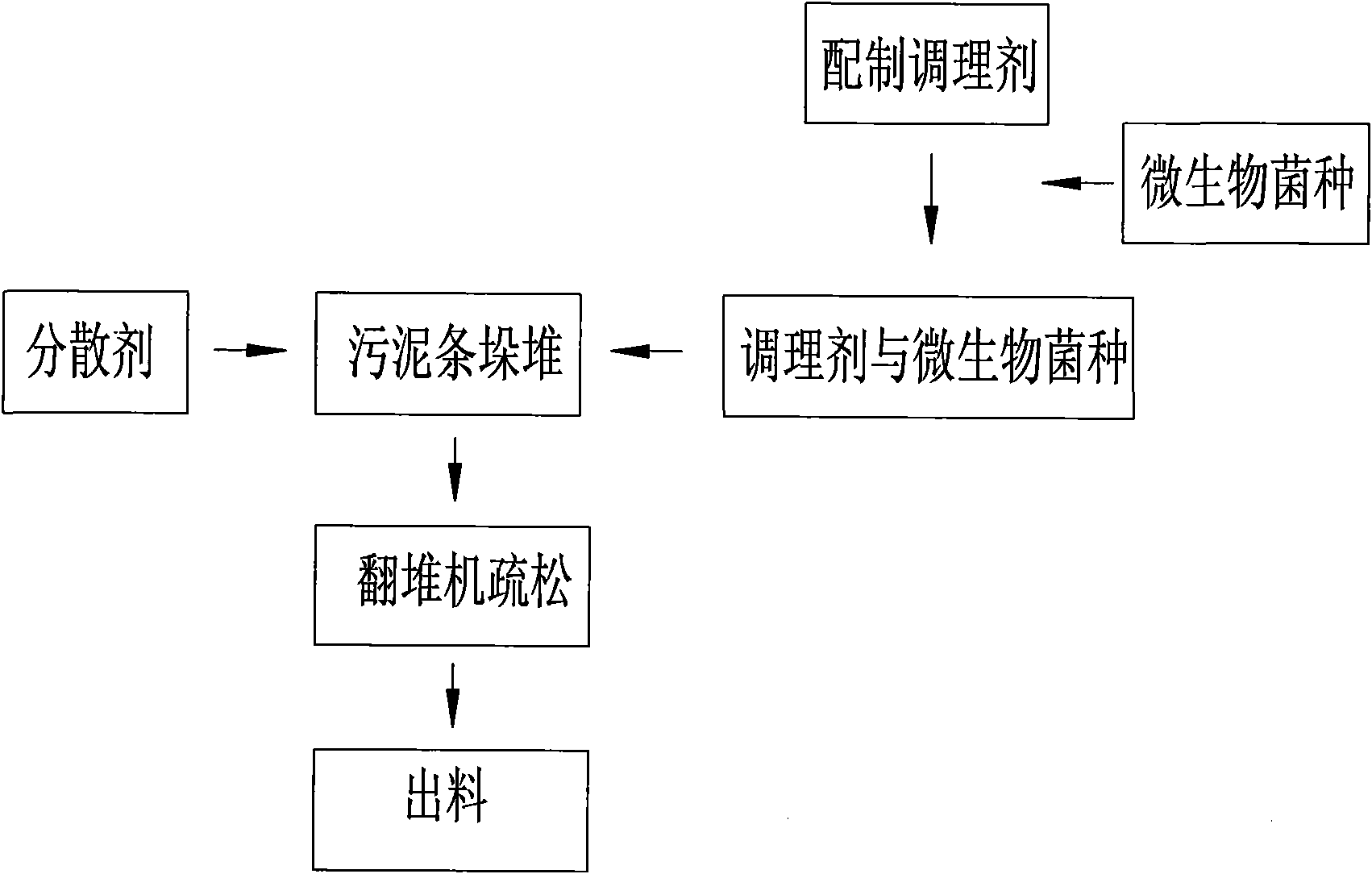

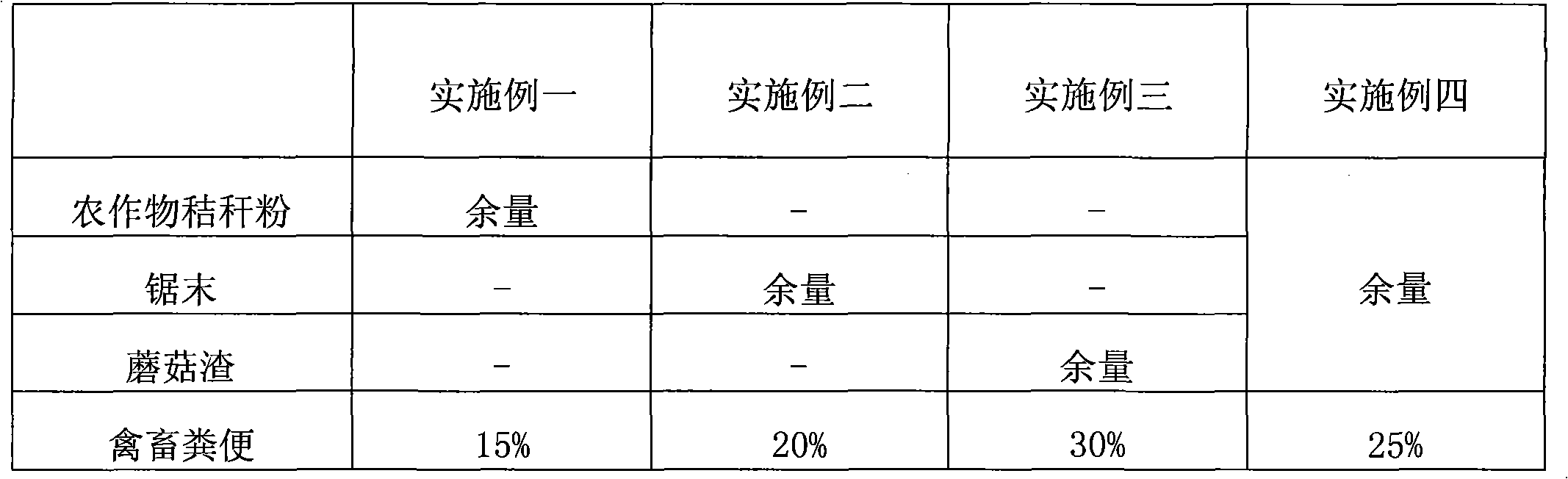

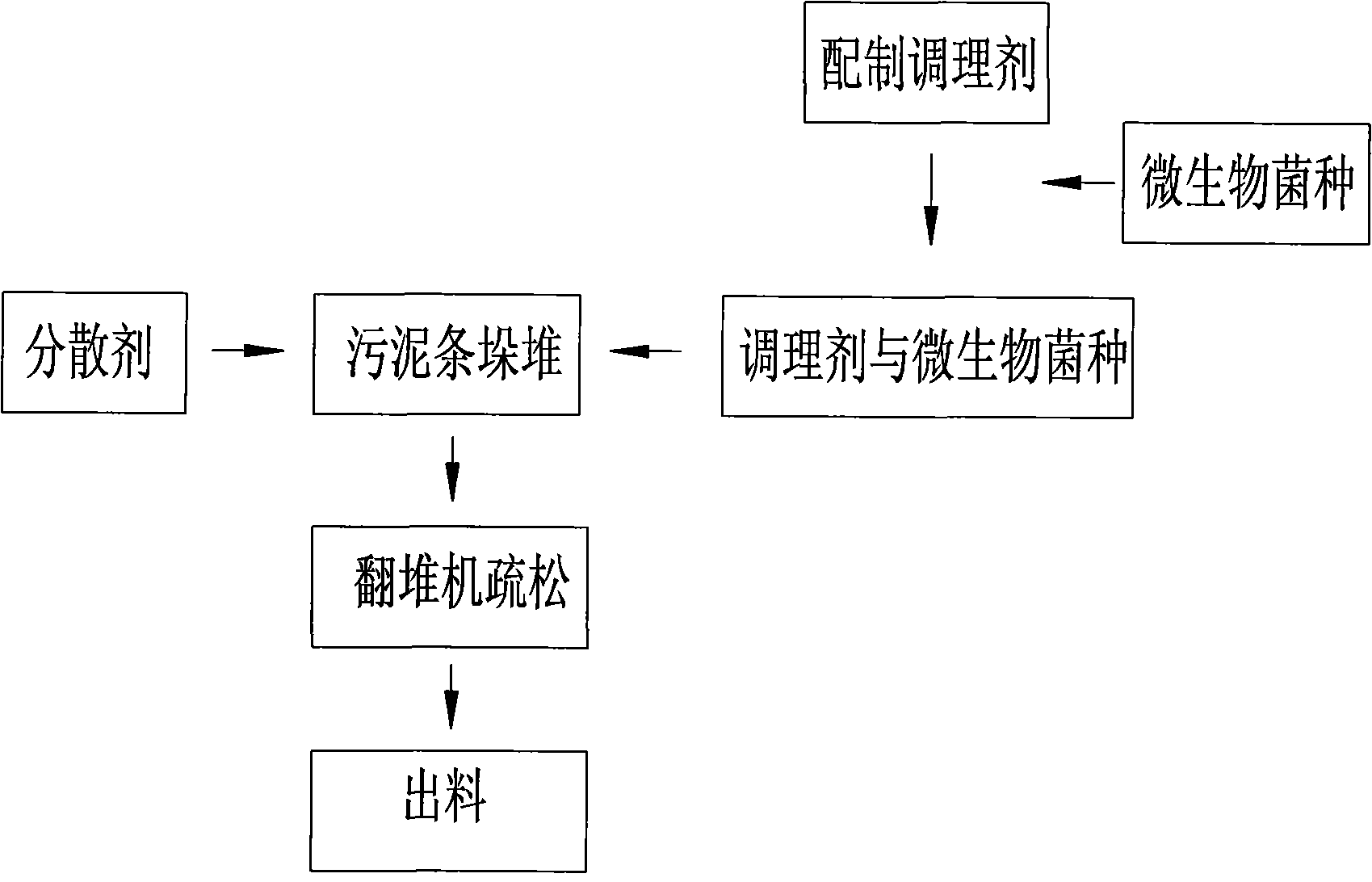

Method for innocent treatment of sludge in sewage plant

The invention discloses a method for the innocent treatment of sludge in a sewage plant, which comprises the following treating steps of: (1) piling sludge on the cement-hardened ground into windrows; (2) uniformly spreading conditioner on the windrows, wherein the weight part ratio of the sludge to the conditioner is 600-800:400-200; (3) preparing nutriment, wherein the nutriment comprises the following component in parts by weight: 5-8 parts of starch, 0.5-1 part of sugar and 0.5-1 part of ethanol of which the volume content is 40%; (4) uniformly mixing the nutriment with compound microorganism microbial inoculum according to the weight ratio of 1-2:1-2; (5) directly spreading the mixture of the nutriment and the compound microorganism microbial inoculum in step (4) on the windrows, wherein the weight ratio of the sludge to the mixture is 600-800:1-2; and (6) using an upender to upend and stir the windrows, and thus finishing the overall treatment 10-15 later. The method is simple in treating process, is applicable to large-scale treatment, and has high innocent treatment degree.

Owner:吴立阳

Sludge conditioning dehydration coupling carbonization reduction treatment method and system

InactiveCN110759626AReduce consumptionImprove energy utilizationSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesExhaust gasProcess engineering

The invention discloses a sludge conditioning dehydration coupling carbonization reduction treatment method. The method comprises the following steps: A, flue gas flow, to be more specific, hot flue gas enters a pyrolysis carbonization system to indirectly heat sludge, heat is absorbed by the carbonization process, discharged flue gas enters a thermal drying dehydration system, the sludge is dried, and tail gas carrying a small amount of dust enters a cyclone dust collector to be subjected to solid-gas separation, enters a deodorization device through a desulfurization and denitrification system and a system induced draft fan to be deodorized and purified, and then is discharged after reaching the standard; and B, a sludge process, to be more specific, wet sludge is sent to a conditioningtank for homogeneous conditioning, to a mechanical filter pressing device for filter pressing, to a semi-dry sludge bin, to a sludge thermal drying dehydration system via a sludge buffer hopper, and to a pyrolysis carbonization system after directly contacting with hot flue gas for heat exchange, the sludge is indirectly heated and carbonized by the high-temperature flue gas, organic matters in the sludge are precipitated in volatile forms, residual water is evaporated and precipitated, the sludge forms sludge carbon in the pyrolysis carbonization system, and after cooling, the sludge is sentto a finished product bin for loading and outward transportation.

Owner:SHANDONG JINFU ENVIRONMENTAL ENG CO LTD

Turbomachine with angular air delivery

ActiveUS7549294B2Mitigate such drawbackSignificant reductionContinuous combustion chamberGas turbine plantsCombustionTurbine

A turbomachine assembly comprising: an annular compression section; a casing formed by an outer annular shell (204) and an inner annular shell (206) secured inside the outer shell by means of a plurality of radial support arms (208); an annular combustion section housed inside the casing; and an annular turbine section. The air coming from the compression section presents rotary motion with an angle of inclination relative to a longitudinal axis (X-X) of the turbomachine, and the combustion section includes angular distribution means for determining air flow direction so as to impart on the gas leaving the combustion section rotary motion with an angle of inclination that is equal to or greater than the angle of inclination of the air leaving the compression section, said angular distribution means being formed by the support arms (208), each of which presents an angle of inclination relative to the longitudinal axis (X-X) of the turbomachine that is greater than or equal to the angle of inclination of the air leaving the compression section.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Method, devices and systems for radon removal from indoor areas

InactiveUS20180339262A1Reduce radon levelSignificant reductionMechanical apparatusGas treatmentEngineeringMultiple pass

Embodiments of the present disclosure are directed to a method for reducing radon contained in indoor air from an indoor area. In some embodiments, indoor air containing radon from indoor air is directed through at least one layer of an adsorbent medium configured for capturing radon from air. In some embodiments, the indoor air is directed through the adsorbent medium at a predetermined flow-rate such that the fraction of radon captured in a single pass though the assembly is very low, approximately 10% or less of the concentration of radon in the incoming air. The low capture rate is offset by multiple passes of the air through the medium.

Owner:ENVERID SYST

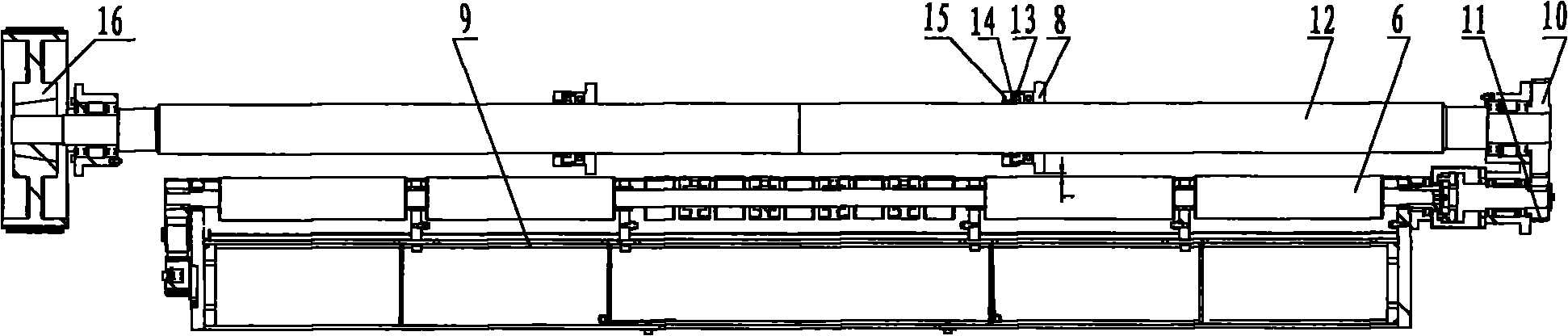

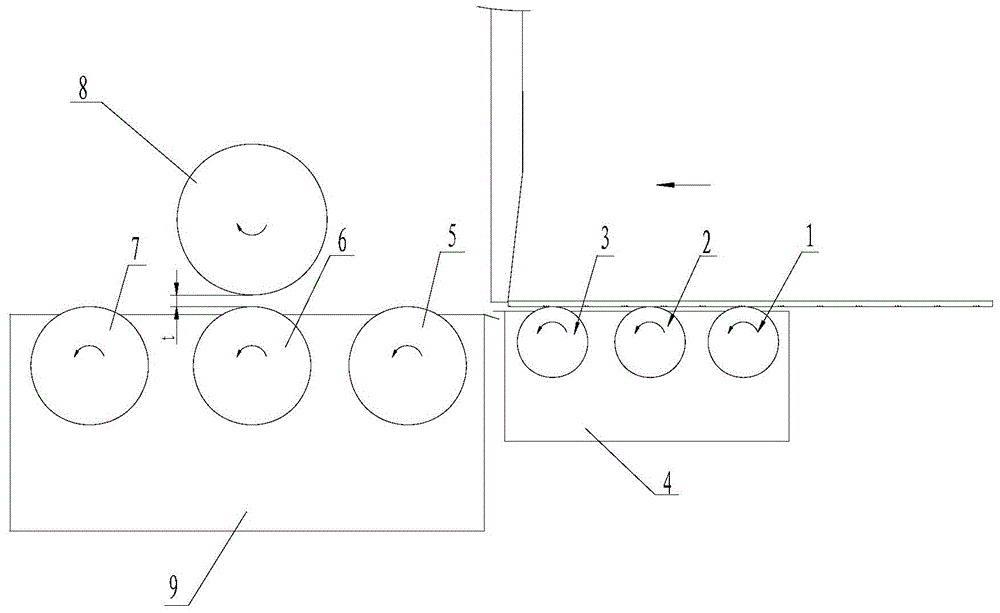

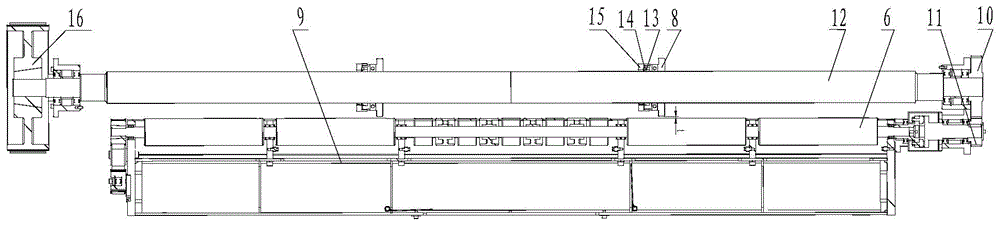

Servo side pressing and paper feeding machine

InactiveCN101935959AHigh precisionImprove efficiencyFunction indicatorsArticle feedersCardboardControl system

The invention provides a servo side pressing and paper feeding machine which is characterized in that a paper feeding mechanism comprises a vacuum absorption variable-speed paper feeding mechanism and a vacuum absorption constant-speed side pressing and paper feeding mechanism; two side pressing wheels are installed on a side pressing and paper feeding wheel shaft arranged above a constant-speed paper feeding wheel in the middle, the gaps between the side pressing wheels and the constant-speed paper feeding wheel are smaller than the thickness of a paper board, and the distance between the two side pressing wheels is adjusted by moving on the side pressing and paper feeding wheel shaft. Under the control of a vacuum absorption servo variable-speed paper feeding mechanism control system, the entire delivery of the corrugated board is realized by accelerating the corrugated board at first, then moving with constant speed and decelerating to stop, and the delivery precision and the delivery efficiency of the paper board are increased. Because of the action of a vacuum bellow, the corrugated board is tightly absorbed on the paper feeding wheel and is transported forward by means of friction force. The side pressing and paper feeding wheel only has auxiliary side pressing action, the pressing action of the side pressing and paper feeding on the corrugated board is reduced, and the strength of the corrugated board can not be substantially reduced.

Owner:QINGDAO MEIGUANG MACHINERY

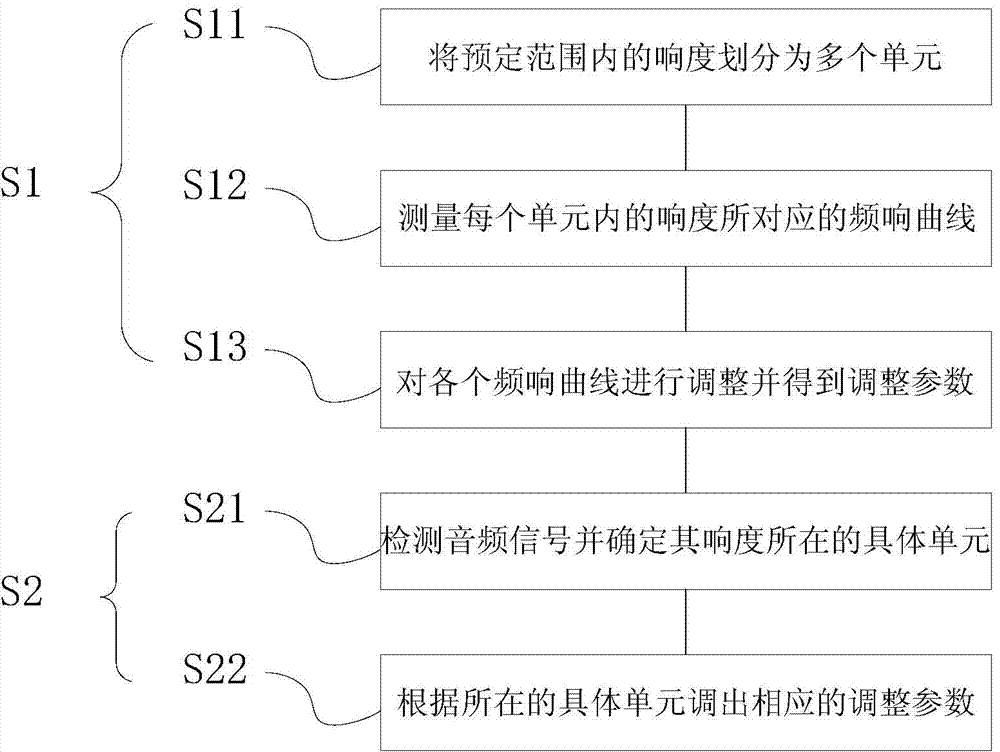

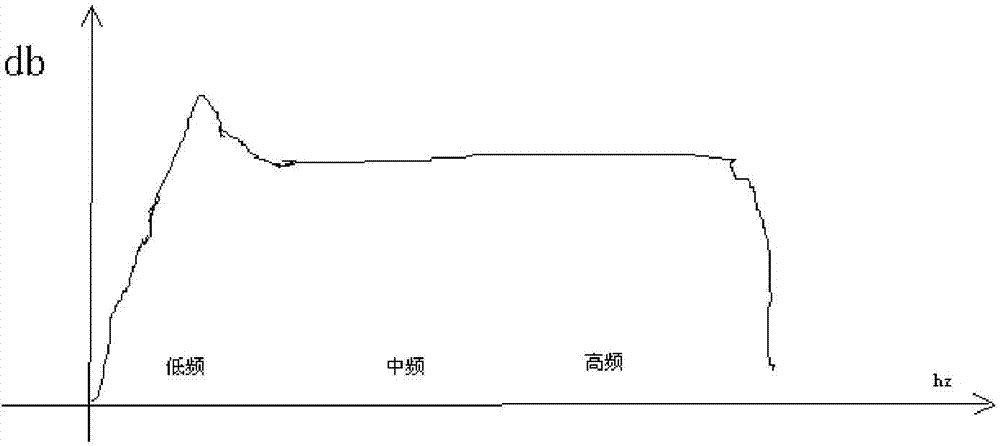

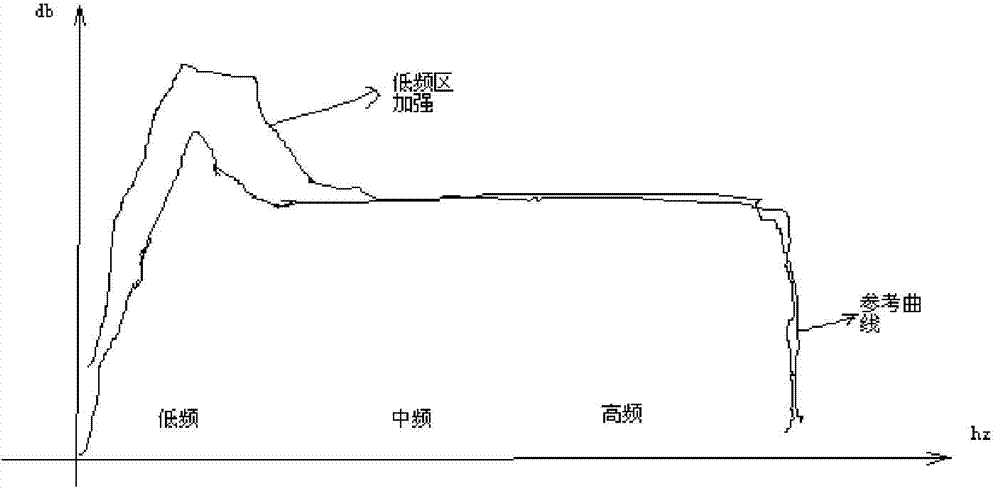

Sound recovering method based on loudness adjustment and control

InactiveCN103888868ASignificant reductionFrequency/directions obtaining arrangementsLoudnessComputer science

The invention discloses a sound recovering method based on loudness adjustment and control. The sound recovering method includes the steps that loudness in a preset range is divided into units, a frequency response curve corresponding to the loudness in each unit is measured, and all the frequency response curves are adjusted to obtain adjustment parameters; an audio signal is detected, the concrete unit where the loudness of the audio signal is located is determined, and the corresponding adjustment parameters are called according to the concrete unit where the loudness of the audio signal is located. Through parameter adjustment, the different frequency response curves are adjusted according to different loudness, so that audio output with any loudness always has a good fidelity effect.

Owner:刘海东

Process for generating combustible gas by virtue of sludge gasification

ActiveCN104031687ASignificant reductionNot producedCombustible gas productionCombustible gasProcess engineering

The invention discloses a process for generating combustible gas by virtue of sludge gasification. The process comprises the following steps: 1, dewatering sludge; 2, granulating the dewatered sludge, airing and drying; 3, feeding dried sludge granules into an integrated sealed pyrolysis gasification device, and gradually drying, drily distilling, carbonizing, gasifying and combusting the sludge granules from top to bottom in the integrated sealed pyrolysis gasification device; and finally discharging gas generated in the device through a pipeline, collecting the gas, combusting organic matter residues and inorganic matters at high temperature to obtain harmless molten slag, and discharging the molten slag through a slag outlet. According to the process, 200 tons of sludge with the water content of less than 60% can be treated by a monomer gasification device each day; the reduction, the harmlessness and the energization of the sludge treatment are realized; the dioxin generation conditions are avoided; the operating cost is low, namely a large quantity of manpower cost can be reduced due to automated operation and management; 1 ton of sludge with the water content of less than 30% can be averagely gasified to generate 1600Nm<3> of combustible gas.

Owner:河南华天环保科技有限公司

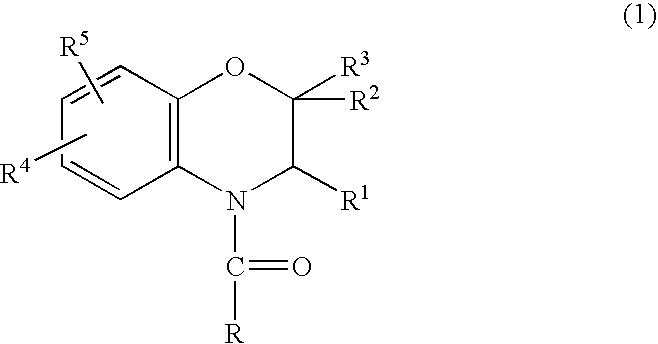

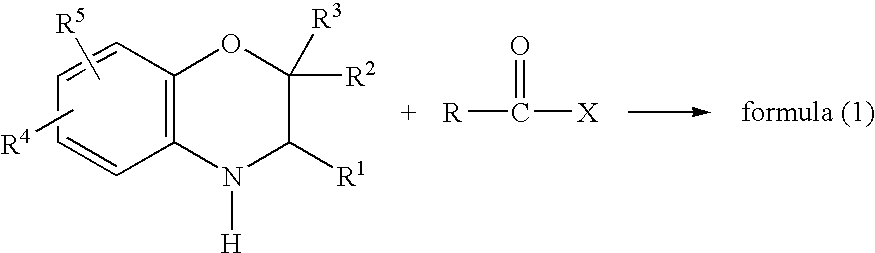

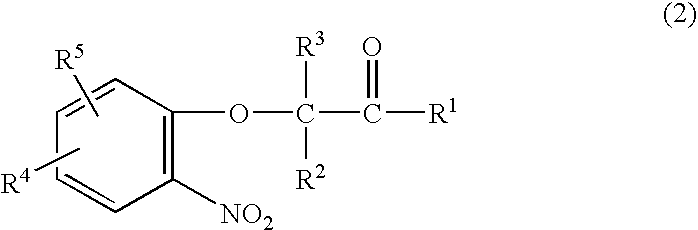

Method for making acylamides by synthesizing and acylating benzoxazines

InactiveUS20060014946A1Reduced by-product formationImproved o-nitrophenoxyketone feed rateOrganic chemistryPhotochemistryNitrophenol

A method is provided for synthesizing acylamides, useful as protectant for cultivated plants. A benzoxazine, such as 3,4-dihydro-3-methyl-2H-1,4-benzoxazine, is made in a stepwise manner by initially forming an o-nitrophenoxyketone by reacting a haloketone and a nitrophenol. The o-nitrophenoxyketone is hydrogenated to form the corresponding benzoxazine, which is thereafter acylated with an acylhalide to produce the acylamide, such as 4-dichloroacetyl-3,4-dihydro-3-methyl-2H-1,4-benzoxazine.

Owner:SYNGENTA CROP PROTECTION INC

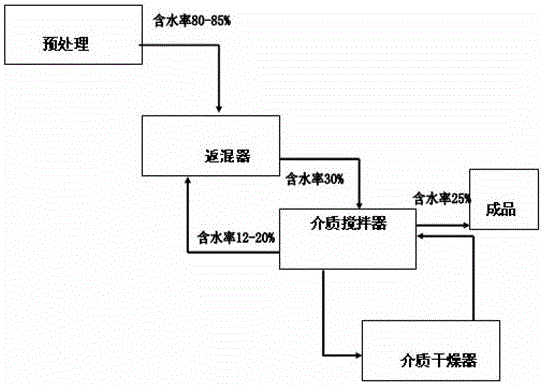

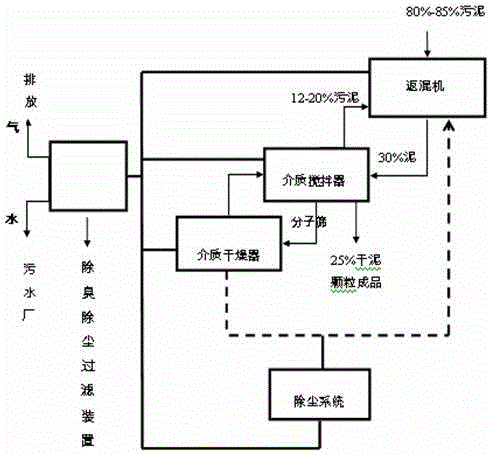

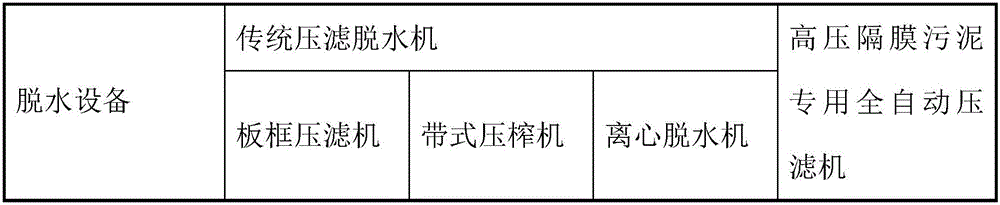

Dyeing sludge deep dehydrating-drying treatment device and process

ActiveCN105693052ALow solid contentSignificant reductionSludge treatment by de-watering/drying/thickeningWaste water treatment from textile industrySludgeSmall footprint

The invention discloses a dyeing sludge deep dehydrating-drying treatment device and process. The device comprises a dyeing sludge storage tank, a back-mixing machine, a medium stirrer and a medium dryer, wherein sludge is stored in the storage tank and enters the medium stirrer after being subjected to biological pretreatment and mixed with a water absorption medium, the water absorption medium and the sludge are vibrated, sieved and separated through the medium stirrer, the separated water absorption medium enters the medium dryer, moisture in the water absorption medium is evaporated though the medium dryer, the water absorption medium is dried by the medium dryer, the heated water absorption medium enters the medium stirrer again, the water absorption medium and the sludge are vibrated, sieved and separated through the medium stirrer again, the moisture content of separated dry sludge particles is reduced to be 25%, the dry sludge particles are transported outwards and packaged as finished dry sludge particles, and part of sludge with the moisture content of 12-20% in the medium stirrer enters the back-mixing machine to be mixed with original sludge with the moisture content of 80-85%. The device is small in occupied area, low in investment and low in operation cost.

Owner:GUANGDONG UNIV OF TECH

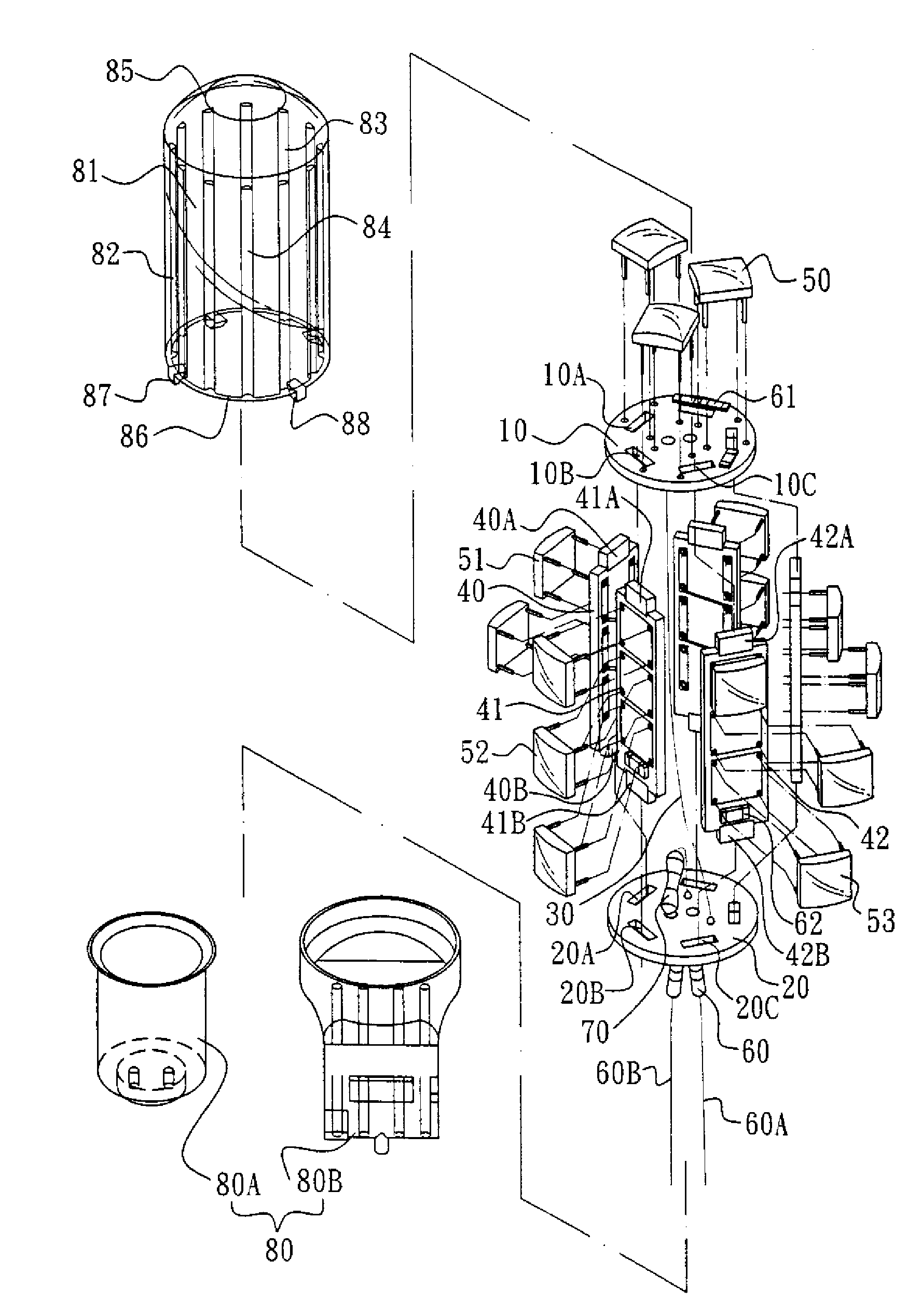

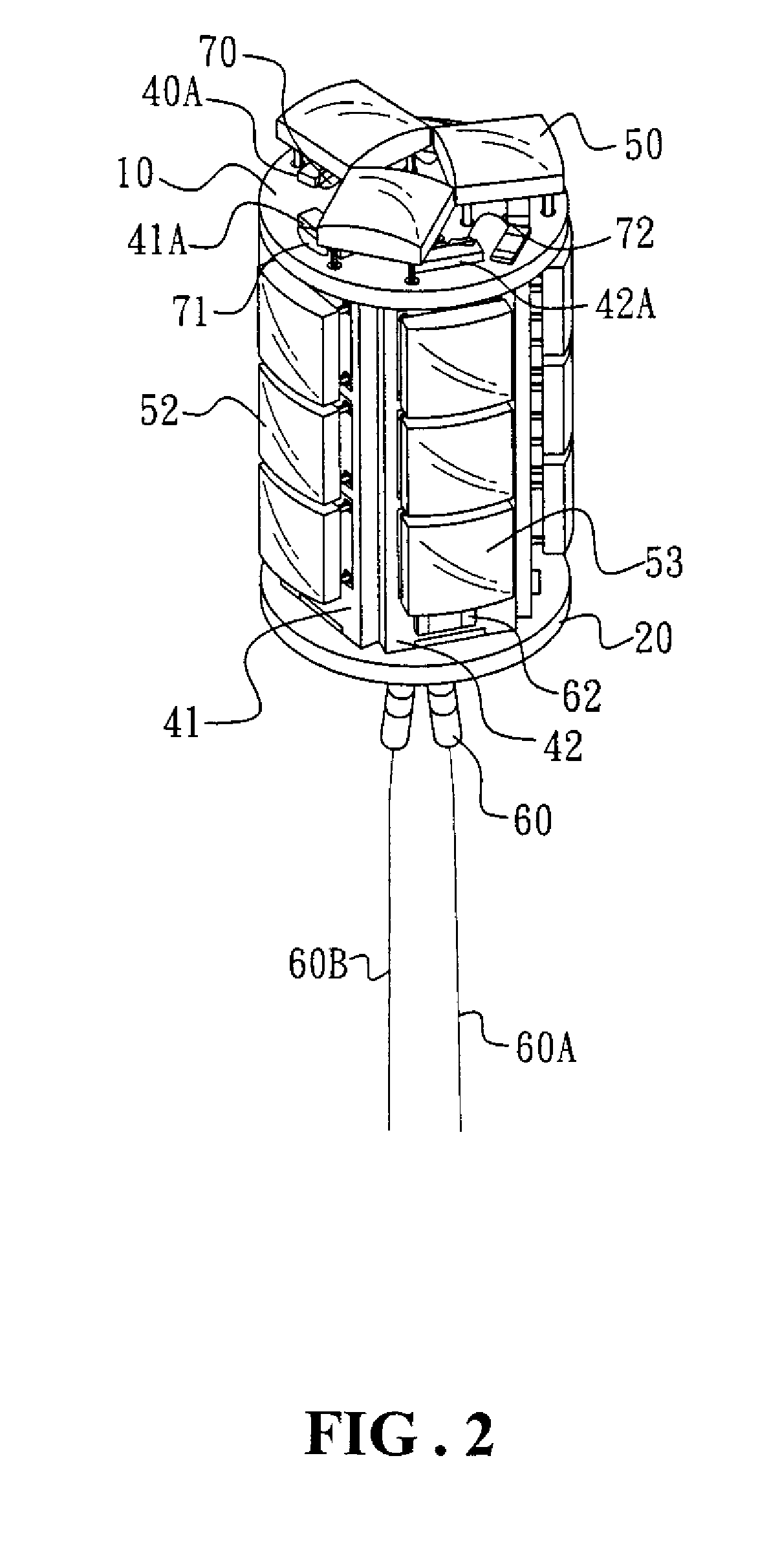

Light-emitting diode stacked lighting core for lamp bulb

InactiveUS20090116236A1Improve lighting effectsLess heat resistanceNon-electric lightingPoint-like light sourceElectricityEffect light

A light-emitting diode stacked lighting core includes a core top board, a core bottom board, and vertical boards, all being circuit boards. The core top board and the vertical boards are provided with light-emitting diodes and the core bottom board is provided with a circuit that is formed of a rectifier and a voltage reduction element and having two terminals extending outward. The vertical boards form extended fitting tabs and the core top board and the core bottom board respectively form openings corresponding to the fitting tabs to receive the fitting tabs to fit therein and to be fixed thereto by means of soldering, whereby the light-emitting diodes of the core top board and the vertical boards are put in electrical connection with each other to form the lighting core that is receivable and fixed in a light-transmitting enclosure.

Owner:CHIANG WEN CHIANG

Method for making biological coal by reaction of fly ash and municipal sludge

The invention discloses a method for making biological coal by the reaction of fly ash and municipal sludge, comprising the following steps of: firstly determining water content of the municipal sludge in pipelines by utilizing a computer system, and adding the fly ash to municipal sludge pipelines through fly ash pipelines according to the determined water content to make the fly ash mix with the municipal sludge to react and absorb water, wherein the water content of the mixture after the reaction at the discharge opening is 1-5%; and then adding a liquid deodorizer to the mixture and mixing in an agitator tank, wherein the water content of the mixed municipal sludge is 8-10%; finally making grains with different gradations by a pelletizer. The weight percentage of calcium oxide to the fly ash is 15-35%, and the weight percentage of free calcium to the fly ash is 0.2-0.4%. By utilizing the method of the invention, the floor area stacking the fly ash of a power plant is also reduced while the municipal sludge is treated, the volatile matter of the produced biological coal as received basis ranges 27-35%, the low calorific value of the as received basis is 3000-4000 kcal / kg totally similar to that of the coal, and the sustained combustion of the biological coal can be completely realized.

Owner:SHANXIN KETAO TECH BEIJING +1

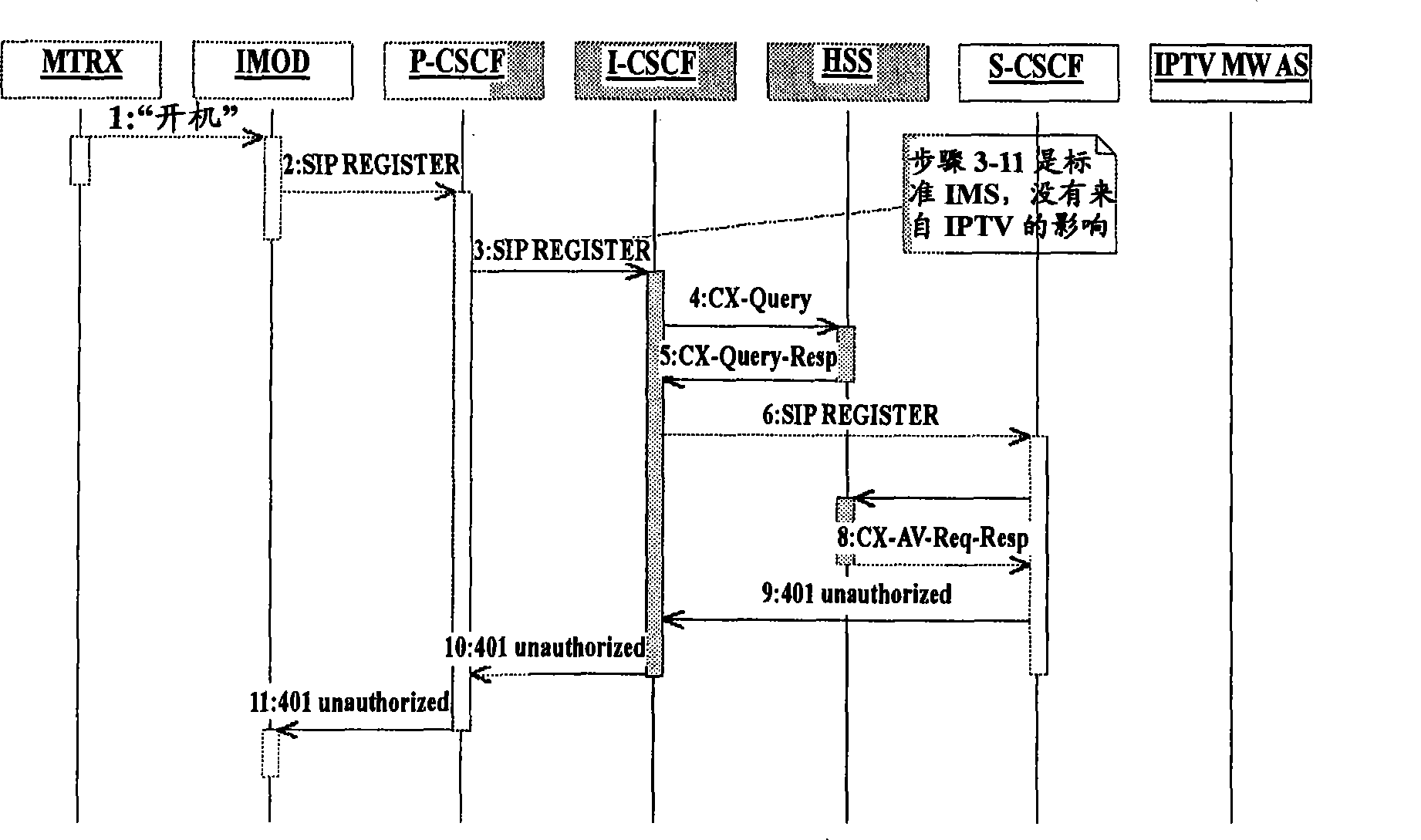

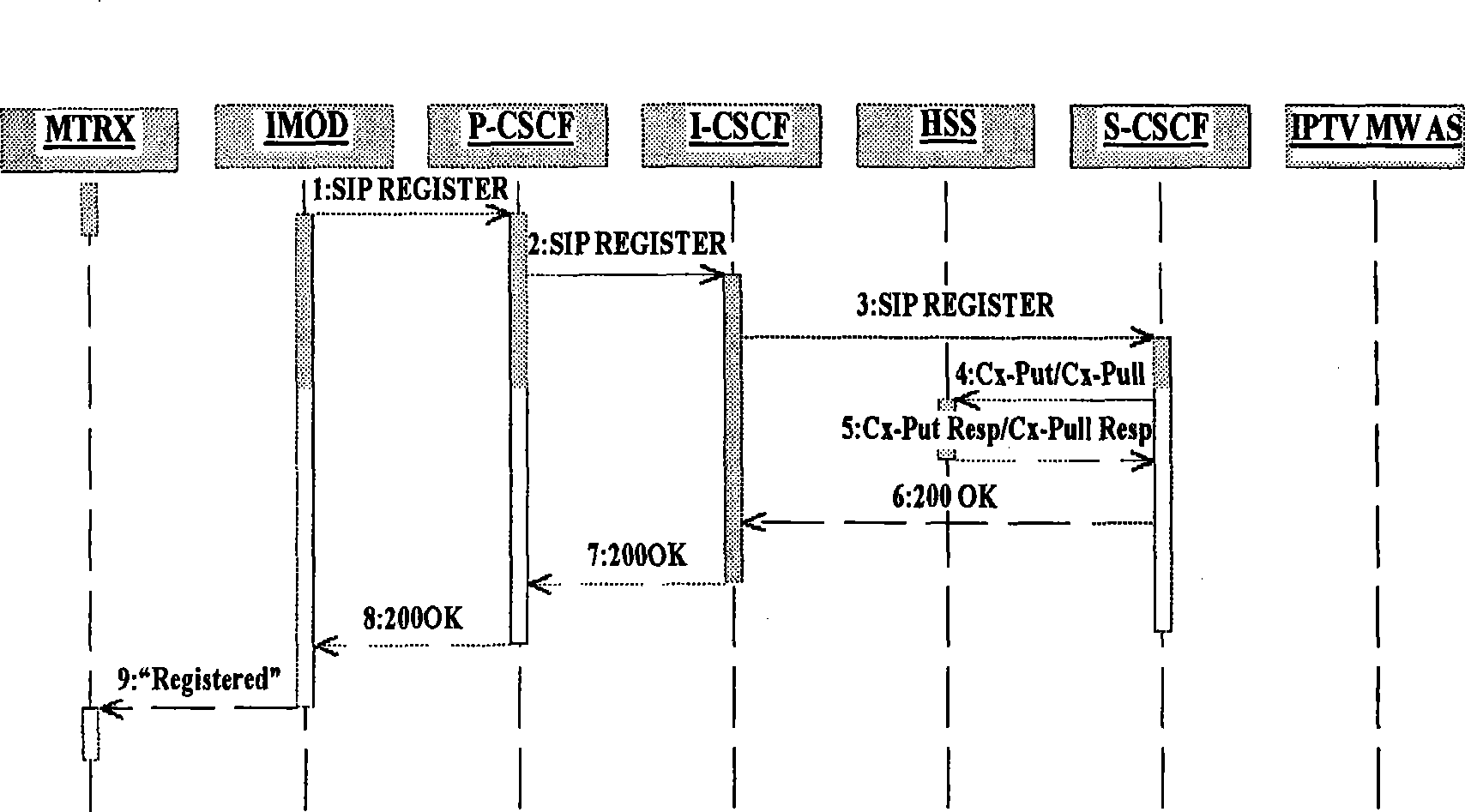

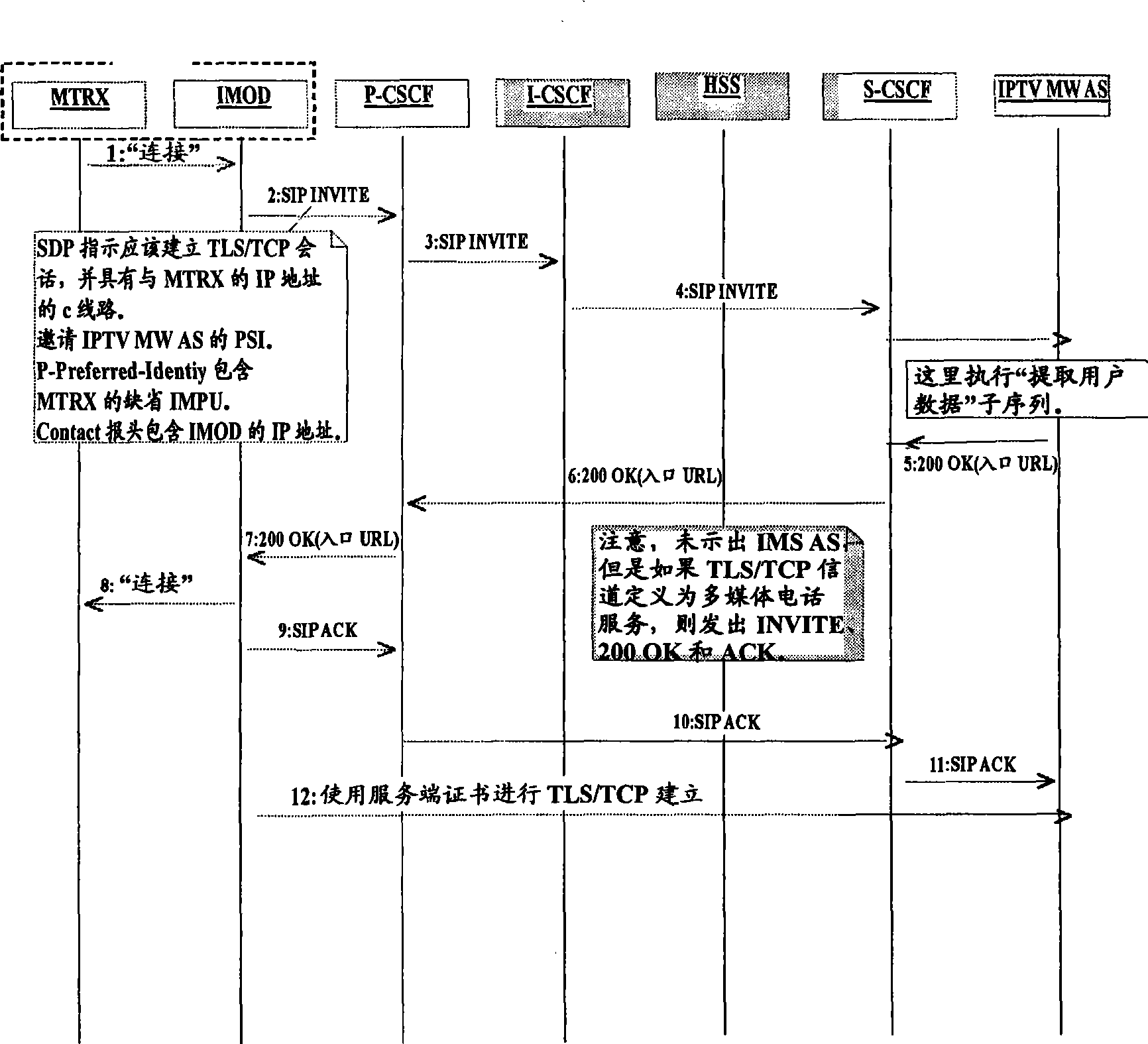

Control channel enabling IMS for IPTV service

InactiveCN101385303ASignificant reductionEasy accessTransmissionPersonalizationSession Initiation Protocol

An IMS-enabled control channel for an IPTV service is provided by receiving at a Serving Call / State Control Function (S-CSCF) a Session Initiation Protocol (SIP) REGISTER message, the SIP REGISTER message identifying the originating user, receiving at the originating user a response from the S-CSCF indicating that the originating user has been authorised, and sending a SIP INVITE message from the S-CSCF to establish an open channel connection with a selected IPTV Application Server (AS). This open channel connection can then be used for the transmission of control messages, such as for starting play, starting recording, stopping play, etc., between the STB and the IPTV applications server, as well as for the delivery of personalized content, such as advertisements, voting responses, personalized voting triggers and targeted interactive events. By maintaining an open control channel with the IPTV AS, this offers a substantial reduction in the setup delay times for different applications.

Owner:TELEFON AB LM ERICSSON (PUBL)

Servo side-pressing paper feeder

The invention provides a servo side-pressing paper feeder. The servo side-pressing paper feeder is characterized in that a paper feeding mechanism comprises a vacuum suction speed-changing paper feeding mechanism and a vacuum suction constant-speed side-pressing paper advance mechanism; two side-pressing wheels are installed on a side-pressing paper feeding wheel shaft arranged above constant-speed paper feeding wheels in the middle; a gap with the width less than the thickness of a cardboard is formed between each side-pressing wheel and the constant-speed paper feeding wheels in the middle. The two side-pressing wheels can be moved on the side-pressing paper feeding wheel shaft for adjustment of the separation distance. Under control of a control system, the vacuum suction servo speed-changing paper feeding mechanism conveys corrugated boards in the mode of accelerating at first, then keeping a constant speed and finally decelerating and stopping, and the feeding accuracy and the feeding efficiency of the cardboards are improved. Due to vacuum air suction boxes, the corrugated boards are tightly attached to paper feeding wheels and conveyed forwards through friction force; the side-pressing paper feeding wheels only achieve the auxiliary side-pressing effect, and the flattening effect of the side-pressing paper feeding wheels on the corrugated boards is reduced, so that the strength of the corrugated boards will not be lowered substantially.

Owner:QINGDAO MEIGUANG MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com