Servo side pressing and paper feeding machine

一种送纸机、送纸机构的技术,应用在造纸机、造纸、纺织品和造纸等方向,能够解决不能保证输送纸板尺寸一致、瓦楞纸板强度降低等问题,达到提高送出精度和送出效率、提高纸箱强度、减轻压扁作用的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

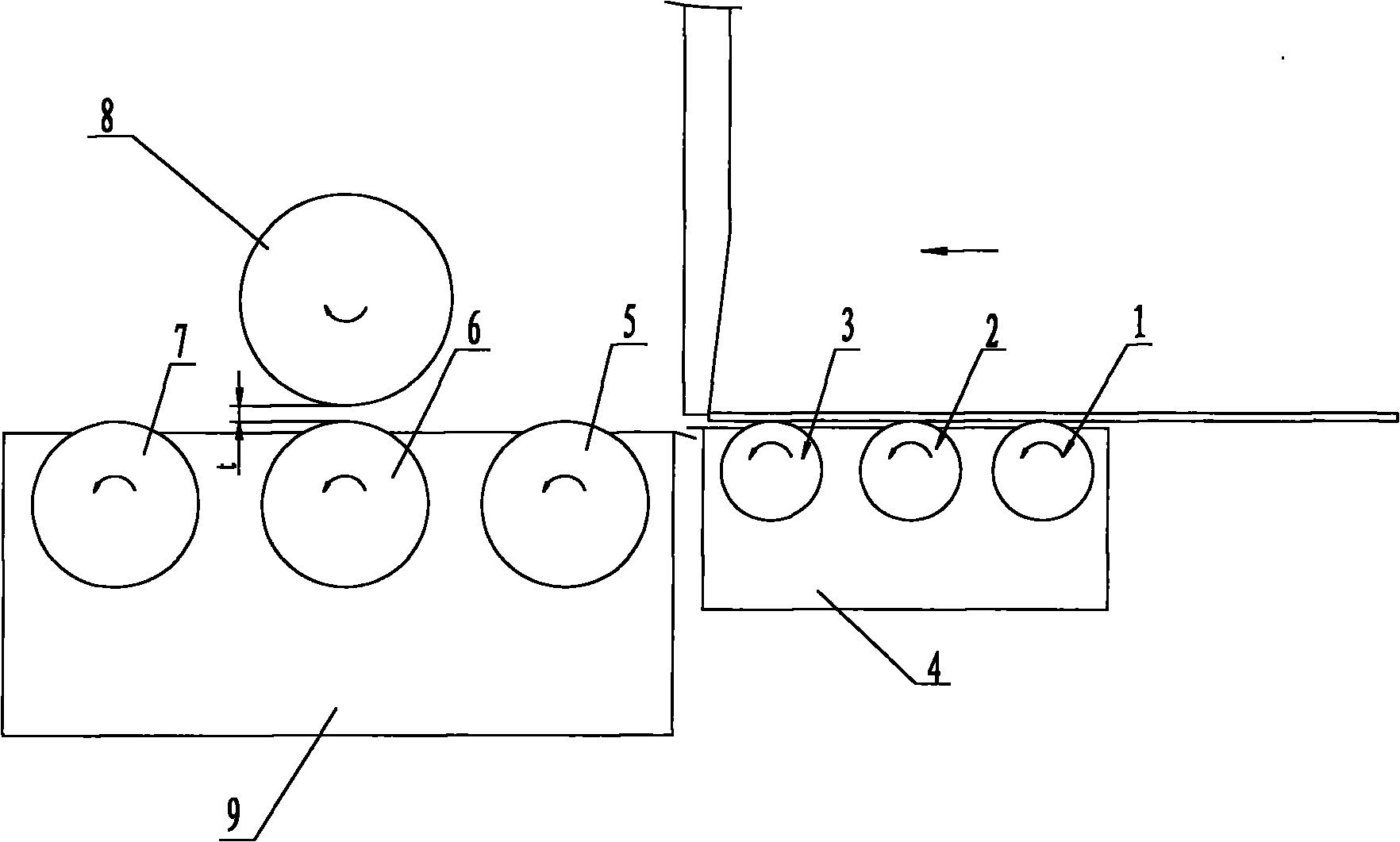

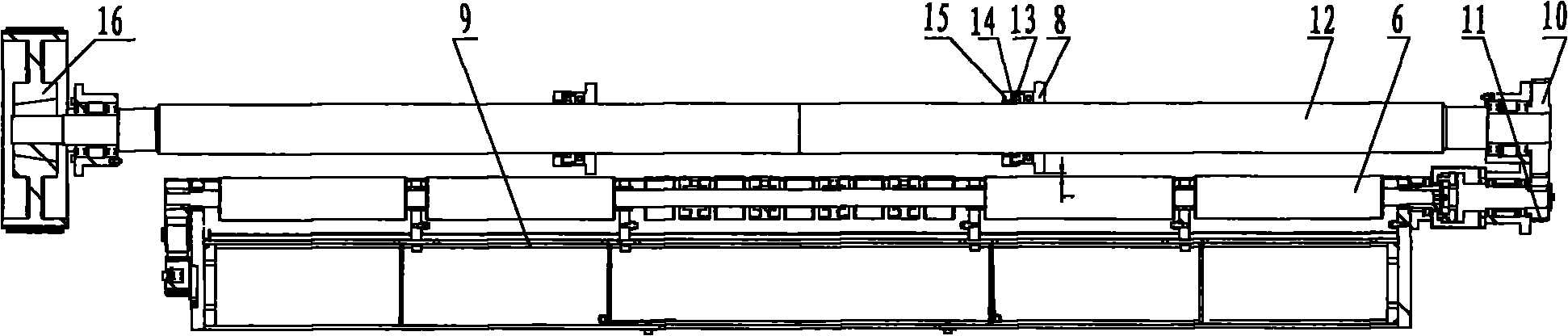

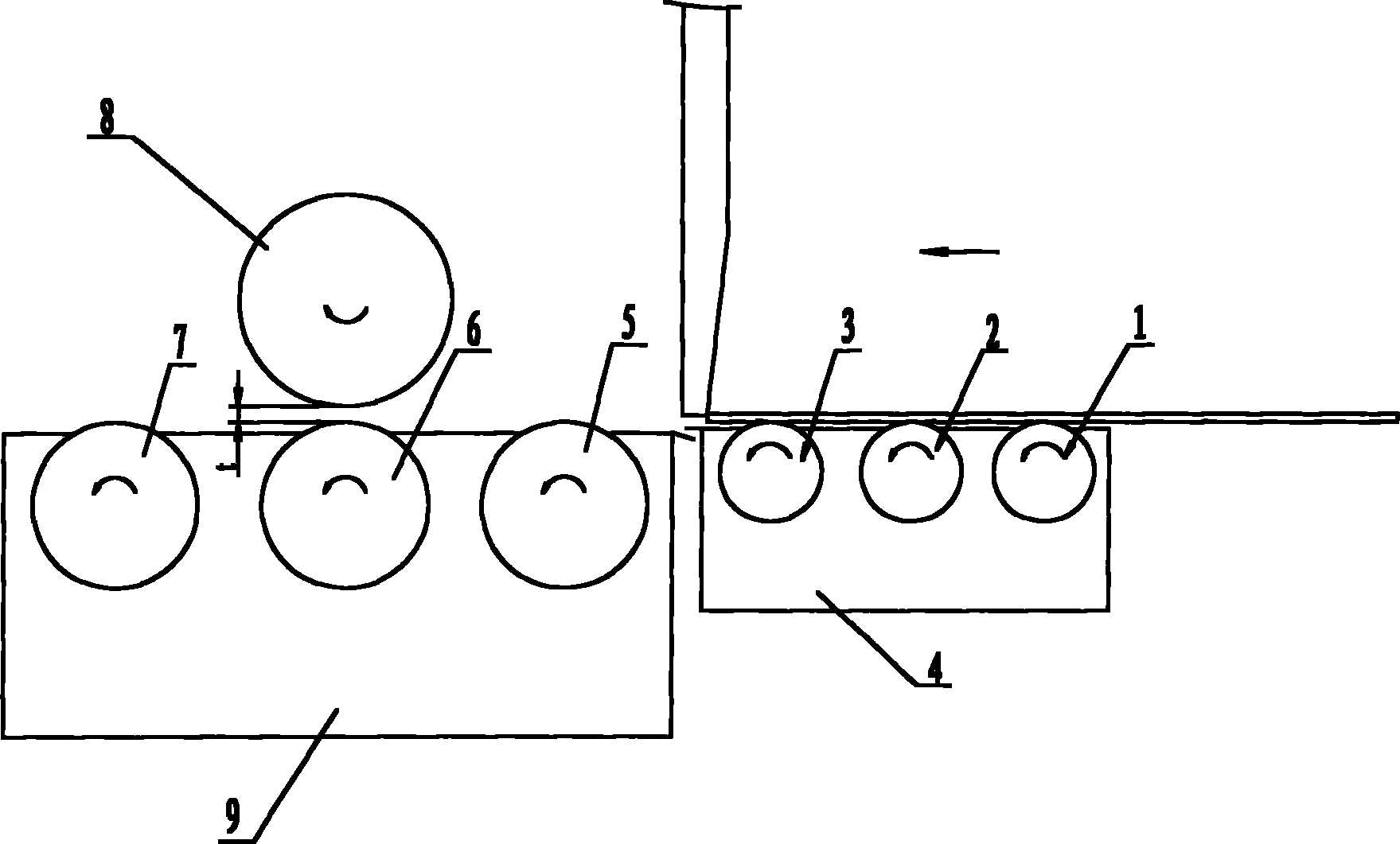

[0014] see figure 1 , figure 2 , an embodiment of a corrugated cardboard servo edge feeding machine of the present invention, including: a paper feeding mechanism and a control system composed of a paper feeding wheel set and a vacuum suction box. The paper feeding mechanism includes a vacuum adsorption variable speed paper feeding mechanism composed of 3 sets of servo variable speed paper feeding wheel sets 1, 2, 3 and its vacuum suction box 4 and 3 rows of uniform speed paper feeding wheel sets 5, 6, 7, two pressure The vacuum adsorption uniform-speed paper-feeding mechanism formed by the side wheel 8 and its vacuum suction box 9, the two side-press wheels 8 are installed on a side-press paper wheel shaft 12 arranged above the constant speed paper-feed wheel 6 in the middle, and There is a gap t smaller than the thickness of the cardboard between the edge roller 8 and the middle constant speed paper feeding roller 6 . 2 crimping rollers 8 can move on the crimping paper fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com