Patents

Literature

31results about How to "Save landfill space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

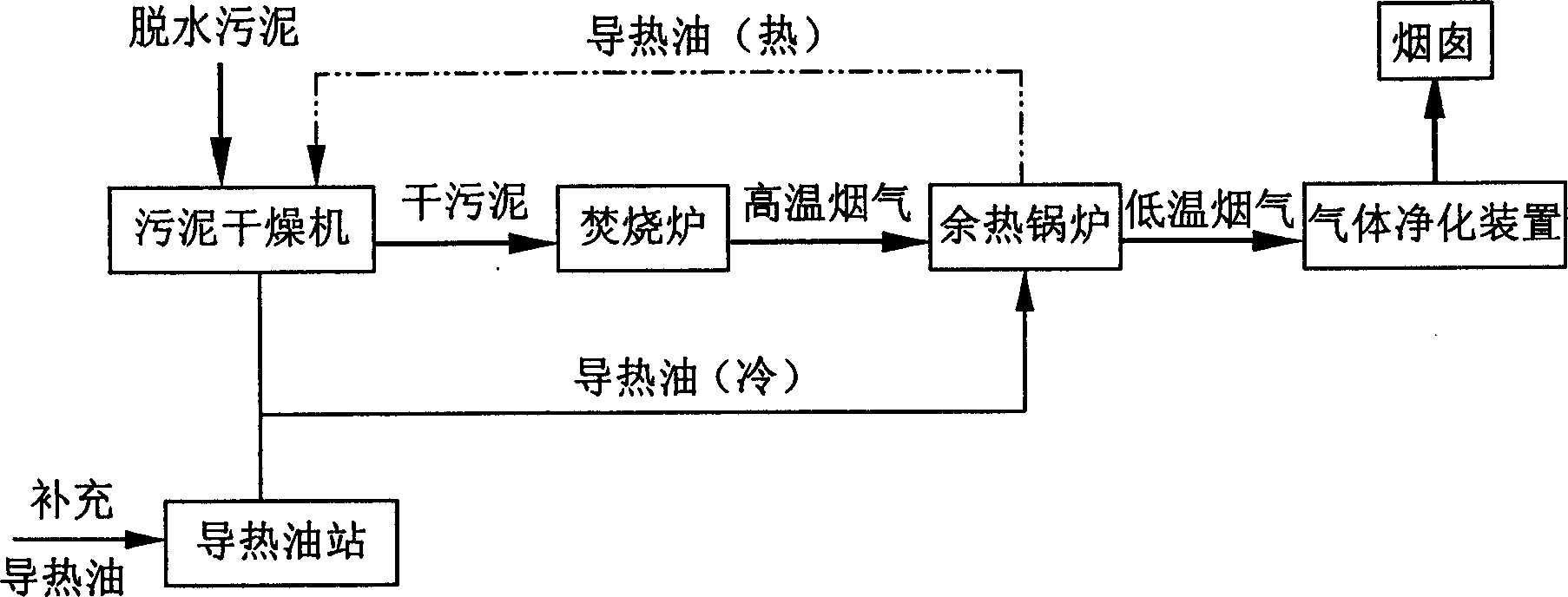

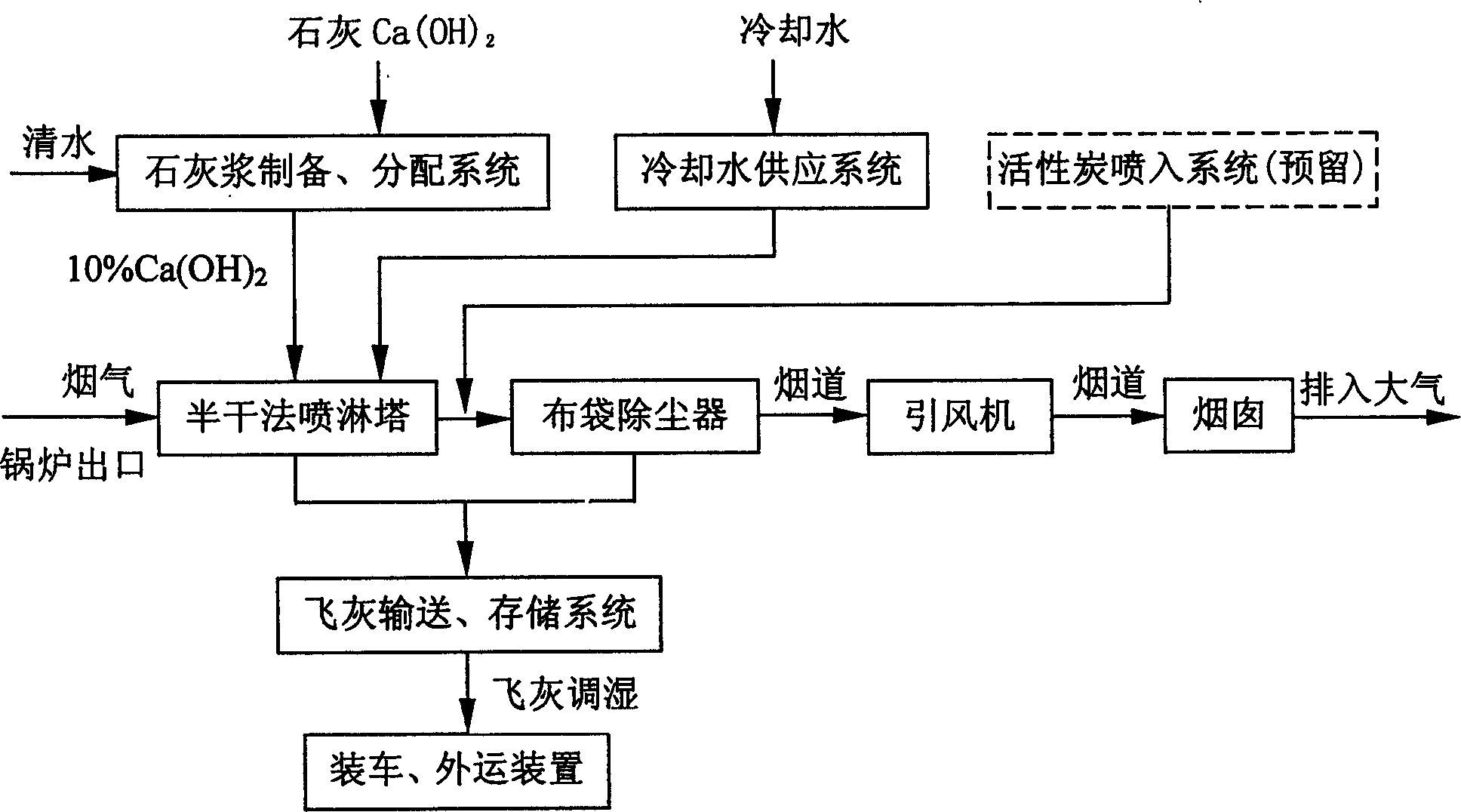

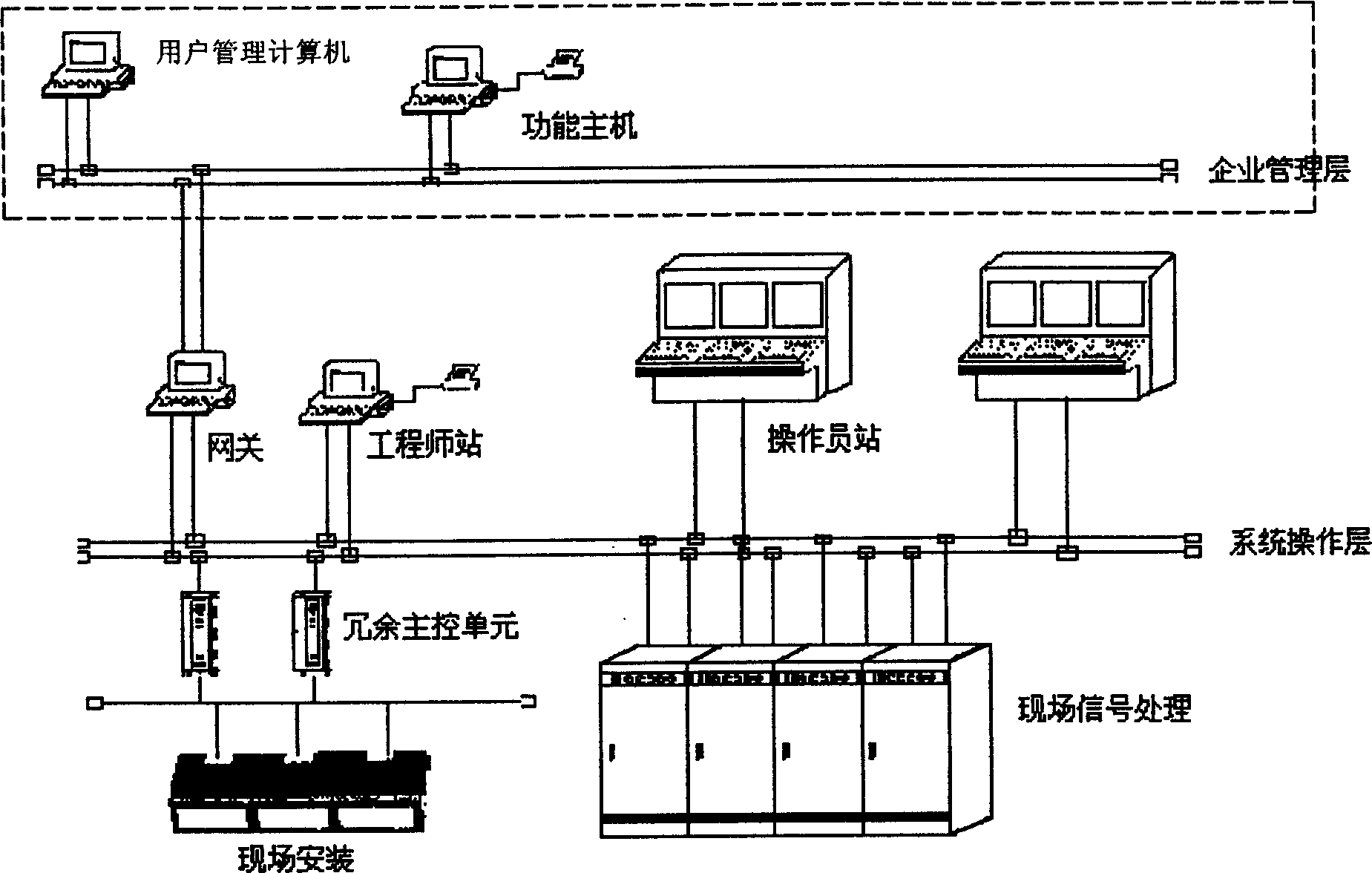

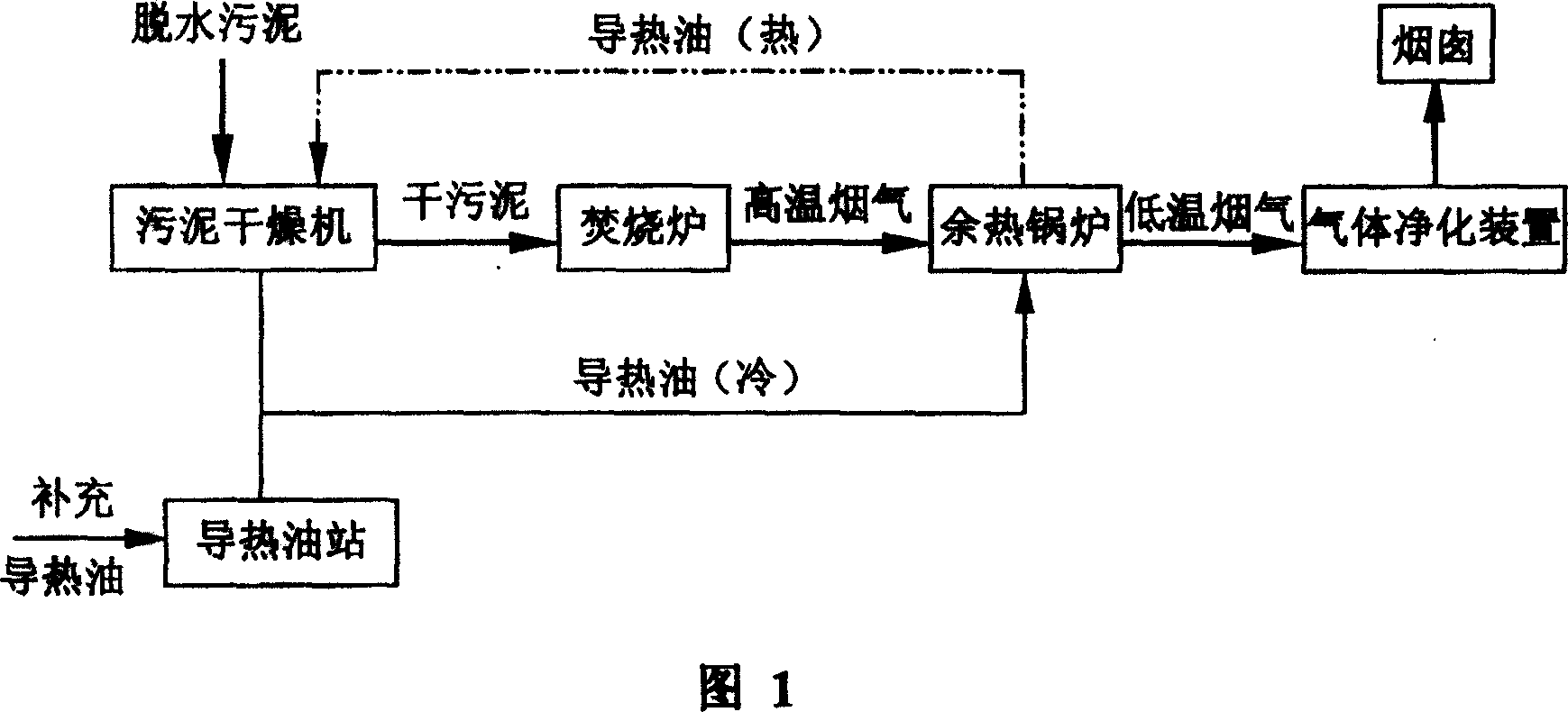

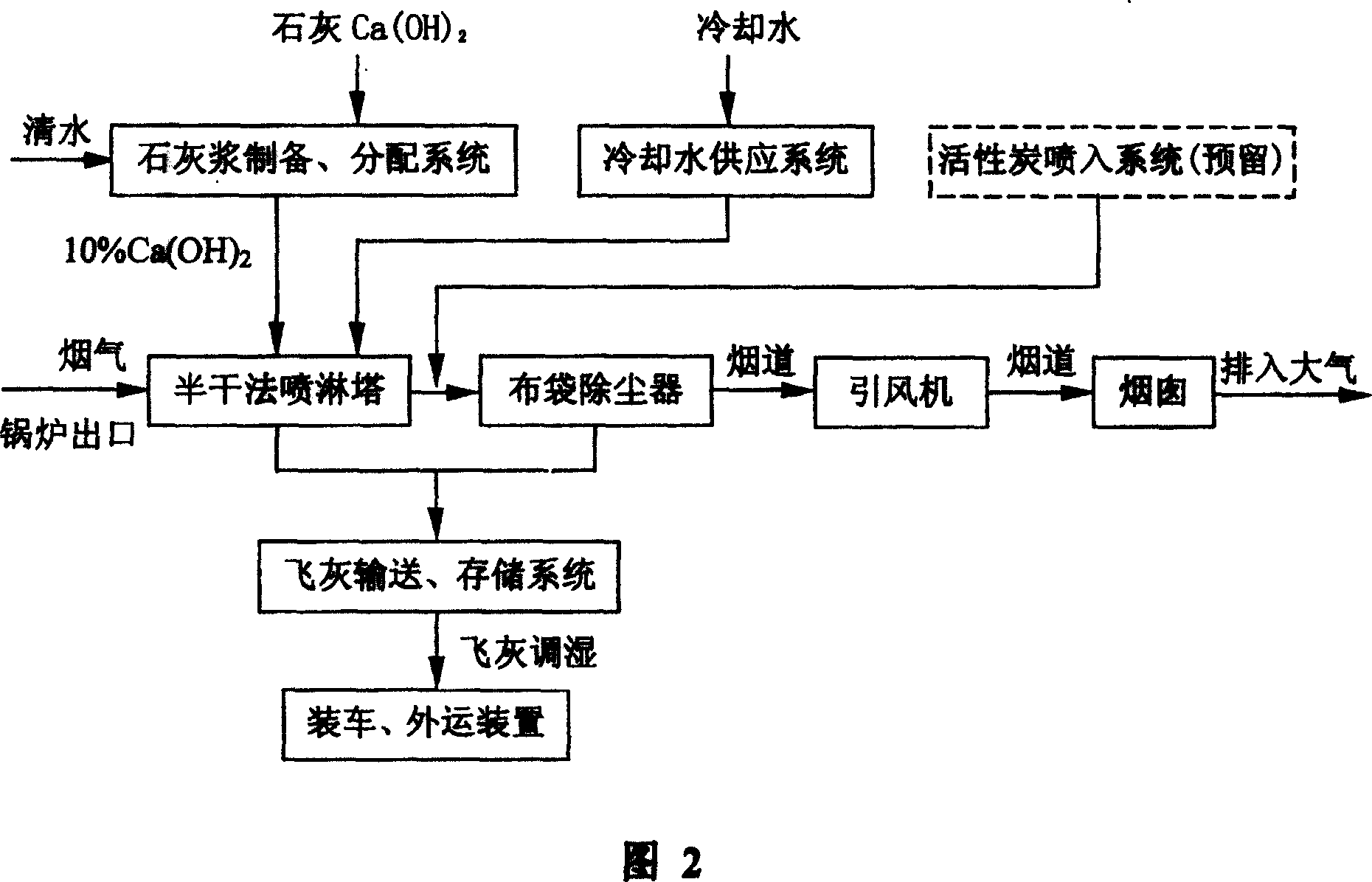

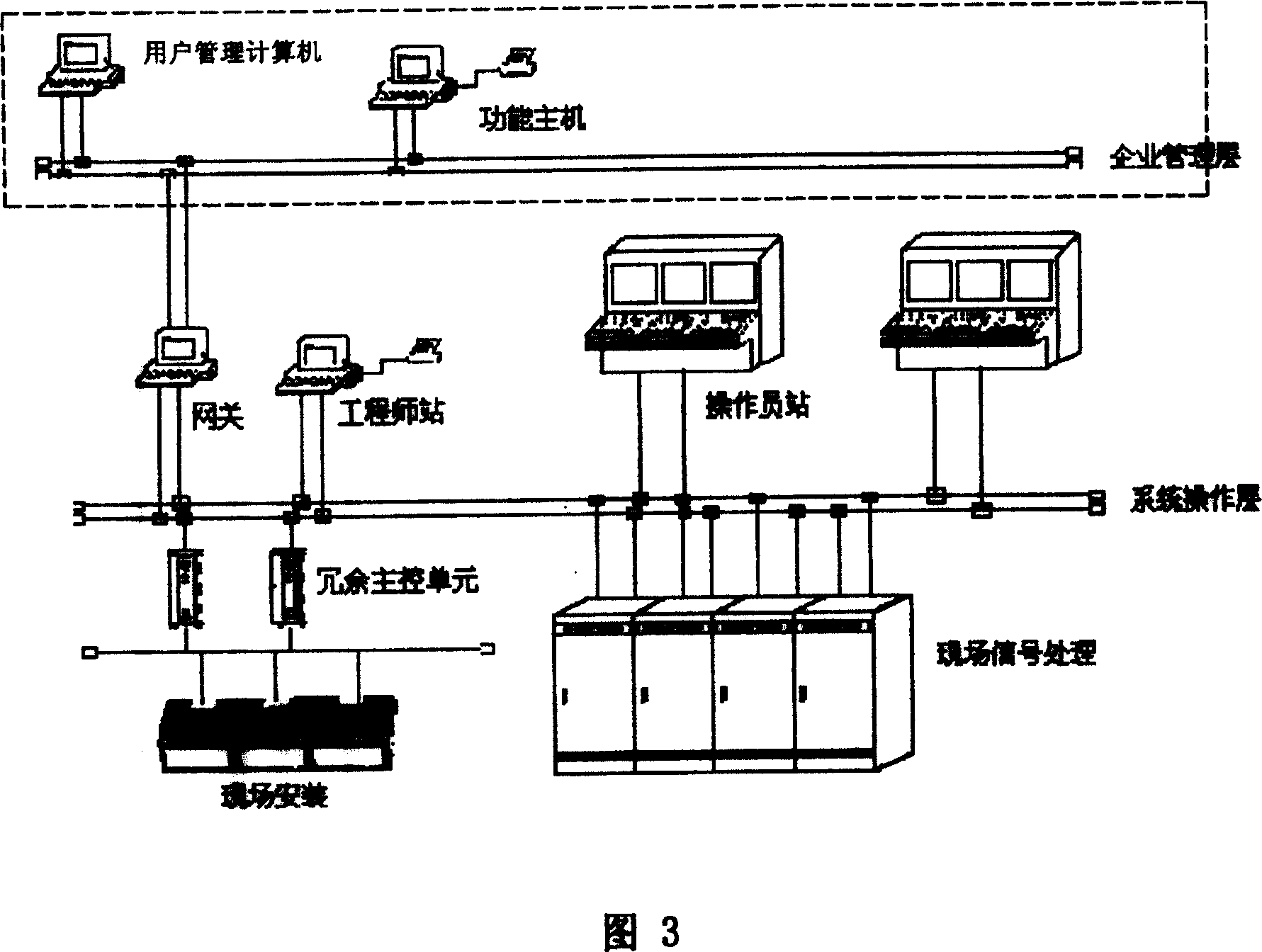

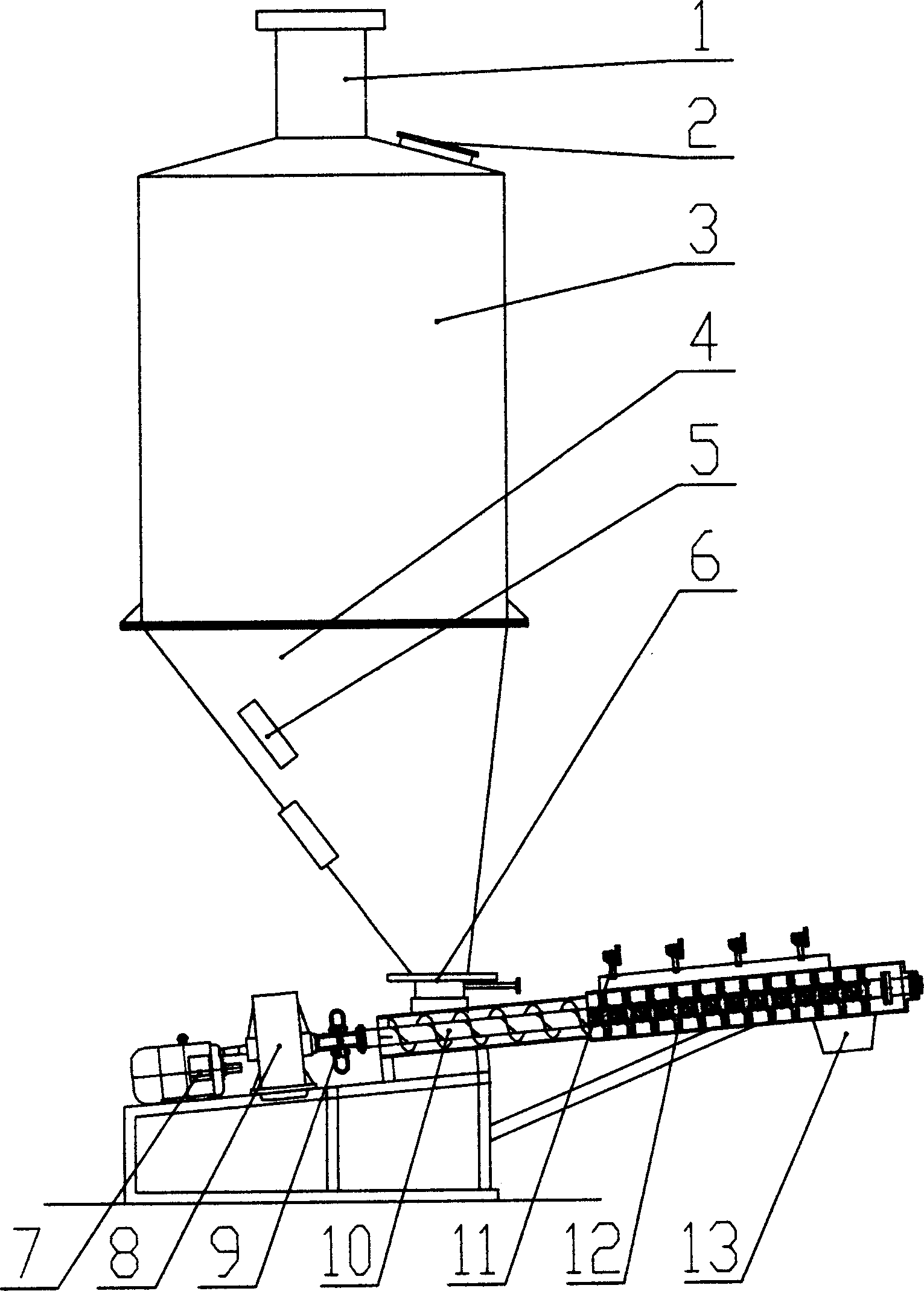

Sludge anhydration and burning process, and its systematic device

ActiveCN1800062ALow investment costLow running costSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationAir preheaterHeat conducting

The invention relates to a sludge drying and burning technique and its system devices, applying to the handling of active sludge in urban sewage treatment plants, its process flows through: wet sludge stock house, measuring bin, sludge mixer, sludge dryer, granular splitter, cooler, drying products storage bin, incinerator, smoke gas cleaning devices, which is characterized by: said incinerator is bubbling fluid bed incinerator with coal economizer, air heater fixed in its end part, high-heat smoke gas generated by burning is used to heat heat-conducting oil and cool air individually, and heat-conducting oil after being heated is transferred to sludge dryer through the circulating pump to dry wet-sludge. The invention is characterized by: take heat-conducting oil as heating medium, use the heat generated by burning dry sludge to heat heat-conducting oil and then dry wet-sludge to make full use of resources; the volume-reducing quantity after drying and burning could reach over 90%; the percentage of desulphurization in incinerator could reach 75% as a result of adopting two stage technology of sulfur removal, and the gross percentage of desulphurization meets national environmental legislation requirements. The invention accomplishes the resources, volume reduction, and innocence of sludge.

Owner:贵州筑信水务环境产业有限公司

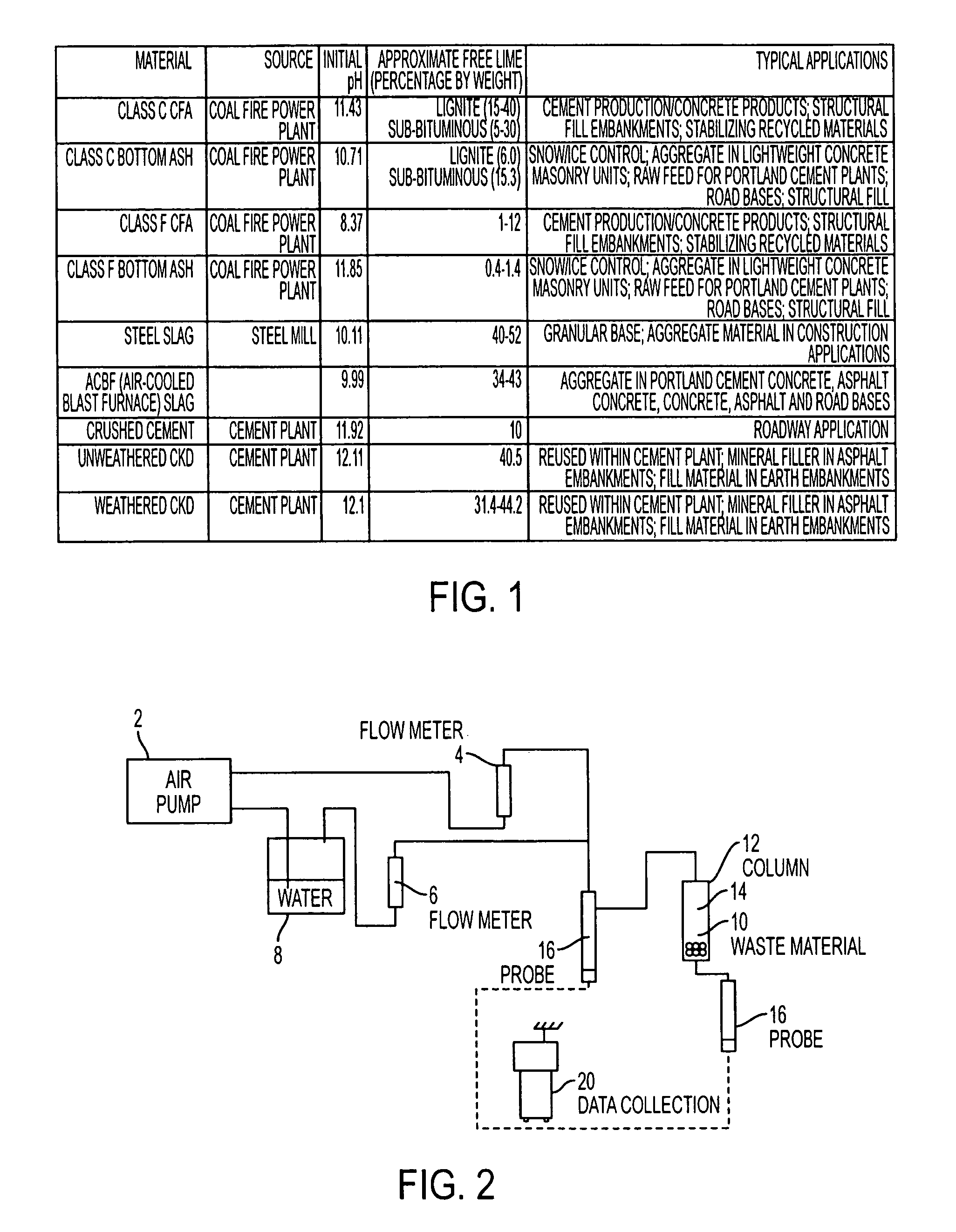

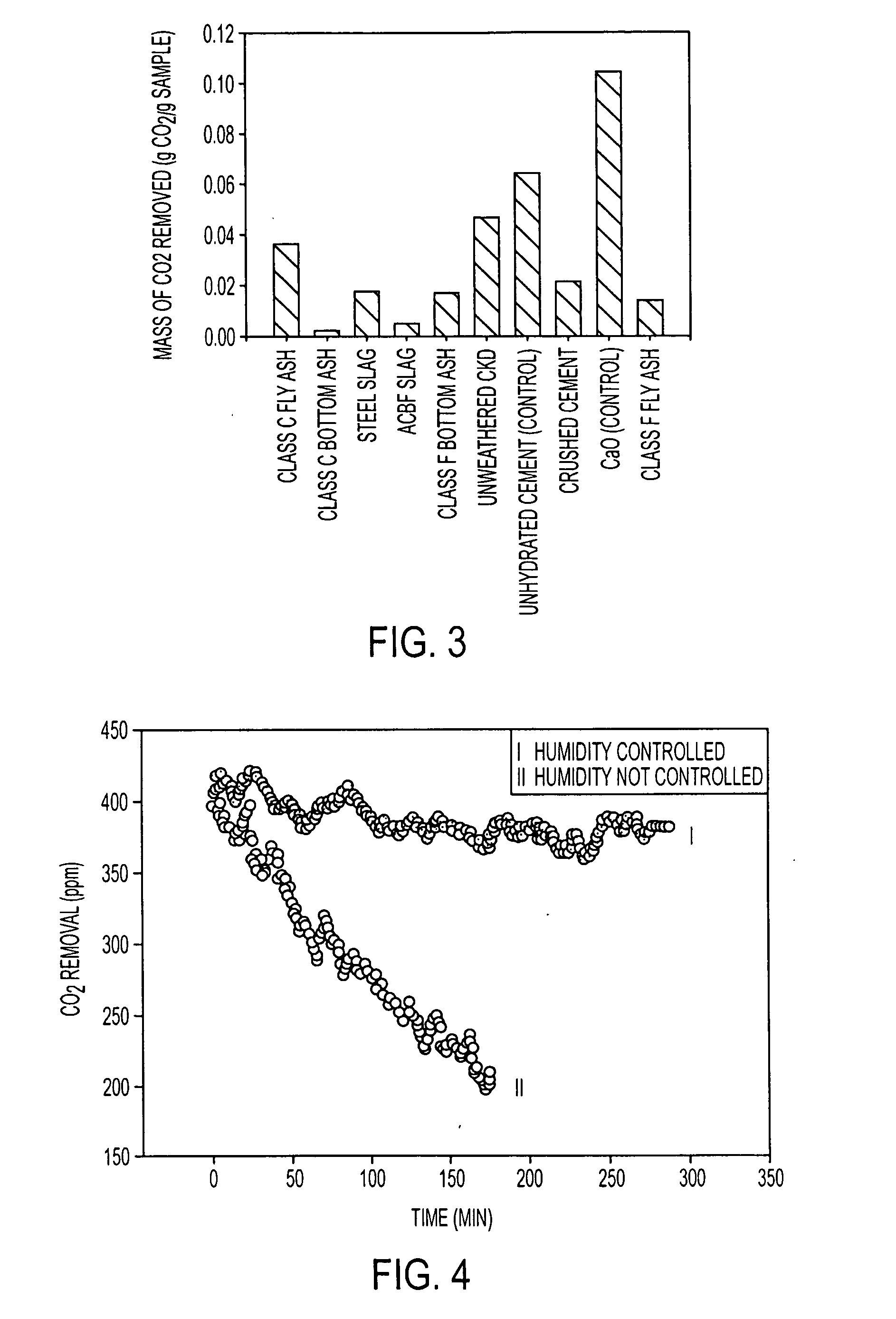

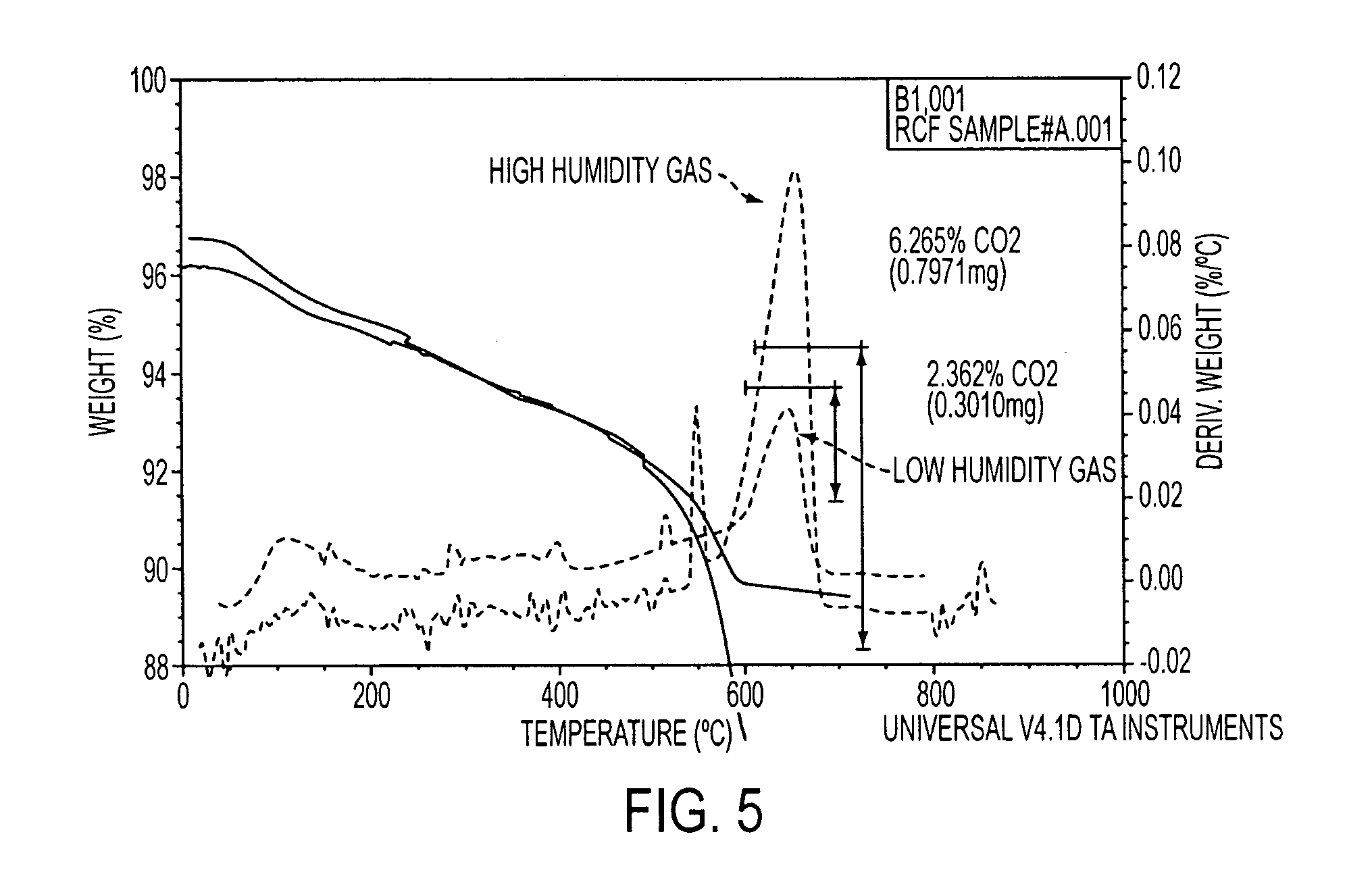

Method for sequestering carbon dioxide

InactiveUS20050238563A1Save landfill spaceCalcium/strontium/barium carbonatesProductsWaste materialCarbonate

A method for permanently sequestering CO2 by bringing a gas containing the CO2, which may be the atmosphere, into contact with alkaline waste materials containing Ca to form a carbonate that is stable and environmentally benign.

Owner:NEW HAMPSHIRE UNIV OF

A method for comprehensive treatment of construction refuse

InactiveCN1990129AProtect environmentSave land resources and building material resourcesConstruction waste recoveryWaste processingScrapPulverizer

An integrated approach to construction waste, first the construction waste including demolished the buildings, housing renovation and improvement of road will be sent to the garbage handling sites by the car, and then the construction waste that could be directly in the use of renewable materials, such as metal, wood and plastic materials use artificial methods for separating classified, then supplying company directly for the corresponding treatment. The bulk of concrete waste, scrap brick, marble and other materials, using the large broken hammer or crusher broken to the size that mill can crush, typically less than 100 mm, and then using stone crusher breaking these stones and sand until the construction standard, then grading said mixture into big stones, small stones, coarse sand and fine sand, argillo-arenaceous ground and other breeder material using multi-layered grading sieve. The production water uses activated carbon hyperfiltration cleaning domestic sewage which can be used cyclically, it can save water and can prevent the reemission of sewage water polluting environment.

Owner:罗以杰

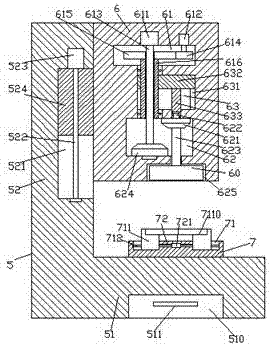

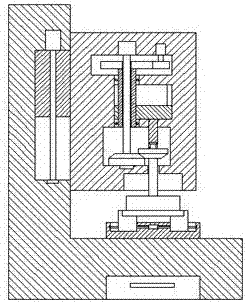

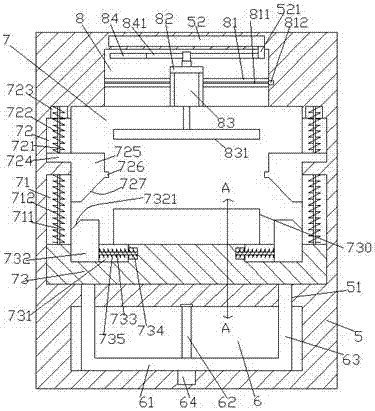

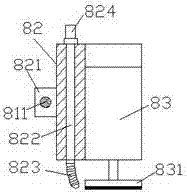

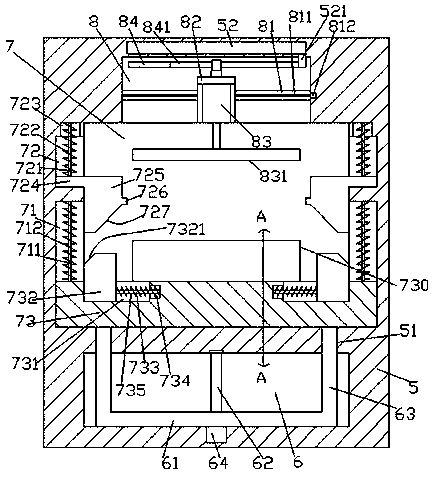

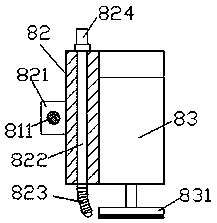

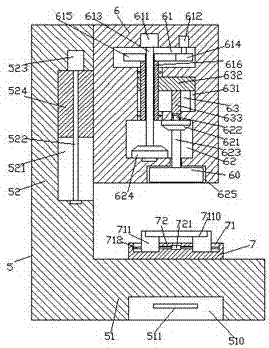

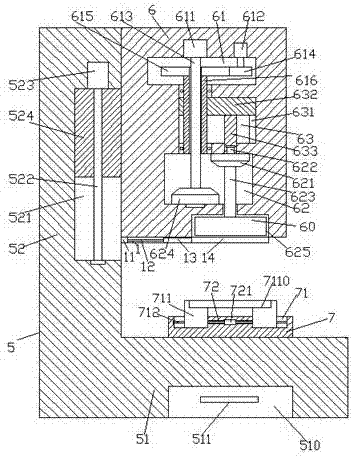

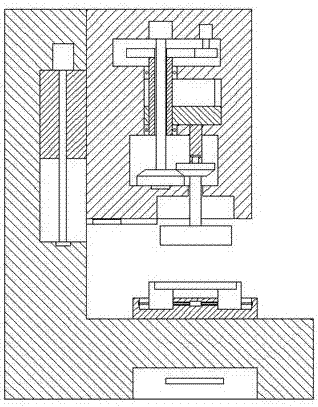

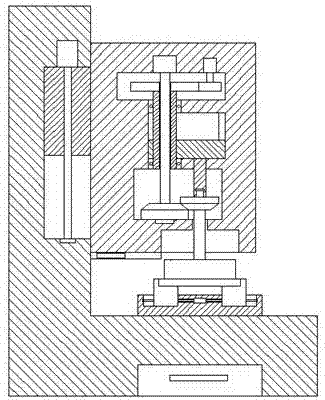

Garbage disposal device

The invention discloses a garbage disposal device. The garbage disposal device comprises a frame body composed of a back plate and a workbench. A compression device is arranged on the right side of the back plate. A fixing device is arranged at the top of the workbench. The top face of the fixing device corresponds to the bottom face of the compression device. A first cavity, a second cavity and a third cavity are formed in the compression device. A second sliding groove is formed in the inner face of the right side of the first cavity. An outer thread tube sleeve arranged in an up-down extending mode is arranged on the left side of the first cavity. A top extension block of the outer thread tube sleeve penetrates through the inner top face of the first cavity and is connected with the inner top face of the first cavity in a rotational fit mode. The tail of the top extension block of the outer thread tube sleeve extends into the second cavity. A bottom extension block of the outer thread tube sleeve penetrates through the inner bottom face of the first cavity and is connected with the inner bottom face of the first cavity in a rotational fit mode. A second sliding block extending rightwards is connected to the part, in the first cavity, of the outer thread tube sleeve in a helical fit mode. The garbage disposal device is simple in structure and convenient to operate, garbage can be compressed into garbage blocks with different sizes and densities according to different requirements, the size is reduced, and the landfilling space is saved.

Owner:盐城市欧奇机械有限公司

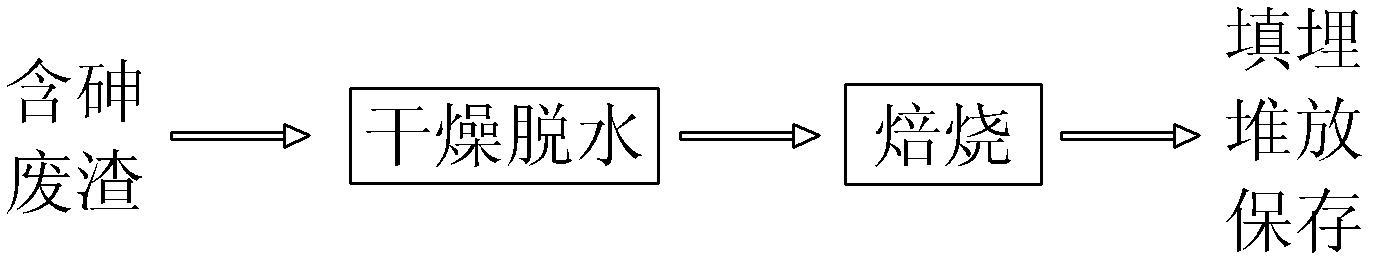

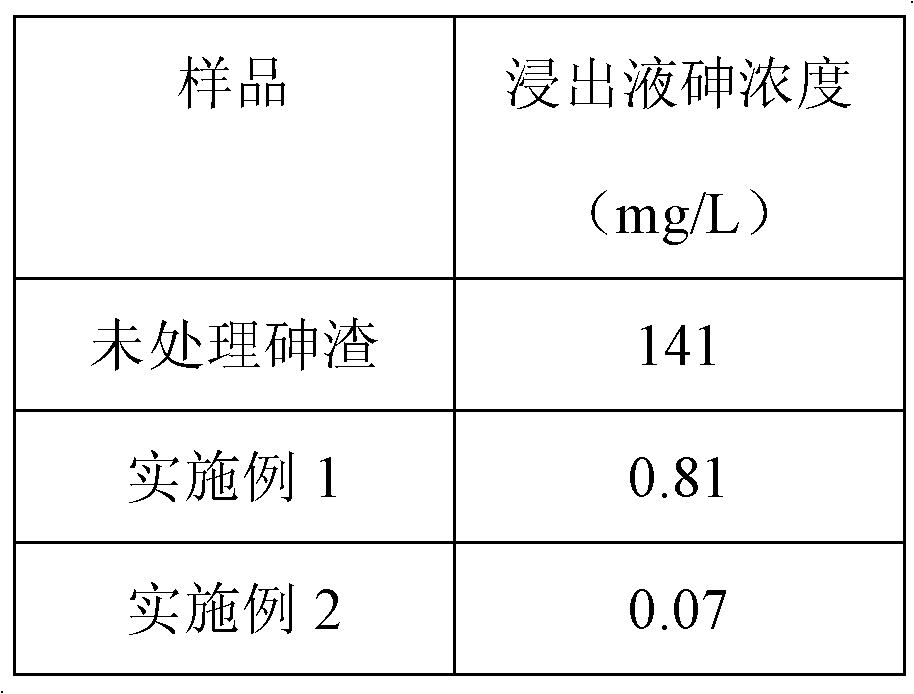

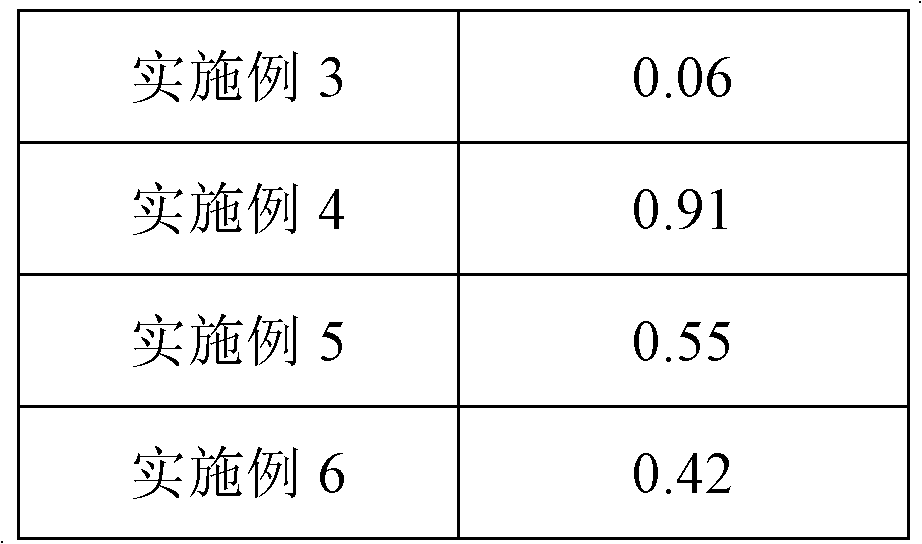

Method for solidifying arsenic-calcium residue or arsenic-iron residue

InactiveCN103028587AGuaranteed stabilityReduce As leaching toxicitySolid waste disposalPregnant leach solutionLimit value

The invention discloses a method for solidifying arsenic-calcium residue or arsenic-iron residue, comprising the following steps of: (1) drying arsenic-containing waste residue under 150-200 DEG C, and removing most moisture in the waste residue, so that the water content of arsenic residue is less than 20%; and if necessary, oxidizing the waste residue before drying; and (2) carrying out oxidizing roasting on the dried arsenic-containing waste residue under 600-1000 DEG C, wherein the roasting time is 1-3hours, and blowing in air or oxygen in the manner of natural air charge or initiative air supply in the process of roasting. The As concentration of leaching agent of arsenic-calcium residue or arsenic-iron residue treated by the method disclosed by the invention is much less than the nationally-regulated limiting value (5mg / L), so that the arsenic can be effectively solidified, a treatment technology is compact in technological process, the operation is easy to control, and the method is lower in treatment cost.

Owner:SHENZHEN MINGDENG TECH

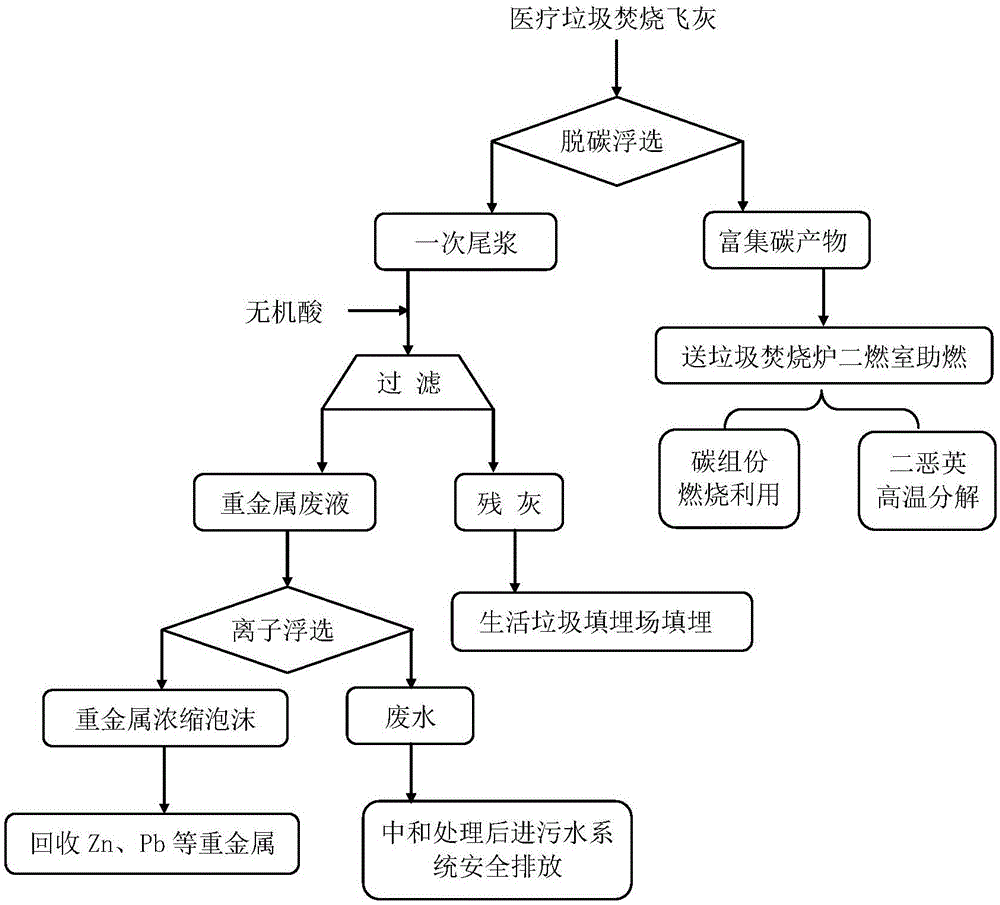

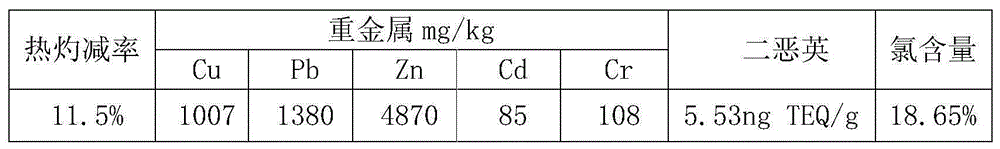

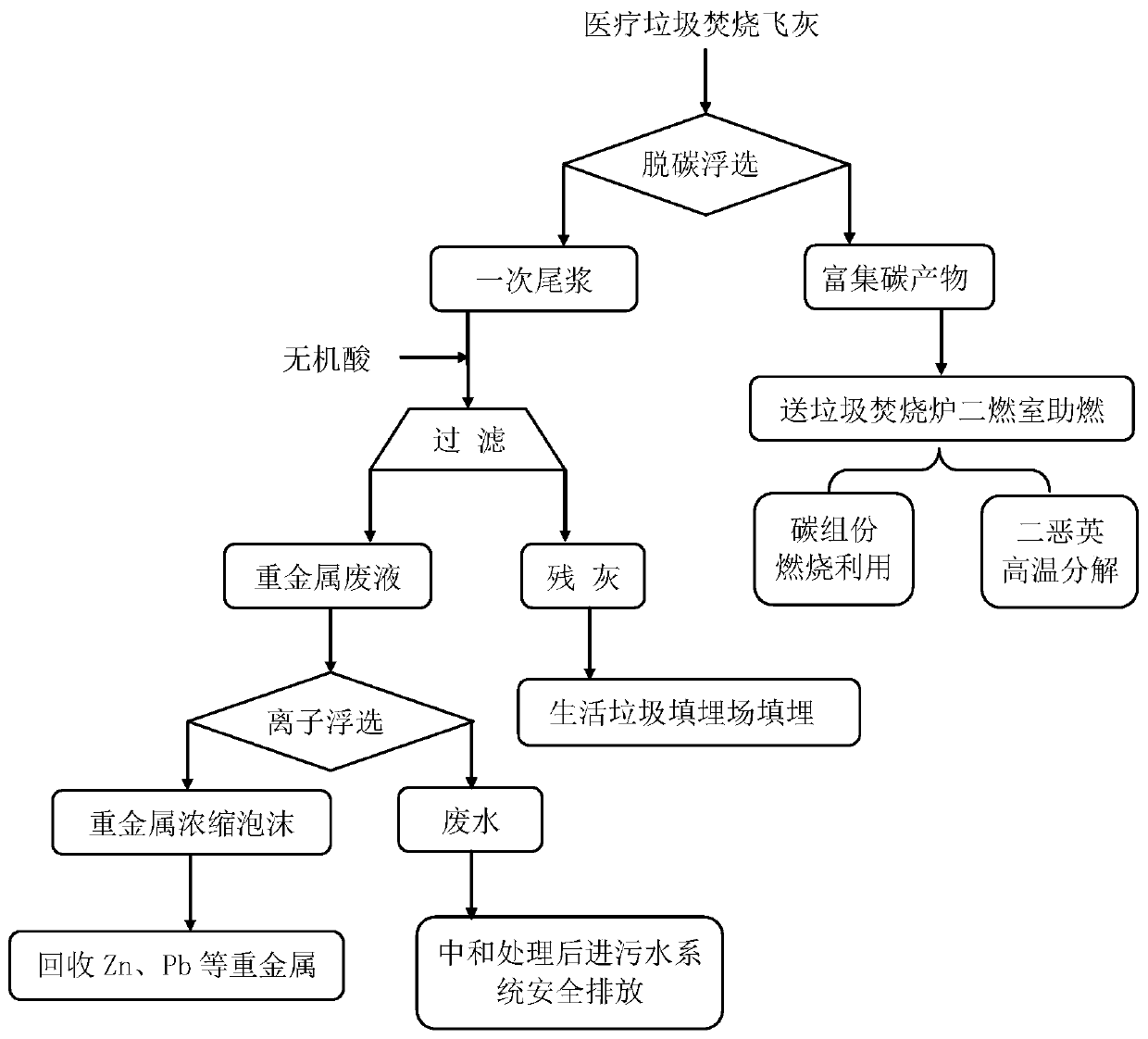

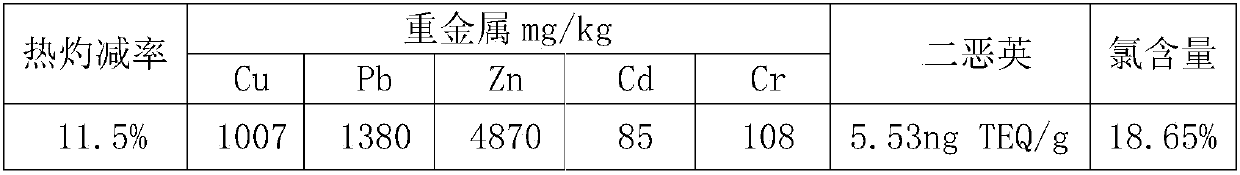

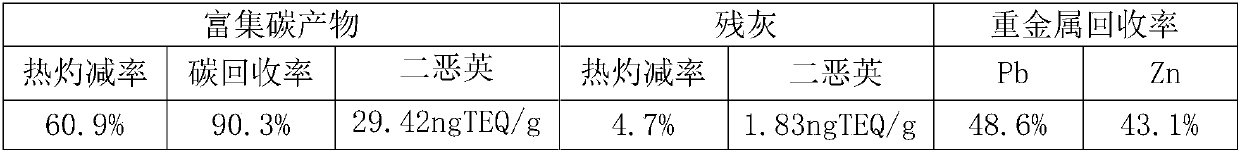

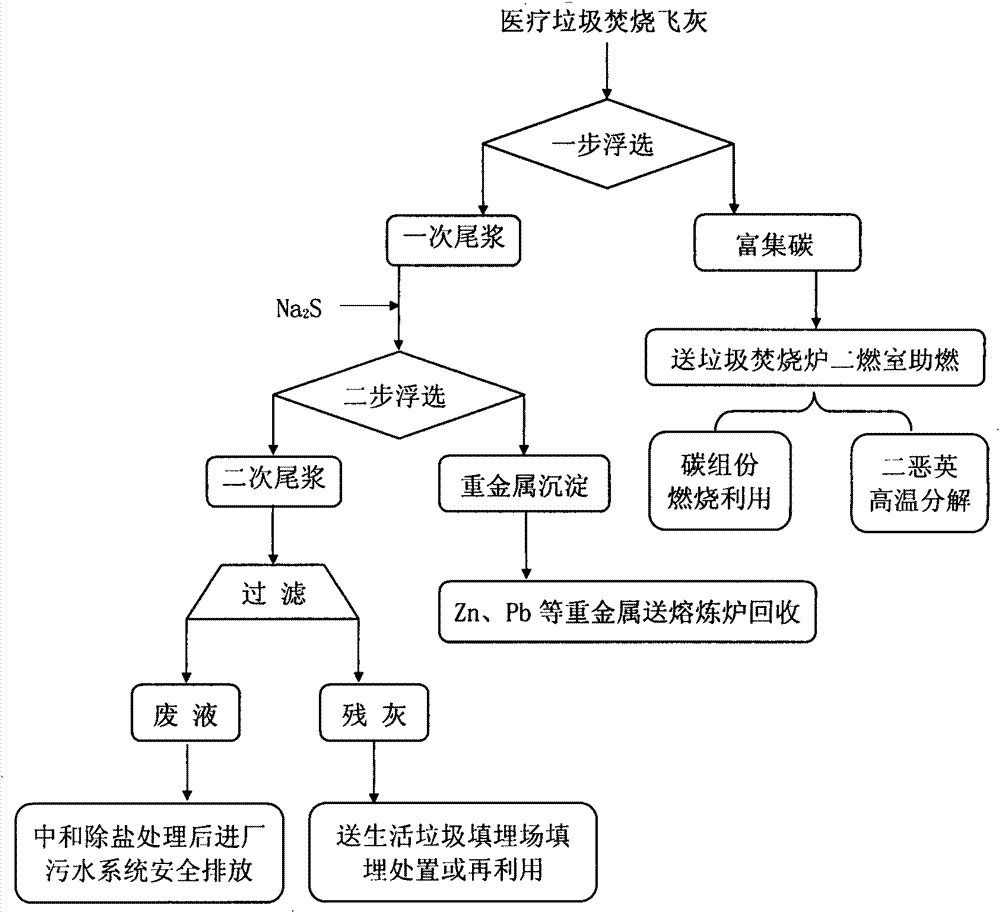

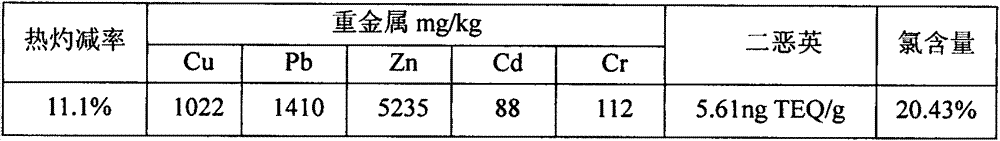

Treatment method for two-step flotation of medical waste incineration fly ash

ActiveCN105149101AReduce secondary synthesisRealize the utilization of fuelFlotationCombustion chamberMunicipal solid waste landfill

The invention discloses a treatment method for two-step flotation of medical waste incineration fly ash. The method includes the following steps that (1) decarbonization flotation is conducted, the two products of enriched carbon and primary tail pulp are obtained, and the enriched carbon product is fed into a secondary combustion chamber of a waste incinerator for helping to combust; (2) acid leaching and filtering are carried out, inorganic acid is added into the primary tail pulp which is obtained in the first step to be filtered after acid leaching is completed, and the two products of residual ash and heavy metal waste liquor are obtained; the residual ash is directly conveyed to a municipal solid waste landfill to be subjected to secure landfill disposal or reuse; (3) ion flotation is performed, flotation reagents are added into the heavy metal waste liquor which is obtained in the second step for ion flotation, and the two products of heavy metal concentration foam and waste water are obtained; the heavy metal concentration foam is fed into a smelting plant to recycle heavy metal Pb and Zn, and after reaching the standard through neutralizing treatment, the waste water is discharged into a sewage system. The treatment method has the advantages of being easy to operate, low in cost, good in treatment effect, free of secondary pollution and the like.

Owner:TIANJIN CHENGJIAN UNIV

Composite sludge deep dehydration conditioner as well as application and application method thereof

ActiveCN111484230AImprove settlement performanceImprove dehydration effectSludge treatment by oxidationWater treatment compoundsCationic polyelectrolytesProcess engineering

The invention relates to a composite sludge deep dehydration conditioner as well as an application and an application method thereof, which belong to the technical field of resource environment and sludge treatment. The conditioner is prepared from the following raw materials in percentage by mass: 1 to 2 percent of a strong oxidant, 19 to 40 percent of an inert substance and 59 to 80 percent of strong cationic polyelectrolyte. The compound sludge deep dehydration conditioner designed by the invention has the advantages of high conditioning speed, high sludge dehydration rate, small sludge increment, simplicity in operation, high sludge volume reduction rate and the like, so that the compound sludge deep dehydration conditioner can be widely applied to conditioning and enhanced deep dehydration of sludge.

Owner:山东益源环保科技有限公司

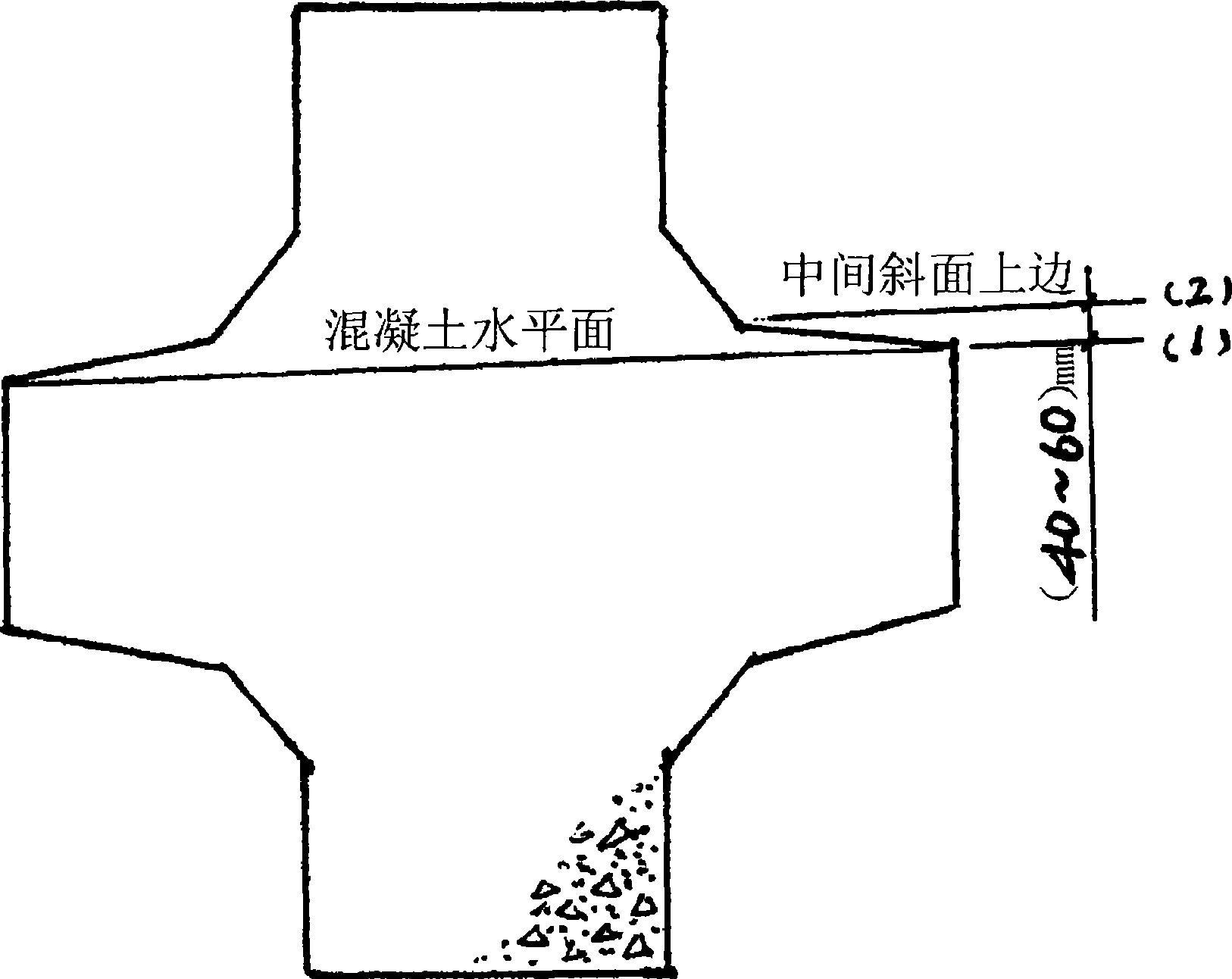

Method for producing concrete building block by using pipe pile wastewater slurry

The invention relates to a method for producing concrete water conservancy prefabricated-part with tubular pile waste water slurry. Firstly concrete, medium sand and gravel are launched into a concrete mixer to be mixed for 30 seconds to 60 seconds according to proportion by weight; and then the tubular pile waste water slurry is added when stirring; the quantity of the water slurry added into is subject to slump constant of the concrete mix which is between 30 mm to 120mm; the concrete mix is produced after the wet mixture is acted for 30 to 60 seconds. And then the concrete mix is launched into a prefabricated-part mould; a concentrated vibro is adopted for processing, and the distance between vibro points is 0.8 times to 1.2 times of the working radius of a vibrating spear. When in pouring, the concrete mix needs to be processed for pouring layer upon layer in the mould in a horizontal plane rising way. At last maintenance is processed according to a conventional maintenance process method. Aiming at the mechanical property requirements of the concrete water conservancy prefabricated-part, the pressive strength grade of the produced concrete water conservancy prefabricated-part is C30 through improving the mix proportion of the concrete and the pouring technology; the appearance quality measures up to the standard requirements.

Owner:上海亿航工贸发展有限公司

Soilless cover material for sanitary landfill of solid waste garbage

The invention provides a soilless cover material for sanitary landfill of solid waste garbage. The soilless cover material for sanitary landfill of the solid waste garbage comprises components with parts by weight: water-soluble cellulose polymers 2-25 parts, plant fibers 20-100 parts, clay 10-100 parts, gypsum 5-50 parts and water 500-3000 parts, wherein the water-soluble cellulose polymers is an ionic type, and the plant fibers are an expanded type. The soilless cover material for sanitary landfill of the solid waste garbage is degradable, is about 5%-10% in water penetration rate, also has a certain amount of water permeability, and has great promotion effect for breeding of garbage natural degradation bacteria. The soilless cover material for sanitary landfill of the solid waste garbage eliminates garbage layering after being degraded, enables garbage of a whole landfill to be an entirety, and plays great role for improving garbage density. Compared with other cover methods, the soilless cover material for sanitary landfill of the solid waste garbage has great advantages in cost.

Owner:深圳市五大湖新概念环保科技有限公司

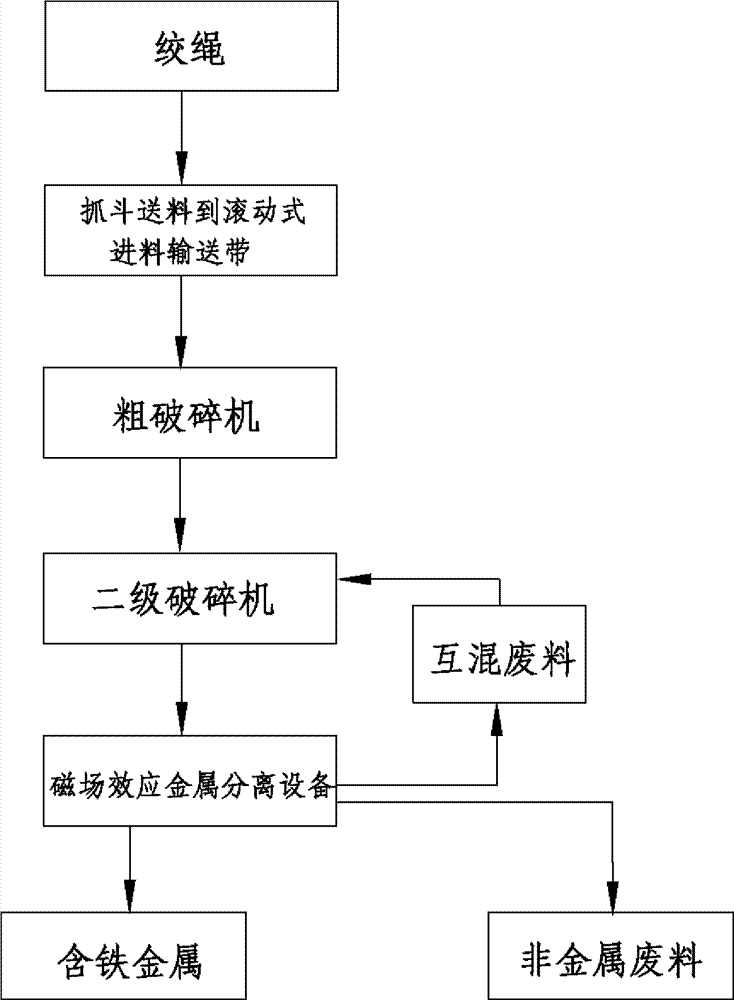

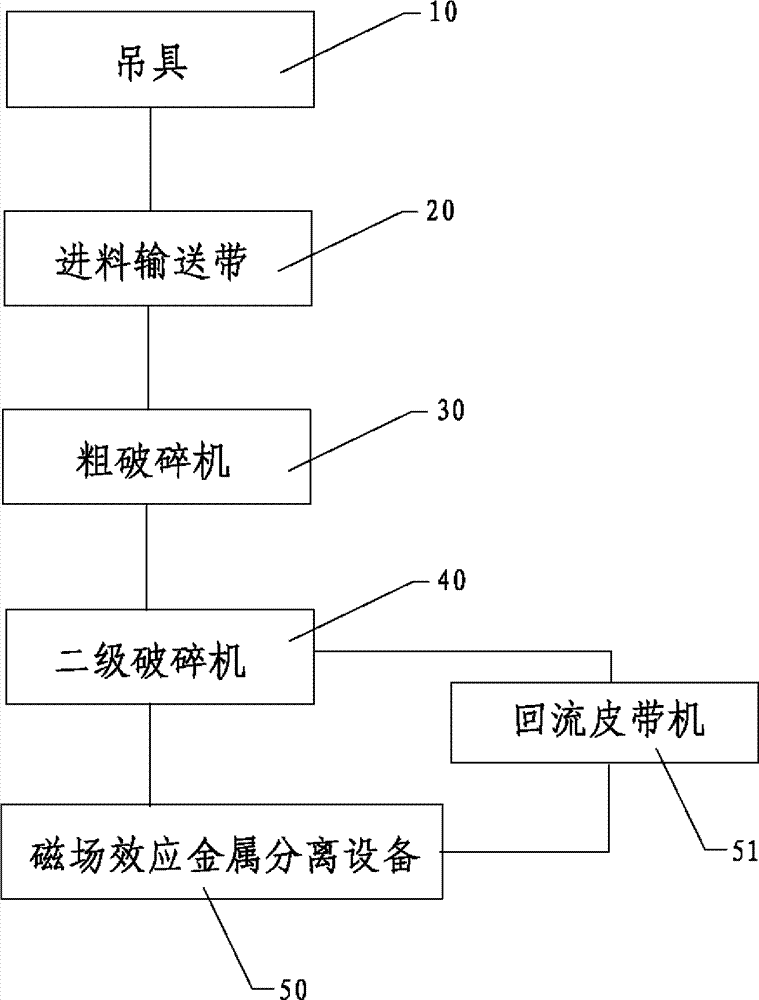

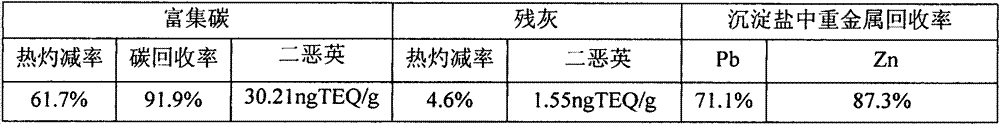

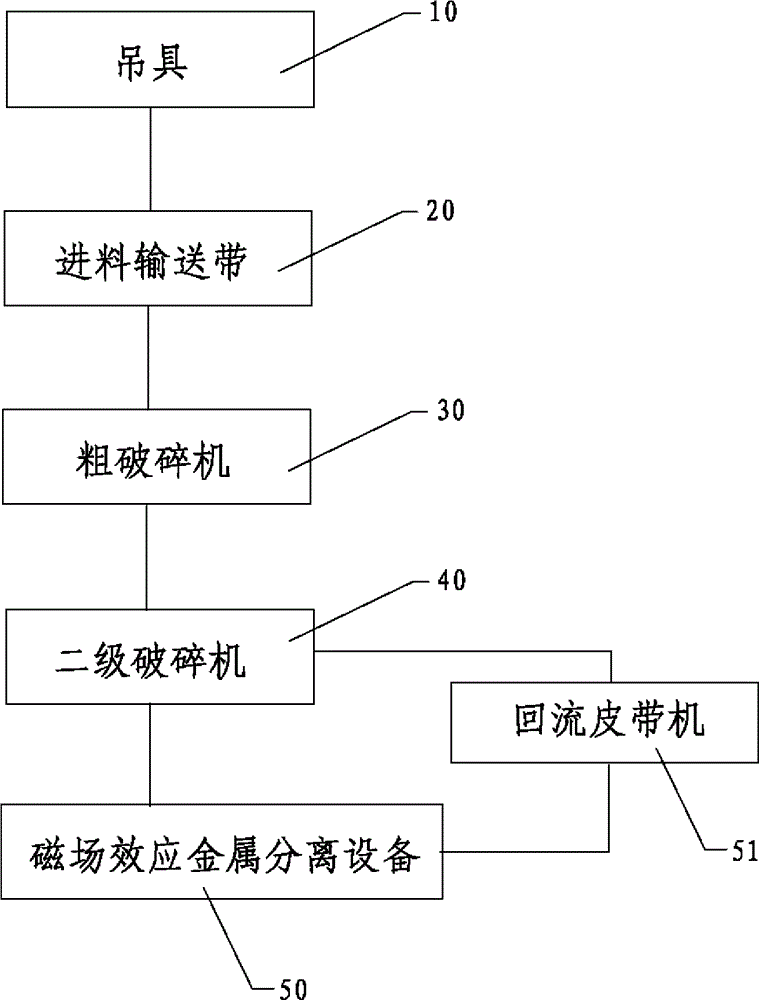

Method and system for crushing and recycling twisted ropes

ActiveCN103240158ASimple structureIncrease profitMagnetic separationGrain treatmentsSocial benefitsEconomic benefits

The invention relates to the technical field of paper-making machinery, and in particular relates to a method and a system for crushing and recycling twisted ropes. The recycling method comprises the following process steps of: feeding materials, namely, feeding the twisted ropes to a feeding conveyer belt by using a hanger; roughly crushing, namely, conveying the twisted ropes to a rough crusher to crush so as to make strip rough materials which is 16-25cm long and 5-10cm wide; secondarily crushing, namely, feeding the strip rough materials into a secondary crusher to crush so as to make strip fine materials which are 5-10cm long and 2-8cm wide; and separating and recycling, namely, conveying the strip fine materials to magnetic field effect metal separation equipment to separate, and collecting so as to obtain ferrous metals and non-metal waste. The method and the system have the advantages that the process is simple and developed, the operation is simple, the utilization rate of the raw material is high, and the economic benefits and the social benefits are good.

Owner:NINE DRAGONS PULP PAPER LESHAN CO LTD

Sludge anhydration and burning process, and its systematic device

ActiveCN100351188CSignificant reductionSave landfill spaceSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningActivated sludgeCold air

The invention relates to a sludge drying and burning technique and its system devices, applying to the handling of active sludge in urban sewage treatment plants, its process flows through: wet sludge stock house, measuring bin, sludge mixer, sludge dryer, granular splitter, cooler, drying products storage bin, incinerator, smoke gas cleaning devices, which is characterized by: said incinerator is bubbling fluid bed incinerator with coal economizer, air heater fixed in its end part, high-heat smoke gas generated by burning is used to heat heat-conducting oil and cool air individually, and heat-conducting oil after being heated is transferred to sludge dryer through the circulating pump to dry wet-sludge. The invention is characterized by: take heat-conducting oil as heating medium, use the heat generated by burning dry sludge to heat heat-conducting oil and then dry wet-sludge to make full use of resources; the volume-reducing quantity after drying and burning could reach over 90%; the percentage of desulphurization in incinerator could reach 75% as a result of adopting two stage technology of sulfur removal, and the gross percentage of desulphurization meets national environmental legislation requirements. The invention accomplishes the resources, volume reduction, and innocence of sludge.

Owner:贵州筑信水务环境产业有限公司

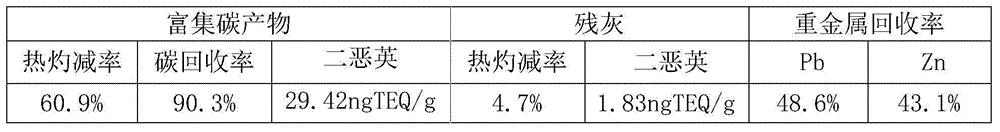

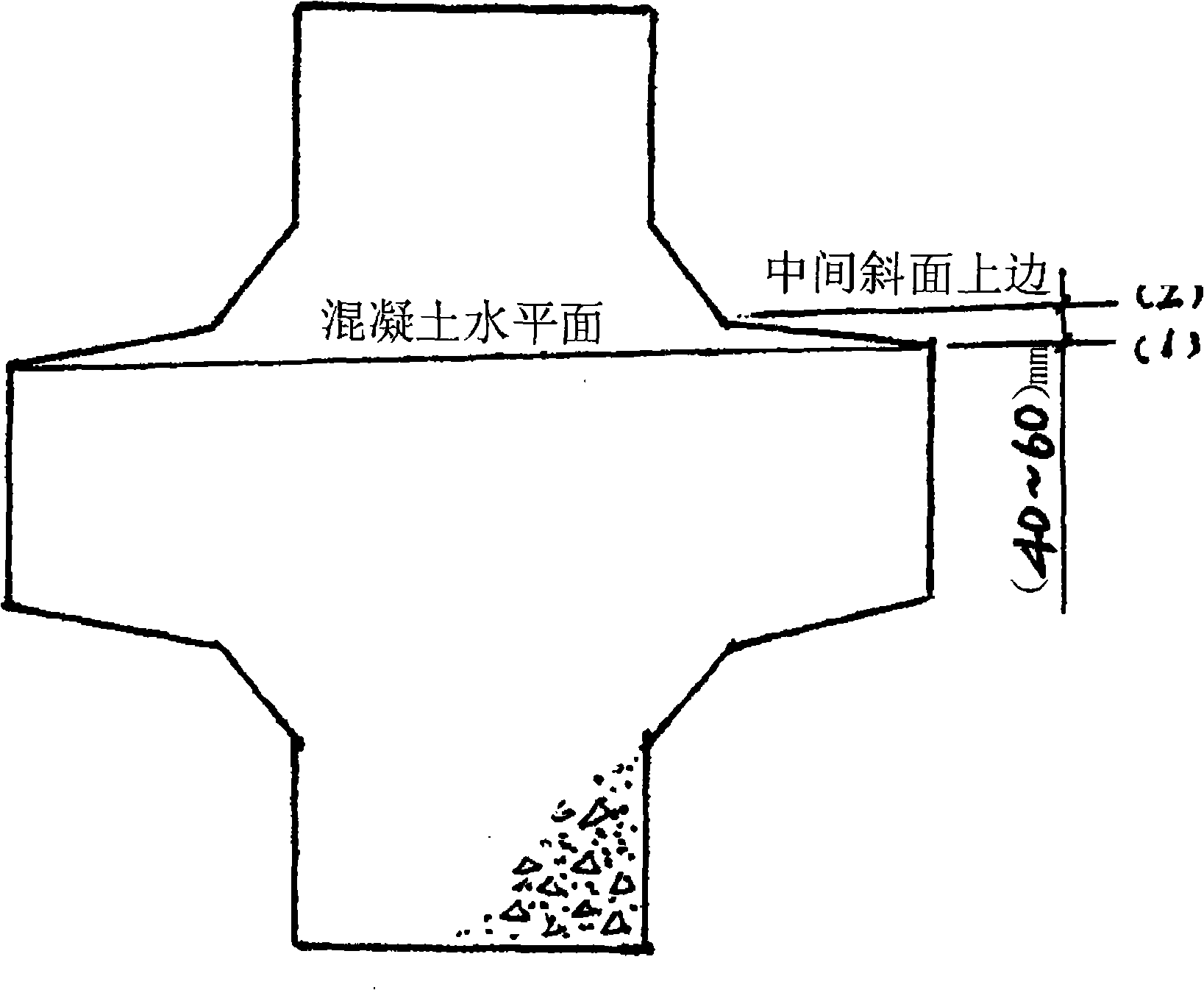

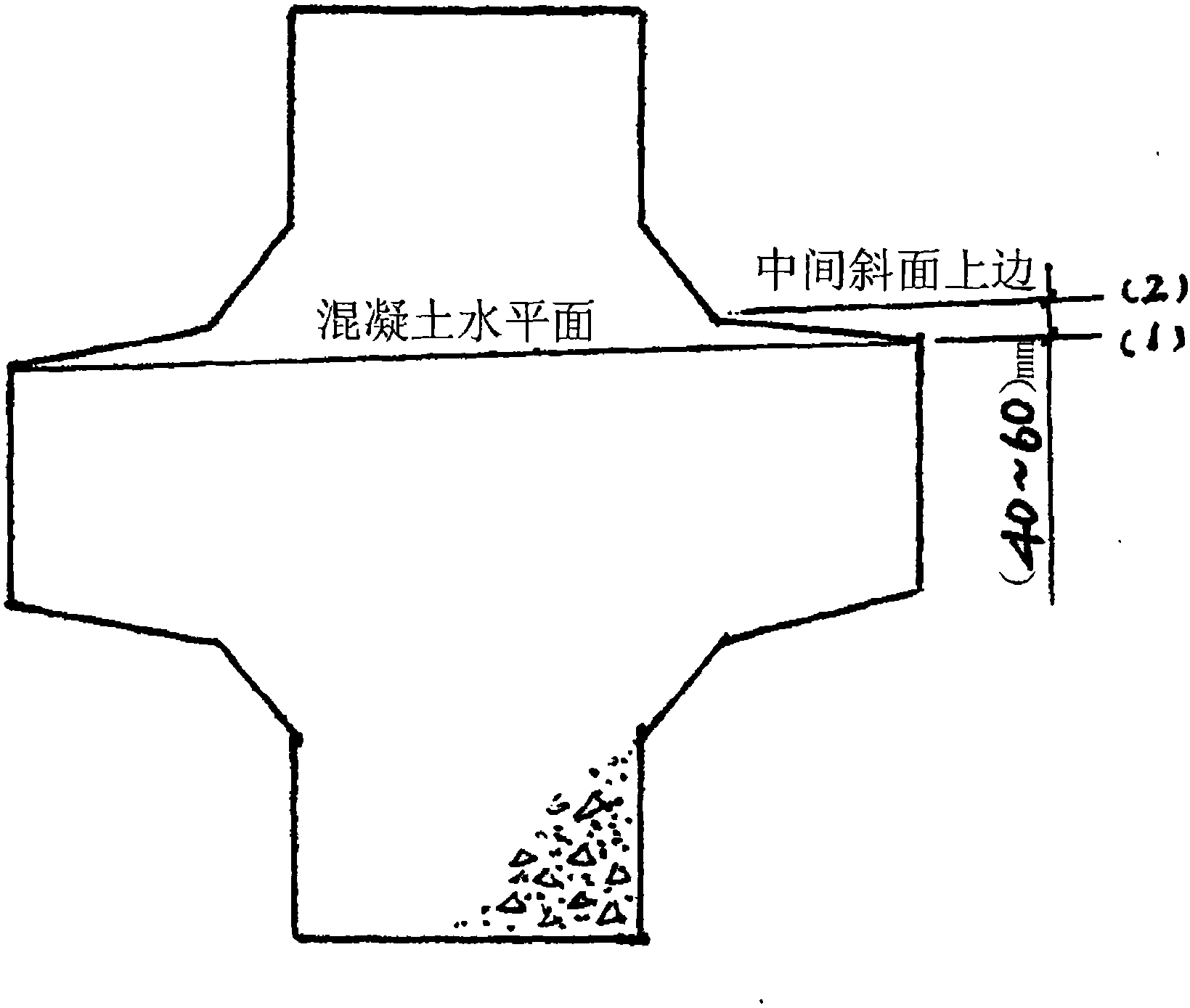

Method for producing water conservancy concrete wrest block and four-pin hollow block by using pipe pile wastewater slurry

InactiveCN101269519AIncrease dosageLow costMouldsMixing operation control apparatusWastewaterCrushed stone

The invention relates to a method for producing armour block and hollow block with four legs of water conservancy concrete by utilizing tubular pile waste water slurry. The method mainly comprises the steps that: concrete, medium sand and gravel are launched into a concerete mixer to be mixed for 30 seconds to 60 seconds according to proportion by weight; and then the tubular pile waste water slurry is added when stirring; the quantity of the water slurry added into is subject to slump constant of the concrete mix which is between 30 mm to 120mm; the concrete mix is produced after the wet mixture is acted for 30 to 60 seconds. And then the concrete mix is launched into a prefabricated-part mould; a concentrated vibro is adopted for processing, and the distance between vibro points is 0.8 times to 1.2 times of the working radius of a vibrating spear. When in pouring, the concrete mix needs to be processed for pouring layer upon layer in the mould in a horizontal plane rising way. At last maintenance is processed according to a conventional maintenance process method. Aiming at the mechanical property requirements of the concrete water conservancy prefabricated-part, the pressive strength grade of the produced concrete water conservancy prefabricated-part is C30 through improving the mix proportion of the concrete and the pouring technology; the appearance quality measures up to the standard requirements.

Owner:上海亿航工贸发展有限公司

Waste treatment equipment

ActiveCN106976268ALimit the maximum push slip distanceLimit push slip distanceShaping pressTransverse grooveVolumetric Mass Density

The invention discloses waste treatment equipment which comprises a main body. An extruding cavity is formed in the main body; a regulating cavity is formed in the position, on the lower portion of the extruding cavity, in the main body; a transverse groove is formed in the inner top wall of the extruding cavity in a left and right extending mode; a sliding block is arranged in the transverse groove; an extruding power device is fixedly arranged on the end face of the front side of the sliding block; the bottom of the extruding power device is provided with an extruding head which stretches into the extruding cavity and is rotatably connected with the extruding cavity in a matched mode; first guiding grooves and second guiding grooves formed in the upper portions of the first guiding grooves are formed in the inner side faces of the left side and the right side of the extruding cavity correspondingly; first guiding rods are arranged in the first guiding grooves in an up and down extending mode; and first square grooves are formed in the inner top walls of the second guiding grooves. The waste treatment equipment is simple in structure, waste can be extruded into waste blocks with different sizes and different densities according to different requirements, the size is reduced, the landfill space is saved, the deodorization effect is good, the requirement of extrusion work of the waste in waste boxes with different specifications is met, self fixation can be achieved, and the working efficiency is high.

Owner:天长市天香源粮油食品有限公司

Ecologic cement clinker fired through municipal waste incineration ash

InactiveCN105399351AEliminate landfill disposal processWill not cause secondary pollutionCement productionNatural resourceSlag

The invention relates to an ecologic cement clinker fired through municipal waste incineration ash, and belongs to the technical field of building materials. The ecologic cement clinker is prepared from the following components in parts by weight: 15-82 parts of municipal waste incineration ash, 75-85 parts of sand stone, 20-25 parts of slag, 5-15 parts of yellow sand stone, 2-5 parts of powdered iron, and the balance of water, wherein the municipal waste incineration ash is obtained in a manner that after being crushed, municipal waste is conveyed to a waste incinerator to be subjected to high temperature processing through hot air at the temperature of 850-1250 DEG C to generate cured ash, namely the municipal waste incineration ash; concrete performance tests on cement show that test results of cement mixed concrete produced by mixing the municipal waste incineration ash and cement mixed concrete without the municipal waste incineration ash are similar, but the consumption of natural resources is reduced, so that the cement production cost is reduced, and the sustainable development of cement industries is facilitated.

Owner:赖清甜

A garbage disposal device

ActiveCN106976268BLimit the maximum push slip distanceLimit push slip distanceShaping pressTransverse grooveVolumetric Mass Density

Owner:天长市天香源粮油食品有限公司

A garbage disposal device

Owner:盐城市欧奇机械有限公司

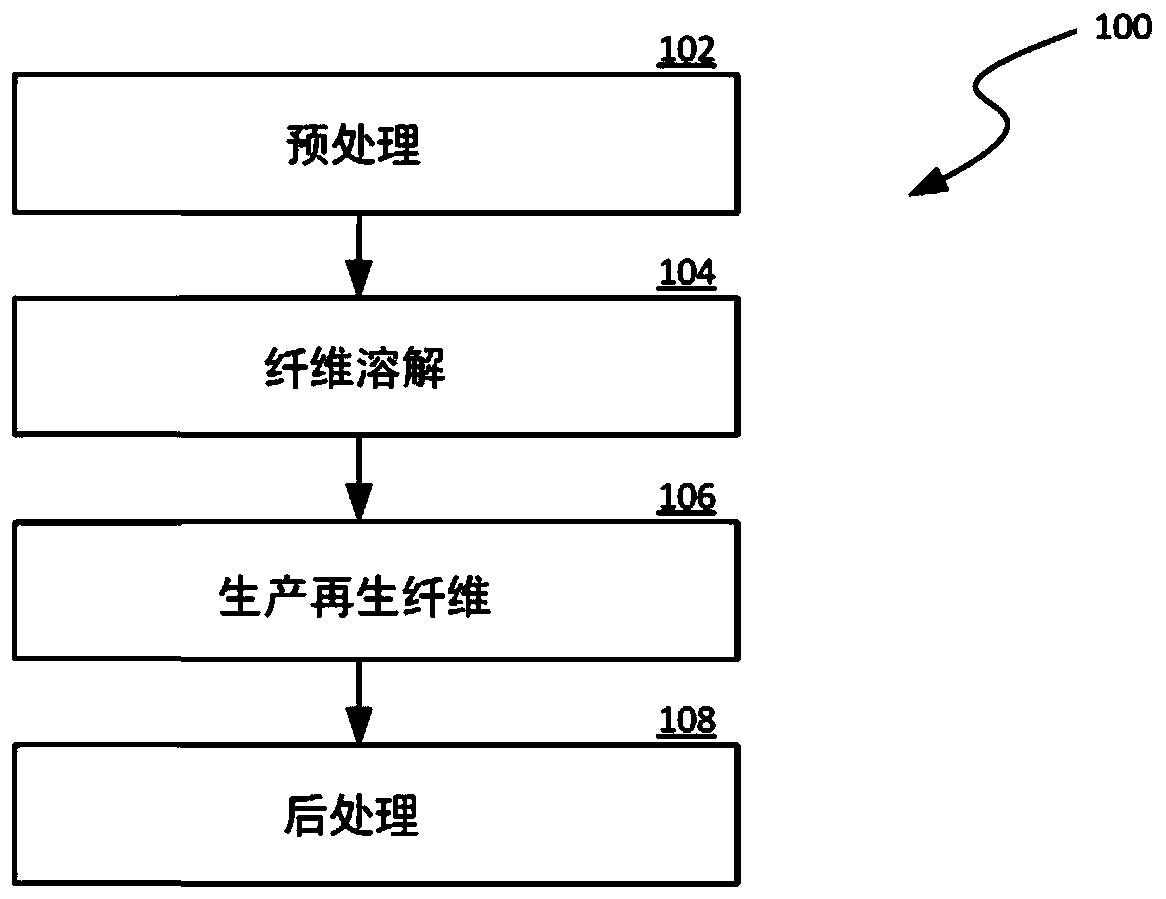

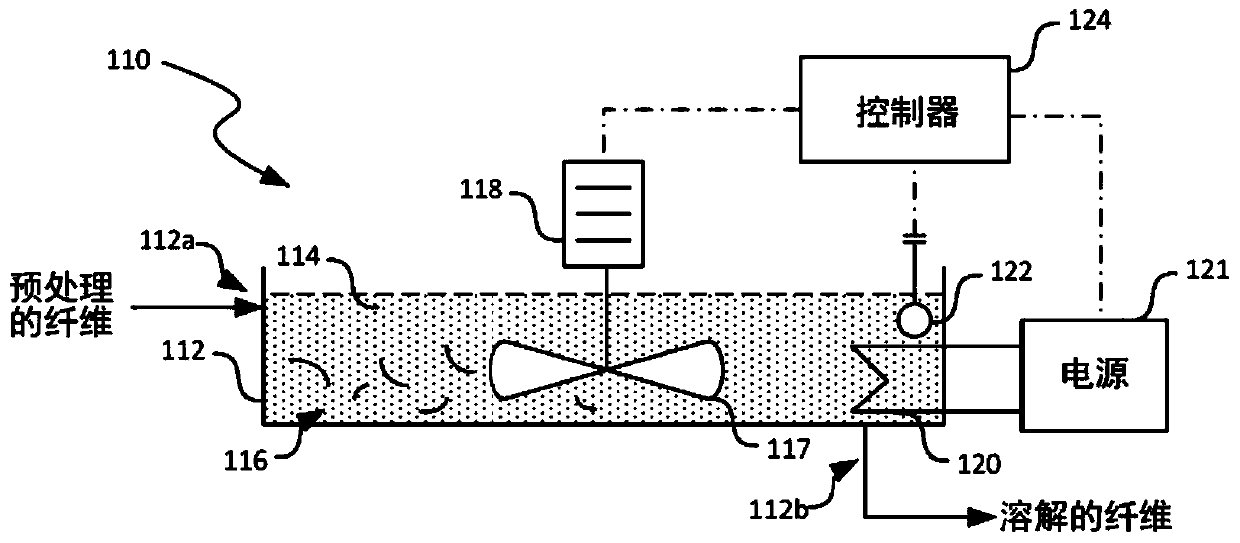

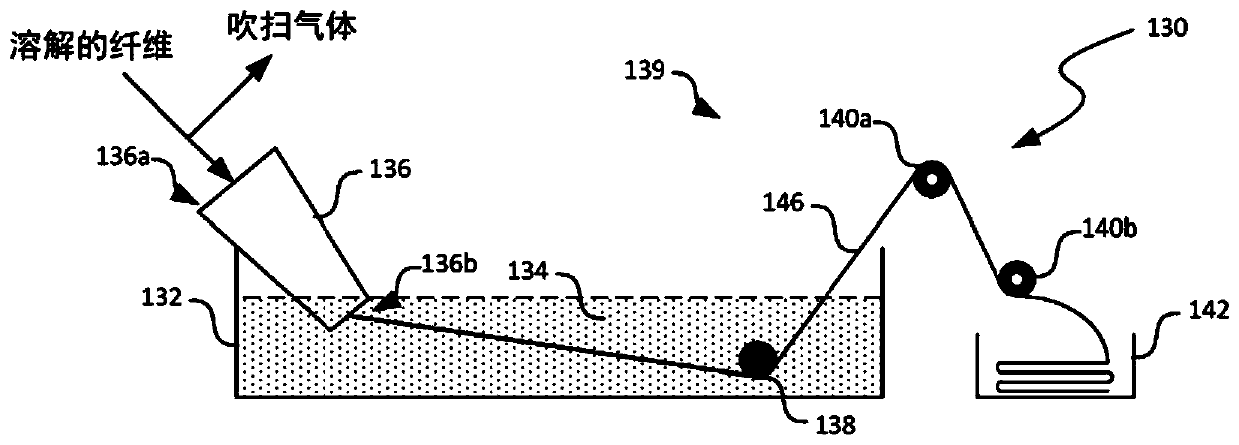

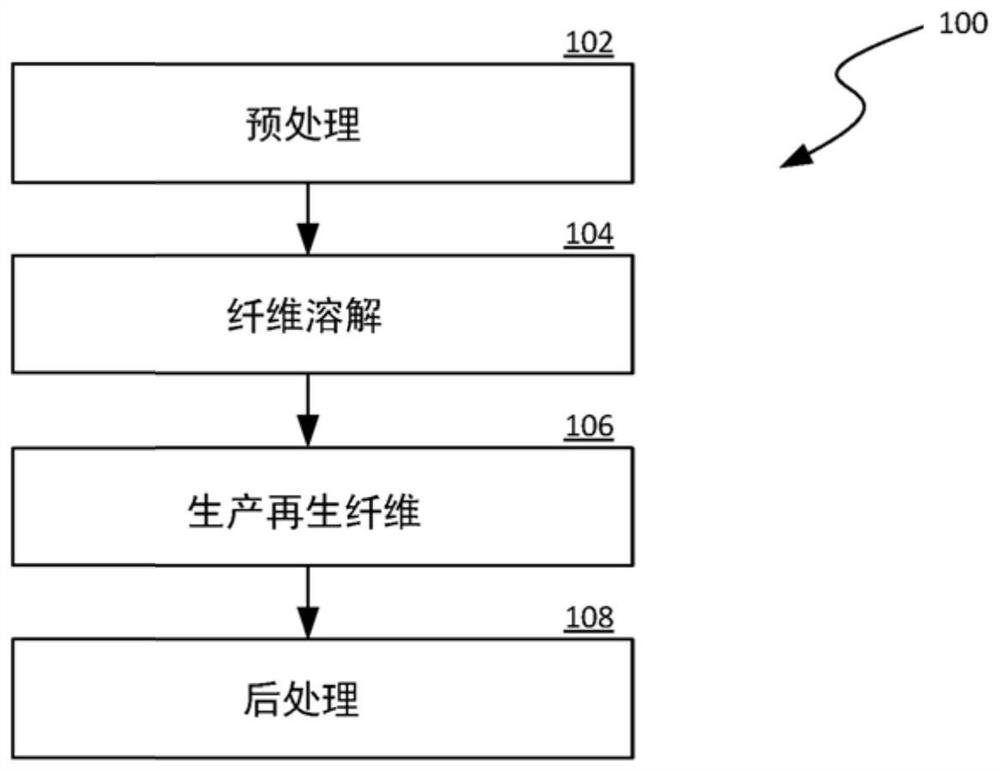

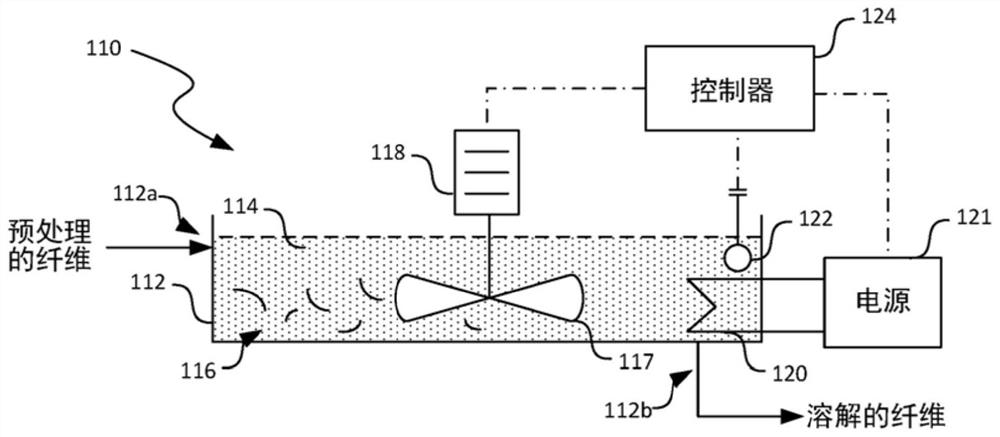

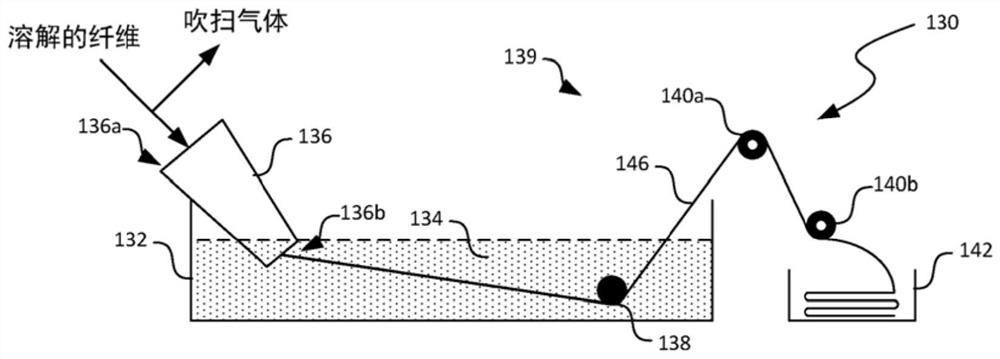

Environmentally friendly cellulose waste recycling

Techniques for chemically recycling cellulose waste such as cotton are disclosed herein. In one embodiment, a method includes hydrolyzing a cotton waste and dissolving cellulose in the hydrolyzed cotton waste in an aqueous solution containing an alkali and one or more of urea ((NH2)2CO), polyethylene glycol, or thiourea (SC(NH2)2) to produce another aqueous solution containing dissolved cellulose.Then the another aqueous solution containing the dissolved cellulose can be extruded into a coagulation bath to coalesce the dissolved cellulose in the extruded solution, thereby reforming the dissolved cellulose from the cotton waste into a regenerated fiber.

Owner:WASHINGTON STATE UNIVERSITY

Anti-freezing sludge deep dehydration conditioner as well as preparation and application methods thereof

The invention relates to an anti-freezing sludge deep dehydration conditioner as well as preparation and application methods thereof, and belongs to the technical field of sludge treatment. The anti-freezing sludge deep dehydration conditioner is prepared from the following components in parts by mass through reaction: 600 to 800 parts of polydimethyldiallyl ammonium chloride, 100 to 200 parts ofethylene glycol, 1 to 5 parts of a cationic guar gum polymer and 5 to 25 parts of polyferric sulfate. After sludge is conditioned by the anti-freezing sludge deep dehydration conditioner, the dehydration performance is obviously improved, and the water content of a filter cake can be reduced to 50-60% from 95-99.9%. The anti-freezing sludge deep dehydration conditioner has the advantages of low freezing point, convenience in transportation, storage and use, high conditioning speed, high sludge dehydration rate, less increment of sludge generated by the conditioner, simplicity in operation, high sludge volume reduction rate and the like, so that the anti-freezing sludge deep dehydration conditioner can be widely applied to sludge conditioning and enhanced deep dehydration.

Owner:山东益源环保科技有限公司

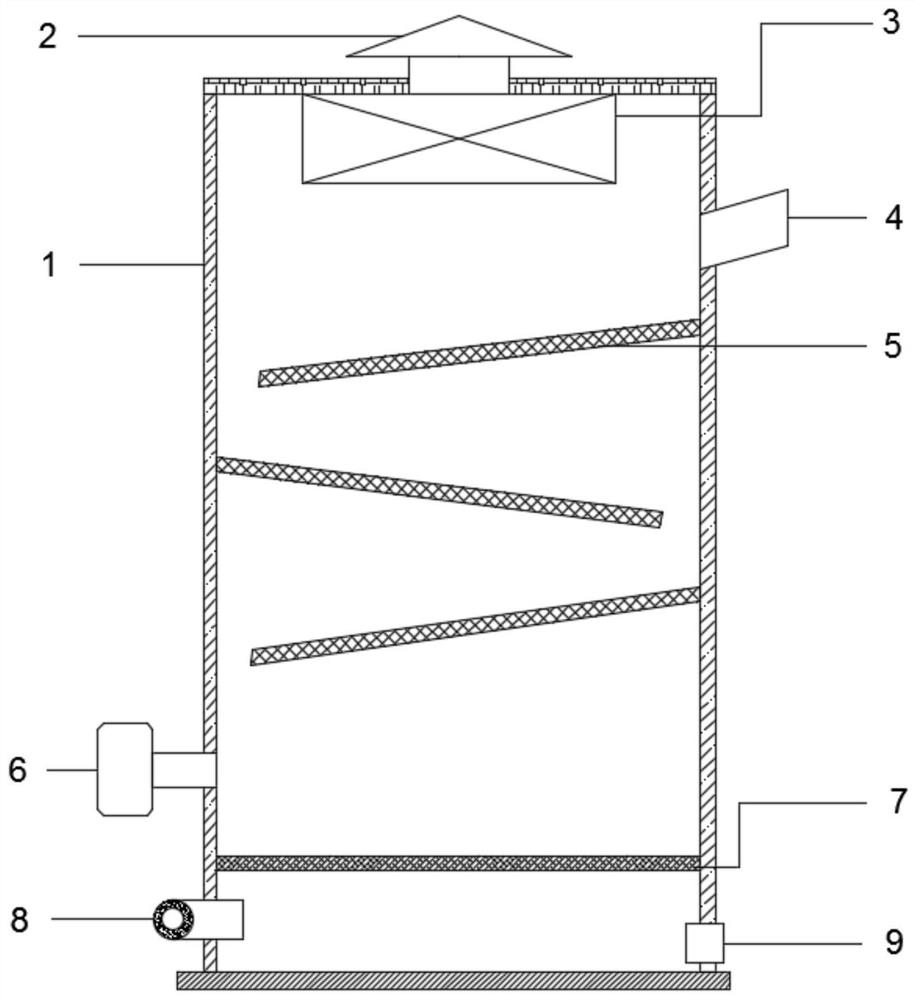

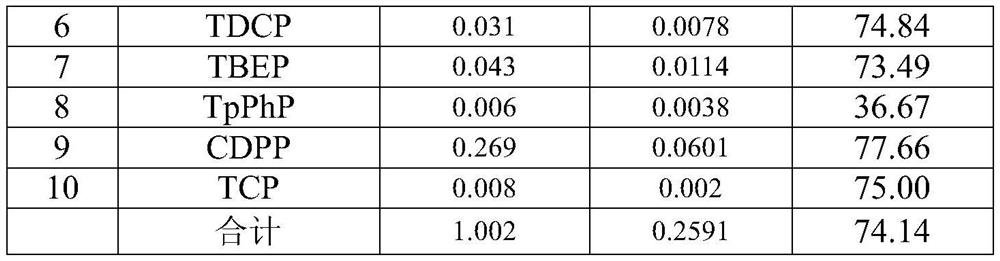

A method for detection and resource utilization of simulated incineration products of phosphorus-based flame retardants in electronic waste

ActiveCN111380061BLight in massReduce volumeComponent separationIncinerator apparatusEnvironmental engineeringElectronic waste

The invention discloses a method for detecting simulated incineration products of phosphorus-based flame retardants in electronic waste, comprising the following steps: (S1) analysis of phosphorus-based flame retardants in electronic waste; (S2) designing a simulated incinerator; (S3) electronic waste Simulated incineration of waste; (S4) analysis of incineration products; (S5) resource utilization of phosphorus components in electronic waste incineration products. This method simulates incineration in an incinerator and detects the type and content of phosphorus-containing components in the products before and after the simulated combustion of phosphorus-based flame retardants in electronic waste. A resource utilization method for phosphorus-containing components in products.

Owner:GUANGDONG TESTING INST OF PROD QUALITY SUPERVISION

A two-step flotation treatment method for medical waste incineration fly ash

ActiveCN105149101BReduce secondary synthesisRealize the utilization of fuelFlotationLiquid wasteCombustion chamber

The invention discloses a two-step flotation treatment method for incineration fly ash of medical waste. The following steps are adopted: 1) decarbonization flotation to obtain two products of enriched carbon and primary tailings, and sending the enriched carbon product into garbage Combustion in the second combustion chamber of the incinerator; 2) acid leaching filtration: add inorganic acid to the primary tailings obtained in step 1) to carry out acid leaching and then filter to obtain two products: residual ash and heavy metal waste liquid; the residual ash is directly sent to domestic garbage Landfill for safe landfill disposal or reuse; 3) Ion flotation: Add flotation agents to the heavy metal waste liquid obtained in step 2) to carry out ion flotation to obtain two products of heavy metal concentrated foam and waste water; concentrate the heavy metal The foam is sent to the smelter to recover heavy metals Pb and Zn, and the wastewater is neutralized and discharged into the sewage system after reaching the standard. The invention has the advantages of simple operation, low cost, good treatment effect and no secondary pollution.

Owner:TIANJIN CHENGJIAN UNIV

Sludge gasifier

PendingCN109486530AReduce volumePrevent leakageGasification processes detailsCombustible gas productionSludgeFuel gas

The invention discloses a sludge gasifier, comprising a sludge storage bin, a feeding mechanism, a body, a sealed ash bin and a residue discharge mechanism which are connected sequentially from top tobottom. The feeding mechanism includes a feeding buffer bin; the feeding buffer bin is connected with the sludge storage bin and the body through feed pipes; a first rotary feed valve is arranged between the feeding buffer bin and the sludge storage bin; a second rotary feed valve is arranged between the feeding buffer bin and the body. The feeding mechanism is arranged between the sludge storagebin and the body and helps prevents fuel gas in the body from leaking out of a feed port during sludge feeding; fuel gas recycling efficiency is improved, and it is ensured that the whole sludge gasifier runs safely and stably.

Owner:上海迪琰环保科技有限公司

Environmentally Friendly Cellulose Waste Recycling

Techniques for chemically recycling cellulosic waste such as cotton are disclosed herein. In one embodiment, the method comprises, hydrolyzing cotton waste and dissolving the cellulose in the hydrolyzed cotton waste in a solution containing alkali and selected from urea ((NH 2 ) 2 CO), polyethylene glycol, or thiourea (SC(NH 2 ) 2 ) in an aqueous solution of one or more of them to produce another aqueous solution containing dissolved cellulose. Another aqueous solution containing dissolved cellulose may then be extruded into a coagulation bath to coagulate the dissolved cellulose in the extruded solution, thereby reforming the dissolved cellulose from the cotton waste into regenerated fibers.

Owner:WASHINGTON STATE UNIVERSITY

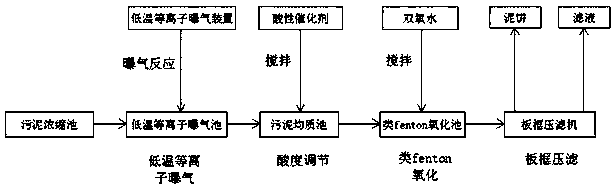

A Process for Improving the Dewatering Performance of Excess Sludge

ActiveCN106746407BReduce moisture contentImprove dehydration effectSludge treatment by oxidationSpecific water treatment objectivesPlasma technologyFiltration

The invention discloses a technology for improving the dewaterability of excess sludge. The technology includes the first step of low-temperature plasma aeration, the second step of acidity regulation, the third step of fenton-like oxidation and the fourth step of plate-frame pressure filtration. The low-temperature plasma technology is combined with fenton-like oxidation for treatment the excess sludge together, sludge cell walls are effectively damaged, and the dewaterability of the sludge is improved. The water content after sludge dewatering is lower than 60%, the salt content is low, the heat value is high, and the technology is suitable for sanitary landfill and incineration and also suitable for aerobic fermentation to prepare biological organic fertilizers.

Owner:山东益源环保科技有限公司

Stabilization treatment method of domestic garbage incineration fly ash

A method for stabilizing the fly ash generated by incinerating garbage includes such steps as loading the fly ash in a tank truck, directly transporting it to the movable storage tank close to a burying pit, pneumatically delivering the fly ash into said storage tank, delivering the fly ash from the bottom of tank into said burying pit via a screw conveyer while spraying liquid chemical, mechanical spreading in pit, and tampering.

Owner:上海寰保渣业处置有限公司

A Soilless Covering Material for Sanitary Landfill of Solid Waste

The invention provides a soilless cover material for sanitary landfill of solid waste garbage. The soilless cover material for sanitary landfill of the solid waste garbage comprises components with parts by weight: water-soluble cellulose polymers 2-25 parts, plant fibers 20-100 parts, clay 10-100 parts, gypsum 5-50 parts and water 500-3000 parts, wherein the water-soluble cellulose polymers is an ionic type, and the plant fibers are an expanded type. The soilless cover material for sanitary landfill of the solid waste garbage is degradable, is about 5%-10% in water penetration rate, also has a certain amount of water permeability, and has great promotion effect for breeding of garbage natural degradation bacteria. The soilless cover material for sanitary landfill of the solid waste garbage eliminates garbage layering after being degraded, enables garbage of a whole landfill to be an entirety, and plays great role for improving garbage density. Compared with other cover methods, the soilless cover material for sanitary landfill of the solid waste garbage has great advantages in cost.

Owner:深圳市五大湖新概念环保科技有限公司

Sanitary garbage disposal device

The invention discloses a sanitary garbage disposal device, which comprises a frame body composed of a backboard and a workbench, a compression device is arranged on the right side of the backboard, a fixing device is arranged on the top of the workbench, and the top surface of the fixing device and the bottom surface of the compression device are connected to each other. Correspondingly, the first empty box, the second empty box and the third empty box are arranged inside the compression device, the inner surface of the right side of the first empty box is provided with a second sliding groove, and the left side of the first empty box is provided with an outer screw extending up and down. The top extension block of the outer spiral sleeve sleeve penetrates the top surface of the first cavity and is screwed and connected, the tip of the top extension block of the outer screw sleeve sleeve extends into the second cavity, and the outer spiral The stretching block at the bottom of the sleeve sleeve penetrates through the inner bottom surface of the first cavity and is screwed and connected, and the outer threaded sleeve sleeve in the first cavity is screw-fitted and connected with a second sliding block extending to the right; The invention has simple structure and convenient operation, can compress garbage into garbage blocks of different sizes and densities according to different needs, reduces volume and saves landfill space.

Owner:HUANGSHAN KETAI ENVIRONMENTAL PROTECTION TECH CO LTD

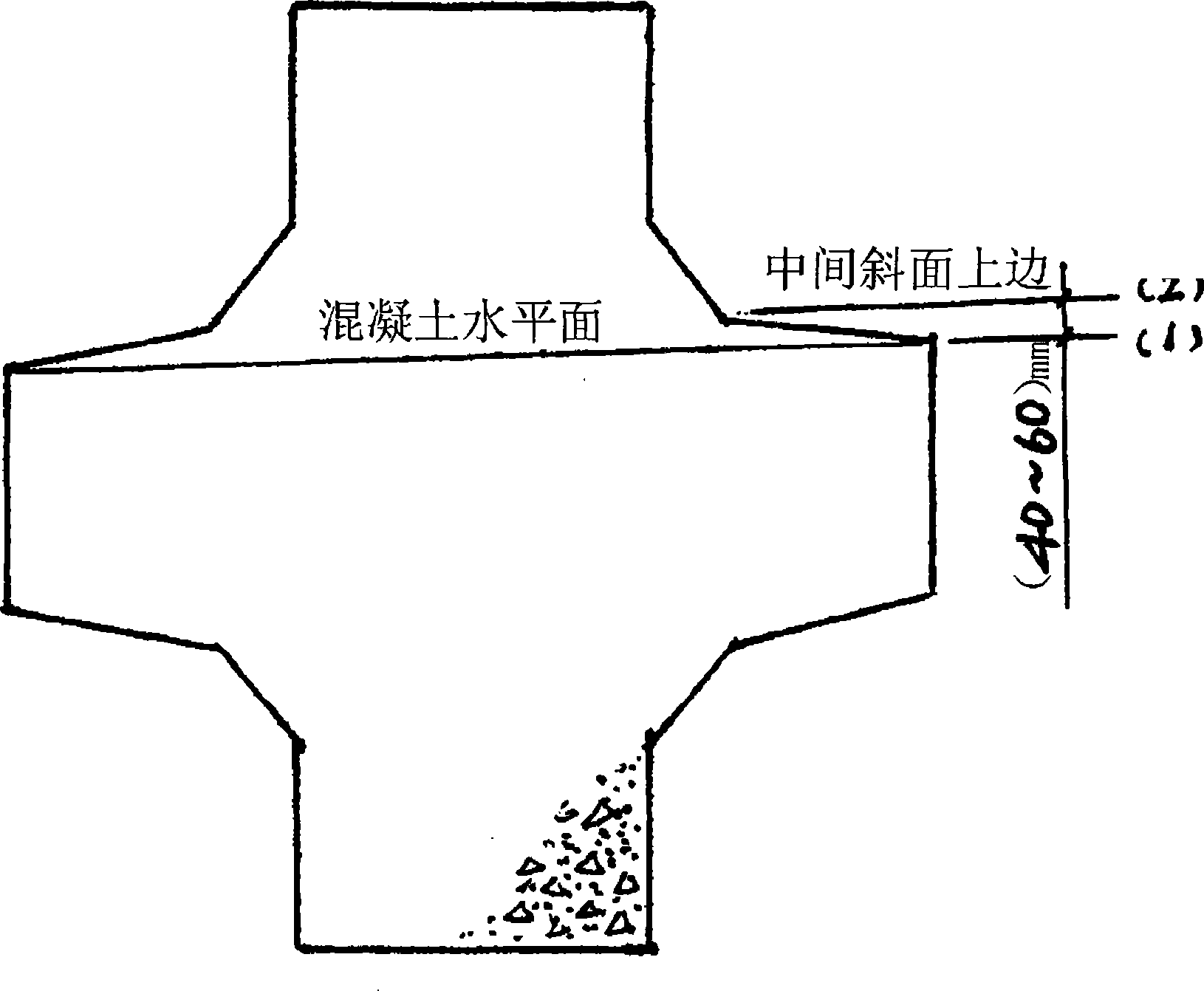

Method for producing concrete building block by using pipe pile wastewater slurry

InactiveCN101269520BIncrease dosageLow costMouldsMixing operation control apparatusCrushed stoneWastewater

The invention relates to a method for producing concrete water conservancy prefabricated-part with tubular pile waste water slurry. Firstly concrete, medium sand and gravel are launched into a concrete mixer to be mixed for 30 seconds to 60 seconds according to proportion by weight; and then the tubular pile waste water slurry is added when stirring; the quantity of the water slurry added into issubject to slump constant of the concrete mix which is between 30 mm to 120mm; the concrete mix is produced after the wet mixture is acted for 30 to 60 seconds. And then the concrete mix is launched into a prefabricated-part mould; a concentrated vibro is adopted for processing, and the distance between vibro points is 0.8 times to 1.2 times of the working radius of a vibrating spear. When in pouring, the concrete mix needs to be processed for pouring layer upon layer in the mould in a horizontal plane rising way. At last maintenance is processed according to a conventional maintenance process method. Aiming at the mechanical property requirements of the concrete water conservancy prefabricated-part, the pressive strength grade of the produced concrete water conservancy prefabricated-partis C30 through improving the mix proportion of the concrete and the pouring technology; the appearance quality measures up to the standard requirements.

Owner:上海亿航工贸发展有限公司

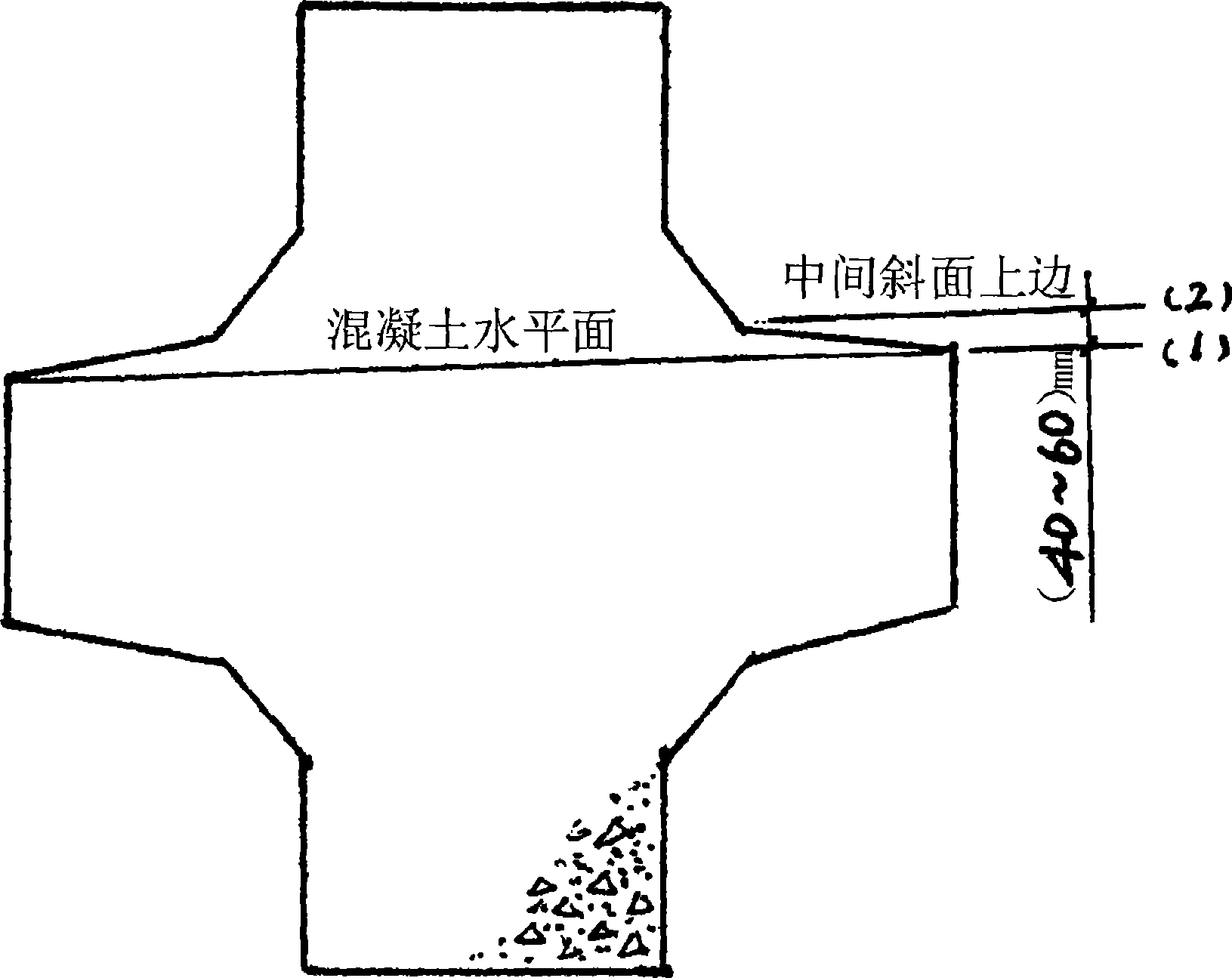

Method for producing water conservancy concrete wrest block and four-pin hollow block by using pipe pile wastewater slurry

InactiveCN101269519BIncrease dosageLow costMouldsMixing operation control apparatusCrushed stoneWastewater

The invention relates to a method for producing armour block and hollow block with four legs of water conservancy concrete by utilizing tubular pile waste water slurry. The method mainly comprises the steps that: concrete, medium sand and gravel are launched into a concerete mixer to be mixed for 30 seconds to 60 seconds according to proportion by weight; and then the tubular pile waste water slurry is added when stirring; the quantity of the water slurry added into is subject to slump constant of the concrete mix which is between 30 mm to 120mm; the concrete mix is produced after the wet mixture is acted for 30 to 60 seconds. And then the concrete mix is launched into a prefabricated-part mould; a concentrated vibro is adopted for processing, and the distance between vibro points is 0.8 times to 1.2 times of the working radius of a vibrating spear. When in pouring, the concrete mix needs to be processed for pouring layer upon layer in the mould in a horizontal plane rising way. At last maintenance is processed according to a conventional maintenance process method. Aiming at the mechanical property requirements of the concrete water conservancy prefabricated-part, the pressive strength grade of the produced concrete water conservancy prefabricated-part is C30 through improving the mix proportion of the concrete and the pouring technology; the appearance quality measures up tothe standard requirements.

Owner:上海亿航工贸发展有限公司

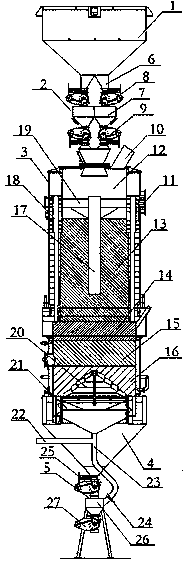

Step-by-step flotation detoxification method for fly ash of medical waste incineration

ActiveCN104275245BAchieve recyclingReduce secondary synthesisFlotationDecompositionResource utilization

The invention discloses a sub-step flotation and detoxification method for incineration fly ash of medical garbage. The sub-step flotation and detoxification method is characterized in that coseparation of dioxin and a carbon component is realized by first-step flotation, so that the toxicity of organic pollutants including the dioxin and the like in the fly ash is reduced; meanwhile, soluble heavy metal is eluted; second-step flotation of tail slurry is subjected to a sulfide precipitation flotation method and heavy metal including Pb, Zn and the like is removed and recycled, so that the harms of the heavy metal are eliminated. Separated final products mainly comprise enriched carbon, residual ash, heavy metal sediment salt and the like, wherein the enriched carbon rich in the dioxin is conveyed into a garbage incinerator secondary incineration chamber to be incinerated, so that the high-temperature decomposition of the dioxin is realized by a low cost; the volume and the toxicity of the residual ash are greatly reduced and the residual ash is directly conveyed into a municipal solid waste landfill to be safely treated or reutilized, so that the subsequent treatment cost is greatly reduced; the heavy metal in the fly ash is leached with an acid and vulcanized and then is precipitated, floated and recycled, so that a plurality of purposes are realized. The method can realize harmless treatment and resource utilization of the incineration fly ash of the medical garbage under environment-friendly and low-cost conditions.

Owner:TIANJIN CHENGJIAN UNIV

Method and system for crushing and recycling twisted ropes

ActiveCN103240158BSimple structureIncrease profitMagnetic separationGrain treatmentsSocial benefitsEconomic benefits

The invention relates to the technical field of paper-making machinery, and in particular relates to a method and a system for crushing and recycling twisted ropes. The recycling method comprises the following process steps of: feeding materials, namely, feeding the twisted ropes to a feeding conveyer belt by using a hanger; roughly crushing, namely, conveying the twisted ropes to a rough crusher to crush so as to make strip rough materials which is 16-25cm long and 5-10cm wide; secondarily crushing, namely, feeding the strip rough materials into a secondary crusher to crush so as to make strip fine materials which are 5-10cm long and 2-8cm wide; and separating and recycling, namely, conveying the strip fine materials to magnetic field effect metal separation equipment to separate, and collecting so as to obtain ferrous metals and non-metal waste. The method and the system have the advantages that the process is simple and developed, the operation is simple, the utilization rate of the raw material is high, and the economic benefits and the social benefits are good.

Owner:NINE DRAGONS PULP PAPER LESHAN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com