Sludge anhydration and burning process, and its systematic device

A sludge drying and system device technology, which is applied in the directions of oxidation treatment of sludge, sludge treatment through temperature control, dehydration/drying/concentrated sludge treatment, etc., can solve the problems of high risk, strong odor, water resources and Human health hazards and other issues to achieve the effect of improving processing efficiency, reducing investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

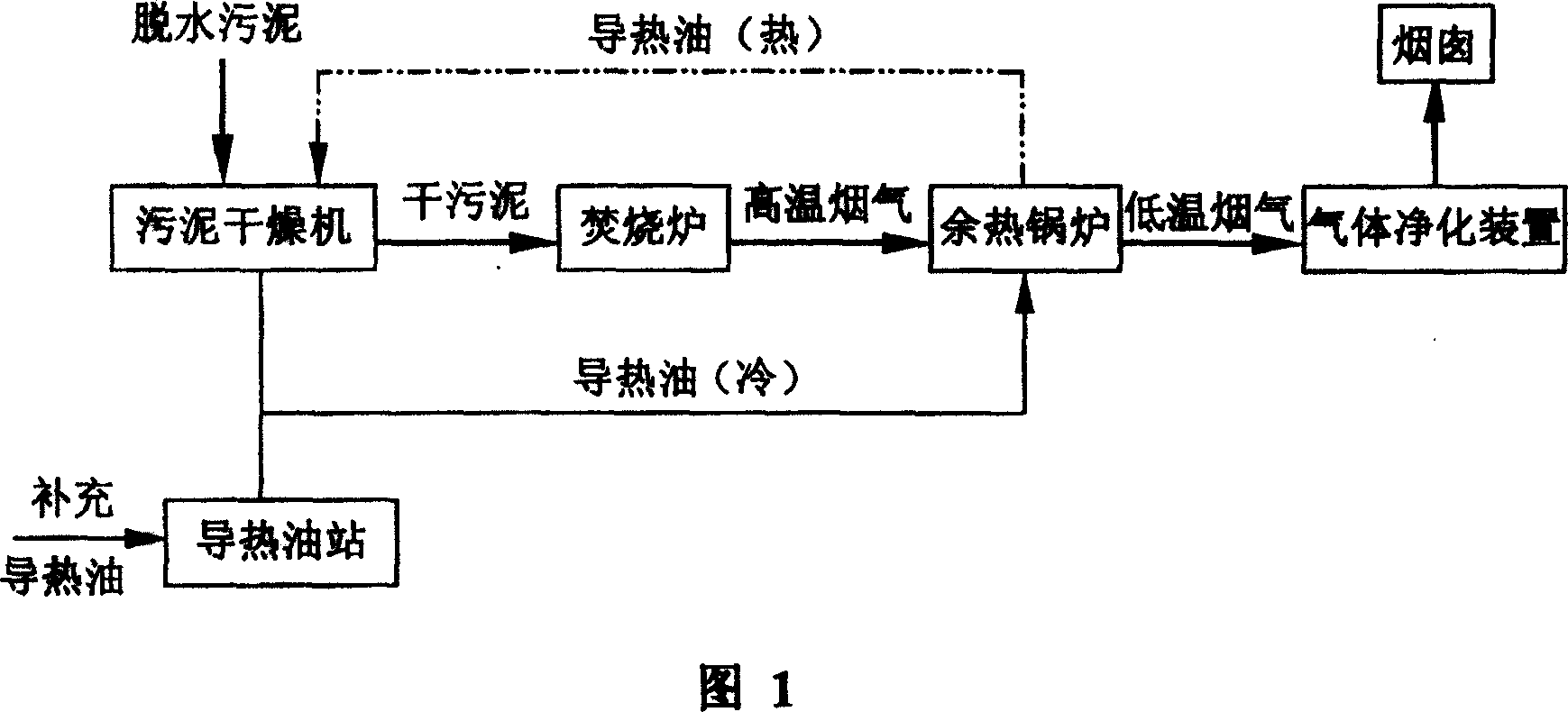

[0036] According to Figure 1, sludge drying process description

[0037] 1 Overview

[0038] The drying system is designed to dry the mechanically dewatered sludge from domestic sewage treatment plants. The dewatered sludge is directly dried in the fluidized bed, without pretreatment of the dewatered sludge (with return material) in the granulator with dry sludge. This system of directly adding sludge is actually an automatic sludge dryer.

[0039] This process is suitable for pumpable sludge from the filter press after mechanical dewatering. The resulting dry pellets can be disposed of in landfill or further processed, for example, as auxiliary fuel in power plants, the cement industry or waste incinerators. The pellets are easy to ship or intermediate store in any area.

[0040] 2. Drying process

[0041] 2.1 Wet mud process

[0042] The mechanically dehydrated sludge of the sludge treatment plant is sent from the user to the sludge metering storage bin (150m 3 ), use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com