Dyeing sludge deep dehydrating-drying treatment device and process

A technology for printing and dyeing sludge and deep dewatering, which is applied in water/sludge/sewage treatment, sludge treatment, biological sludge treatment, etc. The effect of less investment, lower transportation costs, and less exhaust gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

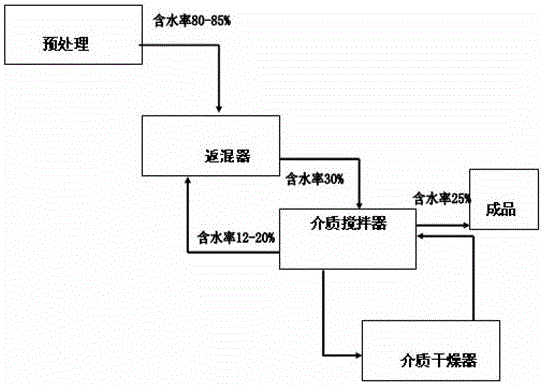

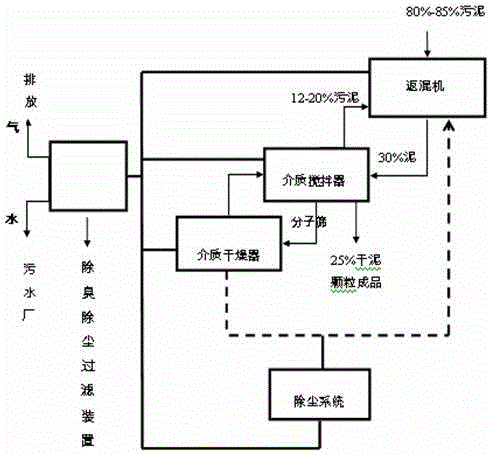

[0017] The working principle diagram of the sludge drying treatment equipment of the present invention is as follows figure 1 As shown, the printing and dyeing sludge advanced dehydration-drying treatment equipment of the present invention includes a printing and dyeing sludge storage tank, a back-mixer, a medium agitator, and a medium dryer, wherein the sludge is stored in the storage tank, and the sludge storage tank After biological pretreatment and mixing with the water-absorbing medium, the sludge inside enters the medium agitator. The medium agitator vibrates and screens the water-absorbing medium and the sludge. The separated water-absorbing medium enters the medium drier, and the medium drier The water in the water-absorbing medium is evaporated, and the water-absorbing medium is heated at the same time, and the heated water-absorbing medium enters the medium agitator, and the medium agitator vibrates and screens the water-absorbing medium and the sludge to separate, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com