Method and system for crushing and recycling twisted ropes

A recycling method and rope twisting technology, applied in the field of papermaking machinery, can solve the problems of low utilization rate of raw materials, high waste disposal cost, increase production cost, etc., and achieve the effects of high utilization rate of raw materials, saving processing cost, and strong practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

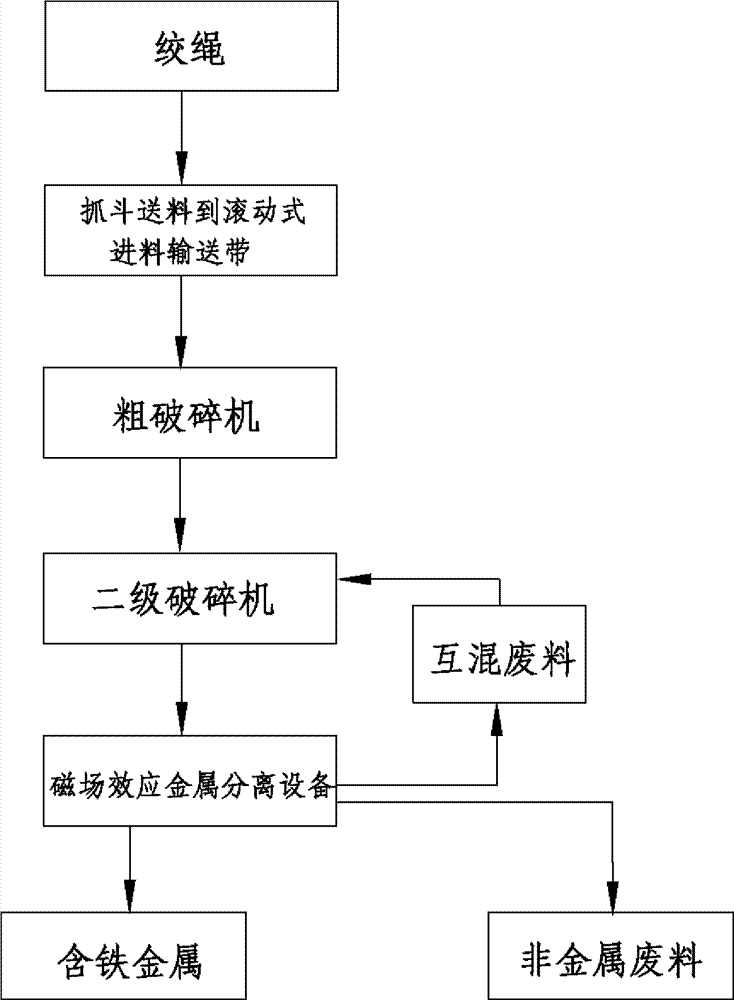

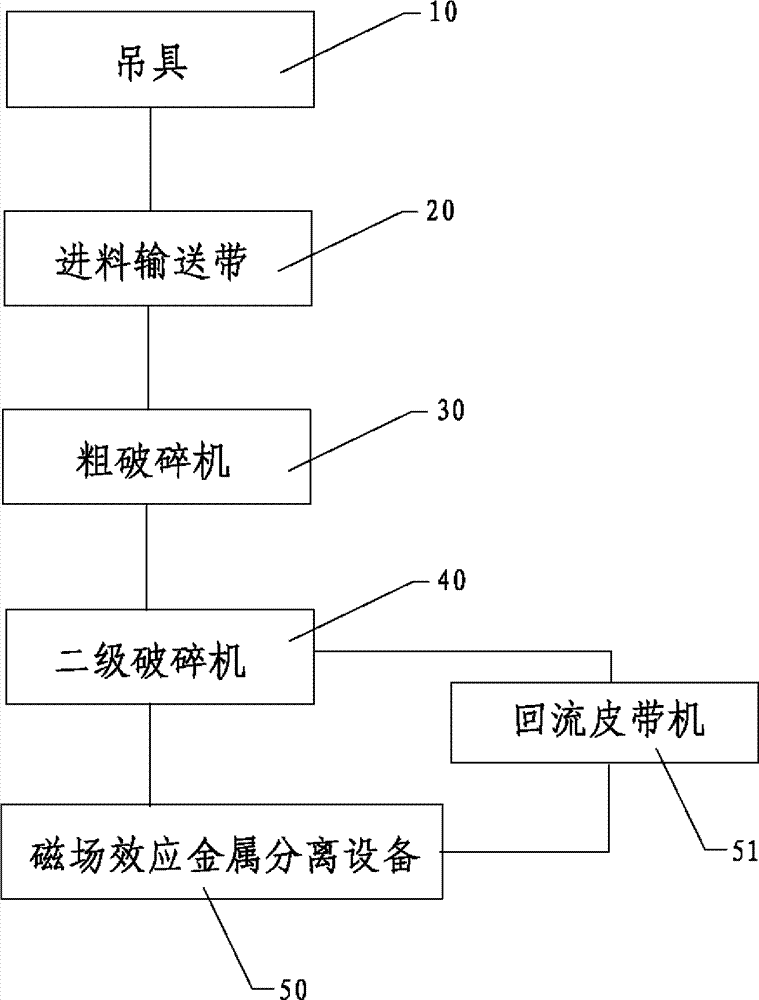

[0043] Such as figure 1 and figure 2As shown, the twisted rope crushing recovery method of the present invention comprises the following processing steps: feeding, utilizing the hanger 10 to feed the twisted rope to the feed conveyor belt 20; the delivery speed of the feed conveyor belt 20 is 2m / s, and the twisted rope The diameter of the rope is 0.5m, and the length of the twisted rope is less than or equal to 1m; for coarse crushing, the twisted rope is transported to the coarse crusher 30 for crushing, and a strip-shaped coarse material with a length of 16cm and a width of 5cm is obtained; for secondary crushing, the strip-shaped The coarse material is fed to the secondary crusher 40 for crushing, and the strip fine material with a length of 5 cm and a width of 2 cm is obtained; separated and recovered, the strip fine material is transported to the magnetic field effect metal separation device 50 for separation, and the obtained Ferrous metal and non-metallic waste: the m...

Embodiment 2

[0050] Such as figure 1 and figure 2 As shown, the twisted rope crushing and recycling method of the present invention comprises the following processing steps: feeding, utilizing the hanger 10 to feed the twisted rope to the feed conveyor belt 20; the conveying speed of the feed conveyor belt 20 is 3m / s, and the twisted rope The diameter of the rope is 1.0m, and the length of the twisted rope is less than or equal to 2m; for coarse crushing, the twisted rope is transported to the coarse crusher 30 for crushing, and a strip-shaped coarse material with a length of 21cm and a width of 8cm is obtained; for secondary crushing, the strip-shaped The coarse material is fed to the secondary crusher 40 for crushing, and the strip-shaped fine material with a length of 7 cm and a width of 5 cm is obtained; separated and recovered, the strip-shaped fine material is transported to the magnetic field effect metal separation device 50 for separation, and the iron remover The magnetic force...

Embodiment 3

[0053] Such as figure 1 and figure 2 As shown, the twisted rope crushing and recycling method of the present invention comprises the following processing steps: feeding, utilizing the hanger 10 to feed the twisted rope to the feed conveyor belt 20; the conveying speed of the feed conveyor belt 20 is 5m / s, and the twisted rope The diameter of the rope is 2.0m, and the length of the twisted rope is less than or equal to 3m; for coarse crushing, the twisted rope is transported to the coarse crusher 30 for crushing, and a strip-shaped coarse material with a length of 25cm and a width of 10cm is obtained; for secondary crushing, the strip-shaped The coarse material is fed to the secondary crusher 40 for crushing and crushing, and the strip-shaped fine material with a length of 10 cm and a width of 8 cm is obtained; separated and recovered, the strip-shaped fine material is transported to the magnetic field effect metal separation device 50 for separation, and the iron remover The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com