Sludge gasifier

A sludge gasification and sludge technology, which is applied in the gasification process, the manufacture of combustible gas, the petroleum industry, etc., can solve the problems of easy leakage, low gas conversion efficiency, low recovery rate, etc., and achieves reduction in volume and filling. The effect of burying space and improving recycling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

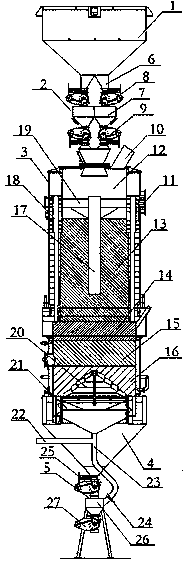

[0034] Such as figure 1 As shown, a sludge gasification furnace includes a sludge storage bin 1, a feeding mechanism 2, a furnace body 3, a closed ash bin 4 and a slagging mechanism 5, a sludge storage bin 1, a feeding mechanism 2, The furnace body 3, the closed ash bin 4 and the slag discharge mechanism 5 are arranged in sequence from top to bottom. The number of feeding mechanisms 2 is two, which are arranged side by side between the sludge storage bin 1 and the furnace body 3 . The feeding mechanism 2 includes a feeding buffer bin 7, which is respectively connected to the sludge storage bin 1 and the furnace body 3 through the feeding pipeline 6, and a The first rotary feed valve 8 and the second rotary feed valve 9 are arranged between the feed buffer bin 7 and the furnace body 3 . The feeding process of this embodiment is as follows. The sludge particles are stored in the sludge storage bin 1. When feeding, first open the first rotary feed valve 8, close the second rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com