Method for producing concrete building block by using pipe pile wastewater slurry

A prefabricated component and concrete technology, which is applied in clay preparation devices, mixing operation control, chemical instruments and methods, etc., to achieve the effect of saving cement, obvious economic and social benefits, and protecting the ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

[0024] First, put 1 part of P.032.5 cement, 3 parts of medium sand, and 7.5 parts of crushed stone with a particle size of 5-40) mm into the concrete mixer for 40 seconds, and then add 4 parts of pipe pile waste slurry and 0.02 parts of pump while stirring. Send agent, then wet mix for 40 seconds to make concrete mixture.

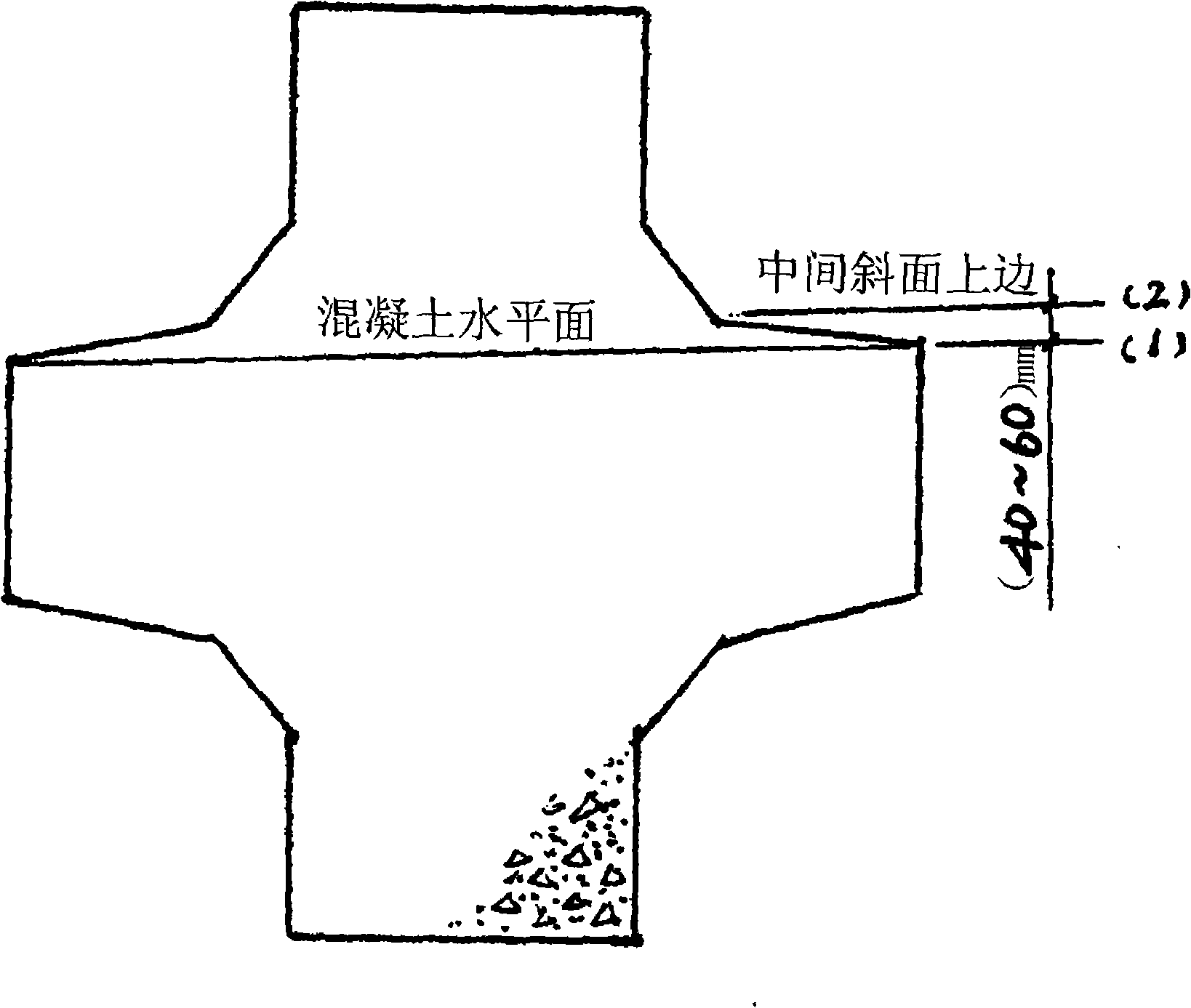

[0025] Put this mixture into the mold of the prefabricated component, and use the flexible shaft vibrating rod to vibrate in the "intensive vibrating method", that is, the distance between the vibrating points is 1 times the radius of action of the vibrating rod; Fully vibrate the feeding side to keep the concrete mixture in the mold rising horizontally without obvious air bubbles escaping, and then perform curing according to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com