Tool-type plaster-applying device for tile

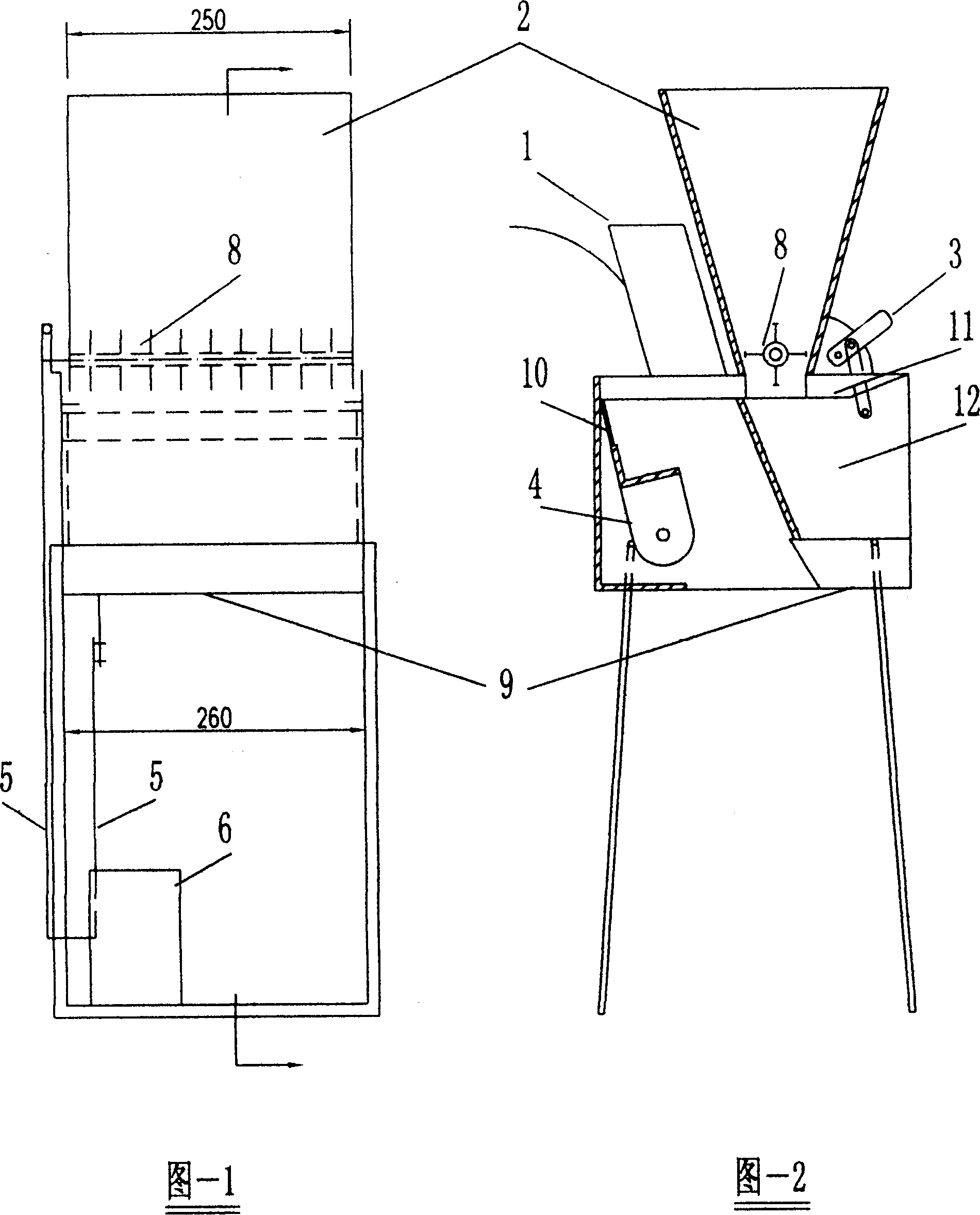

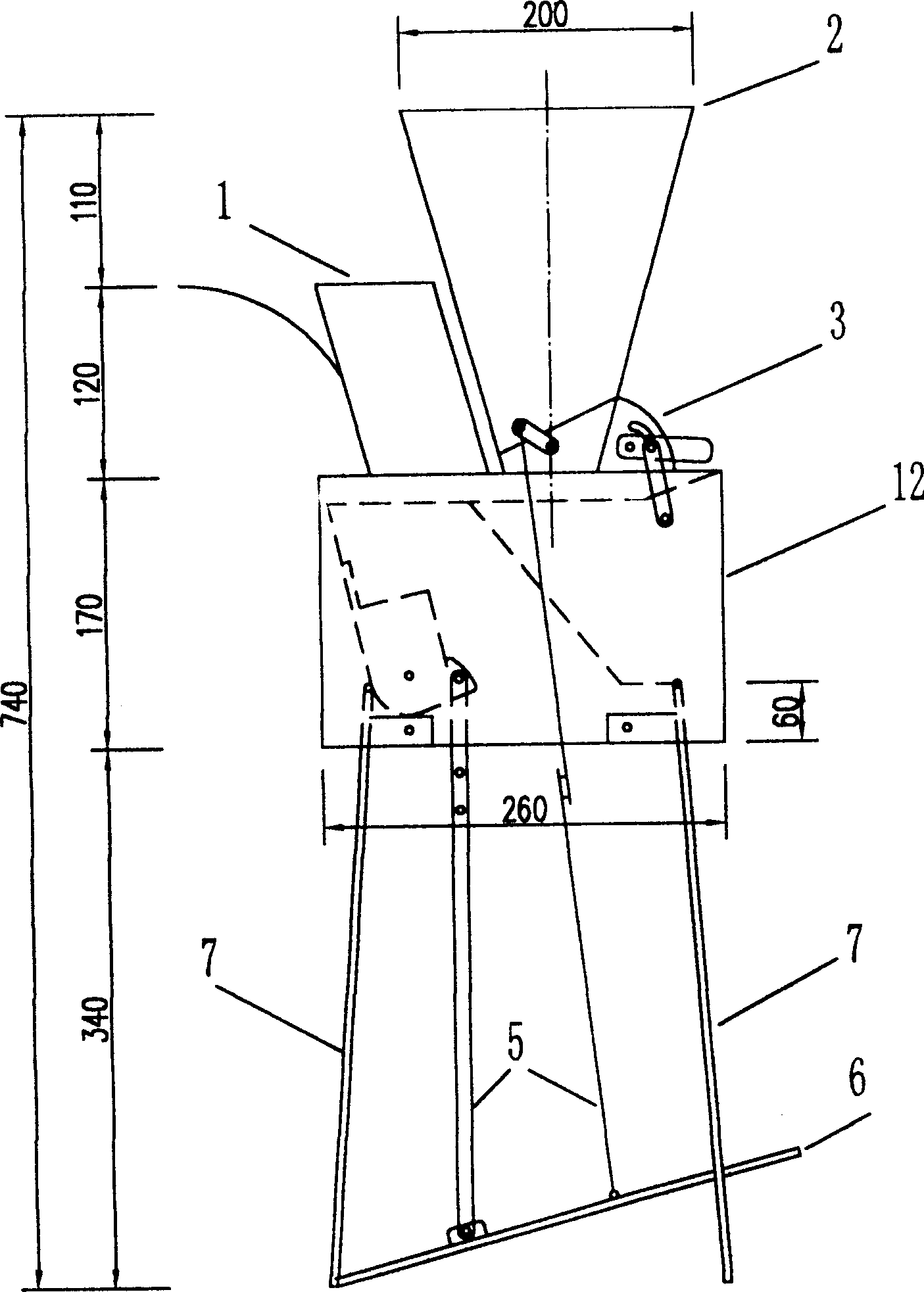

A tool-type ceramic tile technology, which is applied in the direction of construction and building construction, can solve the problems that the fullness of the mortar for laying tiles cannot be fully guaranteed, the upper end of the tiles is prone to hollowing, and the fingers of operators are injured, etc., so as to improve the laying and laying. Quality, save mortar, improve the effect of laying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] (1) The prototype of the tool-type ceramic tile duster has been successfully trial-produced. After the test machine inspection, its performance meets the design requirements. If it can obtain a patent, it is a good idea to cooperate with a manufacturer with a certain production capacity and a sales network (or market). It is the best way to bring the tool-type tile cleaner to the market and transform it into productivity.

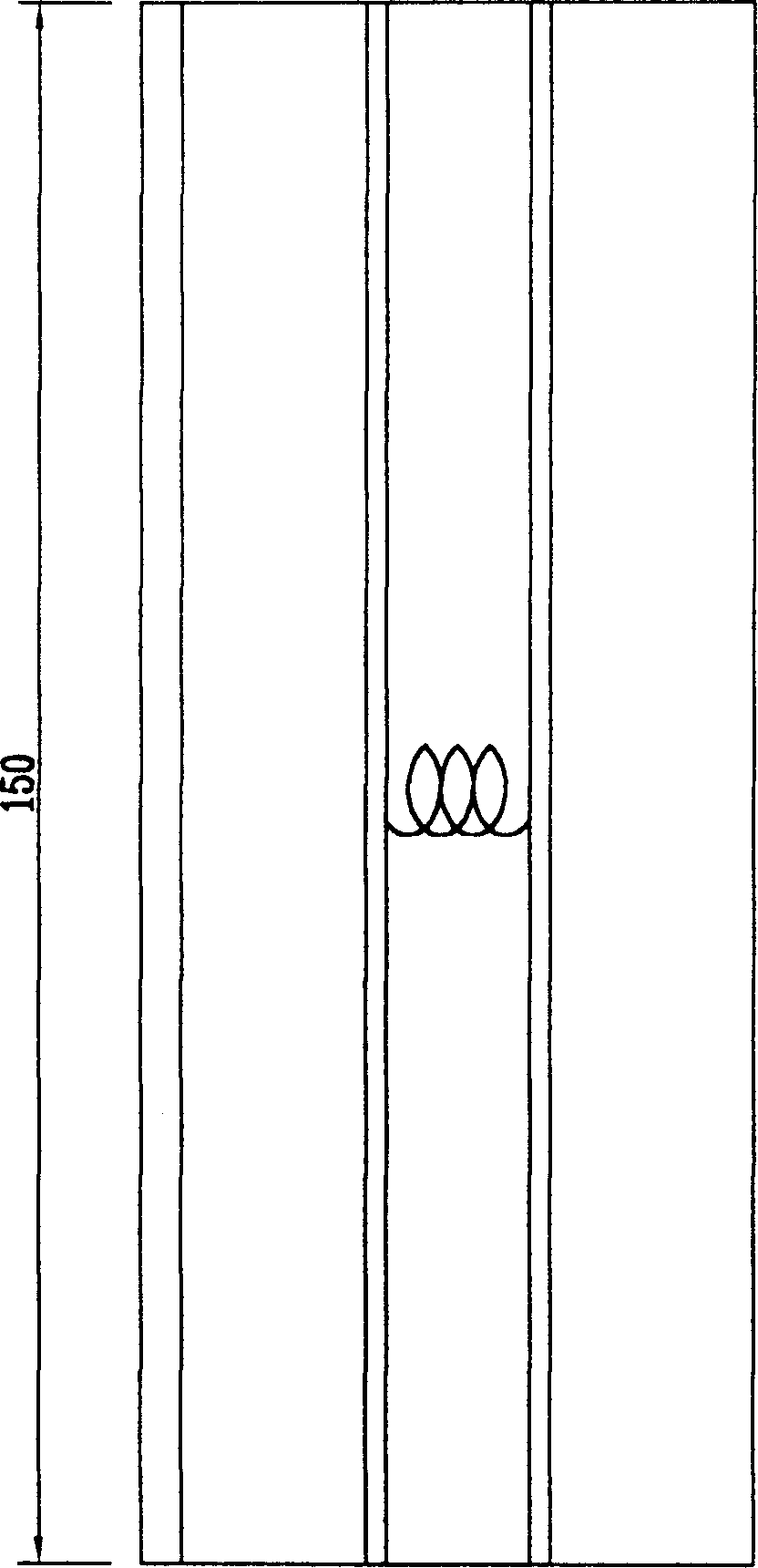

[0043] (2) In mass production, except for special parts that are processed by ourselves or entrusted to others or other manufacturers, standard parts should be used as much as possible. For parts that are directly in contact with cement mortar (such as funnels, movable mortar buckets) The components with low requirements are made of plastics, so as to reduce the manufacturing cost of the tool-type tile ashtray, prolong the service life of the tool-type tile ashtray, and make it affordable for users.

[0044] (3) According to the working principle and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com