Patents

Literature

315results about How to "Laying speed is fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of spherical titanium-alloy powder for 3D printing

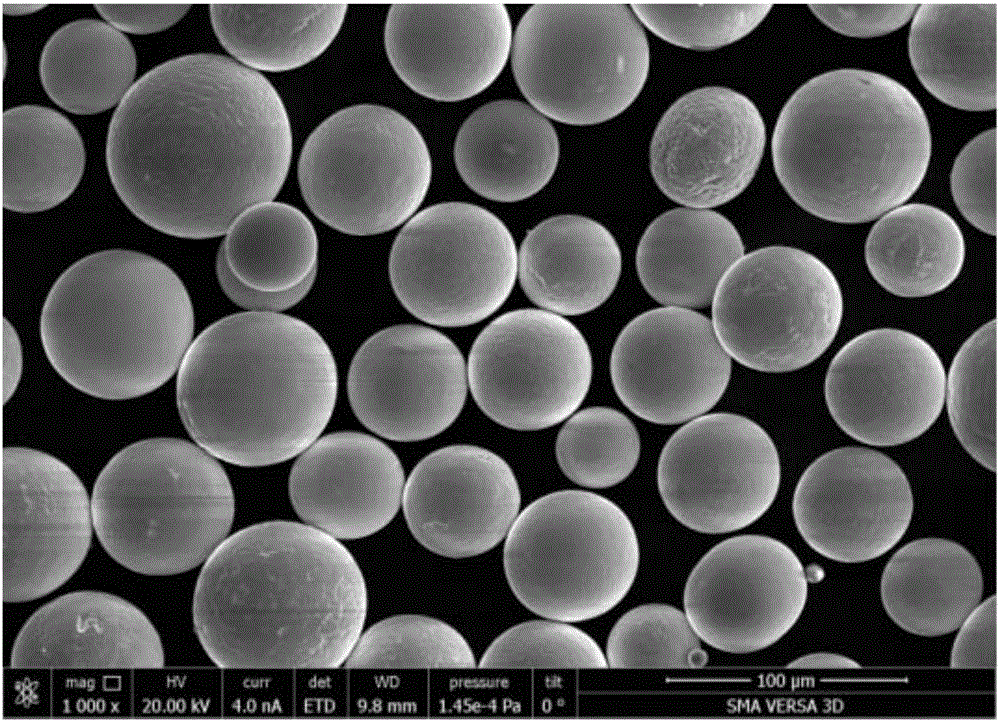

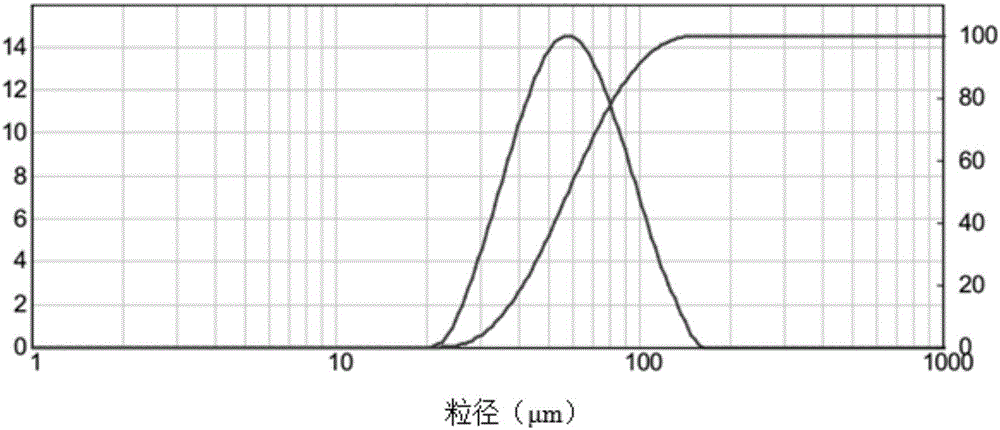

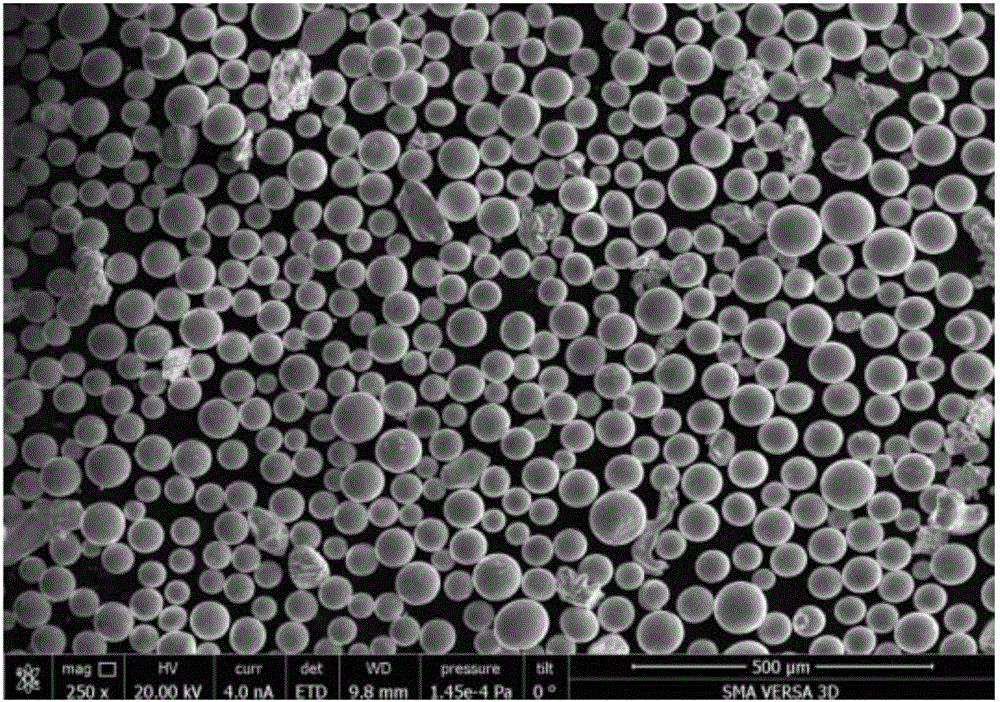

InactiveCN106493350AUniform particle sizeImprove liquidityAdditive manufacturing apparatusTransportation and packagingHydrogenMicrometer

The invention provides a preparation method of spherical titanium-alloy powder for 3D printing, relates to a method for manufacturing 3D printing consumables, and aims at solving the technical problems that existing Ti-6Al-4V alloy powder is nonuniform in particle size and irregular in shape, and cannot meet the usage requirement of 3D printing. The method comprises the steps that Ti powder and alloy powder of contained elements are added into a ball mill for ball milling according to components of titanium alloy, and titanium-alloy powder is obtained; and the titanium-alloy powder is screened and conveyed to thermal plasma spheroidizing equipment for plasma spheroidizing in hydrogen-containing gas, and the spherical titanium-alloy powder for 3D printing is obtained. According to the spherical titanium-alloy powder, the particle size is smaller than or equal to 100 micrometers, the spheroidization degree is larger than 95%, and the spherical titanium-alloy powder can be applied to the field of 3D printing manufacturing.

Owner:HEILONGJIANG HEIKE TECH CO LTD

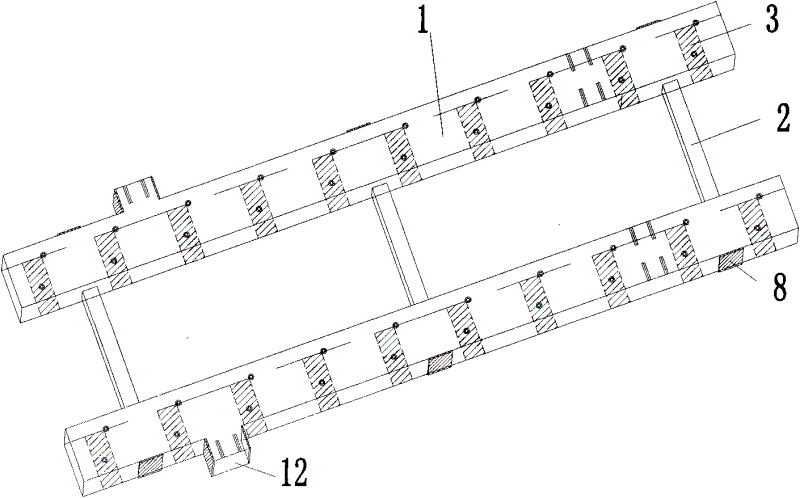

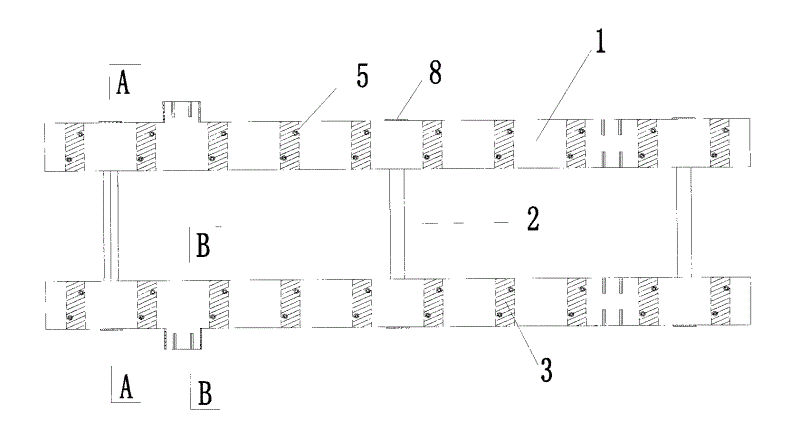

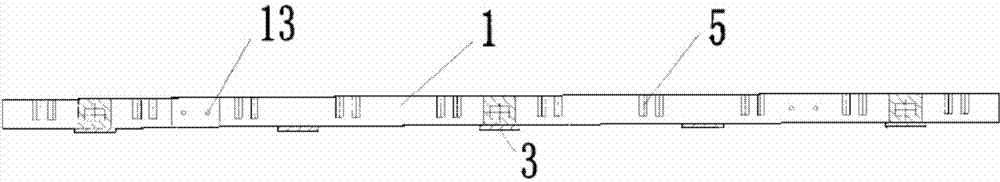

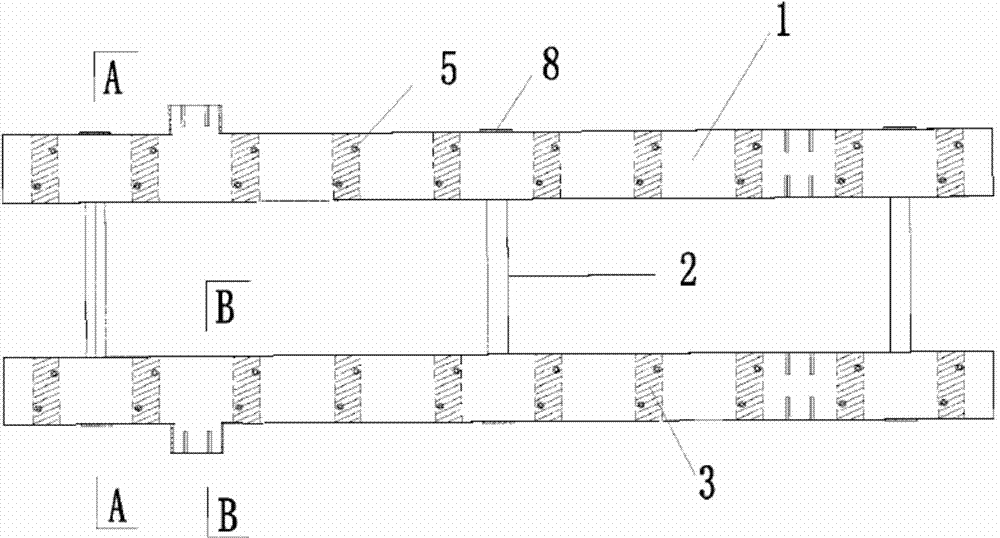

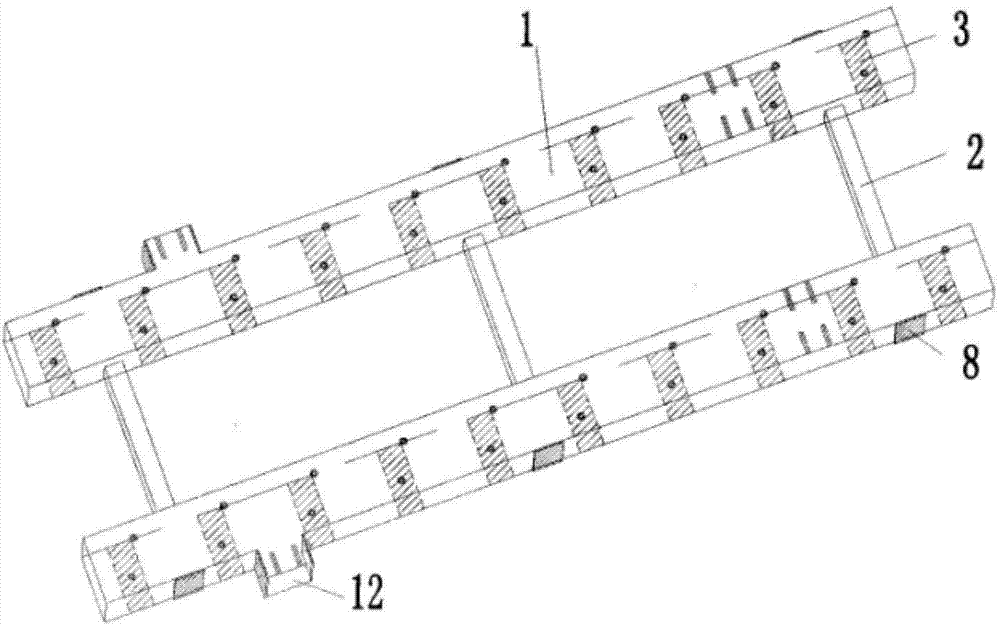

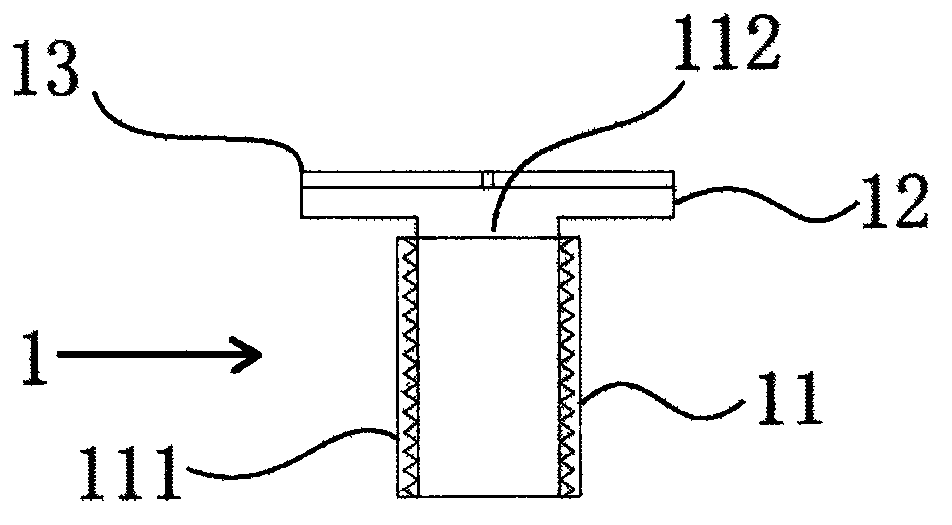

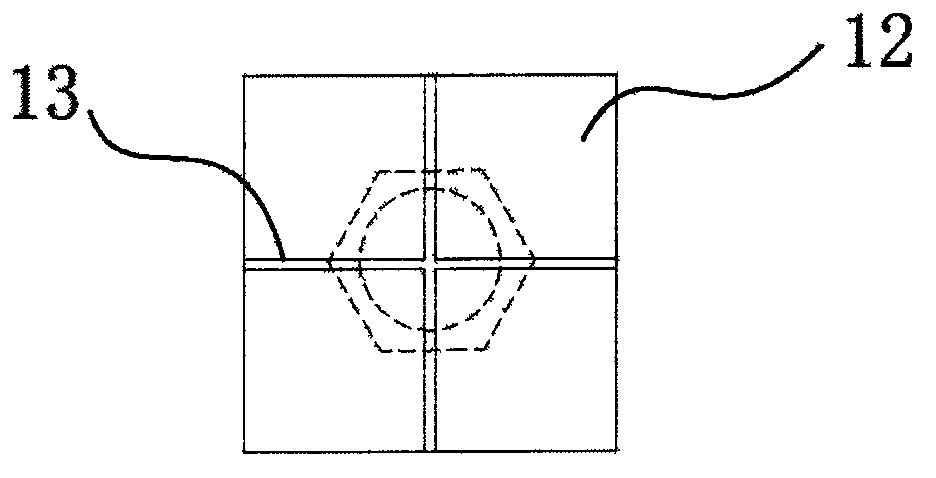

Longitudinal beam type sleeper system

ActiveCN102619145AReduce vibrationReduce rolling noiseBallastwayElastic vibrationStructural engineering

The invention relates to a novel sleeper system, and belongs to the field of railway tracks. The novel sleeper system comprises a longitudinal beam type sleeper and an elastic vibration reduction track system, wherein the longitudinal beam type sleeper is formed by connecting longitudinal beam type sleeper units one by one in series; each two adjacent longitudinal beams of the longitudinal beam type sleeper are fixedly connected with each other in the lateral direction through a connecting piece; the opposite longitudinal beam end parts of each two adjacent longitudinal beam type sleeper units are connected with each other through a sleeper connecting piece; the elastic vibration reduction track system comprises a support saddle; the longitudinal beam type sleeper is mounted on the support saddle; and a vibration reduction facility is arranged between the bottom of the longitudinal beam type sleeper and the support saddle. The novel sleeper system has the advantages that due to the longitudinal sleeper, the bending rigidity of a track is enhanced, and deformation of the track caused by repeated load is reduced; as the lateral resistance of the longitudinal beams is enlarged, the irregularity in the vertical direction of the track is reduced, and the maintenance is reduced; and as the longitudinal beams are connected with each other in the longitudinal direction, the settlement of the track at the end parts of the longitudinal beams is provided from being enlarged or damaged easily; and as rail pads are arranged continuously, foundation shake, rolling noise and wave-like deformation of the track are reduced.

Owner:BEIJING YIKE LUTONG RAILWAY EQUIPEMNT +1

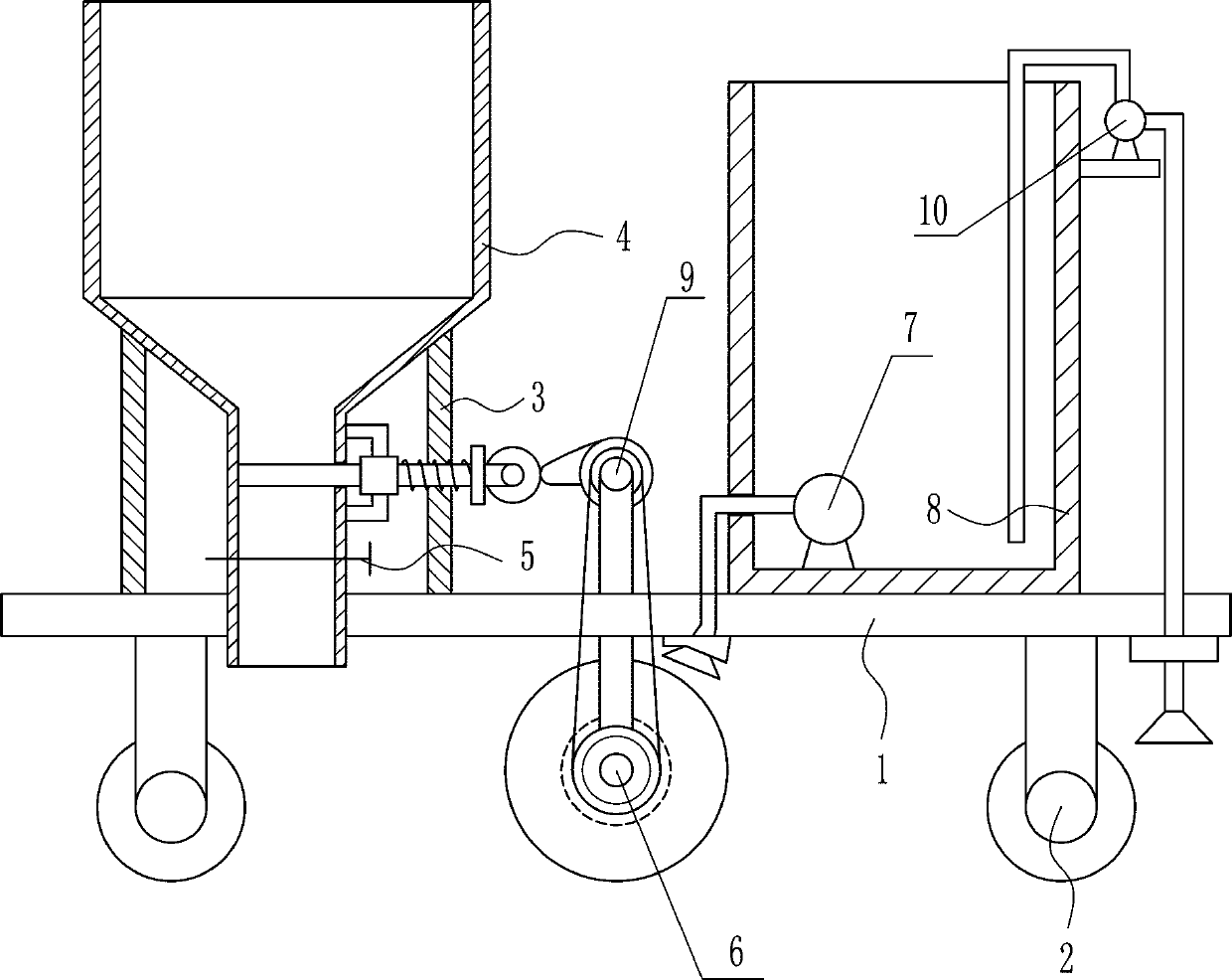

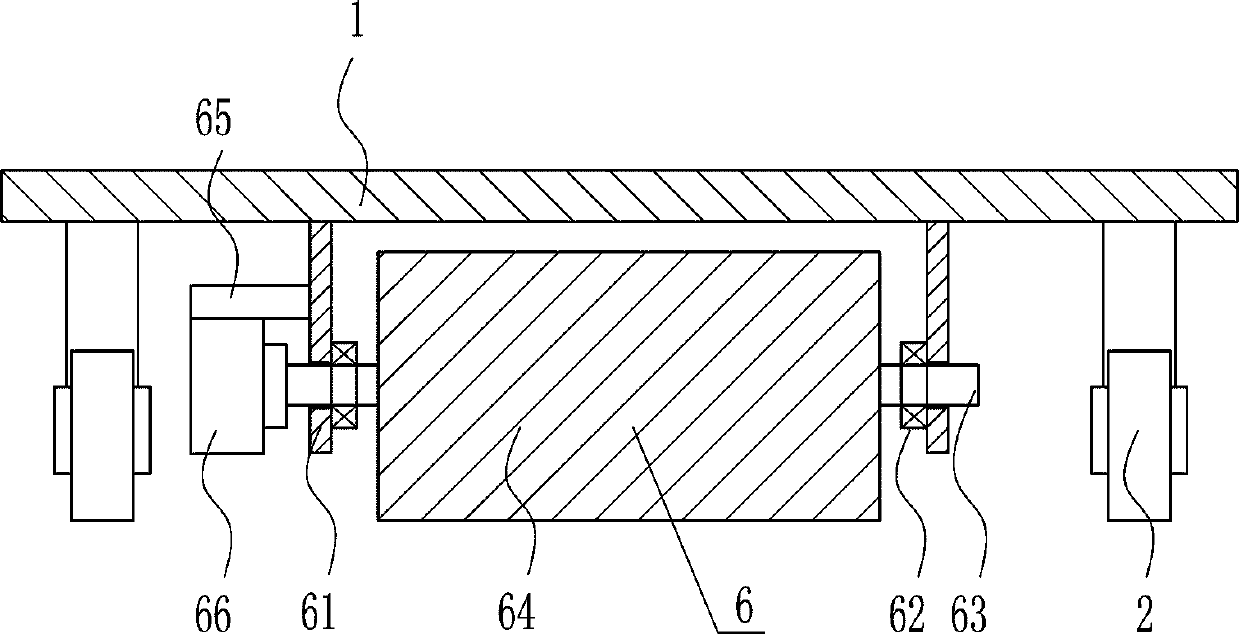

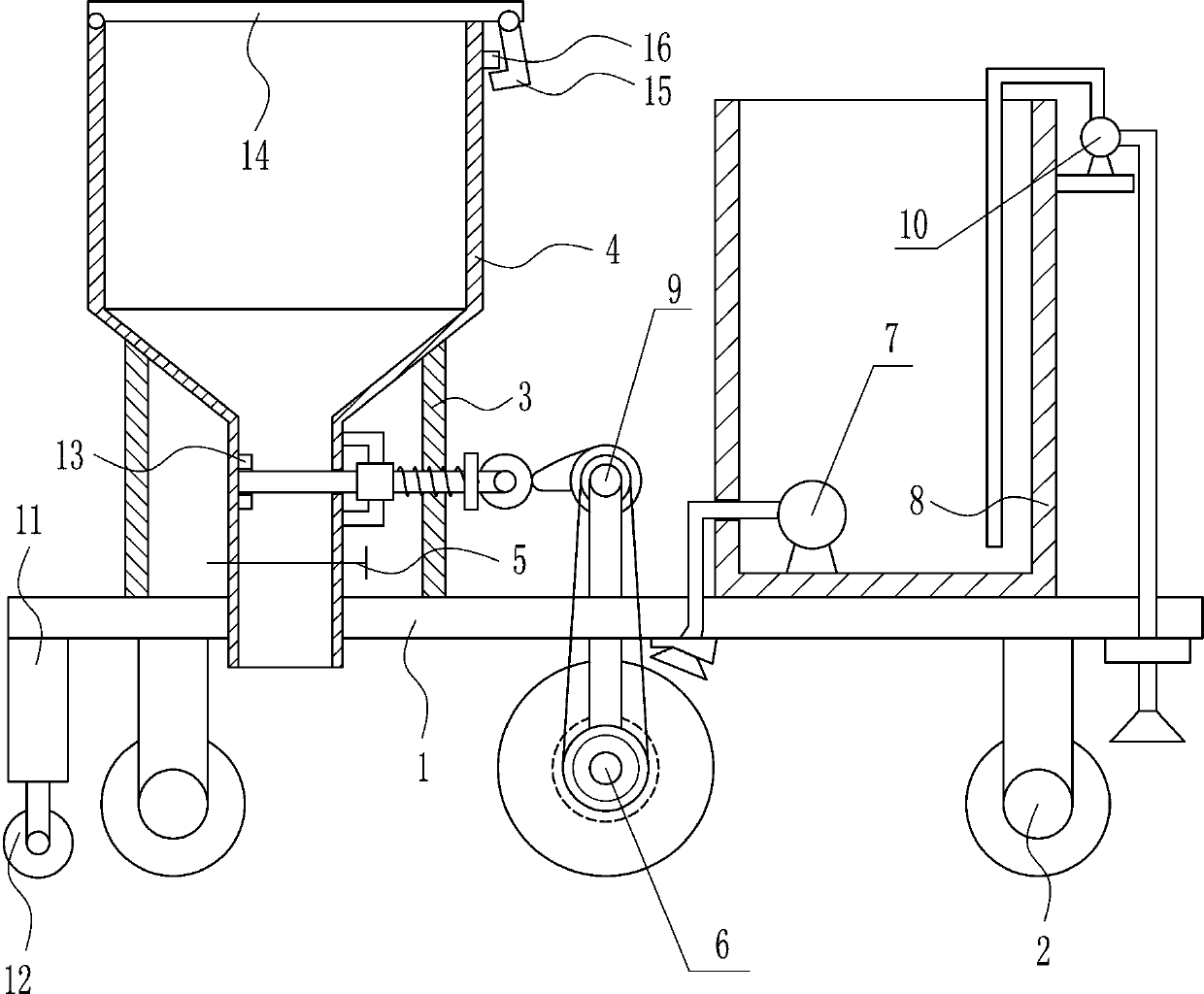

Water-bound macadam road paving device for road construction

ActiveCN107687123ASuitable for laying requirementsLaying high qualityRoads maintainenceCrushed stoneRoad surface

The invention relates to a road paving device, and particularly relates to a water-bound macadam road paving device for road construction. The technical problem to be solved is to provide the water-bound macadam road paving device, and the paving requirement of a water-bound macadam road is met, the paving speed is fast, and the paving effect is good. In order to solve the technical problem, the invention provides the water-bound macadam road paving device for road construction. The water-bound macadam road paving device for road construction comprises a bottom plate, wheels, a support rod, atank body, a valve and a compaction mechanism, the wheels are arranged at the bottom part of the bottom plate, the support rod is vertically connected to the top part of the bottom plate, the tank body is arranged at the top part of the support rod, a discharge position of the tank body is located at the bottom part of the bottom plate, a water tank is arranged on the right side of the top part ofthe bottom plate, and a water-bound treatment mechanism is mounted in the water tank. The water-bound macadam road is paved on a certain degree through the compaction mechanism and the water-bound treatment mechanism, and meanwhile, the paving of the road is better through the assisted optimization of a discharge mechanism and a maintenance mechanism.

Owner:台州贝蕾丝电子商务有限公司

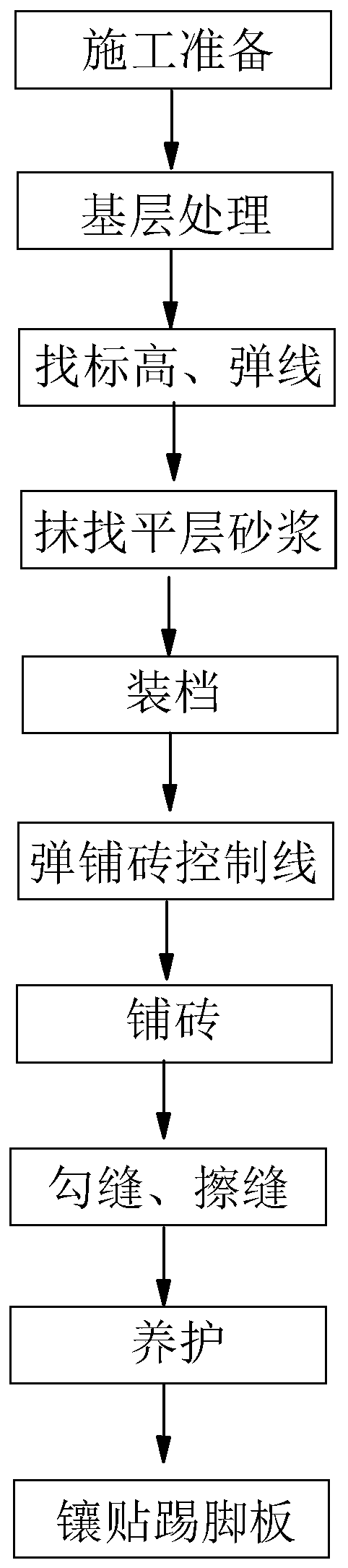

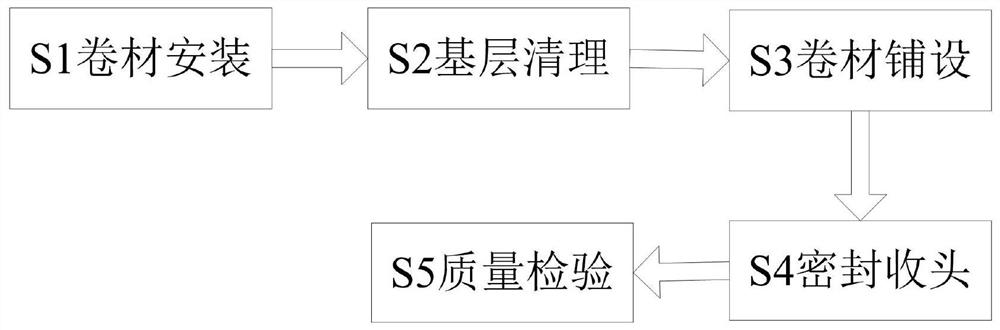

Floor tile floor paving construction method

The invention relates to a floor tile floor paving construction method. The floor tile floor paving construction method comprises the following steps that 1, construction preparation is carried out, specifically, a horizontal elevation line is first calibrated on an inner wall, and floor tiles are screened and selected through a prefabricated mould; 2, base layer treatment is carried out; 3, the elevation and elastic lines locating is carried out; 4, mortar plastering leveling layer is carried out; 5, positions between marking ribs are filled with cement mortar; 6, snapping a tile paving control line is carried out, specifically, a gap width of floor tile paving is determined according to the design requirements, when the compressive strength of the leveling layer mortar reaches 1.2 Mpa, the control line of tiles is snapped by a person; 7, the tiles are paved, specifically, paving according to the control line of the floor tiles is carried out; 8, joint pointing and scraping is carriedout; 9, the maintenance is carried out; and 10, skirting boards are inlaid, specifically, vertical joints of the skirting boards ought to be aligned with floor joints, during paving, a tile ought tobe inlaid at each internal corner of the two end heads of a room wall, the upper edge is served as a standard hanging line, and the paving is started. The floor tile floor paving construction method has the advantages that the construction requirements are met, the method is grasped by workers quickly and conveniently, and the construction effect is obvious.

Owner:北京金碧合力建筑设计工程有限公司

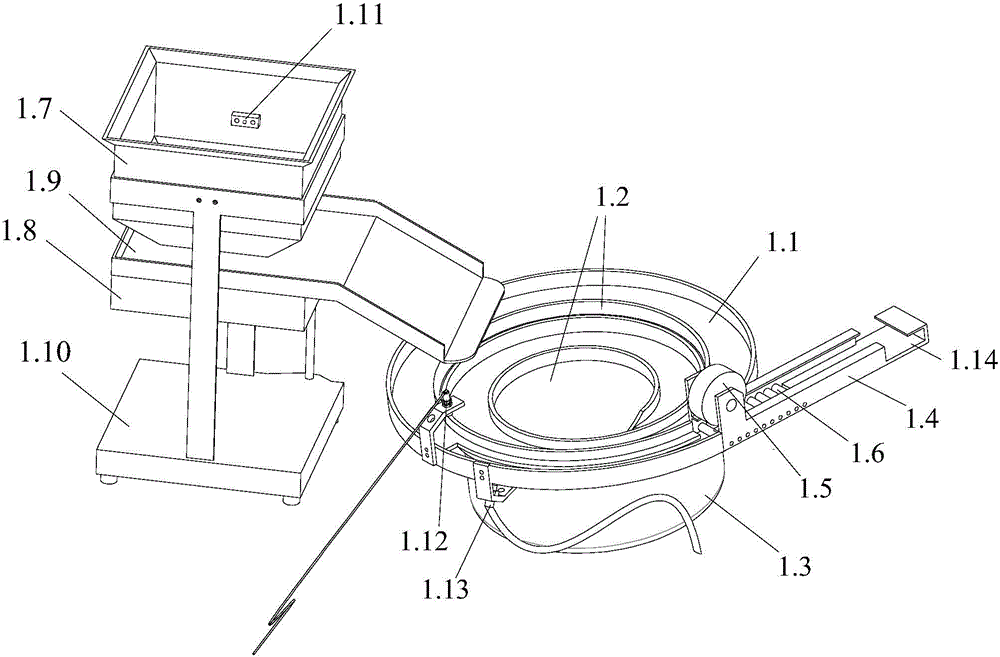

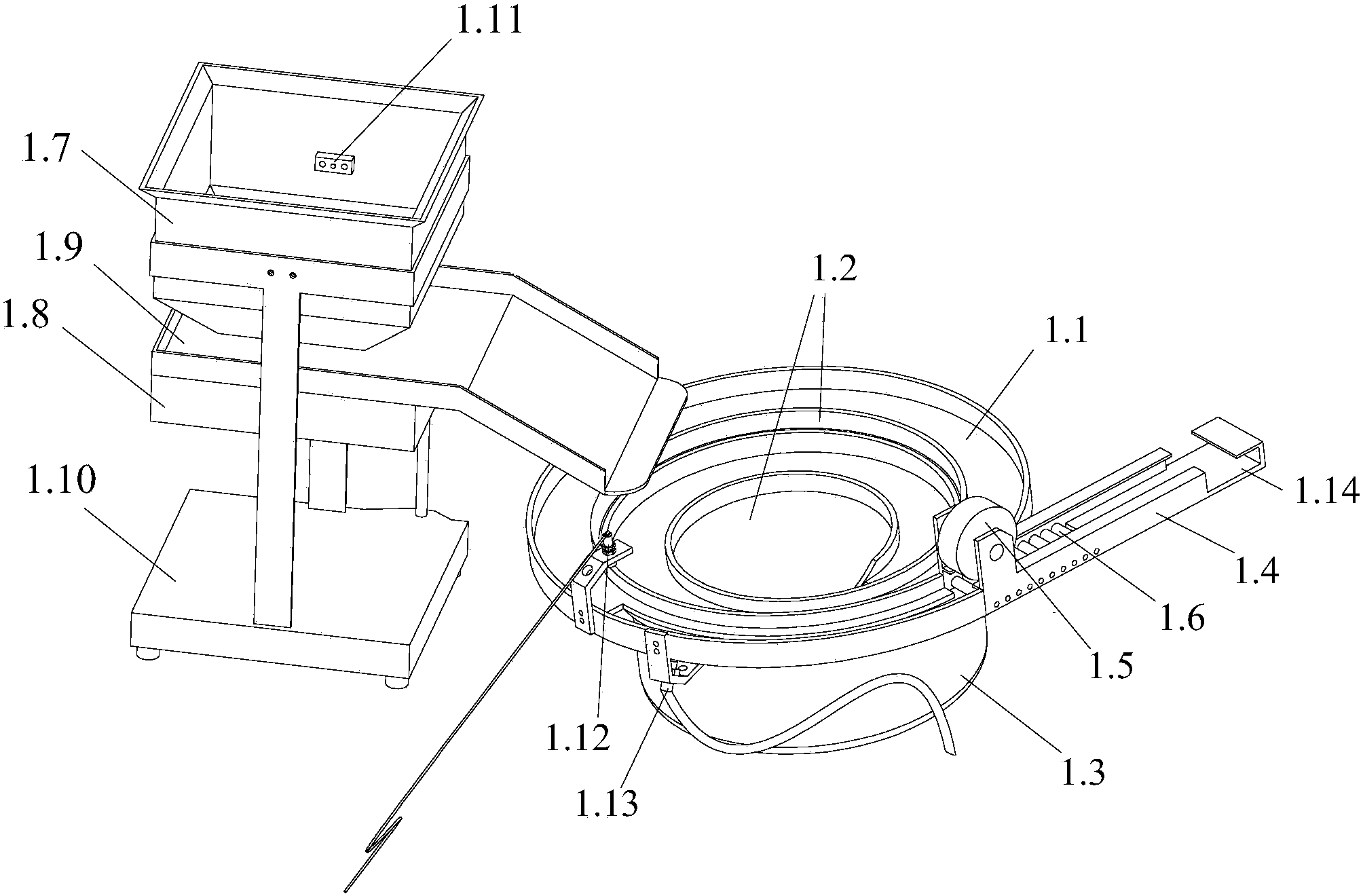

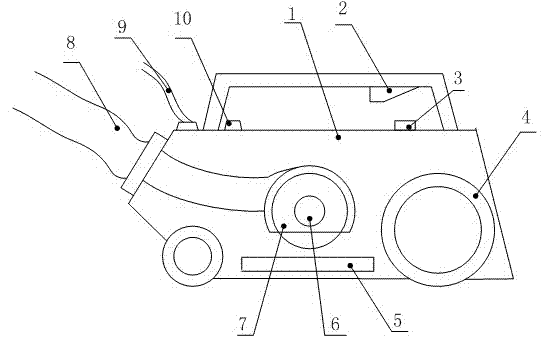

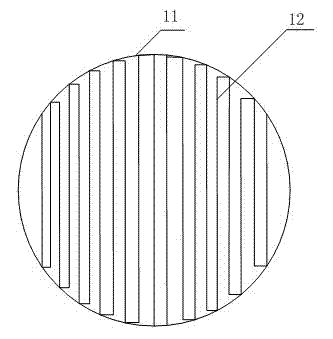

Automatic single-color mosaic-particle lay-up device and lay-up method thereof

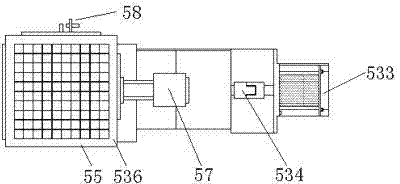

ActiveCN104085241AImprove laying efficiencyHigh speedOrnamental structuresConveyor partsEngineeringAutomatic testing

The invention provides an automatic single-color mosaic-particle lay-up device and a lay-up method of the automatic single-color mosaic-particle lay-up device. The automatic single-color mosaic-particle lay-up device comprises a stander, a mosaic forming die which is arranged on the stander, at least one automatic mosaic-particle single-track lay-up unit, a loading device and a controller, wherein each automatic mosaic-particle single-track lay-up unit is used for gradually collecting mosaic particles one by one after transporting the mosaic particles one by one, arranging the mosaic particles into rows / columns according to a preset rule and then driving the entire row / column of mosaic particles to enter a loading procedure; the loading device is connected with the stander and used for sequentially transporting and loading the well-arranged entire row / column of mosaic particles in each automatic mosaic-particle single-track lay-up unit into the mosaic forming die; the controller is respectively connected with each automatic mosaic-particle single-track lay-up unit and the feeding device by signals. The automatic single-color mosaic-particle lay-up device is high in lay-up stability, high in lay-up speed and capable of effectively improving the lay-up efficiency and lay-up accuracy of the mosaic particles. The automatic lay-up method is used for substituting the traditional manual lay-up process, so that the problems that the current mosaic industry is low in automation degree and low in production efficiency can be solved.

Owner:FOSHAN UNIVERSITY

Fire blanket and laying device

The invention relates to a fire blanket and laying device. The fire blanket and laying device is used for extinguishing and isolating a fire in a fire scene in the grassland, meadow, cornfield, wild flat land or the terrain with mild fluctuation and arranging an earth trail fire line. The fire blanket and laying device comprises a fire blanket and a fire blanket laying device, wherein the fire blanket consists of an inner layer and an outer layer; the outer layer is formed by soft flame-retardant cotton cloth or chemical fabric and a fire glass fiber material; the inner layer consists of fireproof ceramic fine powder; and the fire blanket laying device comprises traveling wheels, a remote controller, a rotating shaft, a receiving antenna, a transmitting antenna, a secondary variable frequency motor and a signal processor. The fire blanket and laying device has the flame-retardant temperature of over 1,000 DEG C, has light weight, is easy to fold, is harmless to the environment, is soft, has toughness, can rapidly cover the large-area fire scene and is particularly suitable for arranging a fire barrier in front of the fire scene.

Owner:付志亮

Method of laying cords of a reinforcement structure for tires

InactiveUS20050028919A1Reduce spacingLaying speed is fastTyresPneumatic tyre reinforcementsEngineeringHead parts

Owner:MICHELIN RECH & TECH SA

Three-in-one plastic sports ground, and preparation method thereof

InactiveCN105713269ALow costLong lasting bright colorsGround pavingsPolyurea/polyurethane coatingsEpoxyAdhesive

The invention discloses a three-in-one plastic sports ground. The three-in-one plastic sports ground is prepared from, by weight, 1.5 to 2.5 parts of epoxy resin, 70 to 90 parts of regenerated rubber, 10 to 14 parts of an adhesive, 1.5 to 2.5 parts of titanium dioxide, 0.1 to 0.3 part of a reinforcing agent, 1.5 to 2.5 parts of a coloring material containing inorganic pigments, 7 to 9 parts of quartz sand, 2.5 to 3.5 parts of a colorant, and 6 to 8 parts of polyurethane; the coloring material comprises 2 parts of a pigment powder, 0.21 part of titanium dioxide, 0.15 part of antioxidant 1010, 0.18 part of an anti-ultraviolet agent, and 0.15 part of a fortifier; the regenerated rubber is recycled waste rubber; the adhesive contains trimethylolpropane and hexamethylene diisocyanate; the anti-ultraviolet agent is phenyl salicylate; and the reinforcing agent is silicon dioxide. The invention also provides a preparation method of the three-in-one plastic sports ground. The preparation method comprises following steps: smearing of a water-proof layer, laying of an elastic layer, gap filling, and spraying of a wear-resistant layer. The cost of the three-in-one plastic sports ground is lower than that of conventional runways; the three-in-one plastic sports ground possesses permeability; and problems such as bulking, cracking, peeling, and discoloration are not caused.

Owner:梁意昌

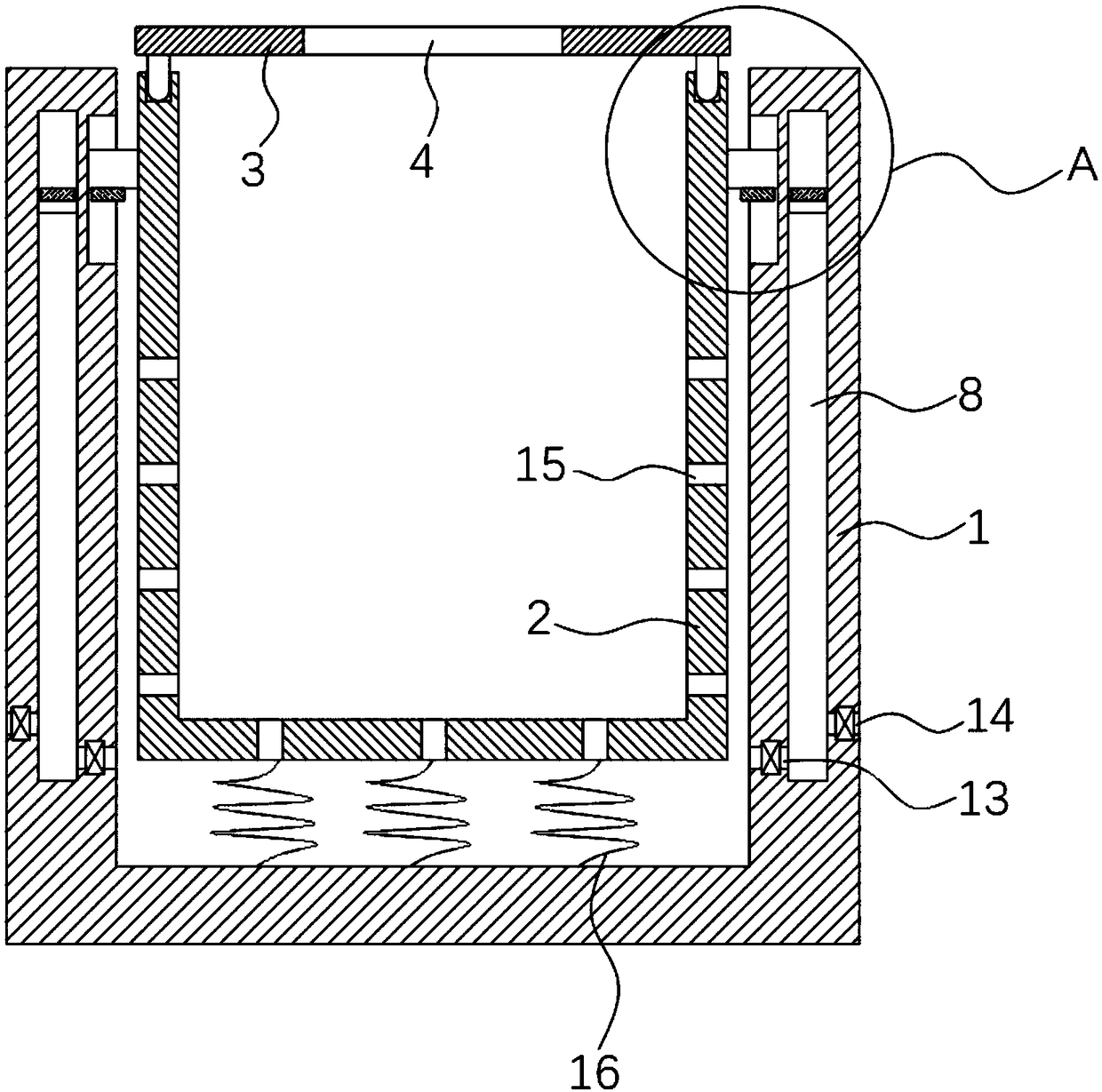

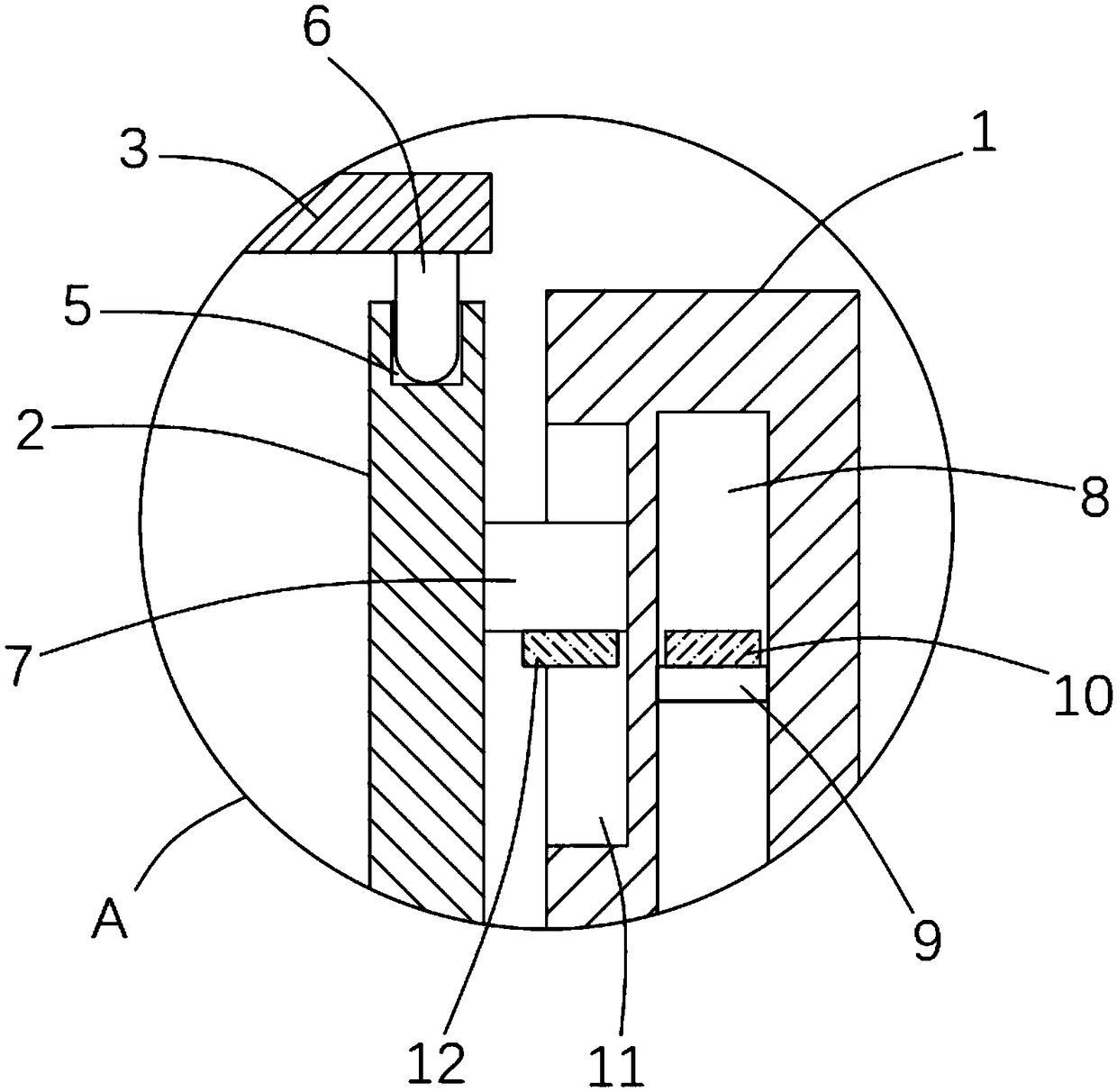

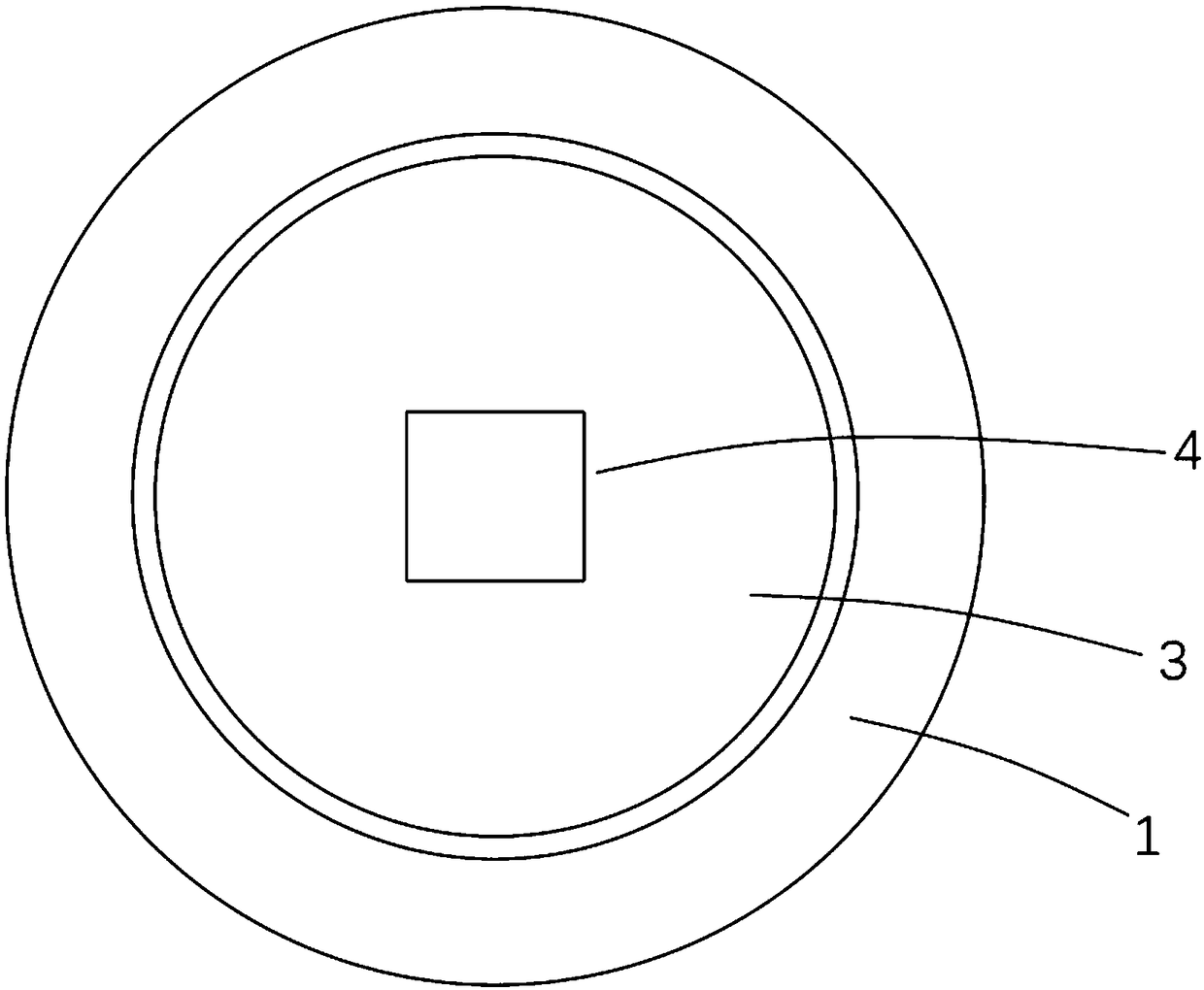

Novel municipal garbage can

ActiveCN109279234AIncrease delivery spaceLaying speed is fastRefuse receptaclesWrinkle skinSelf recovery

The invention discloses a novel municipal garbage can. The novel municipal garbage can comprises an outer barrel, wherein the outer barrel is internally provided with an inner barrel, and the lower end surface of the inner barrel and the inner bottom wall of the outer barrel are jointly and fixedly connected with a plurality of buffer springs. A barrel cover is disposed right above the inner barrel, and a throwing opening for throwing garbage is formed in the upper end surface of the barrel cover. An annular clamping groove is formed in the edge of the upper end of the inner barrel, and the lower end surface of the barrel cover is fixedly connected with an annular clamping block. The upper end outer wall of the inner barrel is fixedly connected with an annular sliding block in a sleeved mode. The novel municipal garbage can has the advantages that cleaning staff presses to release the barrel cover, the characteristics of the self-recovery of the buffer springs and a driving magnetic block attracting a driven magnetic block are used, the movement of the inner barrel drives a piston to intermittently move upwards and downwards, a ventilation cavity intermittently extracts air and discharges the air, and then a garbage bag is laid by being attached to the inner wall of the inner barrel, so that no wrinkles are formed, the garbage throwing space is increased, the speed of laying the garbage bag is accelerated, and the difficulty of laying the garbage bag is reduced.

Owner:山东沂南园区开发建设有限公司

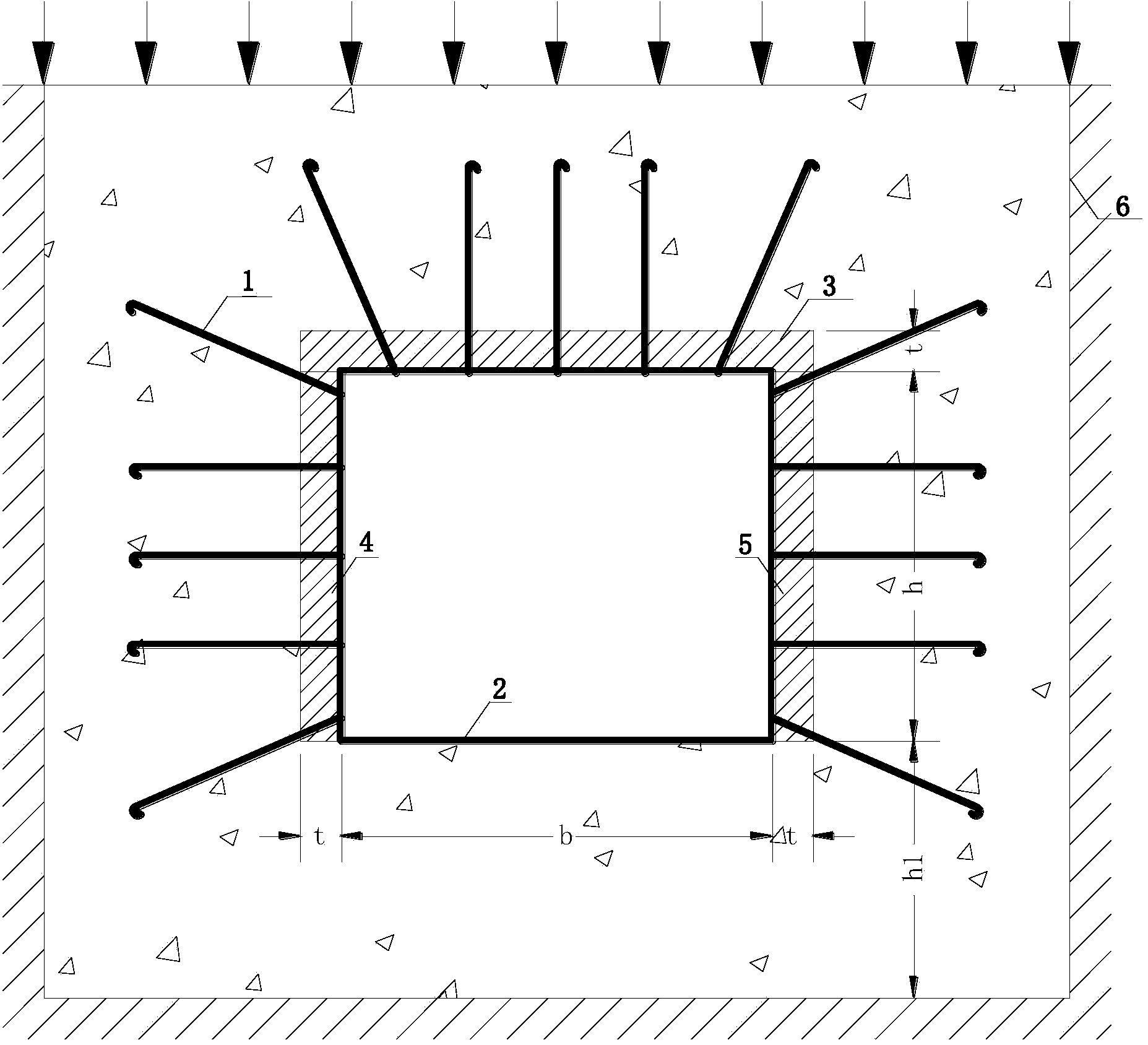

A method for manufacturing a simulation tunnel deformation experiment model

Provided is a method for manufacturing a simulation tunnel deformation experiment model. The position of a simulation tunnel is arranged at the central section of a model case, and simulation tunnel components of set dimensions are placed. Boards with a plurality of anchor pole component holes are respectively arranged in the left and right sides and the top portion positions of the simulation tunnel components. Anchor pole components with hooks at the head portions are inserted from the bottom portions of the boards with the plurality of anchor pole component holes in the left and right sides to the board with the holes at the top portion. At the same time, simulation materials are filled into the model case until the model case is full of the filled simulation materials, and the simulation materials are compacted tightly. After the filled simulation materials are molded, the simulation tunnel components are extracted, and the boards are taken away, the manufacturing of simulation tunnel model is completed. Through the dimensions of the tunnel components and the size of the boards, the size of tunnels in the model can be controlled. Through the thicknesses of the boards, the exposed lengths of the anchor pole components can be controlled. Through the adjusting of the positions of the holes in the boards, the mode of arrangement of the anchor pole components can be changed.

Owner:CHINA UNIV OF MINING & TECH

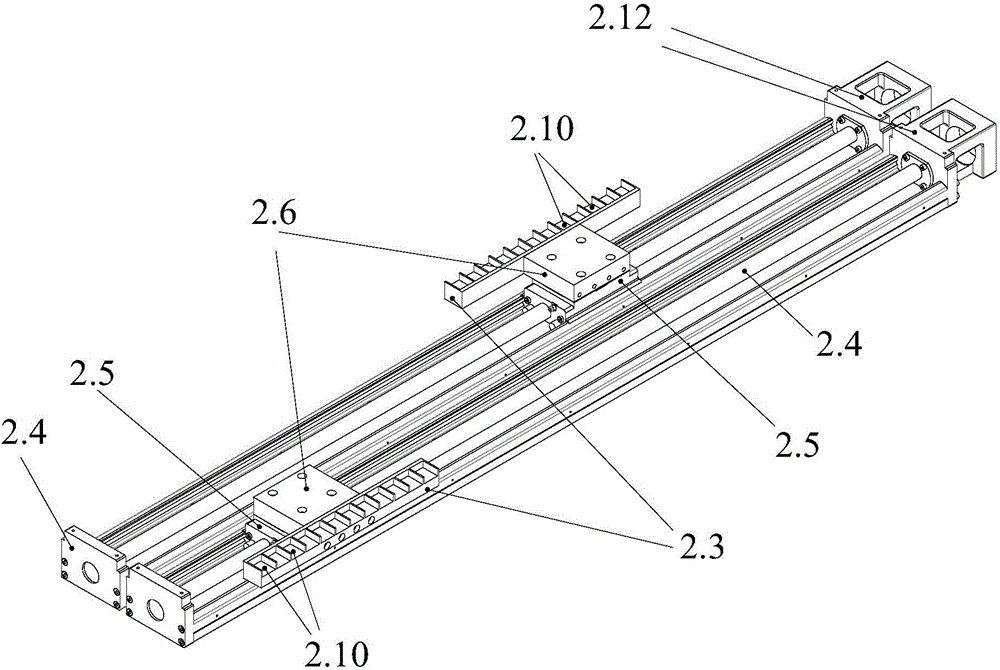

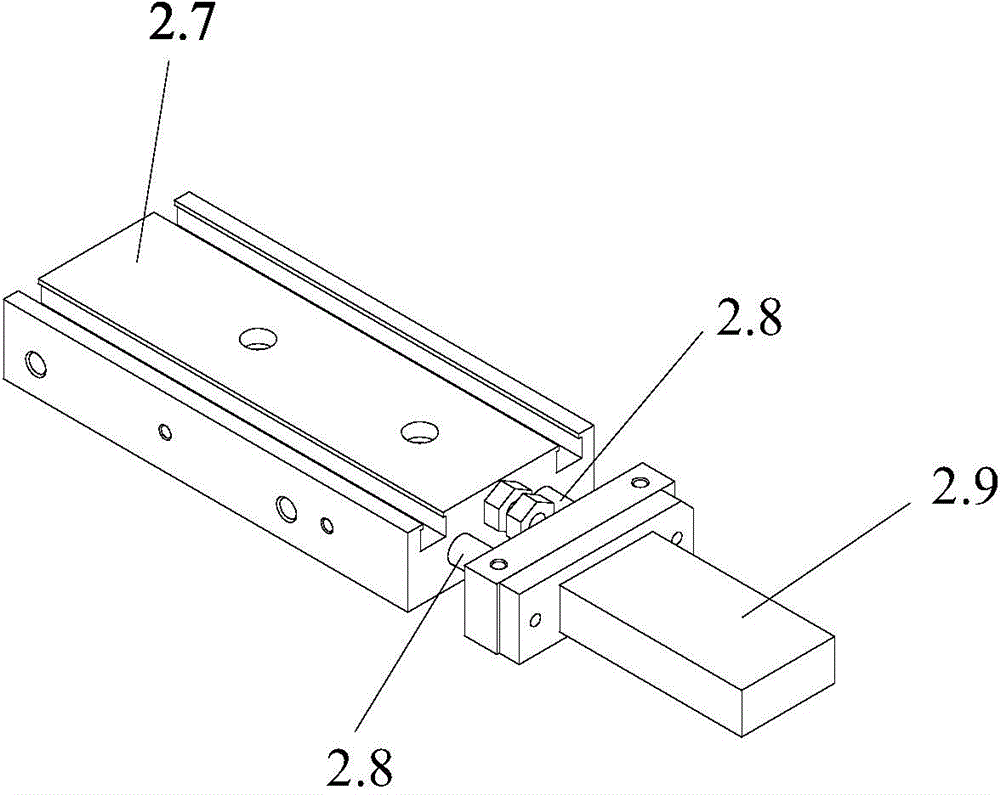

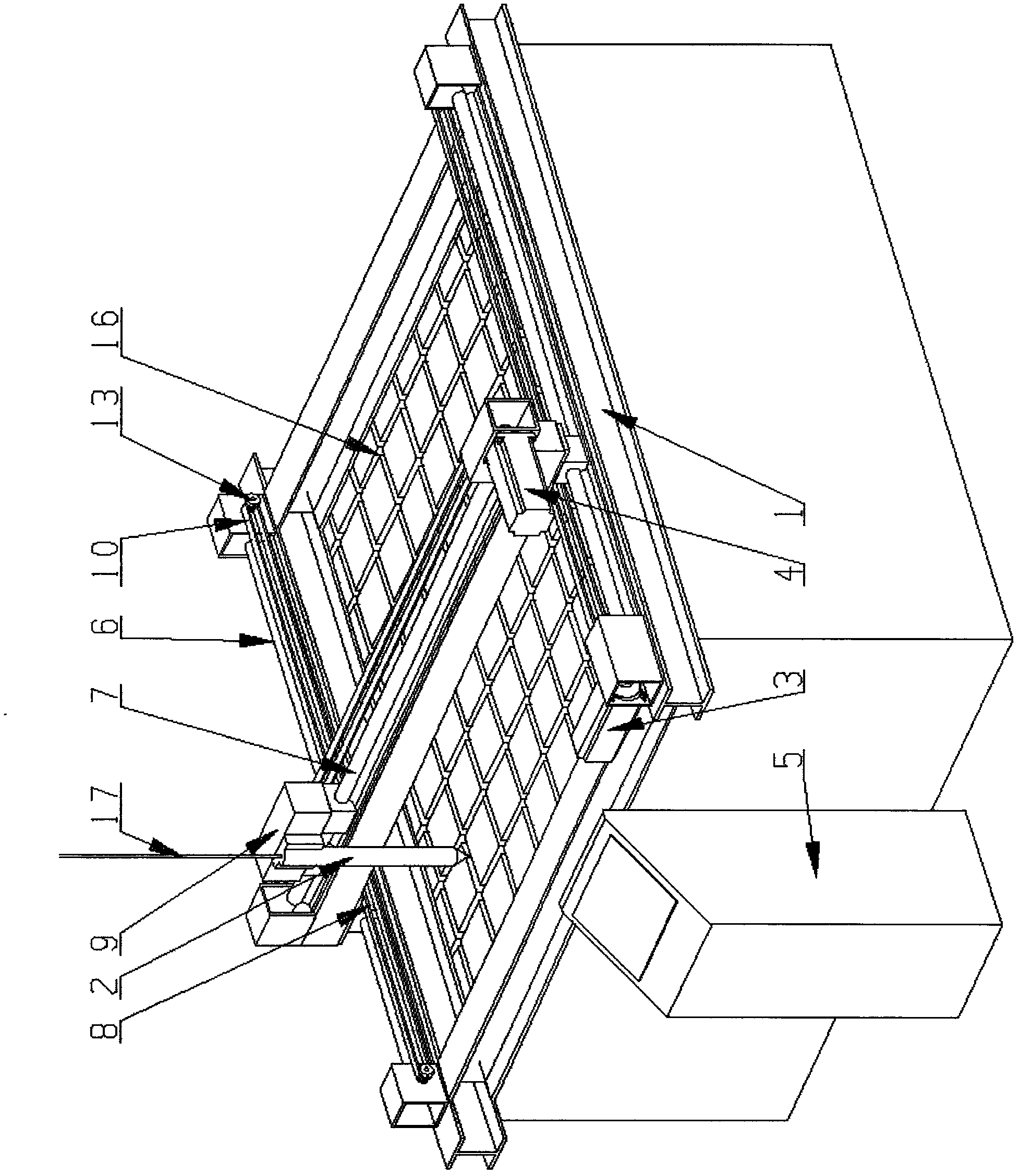

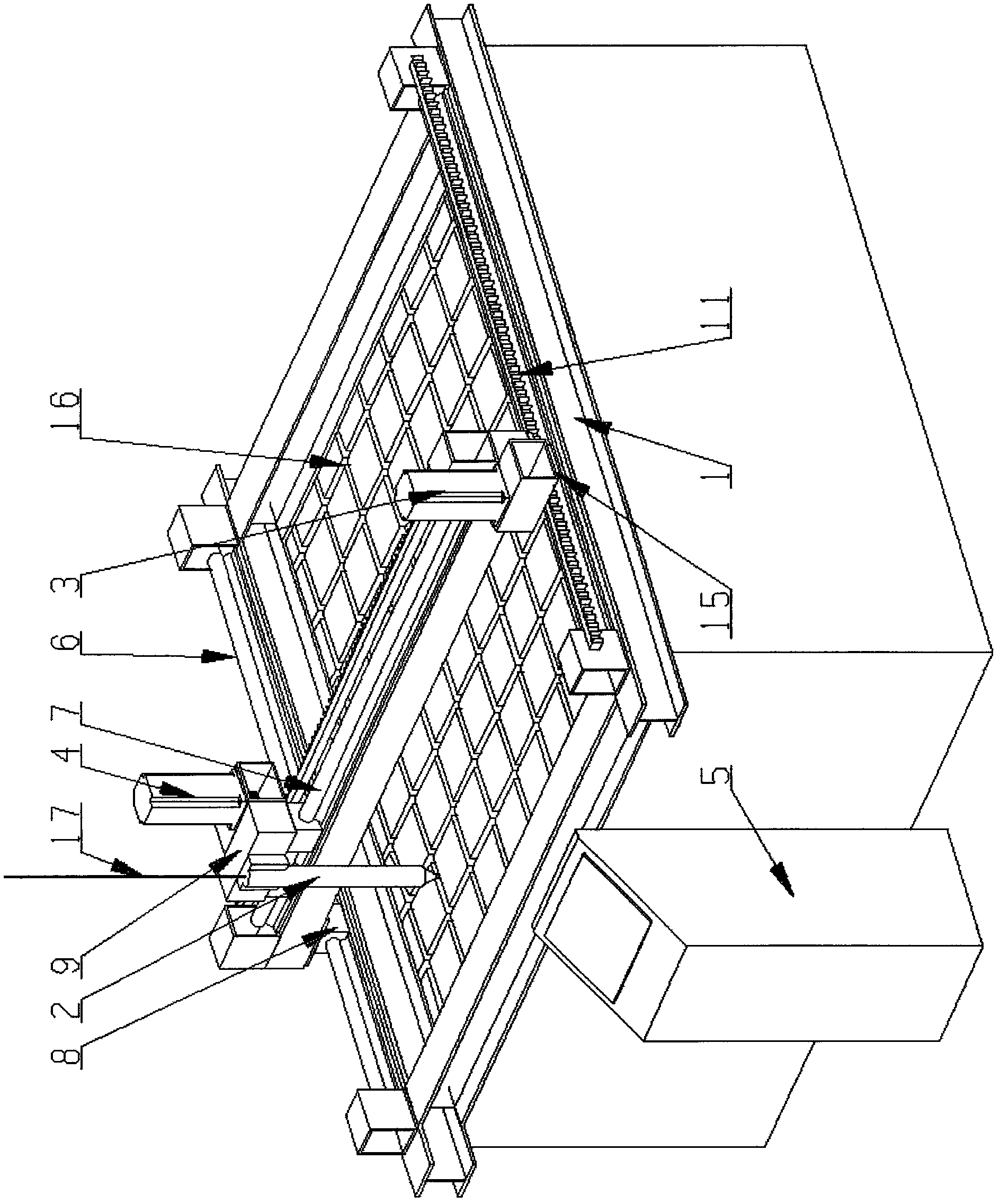

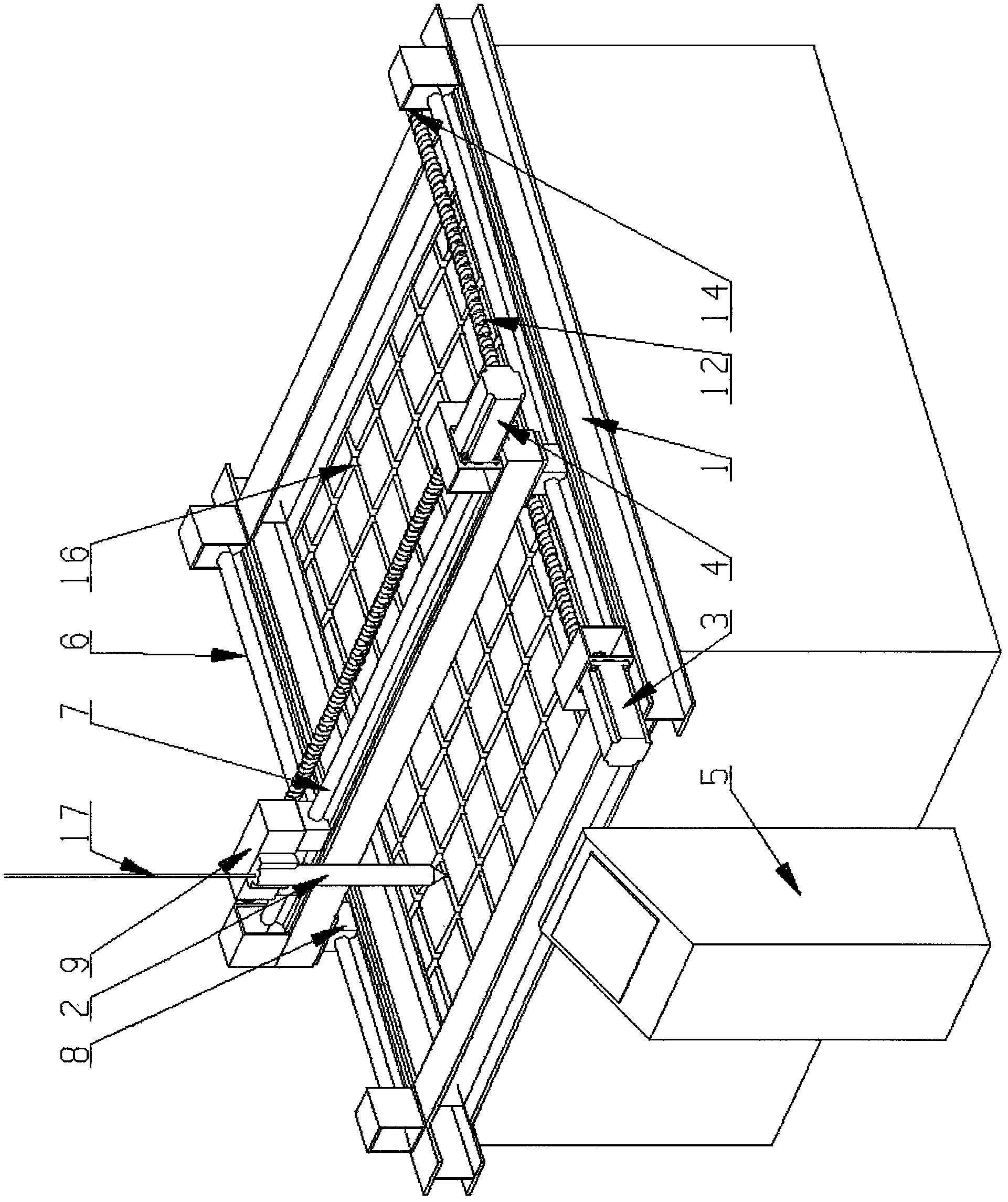

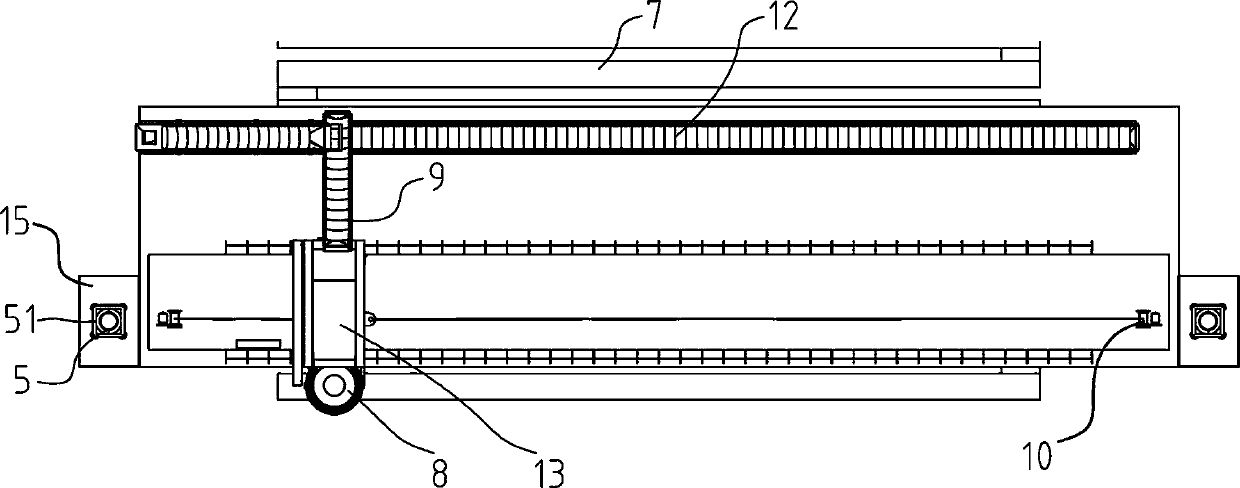

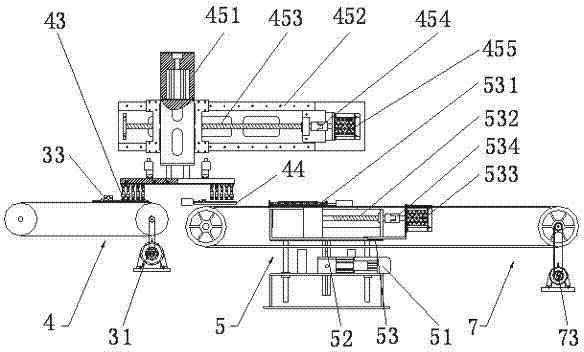

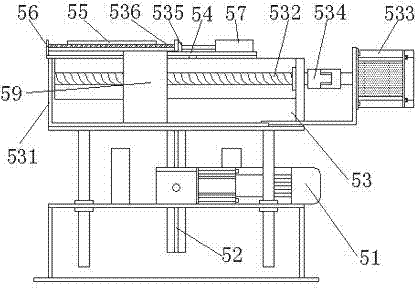

Numerical control paver for glass steel grid fiber

InactiveCN102602009ARealize fully automatic layingLaying speed is fastFiberFiberglass reinforced plastic grating

The invention relates to the technical field of mechanical equipment, in particular to a numerical control automatic device for paving a fiber when a glass steel grid is produced. The invention aims at providing a numerical control automatic fiber paver which can complete liberate the expensive labor on a fiber paving link when the glass steel grid is produced, and is high in production efficiency, stable in product quality, and raw material-saving. The paver comprises a main frame, a fiber conduit, high-speed servo motors and a special numerical control system. The main frame comprises a Y-axis formed by two parallel guide rails and an X-axis formed by a gantry type guide rail, wherein the X-axis is further provided with a dolly which can slide along with the axial direction, and a fiber conduit is arranged on the dolly. A set of driving system is respectively arranged on the Y-axis and the X-axis. The main frame is fixed above a glass steel grid mould, and the two servo motors are connected with the special numerical control system. Only by inputting the relevant data such as the size and the like through the special numerical control system, the paver can be used for automatically paving the fiber, so that the production cost can be saved in many ways, and the product quality can be improved.

Owner:毛英旭

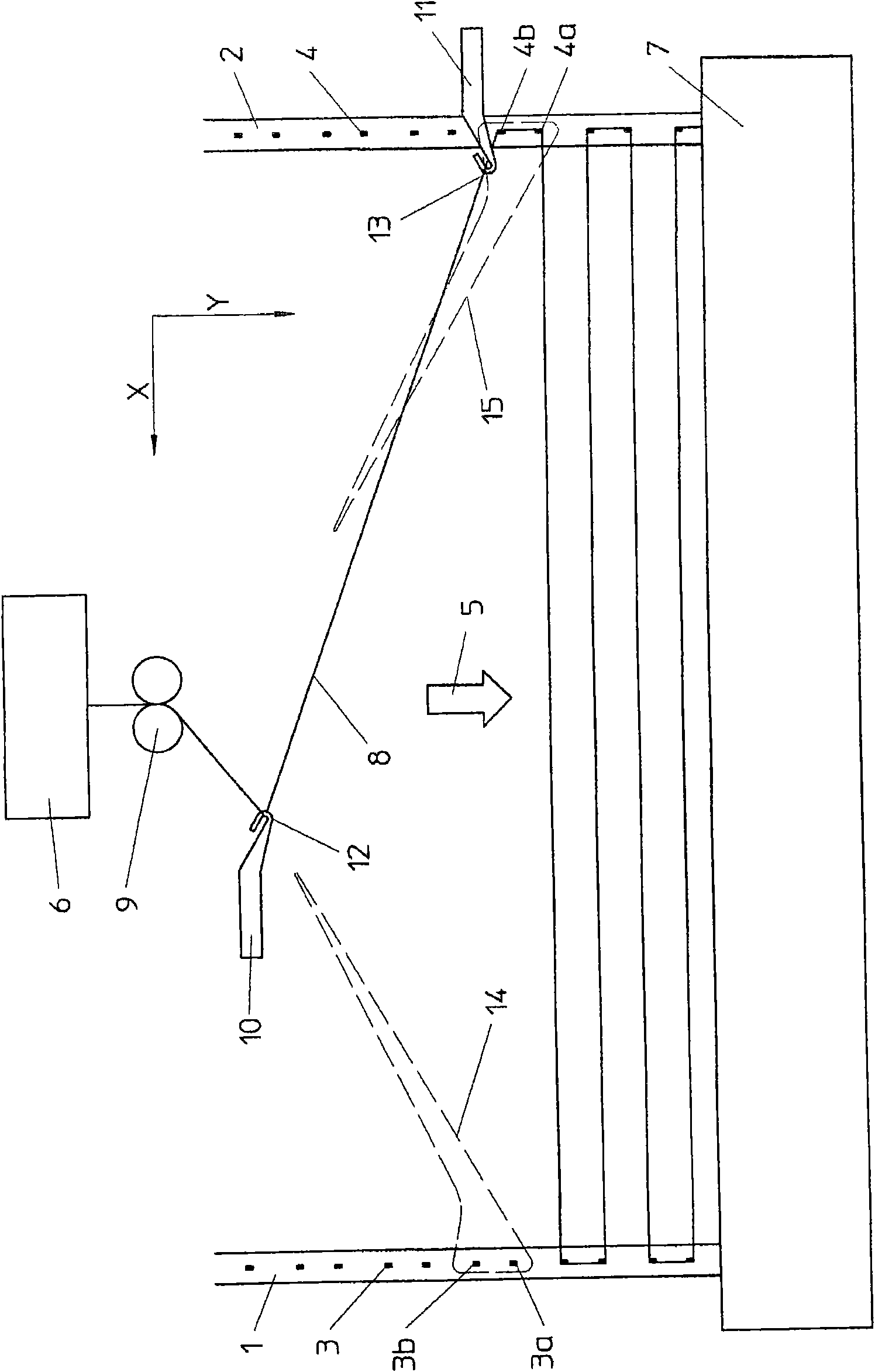

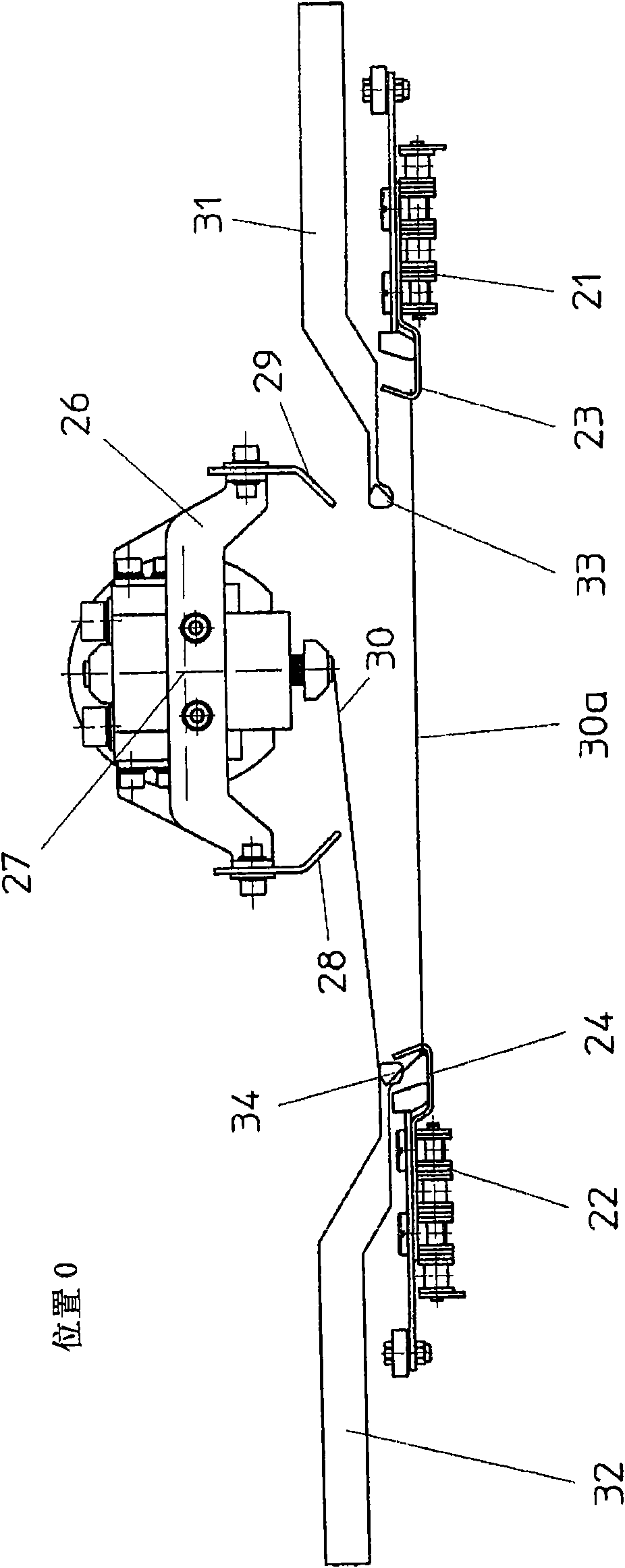

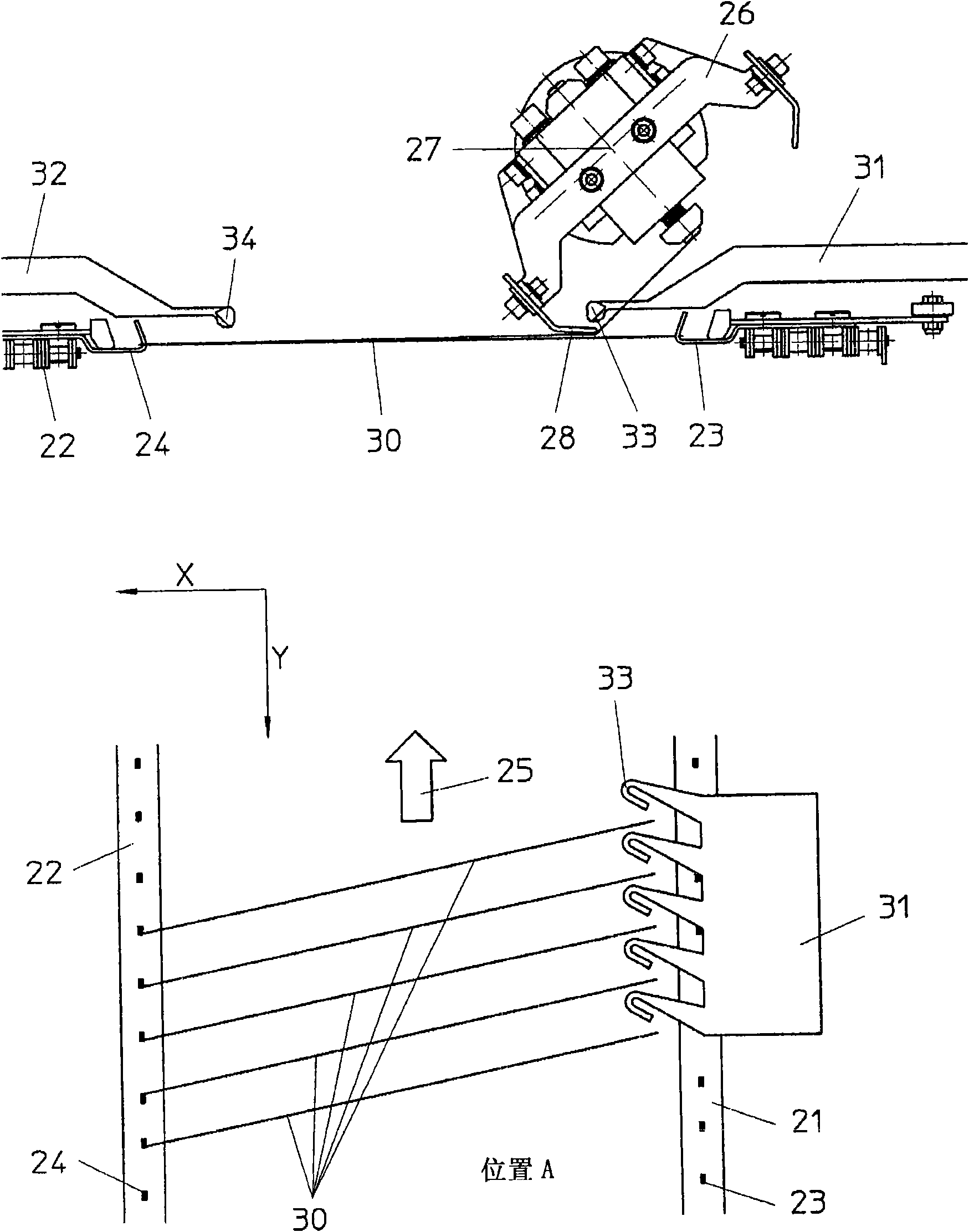

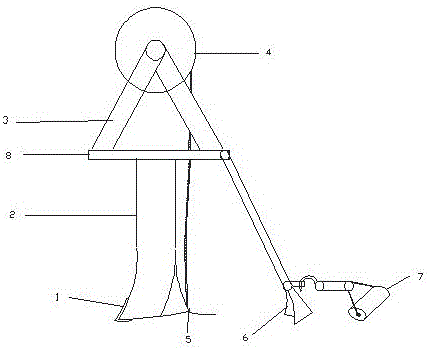

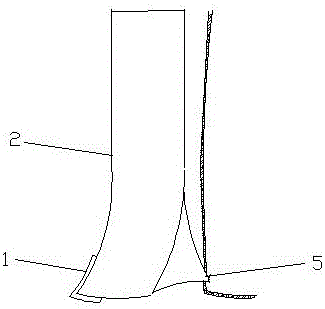

Method and device for placing a unidirectional thread layer on longitudinal conveyors, method for laying weft threads on warp knitting machines, and device to carry out said methods

InactiveCN101525809AIdeal coordination displacementHigh speedNon-woven fabricsFlat warp knitting machinesMulti axisClosed orbit

In the warp knitting machines and knitting machines for multi-axis must be one-way yarn layer (8) to mobile vertical conveyor belt installation (1,2) and hung on the conveyor belt at the vertical (1,2) on a fixed set of hooks (3 , 3a, 3b, or 4,4a, 4b) on the. Above the vertical conveyor (1,2) to send the direction (5) mobile. Described yarn (8) from the storage device (6) was extracted and transferred through the pulley off (9) transmission line to the first input device (10), referred to the input line of the device will hang the yarn to the first vertical conveyor belt (1) a fixed set of hooks (3,3a, 3b) in the. Then, the second transmission line unit (11) will be linked to the second vertical conveyor belt yarn (2) a fixed set of hooks (4,4a, 4b) in the. Described in two transmission-line device (10,11) in two mutually perpendicular extension of the direction of x axis and y-axis movement and the movement to draw a closed orbit (14 and 15). In order to grab yarn (8), referred to the input line of devices (10,11) set up branch with claws (12,13). The methods described can also be achieved through the yarn guide, which referred to the input line of devices (10,11) was designed to shift rake. Yarn made of layers is transported to a warp knitting machine knitting station (7) or knitting tools.

Owner:LIBA MASCHFAB

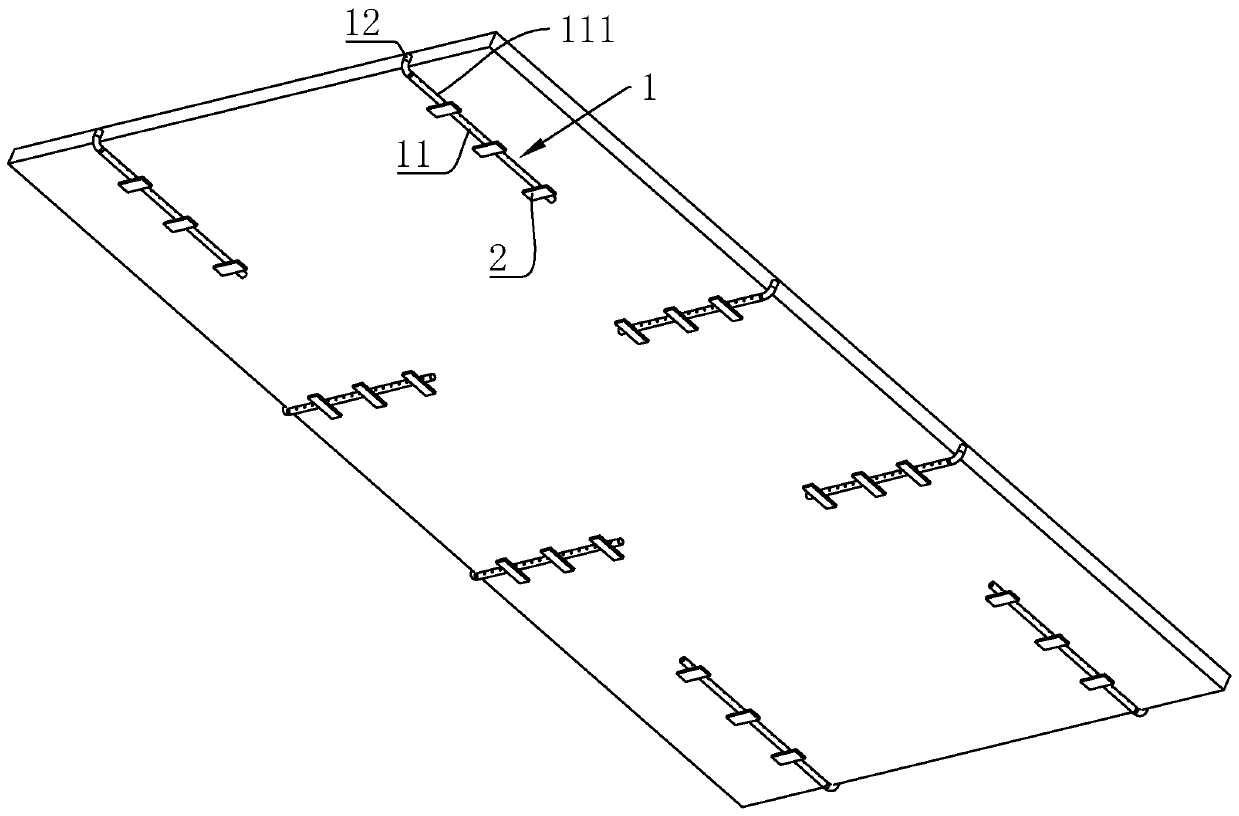

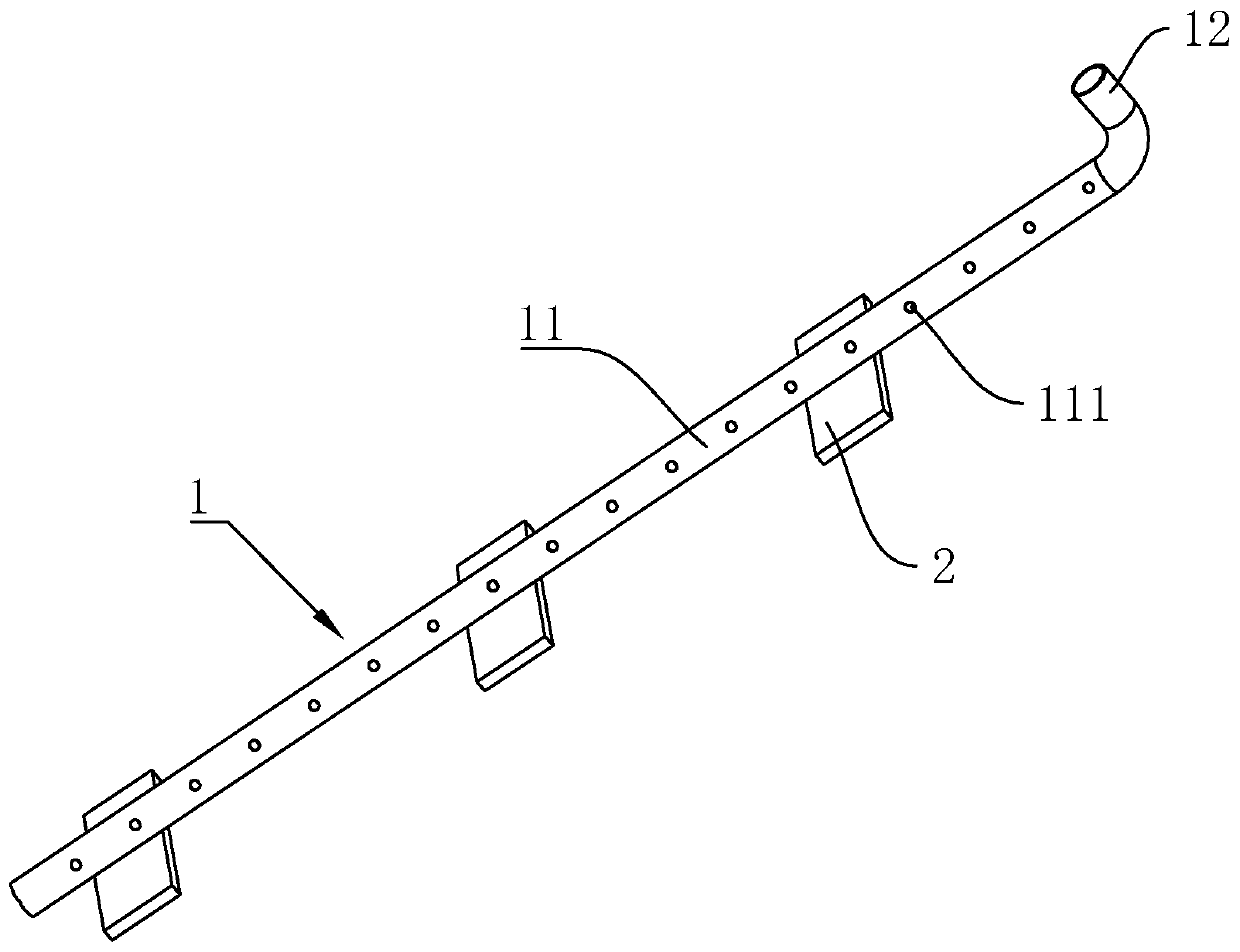

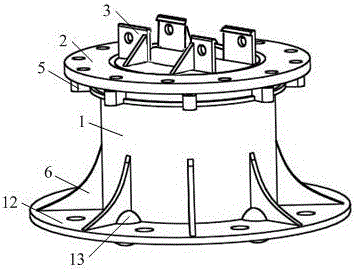

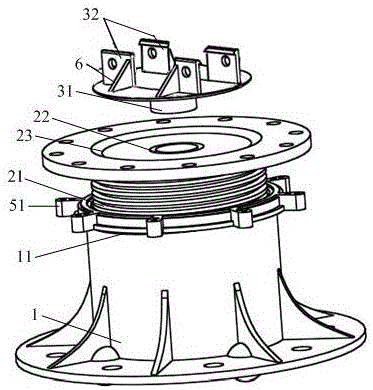

Supporting system special for outdoor floors and outdoor floor paving method

The invention discloses a supporting system special for outdoor floors. The supporting system comprises struts, keels and keel covers; the struts are vertically arranged on the ground; the keels are horizontally supported at the upper ends of the struts; and the keel covers are arranged the two ends of the keels and used for connecting the different keels. Each strut comprises a base, a supporting platform and joggling pieces. Each keel is a hollow long-strip-shaped rod, two of side surfaces of each keel are provided with clamping grooves, and hooks can be buckles with the clamping grooves. One end of each keel cover is a keel port connection part for being engaged with the end of the corresponding keel, and the other end of the keel cover is a keel clamping connection part for being connected with the corresponding clamping groove of the keel. The invention further discloses an outdoor floor paving method. By adopting the supporting system special for the outdoor floors and the outdoor floor paving method, the distance between each base and the corresponding supporting platform can be quickly adjusted so that the required supporting height can be obtained; and the joggling pieces can horizontally rotate relative to the supporting platforms, keel clamping can be facilitated, the paving difficulty is lowered, and the paving speed is increased.

Owner:MEXYTECH

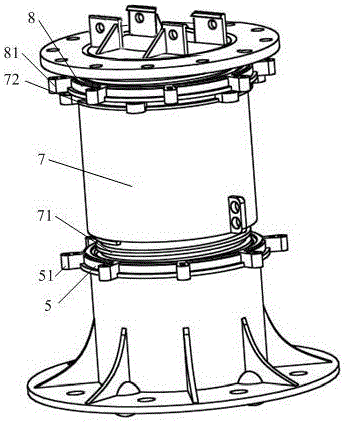

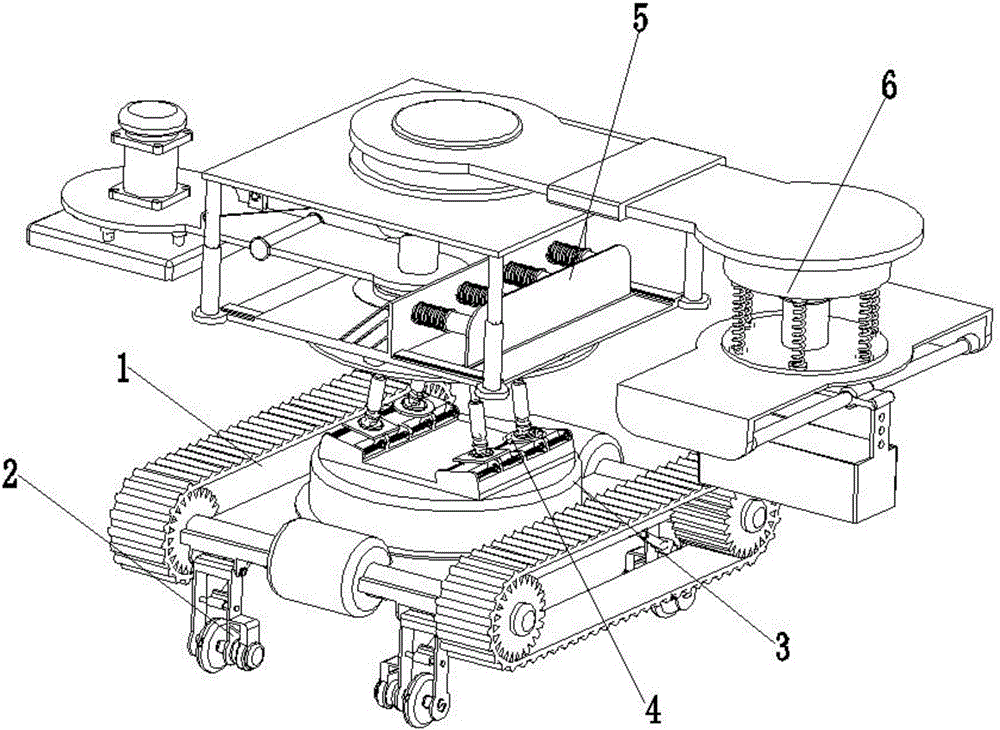

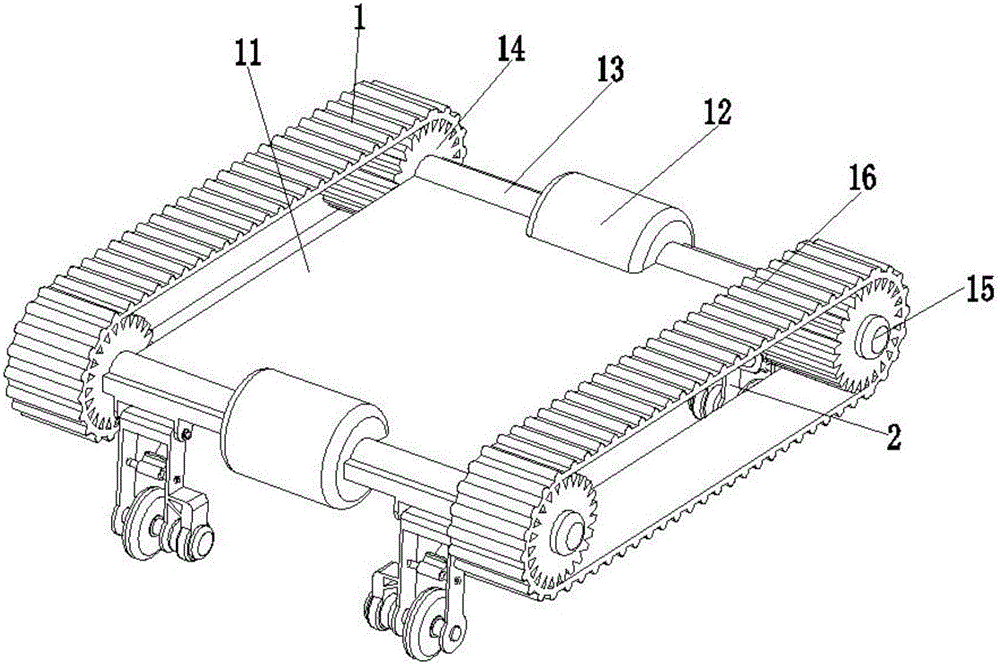

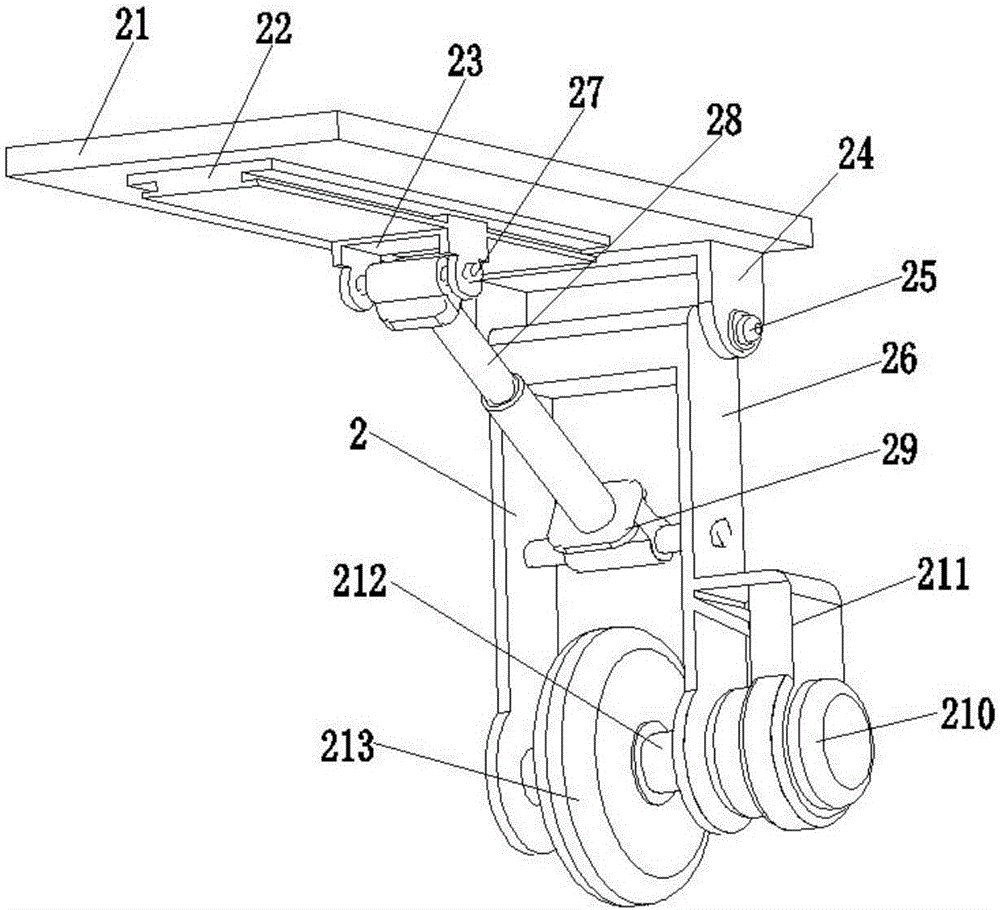

Garden greening floor tile construction intelligent equipment

The invention relates to garden greening floor tile construction intelligent equipment. The garden greening floor tile construction intelligent equipment comprises a crawler walking device, wheeled walking devices, an electric rotating platform, a hybrid mechanism, a suction device and a tile seam mud filling device. The wheeled walking devices are symmetrically arranged on the left side and the right side of the crawler walking device correspondingly. The electric rotating platform is located in the center of the upper end of the crawler walking device and fixedly connected with the crawler walking device. The hybrid mechanism is located between the electric rotating platform and the suction device. The lower end of the hybrid mechanism is connected with the electric rotating platform. The upper end of the hybrid mechanism is connected with the suction device. The tile seam mud filling device is located over the suction device. According to the garden greening floor tile construction intelligent equipment, the multiple functions of composite walking, multi-freedom-degree direction adjustment, floor tile suction, tile seam mud filling fixing and the like are integrated, and thus floor tile laying operation can be conducted on municipal sidewalks; and in addition, the automation degree is high, the laying speed is high, and the laying aesthetics is good, so that the problems that existing floor tile laying is large in occupied labor force, low in laying efficiency, large in laying cost and the like are solved.

Owner:徐鹏

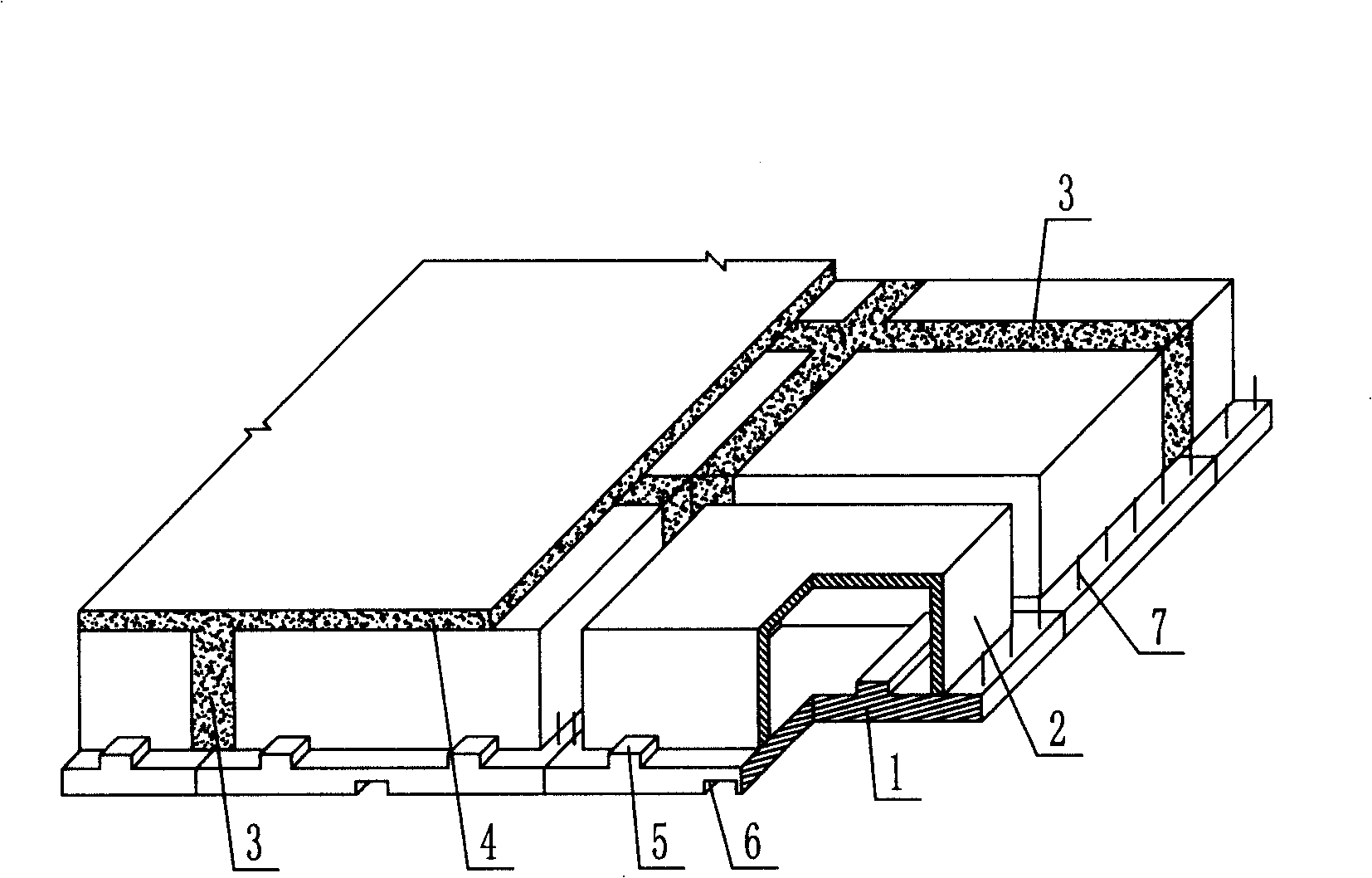

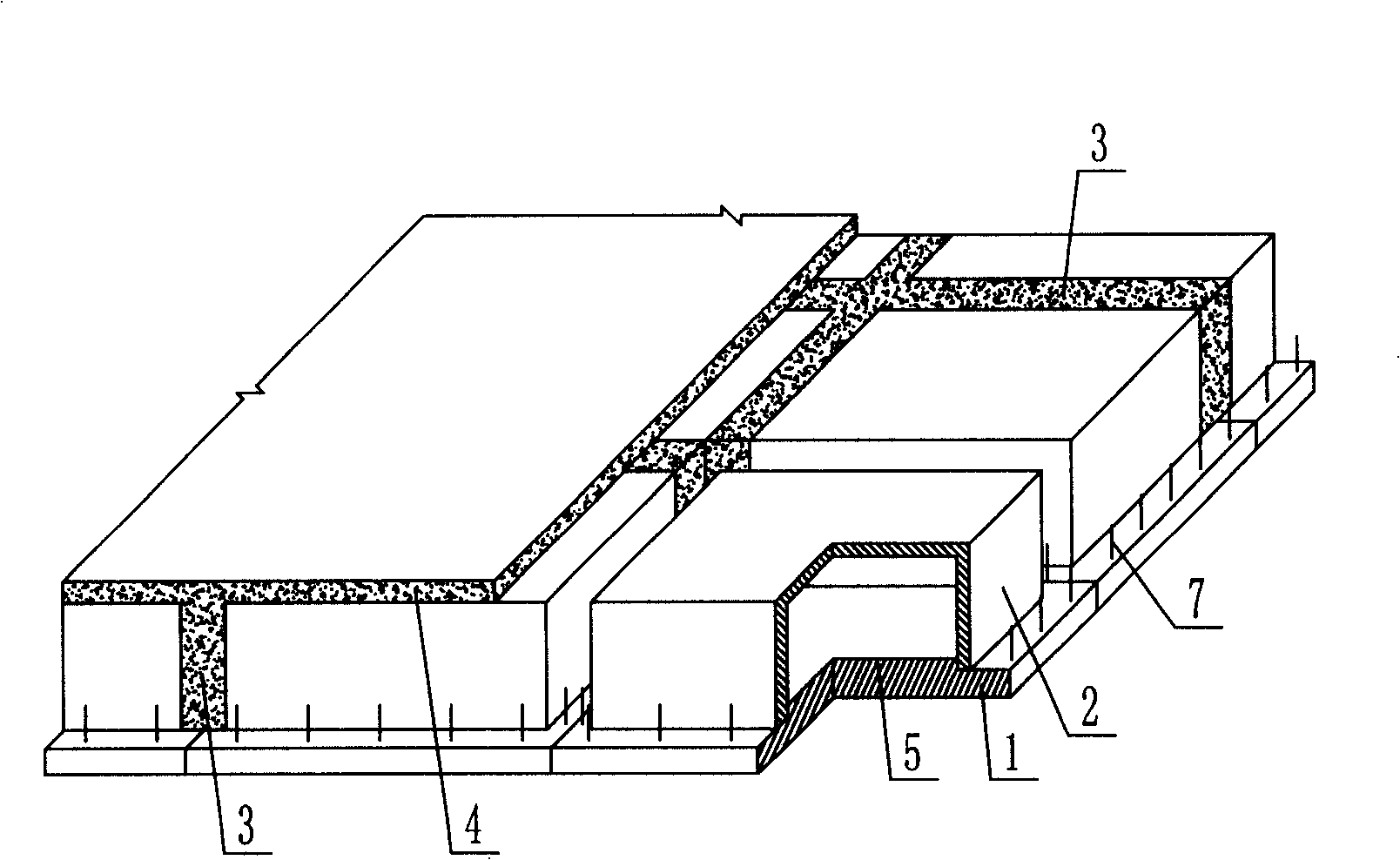

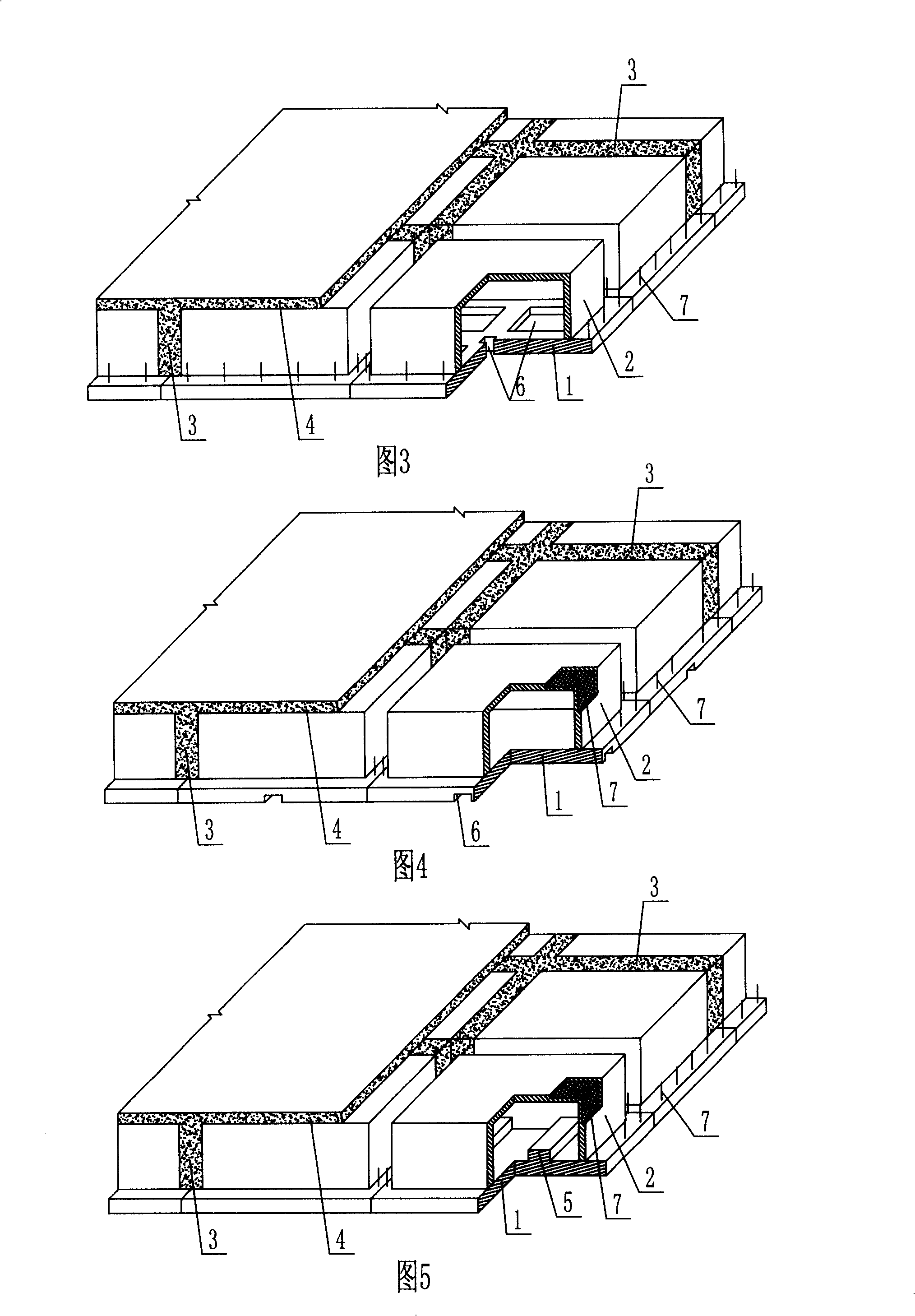

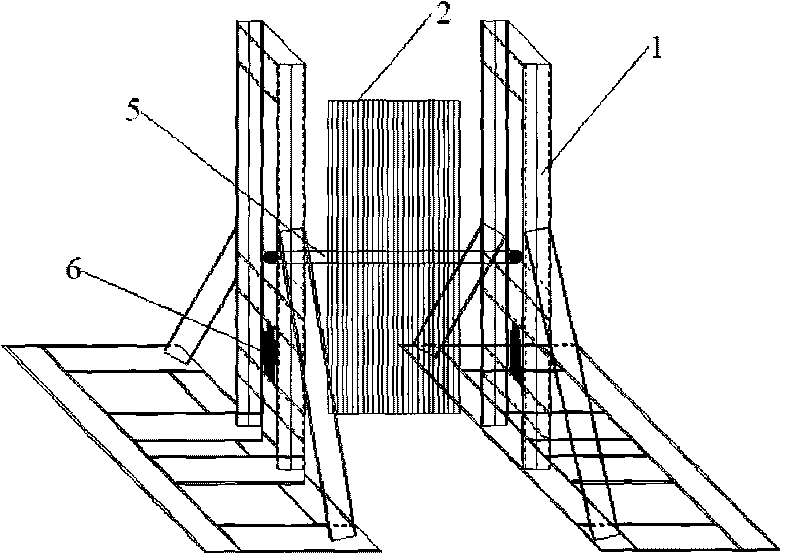

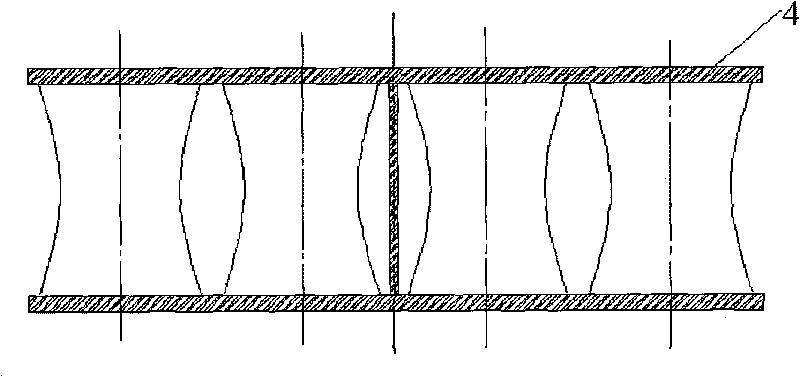

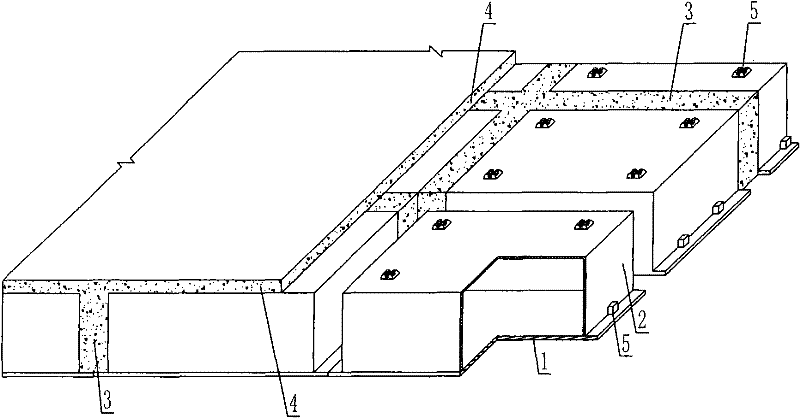

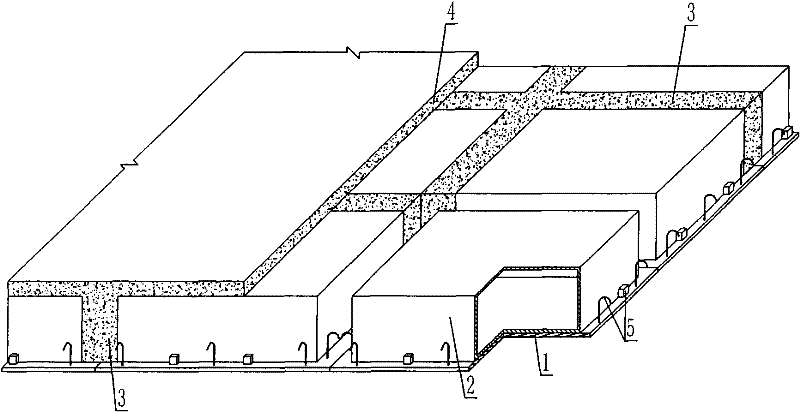

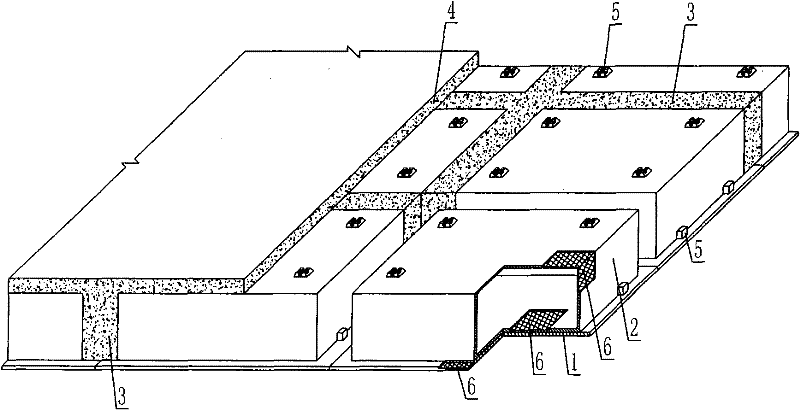

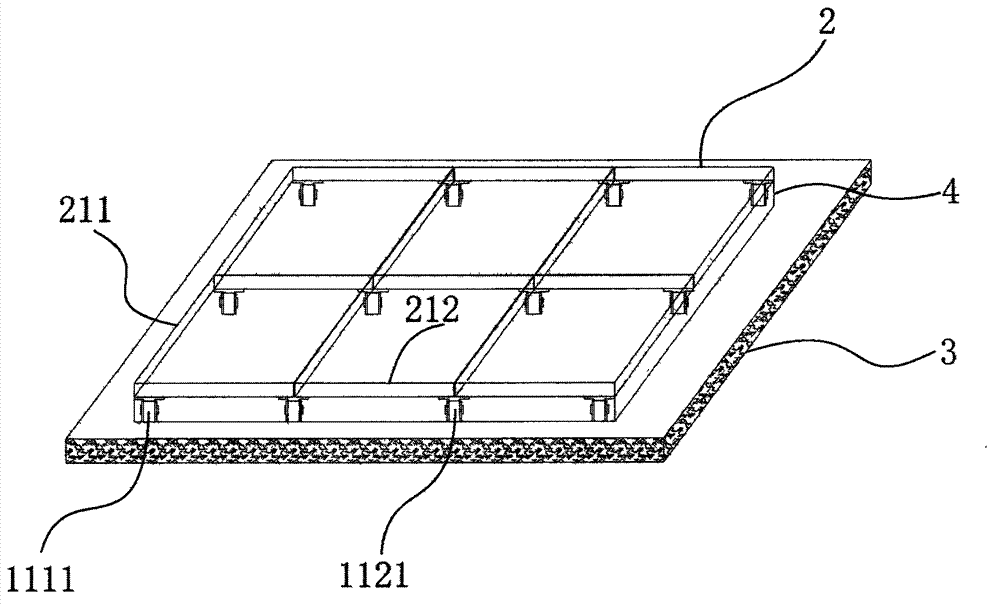

Assembled reinforcing steel bar concrete hollow floor slab

The invention provides a combined reinforced concrete hollow floorslab, comprising a precast thin slab (1), a formwork (2), a hidden rib (3) and an upper slab (4), wherein, the formwork (2) is fixed on the precast thin slab (1); the hidden rib (3) is arranged between adjacent precast thin slabs (1) or formworks (2); and the upper slab (4) is covered on the formwork (2) and is connected with the hidden rib (3) into a whole. The invention is characterized in that at least one of a convex structure (5) or / and a concave structure (6) is arranged on the precast thin slab (1), and grooves (10) are arranged on the formwork (2). Therefore, the combined reinforced concrete hollow floorslab is applicable to various hollow floors, roofs, walls, foundation slabs and hollow bridges of cast-in-situ reinforced concrete or prestressed reinforced concrete, in particular to hollow flat slabs and ribbed slab floors.

Owner:湖南邱则有专利战略策划有限公司

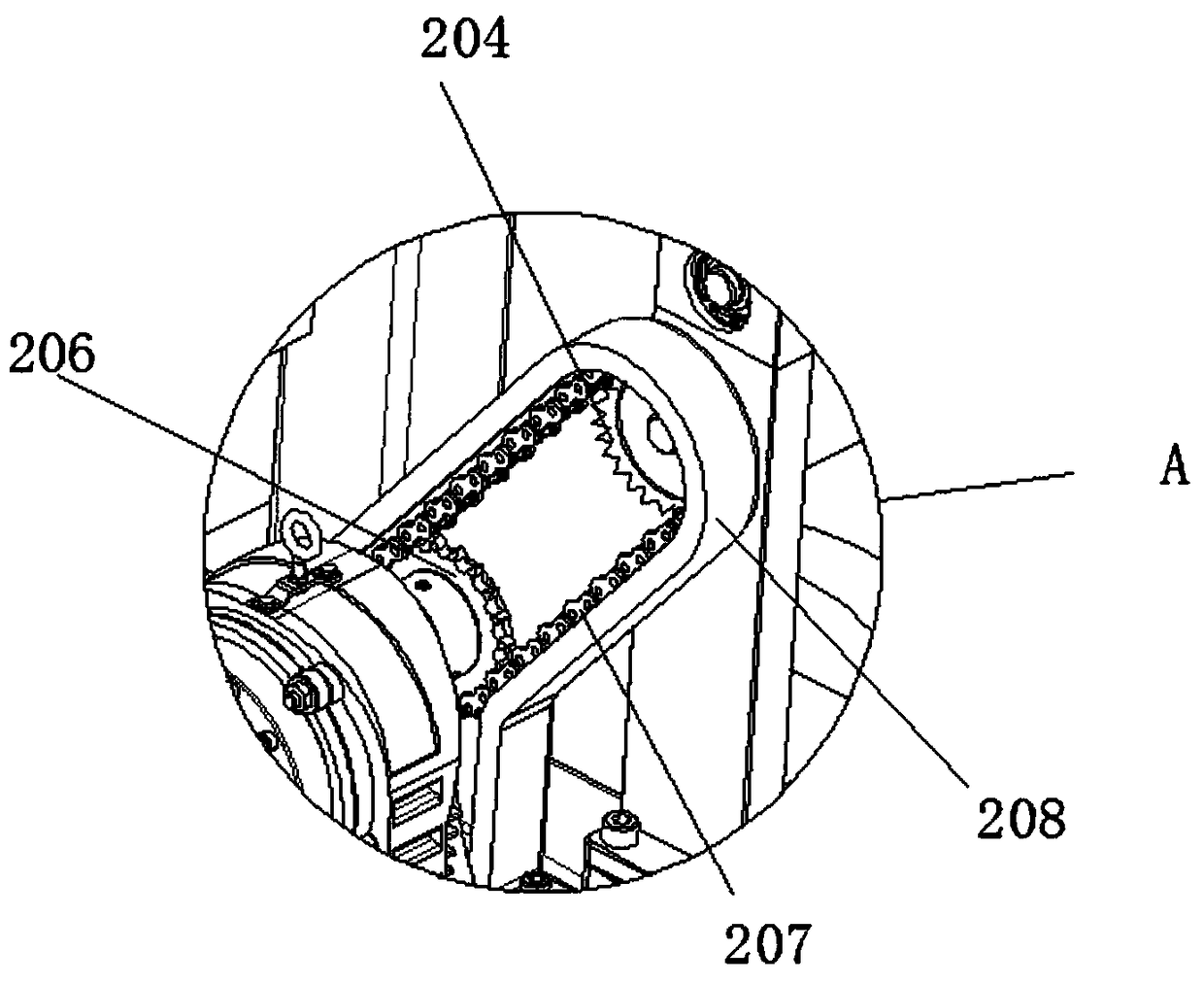

Multi-rail automatic laying equipment for multicolor mosaic particles

ActiveCN104070909AImprove laying efficiencyImprove accuracyOrnamental structuresConveyor partsEngineeringMonorail

The invention provides multi-rail automatic laying equipment for multicolor mosaic particles. The equipment comprises a rack, a mosaic tire mold, more than two multicolor mosaic particle monorail automatic-laying units, a feeding device and a controller, wherein the multicolor mosaic particle monorail automatic-laying units are used for respectively transporting mosaic particles in same colors one by one, then collecting the needed mosaic particles one by one to form rows / lines according to a preset order, and finally enabling the full rows / lines of mosaic particles to enter a feeding process; the feeding device is connected with the rack and used for sequentially transporting the full rows / lines of mosaic particles sorted in the multicolor mosaic particle monorail automatic-laying units into the mosaic tire mold; the controller is connected with each multicolor mosaic particle monorail automatic-laying unit and the feeding device respectively through signals. The equipment is high in laying stability and high in laying speed and can effectively improve the laying efficiency and accuracy rate of the mosaic particles. The automatic laying equipment replaces a traditional manual laying process and solves the problems of low degree of automation and low production efficiency in the mosaic industry.

Owner:FOSHAN UNIVERSITY

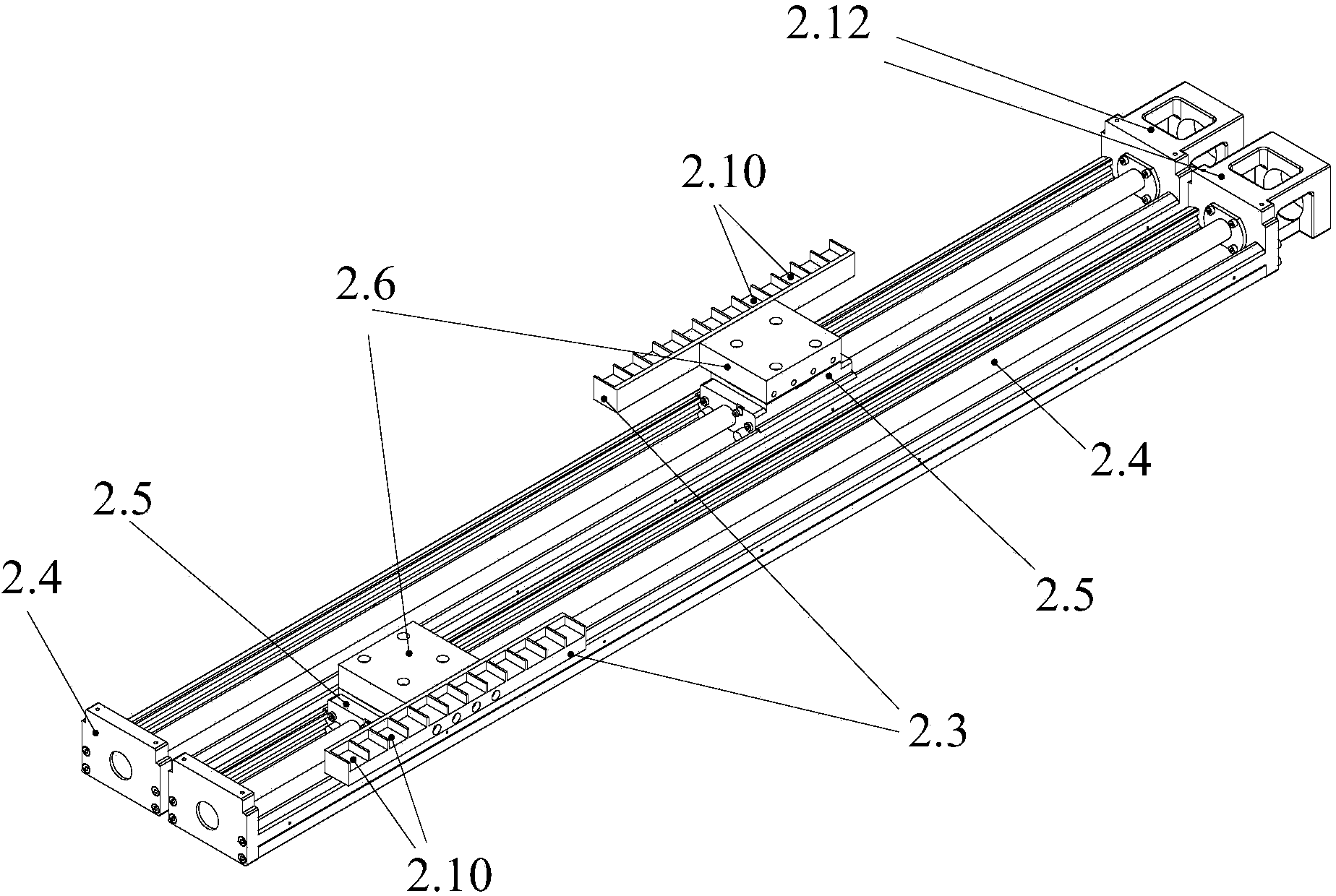

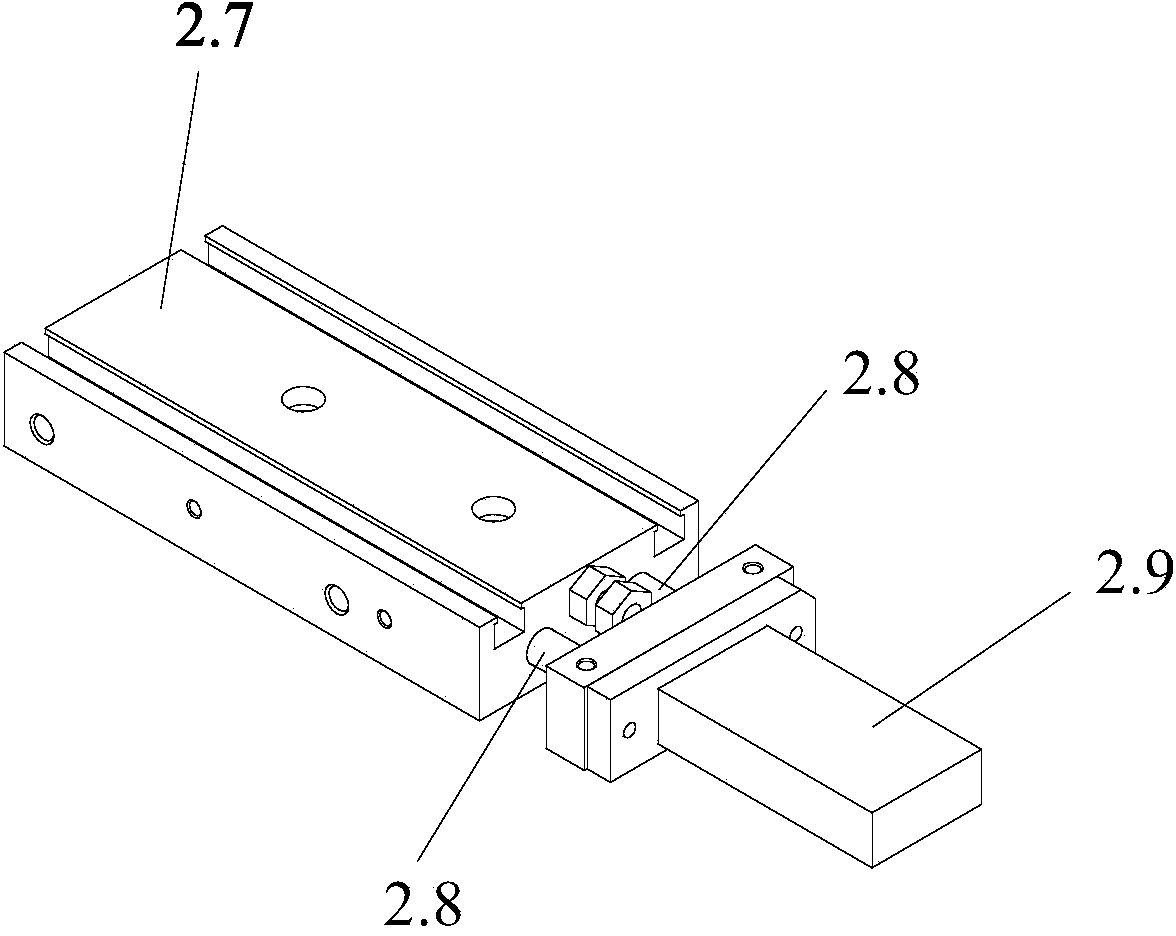

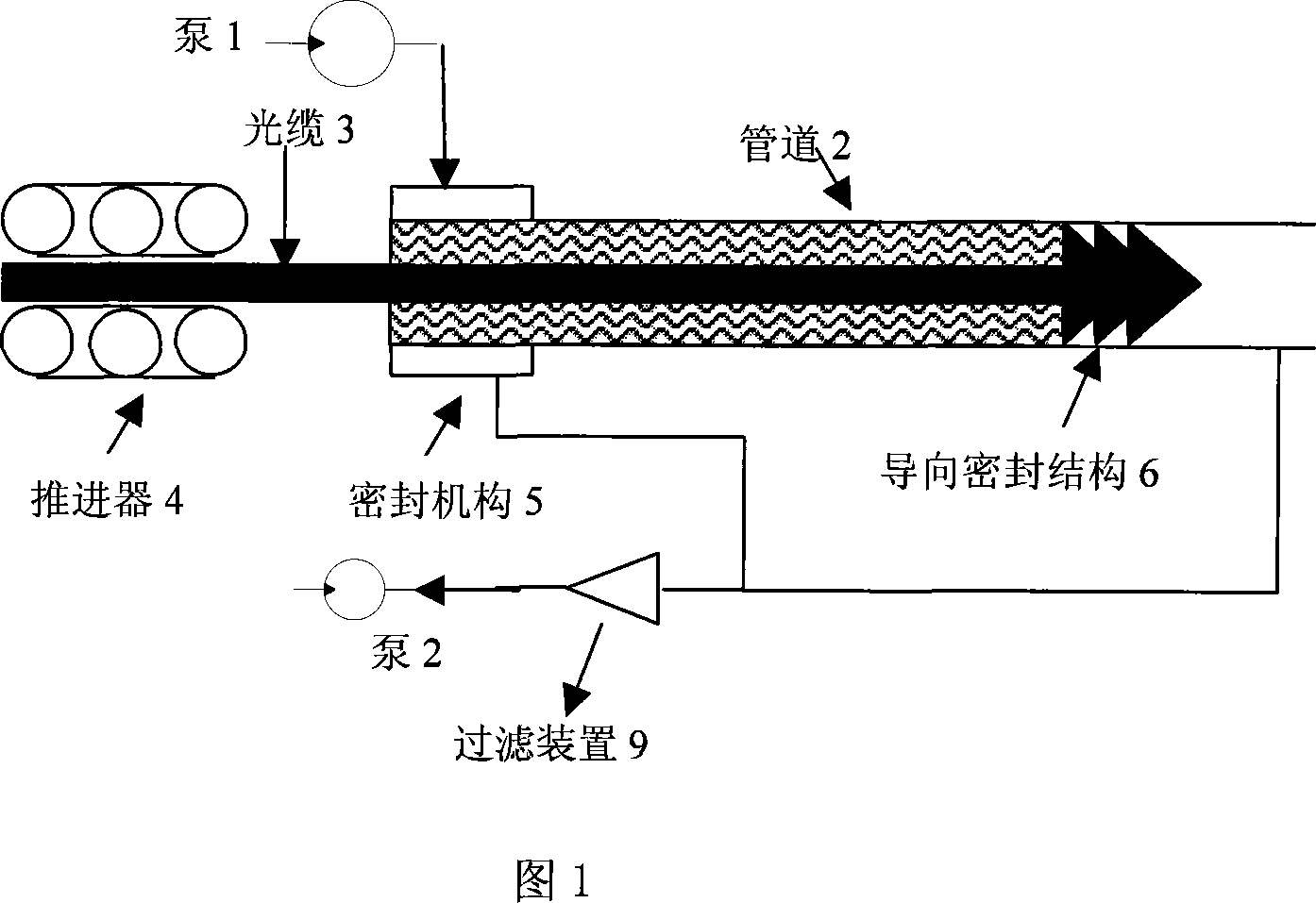

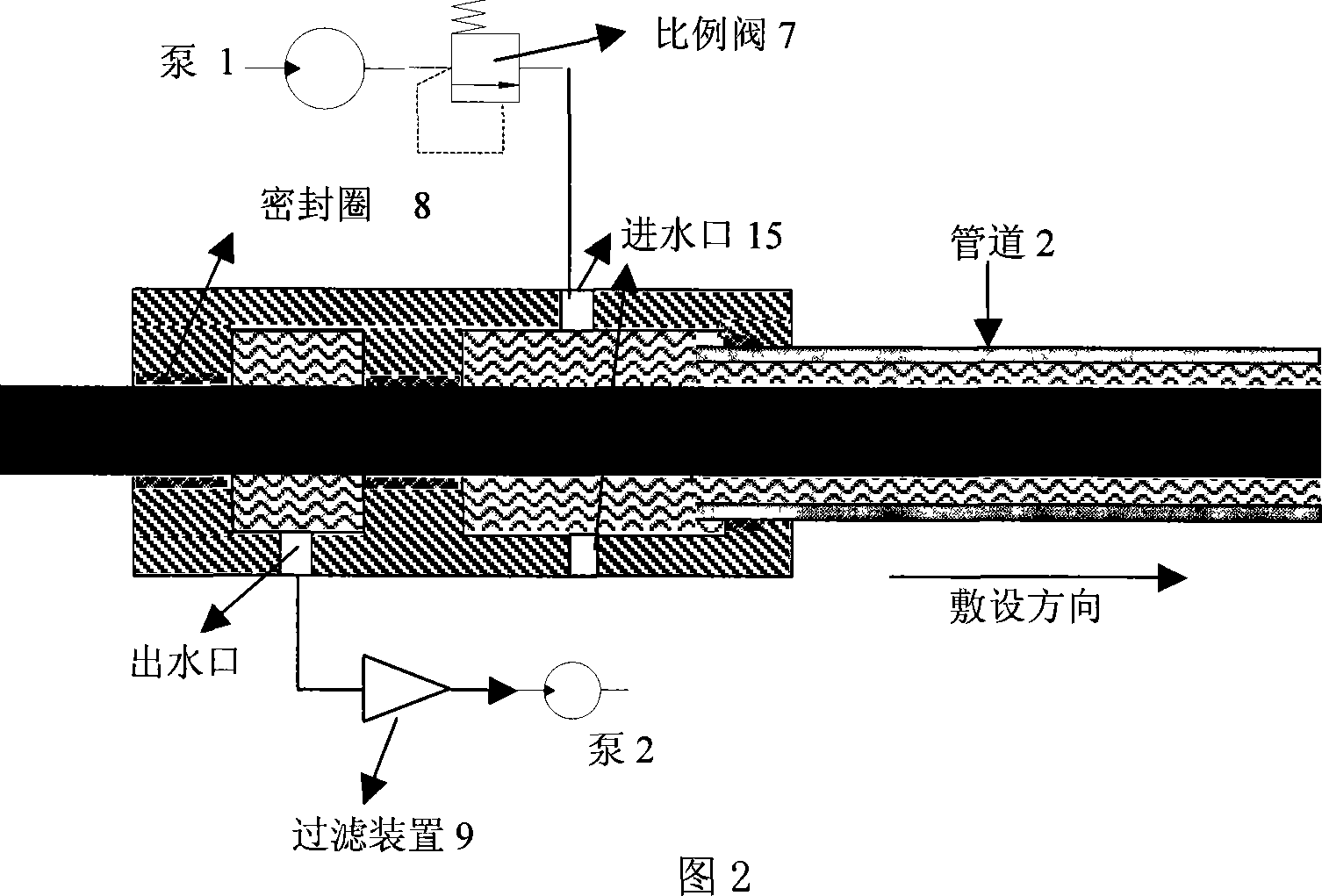

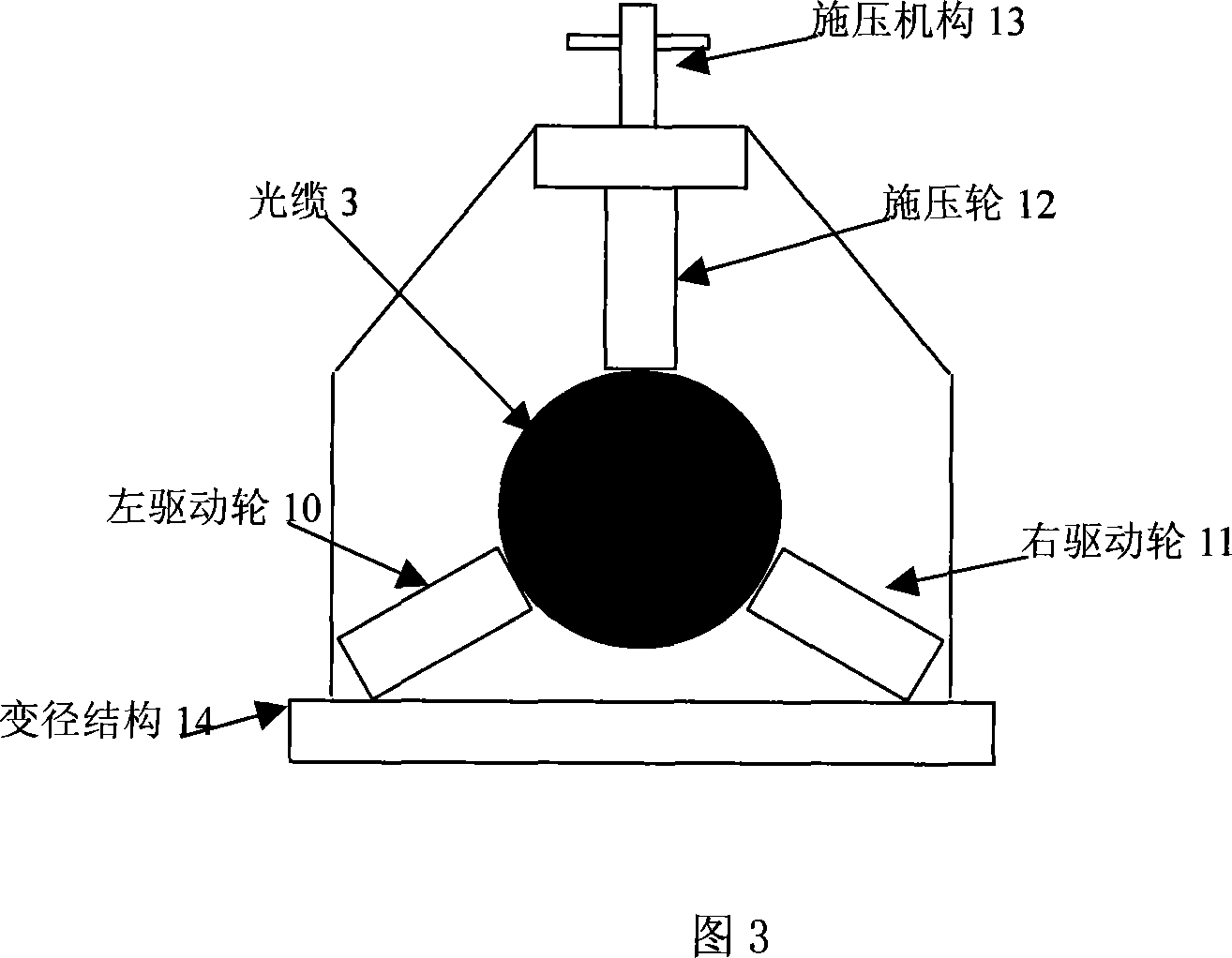

Water application method optical cable laying and construction method

InactiveCN101055340AAvoid wastingFully automatedOptical fibre/cable installationWater flowElectric machinery

A water-installing optical cable installation construction method for construction technique fields pushes the optical cable into a pipe by a mechanical optical cable thruster. Simultaneity, the press-added current which forms a drag force on the surface of the optical cable is inputted into the pipe through a water intake apparatus by using a water press. The press of the water acts on a steering seal structure connected with the optical cable head to form a forward force. The optical cable is under a floating state by the flotage of the water. The AC servo motor and the water press are controlled by a controllor to install the optical cable. The invention has the advantages of: low energy consumption, high speed of installation, applicability of the complicated pipe path, achievement of safe and long-distance optical cable installation, samll volume of the whole equipment and applicability of the field work.

Owner:SHANGHAI JIAO TONG UNIV

Large cable laying device

InactiveCN101707335AProcess OptimizationAccelerate laying speedArrangements using take-up reel/drumApparatus for laying cablesMechanical engineeringBuilding construction

Owner:WUHU XINXING DUCTILE IRON PIPES

Floating-type underwater gravel base bed continuous leveling ship

PendingCN109898514AAdjustable lengthPrecise thickness controlWaterborne vesselsFoundation engineeringSternBuilding construction

The invention provides a floating-type underwater gravel base bed continuous leveling ship, which comprises a hull. Lifting positioning piles are arranged at a bow and a stern of the hull and slidablyconnected with the hull; a conveying trolley is further arranged and driven by a driving device to slide in the length direction of the hull, an articulated chute is arranged on the conveying trolley, a material feeding opening is formed in the top end of the articulated chute, and the bottom end of the articulated chute is close to the water bottom; and one or more conveying belts for supplyingmaterials to the conveying trolley are further arranged. By adopting the scheme that the positioning piles and the hull are slidably connected in the horizontal direction, after riprapping construction is completed in an area, precisely guided continuous moving can be achieved by moving the positioning piles and the hull in a reciprocating mode, thus the situation that the hull needs to be re-positioned every time when the hull is moved is avoided, and high-precision and continuous Z-shaped riprapping paving construction is achieved through the articulated chute.

Owner:CCCC SECOND HARBOR ENG

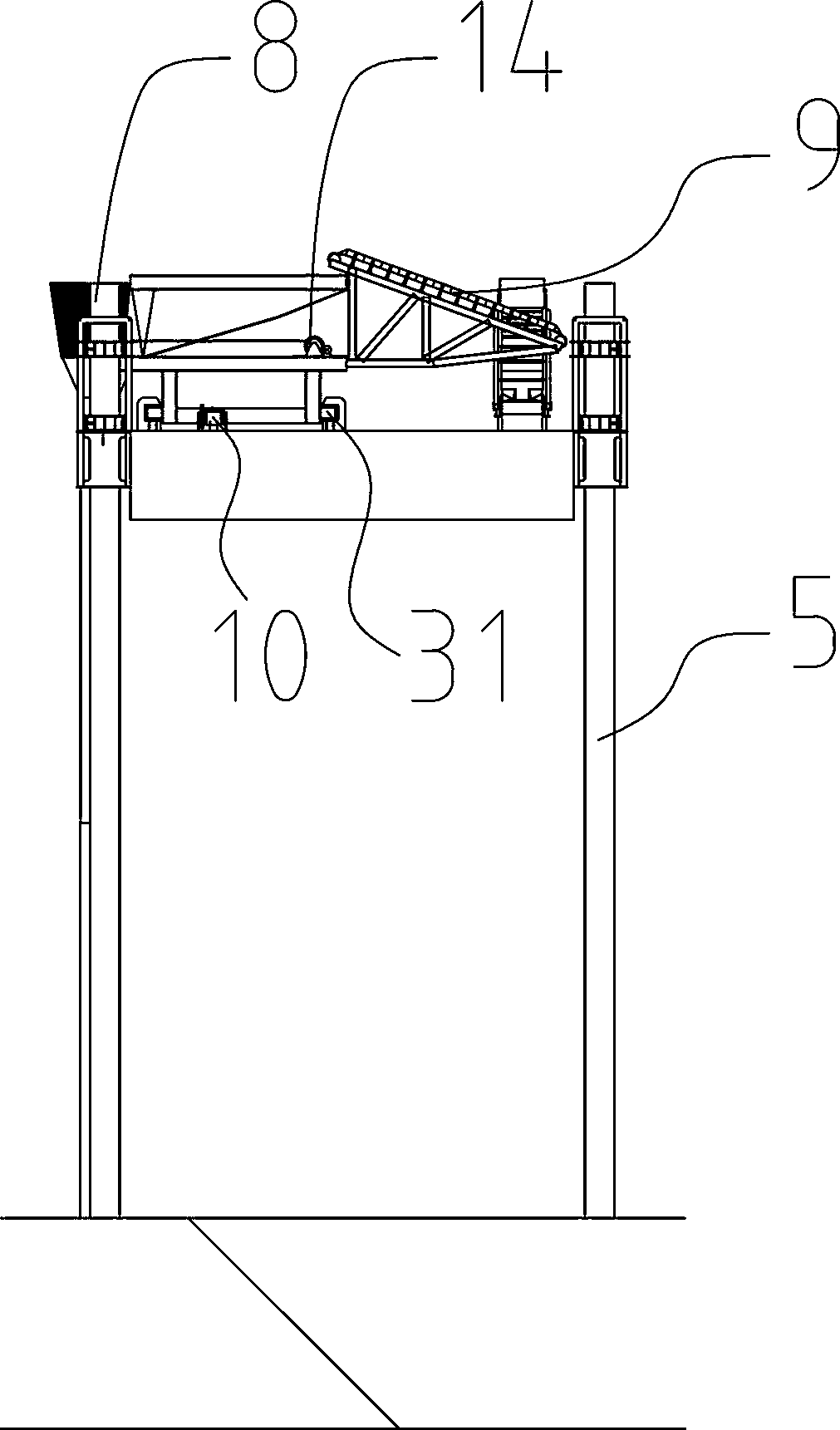

Waterproof construction method for building outer wall

InactiveCN112647721AGuaranteed tightnessLaying speed is fastBuilding material handlingBuilding insulationsConstruction engineeringElectric machinery

Owner:纪萍

Full-automatic paving method of ceramic mosaic tiles and full-automatic paving line

The invention relates to a full-automatic paving method of ceramic mosaic tiles and a full-automatic paving line. The full-automatic paving line comprises the following steps of: forming ceramic mosaic tiles from the ceramic finished tiles by a multi-head cutting machine; orderly arranging the ceramic mosaic tiles on the paving line, and transferring to a positioning receiving disc through a sucker; sticking a nylon net with adhesive on the surfaces of the ceramic mosaic tiles to form a unit connection; turning over the positioning receiving disc, and receiving the unit connection by a flat; and conveying the unit connection borne by the flat to a low-temperature roller kiln through a conveying belt and drying. The full-automatic paving line of ceramic mosaic tiles consists of a feed conveying device, a drying conveying device, an array centering conveying device, a disc loading device and a positioning manipulator arranged sequentially and a disc feeding device, a disc discharge device and an electric cabinet overlapped on the outer side of the positioning manipulator.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK

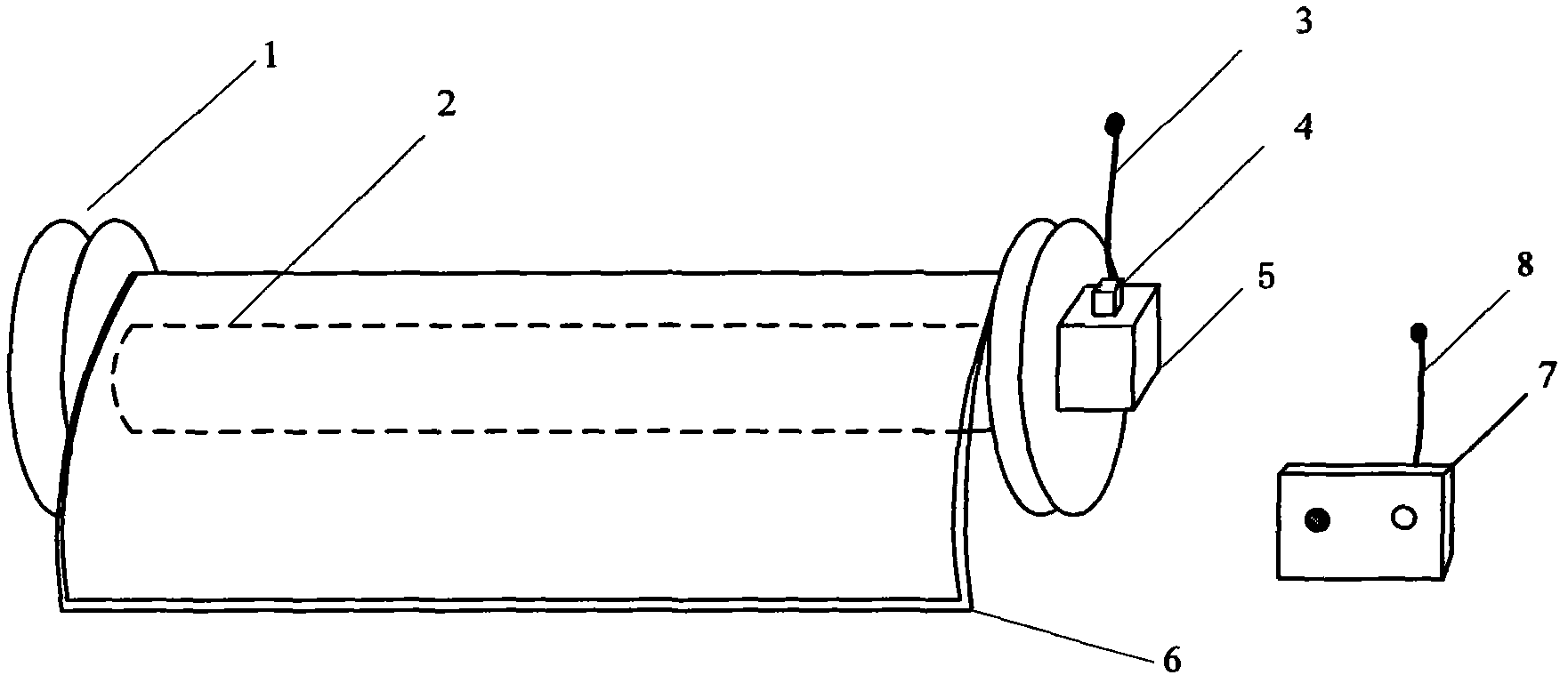

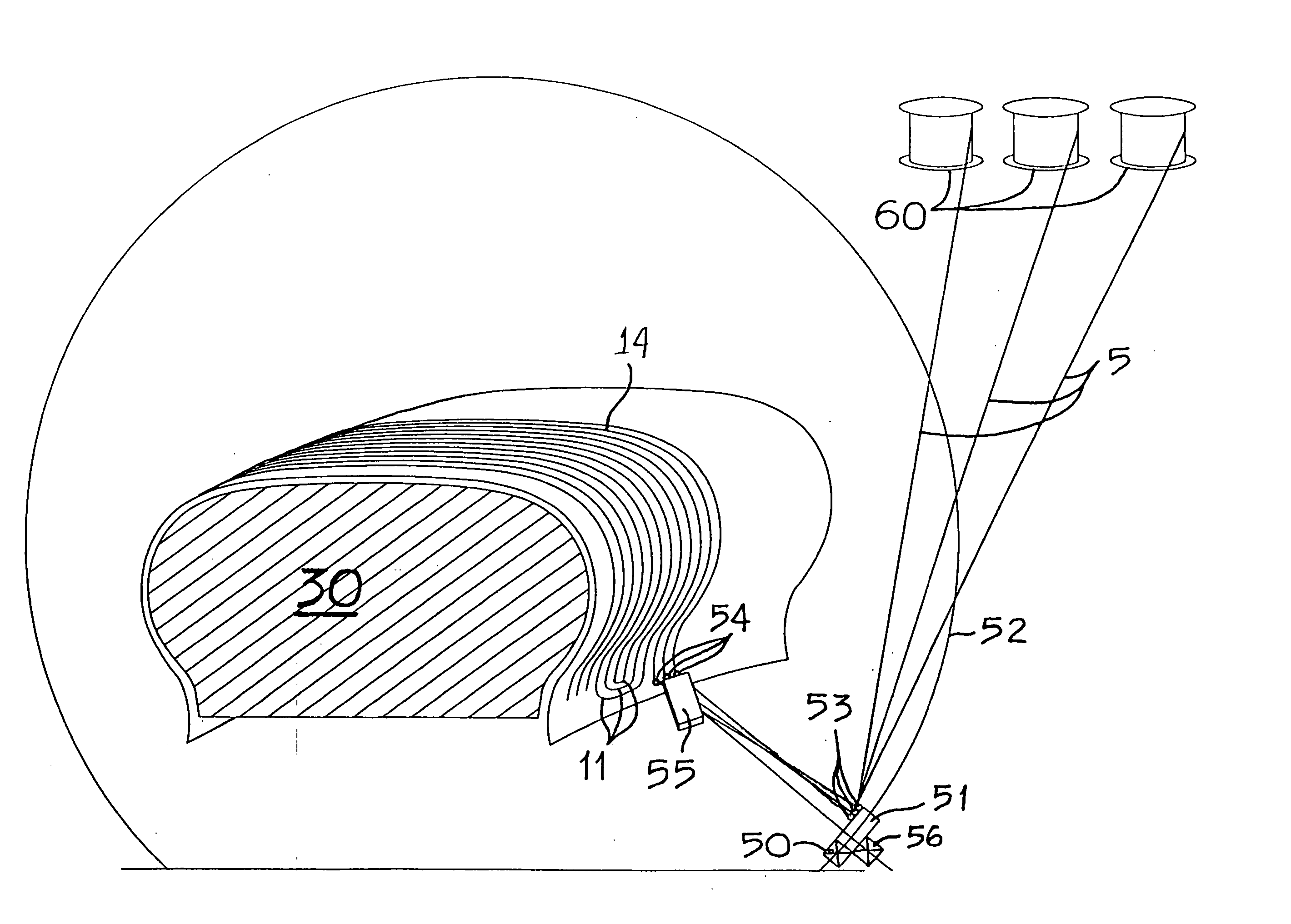

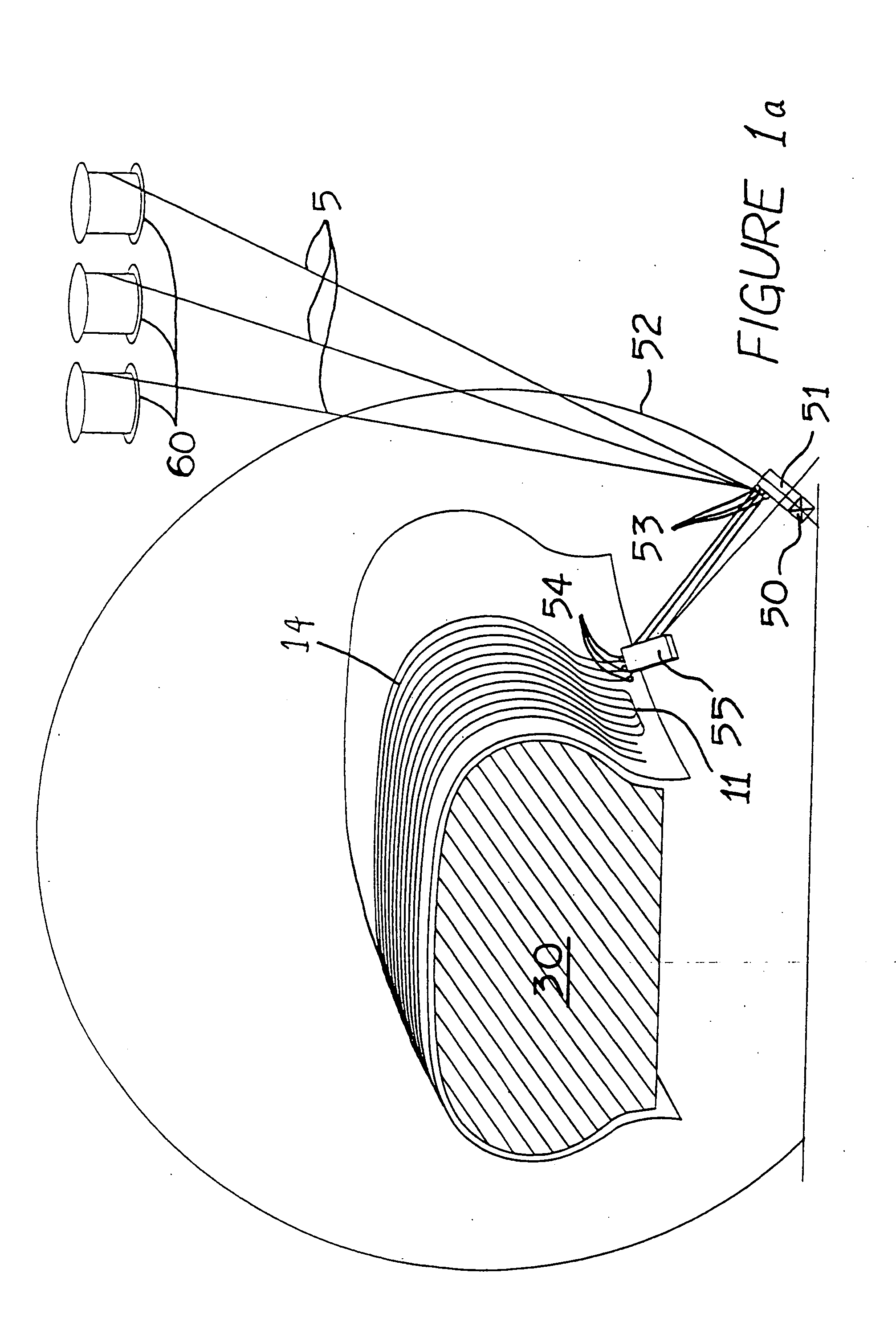

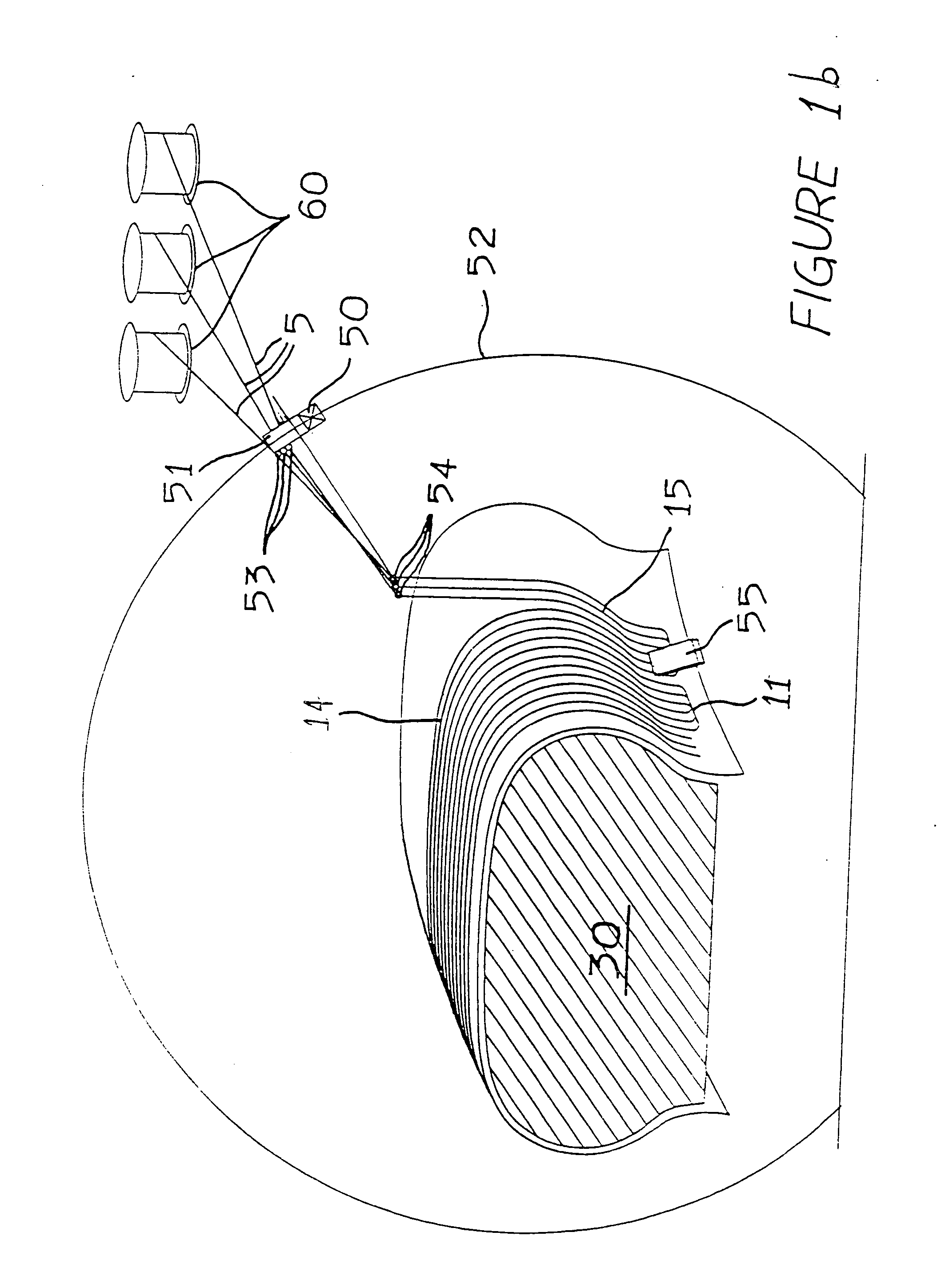

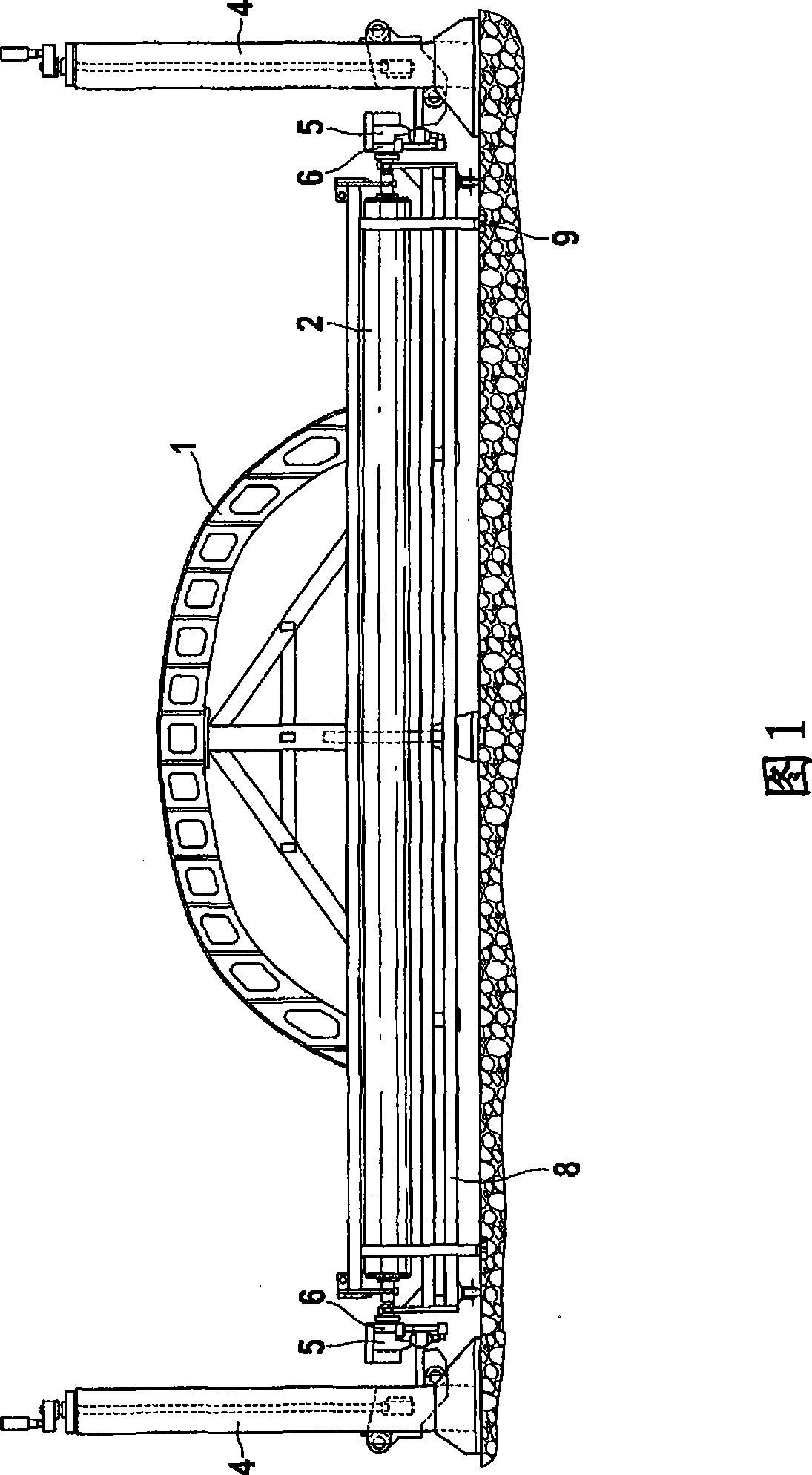

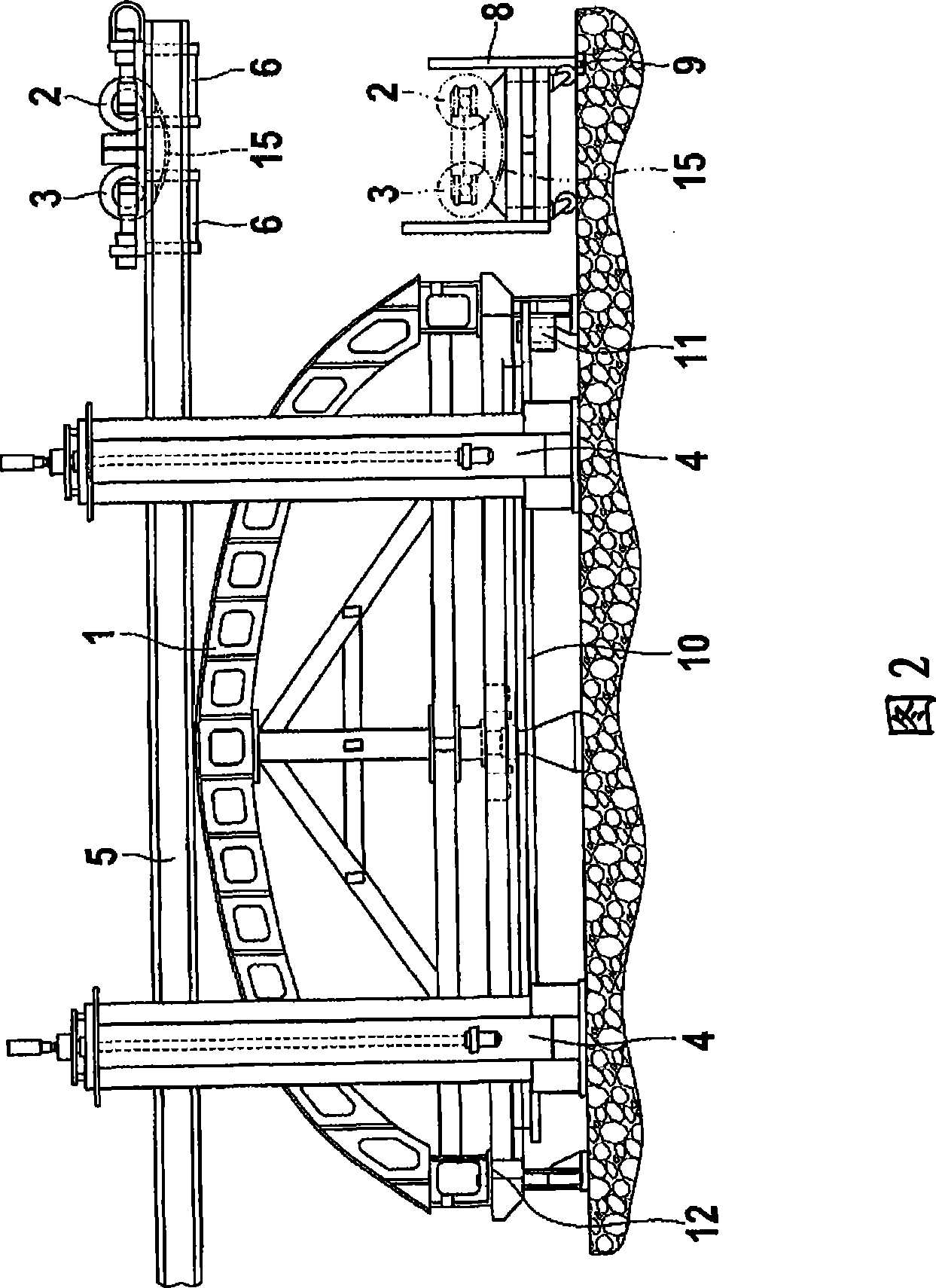

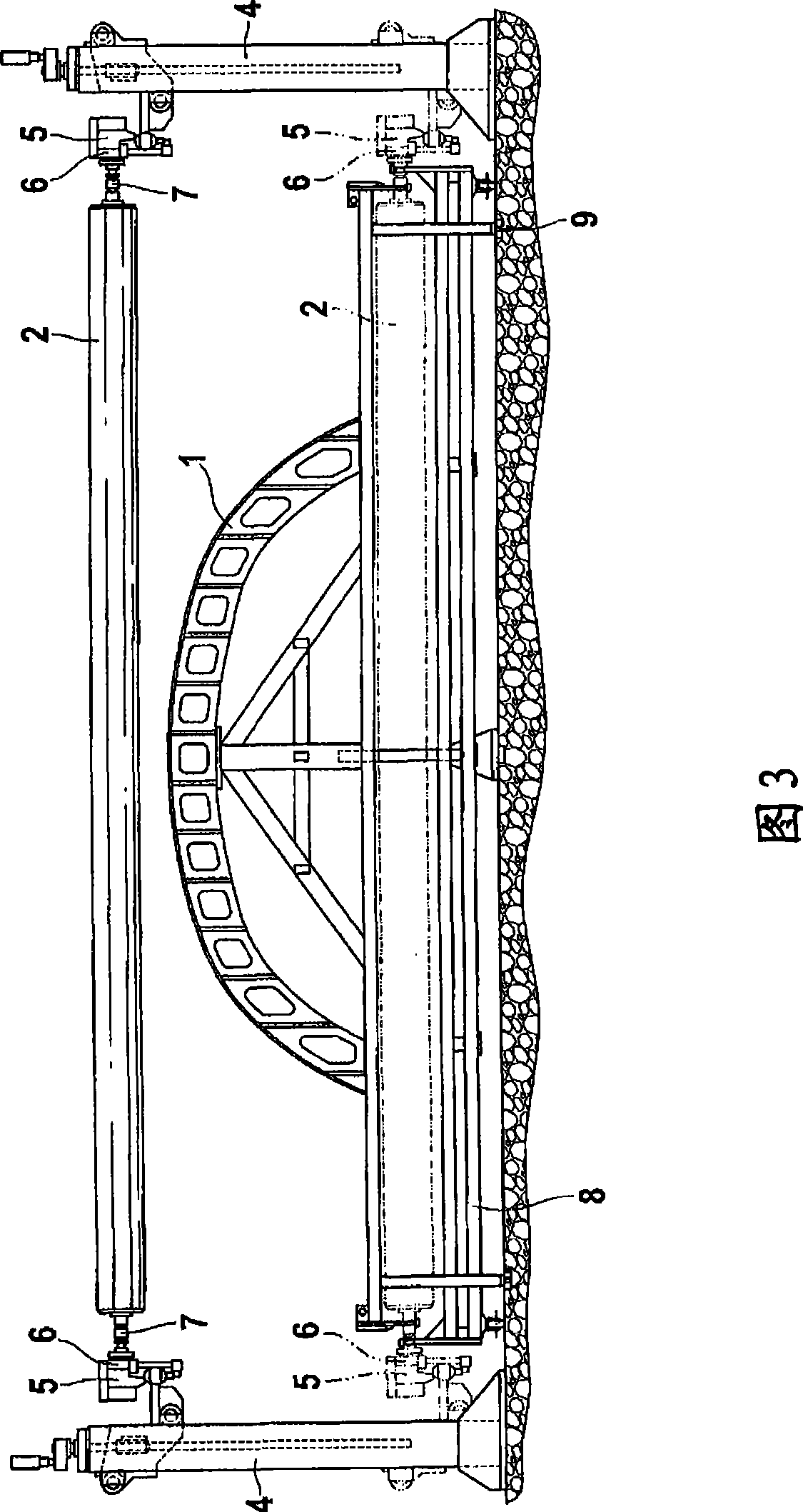

Apparatus and method for producing a large-area fibre-composite structural component

ActiveCN101426636AAvoid foldingAvoid rippleEfficient propulsion technologiesWeight reductionFiberAirplane

The present invention provides an apparatus and a method for producing a large-area fibre-composite structural component, in particular for the aircraft sector, comprising a predetermined shaping element (1) , a controllable laying device (4, 5, 6) for the defined laying of at least one fibrous sheet (15) over or into the predetermined shaping element (1) , a controllable turning device (10) for a defined turning of the predetermined shaping element (1) and of the laying device (4, 5, 6} in relation to each other by a predetermined turning angle, and a central control device, which is connected to the laying device (4, 5, 6) and the turning device (10) for controlling of the same.

Owner:AIRBUS OPERATIONS GMBH

A composite reinforced concrete hollow floor slab

A combined reinforced concrete hollow floor slab, comprising a prefabricated thin slab (1), formwork (2), concealed ribs (3), and an upper slab (4), the formwork (2) is fixed on the prefabricated thin slab (1), adjacent There are hidden ribs (3) between the prefabricated thin plates (1) or the formwork (2), and the upper plate (4) covers the formwork (2) and is connected with the hidden ribs (3) as a whole, which is characterized in that At least one of the prefabricated thin plate (1) or the formwork (2) is provided with a fixed positioning member (5), the prefabricated thin plate (1) is larger than the formwork (2) fixed thereon, and protrudes from the formwork (2) ) and are arranged close to each other to become a superimposed template of the hidden rib (3), and the reinforcement (6) in the prefabricated thin plate (1) extends into the inverted T-shaped cast-in-place concrete hidden rib (3) for anchoring. It is suitable for various hollow floors, roofs, walls, foundation slabs and hollow bridges of cast-in-place reinforced concrete or prestressed reinforced concrete.

Owner:湖南邱则有专利战略策划有限公司

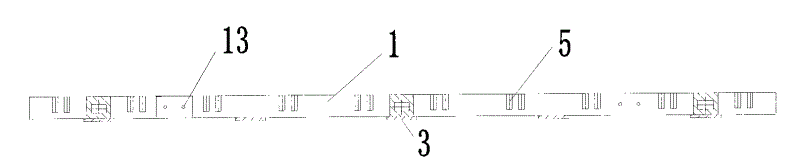

Longitudinal sleeper

ActiveCN104264535AReduce vibrationReduce rolling noiseBallastwayRail fastenersVibration attenuationUltrasound attenuation

The invention relates to a novel sleeper system in the field of railway tracks. The sleeper system comprises a longitudinal beam type sleeper and an elastic vibration attenuation rail system. The longitudinal beam type sleeper is formed by cascading longitudinal beam type sleeper units. Longitudinal beams of the longitudinal beam type sleeper are transversely and fixedly connected together through connecting pieces; the ends of the opposite longitudinal beams of the adjacent longitudinal beam type sleeper units are connected through sleeper connecting pieces. The elastic vibration attenuation rail system comprises a support; the longitudinal beam type sleeper is arranged on the support; a vibration attenuation facility is arranged between the bottom of the longitudinal beam type sleeper and the support; according to the longitudinal type sleeper, the bending rigidity of the rail is increased, and rail deformation caused by repeated loads is reduced; due to the fact that the longitudinal beams increase transverse resistance and irregularity of a perpendicular rail is reduced, the maintenance workloads are reduced. Due to the fact that connection of the continuous longitudinal beams is kept in the longitudinal direction, the phenomena that the rail settling volume of the ends of the longitudinal beams is too large, and consequently the longitudinal beams are prone to being damaged are avoided. Rail pads are continuously arranged, and therefore foundation vibration, rolling noise and rail wavy deformation are reduced.

Owner:BEIJING ZHIYI PUDAO TECH CO LTD

Mechanical equipment for laying optical cable on ground

InactiveCN105891996AAccurate avoidIntelligent avoidanceOptical fibre/cable installationInductorMechanical equipment

The invention provides mechanical equipment for laying an optical cable on the ground. The mechanical equipment comprises an inductor, a coulter, an optical cable bracket, a soil combiner and a soil compactor, wherein the inductor is used for inducting barriers on the front ground in the laying process to realize barrier-free laying; a wire guide hole is formed in the back of the coulter, the optical cable is threaded through the wire guide hole, the laying is realized while digging, and the accuracy of the laying position is guaranteed; and moreover, the mechanical equipment provided by the invention avoid the barriers more intelligently, the digging-laying integrated technology of once ditching, cable laying and backfill construction operation is realized, the ditching width is small, the laying positions of the optical cable are uniform and accurate, the laying speed and quality are high, the time and labor force are saved, and the application value is relatively high.

Owner:ANHUI TELECOMM ENG

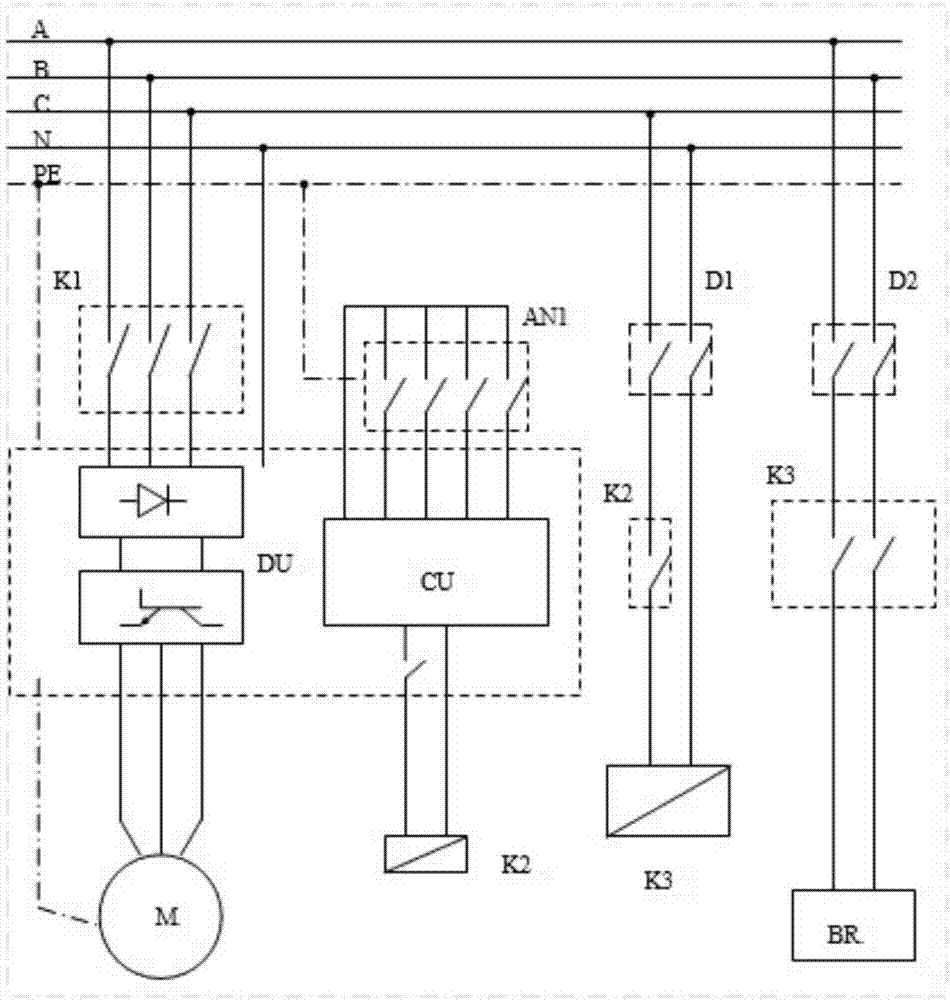

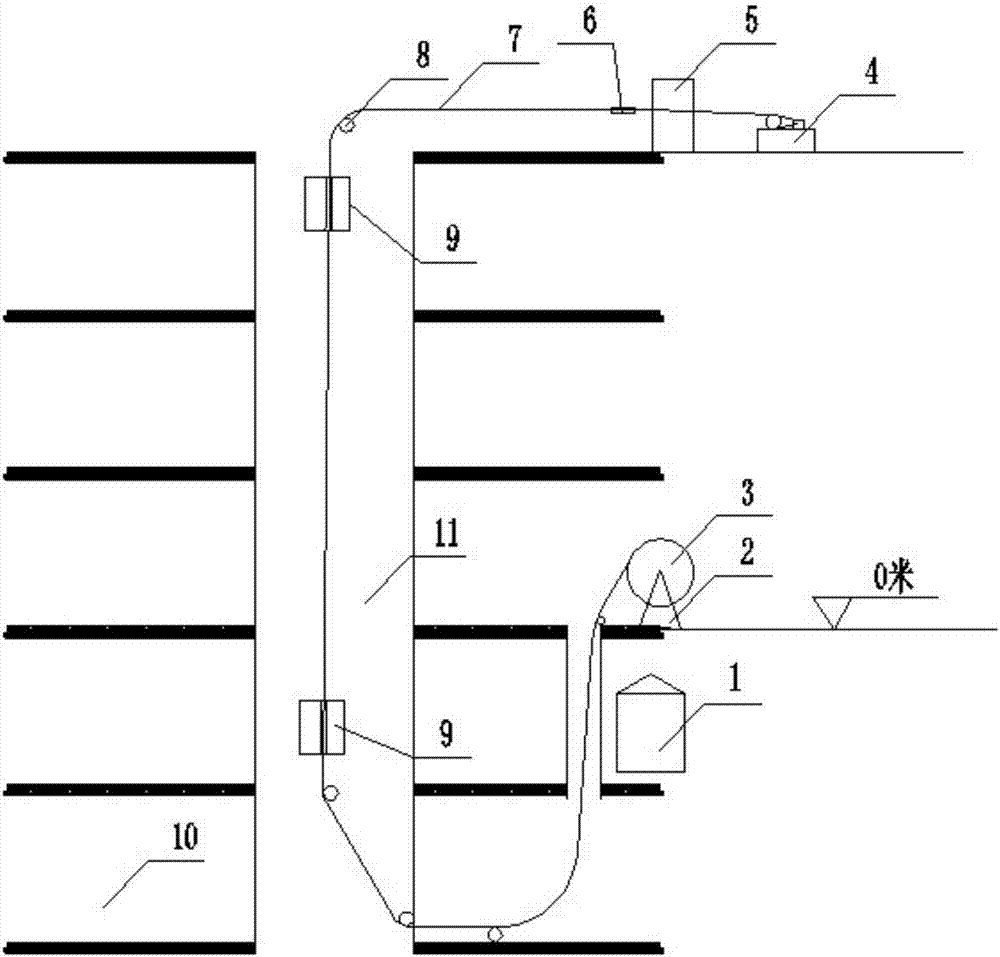

High-rise residential building cable laying control system and method

PendingCN107394682ASimple structureEasy to operateApparatus for laying cablesFrequency changerElectricity

The invention provides a high-rise residential building cable laying control system and a high-rise residential building cable laying control method. The high-rise residential building cable laying control system comprises a control unit, a power unit and an auxiliary unit. The control unit is electrically connected with the power unit. The power unit and the auxiliary unit are connected by means of a cable. The control unit comprises a frequency converter and a button box. The power unit comprises a hoisting machine and a brake. The frequency converter is electrically connected with the hoisting machine, the frequency converter is electrically connected with the button box, and the hoisting machine is electrically connected with the brake. The high-rise residential building cable laying control system and the high-rise residential building cable laying control method have the beneficial effects that: the frequency converter is connected with the hoisting machine, so that the whole high-rise residential building cable laying system is simple in structure and convenient in operation; the frequency conversion technology is combined with a high-rise residential building cable laying method, the unique frequency conversion technology is utilized, the frequency conversion technology is combined with a low-speed hoisting and traction cable laying method, the cable laying speed is accelerated, and the cable laying quality is guaranteed; and the automation level is high, the labor cost is saved and the working efficiency is improved.

Owner:TIANJIN 20 CONSTR

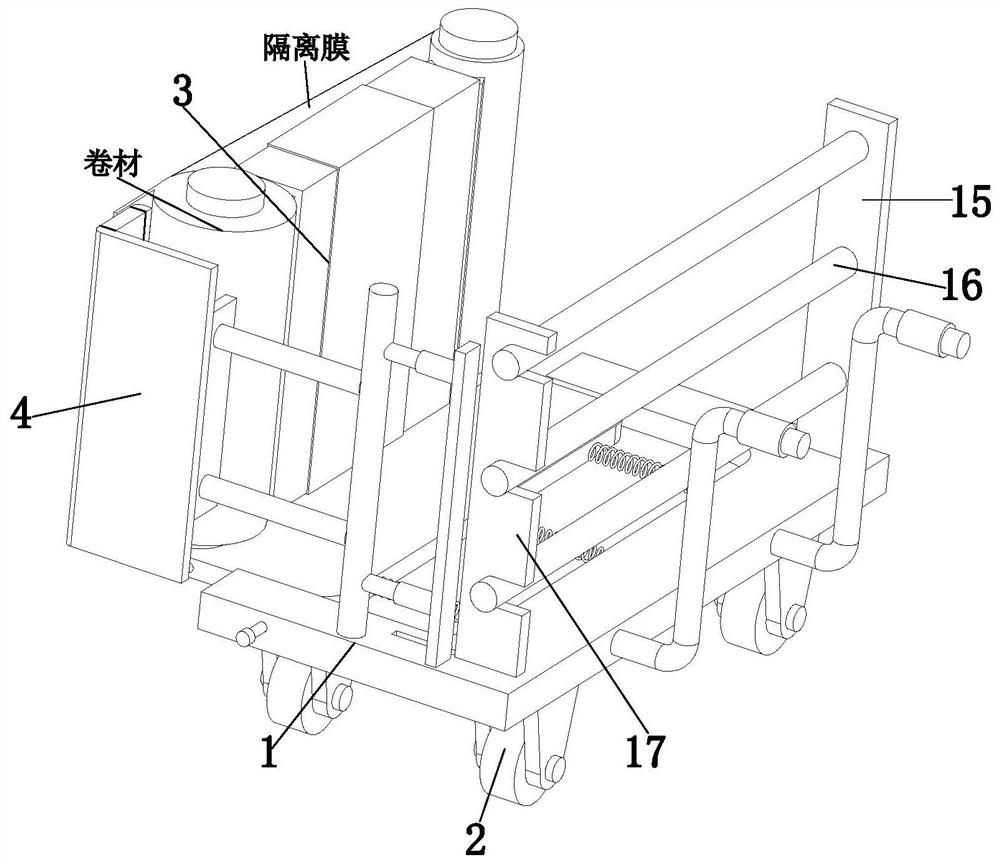

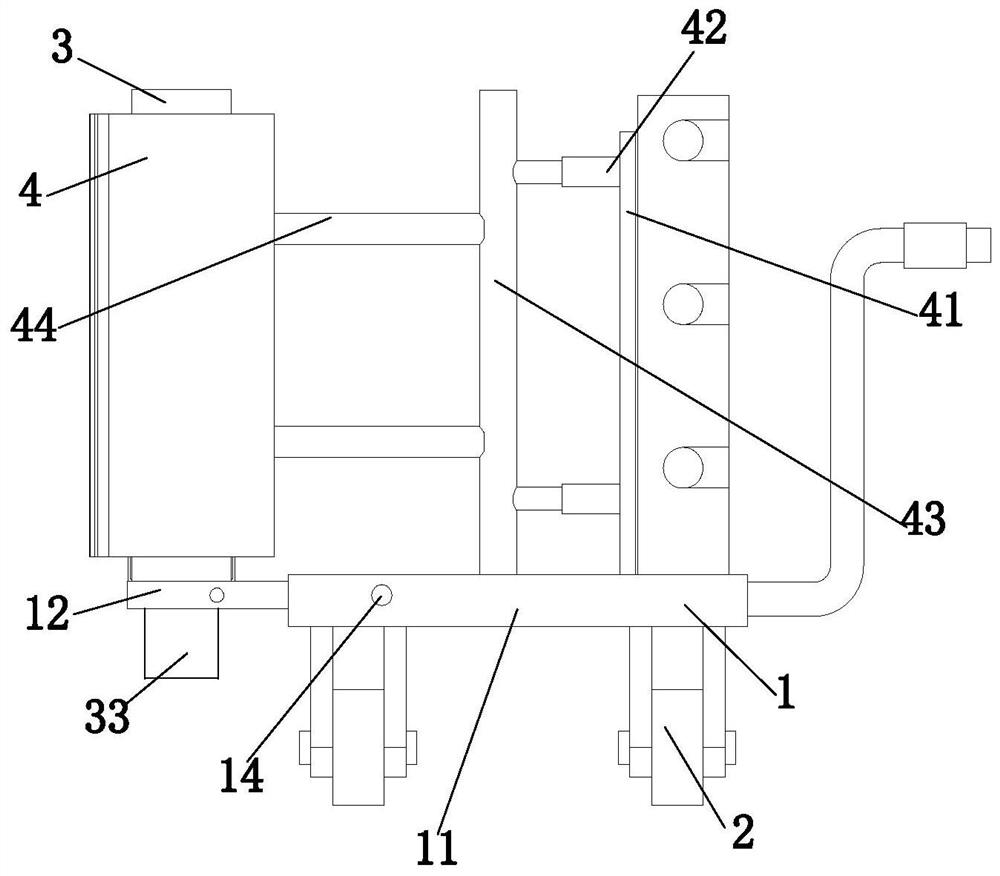

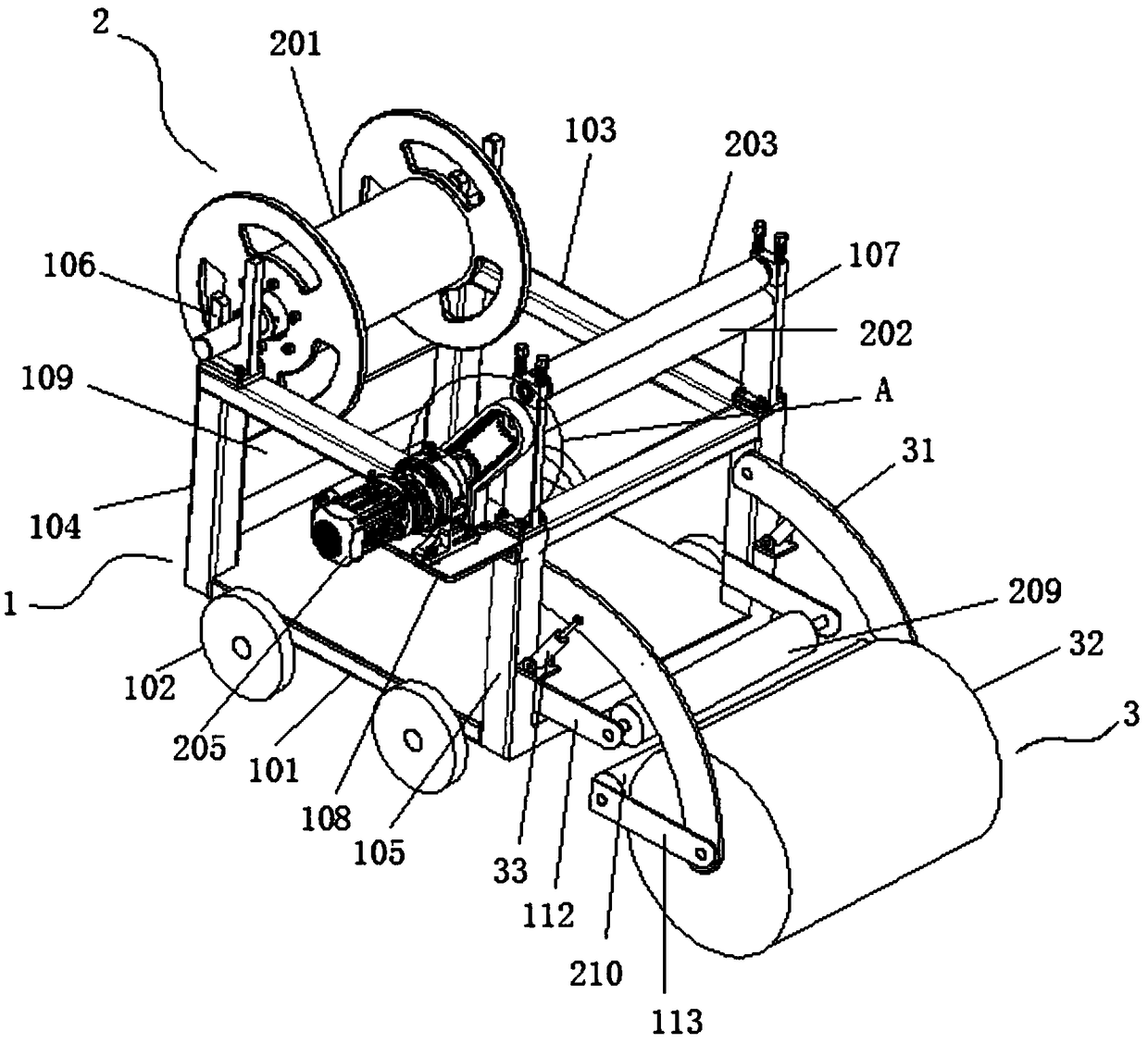

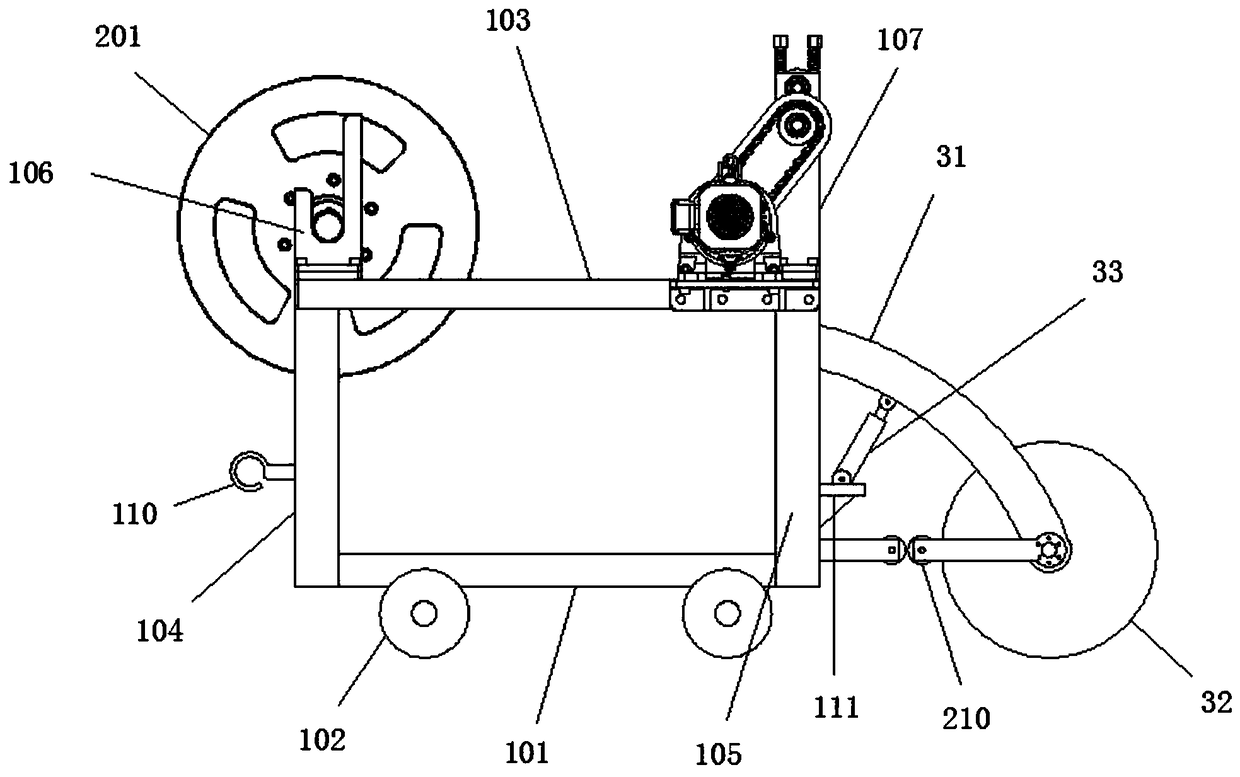

Compressing device for geogrid and working method thereof

The invention discloses a compressing device for a geogrid and a working method thereof. The compressing device comprises a supporting assembly, a discharging assembly connected to the supporting assembly, and a compressing assembly used for compressing the geogrid; the supporting assembly comprises a supporting base, a frame, a first supporting rod and a second supporting rod; the discharging assembly comprises a discharging winding drum, a driving traction roller and a driven traction roller; and the compressing assembly comprises two curved connecting arms and a compressing roller arrangedbetween the two curved connecting arms. According to the compressing device, the curved connecting arms are lowered by starting an air cylinder so as to drive the compressing roller to descend to compact the geogrid, moving is conducted in the mode of traction of a motor vehicle, it is ensured that the laid geogrid is compressed by the compressing roller while the discharging winding drum conductscontinuous discharging, the laying speed is high, the working efficiency is high, meanwhile, the geogrid is closely laid on the ground, and thus the engineering quality is ensured; and the compressing device is simple in structure and convenient to operate, meets the use requirements of people, and is worth popularizing energetically.

Owner:ANHUI HUIFENG NEW SYNTHETIC MATERIALS CO LTD

Device for compacting and snipping resin-based composite prepreg spread layer

The invention provides a device for compacting and snipping a resin-based composite prepreg spread layer, and belongs to the technical field of forming and processing composite materials. The device comprises a supporting and shell mechanism, and a compacting mechanism, a heating mechanism and a snipping mechanism which are arranged in the supporting and shell mechanism; the compacting mechanism comprises a first roller and a second roller; the heating mechanism is arranged in the first roller and the second roller; the snipping mechanism comprises a pressing shim plate, a transmission mechanism of a circular saw and a circular saw blade; a circular saw blade dust absorption mechanism is also arranged in the supporting and shell mechanism; and the circular saw blade dust absorption mechanism is connected with a vacuum filter and a pipeline mechanism. The device can solve the problem that the prepreg cannot be completely attached to a mould due to different softening degrees of the prepreg when single small-size composite members are spread and the problems about spreading and snipping of a curvature radius area. Therefore, the vacuumizing time of the prepreg is greatly reduced, the production efficiency of the composite members is improved, and the production cost is reduced.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Support, paving method for ground stone and cement mortar stirring and conveying all-in-one machine

The invention relates to a support, in particular to a support for ground stone paving. The invention further relates to a paving method for ground stone and a cement mortar stirring and conveying all-in-one machine. The support is mainly and technically characterized by comprising a supporting piece with the adjustable height. The paving method for the ground stone is mainly and technically characterized in that the ground stone is arranged on a building floor through the support, and then cement mortar is injected to the position between the ground stone and the support. The cement mortar stirring and conveying all-in-one machine is mainly and technically characterized by comprising a cement mortar stirring machine, a cement mortar storage tank, an air compressor, a cement mortar conveying pipeline and a spraying head. According to the support, the paving method for the ground stone and the cement mortar stirring and conveying all-in-one machine, the technical problems that in the prior art, the paving method for the ground stone consumes time and wastes labor, and the paved flatness is poor are solved.

Owner:陈友坤

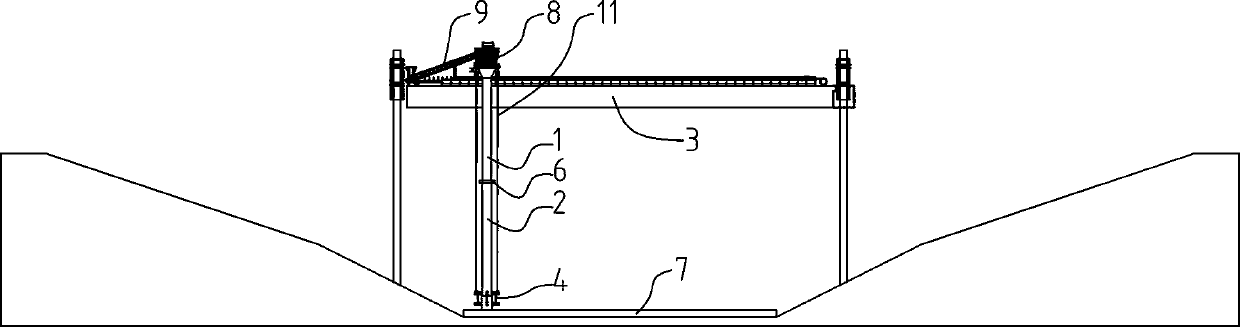

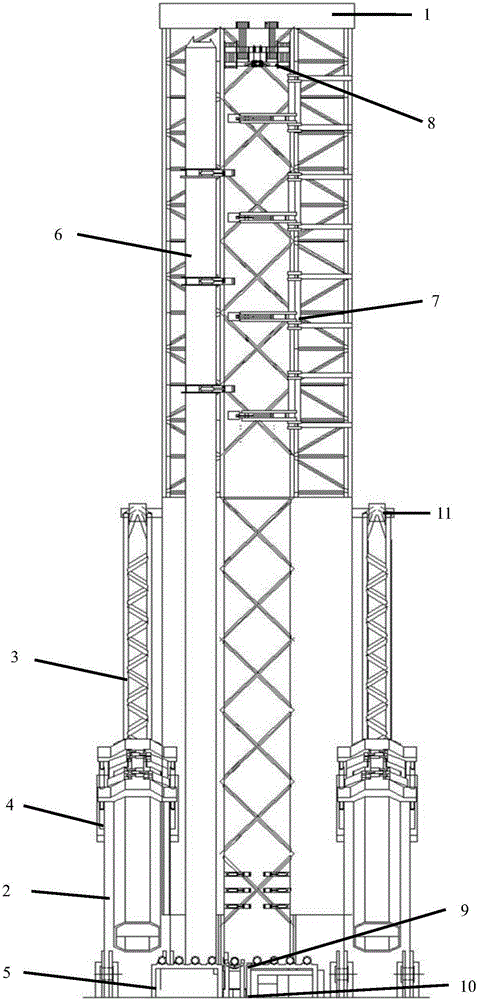

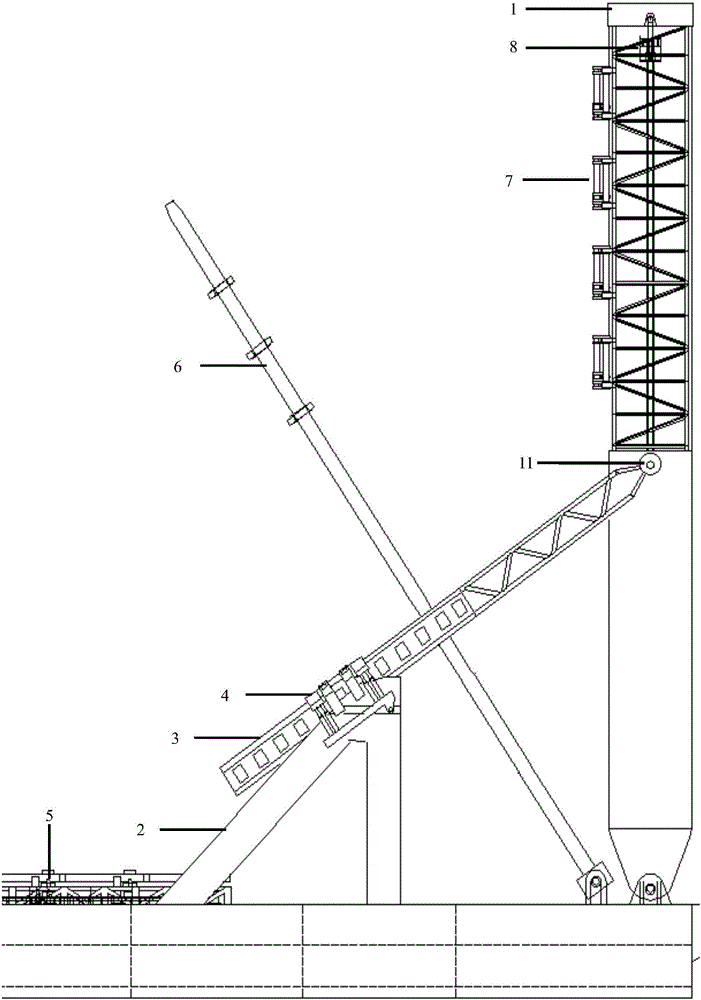

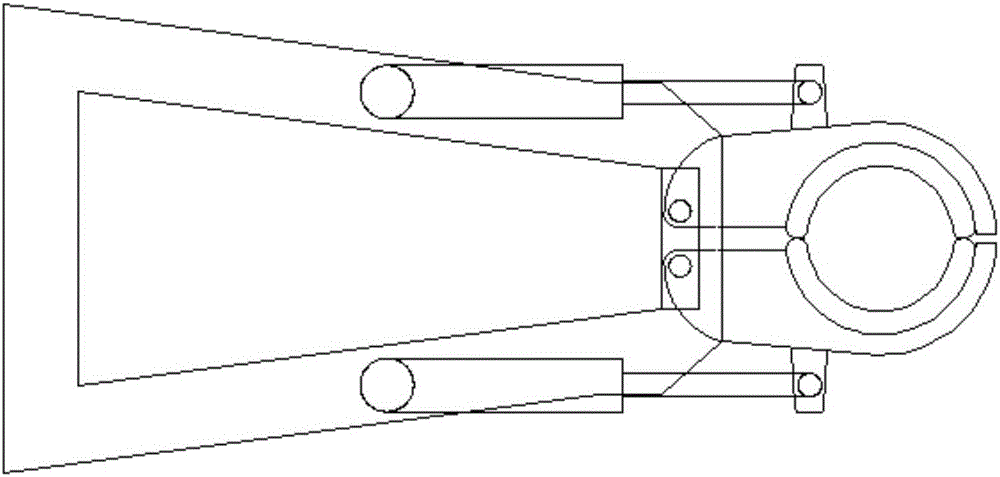

Deep-water quick J-type laying system

ActiveCN105757340ALaying speed is fastImprove efficiencyPipe laying and repairHydraulic cylinderLoading arm

The invention provides a deep-water quick J-type laying system, comprising a laying column, a laying column angle adjusting system, a J-type laying segment conveying system, and J-type laying related equipment. The laying column angle adjusting system mainly comprises an A-shaped frame, an angle adjuster and a hydraulic cylinder, the J-type laying segment conveying system comprises a horizontal conveying system, a loading arm, a rotating arm and an elevator; the J-type laying related equipment generally comprises a centering unit, a welding station and a moving platform. It is possible to provide a 1*4 node (one 4-node segment is laid on the laying tower, and each 4-node segment is 48.8 m in length) laying mode at the premise of controlled height of the laying tower, and by optimizing equipment structure and layout, the laying speed is 80.2% higher than typical J-lay speed of 1.5 km / d and laying cost is reduced.

Owner:哈尔滨航沣科技开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com