Numerical control paver for glass steel grid fiber

A glass fiber reinforced plastic and grid technology, which is applied in the field of CNC automatic fiber laying devices, can solve the problems of uneven product quality, low efficiency of glass fiber reinforced plastic grid, high labor cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

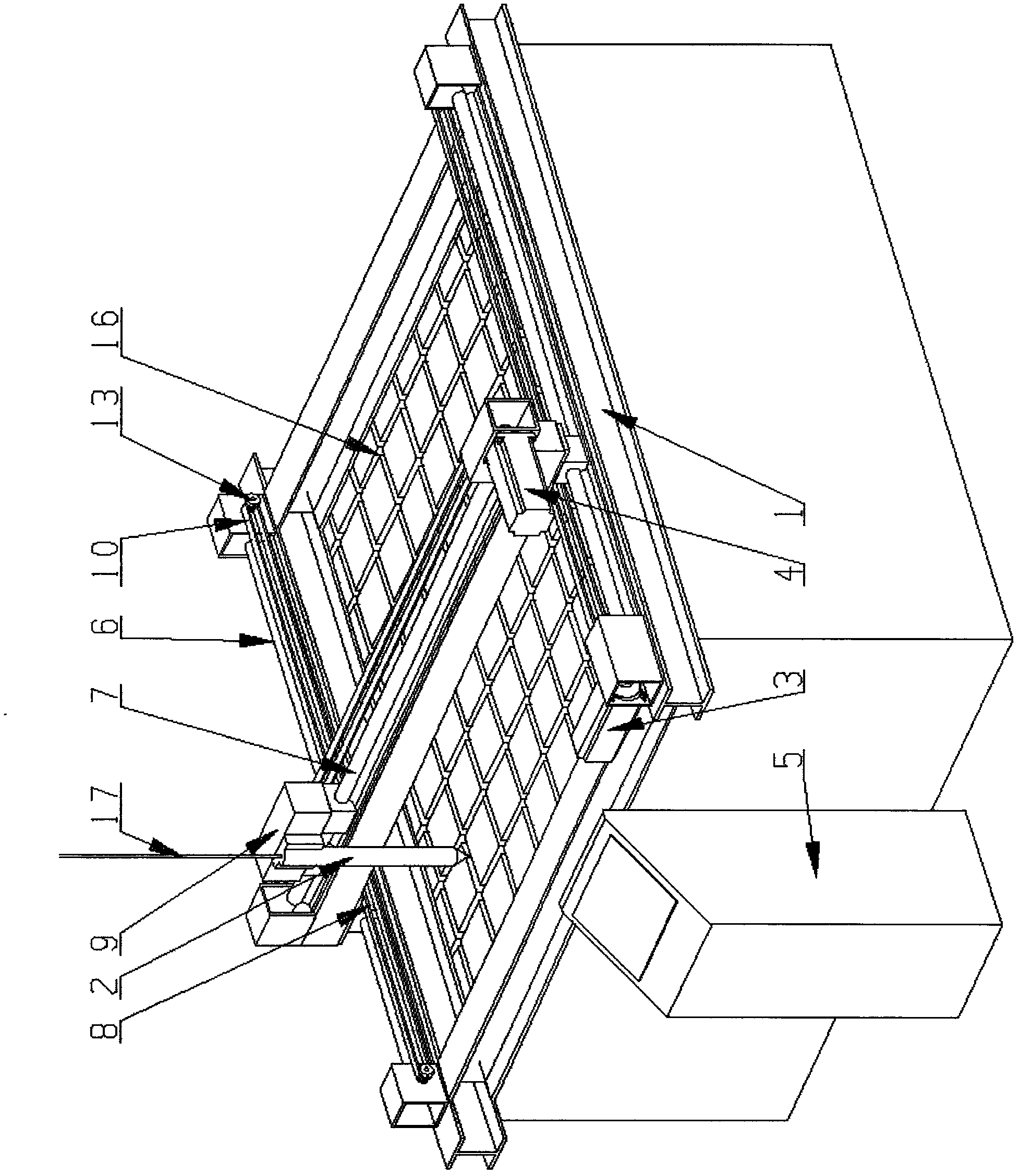

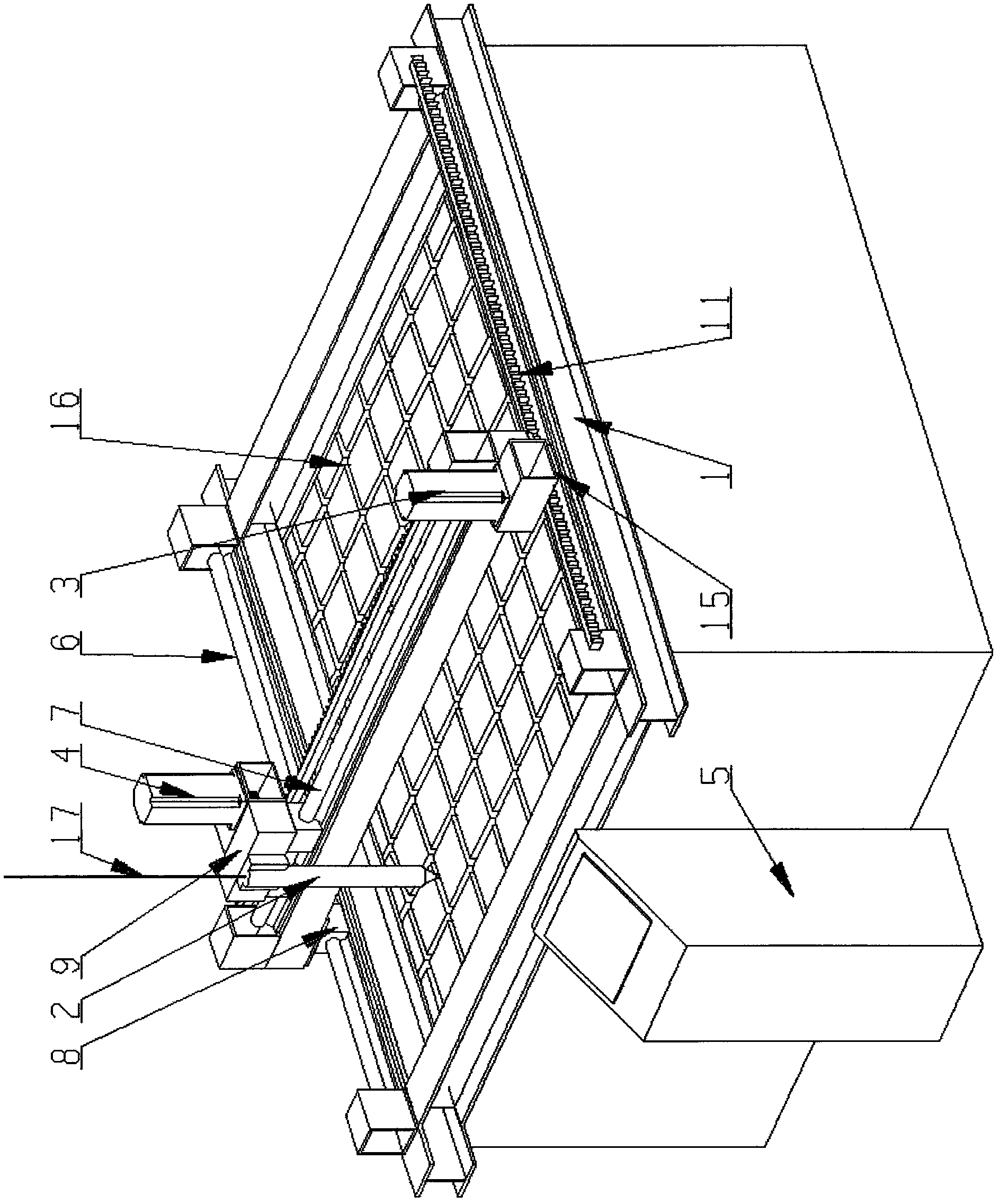

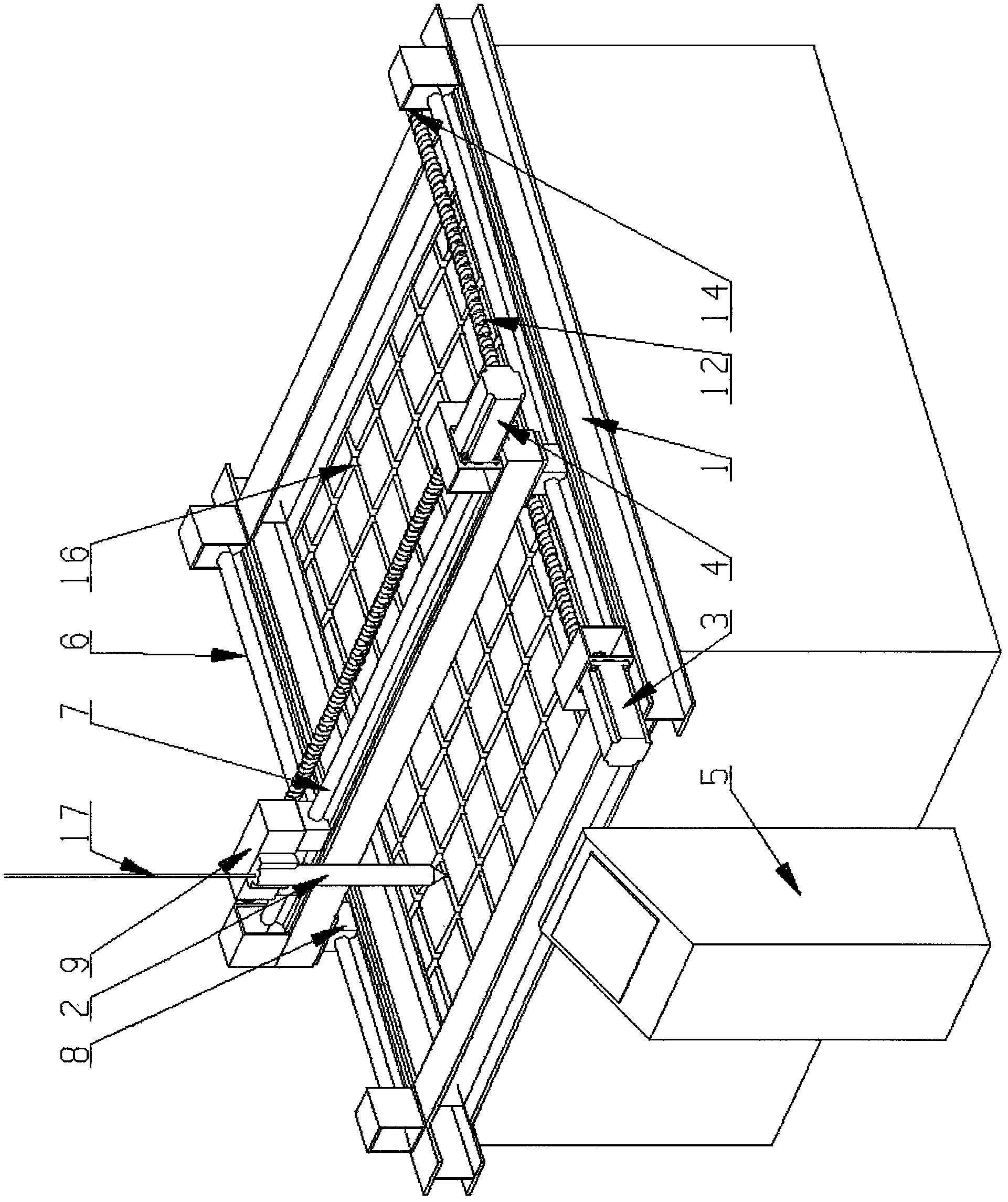

[0007] See attached figure 1 , 2 , 3. The present invention includes a main body frame (1), a fiber conduit (2), a high-speed servo motor (3) (4) and a special numerical control system (5). The main frame includes a Y-axis composed of two parallel guide rails (6) and an X-axis composed of a gantry-type guide rail (7) perpendicular to the Y-axis. Both ends of the X-axis use sliders (8) and Y-axis guide rails (6) ) are connected vertically. Another trolley (9) can slide along the axis on the X axis, and fiber conduit (2) is housed on it. There is a set of transmission systems on the Y axis and the X axis respectively, and a synchronous belt (10), a rack and pinion (11) or a screw mandrel (12) can be used according to the difference of fiber tension requirements. When using synchronous belt or screw drive, install a high-speed servo motor (3) at one end of the Y axis, and install a fixed synchronous wheel (13) or screw bearing (14) at the other end, and fix the opening of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com