Device for compacting and snipping resin-based composite prepreg spread layer

A technology of composite materials and prepregs, which is applied in the field of composite material molding and processing, can solve the problems of reducing the quality of composite material component layup, uncontrollable temperature of electric irons, and low cutting efficiency of ordinary scissors, so as to reduce vacuuming of layup time, increase speed, reduce dust and fiber effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

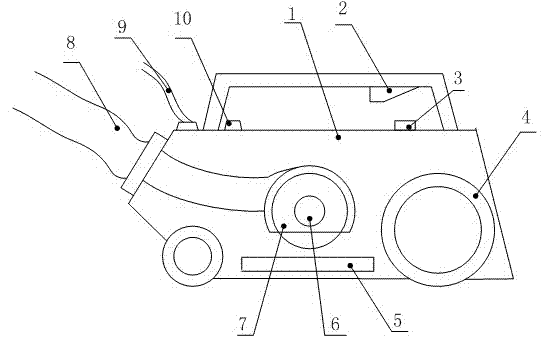

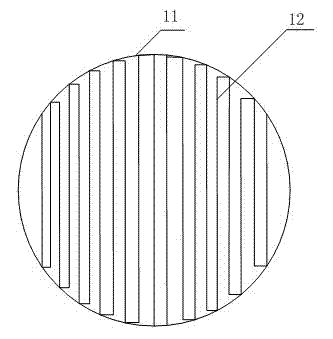

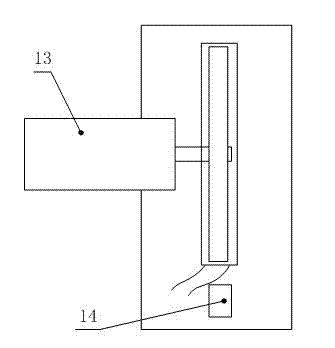

[0023] like figure 1 , figure 2 and image 3 As shown, a device for compacting and notching resin-based composite material prepreg layup of the present invention includes: the support and shell mechanism 1 of the device and the compaction mechanism, heating mechanism and heating mechanism arranged in the support and shell mechanism 1. The notch mechanism, wherein the compacting mechanism includes the first large roller 26 and the second small roller 27, the outer rings of the large roller 26 and the small roller 27 are heat-resistant rubber 4, and the resistance wire heating of the heating mechanism is arranged in the heat-resistant rubber 4 The device 12, the resistance wire heater 12 is arranged in the first large roller 26 and the second small roller 27, the notch mechanism includes the pressing backing plate 5, the transmission mechanism 6 of the circular saw and the circular saw blade 7, wherein the circular The saw blade 7 is arranged between the first large roller a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com