Deep-water quick J-type laying system

A fast, deep-water technology, applied in pipeline laying and maintenance, mechanical equipment, pipes/pipe joints/fittings, etc., can solve the problems of high riser installation cost, unsynchronized process, low laying efficiency, etc., to reduce weight, The effect of accelerating the laying efficiency and improving the laying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

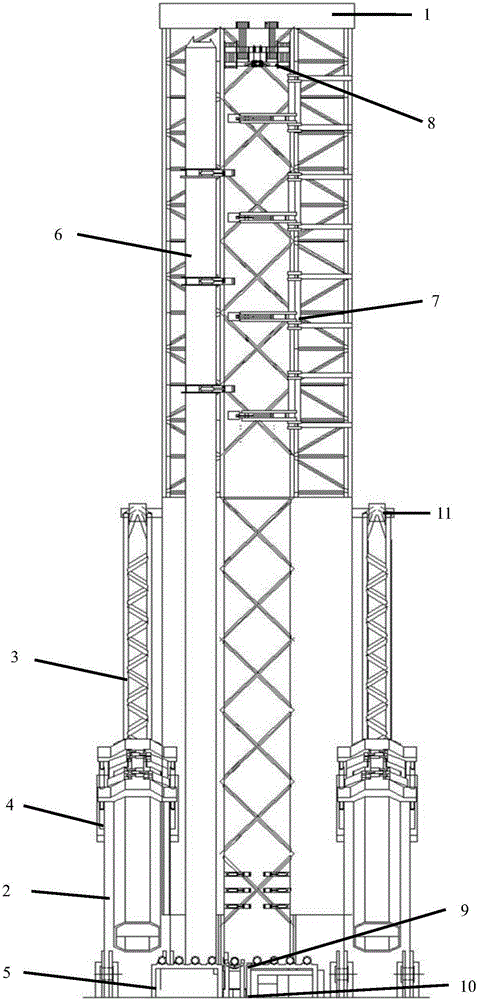

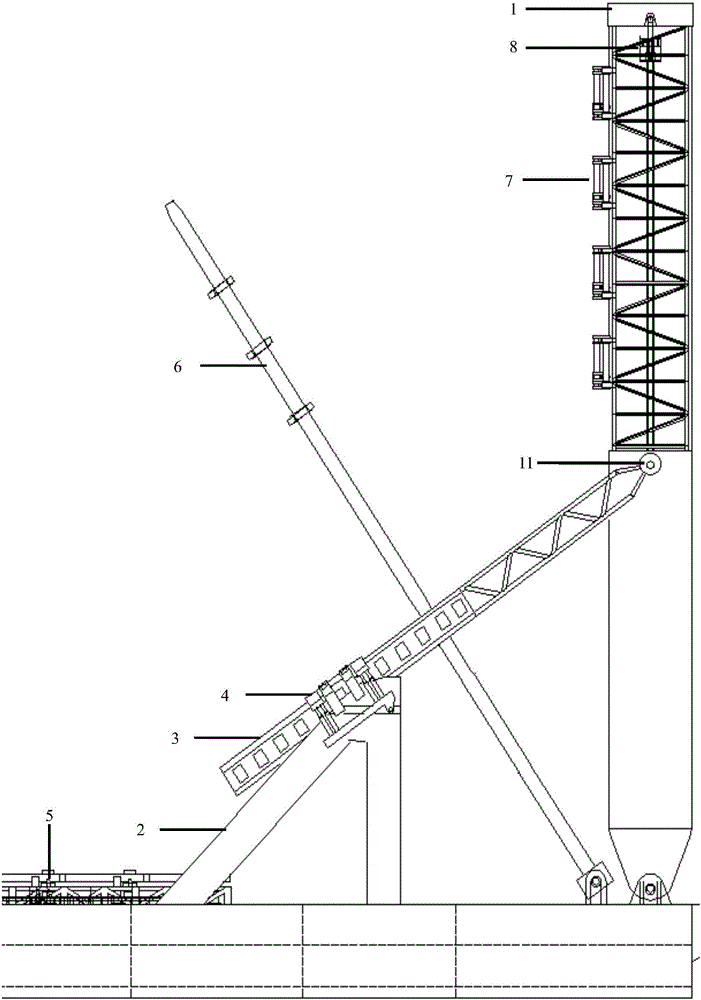

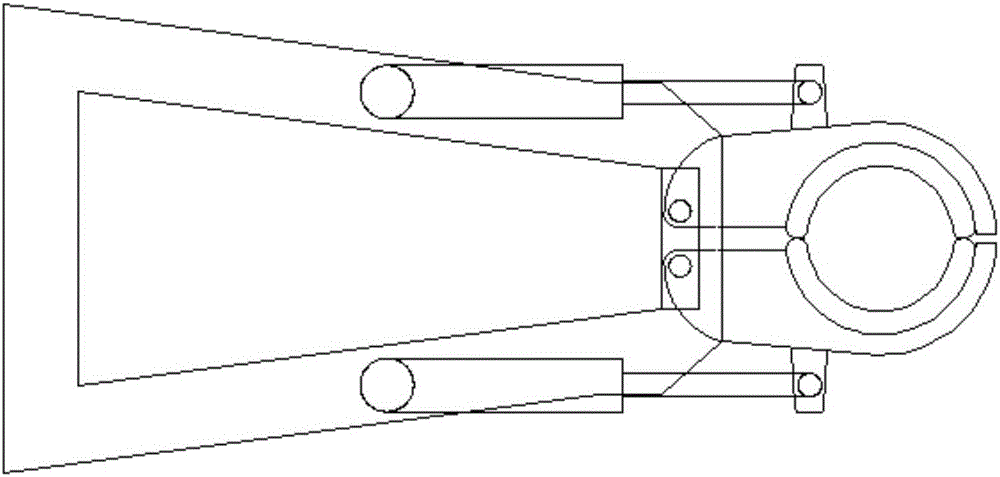

[0028] combine Figure 1 to Figure 11, the J-type laying system mainly includes laying tower 1, A frame 2, angle regulator 3, hydraulic cylinder 4, flat transmission system 5, loading arm 6, rotating arm 7, hoist 8, welding station 9, mobile platform 10 , Angle adjuster connecting shaft 11, rotating arm clip 12, No. 1 rotating arm hydraulic cylinder 13, No. 2 rotating arm hydraulic cylinder 14, support plate 15, No. 1 connecting shaft 16, No. 2 connecting shaft 17, No. 1 connecting plate 18. No. 2 connecting plate 19, No. 3 connecting plate 20, No. 4 connecting plate 21, upper fixing plate 22, lower fixing plate 23, hoist lug 24, shaping clamping claw 25, hoist hydraulic press 26, pipe collar 27 , steel channel 28.

[0029] The main function of the laying tower 1 in this system is to fix and support J-shaped laying related equipment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com