Patents

Literature

39 results about "Ground stone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In archaeology, ground stone is a category of stone tool formed by the grinding of a coarse-grained tool stone, either purposely or incidentally. Ground stone tools are usually made of basalt, rhyolite, granite, or other cryptocrystalline and igneous stones whose coarse structure makes them ideal for grinding other materials, including plants and other stones.

Original ecological stone-stacking cultivation method for dendrobium stem

InactiveCN103392580ASolve the Threat PuzzleEasy to operateCultivating equipmentsSoilless cultivationGround stoneWeed

An original ecological stone-stacking cultivation method for dendrobium stem comprises the following steps of: stacking stones, preparing before cultivating, performing stone-stacking cultivation, performing field management and harvesting. The method is convenient for production operation and management; grasses easily grow and are difficultly removed in a flat-ground stone-blocking cultivation method, while the difficult problem of a threat of weeds to dendrobium is radically solved by the stone-stacking cultivation method; the land space and the sunlight are fully utilized, the single yield is increased by about 4 times, the single yield is 614.2kg during the conventional cultivation rich phase, and the single yield is 1534kg during the stone-stacking cultivation rich phase.

Owner:COMPREHENSIVE OPERATION COMPANY CHISHUI CITY SUPPLY & MARKETING COOP

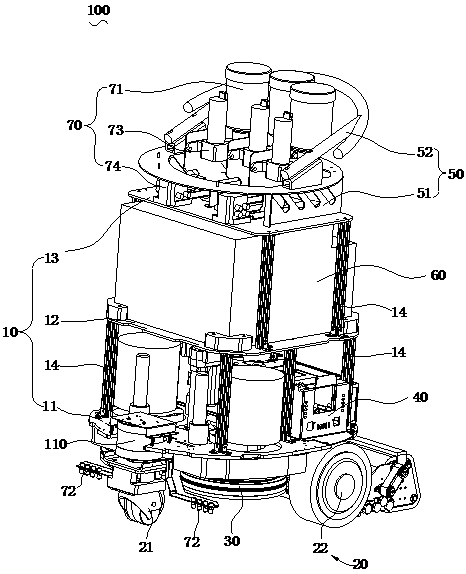

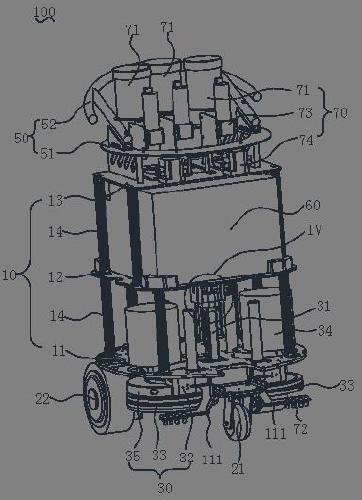

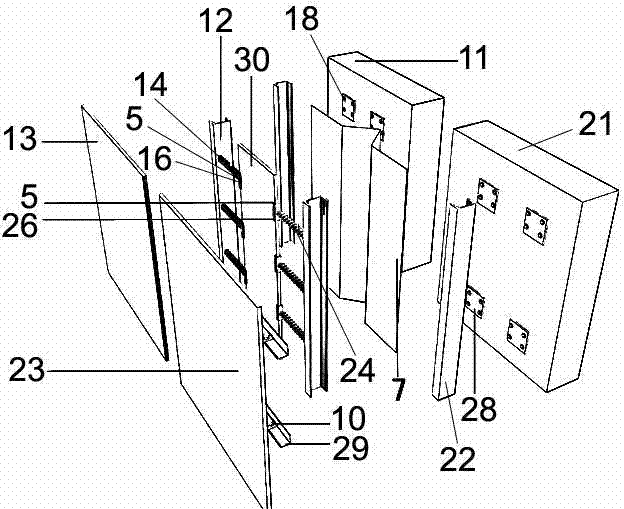

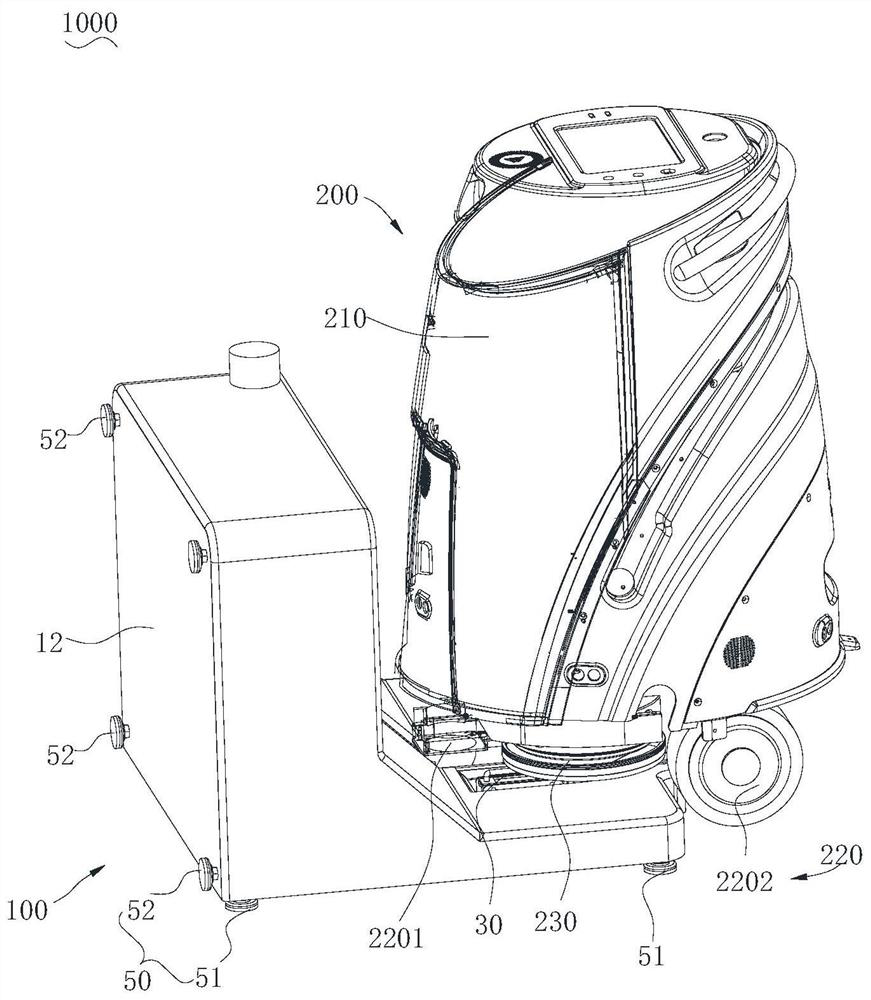

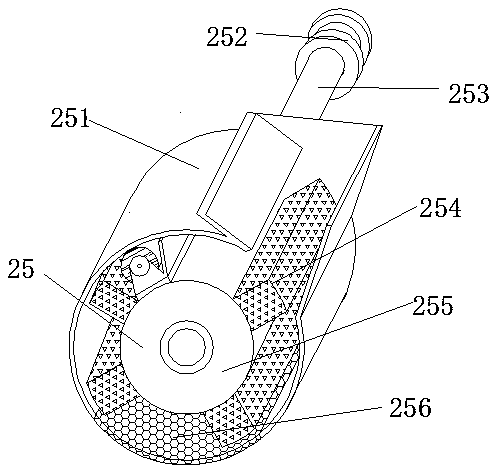

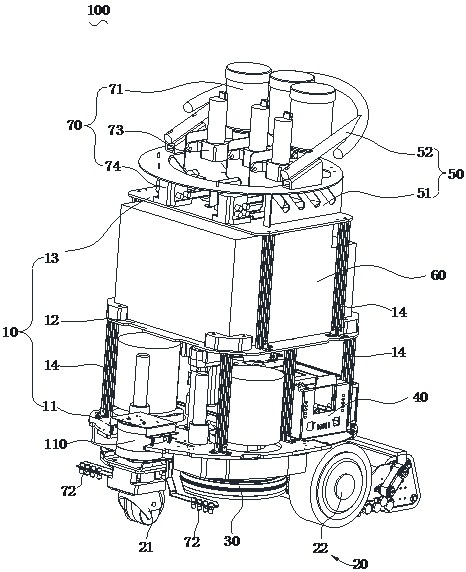

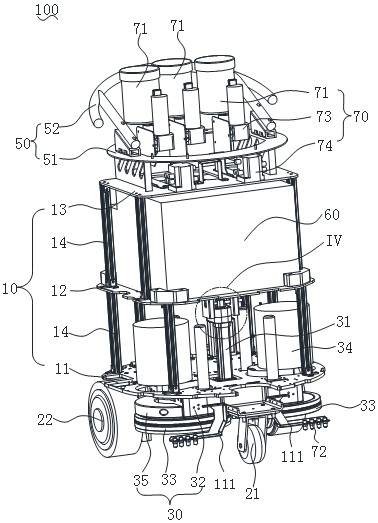

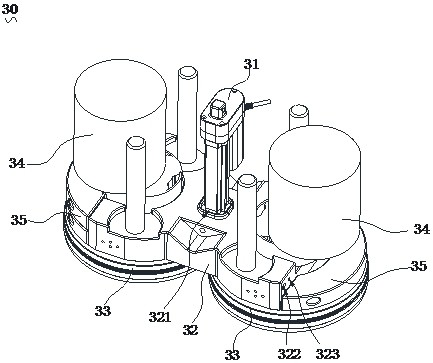

Cleaning robot for stone care

ActiveCN111345733AEasy to adaptAvoid destructionAutomatic obstacle detectionTravelling automatic controlPolishingEngineering

The invention discloses a cleaning robot for stone care. The cleaning robot for stone care comprises a body support, a moving assembly, a polishing assembly and a control module. The moving assembly is installed on the side, close to the ground, of the body support. The cleaning robot for stone care moves through the moving assembly. The polishing assembly is movably arranged on the side, close tothe ground, of the body support, the polishing assembly and the moving assembly are arranged in a spaced mode and used for caring ground stone, and the control module is electrically connected with the polishing assembly and the moving assembly and used for controlling the cleaning robot for stone care to automatically work under unmanned control. According to the cleaning robot for stone care, the control module is electrically connected with the polishing assembly and the moving assembly, so that the moving assembly is controlled to move, the polishing assembly is controlled to polish ground stone, and the cleaning robot for stone care automatically executes a ground stone care task without manual operation.

Owner:苏州高之仙自动化科技有限公司

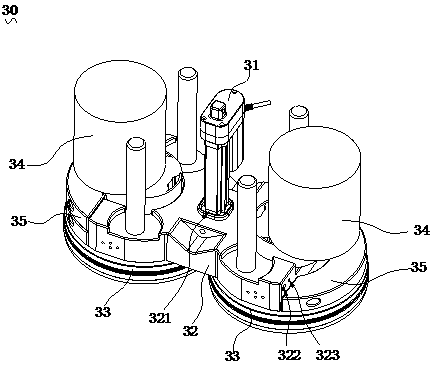

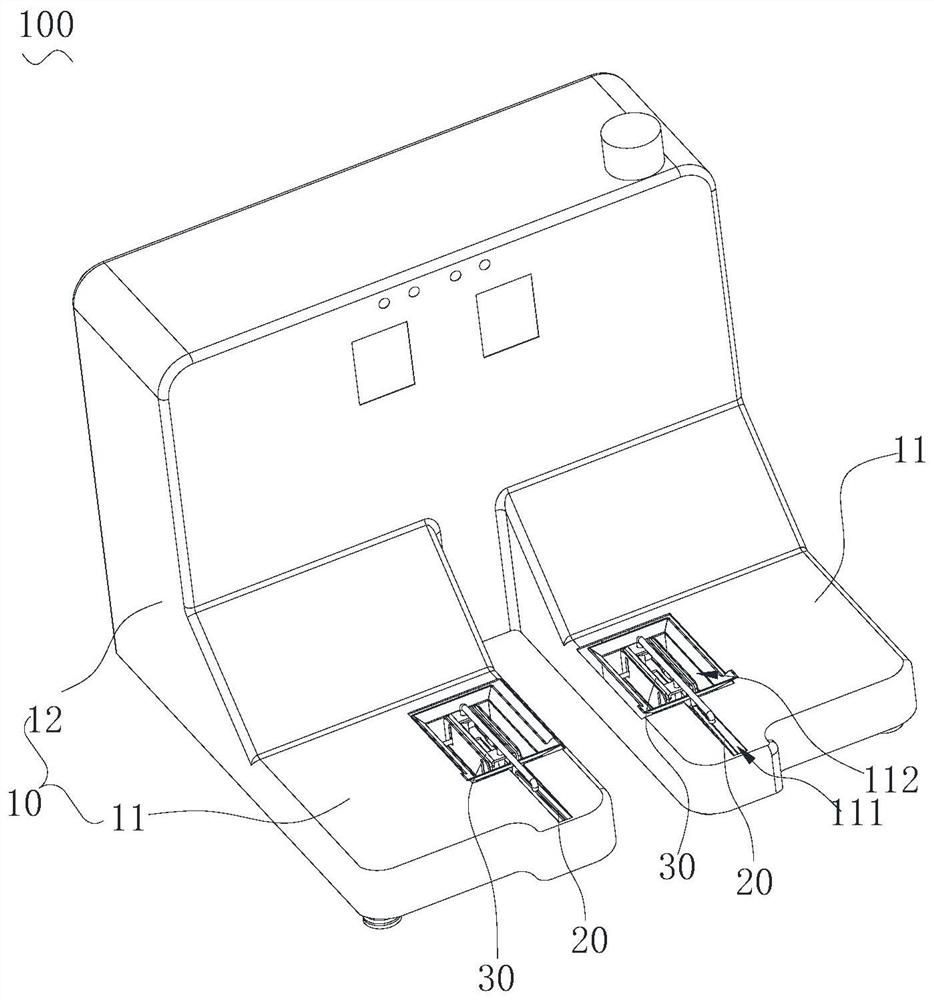

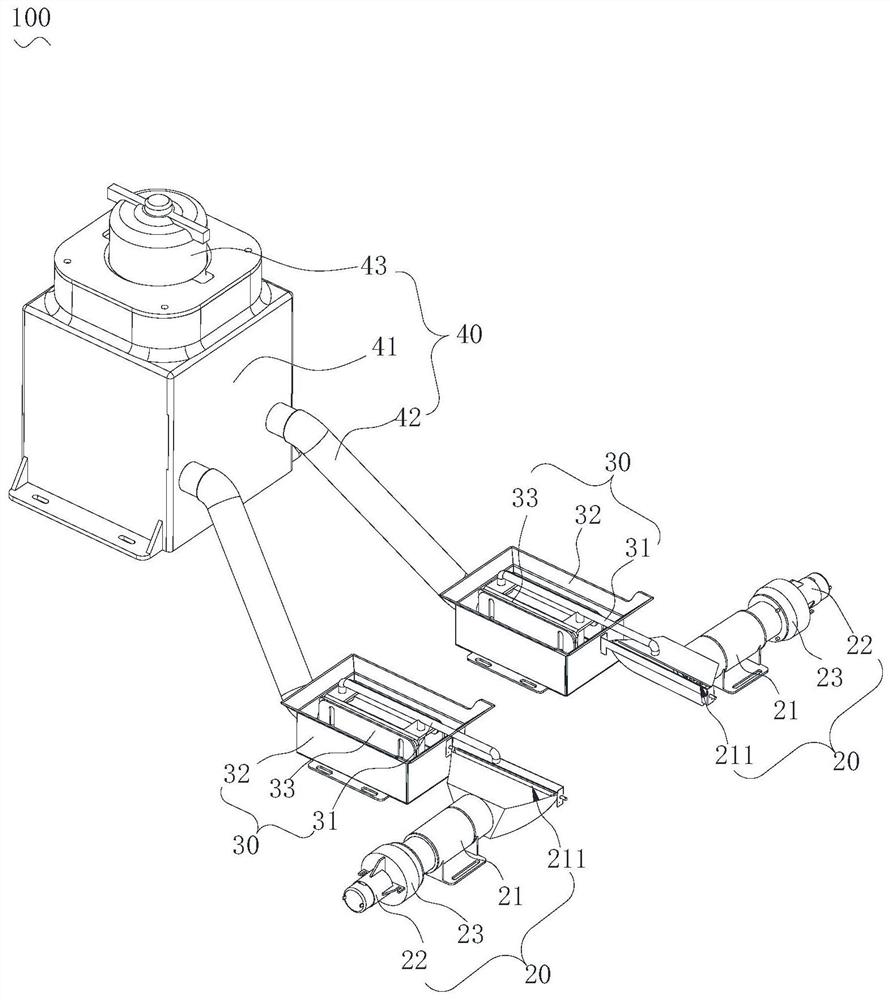

Pad replacing device, ground stone nursing machine and pad replacing method

Owner:苏州高之仙自动化科技有限公司 +1

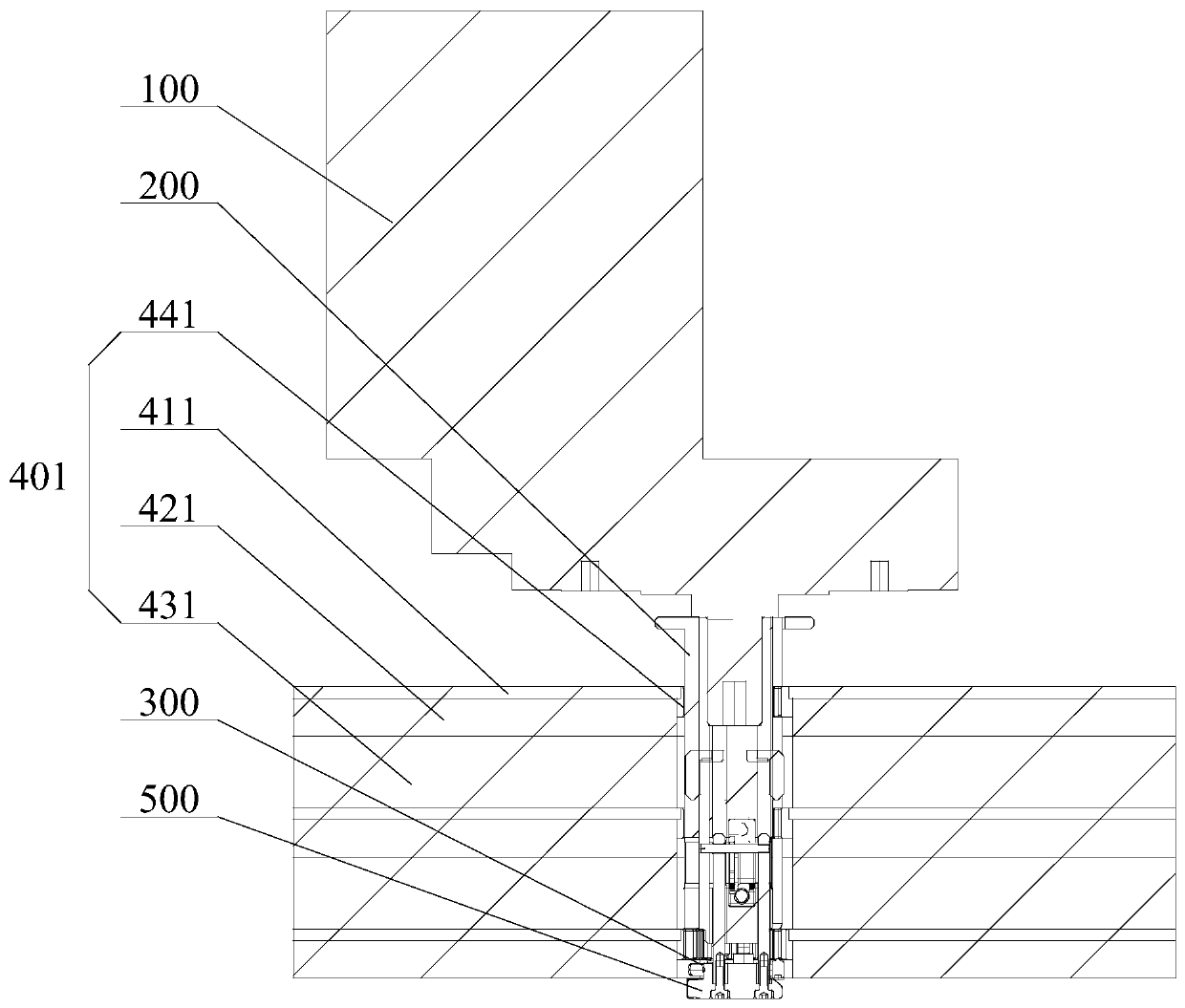

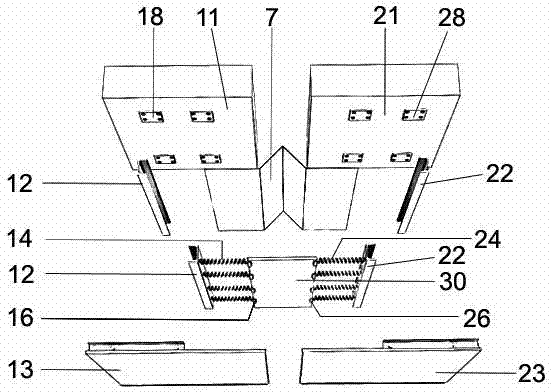

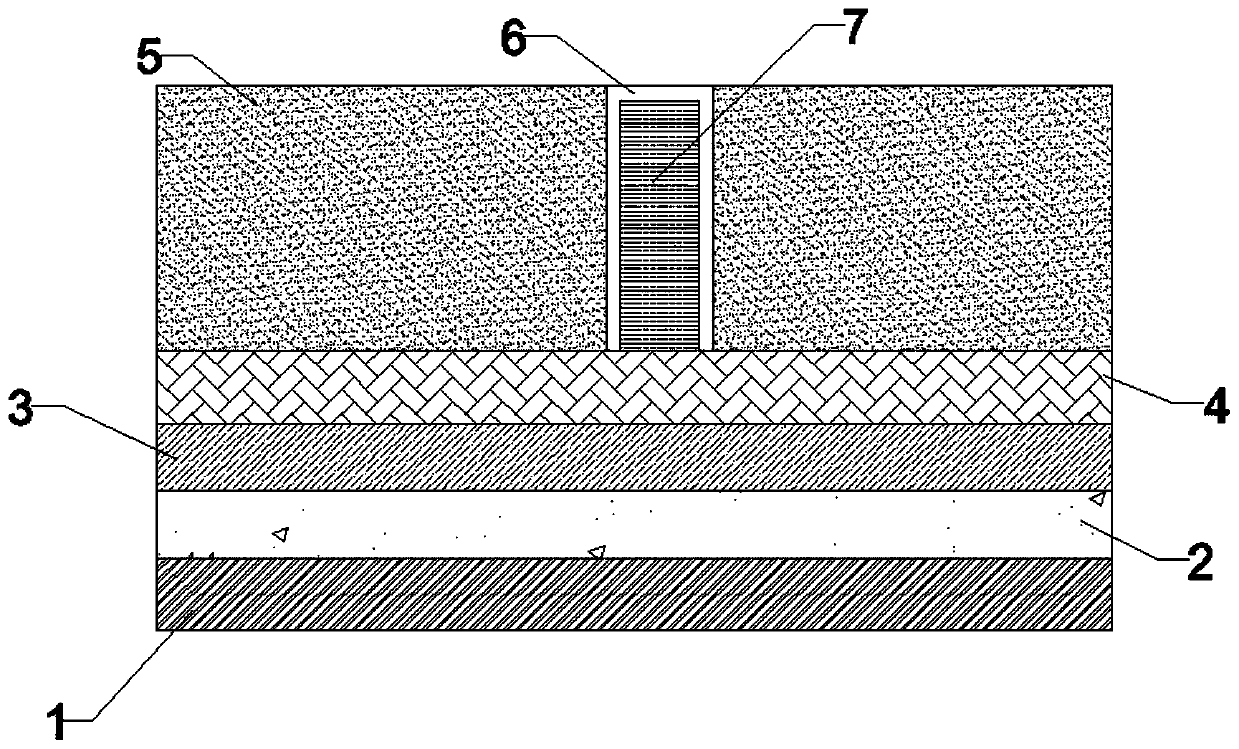

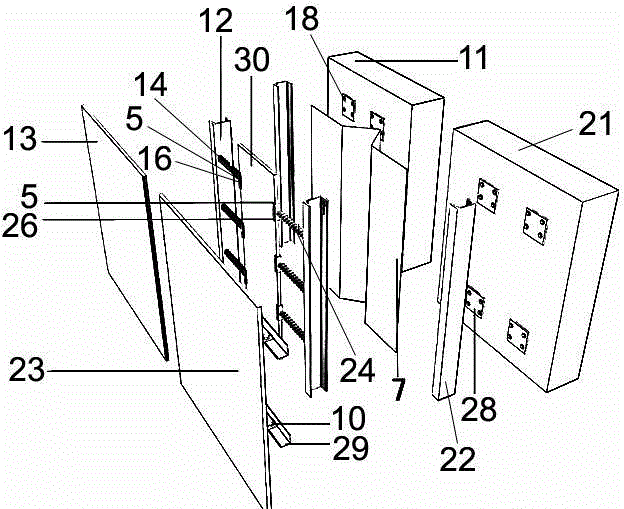

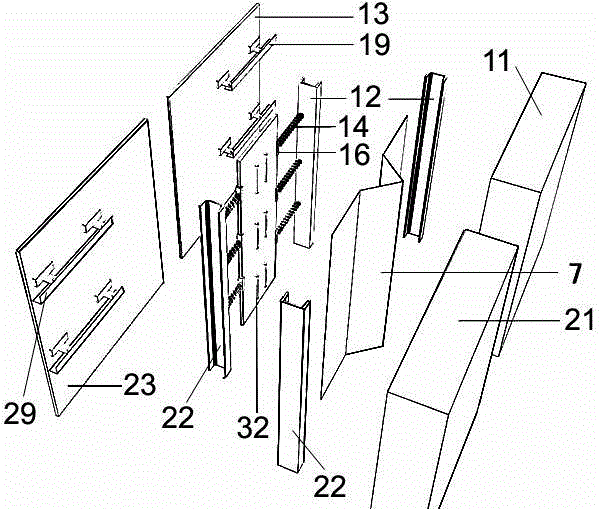

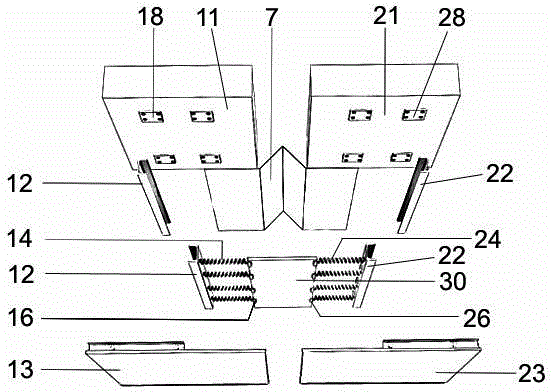

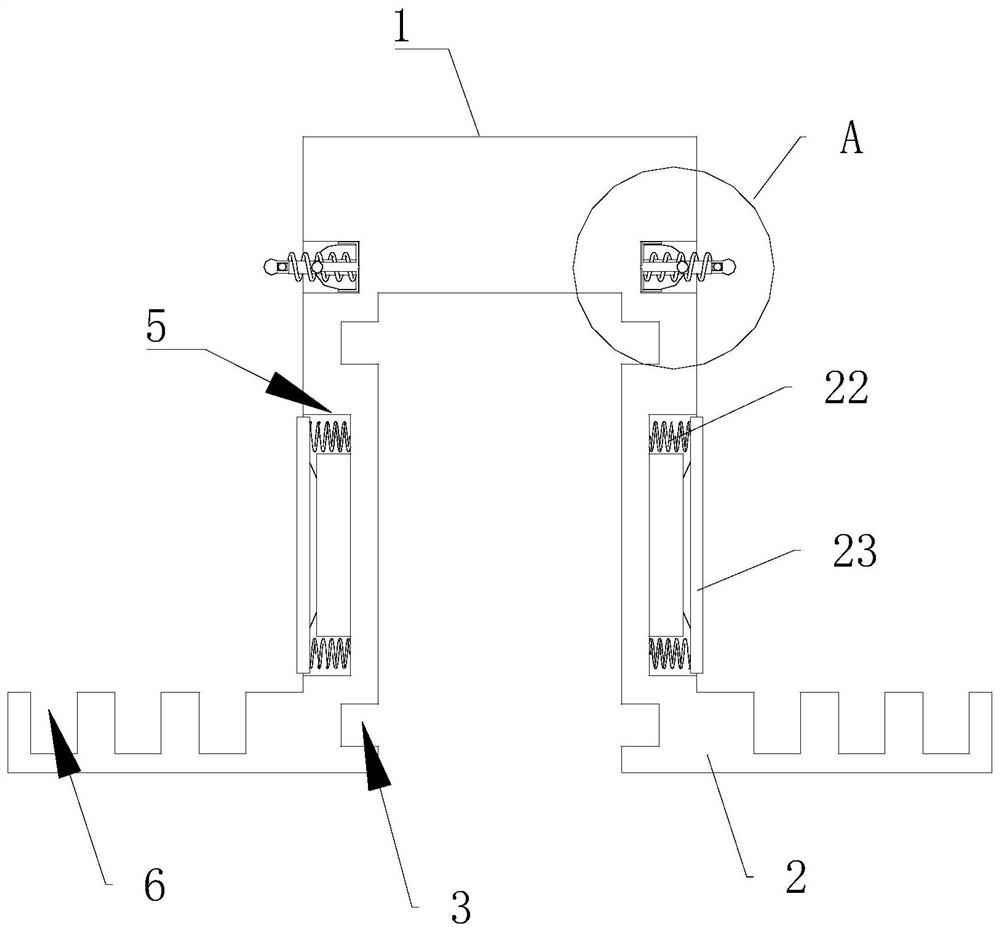

Settlement joint wall ground stone installation structure

ActiveCN102953518ASolve the problem of collision crackingAvoid safety hazardsCovering/liningsGround stoneStructural stability

The invention discloses a settlement joint wall ground stone installation structure, which comprises vertical structural members and horizontal structural members. The vertical structural members are fixedly arranged on a structural wall body. The horizontal structural members are fixedly connected with a face stone. The vertical structural members and the horizontal structural members are fixedly connected together. A movable stone panel assembly is arranged between the vertical structural members closest to the two sides of a settlement joint. The movable stone panel assembly comprises springs and a movable stone veneer. The vertical structural members on the two sides of the movable stone veneer and the two sides of the settlement joint are respectively connected with the movable stone veneer through the springs. The settlement joint wall ground stone installation structure provided by the invention has the advantages that the problem that stones collide and are cracked because a building body is displaced can be solved, the potential safety hazard that the stones fall off are avoided, the troubles in replacing the stones are reduced, the structural stability is improved.

Owner:GOLD MANTIS CONSTR DECORATION

Construction methods for repairing ground stone hollowing

InactiveCN105672684AImprove the protective effectImprove permeabilityBuilding repairsEpoxyRepair material

The invention relates to construction methods for repairing ground stone hollowing. The stone boundary hollowing repairing method and the stone muddle hollowing repairing method include the specific steps of 1, preparation of a repairing material; 2, trepanning of stone; 3, preparation of epoxy resin adhesive; 4, pouring of the epoxy resin adhesive; 5, solidification and clearing of the solidification. The construction methods for repairing ground stone hollowing have the advantages that stone protection performance is enhanced; the solidification content is high, and contraction is small; connection between stone and cement and connection among cement, mortar and grids on the back of the stone can be achieved; repairing can be conducted without knocking off stone, and the stone layout effect is not influenced; repairing time is short, and efficiency is high; connection strength is high, and meanwhile the strength of the ground can be increased.

Owner:曹颖

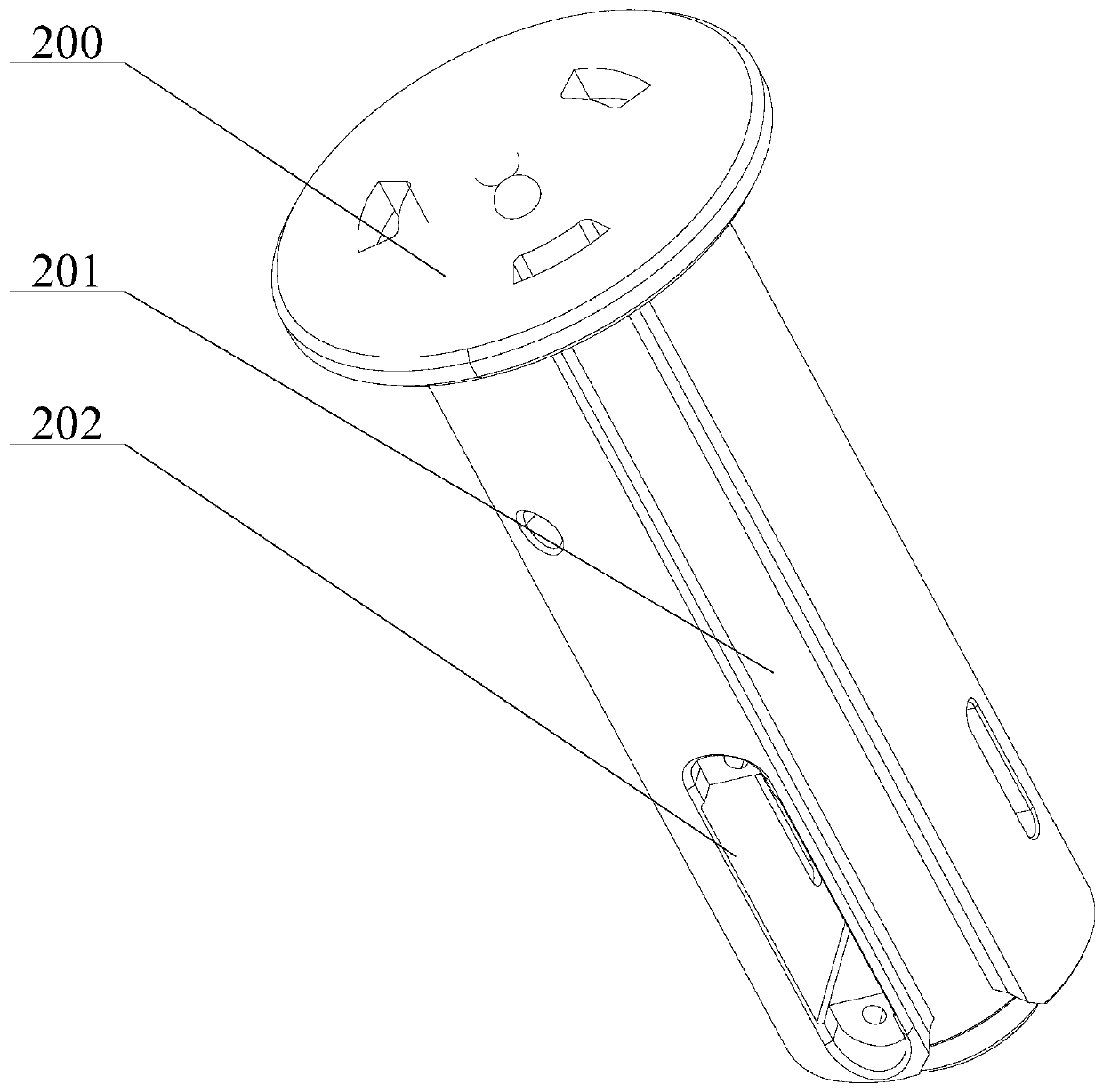

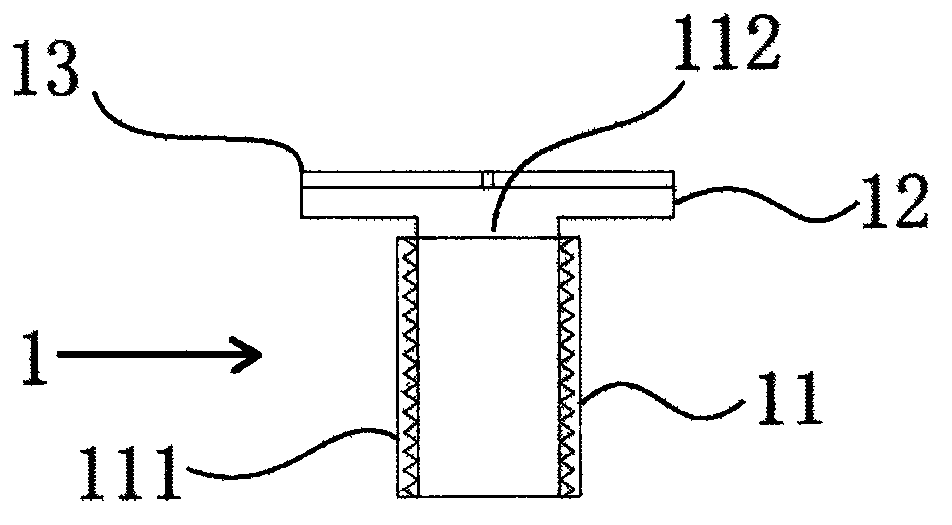

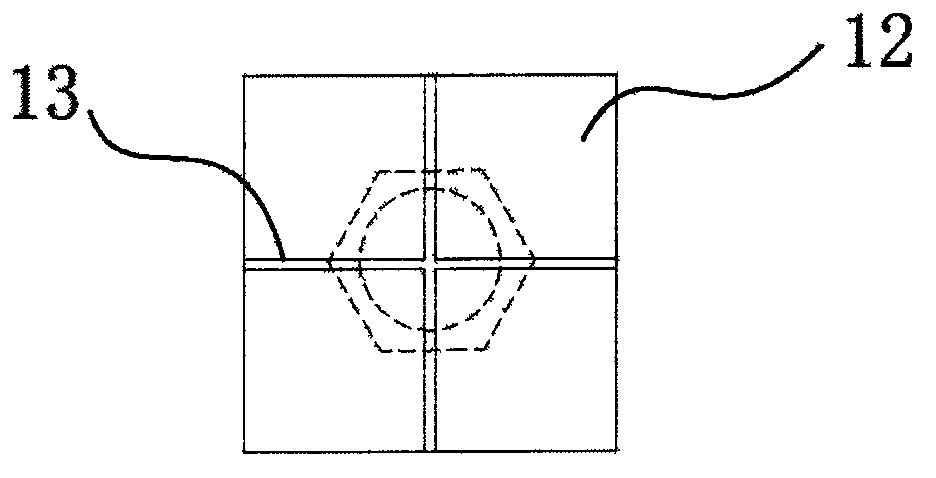

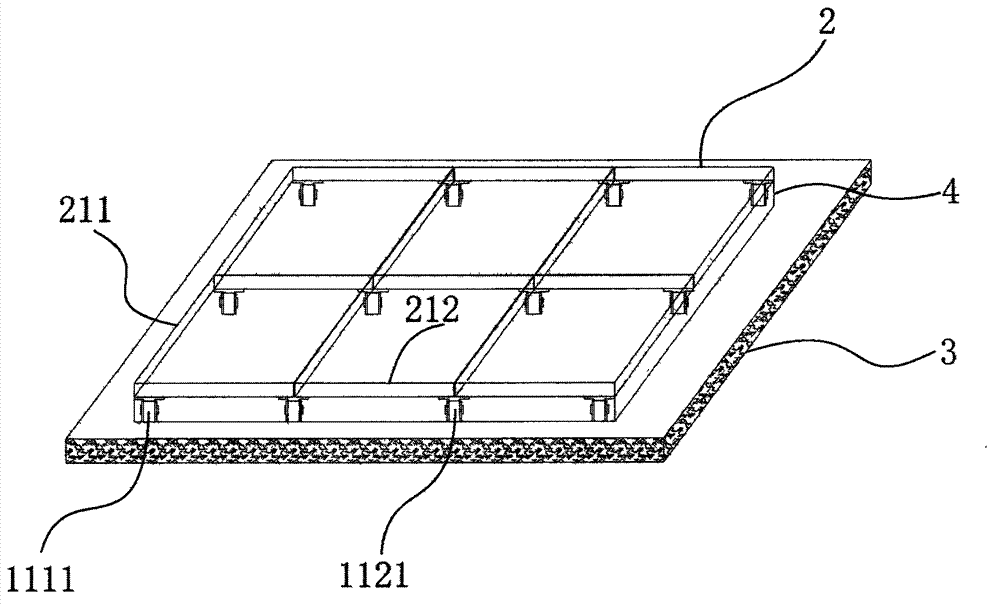

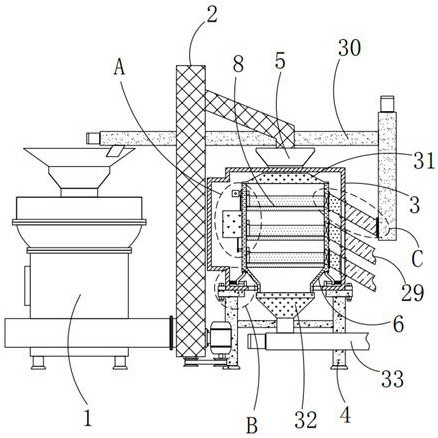

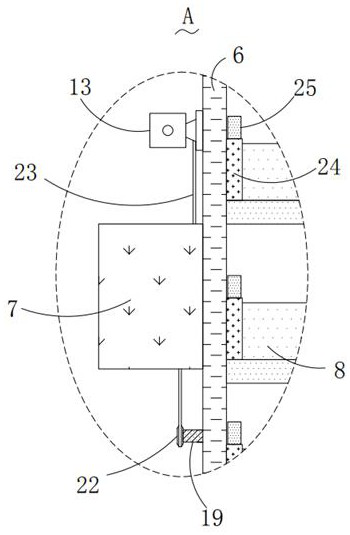

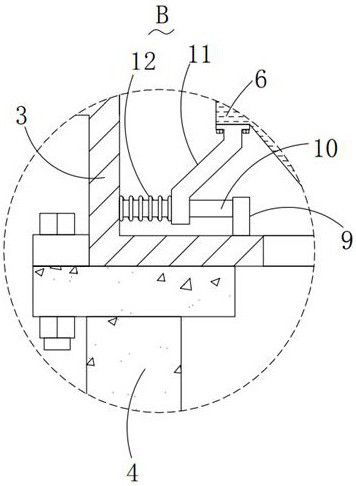

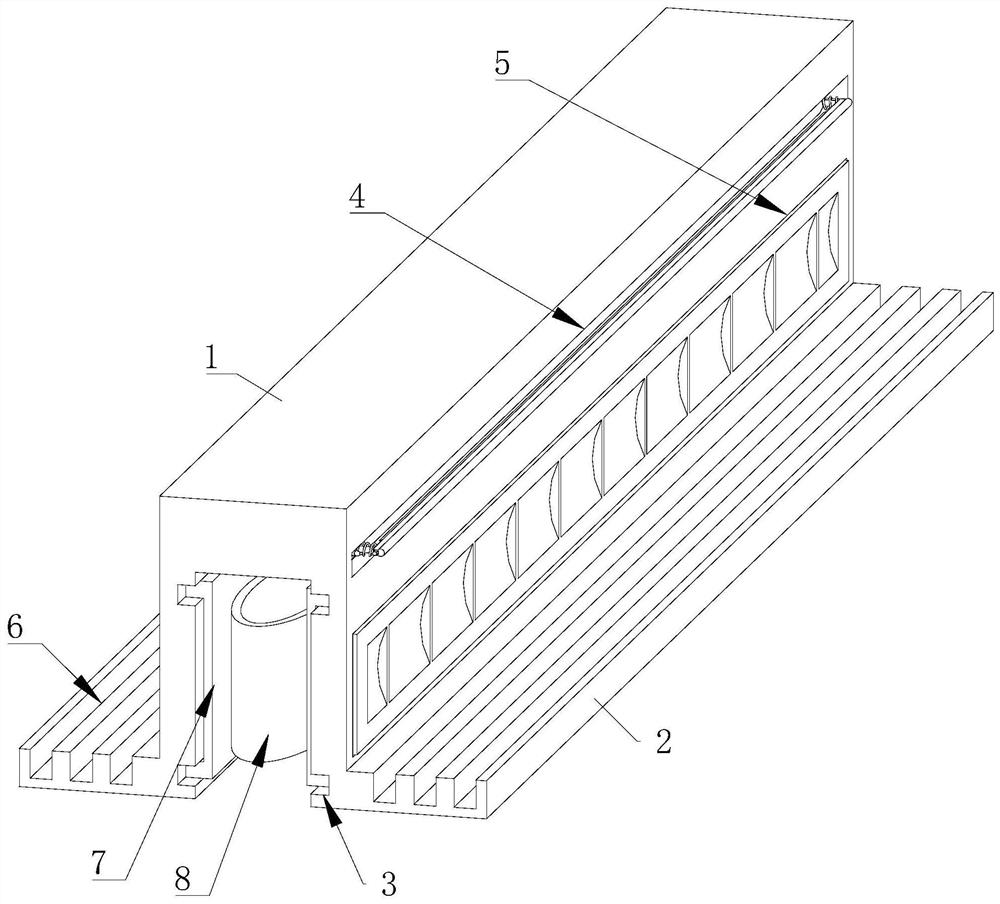

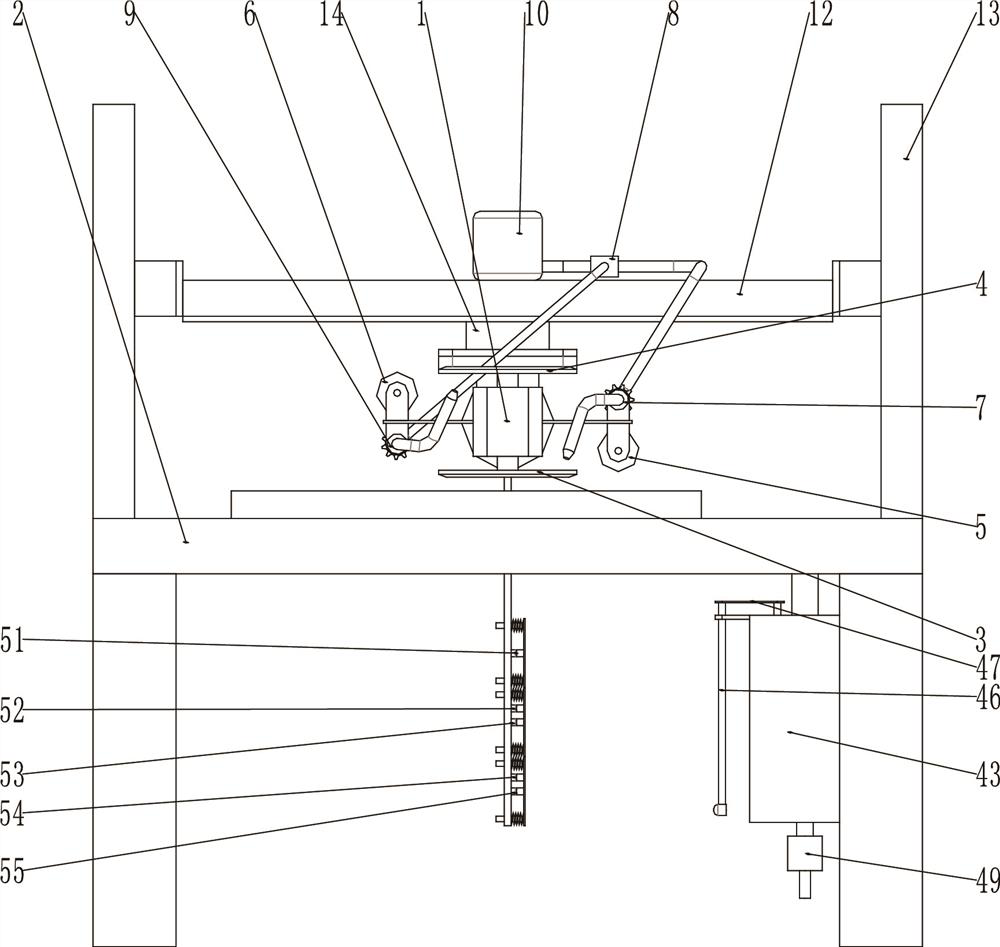

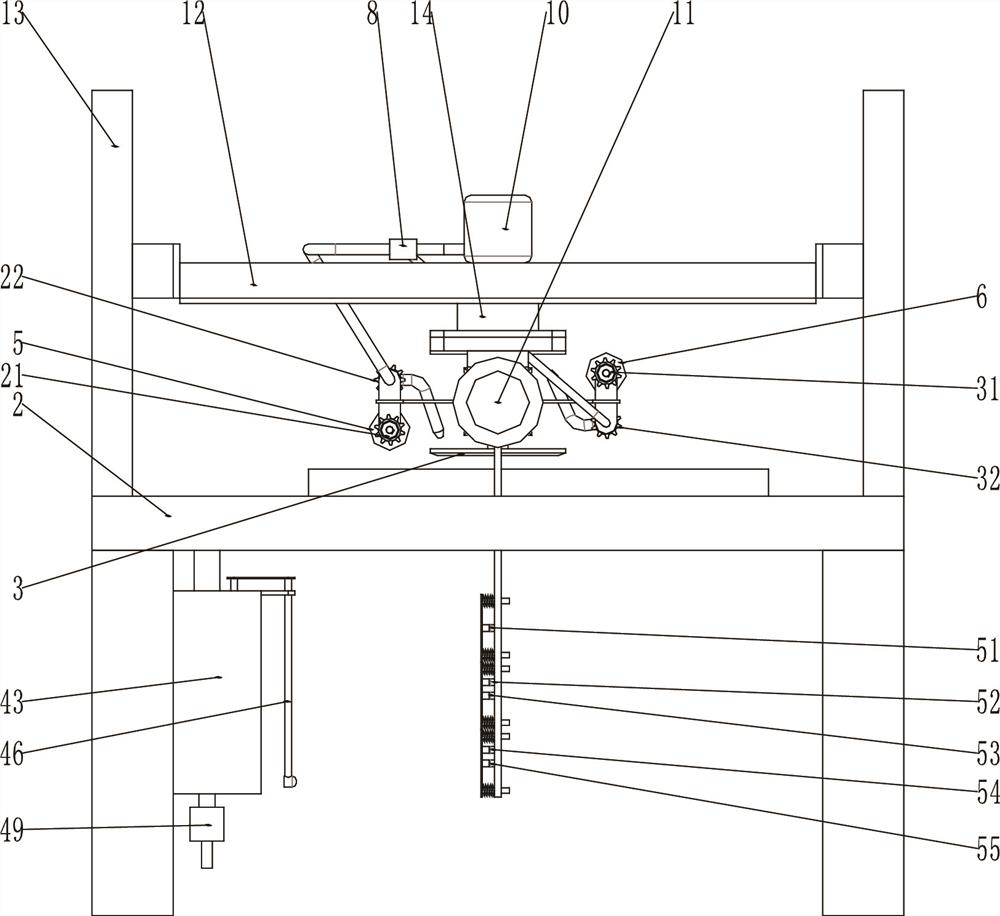

Support, paving method for ground stone and cement mortar stirring and conveying all-in-one machine

The invention relates to a support, in particular to a support for ground stone paving. The invention further relates to a paving method for ground stone and a cement mortar stirring and conveying all-in-one machine. The support is mainly and technically characterized by comprising a supporting piece with the adjustable height. The paving method for the ground stone is mainly and technically characterized in that the ground stone is arranged on a building floor through the support, and then cement mortar is injected to the position between the ground stone and the support. The cement mortar stirring and conveying all-in-one machine is mainly and technically characterized by comprising a cement mortar stirring machine, a cement mortar storage tank, an air compressor, a cement mortar conveying pipeline and a spraying head. According to the support, the paving method for the ground stone and the cement mortar stirring and conveying all-in-one machine, the technical problems that in the prior art, the paving method for the ground stone consumes time and wastes labor, and the paved flatness is poor are solved.

Owner:陈友坤

Processing and utilizing method for quartz sand rock

The invention relates to a method for processing and utilizing quartz sandstones, which belongs to the field of development and utilization of the quartz sandstones, relates to development and utilization of glauconite quartz sandstones, and particularly relates to development and utilization of glauconite quartz sandstone ground tiles. The invention provides a processing method for applying the glauconite quartz sandstones on ground tiles, so as to obtain the glauconite quartz sandstone ground stones having the advantages of naturalness and environmental protection, durability and good non-skid property. The processing method comprises the following technological flow: material selection, gouging, surface grinding, notching, cutting into pieces and surface spray coating.

Owner:王长利

Preparation method of high performance concrete machine-made sand

The invention relates to a preparation method of high performance concrete machine-made sand. The preparation method comprises the following steps: S1, storing incoming main raw material macadam or aggregate chips in a stacking shed to be naturally aired, and feeding the main raw material which is naturally aired to a discharging terrace funnel; S2, raising the temperature and reducing the temperature gradually to prepare lightweight aggregates (a fine aggregate I, a coarse aggregate I and a coarse aggregate II), then processing the lightweight aggregates, ground stones and an abrasive material to obtain machine-made sand; S3, adding winnowing equipment at the tail end of a gravel production line, winnowing fine particles which are crushed and separated only, then selecting powder througha powder selecting machine and collecting and storing fine gravel powder; and S4, acquiring flowability, feeding the powder through a discharging valve, lifting the powder to a sand-making tower through a belt conveyor and a belt-bucket elevator, processing the gravels or aggregate chips through a sand-making shaping machine, an air jet sieve and a moisture mixing machine from top to bottom, and discharging the mixture to obtain finished product machine-made sand. High performance concrete and high strength concrete are prepared favorably, and a lot of water sources are not consumed.

Owner:徐州金盟新型建材有限公司

Boron slag-containing environmentally-friendly lightweight partition plate and making method thereof

The invention discloses a boron slag-containing environmentally-friendly lightweight partition plate. The boron slag-containing environmentally-friendly lightweight partition plate is made by using the following raw materials, by weight, 20-25 parts of cement, 17-19 parts of fly ash, 11-13 parts of ground stone powder, 8-12 parts of polyethylene glycol, 0.2-0.6 parts of copper sulfate, 7-9 parts of of polyisobutylene, 1-3 parts of polycarboxylate, 9-13 parts of polyphenyl waste particles, 12-15 parts of perlite, 6-10 parts of sodium naphthenate, 4-7 parts of Span 60, 11-14 parts of boron lag, 17-22 parts of wheat straw, 1-3 parts of rose essential oil, 3-6 parts of an assistant and a proper amount of water. The boron slag-containing environmentally-friendly lightweight partition plate has the advantages of heat insulation, light weight, good suspension force, workability, drillability, unlikely cracking and high strength.

Owner:CHUZHOU UNIV

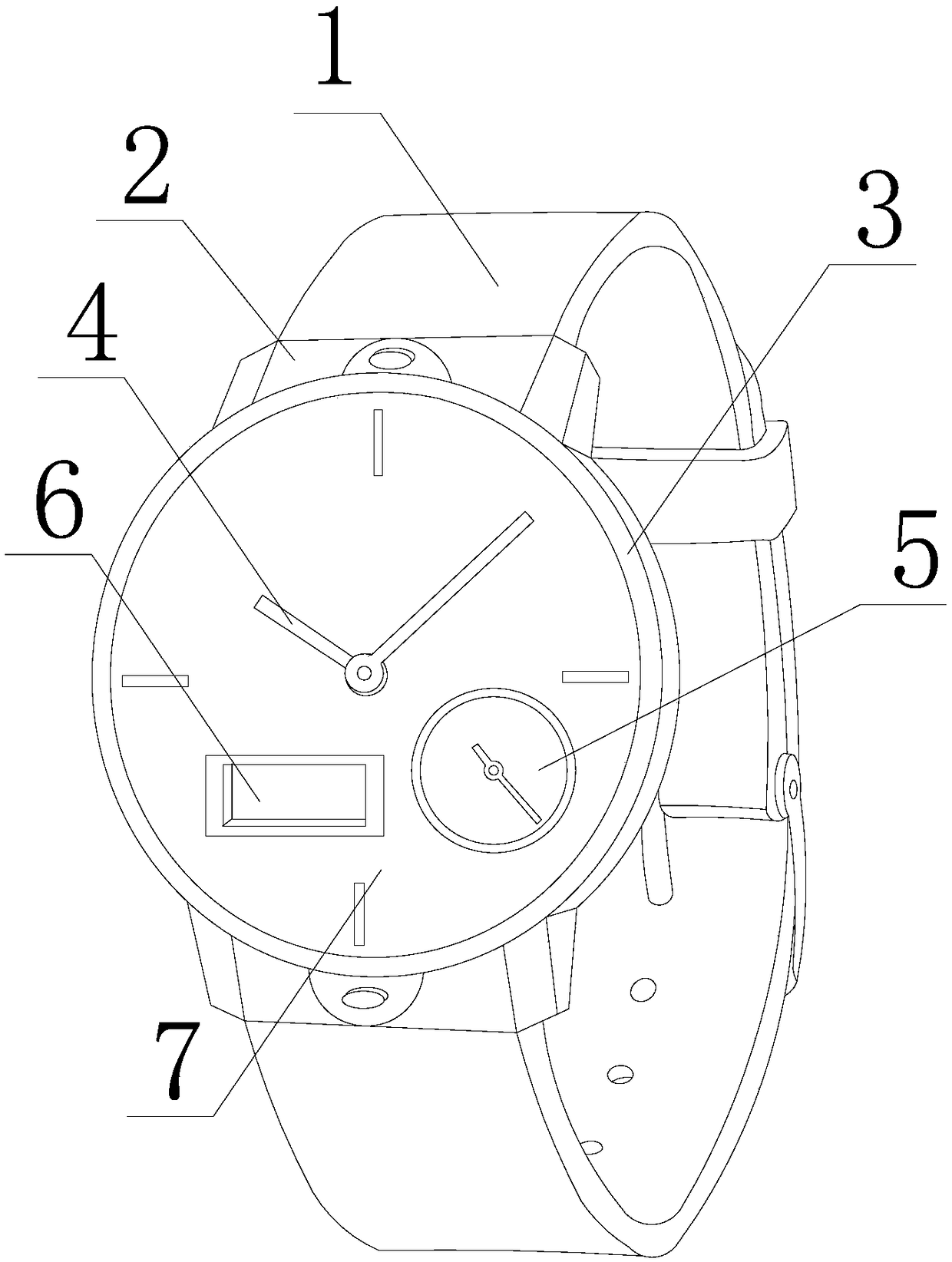

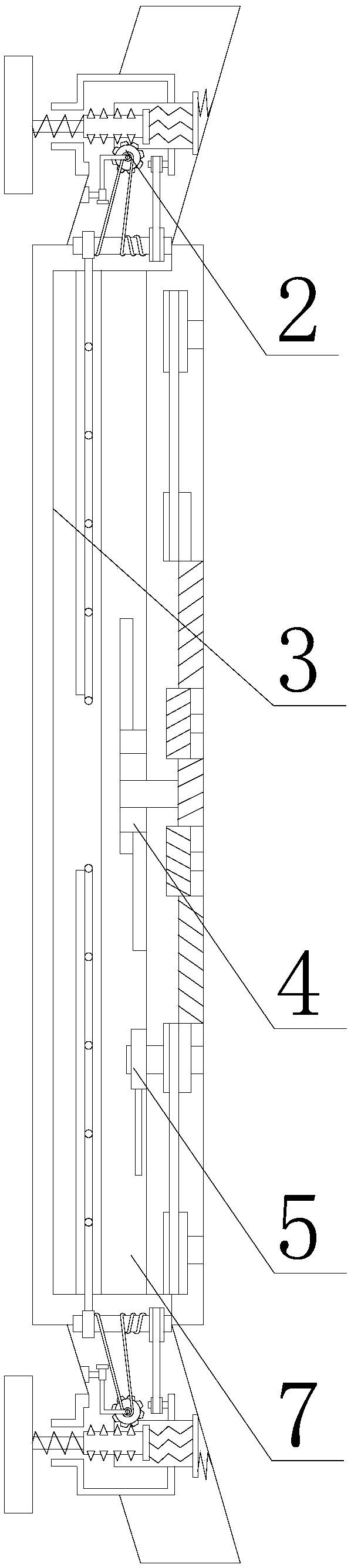

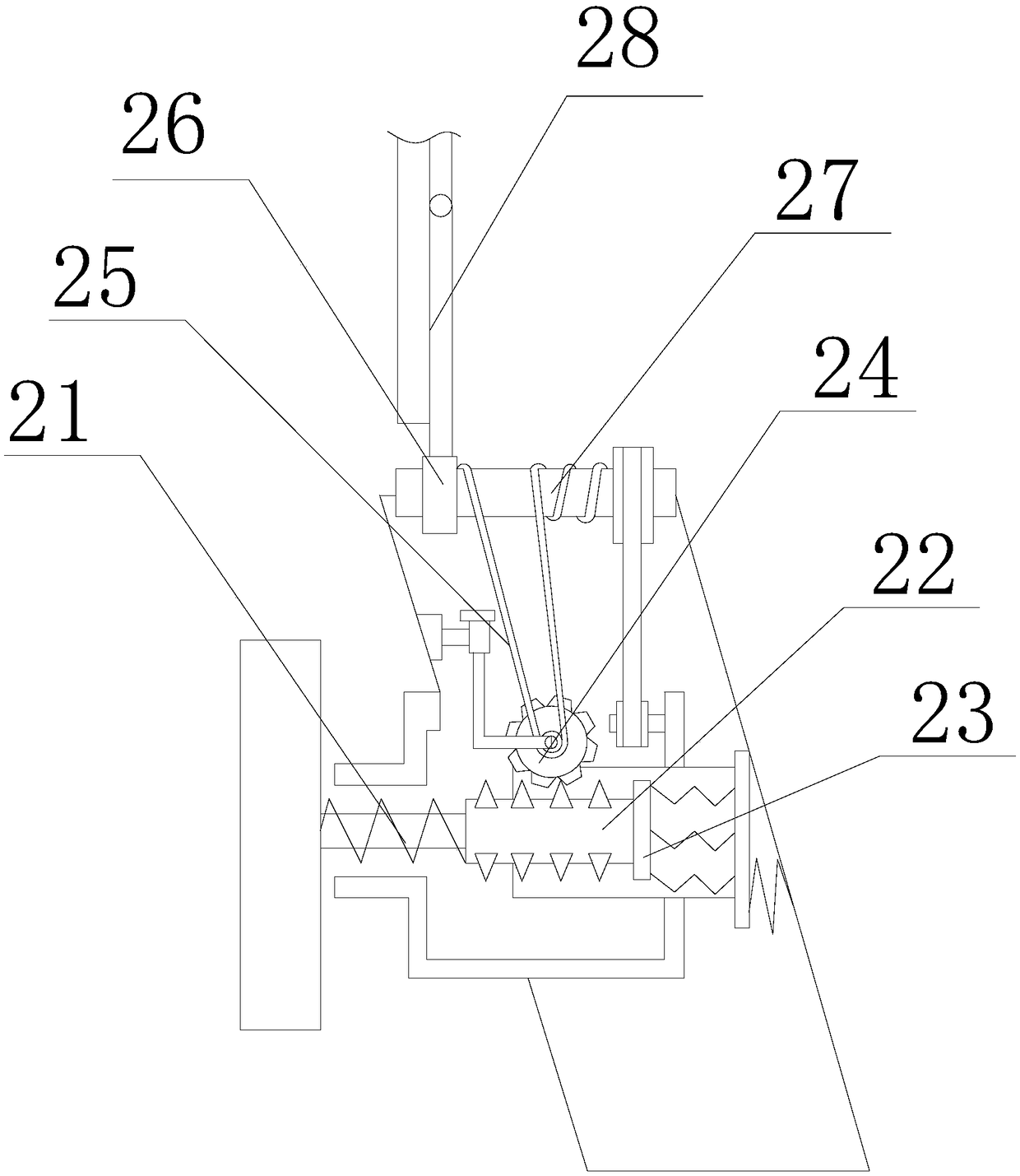

Intelligent wearable equipment scratch-proof device using elastic tension to pull film on dial plate

InactiveCN108762037AProtective glass coverTo achieve the effect of emergency protectionVisual indicationClockwork casesCarbon filmDiamond-like carbon

The invention discloses an intelligent wearable equipment scratch-proof device using elastic tension to pull a film on a dial plate. The scratch-proof device structurally comprises a leather watch strap, scratch-proof triggers, an annular frame slot, time pointers, a stopwatch dial, a digital display tube and a dial plate; the scratch-proof triggers are set to be two and respectively inserted andembedded into the upper end and the lower end of the annular frame slot; the annular frame slot is fastened with the leather watch strap through the scratch-proof triggers; the time pointers are installed on the front side of the center of the dial plate; the time pointers are mechanically connected with the stopwatch dial through a shaft wheel of the dial plate. According to the invention, through cooperation of the scratch-proof triggers with the dial plate, when a watch falls, a reed pipe support plate is triggered to longitudinally squeeze a tooth column block and a spring seat, the toothcolumn block is meshed with a gear, a rubber band is wound around the gear, pulls a roller rod, and drives a rotating connecting frame to fit, rotate and cover a diamond-like carbon film on the glasssurface of the dial plate, so that the diamond-like carbon film can contact ground stone in time; the diamond-like carbon film is resistant to friction and scratch, and protects the glass cover of thedial plate, thereby achieving the effect of triggering the start of protection operation.

Owner:泉州市春川贸易有限公司

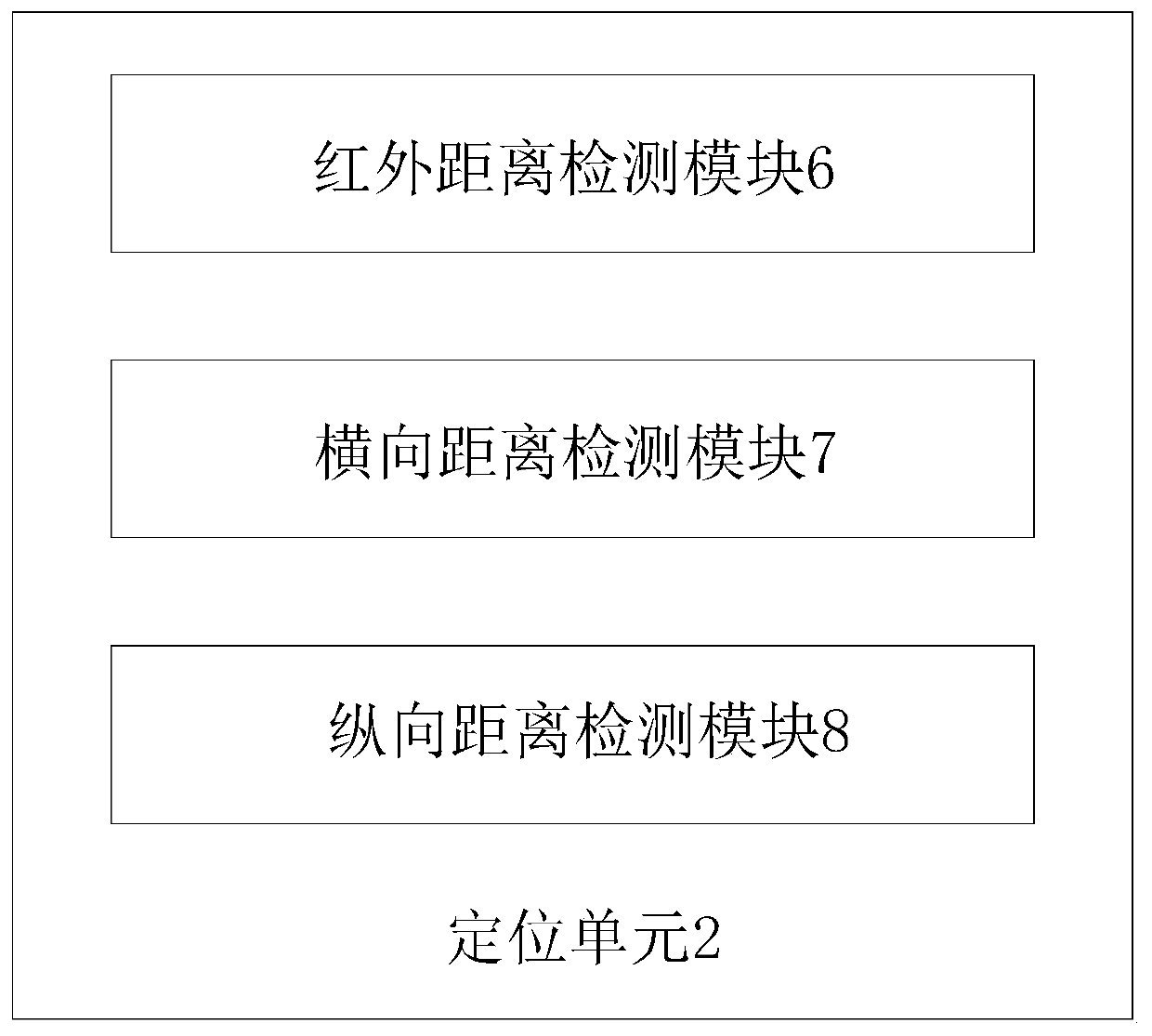

Stone plate grinding and polishing machining control system

InactiveCN110900343ARealize intelligenceGrinding feed controlAutomatic grinding controlMachine controlControl system

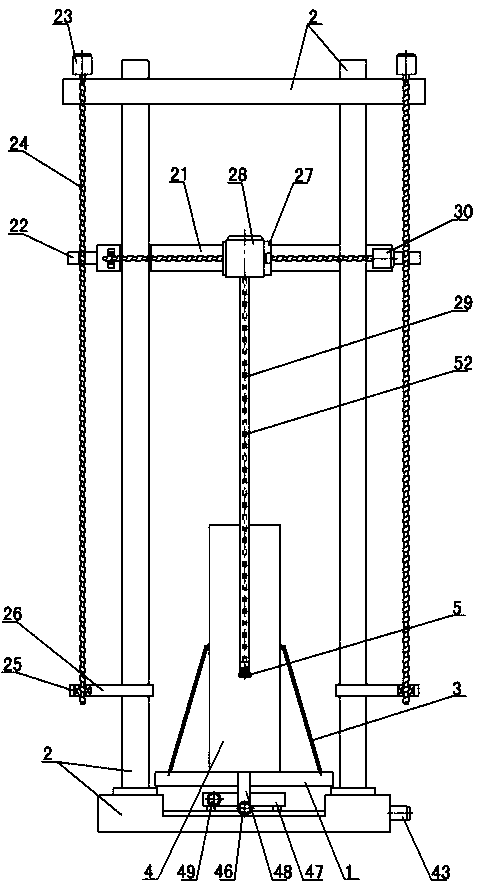

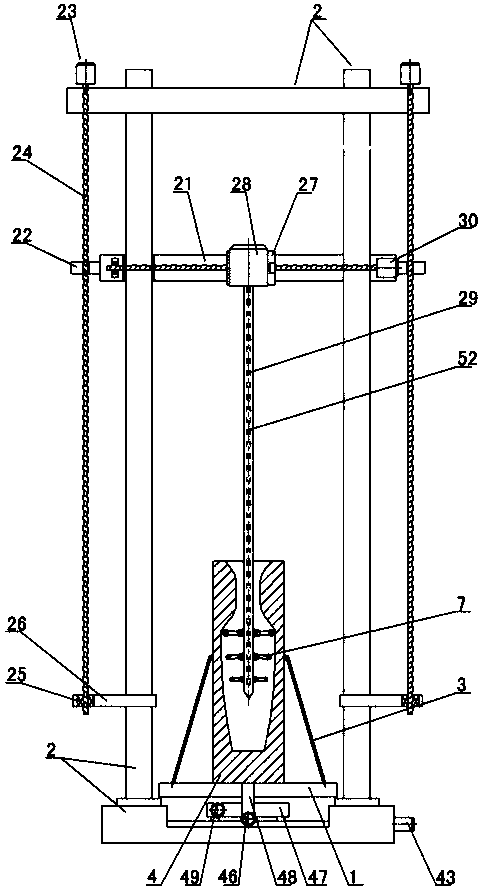

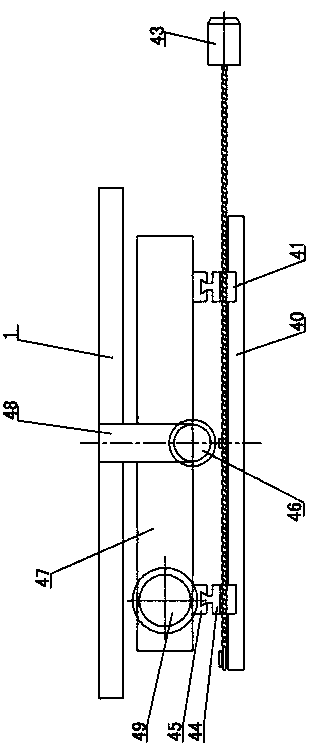

The invention relates to the stone plate grinding related field, and particularly discloses a stone plate grinding and polishing machining control system. A control chip is used for presetting the stone plate grinding position and grinding depth, after setting is finished, a to-be-ground stone plate is placed on a workbench, an infrared distance detection unit is used for detecting the distance between a grinding head of a grinding device and the stone plate, and according to the preset height, a height adjusting module is used for adjusting a telescopic device so that the height of the grinding device can be adjusted. A transverse distance detection module and a longitudinal distance detection module are used for detecting the specific position of the grinding head, then a transverse adjusting module and a longitudinal adjusting module are used for conducting adaptive adjustment, and after adjustment is finished, a grinding device operation module is used for controlling operation ofthe grinding device. Work is conducted according to the grinding depth preset by the control chip, intelligent grinding work is achieved, and a camera shooting module records the grinding process in the whole process in the storage module for later calling.

Owner:苏州嘉睦碧晟建筑装饰有限公司

Processing method of hollow stone container

A processing method of a hollow stone container includes the steps of (1) obtaining natural stone, (2) drilling the rough stone to obtain the stone with a hole, (3) reaming the hole of the stone with the hole to obtain the stone with the reamed hole, (4) grinding the hole wall, wherein the hole wall of the stone with the reamed hole is ground through a diamond grinding wheel to obtain the ground stone, (5) polishing the surface of the inner wall of the hole, wherein abrasive paste is applied to an abrasive cloth wheel, the hole wall is polished through the abrasive cloth wheel, and the polished stone is obtained. The processing method can be used for processing large stone containers as high as several meters, such as a vase and artcraft goods placed in a hall as decorations.

Owner:鲍林富

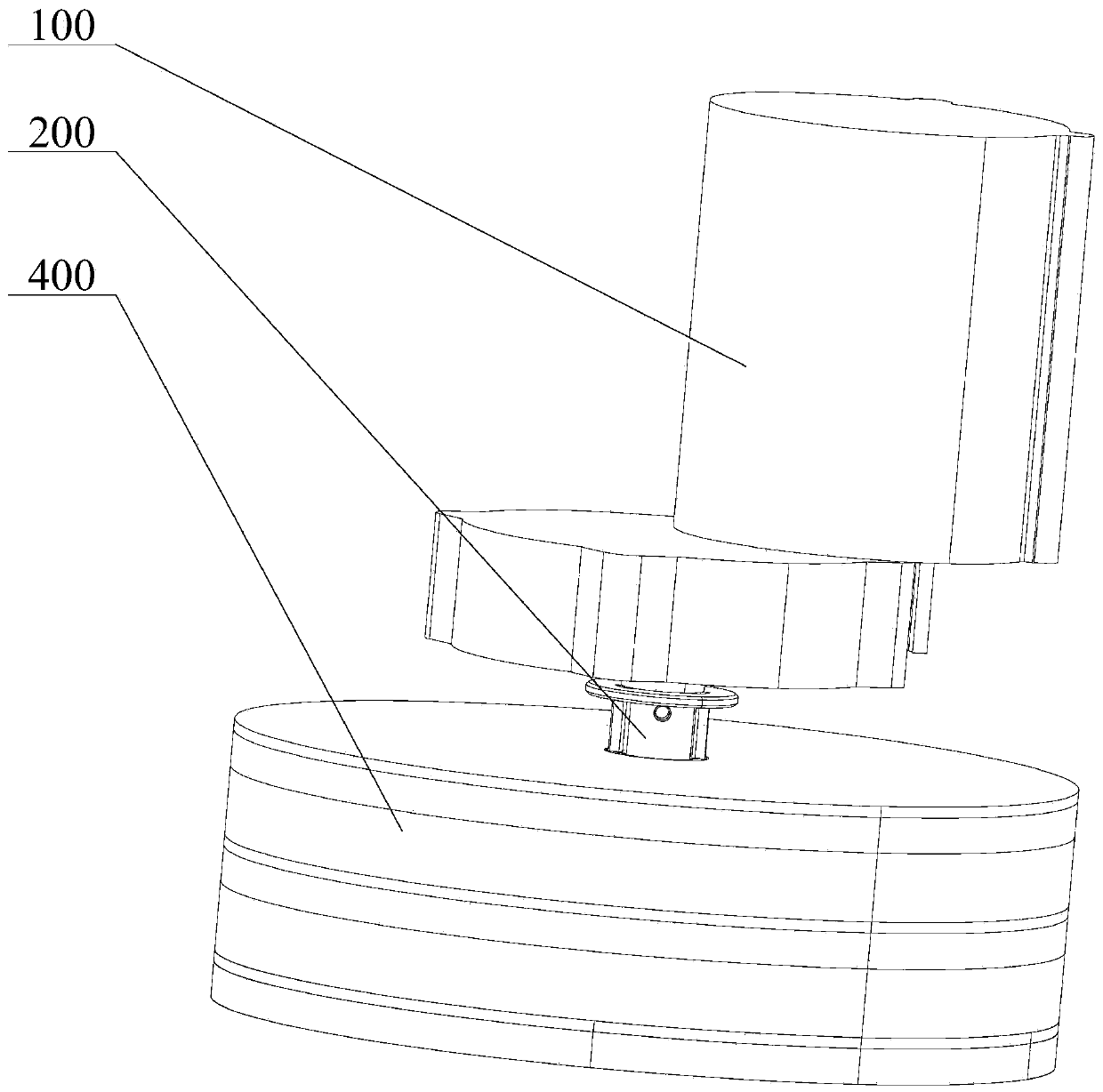

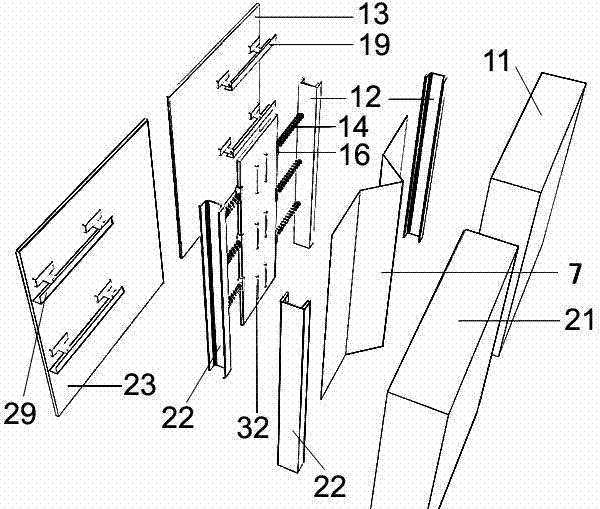

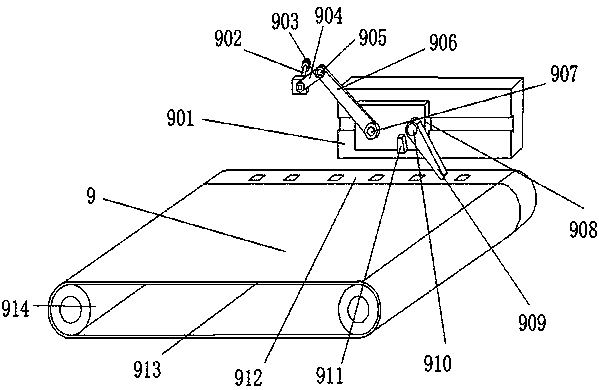

Workstation and operation method thereof

PendingCN111633497AGuaranteed care effectImprove experienceCarpet cleanersFloor cleanersPolishingDust control

The invention discloses a workstation and an operation method thereof. The workstation is used for an intelligent crystal face machine, the intelligent crystal face machine comprises a polishing assembly, the workstation comprises a body, a drying assembly and a dust removal assembly, the body comprises a workbench arranged in a mode of extending in the horizontal direction of the ground, the drying assembly is contained in the body and used for drying the polishing assembly when the intelligent crystal face machine is in butt joint with the workstation, and the dust removal assembly is contained in the body and used for scraping garbage attached to the polishing assembly when the intelligent crystal face machine is in butt joint with the workstation. According to the workstation, when theintelligent crystal face machine is in butt joint with the workstation, the polishing assembly is dried through the drying assembly, then the garbage attached to the polishing assembly is removed through the dust removal assembly, and therefore the maintaining effect of the polishing assembly on ground stone is guaranteed, in this way, manual intervention on the polishing assembly is avoided, andthe user experience is improved.

Owner:苏州高之仙自动化科技有限公司

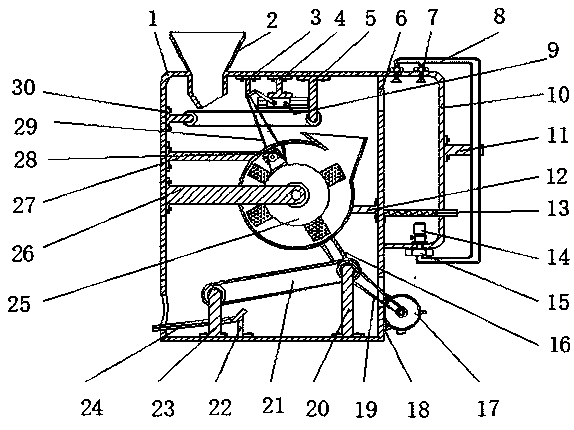

Stone grinding machine

InactiveCN107597290AAchieve recyclingTo achieve the effect of dust removalUsing liquid separation agentGrain treatmentsWater storageWater resources

The invention discloses a stone grinding machine. Stone slows down after passing through a buffer conveying device and enters a grinding device in batch. Ground stone falls down to a screening plate,stone meeting specifications enters a conveying belt device through the screening plate, and large stone is repeatedly ground to reach the optimal effect, enters the screening plate and finally entersa discharge plate through the conveying device, and finally is conveyed out of the strong grinding machine. Dust produced in the process enters a dust removal box through dust collection holes, wateris sprayed by a spray head to remove dust raised during working, used water is filtered by a filter net and conveyed into a water storage box, and the effects of cyclic utilization of water resourcesand dust removal are achieved. Stone is repeated ground by the stone grinding machine so as to achieve the best effect, water is sprayed by the spray head to remove dust raised during working, used water is filtered by the filter net and conveyed into the water storage box, and the effects of cyclic utilization of water resources and dust removal are achieved.

Owner:刘汪钊

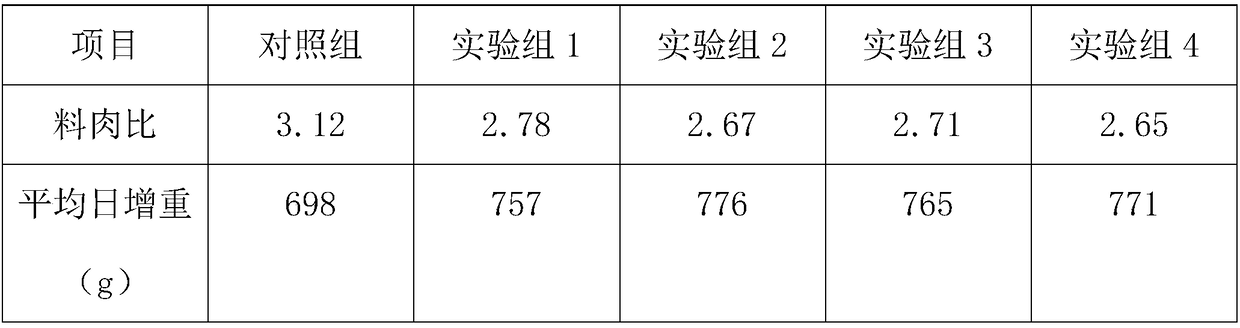

Pig feed capable of promoting growth

InactiveCN108991260ANo negative effects on growthIncrease appetiteFood processingAnimal feeding stuffBiotechnologySide effect

Pig feed capable of promoting growth is disclosed. The feed includes, by weight, 30-45 parts of corn straw, 15-25 parts of soybean straw, 40-60 parts of rice bran, 10-15 parts of pine needle powder, 25-35 parts of corn flour, 20-35 parts of bran, 30-40 parts of soybean meal, 10-15 parts of cotton seed meal, 12-16 parts of rapeseed meal, 3-6 parts of fish meal, 7-15 parts of sweet potato dregs, 4-8parts of ground stone, 3-8 parts of mixed vitamins, 0.5-1 part of table salt and 1-4 parts of a Chinese herbal medicine additive. A preparing method includes weighing all raw materials, crushing thecorn straw and the soybean straw separately, then fully mixing the corn straw and the soybean straw with other components, adding the mixture into a granulating machine and granulating the mixture toobtain granular feed, and cooling the feed. The pig feed prepared adopts the Chinese herbal medicine as the additive, and the feed is green ad free of toxic and side effects. The feed is high in utilization rate and can promote pig growth.

Owner:利辛县鑫圣农业科技有限责任公司

Environment-friendly type golf holder

The invention relates to an environment-friend golf support made from natural material. Wherein, it is made from the composite material as wood section at 40-80%, feldspar at 5-20%, quartz at 5-10%, ground stone at 3-10%, stone at 3-10%, ceramic at 3-10%, and environment-friend adhesive. And the production comprises removing foreign matter; breaking into powder, adding water and adhesive, mixing into paste composite; making the blank; drying and shaping. The invention has low cost, which is degradable.

Owner:姜东源

Ground stone paving method

The invention relates to a ground stone paving method. The method comprises the following steps of firstly, base layer treatment, wherein a foundation base layer is subjected to filling and subjectedto compaction treatment, cement paste is laid for leveling treatment, and a pavement basic plane is obtained; secondly, line popping control, wherein according to a horizontal standard line and designthickness, horizontal elevation lines are mounted on the periphery in a popping manner; thirdly, stone paving, wherein dry hard cement mortar is paved on the pavement basic plane to form a dry hard cement mortar layer, stone is paved on the dry hard cement mortar layer, a stone surface is knocked, the stone surface is located on the elevation lines, the stone is turned over, back impurities are removed, the back face of the stone is coated with a stone binding agent, then, the stone is paved on the surface of the dry hard cement mortar layer and compacted, the stone surface is located on theelevation lines, no gaps exist between stone and stone, gaps are filled with sealants, a U-shaped buckling strip is buckled, and the upper surface of the buckling strip is flush with the stone surface, and the stone bonding agent is selected from waterborne epoxy emulsion. The method is easy and rapid to operate.

Owner:CHINA RAILWAY SIXTH GROUP

Grinding and screening device for stone powder processing

The invention provides a grinding and screening device for stone powder processing. The grinding and screening device for stone powder processing comprises: a grinding machine body; a material elevator which is arranged at a discharge hole of the grinding machine body, wherein a charge hole of the material elevator is matched with the discharge hole of the grinding machine body; a box body which is arranged on one side of the grinding machine body, wherein a charge hole is formed in the top of the box body; a supporting frame which is fixedly mounted at the bottom of the box body; and a charge hopper which is fixedly installed on the top of the box body, and is matched with the charge hole. The grinding and screening device for stone powder processing has the advantages that the ground stone powder is subjected to three-stage screening so as to be used for multiple purposes, the stone powder on the screen can be conveniently pushed out of the screen, and the stone powder with too large roughness can be conveniently ground again until the use standards are met.

Owner:福建泉能石粉综合利用有限公司

A cleaning robot for stone care

ActiveCN111345733BEasy to adaptAvoid destructionAutomatic obstacle detectionTravelling automatic controlPolishingNursing care

The application discloses a cleaning robot for stone care. The cleaning robot for stone care includes a body support, a moving component, a polishing component and a control module. Among them, the mobile component is installed on the side of the main body support close to the ground, and the cleaning robot for stone care is moved through the mobile component. Nursing, the control module is electrically connected with the polishing component and the moving component respectively, and the cleaning robot used to control the stone care works automatically under unmanned control. In the cleaning robot for stone care of the present application, the control module is electrically connected with the polishing component and the moving component, thereby controlling the moving component to move, and controlling the polishing component to polish the ground stone, so that the cleaning robot for stone care does not need to be manually operated. Automate floor stone care tasks.

Owner:苏州高之仙自动化科技有限公司

Construction method for crystallizing of sandstone ground stone materials

The invention discloses a construction method for crystallizing of sandstone ground stone materials. The construction method comprises the steps that (1) white cement is smeared on the bottom faces ofthe sandstone stone materials, the sandstone stone materials are laid on the ground, and a gap between every two adjacent sandstone stone materials is 3-5 mm; (2) protective agents are smeared on thesurfaces of the sandstone stone materials, after the protective agents are absorbed by the sandstone stone materials, waterproof films are laid on the surfaces of the sandstone stone materials in a covering mode, and natural air drying is conducted for at least 10 days; (3) hollowing positions of the sandstone stone materials are subjected to potting treatment; (4) the edges of the sandstone stone materials are cut, and thus the gap between every two adjacent sandstone stone materials is 3-5 mm; and (5) the gap between every two adjacent sandstone stone materials is subjected to caulking treatment through marble glue. The surfaces of the sandstone stone materials are delicate, bright and free from pollution, warping deformation of the sandstone stone materials is avoided, the service lifeof the sandstone stone materials is prolonged, and the overall attractive effect of the sandstone ground stone materials is guaranteed.

Owner:DECAI DECORATION

Stone grinding method

The invention discloses a stone grinding method, including the following steps: a) a plurality of stones are placed in a frame, molten wax fluid or congealable chemicals is placed in, the wax fluid orcongealable chemicals is cooled and forms a tabular body with the stone; b) a grinding machine is used for grinding one surface of the tabular body until a plane is formed on the stone; c) the tabular body after grinding is heated, so that the wax or congealable chemicals in the tabular body is molten, and the ground stone is taken out. The invention causes a plurality of stones and wax fluid orcongealable chemicals to form the tabular body and grinds one surface of the tabular body by the grinding machine and a sawing machine until a plane is formed on the stone, thus grinding the stones inthe tabular body in one step and greatly improving efficiency. In addition, wax fluid or congealable chemicals can be recycled, and production cost is low.

Owner:罗彬鉴

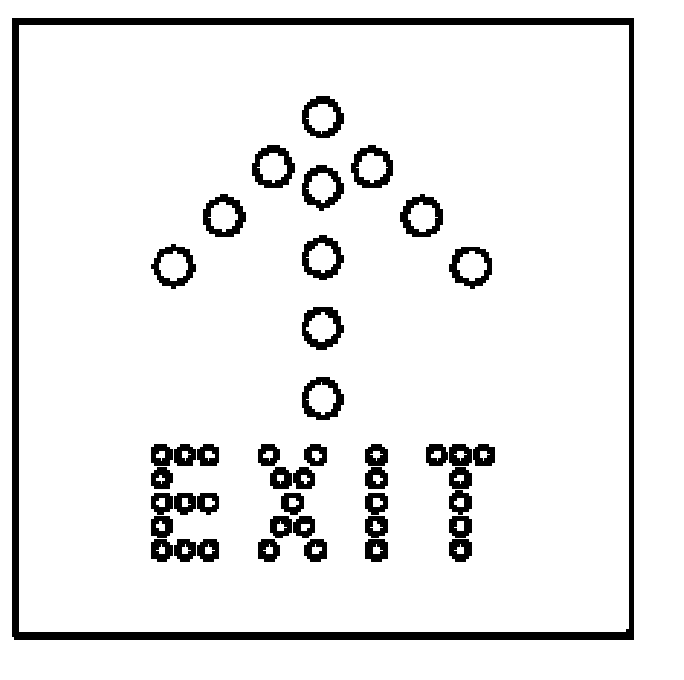

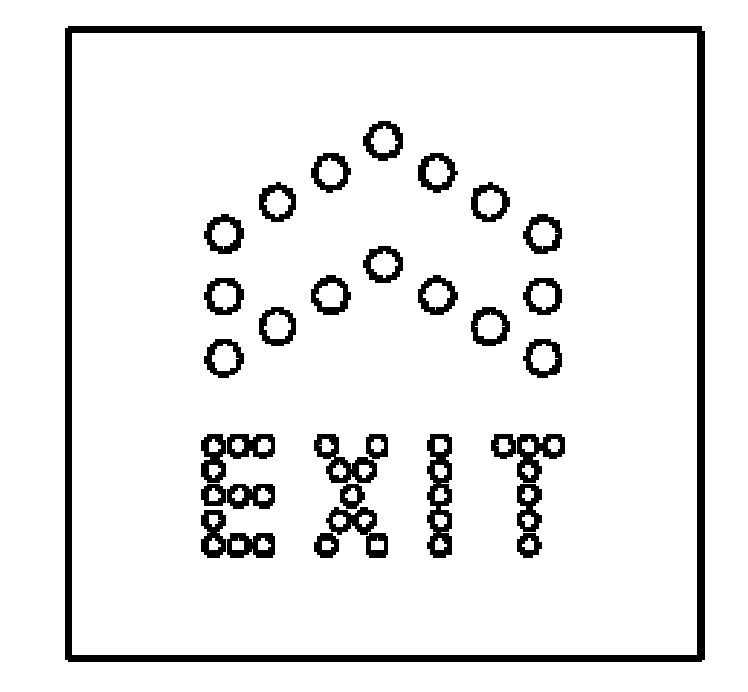

Method for embedding round pot rare earth material into slabstone for composing patterns and characters

InactiveCN101774228ASecurity guidanceAvoid High Carbon ConsequencesIlluminated signsStone-like material working toolsPunchingHaultain operation

The invention discloses a method for embedding round pot rare earth material into slabstone for composing patterns and characters, which comprises the following steps of: firstly, sticking a template printed with patterns and characters on a ground or wall sheet which needs to be set up with leading marks; then slotting by a punching machine according to the template; sticking round pot rare earth material into hole slots by glass cement; and after the glass cement is dried, comprehensively polishing and regulating. The product manufacture of the method can be carried out after ground stones are installed; circular holes with different specifications are hollowed out on various stones and ground and wall sheets; the combined patterns and the characters of the rare earth luminescent material are embedded; on-site construction solves the working problems of all transport operation; and a large number of tardy tasks are relatively reduced.

Owner:天津光辉现代科技文化艺术发展有限公司

Comprehensive land improvement soil layer stone crushing device and application method

ActiveCN113441223BEvenly brokenImprove crushing efficiencyCocoaClod-crushersSoil scienceLand consolidation

Owner:广西壮族自治区自然资源生态修复中心

A construction method for repairing hollow stones on the ground

InactiveCN105672684BImprove the protective effectImprove permeabilityBuilding repairsEpoxyRepair time

The invention relates to construction methods for repairing ground stone hollowing. The stone boundary hollowing repairing method and the stone muddle hollowing repairing method include the specific steps of 1, preparation of a repairing material; 2, trepanning of stone; 3, preparation of epoxy resin adhesive; 4, pouring of the epoxy resin adhesive; 5, solidification and clearing of the solidification. The construction methods for repairing ground stone hollowing have the advantages that stone protection performance is enhanced; the solidification content is high, and contraction is small; connection between stone and cement and connection among cement, mortar and grids on the back of the stone can be achieved; repairing can be conducted without knocking off stone, and the stone layout effect is not influenced; repairing time is short, and efficiency is high; connection strength is high, and meanwhile the strength of the ground can be increased.

Owner:曹颖

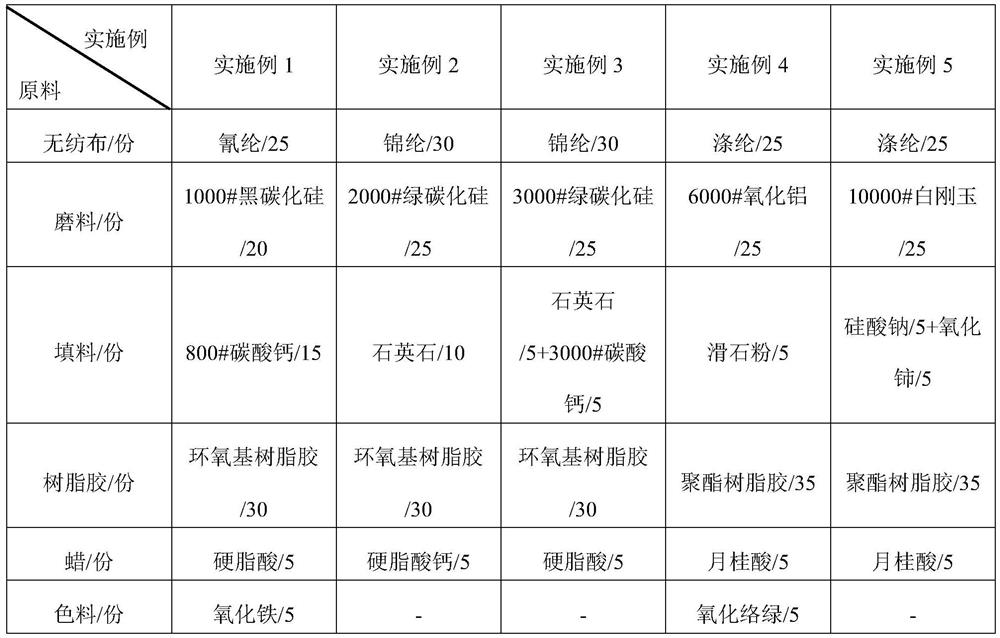

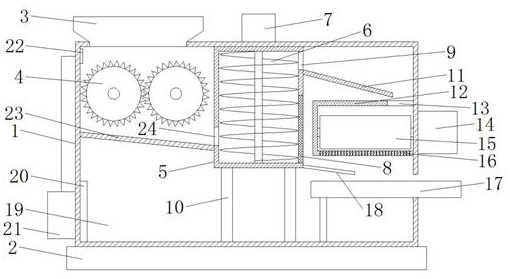

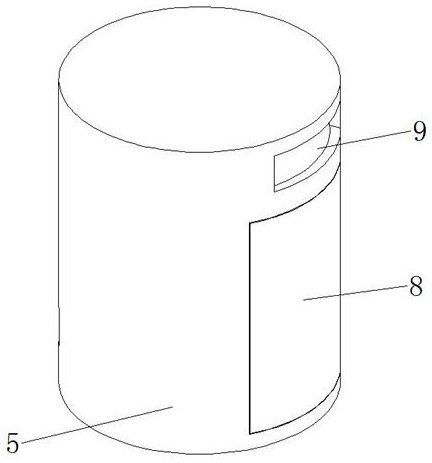

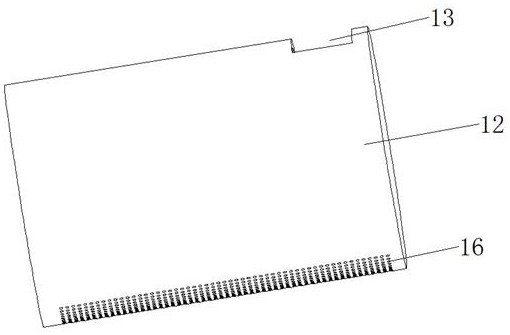

Non-woven fabric grinding block for stone polishing and manufacturing method of non-woven fabric grinding block

PendingCN114523429AHigh glossNo "hard" impact scratchesSolid waste managementAbrasion apparatusOXALIC ACID DIHYDRATEAdhesive cement

The invention discloses a non-woven fabric grinding block for stone polishing and a manufacturing method of the non-woven fabric grinding block. The non-woven fabric grinding block comprises the following components in percentage by weight: 20-30% of non-woven fabric fiber, 15-30% of grinding material, 5-15% of filler, 20-35% of resin adhesive, 0-5% of wax and 0-5% of pigment. The characteristic that a hard material is used as a grinding tool in the prior art is changed, relatively soft non-woven fabric fibers and soft resin are selected as carriers of the grinding material, proper softness is controlled by utilizing a three-dimensional structure of the non-woven fabric, the grinding tool is well attached to the surface of the stone in the grinding and polishing process, hard collision scratches are avoided, and shadows and scratches are not likely to be generated. In addition, the grinding material held by the resin also has a certain grinding effect, so that the polished and ground stone surface is finer and smoother, and the glossiness is higher. And the board surface is beautiful and bright. The polishing agent is used for polishing stones, and the glossiness can be improved by 5-20 degrees after the polishing agent is arranged behind a magnesia abrasive block or an oxalic acid composite abrasive block.

Owner:YANGJIANG WEIYI POLISHING MATERIAL

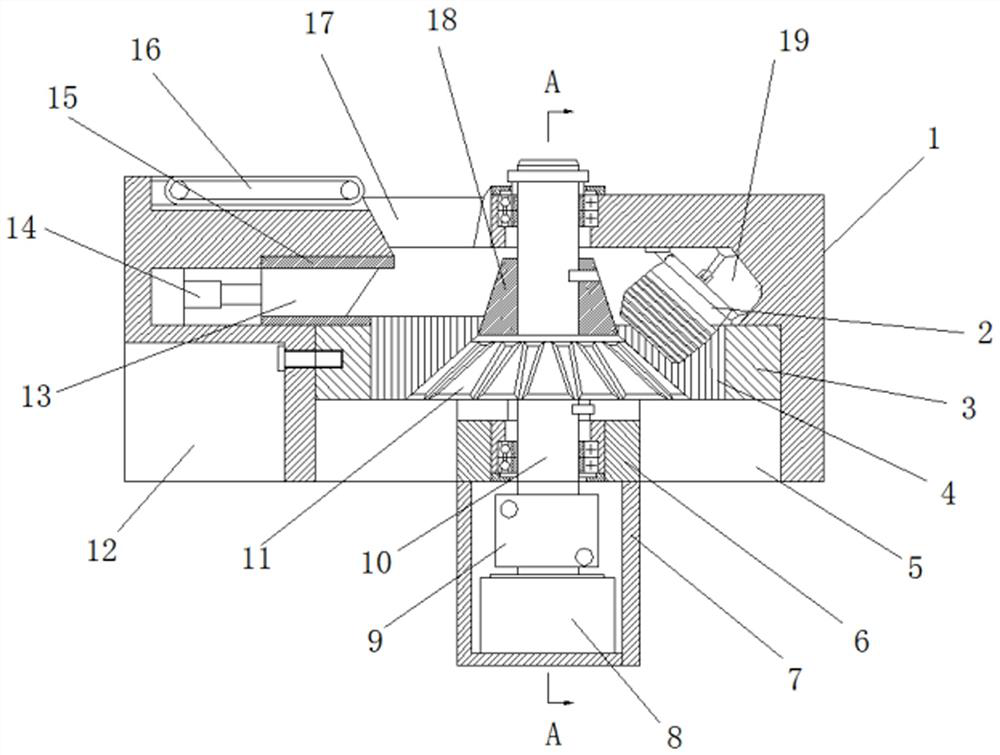

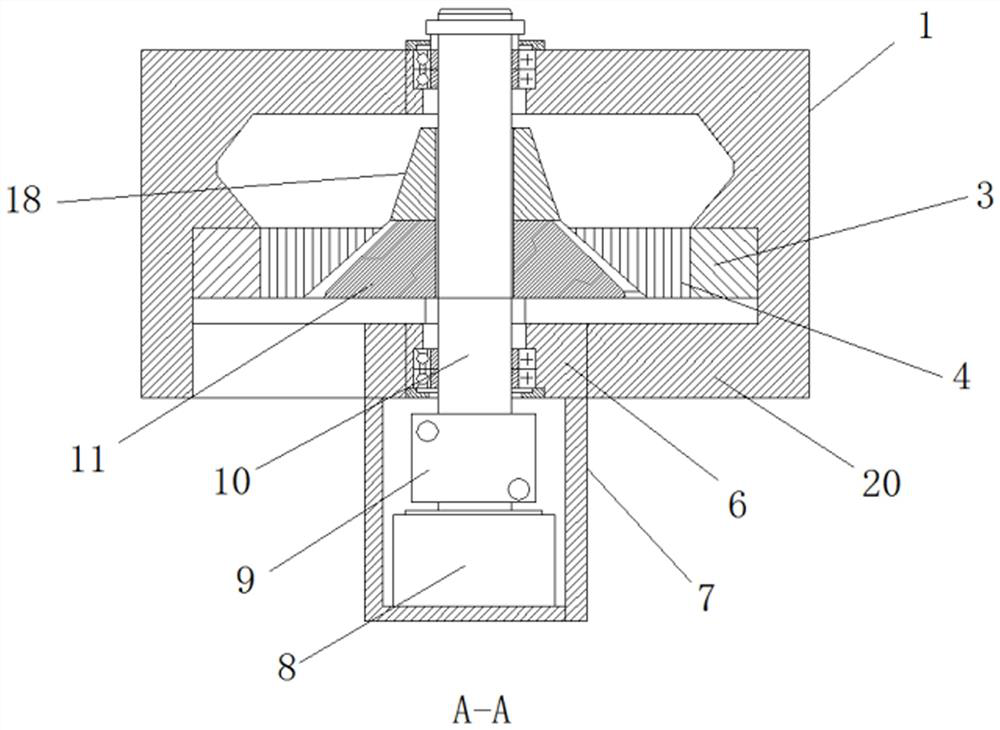

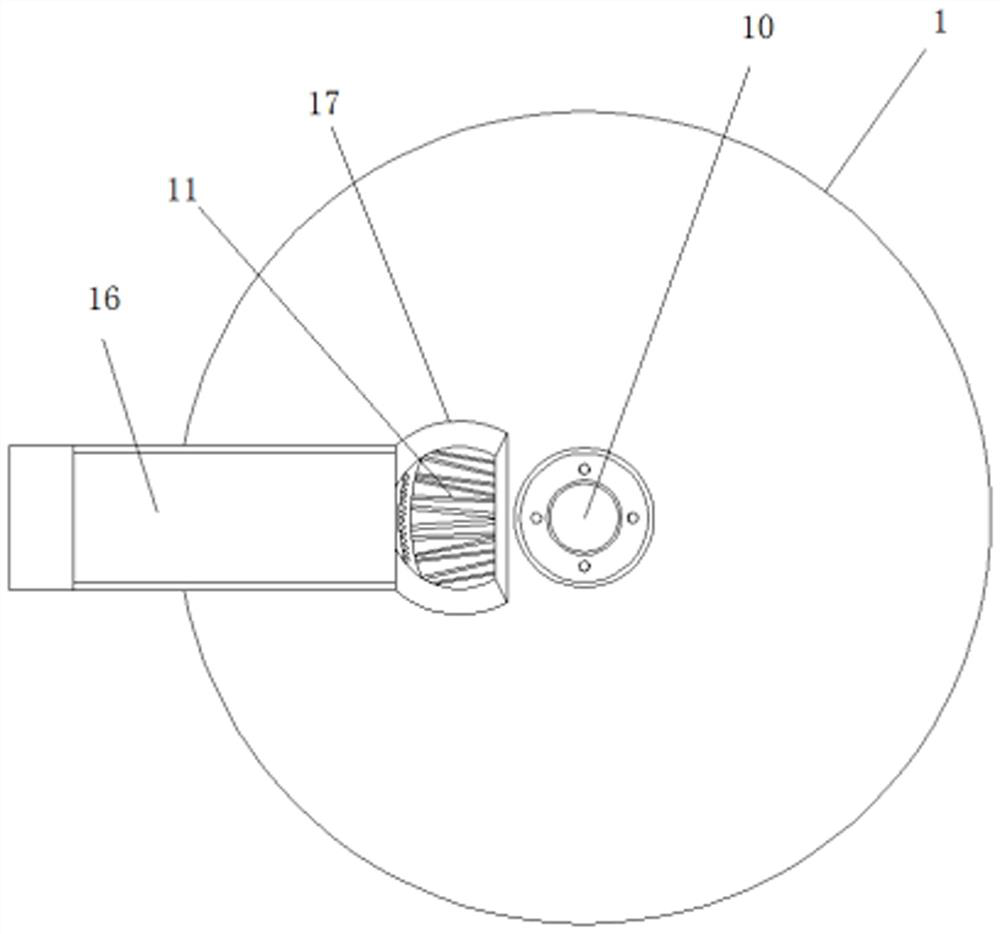

A stone crusher with eccentric structure and fine grinding

ActiveCN110898906BImprove crushing efficiencyGrind evenlyGrain treatmentsSpiral bladeStructural engineering

The invention belongs to the field of stone processing and discloses an eccentric structure-based stone material crusher with a fine grinding function. The stone material crusher comprises a shell, adamping base, a feeding hopper and crushing rollers; vertical spiral blades are coaxially mounted in a separation cylinder; a powder discharging screen plate is mounted on the right side wall of the separation cylinder in an embedded manner; a grinding mechanism is arranged below a second material guide plate and comprises a grinding cylinder, a second motor and a grinding roller; the grinding cylinder is internally provided with the horizontal grinding roller; the center axis of the grinding roller and the center axis of the grinding cylinder are eccentrically arranged; and a plurality of discharging holes are formed in the bottom of the grinding cylinder. According to the eccentric structure-based stone material crusher with the fine grinding function of the invention, the powder discharging screen plate arranged on the side wall of the separation cylinder discharges stone materials which meet requirements and have been subjected to primary crushing, so that the stone materials can be separated in time; the grinding mechanism gradually grinds and crushes large stone materials; the stone materials will not be stuck in the grinding mechanism, so that grinding is smooth; the groundstone materials are discharged from the bottom of the grinding mechanism so as to be collected; and continuous grinding and crushing can be conducted.

Owner:ZAOZHUANG SNKSAN INTELLIGENT MACHINERY CO LTD

Settlement joint wall ground stone installation structure

ActiveCN102953518BSolve the problem of collision crackingAvoid safety hazardsCovering/liningsGround stoneEngineering

The invention discloses a settlement joint wall ground stone installation structure, which comprises vertical structural members and horizontal structural members. The vertical structural members are fixedly arranged on a structural wall body. The horizontal structural members are fixedly connected with a face stone. The vertical structural members and the horizontal structural members are fixedly connected together. A movable stone panel assembly is arranged between the vertical structural members closest to the two sides of a settlement joint. The movable stone panel assembly comprises springs and a movable stone veneer. The vertical structural members on the two sides of the movable stone veneer and the two sides of the settlement joint are respectively connected with the movable stone veneer through the springs. The settlement joint wall ground stone installation structure provided by the invention has the advantages that the problem that stones collide and are cracked because a building body is displaced can be solved, the potential safety hazard that the stones fall off are avoided, the troubles in replacing the stones are reduced, the structural stability is improved.

Owner:GOLD MANTIS CONSTR DECORATION

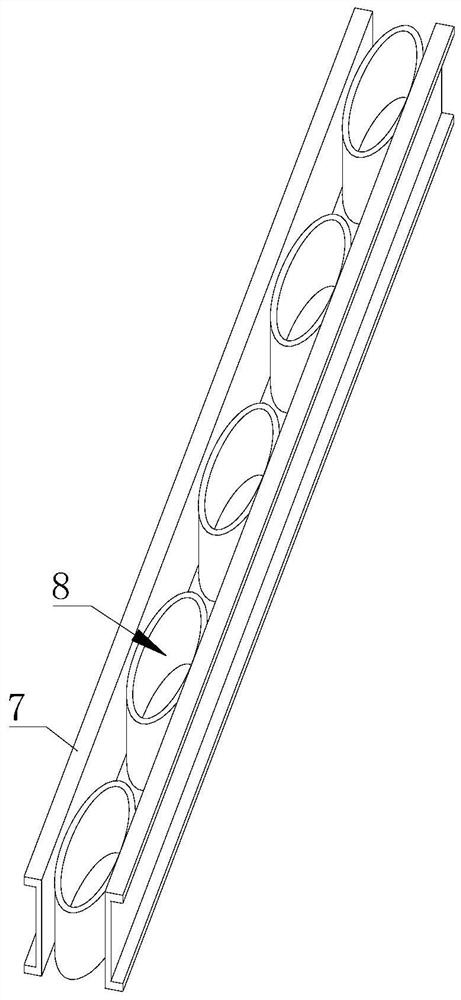

A ground stone installation expansion joint metal strip

The invention discloses a metal strip for installation of expansion joints on ground stone, belonging to the field of installation of ground stone. A set of chute grooves are provided on the inner walls of the opposite sides of the inverted U-shaped bar, both sides of the inverted U-shaped bar are provided with connecting grooves and adsorption grooves, and a detachable elastic mechanism is slidably connected between the two sets of the chute grooves. The connecting groove is provided with a connecting mechanism, and the adsorption groove is provided with an adsorption mechanism. The elastic mechanism is used to make the stone material and the inverted U-shaped bar in close contact, and the connecting mechanism is used to stick the inverted U-shaped bar and the stone material. Connected together, the adsorption mechanism is used to adsorb the inverted U-shaped bar and the stone together, and the tops of the two side bars are provided with evenly distributed waterproof grooves, which can be realized and can effectively reduce the thermal expansion and contraction due to thermal expansion. effect, resulting in bulging at the connection of the stone.

Owner:深圳文业装饰设计工程有限公司

Stone artware manufacturing method

InactiveCN109747305AWide variety of sourcesVarious formsModel makingEngravingManufacturing technologySurface roughness

The invention discloses a stone artware manufacturing method. The stone artware manufacturing method comprises the following steps that firstly, granite with the hard texture is selected and cut intoa cuboid, a ball or other shapes according to needs; secondly, the cut stone is placed in limewater to be immersed for 3 h-5 h; thirdly, after cleaning, natural drying is conducted; fourthly, carvingis conducted according to needs, and the surface roughness is controlled to be 1-1.6 in the carving process; fifthly, the carved stone is ground; sixthly, the ground stone is cleaned, an the surface of the stone is painted with an anti-corrosion coating, and the thickness of the anti-corrosion coating is 1 mm-3 mm; and seventhly, drying is conducted for 3 h-5 h at the temperature ranging from 120DEG C to 150 DEG C. The manufacturing technology is simple and fast, and technology conditions are easy to control.

Owner:成都正碧园林景观工程有限公司

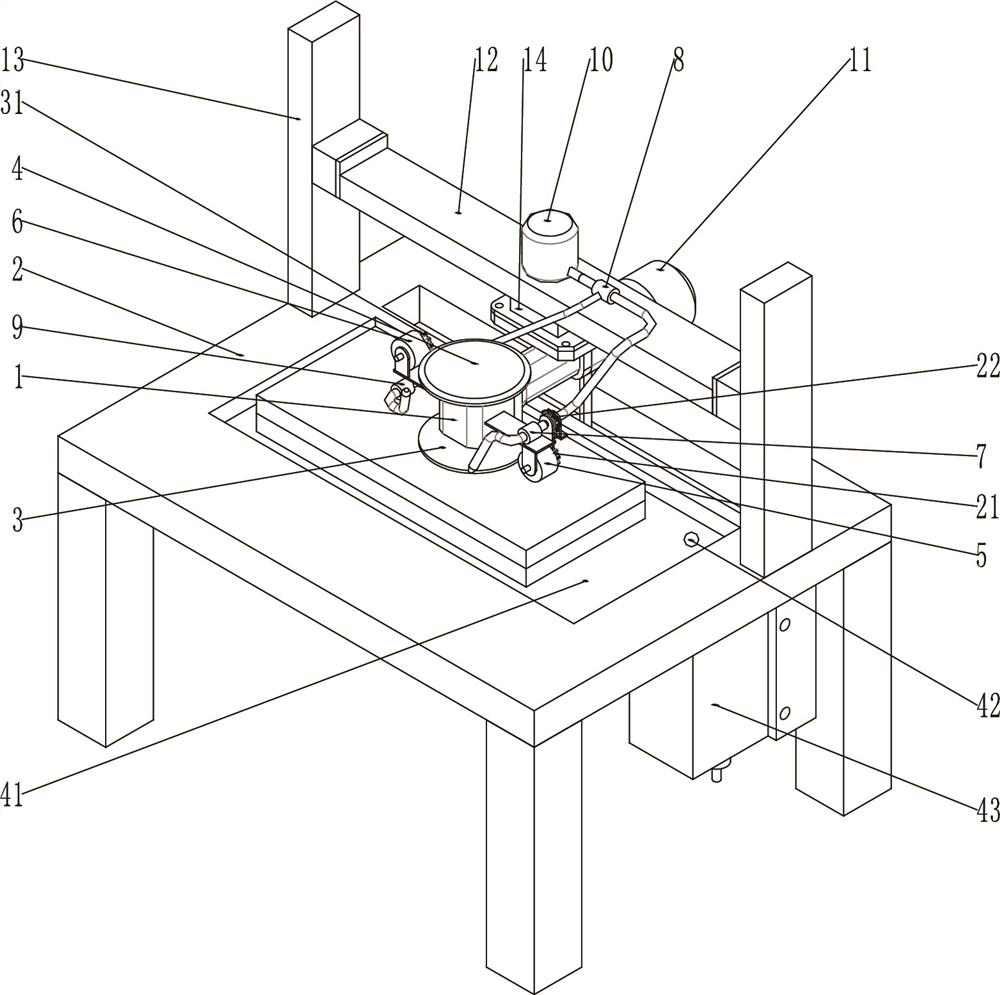

High-stability angle grinder

ActiveCN113547427ACan control the start and stopControl the amount of waterGrinding carriagesGrinding feed controlAngle grinderGround stone

The invention discloses a high-stability angle grinder which comprises an angle grinder body and a rack matched with the angle grinder body. A first water grinding disc and a second water grinding disc are symmetrically arranged on the angle grinder body, and a first induction wheel matched with the first water grinding disc and a second induction wheel matched with the second water grinding disc are arranged on the angle grinder body; and the first induction wheel is connected with a first adjusting part, the second induction wheel is connected with a second adjusting part, and the first adjusting part and the second adjusting part are both used for adjusting the amount of water passing through the adjusting parts. By means of the high-stability angle grinder, the grinding water yield is controlled by detecting the surface smoothness of ground stone, then whether grinding reaches the grinding quality of the water grinding discs or not is detected according to the collected water level change, then conversion from rough grinding to fine grinding is achieved, and an operator is reminded after fine grinding is completed.

Owner:永康市晓诚电器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com