Ground stone paving method

A laying method and stone technology, applied in the direction of floors, buildings, building structures, etc., can solve or improve the problems of stone discoloration, etc., and achieve the effects of excellent physical properties, enhanced waterproof performance, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

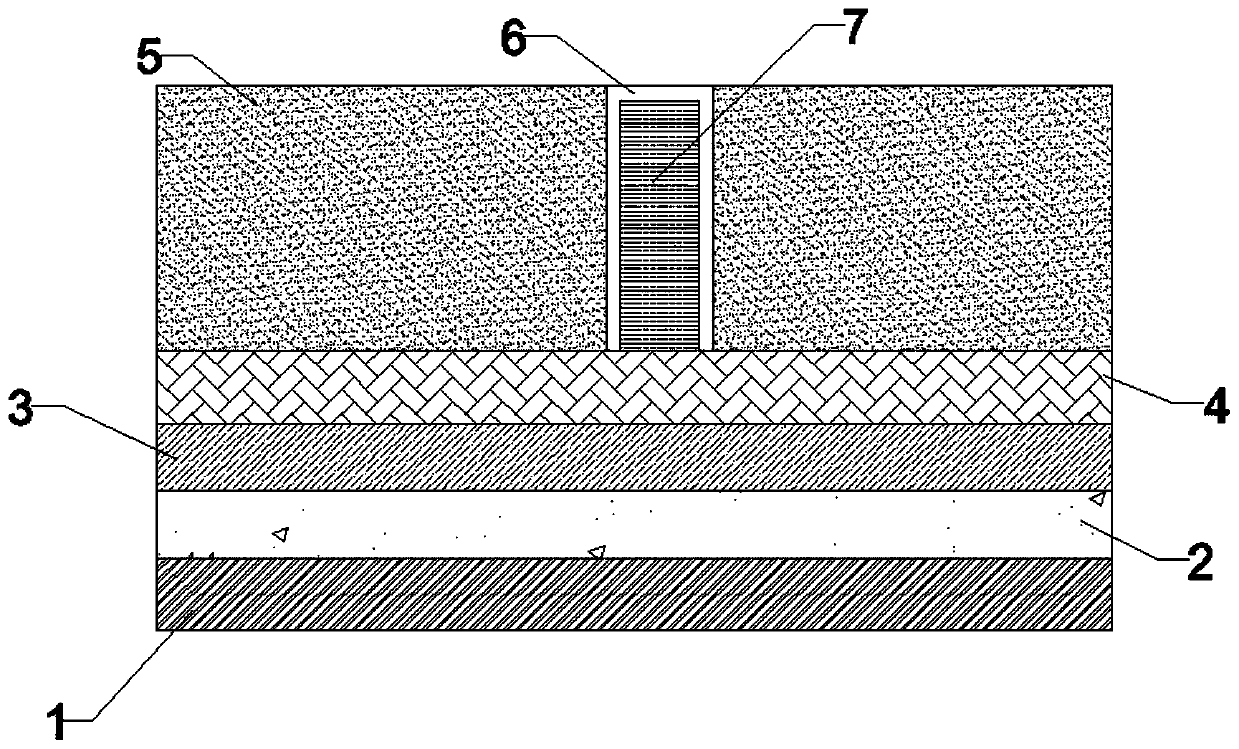

Image

Examples

Embodiment 1

[0039] A ground stone laying method, comprising the following:

[0040] 1) Basic treatment:

[0041] Use powdered coal slag, slag, etc. as fillers, crush them to a particle size of 1-4mm, fill the foundation base, and use a tamping machine to tamp it, and lay a cement slurry with a mass ratio of cement and sand of 1:20 And leveling, that is, the pavement foundation surface;

[0042] 2) Elastic string control:

[0043] According to the horizontal standard line and the design thickness, the horizontal elevation line pops up around;

[0044] 3) Laying stone:

[0045] Lay dry hard cement mortar with a mass ratio of cement and sand of 1:2 on the pavement foundation surface to form a dry hard cement mortar layer, lay stones on the dry hard cement mortar layer, and tap the stone surface with a rubber hammer to make the stone surface slightly lower At the elevation line or at the same level as the elevation line, the thickness of the dry hard cement mortar layer is about 3cm; turn...

Embodiment 2

[0049] A ground stone laying method, comprising the following:

[0050] 1) Basic treatment:

[0051] Use powdered coal slag, slag, etc. as fillers, crush them to a particle size of 1-4mm, fill the foundation base, and use a tamping machine to tamp it, and lay a cement slurry with a mass ratio of cement and sand of 2:25 And leveling, that is, the pavement foundation surface;

[0052] 2) Elastic string control:

[0053] According to the horizontal standard line and the design thickness, the horizontal elevation line pops up around;

[0054] 3) Laying stone:

[0055]Lay dry hard cement mortar with a mass ratio of cement and sand of 1:2 on the pavement foundation surface to form a dry hard cement mortar layer, lay stones on the dry hard cement mortar layer, and tap the stone surface with a rubber hammer to make the stone surface slightly lower At the elevation line or at the same level as the elevation line, the thickness of the dry hard cement mortar layer is about 4cm; turn ...

Embodiment 3

[0058] A ground stone laying method, comprising the following:

[0059] 1) Basic treatment:

[0060] Use powdered coal slag, slag, etc. as fillers, crush them to a particle size of 1-4mm, fill the foundation base, and use a tamping machine to tamp it, and lay a cement slurry with a mass ratio of cement and sand of 3:30 And leveling, that is, the pavement foundation surface;

[0061] 2) Elastic string control:

[0062] According to the horizontal standard line and the design thickness, the horizontal elevation line pops up around;

[0063] 3) Laying stone:

[0064] Lay dry hard cement mortar with a mass ratio of cement and sand of 1:3 on the pavement foundation surface to form a dry hard cement mortar layer, lay stones on the dry hard cement mortar layer, and tap the stone surface with a rubber hammer to make the stone surface slightly lower At the elevation line or at the same level as the elevation line, the thickness of the dry hard cement mortar layer is about 5cm; turn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com