Non-woven fabric grinding block for stone polishing and manufacturing method of non-woven fabric grinding block

A non-woven, abrasive block technology, applied in grinding/polishing equipment, grinding/polishing hand tools, abrasives, etc., can solve the problems of insufficient softness, scratches, troublesome processing, etc., and achieve the effect of high gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

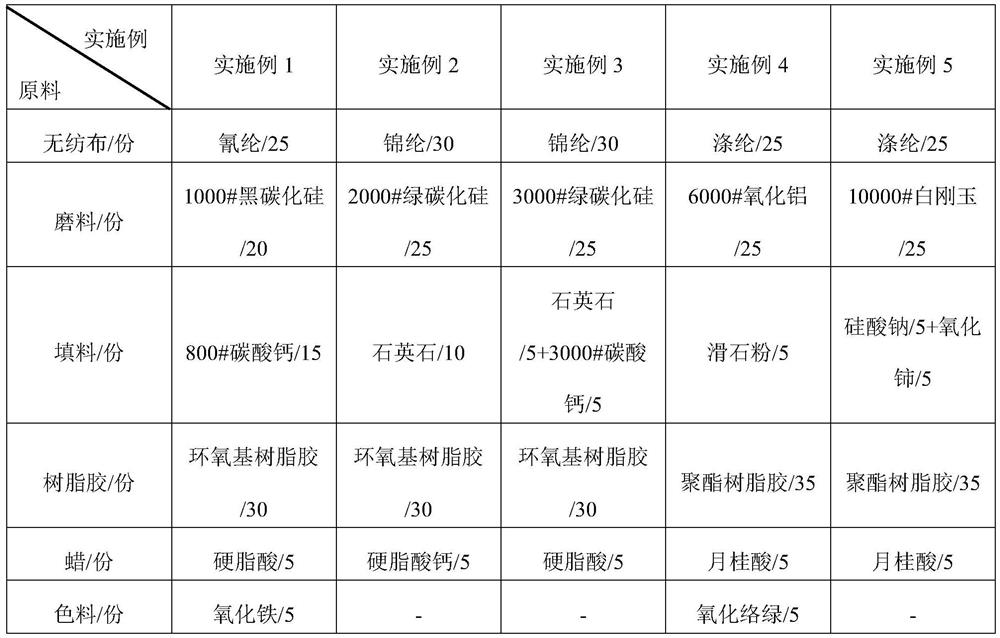

Embodiment 1

[0023] Weigh 20 parts of 1000# black silicon carbide, 15 parts of 800# calcium carbonate, 5 parts of iron oxide, 30 parts of epoxy resin glue, and 5 parts of stearic acid according to the proportion. It is evenly coated in 25 parts of cyanoamide non-woven fabric, compressed to a thickness of 1.3CM at a mass density of 3.0 kg / square, and then punched into a horseshoe shape of 7.5CM×9.5CM after curing. Paste it on the horseshoe rubber cover, install the polishing machine to polish the marble, and the gloss can be increased by 5 degrees on the basis of the grinding of the bitter earth grinding block and the oxalic acid composite grinding block.

[0024] The marble polishing production line generally has to go through several processes of bitter earth grinding block and oxalic acid composite grinding block. The luminosity of different slates, different brittle earth grinding blocks and oxalic acid composite grinding blocks will be very different after polishing. Generally, it is ...

Embodiment 2

[0026] Weigh 25 parts of 2000# green silicon carbide, 10 parts of quartz stone, 30 parts of epoxy resin glue, and 5 parts of calcium stearate in proportion. After stirring at high speed with a mixer to form a uniform mortar, apply the mortar to 30 parts evenly. In the nylon fiber non-woven fabric, it is compressed into a thickness of 1.3CM at a mass density of 3.0 kg / square. After curing and forming, it is punched into a horseshoe shape of 7.5CM×9.5CM. Paste it on the horseshoe rubber cover, and install the polishing machine to polish the marble, so that the glossiness of the marble can continue to increase by 8 degrees after polishing with different combination of bitter earth grinding blocks and oxalic acid composite grinding blocks.

Embodiment 3

[0028] Weigh 25 parts of 3000# green silicon carbide, 5 parts of 3000# calcium carbonate, 5 parts of quartz stone, 30 parts of epoxy resin glue, and 5 parts of stearic acid in proportion, and stir the mortar at high speed with a mixer to form a uniform mortar. It is evenly coated in 30 parts of nylon fiber non-woven fabric, compressed to a thickness of 1.3CM at a mass density of 3.0 kg / square, and then punched into a horseshoe shape of 7.5CM×9.5CM after curing and forming. Paste it on the horseshoe rubber cover, and install the polishing machine to polish the marble, so that the gloss of the marble can continue to increase by 12 degrees after polishing with different combination of bitter earth grinding blocks and oxalic acid composite grinding blocks.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com